A. O. Smith DSE-10 Service Manual

Service Handbook

COMMERCIAL ELECTRIC WATER HEATERS

MODELS DSE-5 THRU DSE-120

SERIES 100 and 102

INSTALLATION CONSIDERATIONS - PRE SERVICE

CHECKS - WATER HEATER CONSTRUCTION -

500 Tennessee Waltz Parkway

Ashland City, TN 37015

OPERATION & SERVICE - TROUBLESHOOTING

SERVICING SHOULD ONLY BE PERFORMED BY A QUALIFIED SERVICE AGENT.

PRINTED IN THE U.S.A 1008 198335-000

1

COMMERCIAL ELECTRIC WATER HEATER

SERVICE MANUAL

TABLE OF CONTENTS

INTRODUCTION .......................................................................2

Qualifications......................................................................2

Service Warning .................................................................2

Tools Required....................................................................3

INSTALLATION CONSIDERATIONS........................................4

Closed Water Systems.......................................................4

Thermal Expansion.............................................................4

Electrical Requirements......................................................5

PRE SERVICE CHECKS...........................................................6

Service Precautions............................................................5

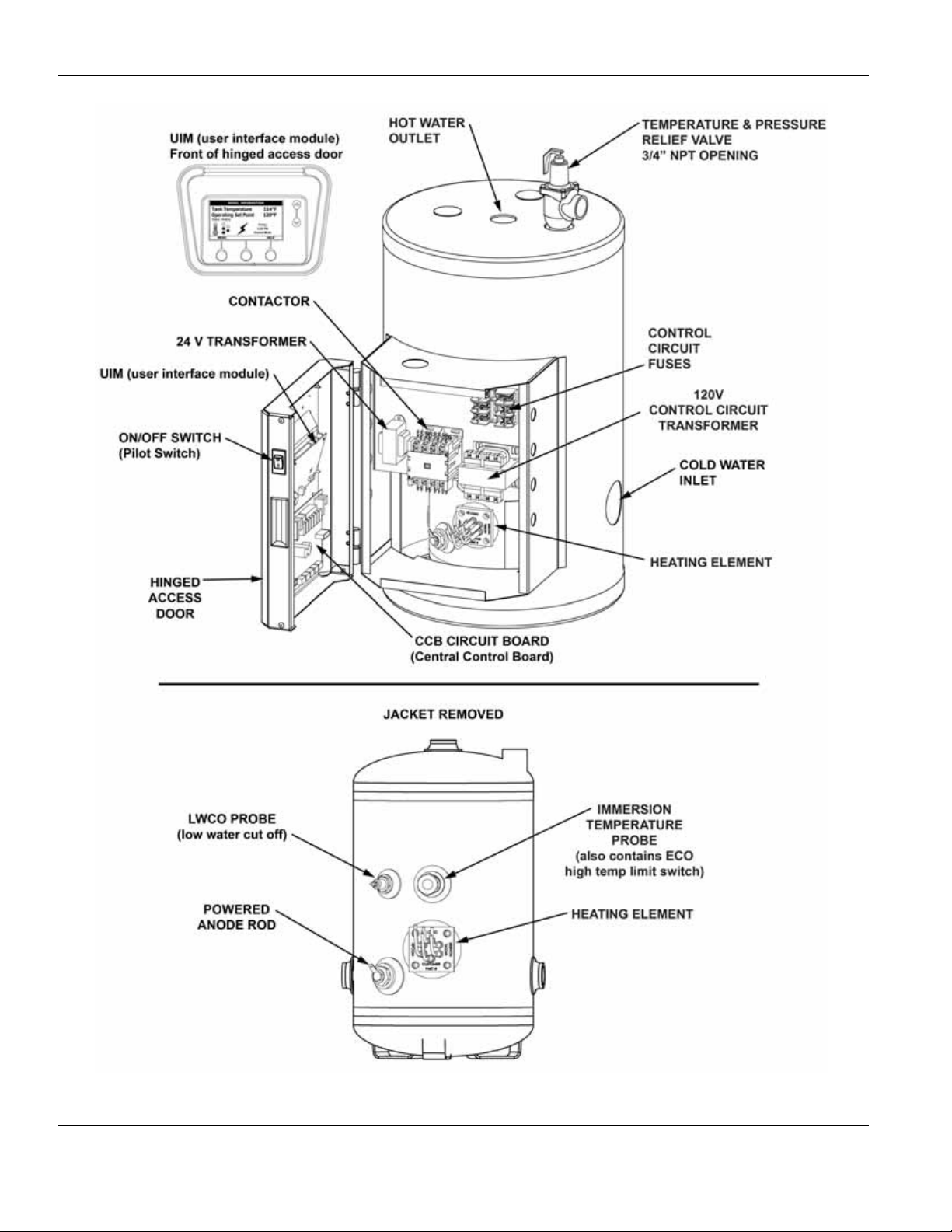

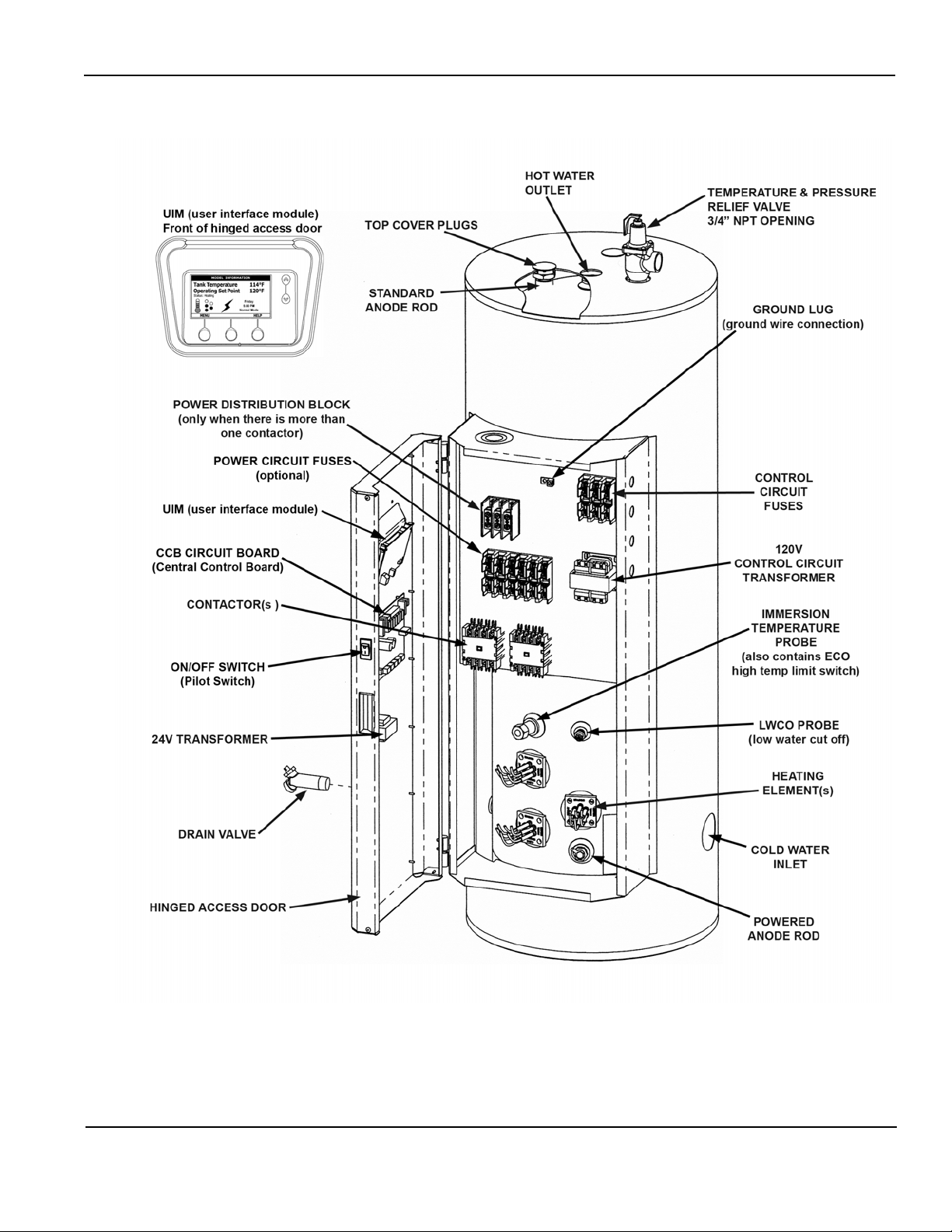

WATER HEATER CONSTRUCTION ........................................7

5 - 20 Gallon Models ..........................................................8

30 - 120 Gallon Models ......................................................9

OPERATION & SERVICE........................................................10

Principles of Electricity......................................................10

Single And Three Phase Power ....................................... 12

Checking Single Phase Power..................................13

Checking Three Phase Power...................................14

Fuses................................................................................15

Heating Elements ............................................................ 16

Heating Element Construction...................................16

Six and Three Wire Heating Elements ......................17

Single Phase Element Wiring.............................18 - 19

Three Phase Element Wiring..............................20 - 22

Heating Element Ratings & Configurations...............23

Heating Element Amperage Tables...........................24

Heating Element Amperage Test...............................25

Heating Element Voltage Test...................................26

Heating Element Resistance Tables..........................28

Heating Element Resistance Test..............................29

Heating Element Ground Test...................................30

Replacing Heating Elements.....................................31

Heating Element Sensors.................................................32

Element Sensor Operation........................................33

Contactors........................................................................34

Contactor Configurations...........................................35

Contactor Inspection..................................................36

Contactor Coil Voltage - At Contactor........................37

Contactor Coil Voltage - At CCB................................38

Transformers ....................................................................39

120 VAC Control Circuit Transformer Wiring.... 39 & 40

120 V AC Control Circuit Transformer Test.................41

24 VAC Transformer Test..........................................42

Immersion Temperature Probe.........................................43

Temperature Sensor Resist ance Test........................44

Temperature Sensor DC Vo ltage Test................. ... ...45

ECO Continuity Test..................................................45

ECO Voltage Test......................................................46

LWCO (Low Water Cut Off)..............................................47

Powered Anode Rod........................................................48

Electronic Controls ...........................................................49

