A. O. Smith 81-140 Installation Manual

COMMERCIAL GAS

Lined Tank Type Water Heater

• Installation • Service • Maintenance

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS

INFORMATION RELATIVE TO YOUR SAFETY. PLEASE READ

THOROUGHLY BEFORE INSTALLING AND USING THIS

APPLIANCE.

PLACE THESE INSTRUCTIONS ADJACENT TO HEATER AND

NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

PRINTED IN U.S.A. 1102 PART NO. 195091-000

1

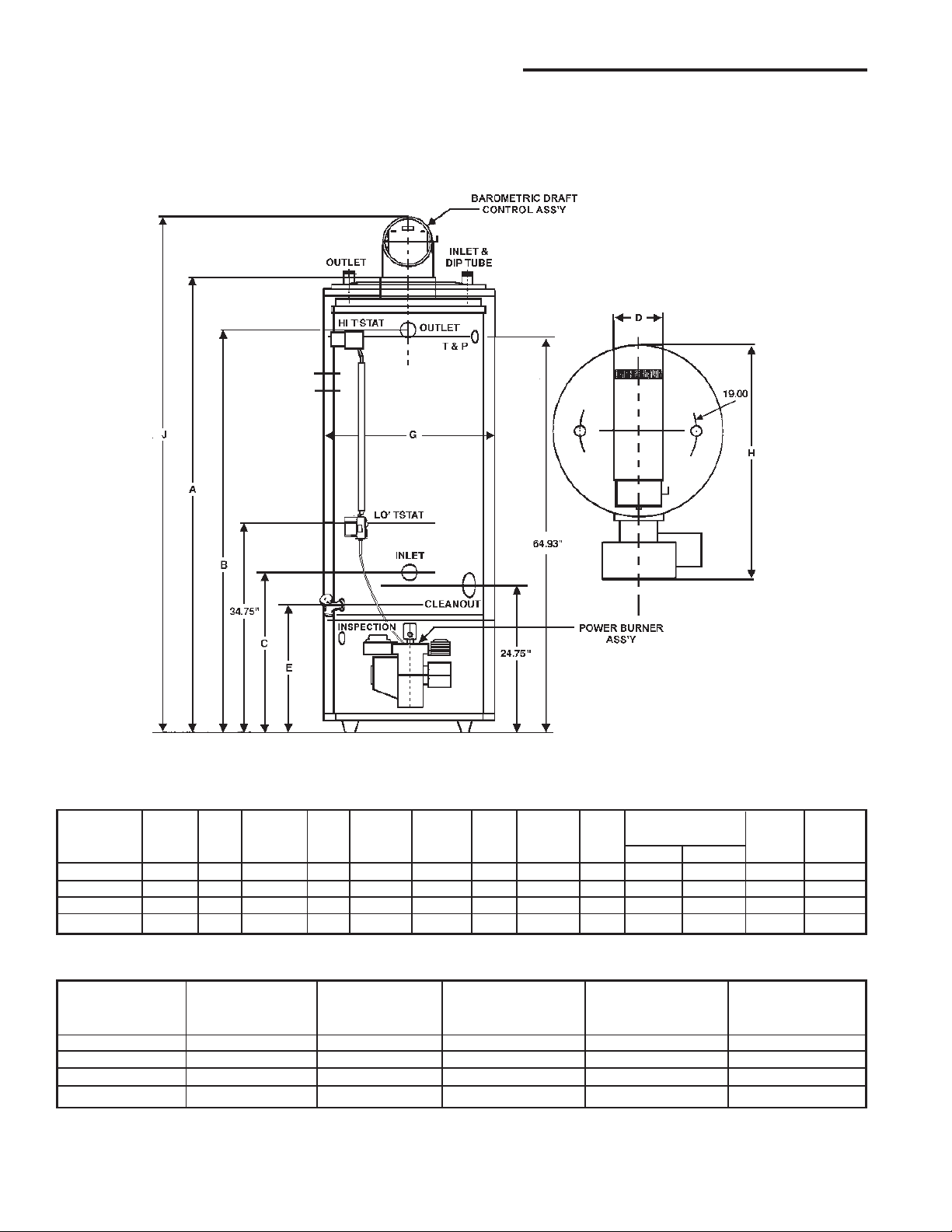

FEATURES AND SPECIFICATIONS

The illustration shows a typical gas-fired commercial gas power burner, tank-type

water heater. The principal components of the heater are shown and identified

here. By referring to the plate on the heater jacket the unit may be identified in the

specifications presented in Table 1 and 2.

TABLE 1 - NOMINAL MODEL DIMENSIONS AND WEIGHTS

MODELS A B C D E G H J GAS APPROX. SHIP. IN OUT

WT. (LBS.)

ASME STD.

***81-140 74 3/4 65 26 3/4 6 21 3/8 27 3/4 38 85 1/4 1/2 658 556 1 1/2 1 1/2

***81-199 74 3/4 65 26 3/4 6 21 3/8 27 3/4 38 85 1/4 1/2 635 545 1 1/2 1 1/2

***81-270 74 3/4 65 26 3/4 8 21 3/8 27 3/4 38 85 1/4 3/4 632 547 1 1/2 1 1/2

***81-370 74 3/4 65 26 3/4 8 21 3/8 27 3/4 38 85 1/4 3/4 731 634 1 1/2 1 1/2

TABLE 2 - MODEL ENERGY CONSUMPTION AND PERFORMANCE DATA

STORAGE MAXIMUM

MODELS CAPACITY IMPUT RATING RECOVERY RATE RECOVERY RATE AMPERES

U.S. GALLONS BTU/HR. GPH@100°F RISE GPH@140°F RISE 120V, 60Hz, 1Ø

***81-140 81 140,000 136 97 5

***81-199 81 199,000 193 138 5

***81-270 81 270,000 262 187 5

***81-370 81 370,000 359 256 5

Model Designator: Sample ***81-140NEA N = Natural Gas

*** = Letter designator E = 3 Year Warranty

81 = Gallon Capacity A = ASME Construction

140 = 140,000 BTU/HR imput

2

FOREWORD

These designs comply with the latest version of the American

National Standard for Gas Water Heaters, Volume III,

ANSI Z21.10.3 - CSA 4.3.

Detailed installation diagrams are found in this manual. These

diagrams will serve to provide the installer with a reference for

the materials and methods of piping necessary. It is highly

essential that all water, gas piping and wiring be installed as shown

on the diagrams.

Particular attention should be given to the installation of

thermometers at the locations indicated on the diagrams as these

are necessary for checking the proper functioning of the heater.

The ***81-140 through ***81-370 models are designed to

operate on either natural or propane gases. HOWEVER, MAKE

SURE the gas on which the heater will operate is the same as

that specified on the heater model and rating plate.

