Page 1

COPPER BOILERS FOR

HYDRONIC HEATING AND

HOT WATER SUPPLY

• Installation

• Operation

• Maintenance

• Limited Warranty

WARNING: If the information in this

manual is not followed exactly , a fire or

explosion may result causing property

damage, personal injury or loss of life.

Do not store or use gasoline or other

•

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Extinguish any open flame.

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor's phone. Follow the

gas supplier's instructions.

• If you cannot reach your gas supplier,

call the fire department.

Installation and service must be

•

performed by a qualified installer,

service agency or the gas supplier.

Instruction Manual

GB/GW MODELS:

1000, 1300, 1500, 1850, 2100, 2500

SERIES: 400, 401, 402, 403, 404, 405

CAUTION

TEXT PRINTED OR OUTLINED IN RED CONTAINS

INFORMATION RELATIVE TO YOUR SAFETY.

PLEASE READ THOROUGHLY BEFORE INSTALLING

AND USING THIS APPLIANCE.

for buying this cost

Thank You

You should thoroughly read and understand this

manual before installation and/or operation of this

boiler. Please pay particular attention to the

important safety and operating instructions as well

as the WARNINGS and CAUTIONS.

CONTENTS P AG E

DIMENSIONS/CAPACITIES DA T A .......................... 2 - 3

FOREWORD......................................................... 4 - 5

FEATURES/CONTROLS..................................... 5 - 7

INSTALLA TION INSTRUCTIONS ....................... 7 - 9

VENTING ........................................................... 9 - 11

SYSTEM INSTALLATION ................................ 11 - 16

HYDRONIC INSTALLA TION ............................ 16 - 18

HOT WATER SUPPLY INSTALLATION ........... 18 - 31

GAS CONNECTIONS...................................... 18 - 23

OPERATION.................................................... 31 - 34

LIGHTING AND OPERATING .......................... 32 - 33

CONTROL SYSTEM ....................................... 34 - 44

PREVENTATIVE MAINTENANCE.................. 44 - 46

TROUBLE SHOOTING .................................... 42 - 44

WIRING DIAGRAM/SCHEMATIC ................... 24 - 27

LIMITED WARRANTY ............................................. 47

efficient, high recovery unit from

A. O. Smith Water Products Co.

PLACE THESE INSTRUCTIONS ADJACENT TO BOILER AND

NOTIFY OWNER TO KEEP FOR FUTURE REFERENCE.

PRINTED IN U.S.A. 0906

MC BEE, SC., RENTON, WA.,

STRATFORD-ONTARIO, VELDHOVEN-THE NETHERLANDS,

NANJING, CHINA

ww w.hotwater.com / email:parts@hotwater.com

1

212511-000

Page 2

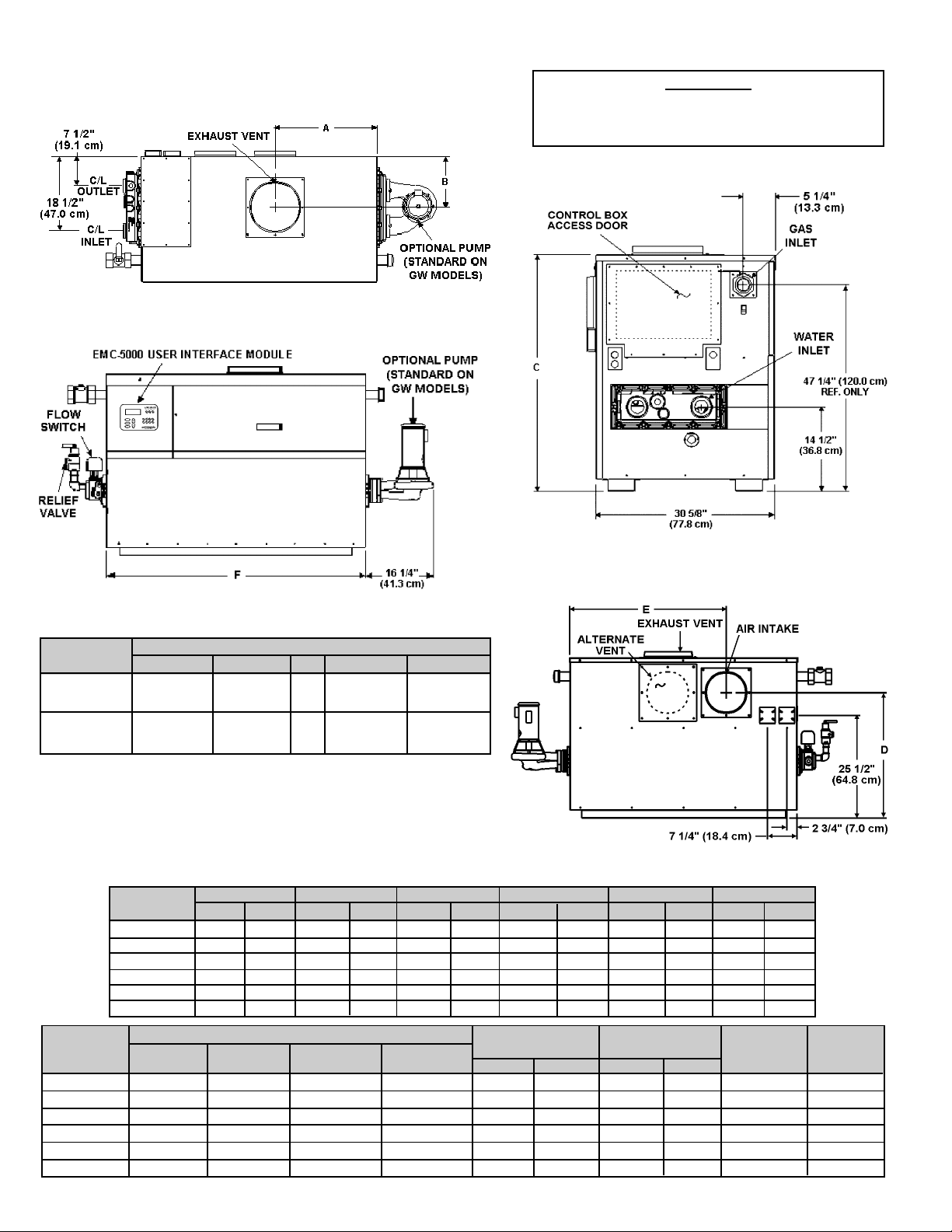

DIMENSIONS/CAP ACITIES DAT A

TOP VIEW

FRONT VIEW

IMPORT ANT!

Refer to "Installation Clearances" section of manual

(page 7) for recommended service clearances prior

to boiler placement.

LEFT SIDE

REAR VIEW

TABLE 1: GAS AND ELECTRICAL REQUIREMENT

Manifold Pressure Electrical Characteristics

MODEL Type of Gas Inches W.C. kPa Volts/Hz Amperes

GW/GB-1000

thru 2500 NATURAL 3.5 0.87 120/60 30

GW/GB-1000

thru 2500 PROPANE 10 2.49 120/60 30

All Models - Maximum Supply Pressure: 14.0 In. W.C. (3.49 kPa)

Minimum Supply Pressure Natural Gas: 6.0 In. W.C. (1.22 kPa)

Minimum Supply Pressure Propane Gas: 1 1.0 In. W.C. (2.74 kPa)

Minimum Pressures must be maintained during operating conditions.

Figure 1.