CCB - Central Control Board.....................................50

CCB Socket & Wiring Terminal Identification ............51

CCB Enable Disable Circuit(s) Test...........................53

Checking Power And Ground To The CCB...............54

UIM - User Interface Module.....................................55

ELECTRONIC CONTROL SYSTEM.......................................56

Heating Element Operation..............................................56

Control System Features..................................................57

Control System Navigation...................................... ... ......57

The Desktop Screen.........................................................58

Status Icons...............................................................59

Operating States............................................ ............60

Control System Menus..............................................60

Temperatures Menu..........................................................61

Temperature Settings................................................62

Heater Status Menu..........................................................63

Economy Mode Setup Menu............................................64

Setpoint Adjustment Value........................................65

Time Clock Settings ..................................................66

Daily Operating Mode Settings..................................67

Alarm Output Setup Menu................................................68

Display Settings Menu......................................................69

Heater Information Menu..................................................70

Current Fault/Alert Menu..................................................71

Fault History Menu ............................ ... .. ..........................71

Fault Occurrence Menu...................................... ..............71

Restore Factory Defaults Menu........................................72

TROUBLESHOOTING.............................................................73

Common Service Problems..............................................73

Control System Diagnostics .............................................74

Fault Conditions ........................................................74

Alert Conditions.........................................................74

Resetting The Control System ..................................74

Control System Unresponsive....................................... ...74

UIM Display Is Blank.................................................74

UIM Is Inoperable......................................................75

Heating Cycle Disabled.............................................75

Fault & Alert Messages....................................................76

No Current Detected .................................................76

Temp Probe Open.....................................................77

Temp Probe Short.....................................................77

Energy Cut Out (ECO) ..............................................78

LWCO Fault...............................................................79

No Anode Current .....................................................80

INTRODUCTION

INTRODUCTION

This Service Manual is designed to be an aid in servicing and troubleshooting the

commercial electric water heater models listed on the cover .The instructions, illustrations

and procedures contained in this manual are used to verify proper operation and to

diagnose and repair common service problems.

This manual does not replace or supersede the Instruction Manual that came with the water

heater. Always refer to the Instruction Manual that came with the water heater for complete

installation instructions. If the Instruction Manual is not available copies can be obtained

from the manufacturers web site or by calling the technical support phone number shown on

the back cover of this manual.

Review the Common Service Problems on page 73 prior to performing any service

procedures.

QUALIFICATIONS - QUALIFIED SERVICE AGENT

Servicing the products referenced in this manual requires ability equivalent to that of a

Qualified Agency (as defined by ANSI below) in the field involved. Installation skills such as

plumbing, electrical supply are required in addition to diagnostic and electrical testing skills

when performing service.

ANSI Z223.1 2006 Sec. 3.3.83: “Qualified Agency” - “Any individual, firm, corporation or

company that either in person or through a representative is engaged in and is responsible

for (a) the installation, testing or replacement of gas piping or (b) the connection, installation,

testing, repair or servicing of appliances and equipment; that is experienced in such work;

that is familiar with all precautions required; and that has complied with all the requirements

of the authority having jurisdiction.”

SERVICE WARNING

If you are not qualified (as defined by ANSI above) and licensed or certified as required by

the authority having jurisdiction to perform a given task do not attempt to perform any of the

service, diagnostic or troubleshooting procedures described in this manual. If you do not

understand the instructions given in this manual or do not feel confident in your abilities to

perform a given task do not attempt to perform any procedures outlined in this manual.

IMPORTANT SERVICE REMINDER

When performing any troubleshooting step outlined in this manual always consider the

wiring and connectors between components. Perform a close visual inspection of all wiring

and connectors to and from a given component before replacement. Ensure wires were

stripped before being crimped in a wire connector. Ensure wires are crimped tightly in their

connectors. Ensure connection pins in sockets and plugs are not damaged or worn. Also

ensure plugs and sockets are mating properly and providing good contact.

Failure to perform this critical step or failing to perform this step thoroughly often results in

needless down time, unnecessary parts replacement, and customer dissatisfaction.

Servicing should only be performed by a Qualified Service Agent

2

INTRODUCTION

INSTRUCTION MANUAL

Have a copy of the Instruction Manual that came with the water heater on hand for the

correct model water heater you are working with before servicing.

Installation information given in this Service Manual IS NOT a complete installation

instruction. Installation information covered in this Service Manual has a limited focus as it

applies to servicing. This Service Manual does not replace or supersede the Instruction

Manual that came with the water heater. Always refer to the Instruction Manual that came

with the water heater for complete installation instructions.

If the Instruction Manual is not on hand copies can be obtained from the manufacturers web

site or by calling the technical support phone number shown on the water heater labeling

and the back cover of this Service Manual.

TOOLS REQU IRED

• Instruction Manual that came with the water heater.

• All tools common to installation and service of commercial water heaters such as hand

tools, torch, pipe wrenches etc.

• Electrical switch lock out device - used to secure disconnect switches/breaker panels

while servicing.

• Insulated fuse puller(s).

• Adhesive numbered/colored wire markers - 3M Scotch Code SDR0-9 Numbered Wire

Markers; 3M Scotch Code STD-C Colored Wire Markers or equivalent.

• Volt-Ohm Multi Meter - recommend Fieldpiece HS36, Fluke 187, UEI model DL289 or

equivalent capable of measuring:

• AC Voltage up to 600 VAC

• DC Voltage up to 24 VDC

• Ohms up to 2,000,000 ohms

• AC amp meter - recommend UEI model DL289 or equivalent capable of measuring:

• AC amperage up to 400 amps

Servicing should only be performed by a Qualified Service Agent

3

INSTALLATION CONSIDERATIONS

INSTALLATION CONSIDERATIONS

Installation information given in this Service Manual IS NOT a complete installation

instruction. Installation information covered in this Service Manual has a limited focus as it

applies to servicing. This Service Manual does not replace or supersede the Instruction

Manual that came with the water heater. Always refer to the Instruction Manual that came

with the water heater for complete installation instructions.

If the instruction Manual that came with the water heater is not on hand copies can be

obtained from the manufacturers web site or by calling the technical support phone number

shown on the water heater labeling and the back cover of this Service Manual.

CLOSED WATER SYSTEMS

Water supply systems may, because of code requirements or such conditions as high line

pressure, among others, have installed devices such as pressure reducing valves, check

valves, and back flow preventers. Devices such as these cause the water system to be a

closed system.

Virtually all commercial and most residential water supply systems are closed systems

today. Closed water systems will experience thermal expansion which, if not controlled with

a properly installed and sized thermal expansion tank, can cause premature failure

(leakage) of the water heater. Water heater failure (leakage) on closed systems where there

is not a thermal expansion tank installed is not covered under the limited warranty.

THERMAL EXPANSION

As water is heated, it expands (thermal expansion). In a closed system the volume of water

will grow when it is heated. As the volume of water grows there will be a corresponding

increase in water pressure due to thermal expansion. Thermal expansion can cause

premature tank failure (leakage). This type of failure is not covered under the limited

warranty. Thermal expansion can also cause intermittent temperature-pressure relief valve

operation: water discharged from the valve due to excessive pressure build up. This

condition is not covered under the limited warranty. The temperature-pressure relief

valve is not intended for the constant relief of thermal expansion.

A properly sized thermal expansion tank should be installed on all closed systems to control

the harmful effects of thermal expansion.

Servicing should only be performed by a Qualified Service Agent

4

INSTALLATION CONSIDERATIONS

ELECTRICAL REQUIREMENTS

Grounding

Review the electrical ground requirements given in the Instruction Manual that came with

the water heater and ensure the water heater has been properly grounded.

The water heater must be grounded in accordance with the National Electric Code and/or

local codes. These codes must be followed in all cases.

The water heater must be connected to a grounded metal, permanent wiring system; or an

equipment grounding conductor must be run with the circuit conductors and connected to

the equipment grounding terminal or lead on the water heater.

Service Note: The water heaters covered in this manual are equipped with electronic

controls that may experience erratic operation if the water heater is not properly grounded.

These water heaters are also equipped with a LWCO (low water cut off). Some models will

also be equipped with a powered anode rod. LWCO devices and powered anode rods

require an adequate earth ground to work properly. See pages 47 and 48.

Power Supply

Review the electrical requirements listed on the water heater’s rating label and in the

Instruction Manual that came with the water heater. Ensure the branch circuit supplying

power to the water heater is within these requirements and properly connected.

Ensure the power supply phase (single or three phase / 1Ø, 3Ø) and power supply voltage

match the water heater’s rating label. Some of the commercial electric water heater models

covered by this Service Manual are phase convertible. Voltage and KW conversions ARE

NOT permitted.

Servicing should only be performed by a Qualified Service Agent

5

PRE SERVICE CHECKS

WIRING CONNECTIONS

With the power supply to the water heater turned off ensure the wiring connections are

properly tightened to all components including: high voltage terminal blocks, fuse blocks,

contactors and transformers.

Loose connections at any connection point will cause increased amperage and excessive

heat which can damage wiring and components. Whenever worn or damaged wiring and

components must be replaced ensure all wiring connections are properly tightened before

putting the water heater back in service.

SERVICE PRECAUTIONS

1 DO NOT energize the branch circuit supplying power to the water heater or test the

water heater electrical system before the water heater is completely filled with water.

Read the start up procedures in the Instruction Manual that came with the water heater.

2 Be sure to turn off power and use a lock out device at the branch circuit power supply

disconnect switch or breaker when servicing the electrical system of the water heater.

Never touch electrical components with wet hands or when standing in water.

PRE SERVICE CHECKS

3 When replacing heating elements ensure they are rated at the correct voltage and KW

for the water heater being serviced see pages 23 and 31.

4 When replacing fuses use an insulated fuse puller to remove and install fuses. Always

use the correct size for the circuit. See the Instruction Manual that came with the water

heater for fuse size requirements. See page 15 in this manual.

5 Using an AC volt meter measure the branch circuit power supply voltage to the water

heater. Ensure the measured voltage of the branch circuit supplying power to the water

heater matches the water heater’s rating label - see pages 12 - 14.