TABLE OF CONTENTS

PAGE

FEATURES AND SPECIFICATIONS ........................................... 2

FOREWORD ............................................................................... 3

GENERAL SAFETY INFORMATION

Precautions ............................................................................. 3

Chemical Vapor Corrosion ...................................................... 3-4

Improper Combustion ............................................................. 4

Liquid Petroleum Models ......................................................... 4

Extended Non-Use Periods ..................................................... 4

Insulation Blankets .................................................................. 4

High Altitude Installation ......................................................... 4-5

FEATURES

High Limit Switch (E.C.O.) ...................................................... 5

Circulating Pump ..................................................................... 5

Dishwashing Machine Requirements ...................................... 5

INSTALLATION INSTRUCTIONS

Required Ability ....................................................................... 5

Uncrating ................................................................................. 5

Locating the Heater ................................................................. 5-6

Clearances .............................................................................. 6

Levelling .................................................................................. 6

Hard Water .............................................................................. 6

Air Requirements .................................................................... 6-7

Mechanical Exhausting of Room Air ....................................... 7

Venting .................................................................................... 7

Barometric Draft Control Assembly ........................................ 7

Vent Connection ...................................................................... 7-8

Drain Valve and Access Panels .............................................. 8

Burner Installation ................................................................... 8

Gas Meter Size-City Gases Only ............................................ 8

Gas Pressure Regulation ........................................................ 8-9

Gas Piping ............................................................................... 9

THESE HEATERS MUST NOT BE INSTALLED DIRECTLY ON

COMBUSTIBLE FLOORS.

In addition to these instructions, the equipment shall be installed

in accordance with those installation regulations in force in the

local area where the installation is to be made. These shall be

carefully followed in all cases. Authorities having jurisdiction

should be consulted before installations are made.

The installation must conform to these instructions and the local

code authority having jurisdiction. In the absence of local codes

the installation must comply with the latest editions of the National

Fuel Gas Code, ANSI Z223.1/NFPA 54 and the National Electric

Code, NFPA 70. The former is available from the Canadian

Standards Association, 8501 Pleasant Valley Road, Cleveland,

OH 44131 and both documents are available from the National

Fire Protection Association, 1 Batterymarch Park, Quincy,

MA 02269.

PAGE

Heater Wiring Instructions ...................................................... 9-10

Water Line Connection .......................................................... 10

Water (Potable) Heating and Spacing.................................. 10

Relief Valve ............................................................................ 10

Thermometers (Not Supplied) ............................................... 10

Wiring for ***81-140 thru ***81-370 ....................................... 11

INSTALLATION DIAGRAMS ...................................................... 12-15

Manifold Kits .......................................................................... 1 6

PRIOR TO START UP

Required Equipment And Ability .......................................... 1 7

Purging ................................................................................... 1 7

Water Temperature Control ................................................... 17

Operation & Adjustment Procedure ...................................... 18

Adjustment Procedure ........................................................... 19-20

MAINTENANCE

Maintenance Schedule ......................................................... 20

Flushing .................................................................................. 20

Draining .................................................................................. 20

Sediment Removal ................................................................ 20

Lime Scale Removal ............................................................. 20-21

Relief Valve ........................................................................... 21

Circulating Pump ................................................................... 2 1

Power Burner .......................................................................... 21

Vent System ............................................................................ 21

Barometric Draft Control ........................................................ 21-22

Electrical Servicing ................................................................ 22

CHECKLIST AND SERVICE INFORMATION ............................ 22-23

TROUBLESHOOTING ................................................................ 2 3

Replacement Parts ................................................................. 23

PARTS LIST................................................................................ 24-27

GENERAL SAFETY INFORMATION

PRECAUTIONS

DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN

UNDERWATER. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the control

system and any gas control which has been under water.

IF THE UNIT IS EXPOSED TO THE FOLLOWING, DO NOT

OPERATE HEATER UNTIL ALL CORRECTIVE STEPS HAVE

BEEN MADE BY A QUALIFIED SERVICEMAN.

1. EXTERNAL FIRE.

2. DAMAGE.

3. FIRING WITHOUT WATER.

4 SOOTING.

Heater must be protected from freezing downdrafts during

shutdown periods.

CORROSION OF THE FLUEWAYS AND VENT SYSTEM MAY

OCCUR IF AIR FOR COMBUSTION CONTAINS CERTAIN

CHEMICAL VAPORS WHICH BREAK DOWN INTO ACIDS AT

HIGH TEMPERATURE. SUCH CORROSION MAY RESULT IN

FAILURE AND RISK OF ASPHYXIATION.

3

CHEMICAL VAPOR CORROSION

WARNING

Spray can propellants, cleaning solvents, refrigerator and air

conditioning refrigerants, swimming pool chemicals, calcium

and sodium chloride (water softener salt), waxes, and process

chemicals contain typical compounds which are potentially

corrosive. Do not store products of this sort near the heater.

Also, air which is brought in contact with the heater should not

contain any of these chemicals. If necessary, uncontaminated

air should be obtained from remote or outside sources. The

limited warranty is voided when failure of water heater is due to

a corrosive atmosphere. (Refer to the limited warranty for

complete terms and conditions).

IMPROPER COMBUSTION

WARNING

ATTIC AND/OR EXHAUST FANS OPERATING ON THE PREMISES

WITH A WATER HEATER CAN RESULT IN CARBON MONOXIDE

POISONING AND DEATH.

OPERATING THESE FANS CAN PRODUCE A NEGATIVE DRAFT

IN THE AREA OF THE WATER HEATER PREVENTING THE

PRODUCTS OF COMBUSTION FROM EXHAUSTING THROUGH

THE CHIMNEY OR VENT PIPE.

recommended that the hot water faucet be opened for several

minutes at the kitchen sink before using any electrical appliance

connected to the hot water system. If hydrogen is present, there

will probably be an unusual sound such as air escaping through

the pipe as the water begins to flow. THERE SHOULD BE NO

SMOKING OR OPEN FLAME NEAR THE FAUCET AT THE TIME

IT IS OPEN.

INSULATION BLANKETS

Insulation blankets available to the general public for external

use on gas water heaters are not approved for use on your water

heater. The purpose of an insulation blanket is to reduce the

standby heat loss encountered with storage tank water heaters.

Your water heater meets or exceeds the ASHRAE/IES

90.1b-1992 standards with respect to insulation and standby

loss requirements making an insulation blanket unnecessary.

WARNING

Should you choose to apply an insulation blanket to this heater,

you should follow these instructions. Failure to follow these

instructions can result in fire, asphyxiation, serious personal injury

or death.

The venting of the water heater should be inspected by a qualified

service technician at the time of installation and periodically

thereafter to ensure a down-draft condition does not exist.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION AND

VENTILATING AIR. ADEQUATE AIR FOR COMBUSTION AND

VENTILATION MUST BE PROVIDED FOR SAFE OPERATION.

LIQUID PETROLEUM MODELS

Water heaters for propane or liquefied petroleum gas (LPG) are

different from natural gas models. A natural gas heater will not

function safely on LP gas and no attempt should be made to

convert a heater from natural gas to LP gas.