T ABLE 2. DIMENSIONAL DA T A

ABCD EF

Model Inches c m Inches c m Inches cm Inches c m Inches cm Inches cm

GW/GB-1000 14.1 35.8 12.2 31.0 40.3 102.4 31.6 80.3 26.0 66.0 46.8 118.9

GW/GB-1300 24.8 63.0 12.2 31.0 40.3 102.4 31.6 80.3 39.3 99.8 57.3 145.5

GW/GB-1500 30.2 76.7 12.2 31.0 40.3 102.4 31.6 80.3 44.6 113.3 64.3 163.3

GW/GB-1850 27.7 70.4 11.2 28.4 43.0 109.2 32.3 82.0 44.0 111.8 78.3 198.9

GW/GB-2100 31.0 78.7 11.2 28.4 43.0 109.2 32.3 82.0 49.5 125.7 85.3 216.7

GW/GB-2500 38.1 96.8 10.5 26.7 43.0 109.2 32.3 82.0 56.5 143.5 99.3 252.2

Input Rating Exhaust Air Intake

Model Natural Gas Natural Gas Propane Gas Propane Gas Inches cm Inches c m Size

GW/GB-1000 990,000 289.95 990,000 289.95 10 25.4 8 20.3 2 1/2 NPT 2 NPT

GW/GB-1300 1,300,000 380.74 1,300,000 380.74 12 30.5 10 25.4 2 1/2 NPT 2 NPT

GW/GB-1500 1,500,000 439.31 1,500,000 439.31 12 30.5 10 25.4 2 1/2 NPT 2 NPT

GW/GB-1850 1,850,000 541.82 1,850,000 541.82 14 35.6 10 25.4 2 1/2 NPT 2 1/2 NPT

GW/GB-2100 2,100,000 615.04 2,100,000 615.04 14 35.6 12 30.5 2 1/2 NPT 2 1/2 NPT

GW/GB-2500 2,490,000 729.26 2,490,000 729.26 16 40.7 12 30.5 2 1/2 NPT 2 1/2 NPT

BTU/Hr. KW BTU/Hr. KW Vent Diameter Diameter Water Conn. Gas Inlet

2

Page 3

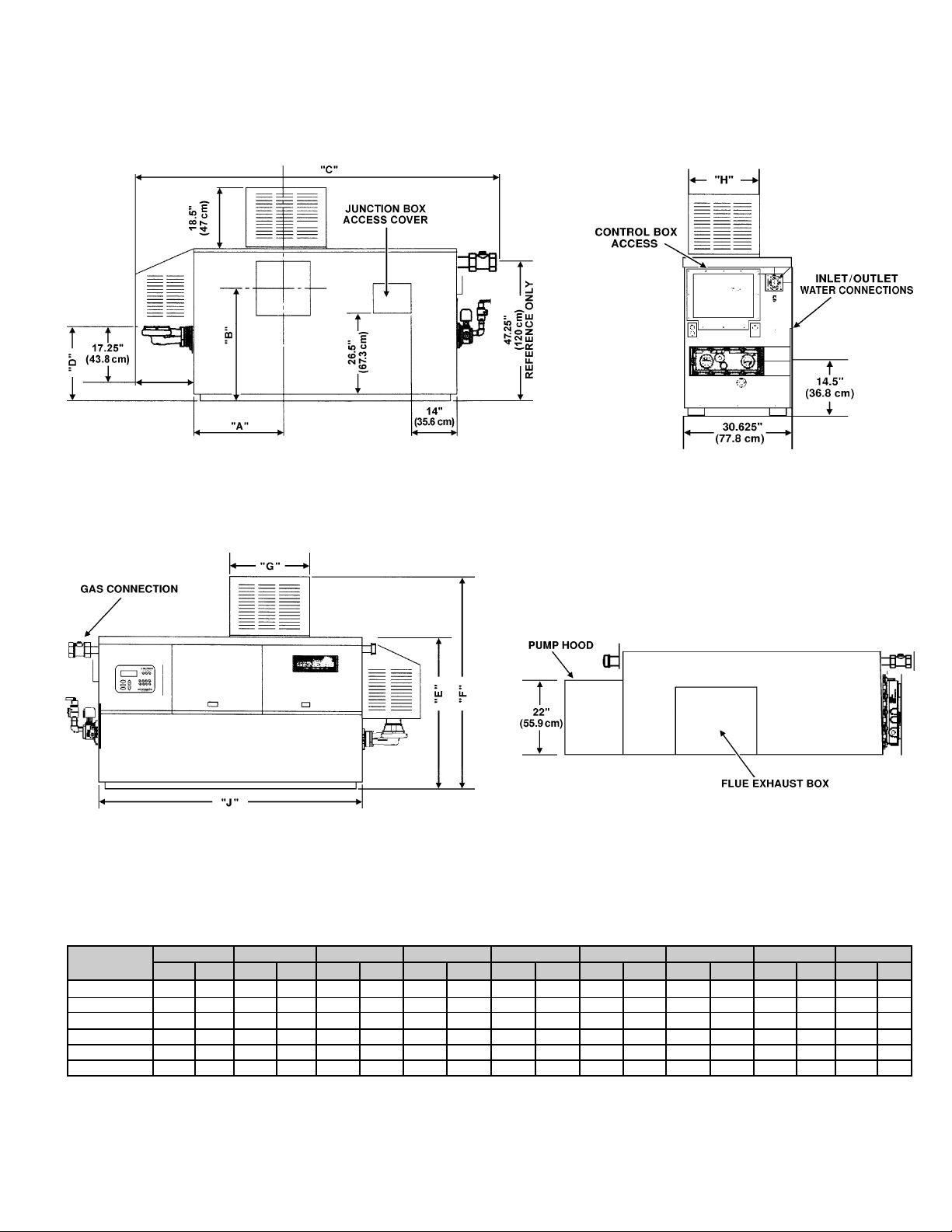

DIMENSIONS DA TA FOR OUTDOOR CONFIGURATION

REAR VIEW

FRONT VIEW

LEFT SIDE

TOP VIEW

Figure 2.

T ABLE 3. DIMENSIONAL DA TA

AB C D E F G HJ

Model Inches cm Inches cm Inches cm Inches cm Inches cm Inches cm Inches cm Inches cm Inches cm

GBO/GWO-1000 14 35.5 31.6 80.3 71.8 182.4 15.5 39.4 39.75 101 58.25 148 15.9 40.83 16 40.64 46.8 118.9

GBO/GWO-1300 24.75 62.9 31.6 80.3 82 208.3 15.5 39.4 39.75 101 58.25 148 15.9 40.83 16 40.64 57.3 145.5

GBO/GWO-1500 30 76.2 31.6 80.3 89 226 15.5 39.4 39.75 101 58.25 148 15.9 40.83 16 40.64 64.3 163.3

GBO/GWO-1850 27.5 69.9 32.3 82 103 261.6 18.9 48 43 109.2 61.5 156.2 23.9 60.7 20 50.8 78.3 198.9

GBO/GWO-2100 31 78.7 32.3 82 110 279.4 18.9 48 43 109.2 61.5 156.2 23.9 60.7 20 50.8 85.3 216.7

GBO/GWO-2500 38 96.5 32.3 82 124 315 18.9 48 43 109.2 61.5 156.2 23.9 60.7 20 50.8 99.3 252.2

3

Page 4

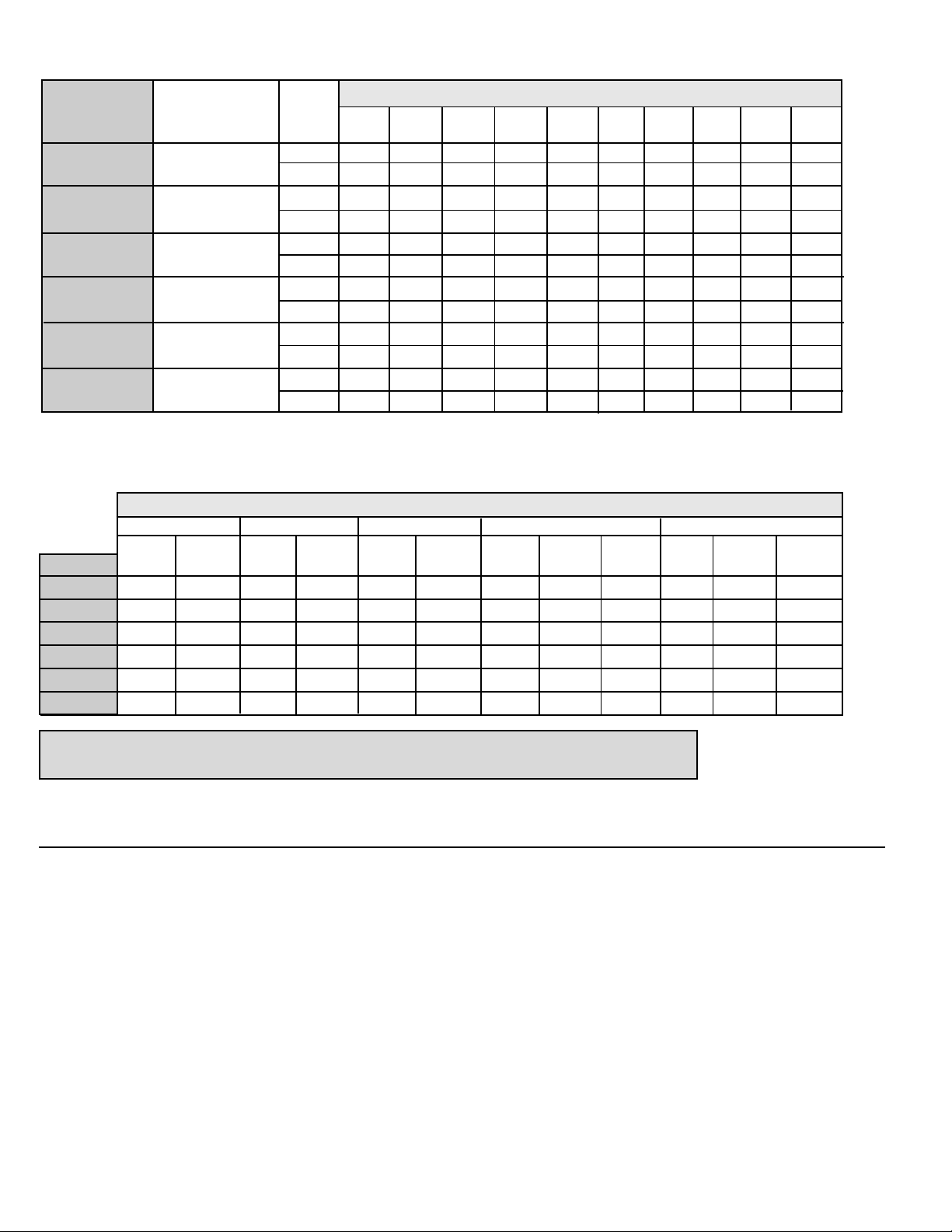

TABLE 4: RECOVERY CAPACITIES

TEMPERATURE RISE - DEGREES °F (°C)

Input Rating Water 40°F 50°F 60°F 70°F 80°F 90°F 100°F 110°F 120°F 130°F

MODEL BTU/Hr. (kW) Flow (22.2°) (27.7°) (33.3°) (38.8°) (44.4°) (50°) (55.5°) (61.1°) (66.7°) (72.2°)

GW - 1000 990,000 (290.1) GPH 2520 2016 1680 1440 1260 1120 1008 916 840 775

LPH 9526 7620 6350 5443 4763 4234 3810 3462 3175 2930

GW - 1300 1,300,000 (380.9) GPH 3309 2647 2206 1891 1655 1471 1324 1203 1103 1018

LPH 12508 10006 8339 7148 6256 5560 5005 4547 4169 3848

GW - 1500 1,500,000 (439.5) GPH 3818 3055 2545 2182 1909 1697 1527 1388 1273 1175

LPH 14432 11548 9620 8248 7216 6415 5772 5247 4812 4442

GW - 1850 1,850,000 (542.0) GPH 4709 3767 3139 2691 2355 2093 1884 1712 1570 1449

LPH 17800 14239 11865 10172 8902 7912 7122 6471 5935 5477

GW - 2100 2,100,000 (615.3) GPH 5345 4276 3564 3055 2673 2376 2138 1944 1782 1645

LPH 20204 16163 13472 11548 10104 8981 8082 7348 6736 6218

GW - 2500 2,490,000 (729.6) GPH 6338 5071 4225 3622 3169 2817 2535 2305 2113 1950

LPH 23958 19168 15971 13691 11979 10648 9582 8713 7987 7371

TABLE 5: PUMPING PERFORMANCE GUIDE

GB MODELS-FLOW, HEAD LOSS AND TEMPERA TURE RISE

20 Deg. F Rise 30 Deg. F Rise 40 Deg. F Rise Maximum Flow Rate Minimum Flow Rate

GPM PD-FT G PM PD-FT G PM PD-FT GPM PD-FT Deg. F GPM PD-FT Deg. F

MODEL Head Head Head Head Rise Head Rise

GB - 1000 83 5.1 55 2.7 41.6 1.5 1 5 4 12.2 11 42 1.5 40

GB - 1300 109 7.2 72.8 4.2 54.6 3.2 154 14.5 1 4 55 3.2 40

GB - 1500 126 10.1 84 6.3 6 3 4.3 154 16.3 17 64 4.3 40

GB - 1850 154 18.5 103.6 10.1 77.7 6.4 15 4 18.5 20 78 6.4 40

GB - 2100 n/a n/a 117.6 14.5 88 8.3 154 21.3 2 3 89 8.3 40

GB - 2500 n/a n/a 139.4 18.5 104.6 11.6 154 23.2 28 105 11.6 40

Note: GW models (GB optional) are equipped with pumps capable of handling 50 equivalent feet

(15.2 m) of normal pipe fittings.