6 Ensure the phase of the branch circuit supplying power to the water heater matches the

water heater’s rating label. Some water heater models covered by this Service Manual

are phase convertible. Some models are not phase convertible. See the Instruction

Manual that came with the water heater for more information on phase conversions.

7 The water heaters covered by this manual have a multi tap control circuit transformer.

This is a step down transformer that outputs 120 V AC (secondary winding) which is used

to power the electronic control system and energize the contactor coils. The transformer

can accommodate different power supply voltages and has multiple input voltage

connections or “taps.” Ensure the input supply voltage (primary winding) wiring to the

transformer is connected properly. See the Instruction Manual that came with the water

heater and pages 39 & 40 in this manual for more information.

Service Note - Contactor Chatter: Incorrect supply voltage wiring to the multiple tap 120

VAC Control Circuit Transformer will cause low/high output voltage from the transformer.

This can cause contactors to open and close their contacts rapidly (contactor chatter) and

result in permanent damage to the contactors. See pages 39 & 40.

Servicing should only be performed by a Qualified Service Agent

6

WATER HEATER CONSTRUCTION

WATER HEATER CONSTRUCTION

Electronic Controls

The water heaters covered in this Service Manual are equipped with an electronic control

system - see page 56. The control system senses temperature electrically from an

Immersion Temperature Probe. The probe is installed in a threaded opening in the storage

tank (wet well) and senses water temperature directly . As the stored water temperature rises

and falls the control system de-energizes and energizes heating elements indirectly using

electromagnetic contactors. The control system energizes the electromagnetic contactor’s

(120 VAC) coil causing the switch contacts of the contactor to close which in turn supplies

power to the heating elements - see pages 34 - 38.

Heating Element Configurations

Depending on tank size and how they were ordered from the factory the water heaters

covered in this Service Manual may be equipped with 1 to 5 electric heating elements. Tot al

input KW ranges from 3KW to 90KW. The water heaters covered in this manual are

available in storage tanks sizes from 5 to 120 gallons.

Power Conversions

Other than power supply phase conversions on some models the water heaters covered in

this Service Manual cannot be field converted. Voltage and KW conversions ARE NOT

permitted. See the Instruction Manual that came with the water heater for more information.

If the Instruction Manual is not available copies can be obtained from the manufacturers web

site or by calling the technical support phone number shown on the water heater labeling

and the back cover of this Service Manual.

Servicing should only be performed by a Qualified Service Agent

7

5 - 20 GALLON MODELS

Figure 1

WATER HEATER CONSTRUCTION

Servicing should only be performed by a Qualified Service Agent

8

WATER HEATER CONSTRUCTION

Figure 2

30 - 120 GALLON MODELS

Servicing should only be performed by a Qualified Service Agent

9

OPERATION & SERVICE

This section of the manual will cover principles of electricity, single and three phase power,

fuses, heating element construction & operation, heating element sensors, contactors,

common service procedures and more. Information and service procedures presented in

this section will be referenced in the troubleshooting sections at the end of this manual.

PRINCIPLES OF ELECTRICITY

Voltage

The unit of measurement used to quantify electrical pressure or the force that causes

electrical energy to flow is the volt or voltage. V olt meters are used to determine if there is an

adequate supply of electricity or voltage to a heating element.

Amperage

The unit of measurement used to quantify the rate at which electrical current is flowing is the

ampere or amp. Amp meters are used to determine if a heating element is working - if there

is adequate current flowing through the heating element.

Ohms

The unit of measurement used to quantify the opposition or “resistance” to the flow of

electricity is the ohm. As resistance (ohms) in an electrical circuit increases current

(amperage) will decrease and as resistance decreases current will increase. Ohm meters

are used for measuring the resistance of heating elements, for open circuit continuity tests

on heating elements and for shorted to ground continuity tests on heating elements.

OPERATION & SERVICE

Service Note: Volt, ohm and amp meter test instruments are necessary to perform the

service and diagnostic procedures outlined in this manual - see Tools Required on page 3.

Wattage

The unit of measurement used to quantify the rate or amount of electrical energy being used

is the watt. One thousand watts is referred to as one kilowatt. Heating elements are rated in

kilowatts expressed as KW. The higher the kilowatt rating of a heating element the more

power it will use and the more heat it will generate. One kilowatt generates 3412 Btu of heat.

Servicing should only be performed by a Qualified Service Agent

10

OPERATION & SERVICE

Ohms Law

A law that explains the relationship between voltage, current and resistance. The law states

that the electric current flowing through a conductor is equal to the voltage divided by the

resistance. The following equations further explain ohms law.

V=Volts (electrical pressure)

A=Amps (electrical flow/current)

O=Ohms (resistance to electrical flow/current)

W=Watts (rate or amount of electricity used)

Ohms Law applied to single phase power - each loop of a six wire element:

V ÷ A = O W ÷ V = A V ÷ O = A V x A = W A x O = V W ÷ A = V

Ohms Law applied to three phase power - each wiring lead to a three wire element:

0.577 x W ÷ V = A V x A x 1.73 = W

Service Note: See Heating Element Ratings on page 23 to determine the voltage and KW

rating of a heating element.

Servicing should only be performed by a Qualified Service Agent

11

OPERATION & SERVICE

277 Volt 1Ø Power

208/240/480 Volt 1Ø Power

208/240/480 Volt 3Ø Power

Power Distribution Block

Models with more than one heating element only.

See Figures 1 & 2 on pages 8 and 9.

SINGLE AND THREE PHASE POWER

These water heaters can be factory ordered for standard: 277/208/240/480 volt power. 277

volt models are single phase only - other voltages may be single or three phase.

Field Conversions

Some water heaters may be converted for single or three phase power within the guidelines

listed below. Follow the phase conversion instructions provided in the Instruction manual

that came with the water heater. Voltage/KW conversions ARE NOT permitted.

• 208/240 VAC models factory configured 24KW or less are convertible as single or three phase and

include jumpers to make the conversion.

• 208/240 VAC models factory configured as single phase with over 24KW can be converted to three

phase but jumpers are not provided.

• 208/240 VAC models factory configured as three phase with over 24KW cannot be converted to

single phase.

• No 480 VAC models are phase convertible.

• Heating element voltage and KW conversions are not permitted on any models.

V erifying the power supply is correct is typical first step during most service procedures. The

illustrations and instructions on the following pages will outline how this is done.

Servicing should only be performed by a Qualified Service Agent

12

OPERATION & SERVICE

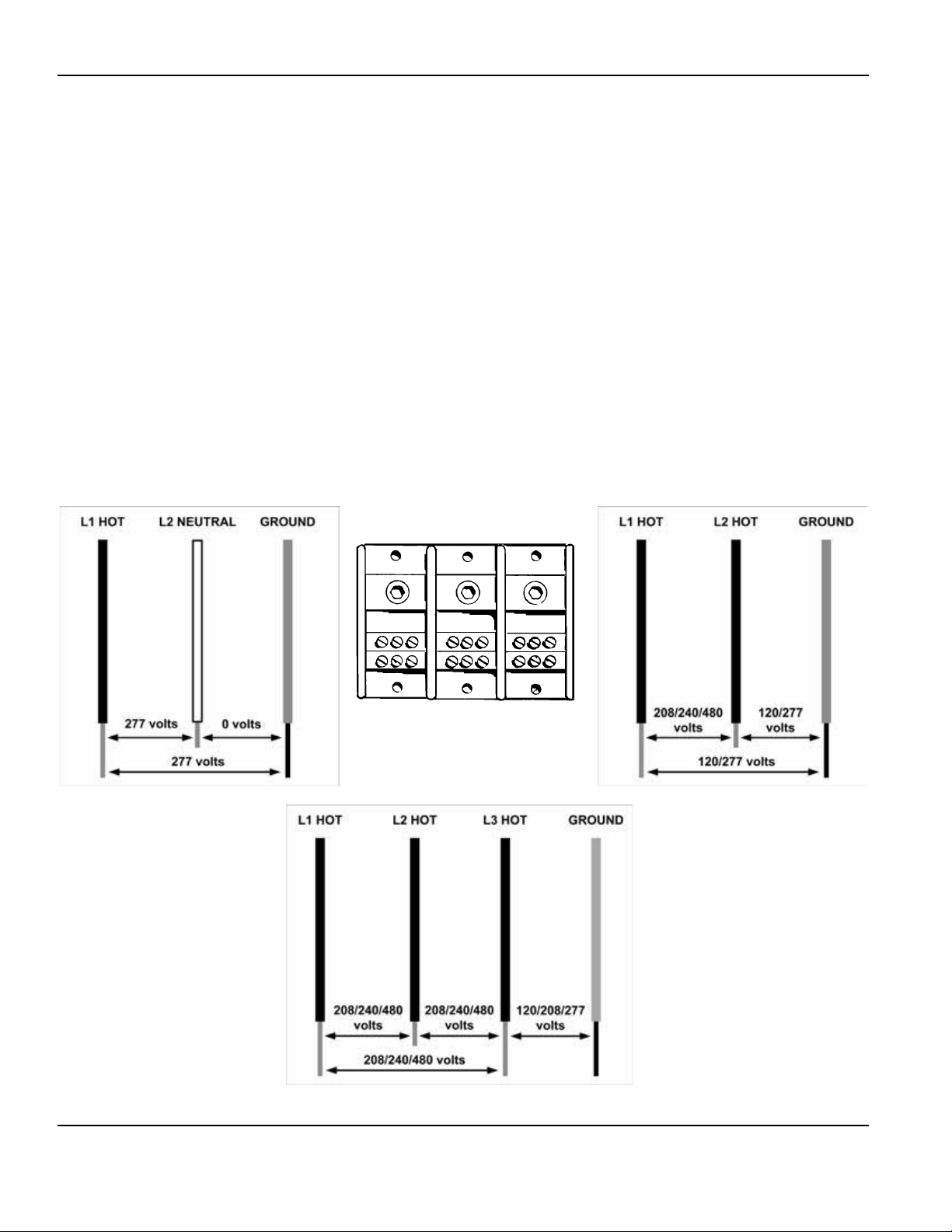

277 Volt 1Ø Power

208/240/480 Volt 1Ø Power

Power Distribution Block

L1 L2

3 Pole Contactor

4 Pole Contactor

Measure power supply

voltage to water heater

on single element models

at upper terminals of the

contactor.