LP gas must be used with great caution. It is highly explosive

and heavier than air. It collects first in the low areas making its

odor difficult to detect at nose level. If LP gas is present or even

suspected, do not attempt to find the cause yourself. Go to a

neighbor’s house, leaving your doors open to ventilate the house,

then call your gas supplier or service agent. Keep area clear

until a service call has been made.

At times you may not be able to smell an LP gas leak. One

cause is odor fade, which is a loss of the chemical odorant that

gives LP gas its distinctive smell. Another cause can be your

physical condition, such as having a cold or diminishing sense

of smell with age. For these reasons, the use of a propane gas

detector is recommended.

Only trained LP professionals should conduct the required safety

checks in accordance with industry standards.

EXTENDED NON-USE PERIODS

WARNING

HYDROGEN GAS CAN BE PRODUCED IN A HOT WATER

SYSTEM SERVED BY THIS HEATER THAT HAS NOT BEEN USED

FOR A LONG PERIOD OF TIME (GENERALLY TWO WEEKS OR

MORE). HYDROGEN GAS IS EXTREMELY FLAMMABLE. To

reduce the risk of injury under these conditions, it is

•

Do not apply insulation to the top of the water heater, as this

will interfere with safe operation of drafthood.

• Do not cover the temperature & pressure relief valve.

• Do not cover the instruction manual. Keep it on the side of the

water heater or nearby for future reference.

• Do obtain new labels from manufacturer for placement on

the blanket directly over the existing labels.

HIGH ALTITUDE INSTALLATIONS

WARNING

INSTALLATIONS ABOVE 2000 FEET REQUIRE REPLACEMENT

OF THE BURNER ORIFICE IN ACCORDANCE WITH SECTION

8.1.2 OF THE NATIONAL FUEL GAS CODE (ANSI Z223.1).

FAILURE TO REPLACE THE ORIFICE WILL RESULT IN

IMPROPER AND INEFFICIENT OPERATION OF THE APPLIANCE

RESULTING IN THE PRODUCTION OF INCREASED LEVELS

OF CARBON MONOXIDE GAS IN EXCESS OF SAFE LIMITS

WHICH COULD RESULT IN SERIOUS PERSONAL INJURY OR

DEATH.

As elevation above sea level is increased, there is less oxygen

per cubic foot of air. Therefore, the heater input rate should be

reduced at high altitudes for satisfactory operation with the

reduced oxygen supply. Failure to make this reduction would

result in an overfiring of the heater, causing sooting, poor

combustion and/or unsatisfactory heater performance.

Ratings specified by manufacturers for most appliances apply

for elevations up to 2000 feet. For elevations above 2000 feet,

ratings must be reduced at the rate of 4% for each 1000 feet

above sea level. For example, if a heater is rated at 120,000 Btu/

hr. at sea level, to rate the heater at 4000 feet, you subtract 4

(once for each thousand feet) x .04 (4% input reduction) x 120,000

(the original rating) from the original rating. Therefore, to calculate

the input rating at 4000 feet: 4 x .04 x 120,000 = 19,200 btu/hr.,

120,000 - 19,200 = 100,800 btu/hr. At 6000 feet elevation, the

heater rating would be 91,200 btu/hr.

4

The input reduction is primarily achieved by reducing the size of

the main burner orifices. To do this, the main burner orifices

require replacement with orifices sized for the particular installation

elevation. Correct orifice sizing and parts may be obtained from

the manufacturer. See the REPLACEMENT PARTS section of

this manual. When ordering, be sure to state the model number

and the altitude of the location where the heater is being

installed.

Refer to the piping diagrams at rear of manual for electrical

hookup information and install in accordance with the latest

version of the

Only all bronze circulators are used with commercial water heaters.

Although circulators are oiled and operated by the manufacturer

some circulators must be oiled again before operating. Please

refer to manufacturer’s instructions.

National Electric Code ANSI/NFPA No. 70.

Upon completion of derating of the heater, adjustment to the gas

pressure regulator may be required. See ADJUSTMENT

PROCEDURE in this manual for inlet and manifold pressure

requirements.

Also, due to the input rating reduction required at high altitudes,

the output rating of the appliance is also reduced and should be

compensated for in the sizing of the equipment for applications.

FEATURES

HIGH LIMIT SWITCH (E.C.O.)

The dual bulb controller ((fig. 1) contains the high limit (energy

cutoff) sensor. The high limit switch interrupts main burner gas

flow should the water temperature reach 205°F (96°C).

In the event of high limit switch operation, the appliance cannot

be restarted unless the water temperature is reduced by at least

20°F (11°C) and the high limit reset button on front of limit control

(fig.1) is depressed.

DISHWASHING MACHINE REQUIREMENT

All dishwashing machines meeting the National Sanitation

Foundation requirements are designed to operate with water flow

pressures between 15 and 25 pounds per square inch. Flow

pressures above 25 pounds per square inch, or below 15 pounds

per square inch, will result in improperly sanitized dishes. Where

pressures are high, a water pressure reducing or flow regulating

control valve should be used in 1800 line to the dishwashing

machine, and should be adjusted to deliver water between these

limits.

The National Sanitation Foundation also recommends circulation

of 1800F water. Where this is done, the circulation should be

very gentle so that it does not cause any unnecessary turbulence

inside the water heater. The circulation should be just enough to

provide 1800F water at the point of take-off to the dishwashing

machine. Adjust flow by means of the plug cock in the circulating

line.

INSTALLATION INSTRUCTIONS

REQUIRED ABILITY

INSTALLATION OR SERVICE OF THIS WATER HEATER

REQUIRES ABILITY EQUIVALENT TO THAT OF A LICENSED

TRADESMAN IN THE FIELD INVOLVED. PLUMBING, AIR

SUPPLY, VENTING, GAS SUPPLY AND ELECTRICAL WORK

ARE REQUIRED.

DUAL-BULB THERMOSTAT (COVER REMOVED)

FIGURE 1

Continued manual resetting of high limit control, preceded by

higher than usual water temperature is evidence of high limit switch

operation. The following is a possible reason for high limit switch

operation.

• A malfunction in the thermostatic controls would allow the gas

valve to remain open causing water temperature to exceed

the thermostat setting. The water temperature would continue

to rise until high limit switch operation.

Contact your dealer or servicer if continued high limit switch

operation occurs, to determine the reason for operation.

CIRCULATING PUMP

A circulating pump is used when a system requires a circulating

loop or there is a storage tank used in conjunction with the heater.

UNCRATING

Uncrate the heater by removing the outside mat and top locator.

The shipping pallet must be removed from the unit. It may be

possible to simply unbolt the base from the pallet and, with the

help of 2 or more persons, work the unit off the pallet. Some

units will be too heavy and will require the use of jacks or lifting

equipment to safely remove the pallet and move the unit into

position. Be careful when moving this heater. It will tip over

easily.

The heater is shipped with a burner and draft control. The burner

and draft control are shipped in separate cartons. They should

be installed as received without any alterations.