FOREWORD

Detailed installation diagrams are in this manual. These diagrams

will provide the installer with a reference of materials needed and a

suggested method of piping. IT IS NECESSARY THAT ALL W ATER

AND GAS PIPING , AND THE ELECTRICAL WIRING BE INST ALLED

AND CONNECTED AS SHOWN IN THE DIAGRAMS.

CHECK DIAGRAMS THOROUGHLY BEFORE STARTING

INSTALLATION TO AVOID POSSIBLE ERRORS AND MINIMIZE

TIME AND MA TERIALS COST. SEE FIGURES 1 THROUGH 5 AND

TABLES 1, 2, AND 3.

This design complies with the current edition of ANSI Z21.13-CSA

4.9 for Gas-Fired Low-Pressure Steam and Hot Water Boilers.

MAKE SURE THE GAS ON WHICH THE BOILER WILL OPERATE

IS THE SAME AS THAT SPECIFIED ON THE BOILER RATING

PLATE.

The boiler installation must conform to these instructions and the

local code authority having jurisdiction. In the absence of local

codes, the installation must comply with the latest editions of

the National Fuel Gas Code, ANSI Z223.1/NFPA 54 and the

National Electrical Code, NFPA 70 or CAN/CSA B149.1, and CSA

2 C22.1. The former is available from the Canadian Standards

Association, 8501 East Pleasant Valley Road, Cleveland, OH

44131, and both documents are available from the National Fire

Protection Association, 1 Batterymarch Park, Quincy, MA 02269.

4

Page 5

GROUNDING INSTRUCTIONS

This boiler must be grounded in accordance with the National

Electrical Code, NFPA 70 or the Canadian Electrical Code CSA 2

C22.1

and/or local codes. The boiler is polarity sensitive, correct

wiring is imperative for proper operation.

This boiler must be connected to a grounded metal, permanent wiring

system, or an equipment grounding conductor must be run with the

circuit conductors and connected to the equipment grounding

terminal or lead on the boiler.

WARNING

YOUR BOILER IS NOT DESIGNED TO OPERA TE WITH A BOILER

INLET WATER TEMPERATURE OF LESS THAN 120°F (49°C).

COLDER INLET WATER TEMPERATURE WILL RESULT IN

SIGNIFICANT CONDENSATION DEVELOPING ON THE HEAT

EXCHANGER. THIS SITUATION CAN CAUSE A CORROSIVE

ENVIRONMENT FOR THE HEAT EXCHANGER, BURNERS AND

VENTING RESULTING IN PREMA TURE DAMAGE, WHICH COULD

RESULT IN SERIOUS PERSONAL INJUR Y OR DEATH.

FOR SYSTEMS THAT USE LARGE VOLUMES OF COLD WATER

OR SYSTEMS UTILIZING HEA VY WA TER DRAWS, CONDENSA TION

CAN BE PREVENTED BY USING A BYP ASS LOOP.

CORRECT GAS

At times you may not be able to smell an LP gas leak. One cause

is odor fade, which is a loss of the chemical odorant that gives LP

gas its distinctive smell. Another cause can be your physical

condition, such as having a cold or diminishing sense of smell with

age. For these reasons, the use of a propane gas detector is

recommended. IF YOU EXPERIENCE AN OUT OF GAS

SITUATION, DO NOT TRY TO RELIGHT APPLIANCES YOURSELF .

Call your local service agent. Only trained LP professionals should

conduct the required safety checks in accordance with industry

standards.

HIGH AL TITUDE INST ALLATION

WARNING

INSTALLATIONS ABOVE 4,500 FEET REQUIRE REPLACEMENT

OF THE BURNER ORIFICES. FAILURE TO REPLACE THE

ORIFICES WILL RESULT IN IMPROPER AND INEFFICIENT

OPERATION OF THE APPLIANCE, PRODUCING CARBON

MONOXIDE GAS IN EXCESS OF SAFE LIMITS, WHICH COULD

RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

GENESIS BOILERS ARE EQUIPPED WITH SELF-REGULATING

PREJET ORIFICES WHICH AUT OMATICALL Y COMPENSATE FOR

HIGHER ELEVATIONS AND ADJUST THE APPLIANCE'S INPUT

RA TE ACCORDINGL Y, MAKING IT UNNECESSARY TO REPLACE

ORIFICES FOR HIGH ALTITUDE (UP TO 4,500 FEET). CONSUL T

THE FACTOR Y FOR HIGHER ALTITUDES.

Make sure the gas on which the boiler will operate is the same as

that specified on the boiler rating plate. Do not install the boiler if

equipped for a different type of gas, consult your gas supplier.

PRECAUTIONS

IF THE UNIT IS EXPOSED TO THE FOLLOWING, DO NOT

OPERA TE UNTIL ALL CORRECTIVE STEPS HA VE BEEN MADE BY

A QUALIFIED SERVICEMAN:

1. EXPOSURE TO FIRE.

2. IF DAMAGED.

3. FIRING WITHOUT WA TER.

4. SOOTING .

IF THE BOILER HAS BEEN EXPOSED TO FLOODING, IT MUST BE

REPLACED.

LIQUID PETROLEUM MODELS

Boilers for propane or liquefied petroleum gas (LPG) are different

from natural gas models. A natural gas boiler will not function

safely on LP gas and no attempt should be made to convert a

boiler from natural gas to LP gas.

LP gas must be used with great caution. It is highly explosive and

heavier than air. It collects first in the low areas making its odor

difficult to detect at nose level. If LP gas is present or even suspected,

do not attempt to find the cause yourself. Leave the building, leaving

doors open to ventilate, then call your gas supplier or service agent.

Keep area clear until a service call has been made.

Some utility companies derate their gas for altitude. You should

contact your gas supplier for any specific changes which may be

required in your area. Call the local gas utility to verify BTU content

of the gas supplied.

Input rating specified on the rating plate applies to elevations up to

4,500 feet (1350 m). For elevations above 4,500 feet (1350 m),

ratings must be reduced, consult the factory.

FEATURES/CONTROLS

MUL TI-ST AGE FIRING AND CONTROL SYSTEM

ALL MODELS - The control system consists of four basic

components: 1) Central Control Board 2) Flame Control Board 3)

User Interface Module 4) Power Distribution Board; see Figures

17, 18, 19 and 21. The Central Control Board, Flame Control

Boards and the Power Distribution Board are located in the

control box and can be accessed through panels on the left side

and top of the unit. The User Interface Module is attached to the

front jacket panel. The control system is a multi-stage control

capable of managing three or four firing stages. Models 1000,

1300, and 1500 operates with 3-stage fire. Models 1850, 2100

and 2500 operates with 4-stage fire. Every system will have one

Central Control Board (CCB), one Power Distribution Board

(PDB), one User Interface Module (UIM) and either two or three

Flame Control Boards (FCB) depending on the model.

The Control Boards Figure 17 and 18, contain dipswitches which

allow the user to control several system options. See Control System

Section.

5

Page 6

DIFFERENTIAL PRESSURE SWITCH

COMBUSTION AIR BLOWER

The differential pressure switch ensures that a sufficient differential

exists between the air pressure in the pre-mix chamber and the inlet

of the burner for safe, combustion and proper low NOx emission. The

switch has two pressure taps marked "+" (positive) and "-" (negative).

Silicone tubing is run from the positive pressure tap of the switch to a

tap on the control panel to measure the air pressure in the pre-mix

chamber. The negative pressure tap measures the pressure taken at

the burner's auxiliary tube. Connections can be seen by removing the

lower front jacket panel. It is important that this panel remain sealed

at all times while the boiler is operating.

The differential pressure switch is normally open and closes when

the combustion blower starts.

BLOCKED FLUE PRESSURE SWITCH

The blocked flue pressure switch ensures that the vent system is

clear. This pressure switch is normally closed and only opens on

fault conditions.

FLAME SENSOR

The flame sensor detects the flame presence on burner's ports. If

no flame is sensed, the gas valve(s) will close automatically. If no

flame is sensed on three ignition trials the boiler will lock out. In the

event of a lockout, depress the SELECT button on the UIM to restart

the boiler.

WA TER FLOW SWITCH

Provides air for combustion process. The blower settings are

adjustable through the use of the air shutter, however, blowers are

set at the factory and might require slight adjustment depending

on site installation.

T ANK PROBE

FOR HOT WA TER SUPPLY SYSTEMS (GW models), a tank probe

is supplied with each hot water supply boiler.

Note: The tank probe must be designated as the controlling probe

using dip switch "4" on Central Control Board (Figure 17) before it

can be used for (GW) hot water supply applications.

"Pigtails" of field-supplied wires should be spliced to "pigtails" of

tank probe and connected to terminal block in the 24VAC junction

box. See Figure 12 for the tank probe installation. Follow the

instructions in the "TANK PROBE INSTALLATION PROCEDURE".

See page 18.

FOR HOT WA TER HEA TING SYSTEMS (GB models), a t ank probe

is not supplied with the GB models due to the many various

types of systems and operating conditions. A tank probe can

be used as an option to control loop temperature and unit

staging. Additionally, the inlet temperature probe can be used

as the loop thermostat in some heating applications. The tank

probe connects to designated wires in the junction box at the

rear of the boiler. Do not operate this boiler using the internal

high limits only, use a tank probe or operating thermostat to

control system temperatures.