Measure power supply

to heating elements on

all models at the lower

terminals of the

contactor(s).

Measure power supply

voltage to water heater

on models with more

than one element at the

Power Distribution Block

Checking Single Phase (1Ø) Power

A single phase power supply will be connected to the L1 and L2 terminals of the Power Distribution

Block or directly to the contactor on models equipped with a single element. On 208/240/480 volt

power supplies both wires are “hot” with voltage present. On a 277 volt power supply one of the two

wires is a “neutral” and does not have any voltage present. Check power supply voltage as follows:

1 With the power supply to the water heater turned on set the volt meter to an AC volt age range above the

expected voltage (600 VAC or higher range initially).

2 Measure and record voltage between the [L1 & L2] ter minals at the water heater’s Power Distribution Bl ock

or at the contactor on a single element model. Models equipped with a single element and a 4 pole

contactor will require two voltage readings; one voltage reading between the first and second terminals of

the contactor and a second voltage reading between the third and fourth terminals of the contactor.

3 Measure and record the voltage between the L1 terminal and the ground wire connection to the water

heater. Ch eck between L2 and g round in the sam e way. Note: models equippe d with a single element and

a 4 pole contactor will require four voltage readings; between the each of the 4 poles of the contactor and

ground. On 208/240 volt power supplies each reading to ground should be approximately 120 volts. On

480 volt power supplies each reading to ground should be appr oximately 277 volts. On 277 volt power on e

of the wires is a neutral wire and will normally read approximately zero volts to ground.

Service Warning: Zero volt readings between terminals and ground can be due to an inadequate earth

ground. TREAT ALL WIRES AS BEING HOT until it has been determined there is no voltage present.

If the voltage readings between terminals (step 2) or the voltage between any of the terminals and

ground (step 3) was less than expected (< 95% expected): check the power supply to the water

heater. Contact a Qualified/Licensed electrician to restore power. If the voltage readings taken in

Step 2 above are a standard voltage (277/208/240/480) but do not match the listed voltage on the

water heater’s rating label secure power to the water heater. DO NOT place the water heater back in

service. Call the toll free Technical Support phone number listed on the b ack cover of this manual for

further assistance.

Servicing should only be performed by a Qualified Service Agent

13

OPERATION & SERVICE

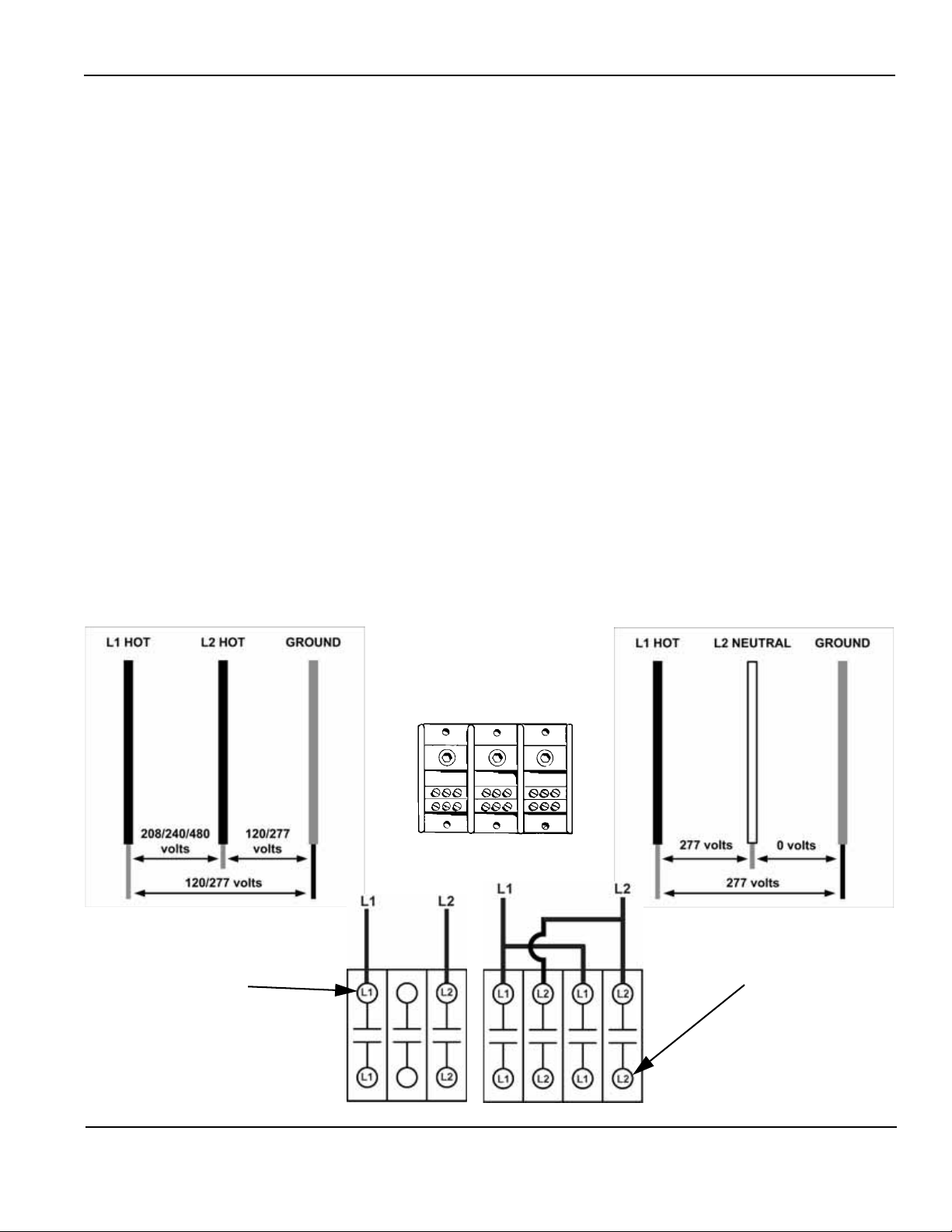

208/240/480 Volt 3Ø Power

L1 L2 L3

Power Distribution Block

3 Pole Contactor

4 Pole Contactor

Measure power supply

voltage to water heater

on single element models

at upper terminals of the

contactor.

Measure power supply

voltage to water heater

on models with more

than one element at the

Power Distribution Block

Measure power supply

to heating elements on

all models at the lower

terminals of the

contactor(s).

Checking Three Phase (3Ø) Power

A three phase power supply will be connected to the L1, L2 and L3 terminals of the Power

Distribution Block or directly to the contactor on models equipped with a single element. All three

wires are “hot” with voltage present. Check power supply voltage as follows:

1 With the power supply to the water heater turned on set the volt meter to an AC volt age range above the

expected voltage (600 VAC or higher range initially).

2 Measure and record the voltage at the water h eater’s Power Distribution Block or at the cont actor on single

element models. Measure voltage between; [L1 & L2], [L2 & L3] and [L1 & L3] terminals. This will be three

voltage readings at a Power Distribution Block or a 3 pole cont actor . Models eq uipped with a single heating

element and a 4 pole contactor will require taking the voltage readings between the [L1 & L2] and [L2 & L3]

terminals twice since there are two L2 terminals on th e contactor - total of 4 voltage readings. All voltage

readings should be approximately the same .

3 Measure and record the voltage between the L1 terminal and the ground wire connection to the water

heater. Ch eck betwe en L2 and gr ound and L3 and ground in the same way. Note: models equipped with a

single element and a 4 pole contactor will require four voltage readings; between the each of the 4 poles of

the contactor and ground. On some 208 volt power supplies each reading to ground will be approximately

120 volts. Some 208 volt models will have a “stinger leg” with one of the three readings to ground

measuring 208 volts - 208 volt stinger legs should be connected to L2. On 240 volt power supplies each

reading to ground should be approximately 120 volts. On 480 volt power supplies each reading to ground

should be approximately 277 volts.

Service Warning: Zero volt readings between terminals and ground can be due to an inadequate earth

ground. TREAT ALL WIRES AS BEING HOT until it has been determined there is no voltage present.

If the voltage readings between terminals (step 2) or the voltage between any of the terminals and

ground (step 3) was less than expected (< 95% expected): check power supply fuses, the breaker

and/or disconnect switch supplying power to the water heater. Contact a Qualified/Licensed

electrician to restore power. If the voltage readings taken in Step 2 above are a standard voltage

(208/240/480) but do not match the listed voltage on the water heater’s rating label secure power to

the water heater . DO NOT place the water heater back in se rvice. Call the toll free Technical Support

phone number listed on the back cover of this manual for further assistance.

Servicing should only be performed by a Qualified Service Agent

14

OPERATION & SERVICE

Volt Meter MethodOhm Meter Method

FUSES

Depending on total amp draw and how they were ordered some water heaters will be

equipped with power circuit fuses to protect the heating element circuits. All models will have

two fuses to protect the primary winding of the 120 Volt Control Circuit Transformer. See

Figures 1 and 2 on pages 8 and 9 for location. Testing fuses requires an ohm meter, an AC

volt meter and an insulated fuse puller - see Tools Required page 3.

Service Note - Replacement Fuses: Replacement fuses MUST BE of the same value and

type as the factory installed fuses - call the toll free technical support or parts department

phone number on the back cover of this manual for further assistance.

Ohm Meter Method

1 Secure power to the water heater at the main breaker or disconnect switch.

2 Remove each fuse to be tested with an insulated fuse puller.

3 Set the Ohm meter to it’s lowest resistance range (< 20 0) or to an audible be ep continuity test setting if

so equipped.

4 Touch the meter probes to both ends of each fuse simultaneously.

5 If the fuse being tested shows a low resistance (< 1 ohms) or the continuity test feature sounds an

audible beep the fuse being tested is good and can be re-installed.

6 If the fuse being tested shows infinite resistance (open circuit) or the continuity test feature does not

sound an audible beep the fuse being tested is blown and must be replaced.