Discard the shipping crate and packaging cartons in an appropriate

manner.

LOCATING THE HEATER

WARNING

THERE IS A RISK IN USING FUEL BURNING APPLIANCES

SUCH AS GAS WATER HEATERS IN ROOMS, GARAGES OR

OTHER AREAS WHERE GASOLINE, OTHER FLAMMABLE

LIQUIDS OR ENGINE DRIVEN EQUIPMENT OR VEHICLES ARE

STORED, OPERATED OR REPAIRED. FLAMMABLE VAPORS

5

ARE HEAVY AND TRAVEL ALONG THE FLOOR AND MAY BE

IGNITED BY THE HEATER’S IGNITION SYSTEM OR MAIN

BURNER FLAMES CAUSING FIRE OR EXPLOSION. SOME

LOCAL CODES PERMIT OPERATION OF GAS APPLIANCES

IN SUCH AREAS IF THEY ARE INSTALLED 18 INCHES OR

MORE ABOVE THE FLOOR. THIS MAY REDUCE THE RISK IF

LOCATION IN SUCH AN AREA CANNOT BE AVOIDED.

WARNING

FLAMMABLE ITEMS, PRESSURIZED CONTAINERS OR ANY

OTHER POTENTIAL FIRE HAZARDOUS ARTICLES MUST

NEVER BE PLACED ON OR ADJACENT TO THE HEATER.

OPEN CONTAINERS OF FLAMMABLE MATERIAL SHOULD

NOT BE STORED OR USED IN THE SAME ROOM WITH THE

HEATER.

THE HEATER SHALL BE LOCATED OR PROTECTED SO IT IS

NOT SUBJECT TO PHYSICAL DAMAGE BY A MOVING

VEHICLE.

THE HEATER MUST NOT BE LOCATED IN AN AREA WHERE

IT WILL BE SUBJECT TO FREEZING.

When installing the heater, consideration must be given to proper

location. Location selected should be as close to a gas vent or

chimney as practicable, with adequate air supply and as

centralized with the piping system as possible.

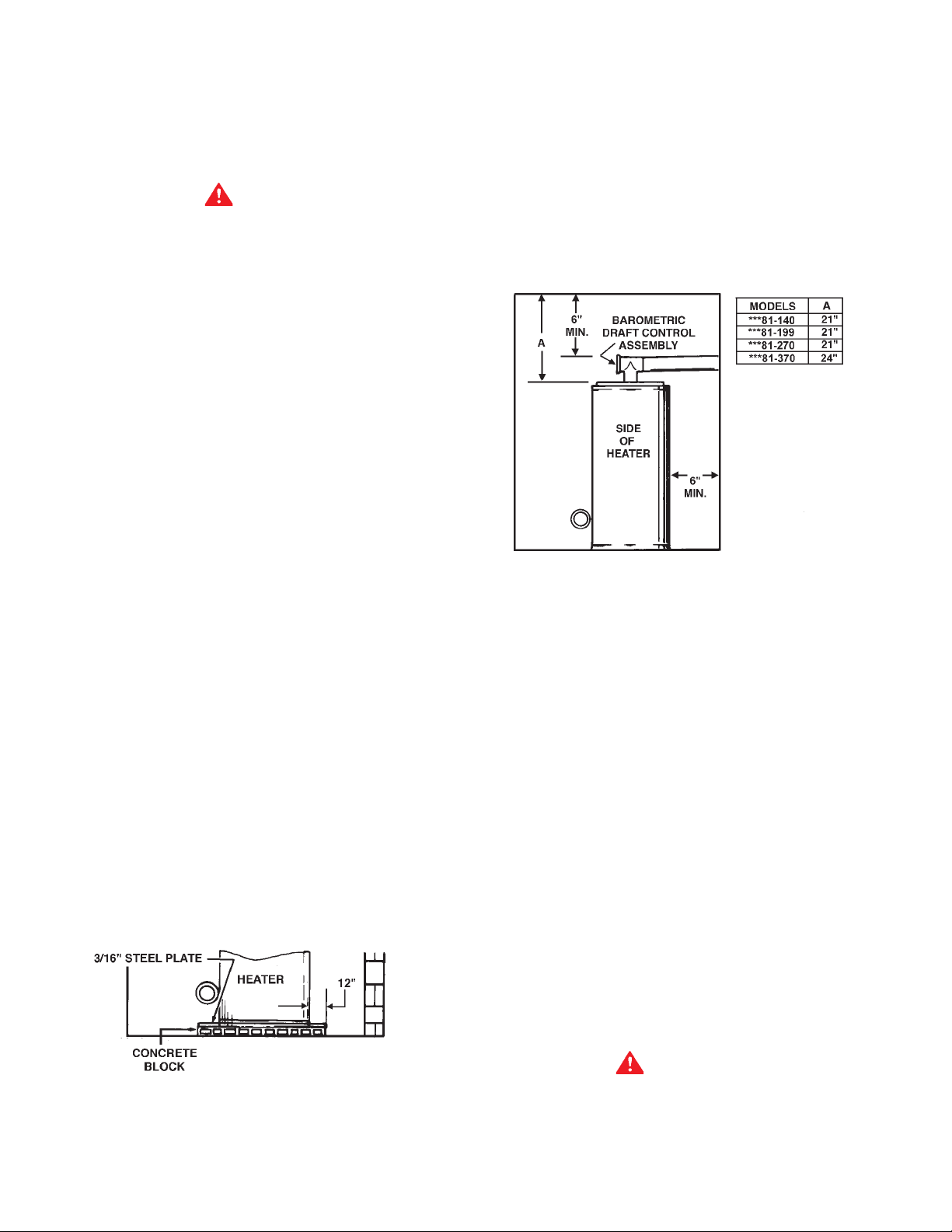

CLEARANCES

These heaters are design certified by the Underwriter’s

Laboratories for installation on non-combustible flooring in an

alcove with clearances to combustible construction of 6" from

the sides and rear, and 6" minimum between vent pipe and ceiling.

Minimum clearance from barometric draft control to combustible

material is 6". A minimum of 21" from top of heater to the ceiling

is required, except for the ***81-370 which requires a minimum

of 24".

A clearance of 24" shall be maintained from serviceable parts,

such as the relief valve, power burner, thermostat and drain valve.

LOCATE HEATER NEAR A FLOOR DRAIN. THE HEATER

SHOULD BE LOCATED IN AN AREA WHERE LEAKAGE FROM

THE TANK OR CONNECTIONS WILL NOT RESULT IN DAMAGE

TO THE ADJACENT AREA OR TO LOWER FLOORS OF THE

STRUCTURE.

WHEN SUCH LOCATIONS CANNOT BE AVOIDED, A SUITABLE

METAL DRAIN PAN, ADEQUATELY DRAINED, SHOULD BE

INSTALLED UNDER THE HEATER. Such pans should be

fabricated with sides at least 2" deep, with length and width at

least 2" greater than the diameter of the heater and must be piped

to an adequate drain. THE PAN MUST NOT RESTRICT

COMBUSTION AIR FLOW.