The water flow switch is installed at the boiler outlet to prevent burner

operation in the event of inadequate water flow through the boiler. It

is a normally open switch that will close its contacts when increasing

water flow rate is detected. The water flow switch is factory-set, but

may require field adjustment. The contacts will open when the flow

rate drops below the adjusted setting causing the gas valve(s) to

close which will turn off the gas to the burners.

LIMIT CONTROLS

CAUTION

LIMIT CONTROLS ARE SAFETY DEVICES AND ARE NOT TO BE

USED AS AN OPERATING CONTROL (THERMOSTA T).

The "G(B/W)" models incorporate an outlet water probe consisting

of two limit controls:

1. An adjustable automatic reset limit control, that can be set

as high as either 210°F (99°C) or 235°F (113°C) depending on

the application.

2. A fixed manual reset limit (ECO) factory set at 244°F

(118°C). If the manual reset should open due to high

temperature, the gas valves will close and the unit will go into

lockout. If lockout occurs, push the SELECTION button on the

UIM to restart the boiler.

ON/OFF SWITCH

The ON/OFF switch is a single-pole, single-throw rocker switch.

The switch provides 120VAC from the line source to the boiler.

Note: The tank probe or additional 24V AC devices must be identified

using Dipswitches on Central Control Board before they are

recognized as a part of the heating system; see Table 5. Refer to

"Control System" section for more information about dipswitch

settings.

CIRCULA TING PUMP

The pump flow rate should not exceed the maximum

recommended flow rate; see Table 5.

FOR HOT WA TER SUPPLY SYSTEMS (GW models), ordered with

the circulator as an integral part of the boiler; the pump has been

lubricated at the factory, and future lubrication should be in

accordance with the motor manufacturer's instructions provided

as supplement to this manual.

FOR HOT WA TER HEA TING SYSTEMS (GB models or GW models

ordered without circulator), the circulator is NOT provided and

must be field-installed.

LOW WA TER CUT OFF (Not Supplied)

If low water level protection is required by the authorities having

jurisdiction, a low water cutoff switch should be installed

next to the boiler in the outlet water line as shown in

"HYDRONIC INSTALLATION" section; see page 16. The switch

should receive periodic (every six months) inspection to assure

proper operation. A low water cutoff device of the float type should

be flushed every six months.

6

Page 7

DRAIN V ALVE (Not Supplied)

Additional drain valves must be obtained and installed on each boiler

and tank for draining purposes.

SAFETY RELIEF V AL VES

side of the tank on a center line within the upper six (6) inches

(15 cm) of the top of the tank. The tapping shall be threaded in

accordance with the latest edition of the Standard for Pipe Threads,

General Purpose (inch), ANSI/ASME B1.20.1. The location of, or

intended location for, the T & P relief valve shall be readily

accessible for servicing or replacement.

Your local code authority may have other specific relief valve

requirements not covered below.

WARNING

THE PURPOSE OF A SAFETY RELIEF VALVE IS TO AVOID

EXCESSIVE PRESSURE WHICH MAY CAUSE T ANK EXPLOSION,

SYSTEM OR BOILER DAMAGE.

TO AVOID W A TER DAMAGE A DRAIN LINE MUST BE CONNECTED

TO A SAFETY RELIEF V AL VE FOR DIRECT DISCHARGE TO A SAFE

LOCATION. A DRAIN LINE MUST NOT BE REDUCED FROM THE

SIZE OF THE V ALVE OUTLET AND IT MUST NOT CONT AIN ANY

VALVES BETWEEN THE BOILER AND THE RELIEF VALVE OR

THE RELIEF VAL VE AND THE DRAIN EXIT. IN ADDITION, THERE

SHOULD NOT BE ANY RESTRICTIONS IN A DRAIN LINE NOR

SHOULD IT BE ROUTED THROUGH AREAS WHERE FREEZING

CONDITIONS MIGHT OCCUR. DO NOT THREAD OR CAP THE

DRAIN LINE EXIT . RESTRICTING OR BLOCKING A DRAIN LINE

WILL DEFEAT THE PURPOSE OF THE RELIEF VALVE AND MA Y

CREATE AN UNSAFE CONDITION. INST ALL A DRAIN LINE WITH

A DOWNWARD SLOPE SUCH THAT IT NATURALLY DRAINS

ITSELF.

If any safety relief valve is replaced, the replacement valve must

comply with the latest version of the ASME Boiler and Pressure

Vessel Code, Section IV (HEATING BOILERS). Select a relief valve

with a discharge rating NOT less than the boiler input, and a set

pressure NOT exceeding the working pressure of any component

in the system.

The storage tank temperature and pressure relief valve must

comply with the applicable construction provisions of the Standard

for Relief V alves for Hot W ater Supply Systems, ANSI Z21.22-CSA-

4.4 (current edition). The valve must be of the automatic reset type

and not embody a single-use type fusible plug, cartridge or linkage.

FOR HOT WATER HEATING SYSTEMS, the boilers are shipped

with a 50 psi pressure relief valve. This relief valve is factory

installed on the water outlet header of the boiler.

FOR HOT WATER SUPPLY SYSTEMS, the boilers are shipped

with a 125 psi pressure relief valve. This relief valve is factory

installed on the water outlet header of the boiler. This ASME-rated

valve has a discharge capacity that exceeds the maximum boiler

input rating and a pressure rating that does not exceed the

maximum working pressure shown on the boiler rating plate.

In addition, a CSA design-certified and ASME-rated temperature

and pressure (T & P) relief valve must be installed on every water

storage tank in the hot water supply system; see

Figures 11 and 13.

The T & P relief valve should have a temperature rating of 210°F

(99°C), a pressure rating NOT exceeding the lowest rated working

pressure of any system component, and a discharge capacity

exceeding the total input of the water boilers supplying water to the

storage tank.

Locate the T & P relief valve (a) in the top of the tank, or (b) in the

INST ALLATION INSTRUCTIONS

REQUIRED ABILITY

INST ALLATION OR SER VICE OF THIS BOILER REQUIRES ABILITY

EQUIV ALENT TO THA T OF A LICENSED TRADESMAN IN THE FIELD

INVOLVED. PLUMBING, AIR SUPPL Y , VENTING, GAS SUPPLY AND

ELECTRICAL WORK ARE REQUIRED.

LOCA TION

When installing the boiler, consideration must be given to proper

location. The location selected should be as close to the stack or

chimney as practical with adequate air supply and as centralized

with the piping system as possible. The location should also be

such that the gas ignition system components are protected from

water (dripping, spraying, etc.) during appliance operation and

service (circulator replacement, control replacement, etc.)

• THE BOILER MUST NOT BE INST ALLED ON CARPETING.

• THE BOILER SHOULD NOT BE LOCATED IN AN AREA WHERE

IT WILL BE SUBJECT TO FREEZING.

• THE BOILER SHOULD BE LOCATED NEAR A FLOOR DRAIN.

• THE BOILER SHOULD BE LOCATED IN AN AREA WHERE

LEAKAGE FROM THE BOILER OR CONNECTIONS WILL NOT

RESULT IN DAMAGE TO THE ADJACENT AREA OR T O LOWER

FLOORS OF THE STRUCTURE.

WHEN SUCH LOCATIONS CANNOT BE AVOIDED, A SUITABLE

DRAIN PAN SHOULD BE INST ALLED UNDER THE BOILER. Such

pans should be fabricated with sides at least 2-1/2" (6.5 cm) deep,

with length and width at least 2" (5.1 cm) greater than the dimensions

of the boiler and must be piped to an adequate drain. The pan

must not restrict combustion air flow.

WARNING

THERE IS A RISK IN USING FUEL BURNING APPLIANCES IN

ROOMS OR AREAS WHERE GASOLINE, OTHER FLAMMABLE

LIQUIDS OR ENGINE DRIVEN EQUIPMENT OR VEHICLES ARE

STORED, OPERA TED OR REP AIRED. FLAMMABLE VAPORS ARE

HEAVY AND TRAVEL ALONG THE FLOOR AND MAY BE IGNITED

BY THE IGNITER OR MAIN BURNER FLAMES CAUSING FIRE OR

EXPLOSION. SOME LOCAL CODES PERMIT OPERA TION OF GAS

APPLIANCES IF INSTALLED 18 INCHES (46.0 CM) OR MORE

ABOVE THE FLOOR. THIS MA Y REDUCE THE RISK IF LOCA TION

IN SUCH AN AREA CANNOT BE AVOIDED.

FLAMMABLE ITEMS, PRESSURIZED CONTAINERS OR ANY

OTHER POTENTIAL FIRE HAZARDOUS ARTICLES MUST NEVER

BE PLACED ON OR ADJACENT TO THE BOILER.

OPEN CONTAINERS OF FLAMMABLE MATERIAL SHOULD NOT

BE STORED OR USED IN THE SAME ROOM WITH THE BOILER.

A hot water boiler installed above radiation level or as required by

7

Page 8

the authority having jurisdiction, must be provided with a low water

cutoff device either as a part of the boiler or at the time of boiler

installation.

WARNING

UNDER NO CIRCUMST ANCES SHOULD THE EQUIPMENT ROOM

WHERE THE BOILER IS INSTALLED EVER BE UNDER NEGA TIVE

PRESSURE. PARTICULAR CARE MUST BE TAKEN WHEN

EXHAUST FANS, COMPRESSORS, AIR HANDLING EQUIPMENT,

ETC., MAY INTERFERE WITH THE COMBUSTION AND

VENTILA TION AIR SUPPLIES OF THIS BOILER.

CHEMICAL V APOR CORROSION

Heat exchanger corrosion and component failure can be caused

by the heating and breakdown of airborne chemical vapors. Spray

can propellants, cleaning solvents, refrigerator and air conditioning

refrigerants, swimming pool chemicals, calcium and sodium

chloride, waxes, and process chemicals are typical compounds

which are corrosive. These materials are corrosive at very low

concentration levels with little or no odor to reveal their presence.

Products of this sort should not be stored near the boiler. Also, air

which is brought in contact with the boiler should not contain any of

these chemicals. If necessary, uncontaminated air should be

obtained from remote or outside sources. Failure to observe this

requirement will void the warranty.