Volt Meter Method

Fuses can also be checked using an AC volt meter. The power supply must be turned on

and a call for heat must be active (all contactors must be closed) during this test. Touch the

two test probes to both ends of each fuse while still in the fuse blocks.

• A high voltage (at or above 120 VAC) reading indicates the fuse is blown.

• A zero volt reading generally indicates the fuse is goo d. Next check for voltage betwee n each end of the fuse

and ground to ensure voltage is pre sent at both ends of the fuse. If no volt age is present b etween either e nd

of the fuse and ground the test has not been conclusive - secure power to the wate r heater and per form th e

ohm meter test method described above.

The voltage test method is a good way to quickly identify fuses that are blown but it is not

always conclusive due to the dependence on power being present at both ends of the fuse,

all contactors being closed and correct wiring. Keep this in mind as there may be times when

a fuse that is blown tests good due to one of these dependencies not being met. The ohm

meter method described above may be more time consuming but it is 100% conclusive.

Servicing should only be performed by a Qualified Service Agent

15

OPERATION & SERVICE

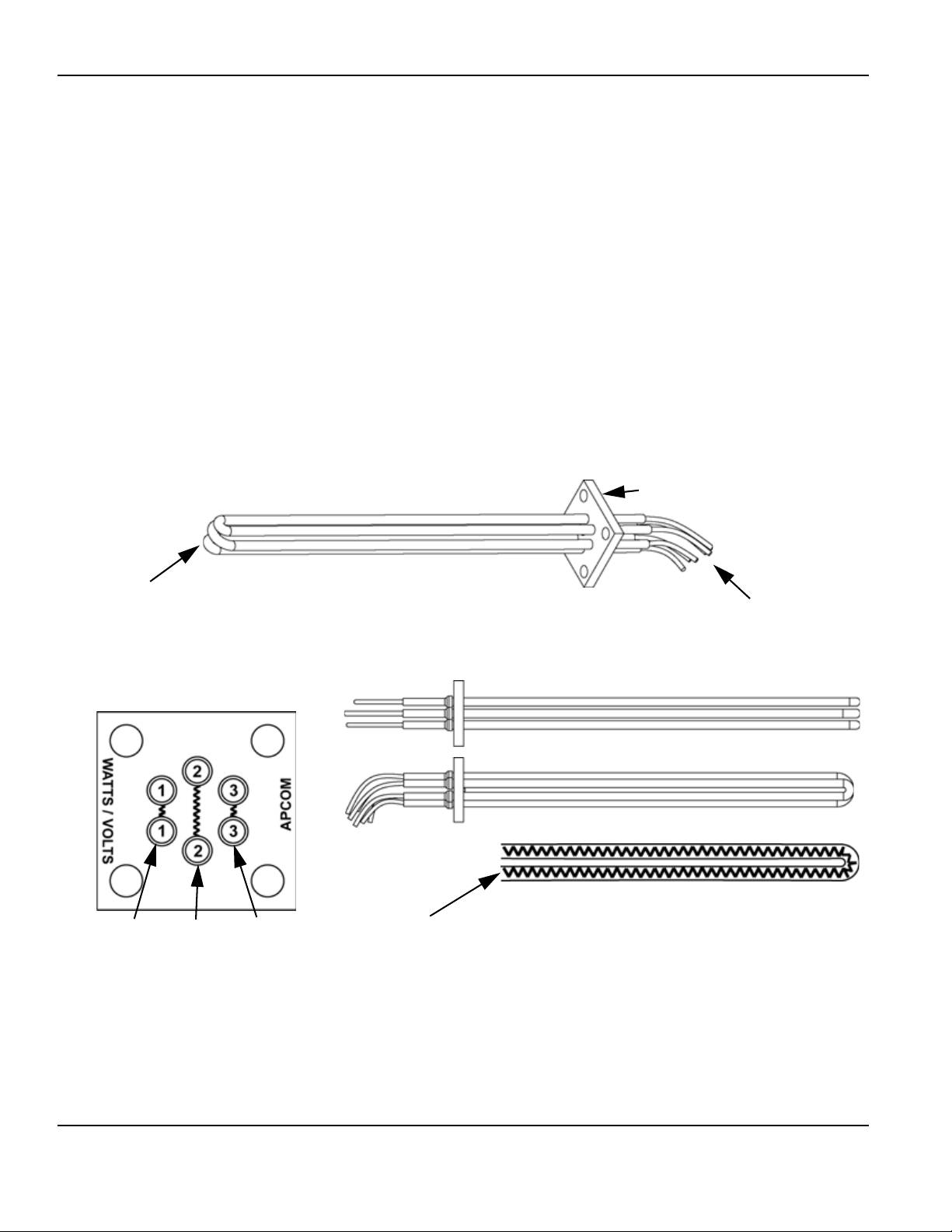

Top View

Heating Element Flange - End View

Side View

Resistive Circuits

Three resistive wire conductors inside three U shaped loops that are

permanently fitted into a flange form the heating element.

Internal View - U Shaped Loop

Six or Three Wire Leads

Three U shaped loops enclose wire conductors

that are surrounded by an insulating material.

Heating Element Flange

Two ends

of loop 1

Two ends

of loop 2

Two ends

of loop 3

HEATING ELEMENTS

Heating Element Construction

The water heaters covered in this manual use electric heating elements to heat water.

Heating elements convert electrical energy into heat energy.

Heating elements are constructed using 3 tubes formed into U shaped loops. The two ends

of each loop are permanently fitted into the element flange. Inside each loop is a wire

conductor (a resistive electrical circuit) surrounded by an insulating material. These wire

conductors pose a relatively high resistance to the flow of electricity . Heat is generated when

the electricity (voltage) applied to the element begins to flow (amperage) and encounters the

resistance (ohms) of the wire conductors inside. See “Principles of Electricity” on page 10.

There are two types of heating elements installed in the water heaters covered in this

manual; one type has six wire leads and the other has three wire leads. Heating elements

with six wire leads are installed on water heaters configured for single phase and three

phase power. Heating elements with three wire leads (Y configured) are installed on water

heaters configured for three phase power only. See “Single And Three Phase Power” on

page 12 and “Heating Element Wiring” section between pages 17 - 22.

Servicing should only be performed by a Qualified Service Agent

16

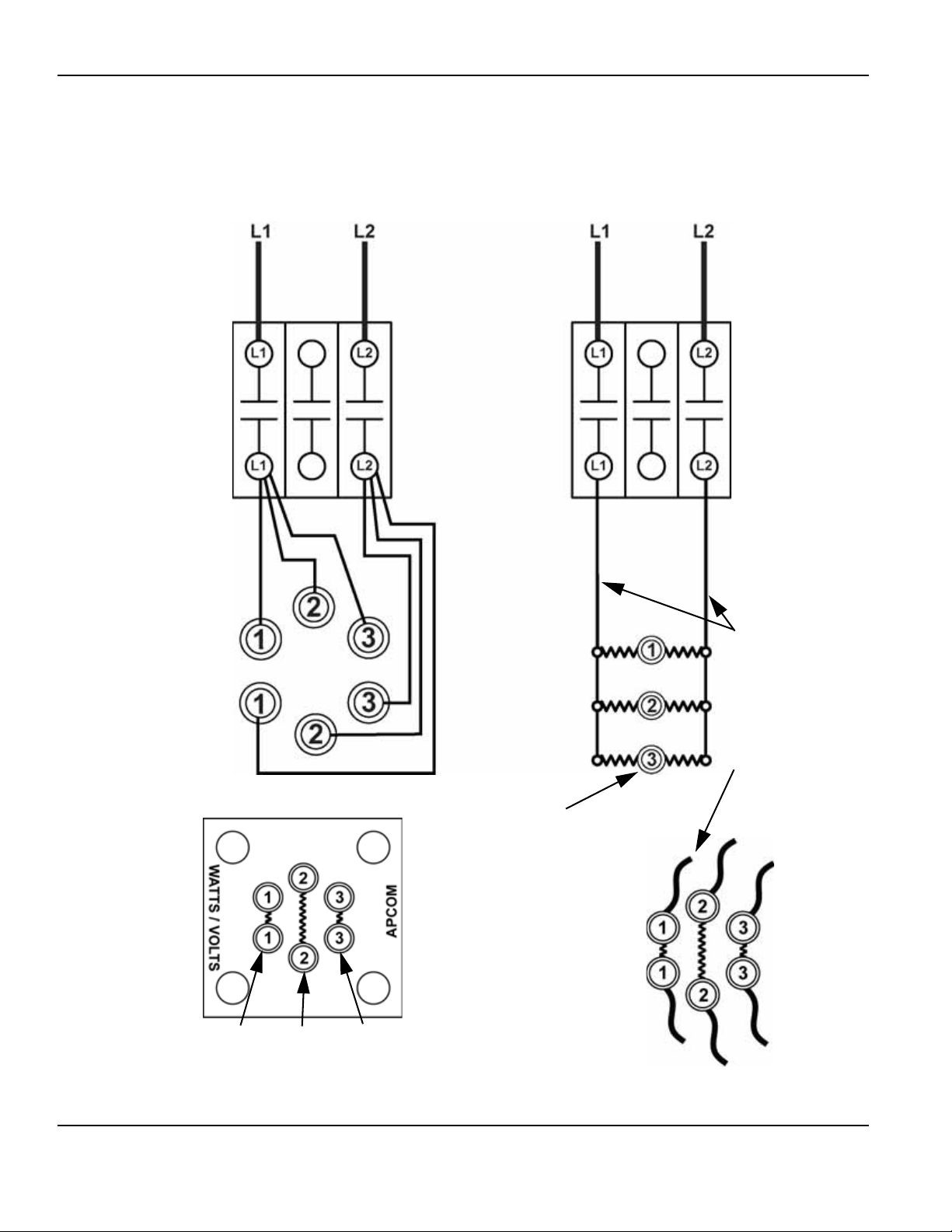

OPERATION & SERVICE

Six wiring leads,

one at both ends

of each loop.

Three wiring leads,

one at one end

of each loop.

Metal bar that joins

or splices together

one end of each loop.

Six Wire Element

Single & Three Phase Power

Three Wire Element - Y Configured

Three Phase Power Only

Metal bar that joins

or splices together

one end of each loop.