Units which are to be installed on combustible flooring must be

supported by a full layer of hollow concrete blocks, from 8" to 12"

thick and extending 12" (minimum) beyond the heater in all

directions. The concrete blocks must provide an unbroken

concrete surface under the heater with the hollows running

continuously and horizontally. A 3/16 inch steel plate must cover

the concrete blocks, see fig. 2.

NOTE: If electrical conduits run under the floor of the proposed

heater location, insulate the floor asrecommended

above.

PROPER INSTALLATION CLEARANCES

FIGURE 3

LEVELLING

The heater shall be installed plumb to the ground. If it is necessary

to adjust the heater, use metal shims under the channel type skid

base.

HARD WATER

Where hard water conditions exist, water softening or the threshold

type of water treatment is recommended. This will protect the

dishwashers, coffee urns, water heaters, water piping and other

equipment.

See MAINTENANCE section for details of tank cleanout

procedures.

AIR REQUIREMENTS

KEEP APPLIANCE AREA FREE FROM COMBUSTIBLE

MATERIALS, GASOLINE AND OTHER FLAMMABLE VAPORS

AND LIQUIDS.

PROPER INSTALLATION ON COMBUSTIBLE FLOORING

FIGURE 2

For appliance installation locations with elevations above 2000

feet, refer to HIGH ALTITUDE INSTALLATIONS section of this

manual for input reduction procedure.

DO NOT OBSTRUCT THE FLOW OF COMBUSTION OR

VENTILATING AIR.

WARNING

FOR SAFE OPERATION PROVIDE ADEQUATE AIR FOR

COMBUSTION AND VENTILATION. AN INSUFFICIENT SUPPLY

OF AIR WILL CAUSE RECIRCULATION OF COMBUSTION

PRODUCTS RESULTING IN AIR CONTAMINATION THAT MAY

BE HAZARDOUS TO LIFE. SUCH A CONDITION OFTEN WILL

RESULT IN A YELLOW, LUMINOUS BURNER FLAME, CAUSING

6

CARBONING OR SOOTING OF THE COMBUSTION CHAMBER,

BURNERS AND FLUE TUBES AND CREATES A RISK OF

ASPHYXIATION.

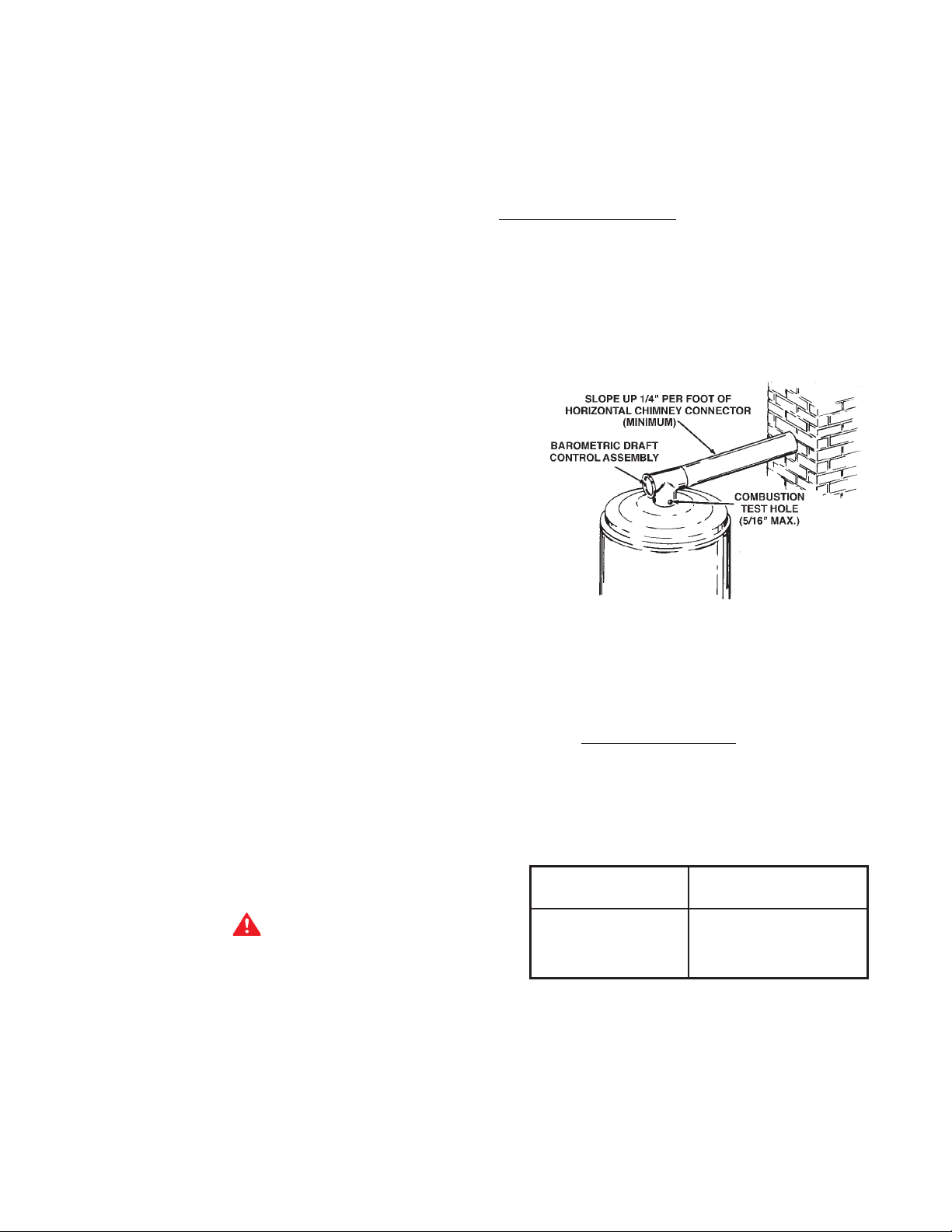

MECHANICAL EXHAUSTING OF ROOM AIR

figure 4. The outlet of the draft control assembly may be rotated

to face in direction needed. The assembly must be fitted to the

jacket cover such that it is plumb and level to the ground. Fasten

the draft control assembly to the top cover using sheet metal

screws at three locations, or more, as required.

Where an exhaust fan is installed in the same room with a heater,

sufficient openings for air must be provided in the walls.

UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRAWN

INTO THE ROOM THROUGH THE CHIMNEY, CAUSING POOR

COMBUSTION. SOOTING MAY RESULT IN SERIOUS DAMAGE

TO THE HEATER AND RISK OF FIRE OR EXPLOSION.

UNCONFINED SPACE

In buildings of conventional frame, brick or stone construction,

unconfined spaces may provide adequate air for combustion,

ventilation, and draft hood dilution.