INST ALLATION CLEARANCES

Sufficient area should be provided at the front and sides of the

unit for proper servicing. For ease of service, minimum

clearances of 24" (61.0 cm) in the front and 18" (46.0 cm) on

the sides are recommended. It is important that the minimum

clearances be observed to allow service to the control box and

other controls. Observing proper clearances will allow service to

be performed without movement or removal of the boiler from its

installed location. Failure to observe minimum clearances may

require removal of the boiler in order to service such items as the

heat exchanger and burners. In a utility room installation, the

door shall be wide enough to allow the boiler to enter or to permit

the replacement of another appliance.

Two inch (5.1 cm) clearance is allowable from combustible

construction to hot water pipes. Sufficient clearance should be

provided at one end of the boiler to permit access to heat exchanger

tubes for cleaning.

Access to control box items such as the Central Control Board,

Flame Control Boards, Power Distribution Board and wiring

harnesses is provided through a panel on the left side of the unit.

A minimum service clearance of 18" (46.0 cm) is required.

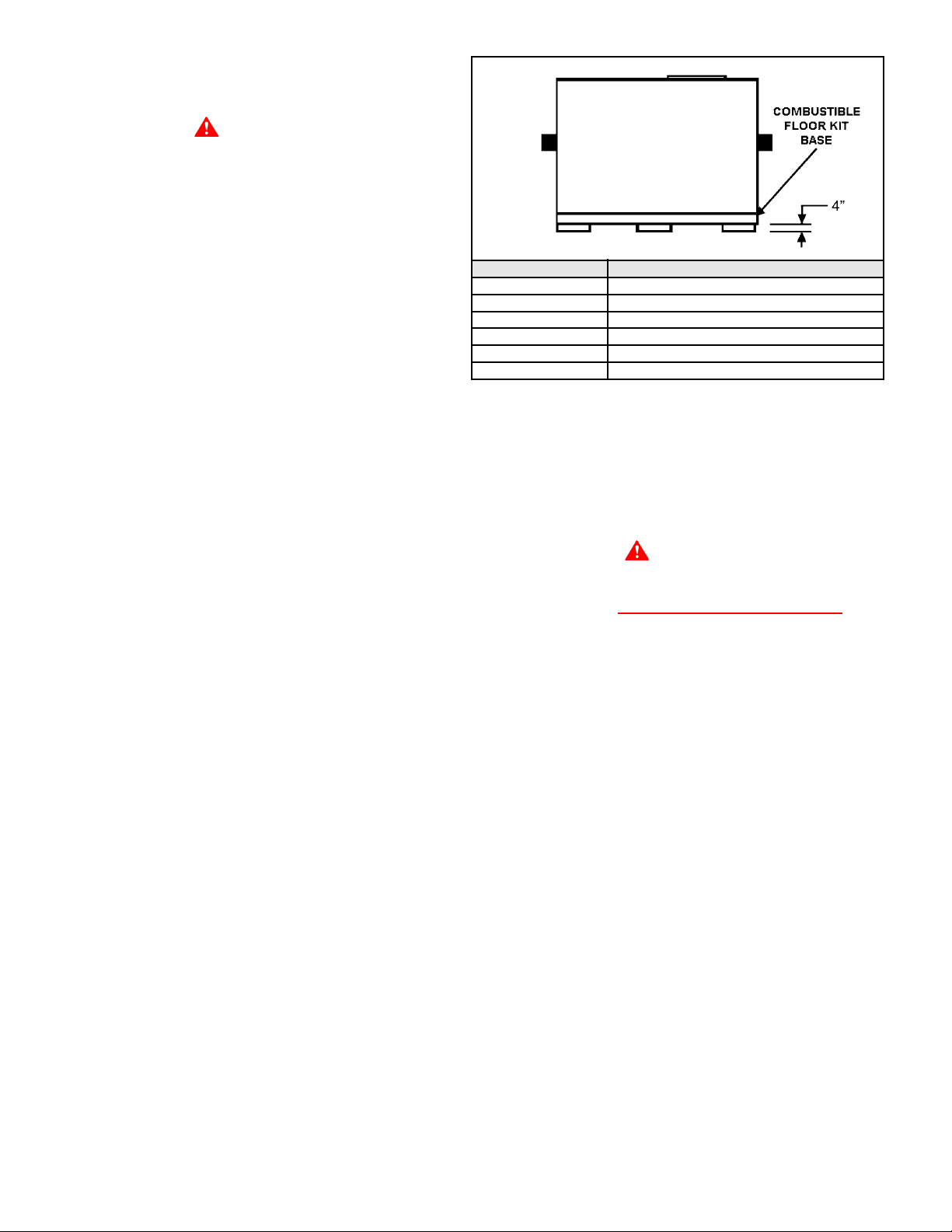

MODEL COMBUSTIBLE BASE KIT NUMBER

G(B,W) - 1000 211093

G(B,W) - 1300 211093-1

G(B,W) - 1500 211093-2

G(B,W) - 1850 211093-3

G(B,W) - 2100 211093-4

G(B,W) - 2500 211093-5

Figure 3. Boiler on Combustible Floor Base and Kit Numbers.

LEVELLING

Each unit must be checked after installation to be ce rtain that it is level.

AIR REQUIREMENTS

WARNING

FOR SAFE OPERATION, AN AMPLE SUPPLY OF AIR MUST BE

PROVIDED FOR PROPER COMBUSTION AND VENTILATION IN

ACCORDANCE WITH THE NATIONAL FUEL GAS CODE, ANSI

Z223.1 OR CAN/CSA-B149.1 CURRENT EDITION OR APPLICABLE

PROVISIONS OF THE LOCAL BUILDING CODES. AN

INSUFFICIENT SUPPLY OF AIR MAY RESULT IN A YELLOW,

LUMINOUS BURNER FLAME, CARBONING OR SOOTING OF THE

FINNED HEAT EXCHANGER, OR CREATE A RISK OF

ASPHYXIATION. DO NOT OBSTRUCT THE FLOW OF

COMBUSTION AND VENTILATION AIR.

UNCONFINED SP ACE

In buildings of conventional frame, brick or stone construction,

unconfined spaces may provide adequate air for combustion.

If the unconfined space is within a building of tight construction

(buildings using the following construction: weather stripping, heavy

insulation, caulking, vapor barrier, etc.), air for combustion,

ventilation, must be obtained from outdoors or spaces freely

communicating with the outdoors. The installation instructions for

confined spaces in tightly constructed buildings must be followed

to ensure adequate air supply.

These boilers are approved for installation on noncombustible

flooring in an alcove with minimum clearance to combustibles of:

3 inches (7.6 cm) Right Side, and Back; 6 inches (15.2 cm) Top;

Front, Alcove; 12 inches (30.5 cm) Left Side; and 6 inches

(15.2 cm) surrounding the Vent.

For installation on combustible flooring use the Combustible Floor

Kit. The combustible floor kit base adds 4" (10.1 cm) to the overall

height of the boiler. See Figure 3.

CONFINED SP ACE

(a) U. S. INST ALLATIONS

When drawing combustion and dilution air from inside a

conventionally constructed building to a confined space, such a

space shall be provided with two permanent openings, ONE

WITHIN 12 INCHES OF THE ENCLOSURE TOP AND ONE WITHIN

12 INCHES OF THE ENCLOSURE BOTTOM. Each opening shall

have a free area of at least one square inch per 1000 Btu/hr

(22 cm2/k W) of the total input of all appliances in the enclosure.

8

Page 9

If the confined space is within a building of tight construction, air

for combustion, ventilation, and draft hood dilution must be

obtained from outdoors. When directly communicating with the

outdoors or communicating with the outdoors through vertical

ducts, two permanent openings, located in the above manner,

shall be provided. Each opening shall have a free area of not less

than one square inch per 4000 Btuh (5.5 cm

2

/kW) of the total input

of all appliances in the enclosure. If horizontal ducts are used, each

opening shall have a free area of not less than one square inch per

2000 Btuh (11 cm

2

/kW) of the total input of all appliances in the

enclosure.

(b) CANADIAN INSTALLA TIONS

Ventilation of the space occupied by the boiler(s) shall be provided

by an opening for ventilation air at the highest practical point

communicating with outdoors. The total cross-sectional area shall

be at least 10% of the area of the combustion air opening but in no

case shall the cross-sectional area be less than 10 square inches

(64.5 cm

2

).

In addition to the above, there shall be permanent air supply

opening(s) having a cross-sectional area of not less than 1 square

inch per 7,000 BTUH (3.2 cm

2

/kW) up to and including 1,000,000

BTUH plus 1 square inch per 14,000 BTU (1.6 cm2/kW) in excess of

1,000,000 BTUH. This opening(s) shall be located at, or ducted to,

a point neither more than 18" (46.0 cm) nor less than 6 inches (15.2

cm) above the floor level.

Where power vented equipment is used in the same room as the

boiler, sufficient air openings must be supplied. UNDERSIZED

OPENINGS MAY RESULT IN INSUFFICIENT AIR FOR

COMBUSTION.

Where an exhaust fan is installed in the same room with a boiler,

sufficient openings for air must be provided in the walls.

UNDERSIZED OPENINGS WILL CAUSE AIR TO BE DRA WN INTO

THE ROOM THROUGH THE CHIMNEY, CAUSING POOR

COMBUSTION. SOOTING MAY RESULT WITH AN INCREASED

RISK OF ASPHYXIA TION.

SEE FIGURE 6). AT LEAST TYPE B VENTING MUST BE USED

WITH THE STANDARD VENTING OPTION (thru-the-roof) USING

THE NA TIONAL FUEL GAS CODE VENT TABLES. TYPE B VENT

CANNOT BE USED IF THE BOILER IS VENTED

PIPE

HORIZONTALLY OR AS A DIRECT VENT (SEE PAGES 12

THROUGH 15). ALL LOCAL UTILITY, STATE/ PROVINCIAL,

REGULATIONS ON VENTING MUST BE FOLLOWED.

VENT SIZING, VENT CONNECTORS, INSTALLATION AND

TERMINATION SHALL BE IN ACCORDANCE WITH THE CURRENT

EDITION OF

NATIONAL FUEL GAS CODE, ANSI Z223.1 OR CAN/

CSA-B149.1 or applicable provisions of the local building codes.

Size and install proper size vent pipe; refer to Table 6.