Three wiring leads.

Six wiring leads.

Heating Element Wiring

This section will provide more detailed information on heating elements and how they are

wired in single phase, three phase Delta and three phase Y configurations. See “Single And

Three Phase Power” on page 12.

Six and Three Wire Heating Elements

Depending on how a water heater is ordered and factory configured it will be equipped with

heating elements that have six wiring leads or three wiring leads. Six wire elements can be

used with single or three phase power. Three wire (also called Y configured) heating

elements are used with three phase power only.

Each heating element has 3 loops, each loop is a resistive circuit see “Heating Element

Construction” on page 16. Six wire heating elements have a wire lead connected to both

ends of the three loops. Three wire heating elements (Y configured) have a metal bar that

joins or splices together one end from each of the three loops and a wire lead connected to

the remaining end of each loop. See the illustrations below.

See also pages 18 - 22 for details on wiring between the heating elements and contactors.

Servicing should only be performed by a Qualified Service Agent

17

OPERATION & SERVICE

Heating Element Flange - End View

Two ends

of loop 1

Two ends

of loop 2

Two ends

of loop 3

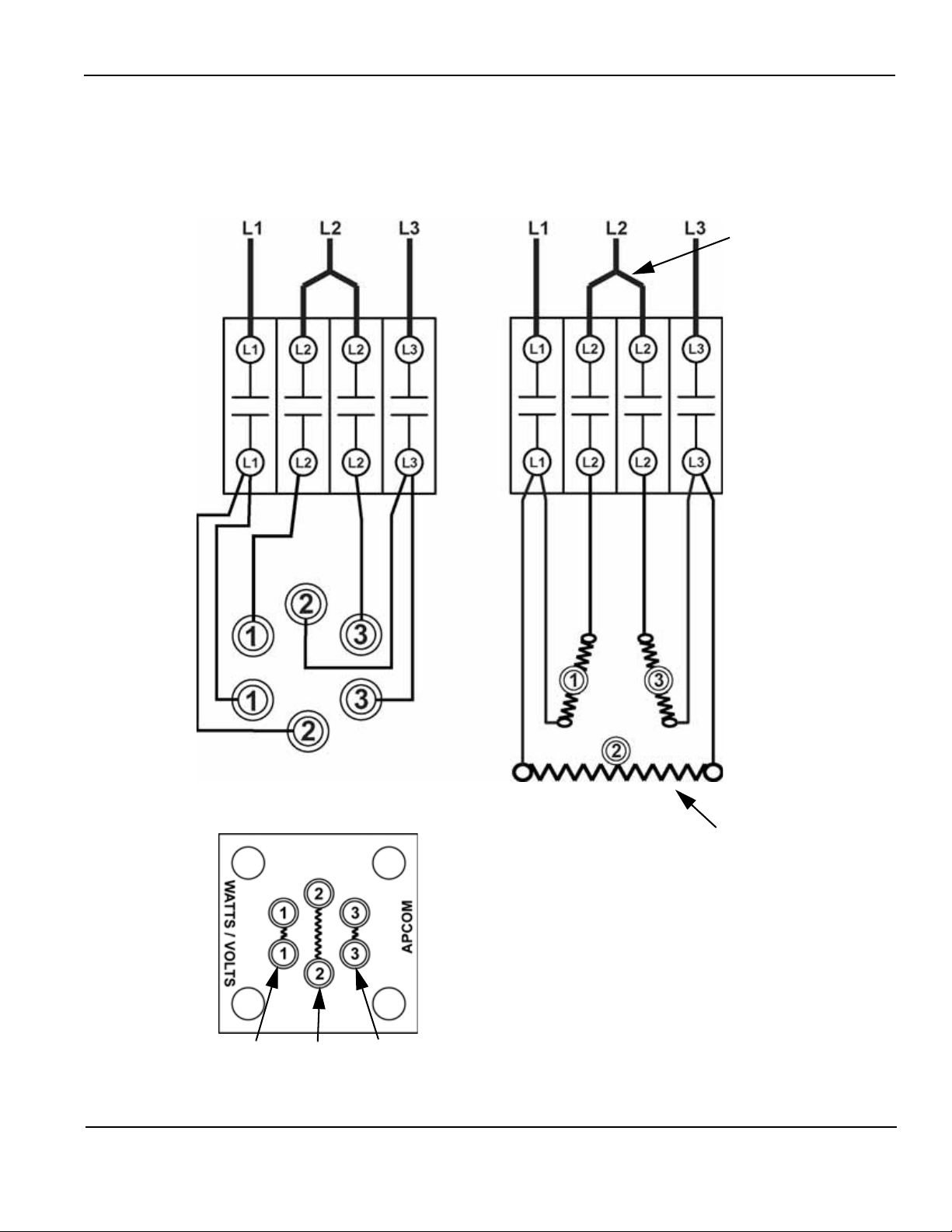

Connection Diagram Wiring Diagram

3 Pole

Contactor

Three loops

of one heating element

Single phase (1Ø)

power supply

Note: these two lines

exiting the bottom

of the contactor

represent six

wiring leads from

a heating element

as shown in the

connection diagram

on the left.

Note: middle pole

of the three pole

contactor is not used

on models configured

for single phase (1Ø

power.

Single Phase Wiring - 3 Pole Contactor

The illustrations below show how six wire heating elements (page 17) are wired to 3 pole

contactors on water heaters connected to a single phase power supply. See the

“Contactors” section of this manual - pages 34 - 38.

Servicing should only be performed by a Qualified Service Agent

18

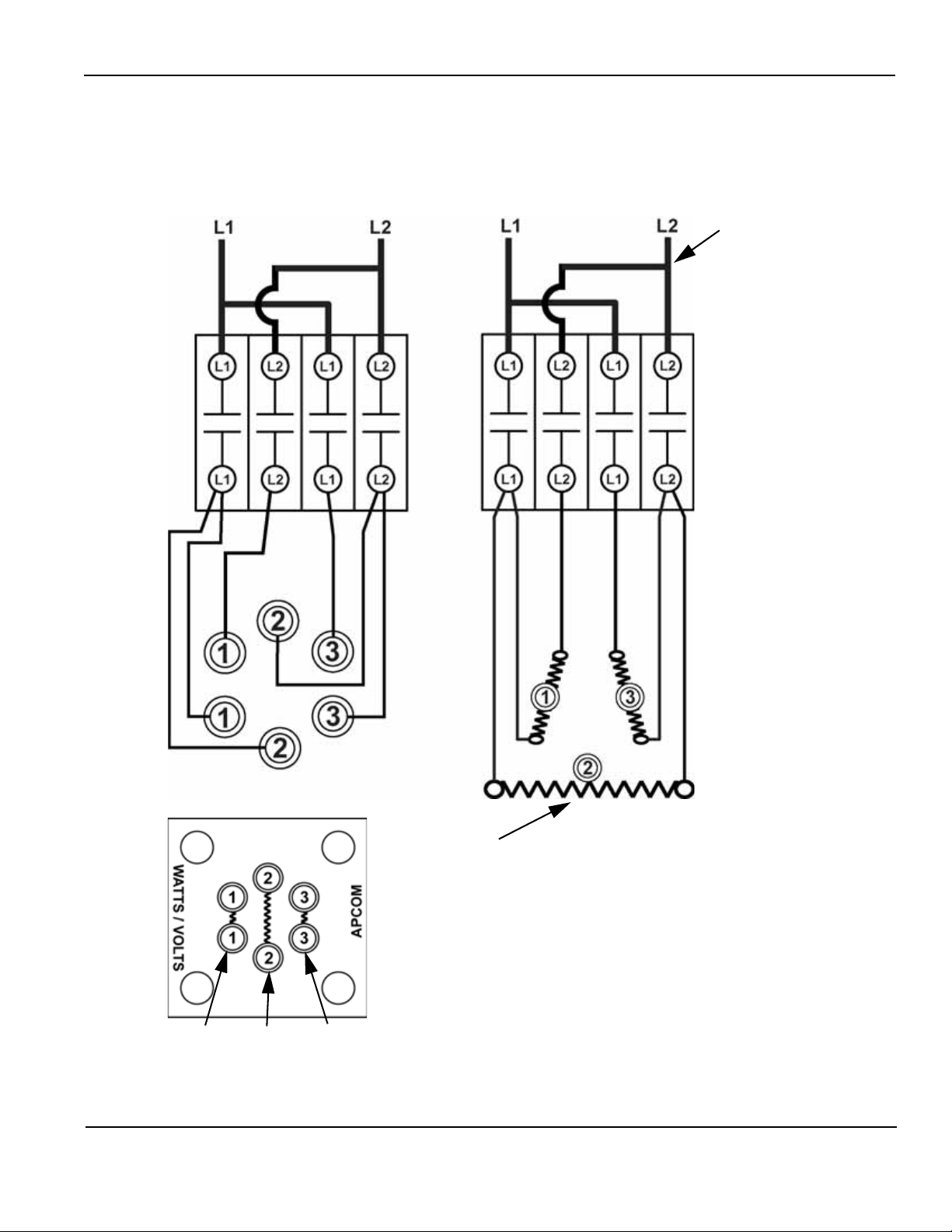

OPERATION & SERVICE

Heating Element Flange - End View

Two ends

of loop 1

Two ends

of loop 2

Two ends

of loop 3

Connection Diagram Wiring Diagram

4 Pole

Contactor

Three loops

of one heating element

Single phase (1Ø)

power supply

Models configured for

single phase power (1Ø)

and equipped with 4 pole

contactors will have two

jumper wires. One

between the 1st and 3rd

poles of the contactor

and one between the 2nd

and 4th poles of the

contactor.

Single Phase Wiring - 4 Pole Contactor

The illustrations below show how six wire heating elements (page 17) are wired to 4 pole

contactors on water heaters connected to a single phase power supply. See the

“Contactors” section of this manual - pages 34 - 38.