If the unconfined space is within a building of tight construction

(buildings using the following construction: weather stripping,

heavy insulation, caulking, vapor barrier, etc.), air for combustion,

ventilation and draft hood dilution must be obtained from outdoors.

The installation instructions for confined spaces in tightly

constructed buildings must be followed to ensure adequate air

supply.

CONFINED SPACE

When drawing combustion and dilution air from inside a

conventionally constructed building to a confined space, such a

space shall be provided with two permanent openings, ONE IN

OR WITHIN 12 INCHES OF THE ENCLOSURE TOP AND ONE

IN OR WITHIN 12 INCHES OF THE ENCLOSURE BOTTOM.

Each opening shall have a free area of at least one square inch

per 1000 Btuh of the total input of all appliances in the enclosure,

but not less than 100 square inches.

If the confined space is within a building of tight construction, air

for combustion, ventilation and draft hood dilution must be

obtained from outdoors. When directly communicating with the

outdoors through vertical ducts, two permanent openings, located

in the above manner, shall be provided. Each opening shall have

a free area of not less than one square inch per 4000 Btuh of the

total input of all appliances in the enclosure. If horizontal ducts

are used, each opening shall have a free area of not less than

one square inch per 2000 Btuh of the total input of all appliances

in the enclosure.

Dampers or other obstructions must not be installed between the

heater and the barometric draft control assembly.

Do not adjust settings on gate. Counterweight washers are factory

adjusted and should result in breeching pressure measurements

at the combustion test hole (fig. 4) within the range shown in

table 6.

NOTE: A negative draft must be maintained in the vent piping.

When installed, the damper gate must pivot freely in the ring

guides. This gate will automatically adjust to regulate the chimney

draft imposed on the heater.

PROPER DRAFT CONTROLLER AND

VENT PIPE INSTALLATION

FIGURE 4

VENT CONNECTION

Vent connections must be made to an adequate stack or chimney.

Refer to the National Fuel Gas Code (latest version) or to the

vent pipe manufacturer’s gas vent and chimney sizing table to

properly design and size the venting system. Refer to Table 3 for

the vent pipe size required for installation to the barometric draft

control assembly outlet.

TABLE 3 - BAROMETRIC DRAFT CONTROL

ASSEMBLY OUTLET SIZE

VENTING

WARNING

THE INSTRUCTIONS IN THIS SECTION ON VENTING MUST

BE FOLLOWED TO AVOID CHOKED COMBUSTION OR

RECIRCULATION OF FLUE GASES. SUCH CONDITIONS

CAUSE SOOTING OR RISKS OF FIRE AND ASPHYXIATION.

Type B venting may be used with these heaters. All local and

utility regulations on venting should be followed.

BAROMETRIC DRAFT CONTROL ASSEMBLY

A double-acting barometric draft control assembly is provided with

each unit. The draft control assembly must be installed without

alteration. This assembly is factory adjusted for horizontal

application only and must be attached to the heater as shown in

DRAFT CONTROL

MODEL OUTLET DIAMETER

***81-140 6”

***81-199 6”

***81-270 8”

***81-370 8”

Where an existing chimney or vent is to be used, be sure that the

chimney or vent has adequate capacity for the number and sizes

of gas appliances being vented through it. Inspect the chimney

or vent and remove all soot or other obstructions which will retard

free draft.

Vent connectors making horizontal runs must have a minimum

upward slope toward the chimney or vent of 1/4 inch per foot.

Vent connector length should be kept as short as possible. Be

sure that the vent pipe does not extend beyond the inside wall of

a chimney.

7

In venting systems where a continuous or intermittent back

(positive) draft is found to exist, the cause must be determined

and corrected. In some cases, a special vent cap may be

required.

Do not install this unit on the positive draft side of a venting system

being served by a power exhauster.

Occasionally, some water seepage will occur at a cleanout port.

To correct this situation, slightly tighten the cleanout cover bolts

until the seepage is eliminated. Do not overly tighten the bolts or

the cleanout gasket will be damaged. Tighten each bolt gradually

and alternate between opposed bolts on the cleanout cover.

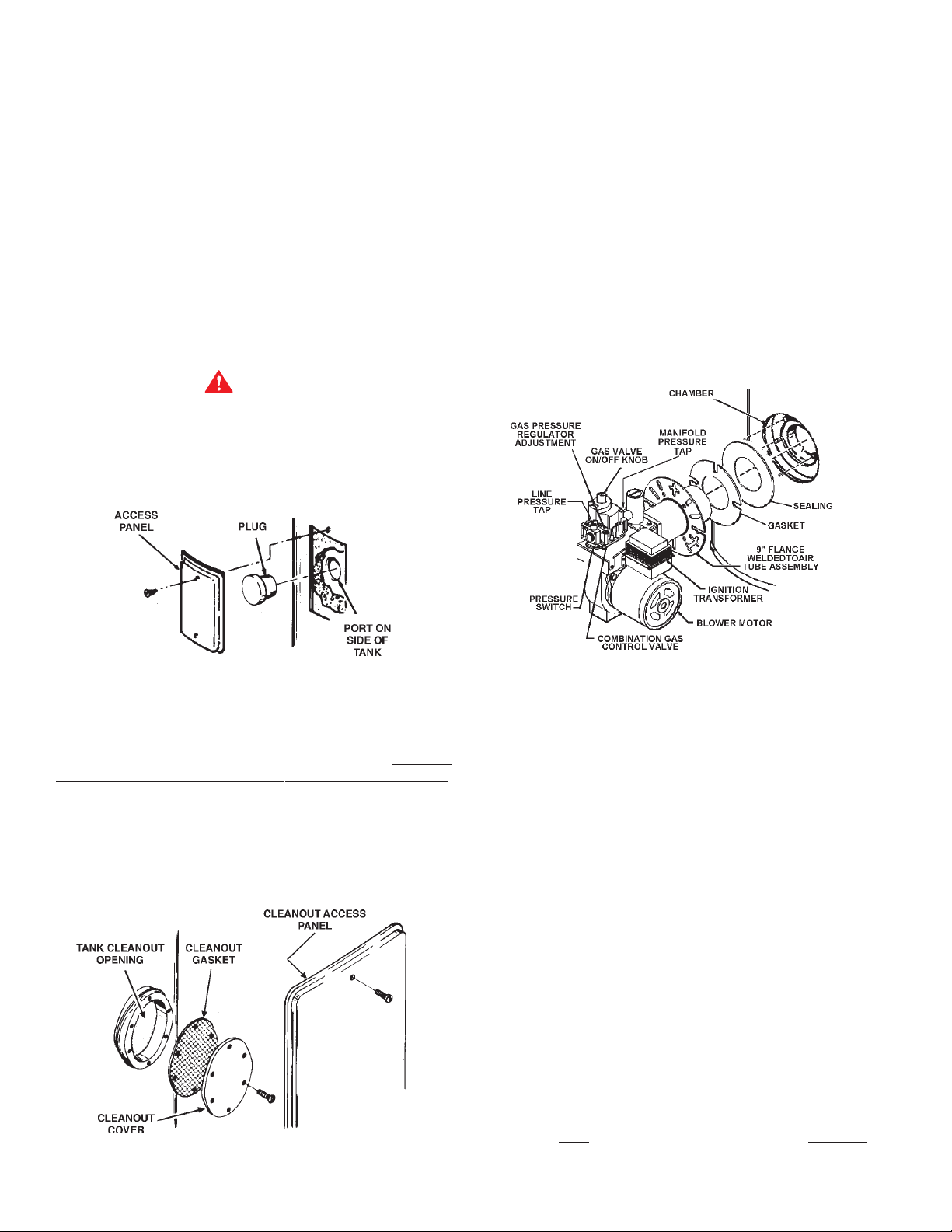

BURNER INSTALLATION

DRAIN VALVE AND ACCESS PANELS

The heaters are equipped with a 3/4" drain valve mounted above

and to the left of the burner. See page 2.