Horizontal runs of vent pipe shall be securely supported by

adequately placed (approximately every 4 feet [1.2 m]),

noncombustible hangers suitable for the weight and design of the

materials employed to prevent sagging and to maintain a minimum

upward slope of 1/4" per foot (2 cm/m) from the boiler to the vent

terminals. Dampers or other obstructions must not be installed in

the vent. Be sure that the vent connector does not extend beyond

the inside wall of the chimney.

TABLE 6: VENT CONNECTION

MODEL NUMBER VENT CONNECTOR

G(B,W) 1000 10" (25.4 cm)

G(B,W) 1300 12" (30.5 cm)

G(B,W) 1500 12" (30.5 cm)

G(B,W) 1850 14" (35.6 cm)

G(B,W) 2100 14" (35.6 cm)

G(B,W) 2500 16" (40.6 cm)

For vent arrangements other than Table 10 and for proper boiler

operation, a barometric damper is required to maintain draft

between -0.02" W.C.. and -0.04" W.C. at 2 feet (0.6 m) above the

boiler vent collar.

VENTING

CAUTION

WHEN VENTING THE GENESIS BOILER THROUGH AN

OVERSIZED CHIMNEY (INCLUDING MASONRY CHIMNEYS),

ADDITIONAL CARE MUST BE EXERCISED T O ASSURE PROPER

DRAFT . FOR PROPER OPERA TION, A MINIMUM DRAFT OF -0.02"

W.C. AND A MAXIMUM DRAFT OF -0.04" W .C. MUST BE MAINTAINED.

IN INSTANCES OF EXCESSIVE DRAFT, A BAROMETRIC DAMPER

MA Y BE REQUIRED T O ASSIST IN MAINTAINING THE PROPER

DRAFT. DRAFT SHOULD BE MEASURED 2 FEET (0.6 M) ABOVE

THE BOILER VENT COLLAR.

WARNING

THE INSTRUCTIONS IN THIS SECTION ON VENTING THE BOILER

MUST BE FOLLOWED TO AVOID CHOKED COMBUSTION OR

RECIRCULATION OF FLUE GASES. SUCH CONDITIONS CAUSE

SOOTING OR RISKS OF FIRE AND ASPHYXIA TION.

This boiler is approved to be vented as a Category I, Category III

(horizontal venting), or a Direct V ent appliance. The Horizont al and

Direct Venting options require a special vent kit.

STANDARD (VERTICAL) VENTING , CA TEGOR Y I

THIS BOILER MAY BE VENTED ACCORDING TO T ABLE 10 (ALSO

STANDARD (HORIZONT AL) VENTING , CA TEGORY III

Vent sizing, installation and termination shall be in accordance

with the

NATIONAL FUEL GAS CODE, ANSI Z223.1 OR

CAN/CSA-B149.1 (Current Editions). If applicable, all local, utility,

state/provincial regulations on venting must be followed. See Table

1 1, Figure 7 for venting specifications. The exhaust vent pipe must

be of a type listed for use with Category III gas burning heaters such

as "Saf-T-Vent" manufactured by Heat-Fab Inc.

For Category III installations, it is important that the Installed vent

be airtight. Please insure that all joints are sealed properly during

installation. For Horizontal Vent Kit part numbers, see Table 7.

T ABLE 7: HORIZONTAL VENT KITS.