Servicing should only be performed by a Qualified Service Agent

19

OPERATION & SERVICE

Heating Element Flange - End View

Two ends

of loop 1

Two ends

of loop 2

Two ends

of loop 3

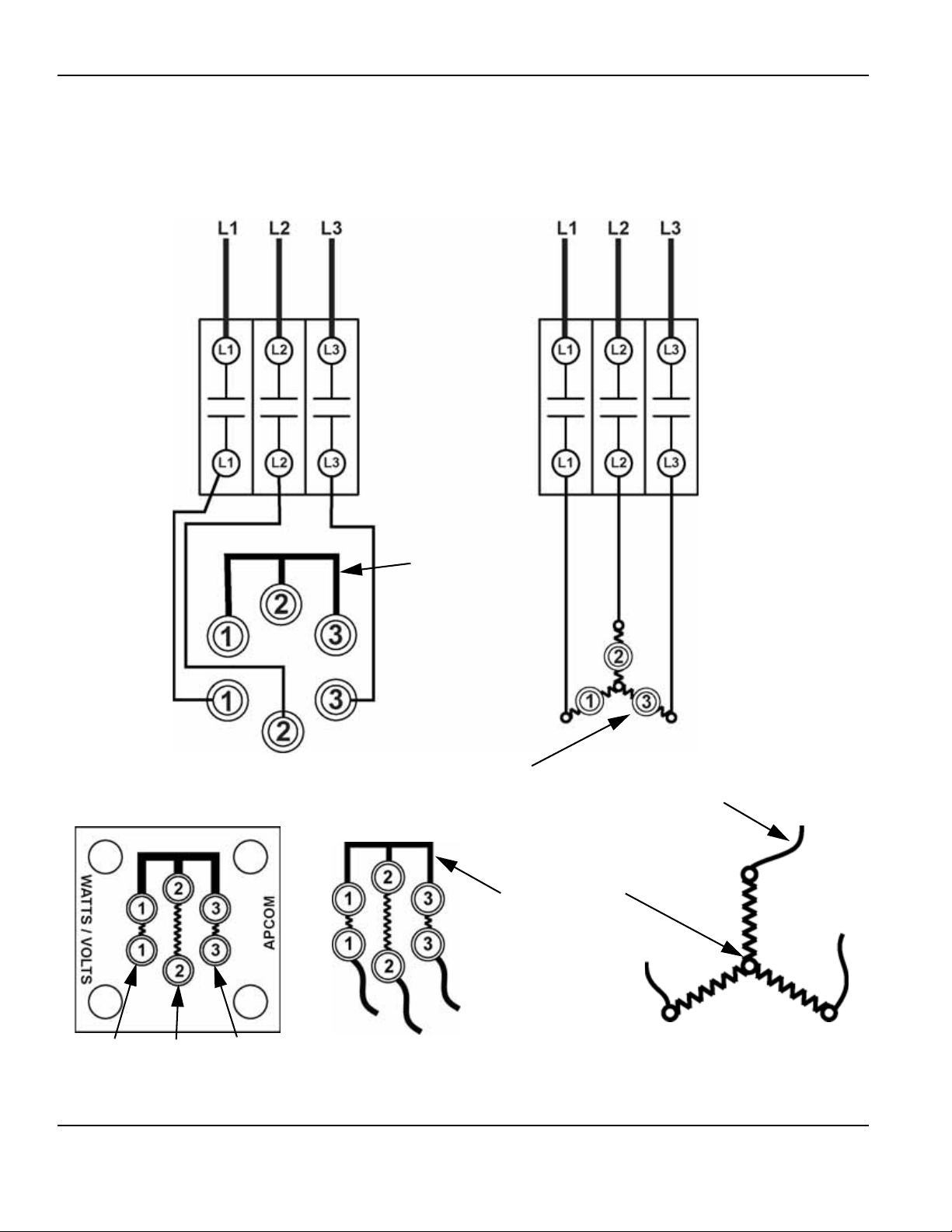

Connection Diagram Wiring Diagram

3 Pole

Contactor

Three loops

of one heating element

Note: each line

from the bottom

of the contactor

represents two

wiring leads from

a heating element

as shown in the

connection diagram

on the left.

Three phase (3Ø)

power supply

Three Phase Delta Wiring - 3 Pole Contactor

The illustrations below show how six wire heating elements (page 17) are wired to 3 pole

contactors on water heaters connected to a three phase power supply. See the “Contactors”

section of this manual - pages 34 - 38.

Servicing should only be performed by a Qualified Service Agent

20

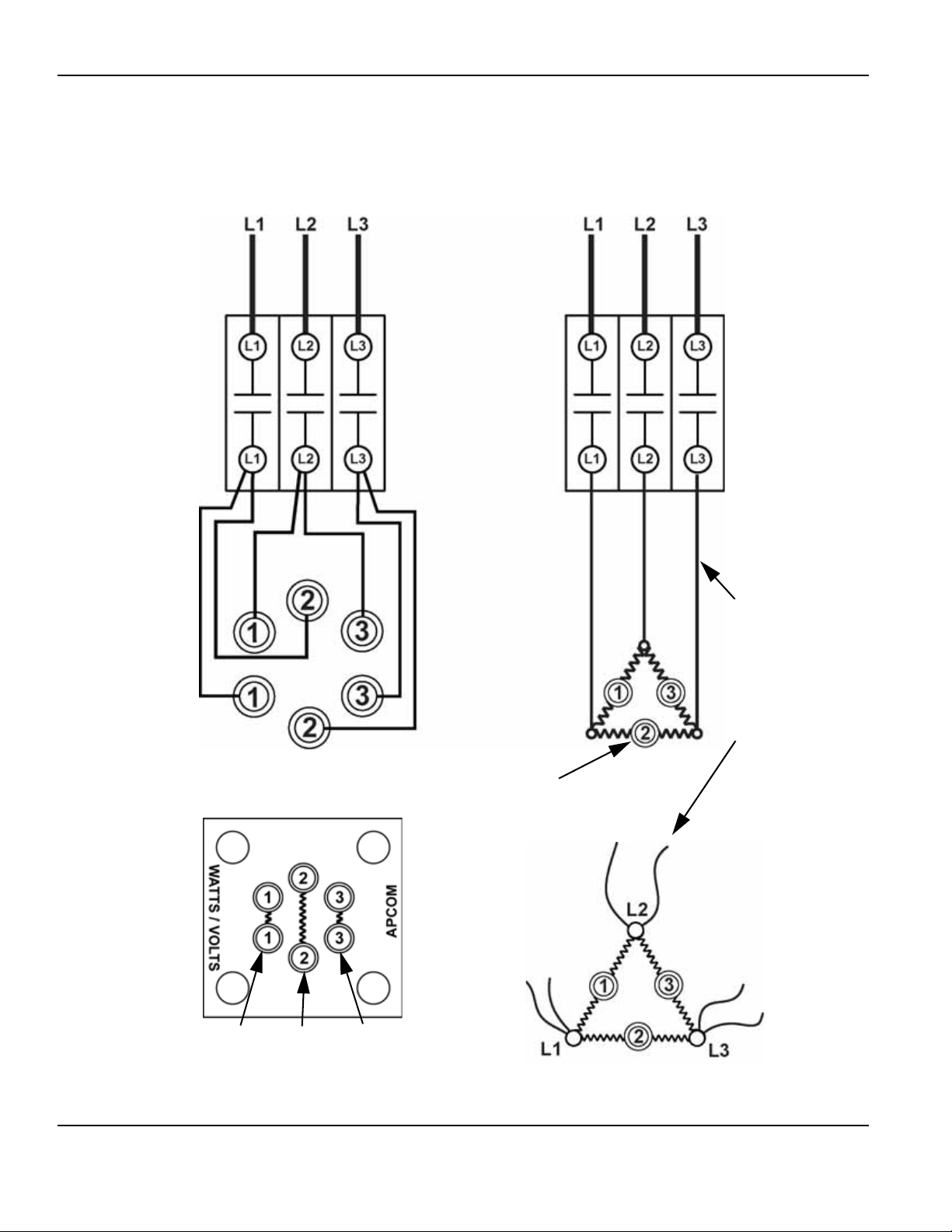

OPERATION & SERVICE

Heating Element Flange - End View

Two ends

of loop 1

Two ends

of loop 2

Two ends

of loop 3

Connection Diagram Wiring Diagram

4 Pole

Contactor

Three loops

of one heating element

Three phase (3Ø)

Models configured for

power supply

three phase power (3Ø)

and equipped with 4 pole

contactors will have a

jumper wire between the

2nd and 3rd poles of

the contactor.

Three Phase Delta Wiring - 4 Pole Contactor

The illustrations below show how six wire heating elements (page 17) are wired to 4 pole

contactors on water heaters connected to a three phase power supply. See the “Contactors”

section of this manual - pages 34 - 38.

Servicing should only be performed by a Qualified Service Agent

21

OPERATION & SERVICE

Heating Element Flange - End View

Two ends

of loop 1

Two ends

of loop 2

Two ends

of loop 3

Connection Diagram Wiring Diagram

3 Pole

Contactor

Three loops

of one heating element

Three phase (3Ø)

power supply

Metal bar that joins

or splices together

one end of each loop.

Wiring leads from

heating element

Metal bar that joins

or splices together

one end of each loop.

Three Phase Y Configuration - 3 Pole Contactor

The illustrations below show how three wire (Y configured) heating elements (page 17) are

wired to 3 pole contactors on water heaters connected to a three phase power supply. See

the “Contactors” section of this manual - pages 34 - 38.