The combustion chamber observation access panel is located

above and to the left of the burner. A plug located under the

panel, see fig. 5, is inserted into the combustion chamber wall.

This plug should not be removed except, in rare cases, when the

combustion chamber requires cleaning or replacement.

WARNING

DO NOT REMOVE THIS PLUG WHILE THE HEATER IS IN

OPERATION. THE COMBUSTION CHAMBER IS UNDER

PRESSURE AND MAIN BURNER FLAMES WILL ESCAPE

THROUGH THE OPENING. THIS IS AN EXTREMELY

HAZARDOUS CONDITION WHICH MAY RESULT IN SERIOUS

INJURY.

Remove the factory-installed insulation covering the combustion

chamber opening. (A utility knife is useful for cutting out the

insulation). Cut the insulation back even with the jacket opening.

Install the flange gasket (which is usually taped to the heater

jacket) over the three bolts protruding from the tank at the

combustion chamber opening.

Remove the hardware (3 hex nuts, 3 flat washers, and 3 lock

washers) from the shipping bag attached to the heater’s electrical

conduit.

COMBUSTION CHAMBER ACCESS PORT

FIGURE 5

IMPORTANT

Before removing the access panel and observation plug, BE SURE

THAT THE ELECTRICAL POWER TO THE HEATER IS “OFF”.

This will prevent the heater from operating while servicing the

unit. Remember to install the plug and access cover BEFORE

restoring electrical power to the heater.

Another access panel is located above and to the right of the

burner, fig. 6. This panel covers the cleanout opening in the tank

which is sealed by a gasket and cover.

TANK CLEANOUT PORT

FIGURE 6

POWER BURNER INSTALLATION

FIGURE 7

Begin assembling the power burner to the tank by placing the

power burner nozzle in the combustion chamber opening. Slide

the nozzle into the tank and rotate the mounting flange to engage

the mounting bolts, refer to Figure 7. Then, place the flat washers

followed by the lock washers, and finally the hex nuts on the

mounting bolts. Hand tighten the nuts. Then gradually tighten

each nut alternating between the 3 mounting bolts. Do not over

tighten as damage to the flange gasket or to the tank may result.

Refer to figure 7.

GAS METER SIZE — CITY GASES ONLY

Be sure that the gas meter has sufficient capacity to supply the

full-rated gas input of the water heater as well as the

requirements of all other gas fired equipment supplied by the

meter. If gas meter is too small, request the gas company to

install a larger meter having adequate capacity.

GAS PRESSURE REGULATION

Main manual pressure to the water heater should be between

4.5" minimum and 10.5" maximum w.c. for natural gas and 11.0"

minimum and 13.0" maximum w.c. for propane gas. The inlet

gas pressure

regulator is necessary if higher gas pressures are encountered.

See Table 6.

8

must not exceed the maximum value. A service

WARNING

THE HEATER IS NOT INTENDED FOR OPERATION AT HIGHER

THAN 10.5" W.C. - NATURAL GAS, 13.0" W.C. - PROPANE GAS

(1/2 POUND PER SQUARE INCH GAUGE) SUPPLY GAS

PRESSURE. HIGHER GAS PRESSURES REQUIRE

SUPPLEMENTAL REDUCING SERVICE REGULATION.

EXPOSURE TO HIGHER GAS SUPPLY PRESSURE MAY CAUSE

DAMAGE TO THE GAS CONTROLS WHICH COULD RESULT IN

FIRE OR EXPLOSION. IF OVERPRESSURE HAS OCCURRED,

SUCH AS THROUGH IMPROPER TESTING OF GAS LINES OR

EMERGENCY MALFUNCTION OF THE SUPPLY SYSTEM, THE

GAS VALVE MUST BE CHECKED FOR SAFE OPERATION. MAKE

SURE THAT THE OUTSIDE VENTS ON THE SUPPLY

REGULATORS AND THE SAFETY VENT VALVES ARE

PROTECTED AGAINST BLOCKAGE. THESE ARE PARTS OF

THE GAS SUPPLY SYSTEM, NOT THE HEATER. VENT

BLOCKAGE MAY OCCUR DURING ICE STORMS.

DISCONNECT THE APPLIANCE AND ITS MAIN MANUAL GAS

SHUTOFF VALVE FROM THE GAS SUPPLY PIPING SYSTEM

DURING ANY SUPPLY PRESSURE TESTING EXCEEDING 1/2

PSIG. GAS SUPPLY LINE MUST BE CAPPED WHEN

DISCONNECTED FROM THE HEATER. FOR TEST

PRESSURES OF 1/2 PSIG OR LESS, THE APPLIANCE NEED

NOT BE DISCONNECTED, BUT MUST BE ISOLATED FROM

THE SUPPLY PRESSURE TESTING BY CLOSING THE MAIN

MANUAL GAS SHUT OFF VALVE.