HORIZONT AL VENT KIT MODEL

211426 G(B,W) 1000

211426-1 G(B,W) 1300

211426-1 G(B,W) 1500

211426-2 G(B,W) 1850

211426-2 G(B,W) 2100

211426-3 G(B,W) 2500

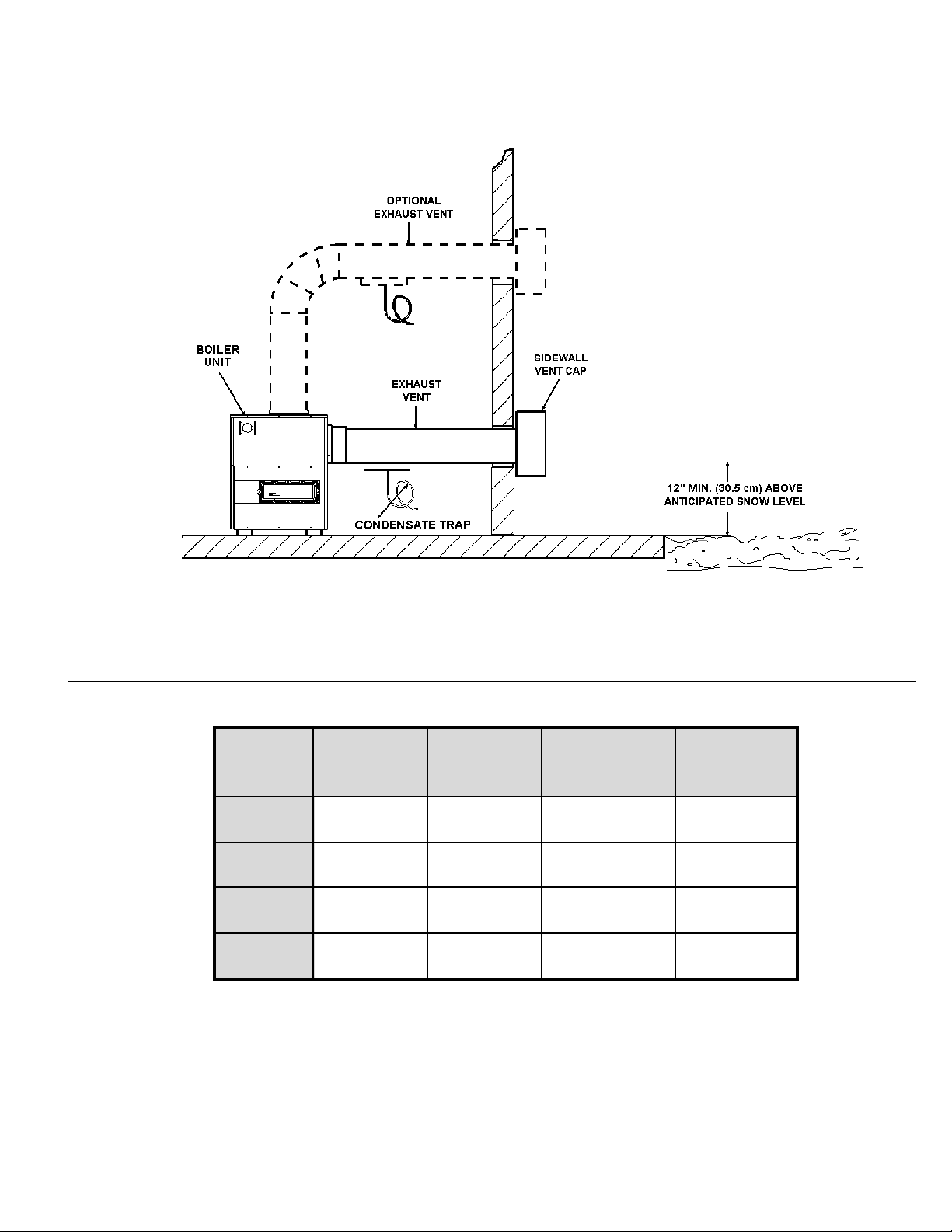

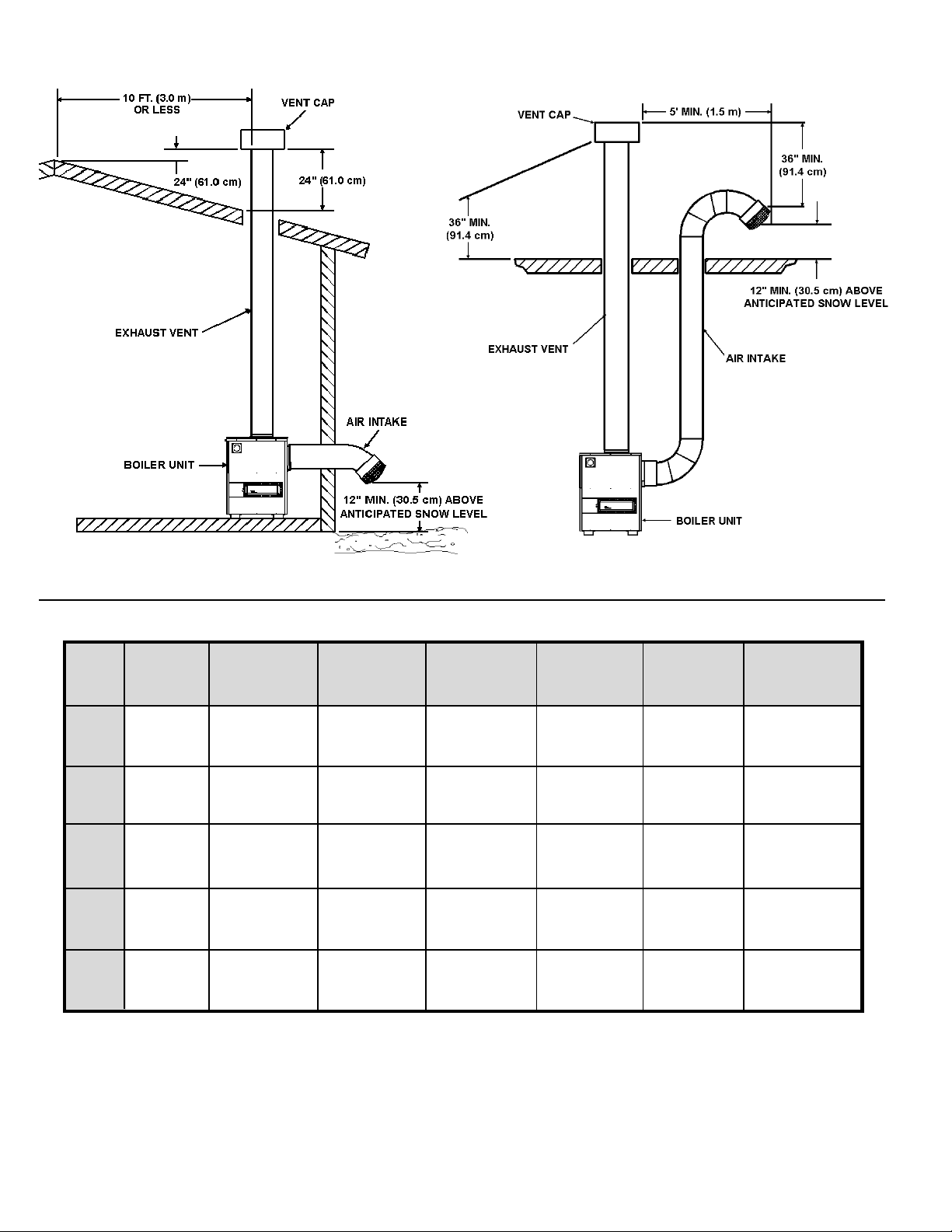

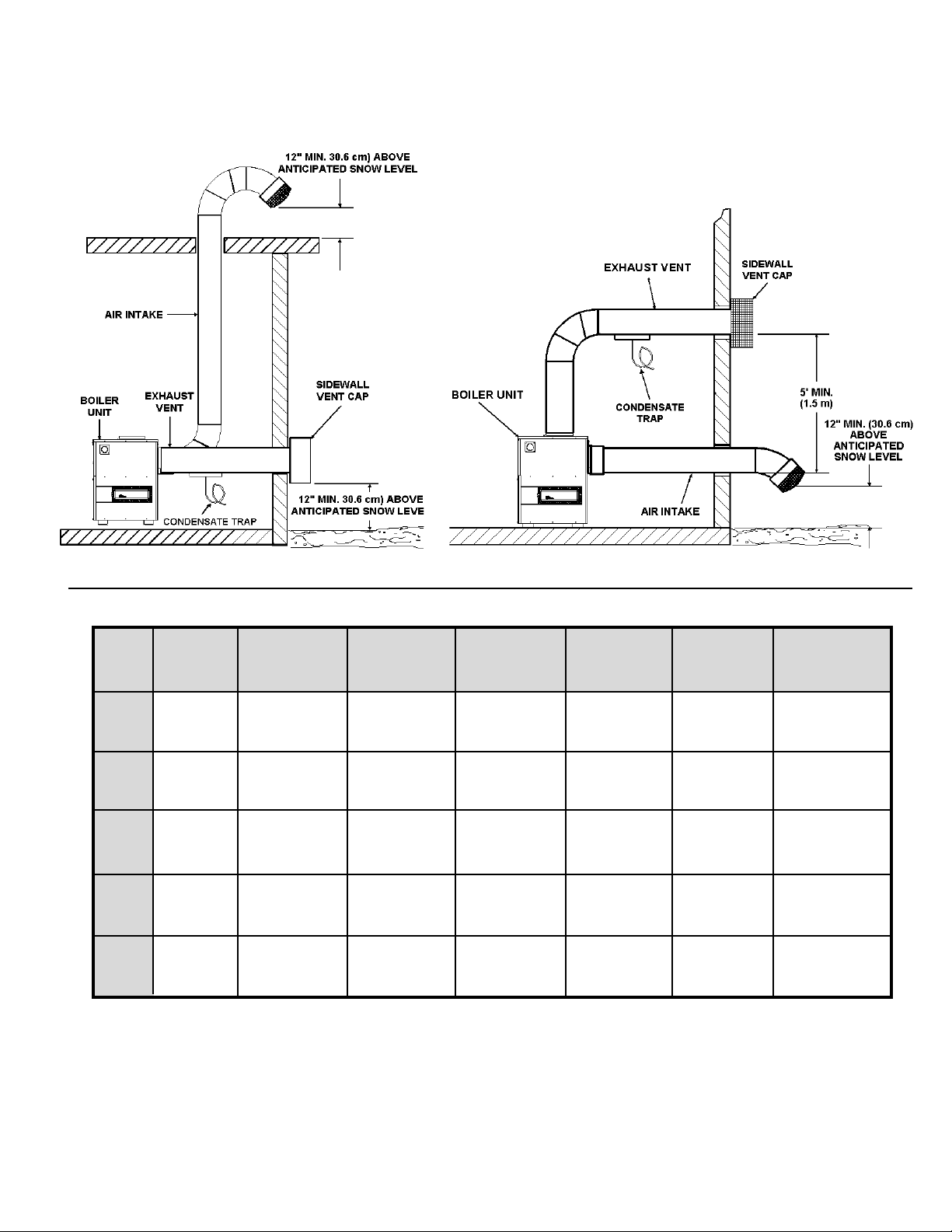

DIRECT VENT VERTICAL AND HORIZONT AL VENTING

For direct vent applications, this boiler may be vented according to

T ables 12 and 13; see Figures 8 and 9. For category III applications,

9

Page 10

the exhaust vent pipe must be listed for use with category III gas

burning heaters such as "Saf-T-Vent" manufactured by Heat-Fab

Inc. This vent system must be 100% sealed with a condensate

trap located as close to the boiler as possible. When sizing exhaust

piping and intake air piping, 90-degree elbows are equivalent to 10

feet (3.1 m) of straight pipe and 45-degree elbows are equal to 5

feet (1.5 m) of straight pipe.

The intake air piping can be PVC, CPVC, ABS, Galvanized steel or

any suit able intake air piping that can be sealed. See Table 8 for

Direct Vent Kit number s.

T ABLE 8: DIRECT VENT KITS.

HORIZONT AL DIRECT VENT KIT NO. MODEL

211090 G(B,W) 1000

211090-1 G(B,W) 1300

211090-1 G(B,W) 1500

211090-4 G(B,W) 1850

211090-2 G(B,W) 2100

211090-3 G(B,W) 2500

VERTICAL DIRECT VENT KIT NO. MODEL

211089 G(B,W) 1000

211089-1 G(B,W) 1300

211089-1 G(B,W) 1500

211089-4 G(B,W) 1850

211089-2 G(B,W) 2100

211089-3 G(B,W) 2500

AIR INTAKE TERMINAL MODEL

191965-2 G(B/W) 1000

211336 G(B/W) 1300,1 500,1850

211336-1 G(B/W) 2100, 2500

HORIZONTAL VENT INST ALLATION

This boiler can be vented through the rear of the cabinet with the

use of the fluebox and vent adaptor. Any of the previous venting

configurations can be installed with rear connections.

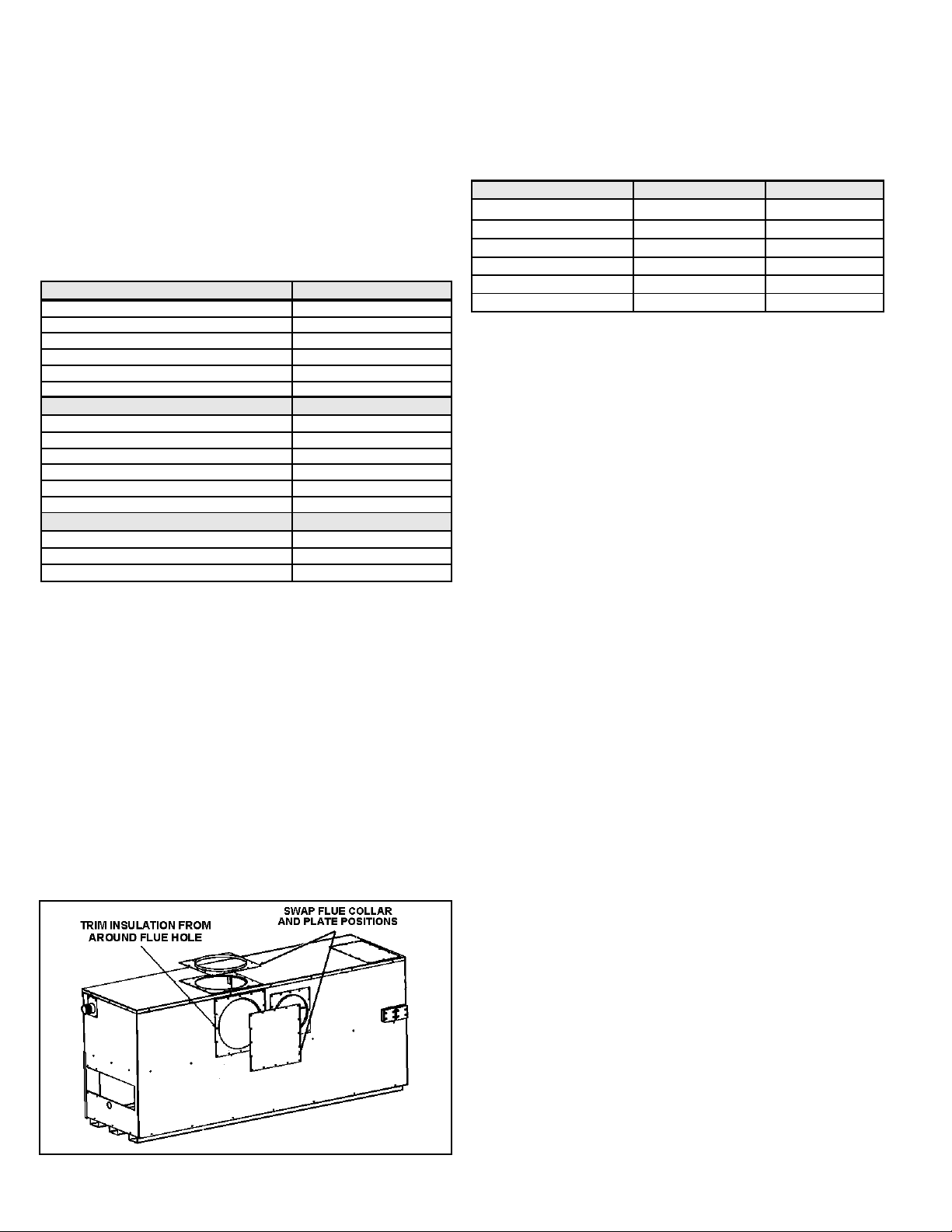

To change the unit to rear exhaust:

1. The vent collar and cover plates must be removed from the top

and rear of the unit.

POWER VENT (OPTIONAL)

The length of vent used in horizontally vented installations can be

extended beyond the lengths shown in Tables 11 and 13 by

implementing the kits listed below:

TABLE 9: POWER VENT KITS.