Servicing should only be performed by a Qualified Service Agent

22

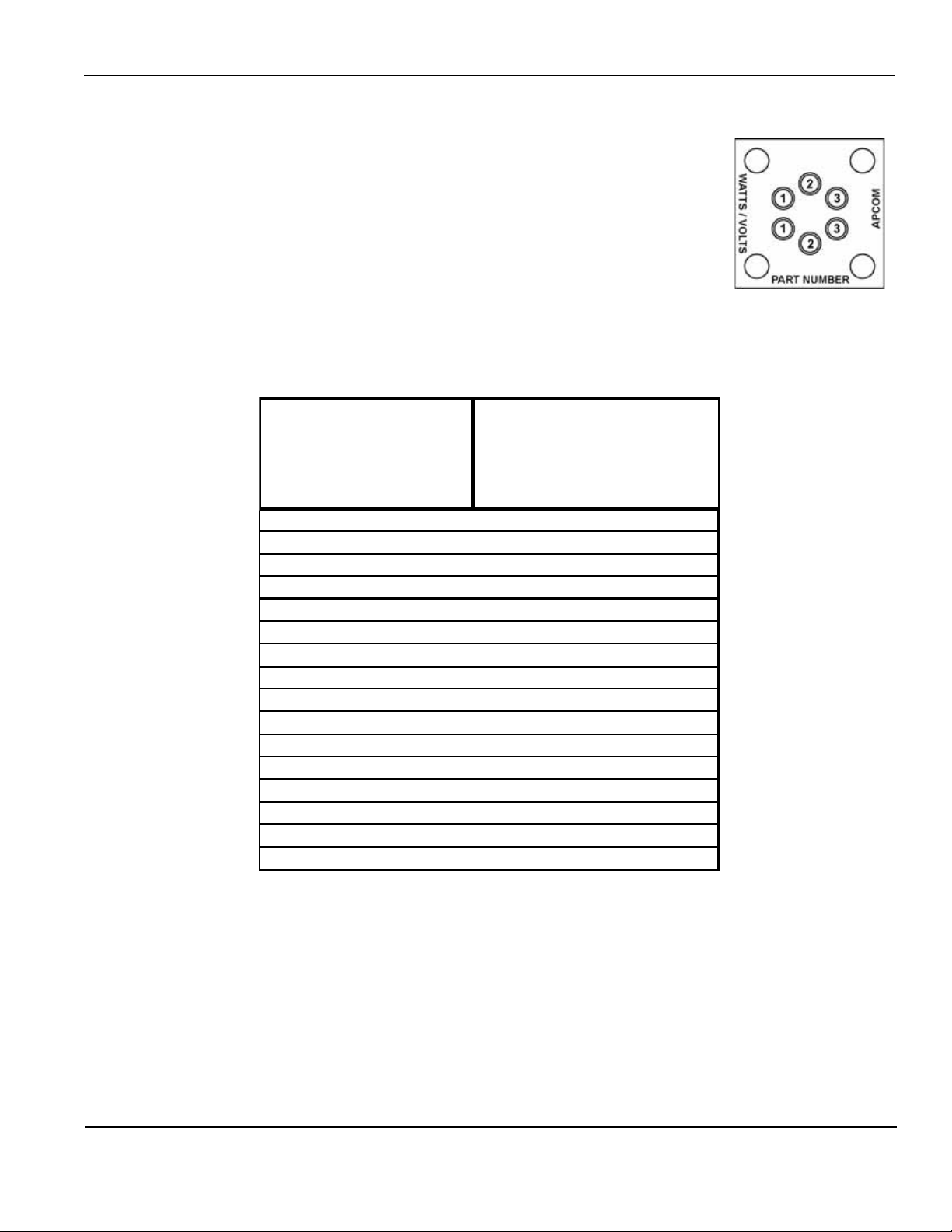

OPERATION & SERVICE

Heating Element Flange

3 1 - 3,000

6 1 - 6,000

9 1 - 9,000

12 1 - 12,000

15 1 - 15,000

18 1 - 18,000

*18 2 - 9,000

24 2 - 12,000

30 2 - 15,000

36 2 - 18,000

*36 3 - 12,000

45 3 - 15,000

54 3 - 18,000

**60 4 - 15,000

**75 5 - 15,000

**90 5 - 18,000

NUMBER

OF ELEMENTS

AND WATTAGE

* 208 Vol t models use one addition al element.

** Only Available in 50 gallon models or larger.

STANDARD

KW INPUT

RATINGS

Heating Element Ratings

There are six “standard” heating element KW ratings used; 3, 6, 9,

12, 15 and 18KW . Heating element flanges are stamped with the part

number, voltage and KW rating - see the illustration to the right.

Heating Element Configurations

The table below shows standard heating element configurations

used. Keep in mind the water heaters covered by this service manual

can be custom ordered with heating element voltage and KW ratings

other than what is shown in this table. Always check the water

heater’s rating label to see how the water heater was configured at the factory.

Service Note: Models at 54 KW and above are not available in 208 single phase (1Ø)

configurations. Also notice that some 208 volt models will contain additional elements.

Servicing should only be performed by a Qualified Service Agent

23

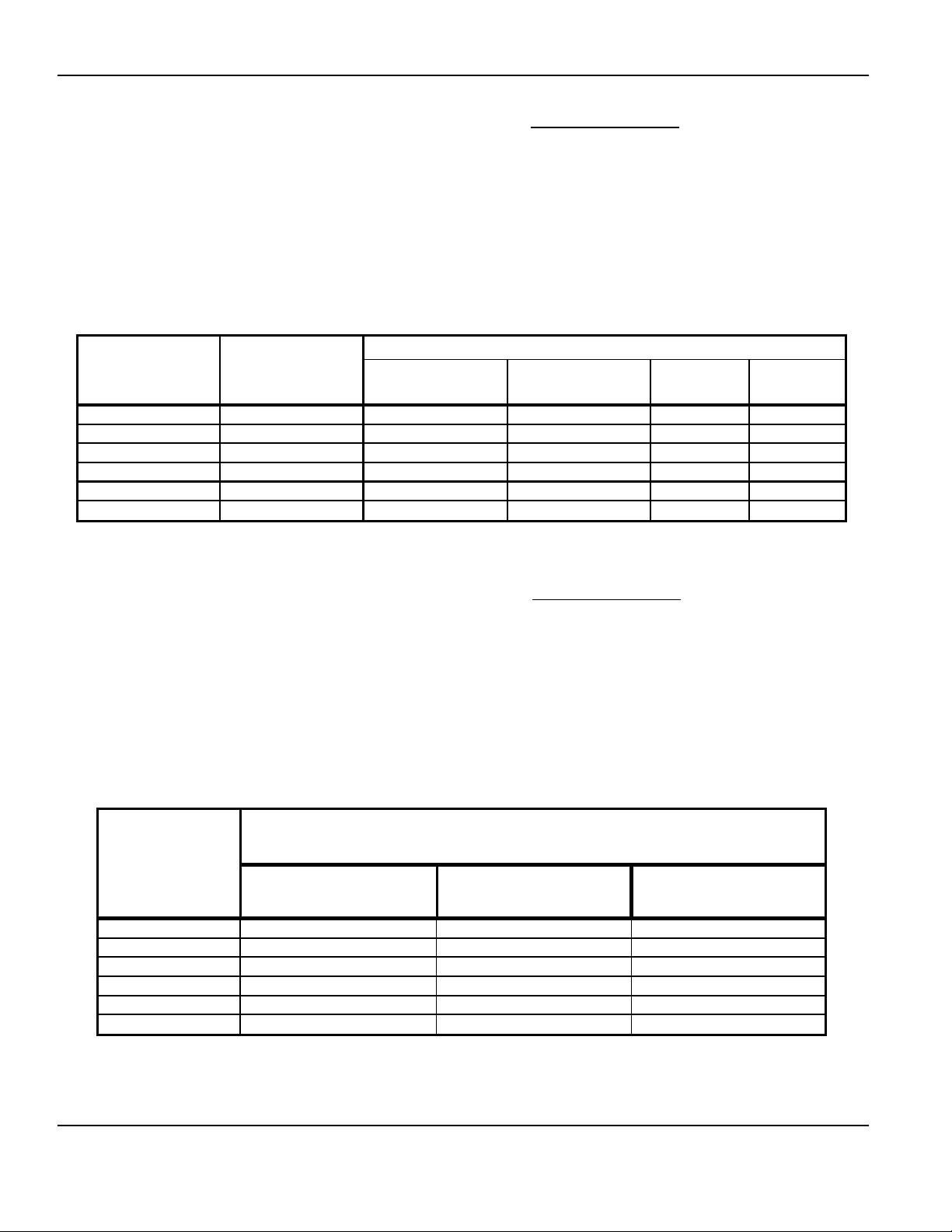

OPERATION & SERVICE

208 VAC 240 VAC 277 VAC 480 VAC

3,000 1,000 4.81 4.17 3.61 2.08

,

9,000

,

3

,

4

18,000

6,000 28.85 25.00 21.66 12.50

TOTAL

ELEMENT

WATTAGE

PE R LOOP

APPROXIMATE AMPS THROUGH EACH LOOP

SIX WIRE ELEMENT TABLE

20 8 VAC 240 VAC 4 80 VAC

3,000 8.32 7.21 3.61

,

12,000 33.29 28.85 14.43

18,000

49.93 43.28 21.64

TOTAL

ELEMENT

WATTAGE

APPROXI MATE A MPS THROUGH EACH WIRE

3 WIRE (Y CONFIGURED) ELEMENT TABLE

Heating Element Amperage - Six Wire Elements

The table below shows the approximate amp draw through each loop (see page 17) of a six

wire heating element. First determine the actual rated wattage and voltage of the element

being tested - see page 23. Then follow the Heating Element Amperage Test procedure on

page 25 to measure amperage through each loop of the six wire heating element being

tested. The 3 amp readings, one for each loop, should be approximately the same. Compare

the measured values to the values in the table below. Keep in mind there may be some

variance between measured values and the values in this table due to fluctuations in

voltage, temperature and the calibration of test instruments being used.

WATTAGE

6,000

12

000 4,000 19.2

15,000

000 9.62 8.33 7.22 4.17

2

3,000 14.42 12.50 10.83 6.25

16.67 14.44 8.33

000 24.0

5

20.83 18.05 10.42

Heating Element Amperage - Three Wire (Y Configured) Elements

The table below shows the approximate amp draw through each wire (see page 17) of a

three wire heating element. First determine the actual rated wattage and voltage of the

element being tested - see page 23. Then follow the Heating Element Amperage test

procedure on page 25 to measure amperage through each wire of the three wire heating

element being tested. The 3 amp readings should be approximately the same. Compare the

measured values to the values in the table below . Keep in mind there may be some variance

between measured values and the values in this table due to fluctuations in voltage,

temperature and the calibration of test instruments being used.

6,000 16.64 14.43 7.21

9

000 24.97 21.64 10.82

15,000 41.61 36.06 18.03

Servicing should only be performed by a Qualified Service Agent

24

Loading...

Loading...