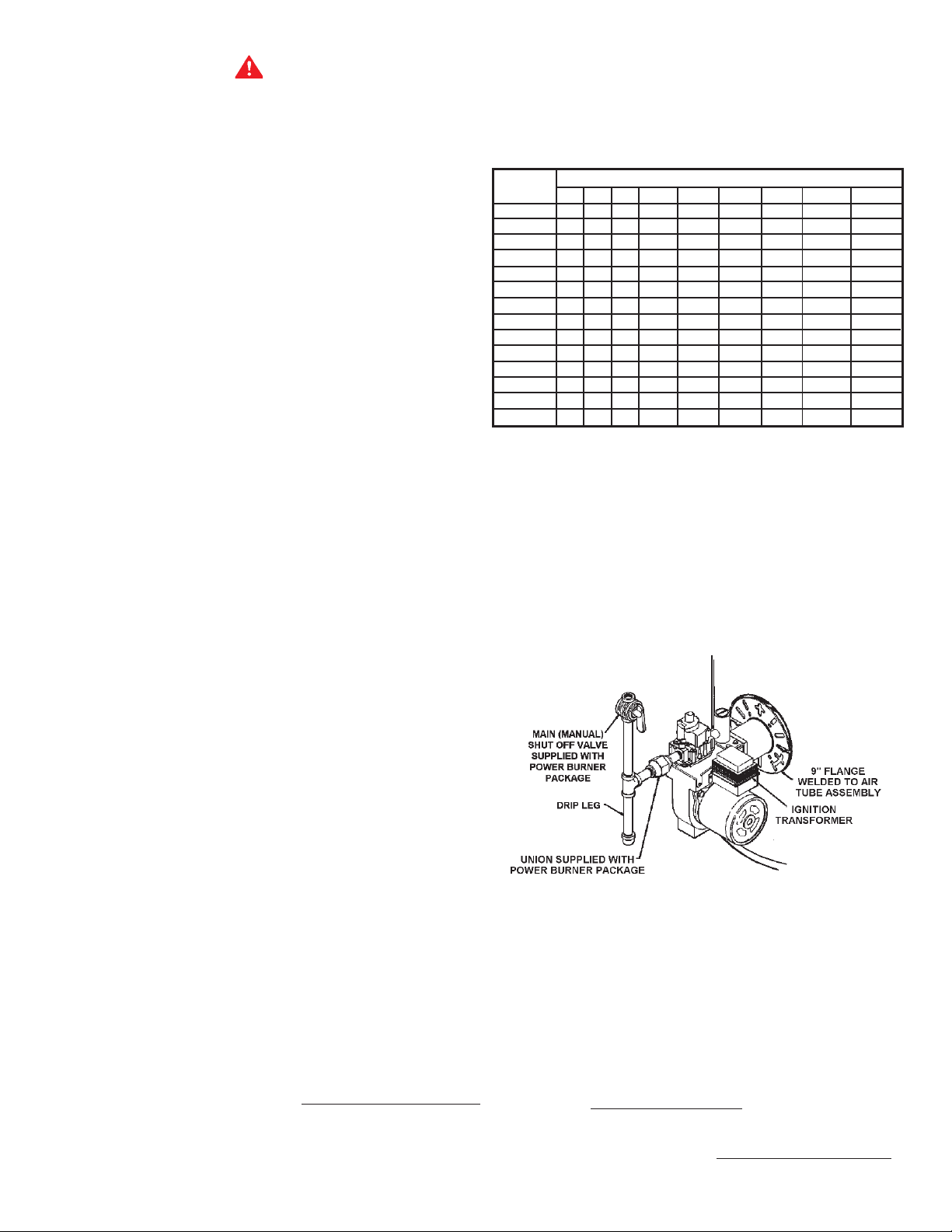

GAS PIPING

Contact your local gas service company to ensure that adequate

gas service is available and to review applicable installation

codes for your area.

TABLE 4

MAXIMUM CAPACITY OF PIPE IN CUBIC FEET

OF GAS PER HOUR

(Based upon a Pressure Drop of 0.5 inch Water Column and

0.6 Specific Gravity Gas and max. gas pressure of .5 psig)

LENGTH NOMINAL IRON PIPE SIZE (INCHES)

IN FEET 1/2 3/4 1 1 1/4 1 1/2 2 2 1/2 3 4

10 175 360 680 1,400 2,100 3,950 6,300 11,000 23,000

20 120 250 465 950 1,460 2,750 4,350 7,700 15,800

30 97 200 375 770 1,180 2,200 3,520 6,250 12,800

40 82 170 320 660 990 1,900 3,000 5,300 10,900

50 73 151 285 580 900 1,680 2,650 4,750 9,700

60 66 138 260 530 810 1,520 2,400 4,300 8,800

70 61 125 240 490 750 1,400 2,250 3,900 8,100

80 57 118 220 460 690 1,300 2,050 3,700 7,500

90 53 110 205 430 650 1,220 1,950 3,450 7,200

100 50 103 195 400 620 1,150 1,850 3,250 6,700

125 44 93 175 360 550 1,020 1,650 2,950 6,000

150 40 84 160 325 500 950 1,500 2,650 5,500

175 37 77 145 300 460 850 1,370 2,450 5,000

200 35 72 135 280 430 800 1,280 2,280 4,600

Apply joint compounds (pipe dope) sparingly and only to the male

threads of pipe joints. Do not apply compound to the first two

threads. Use joint compounds resistant to the action of liquefied

petroleum gases.

BEFORE PLACING THE HEATER IN OPERATION, CHECK FOR

GAS LEAKAGE. USE SOAP AND WATER SOLUTION, OR

OTHER MATERIAL ACCEPTABLE FOR THE PURPOSE IN

LOCATING GAS LEAKS. DO NOT USE MATCHES, CANDLES,

FLAME OR OTHER SOURCES OF IGNITION FOR THIS

PURPOSE.

Size the main gas line in accordance with Table 4. The figures

shown are for iron pipe or equivalent at 0.5 in. w.c. pressure

drop, which is considered normal for low pressure systems.

Note that an excess number of fittings such as elbows and tees

will add to the pipe pressure drop. No additional allowance is

necessary for an ordinary number of fittings.

IF COPPER SUPPLY LINES ARE USED THEY MUST BE

INTERNALLY TINNED AND CERTIFIED FOR GAS SERVICE.

IT IS IMPORTANT TO GUARD AGAINST GAS VALVE FOULING

FROM CONTAMINANTS IN THE GAS WAYS. SUCH FOULING

MAY CAUSE IMPROPER OPERATION, FIRE OR EXPLOSION.

BEFORE ATTACHING THE GAS LINE, BE SURE THAT ALL GAS

PIPE IS CLEAN ON THE INSIDE.

TO TRAP ANY DIRT OR FOREIGN MATERIAL IN THE GAS

SUPPLY LINE, A DRIP LEG (SOMETIMES CALLED DIRT LEG)

MUST BE INCORPORATED IN THE PIPING. SEE FIG. 8. THE

DRIP LEG MUST BE READILY ACCESSIBLE, REFER TO FIG. 8,

AND NOT SUBJECT TO FREEZING CONDITIONS. INSTALL IN

ACCORDANCE WITH RECOMMENDATIONS OF SERVICING

GAS SUPPLIERS. REFER TO THE

NATIONAL FUEL GAS CODE

(LATEST VERSION).

To prevent damage, care must be taken not to apply too much

torque when attaching gas supply pipe to gas valve inlet.

POWER BURNER ASSEMBLY, GAS MANIFOLD AND SUGGESTED

INLET PIPING - FIGURE 8

HEATER WIRING INSTRUCTIONS

The power burner should be wired to the heater as shown in

Figure 9. The model’s rating plate (or see Table 2) provides the

electrical information needed to size the complete heater branch

supply circuit.

All electrical work must be installed in accordance with the latest

version of the

When installed, the appliance must be electrically grounded in

accordance with local codes or, in the absence of local codes,

with the latest version of the National Electrical Code,

ANSI/NFPA 70.

National Electrical Code and local requirements.

9

Loading...

Loading...