POWER VENT KIT NO. MODEL MAX. LENGTH

211499 G(B,W) 1000 110' (33.5 m)

211499-1 G(B,W) 1300 100' (30.5 m)

211499-1 G(B,W) 1500 100' (30.5 m)

211499-2 G(B,W) 1850 100' (30.5 m)

211499-3 G(B,W) 2100 100' (30.5 m)

211499-4 G(B,W) 2500 100' (30.5 m)

CONNECTING BOILER TO A COMMON VENT

Do not connect the boiler to a common vent or chimney with solid

fuel burning equipment. This practice is prohibited by most local

building codes as is the practice of venting gas fired equipment to

the duct work of ventilation systems.

Where a separate vent connection is not available and the vent

pipe from the boiler must be connected to a common vent with an

oil burning furnace, the vent pipe should enter the common vent or

chimney at a point ABOVE the flue pipe from the oil furnace.

UL/ULC listed double wall type B-1 gas vents, through 16" diameter,

can be installed in heated and unheated areas and can pass

through floors, ceilings, partitions, walls and roofs, provided the

required clearance is observed.

At the time of removal of an existing boiler, the following steps shall

be followed with each appliance remaining connected to the

common venting system. Perform these steps while the other

appliances remaining connected to the common venting system

are not in operation.

1. Seal any unused opening in the common venting system.

2. Visually inspect the venting system for proper size and horizontal

pitch and determine there is no blockage or restriction, leakage,

corrosion or other unsafe condition.

2. Trim the insulation from around the rear flue hole in the jacket

and the fluebox. Support insulation from inside the fluebox to

facilitate cutting. Use safety precautions such as gloves. Place

the gasket and vent adaptor in the horizontal position. Place

the gasket and flue plate in the vertical position as shown in

Figure 4.

Figure 4. Switching from Vertical to Horizontal Venting.

3. Insofar as is practical, close all building doors, windows and

all doors between the space in which the appliances remaining

connected to the common venting system are located and other

spaces of the building. Turn on clothes dryers and any

appliance not connected to the common venting system. Turn

on any exhaust fans, such as range hoods and bathroom

exhausts, so they will operate at maximum speed. Do not

operate a summer exhaust fan. Close fireplace dampers.

4. Test fire the appliance(s) being inspected, making sure to follow

the manufacturers lighting and operating instructions.

Appliance(s) operating controls should be adjusted to provide

continuous service.

5. Check vent pressure of the appliance 24 inches (61.0 cm) above

boiler vent collar. Vent pressure should be maintained between

-0.02" W. C. and -0.04" W.C. to assure proper operation. For

appliances with a draft hood, check for spillage with mirror,

smoke or other device five minutes after placing appliance in

operation.

6. After it has been determined that each appliance remaining

connected to the common venting system properly vents when

tested as outlined above, return doors, windows, exhaust fans,

10

Page 11

fireplace dampers and other gas burning appliances to their

previous conditions of use.

All boiler venting systems shall be installed in accordance with

the National Fuel Gas Code, ANSI Z223.1 or CAN/CSA-B149.1

(current edition), or applicable provisions of the local building

codes.

7. Avoid areas where condensate drainage may cause

problems such as above planters, patios, or adjacent to

windows where the steam from the flue gases may cause

fogging.

8. Select the point of wall penetration where the minimum

1/4" per foot (2 cm/m) of slope up can be maintained.

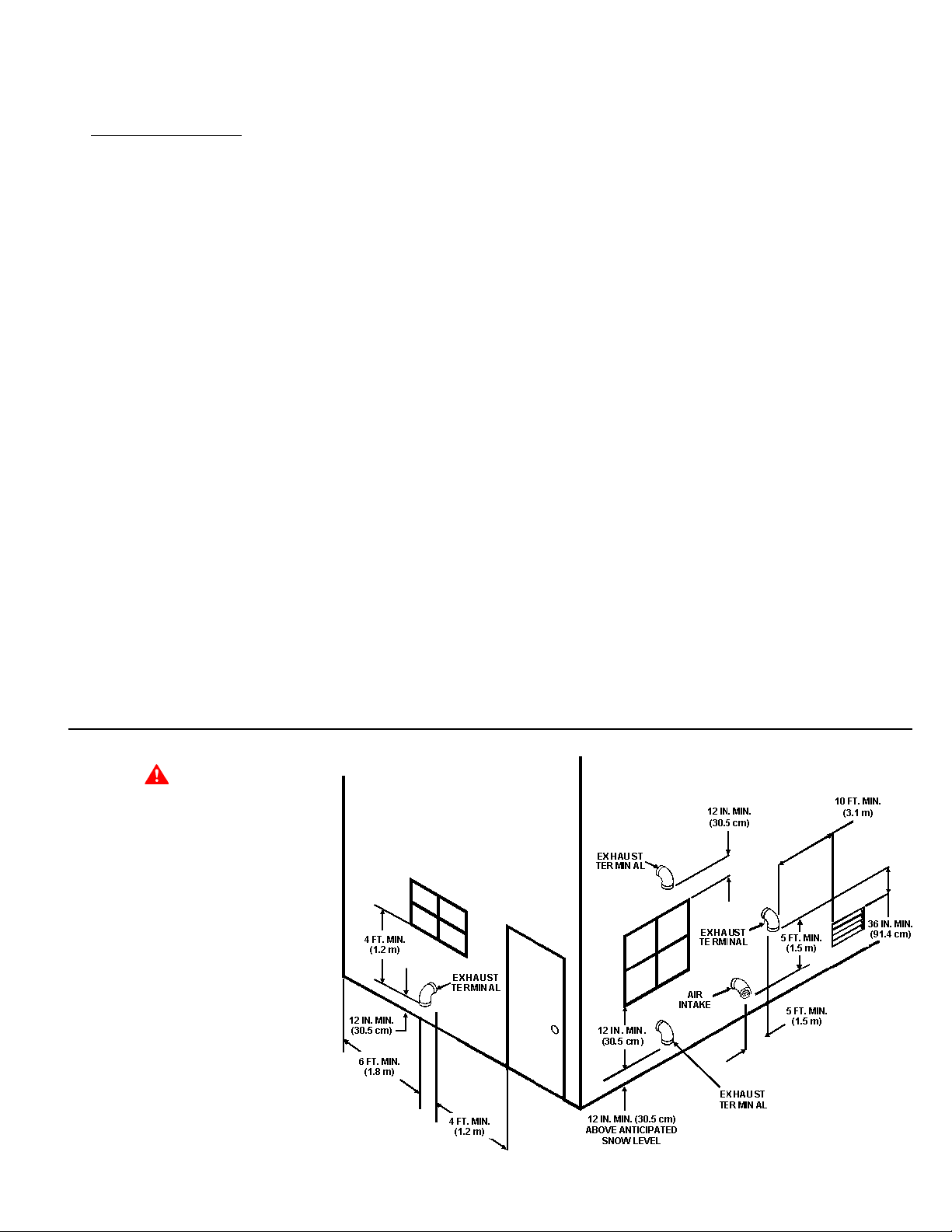

INT AKE/EXHAUST INST ALLA TION REQUIREMENTS

1. The termination must be 12 inches (30.5 cm) above snow

or grade level whichever is higher.

2. Due to normal formation of water vapor in the combustion

process, horizontal terminations must not be located over

areas of pedestrian or vehicular traffic, i.e. public walkways

or over areas where condensate could create a nuisance

or hazard. This is especially true in colder climates where

ice buildup is likely to occur. A.O. Smith Corporation will

not be held liable for any personal injury or property

damage due to any dislodging of ice.

3. The exhaust terminal of the venting system must maintain

a minimum clearance of 4 feet (1.22 m) horizontally from,

and in no case above or below, unless a 4-foot horizontal

distance is maintained, from electric meters, gas meters,

regulators and relief equipment.

4. The minimum distance from inside corner formed by two

exterior walls is 6 feet (1.8 m) but 10 feet (3.1 m) is

recommended where possible.

5. Maintain a minimum distance of 4 feet (1.2 m) from any

soffit or eve vent to the exhaust terminal.

6. Maintain a minimum distance of 10 feet (3.1 m) from

any forced air inlet. Fresh air or make up air inlet such

as a dryer or furnace area is considered to be a forced

air inlet.

9. The through the wall termination kit is suitable for zero

clearance to combustible materials.

10. The mid point of the termination elbow must be a minimum

of 12 inches (30.5 cm) from the exterior wall.

SYSTEM INST ALLA TION

GENERAL

If the system is to be filled with water for testing or other purposes

during cold weather and before actual operation, care must be taken

to prevent a down draft entering the boiler or freezing air from contacting

the system. Failure to do so may cause the water in the system to

freeze with resulting damage to the system. Damage due to freezing

is not covered by the warranty .

Good practice requires that all piping, etc., be properly supported.

The boilers described in this manual may be used for space (hydronic)

heating or for the heating of potable water . If the heater is to be used for

hydronic space heating, follow the instructions on pages 16-17 given for

equipment required for installation as in Figure 10. However, if units

are to be used for heating potable water, the information describing

specific systems is found on pages 18-20; see Figures 11 and 13.

Installations must comply with all local codes.

INST ALLA TION AS BOILER REPLACEMENT

Installation as boiler replacement on an old system with large water

DIRECT VENTING INTO DEAD AIR SPACES

SUCH AS ALLEYS, ATRIUMS AND INSIDE

CORNERS CAN CAUSE RECIRCULATION OF

FLUE GASES. RECIRCULATION OF FLUE

GASES WILL CAUSE SOOTING , PREMA TURE

FAILURE OF THE HEAT EXCHANGER AND

ICING OF THE COMBUSTION AIR INTAKE

DURING SEVERE COLD WEATHER. TO

PREVENT THE RECIRCULATION OF FLUE

GASES, MAINTAIN AS MUCH DISTANCE AS

POSSIBLE BETWEEN THE COMBUSTION AIR

INTAKE AND THE EXHAUST VENT TERMINAL.

Note: Venting system of other than

direct-vent appliance shall terminate at

least 4 ft. (1.2 m) below, 4 ft. (1.2 m)

horizontally from, or 1 ft. (30.0 cm)

above any door window or gravity air

inlet.

CAUTION

Figure 5. Vent Termination Installation Clearances

STANDARD VENTING DIRECT VENT APPLICA TIONS

11

Page 12

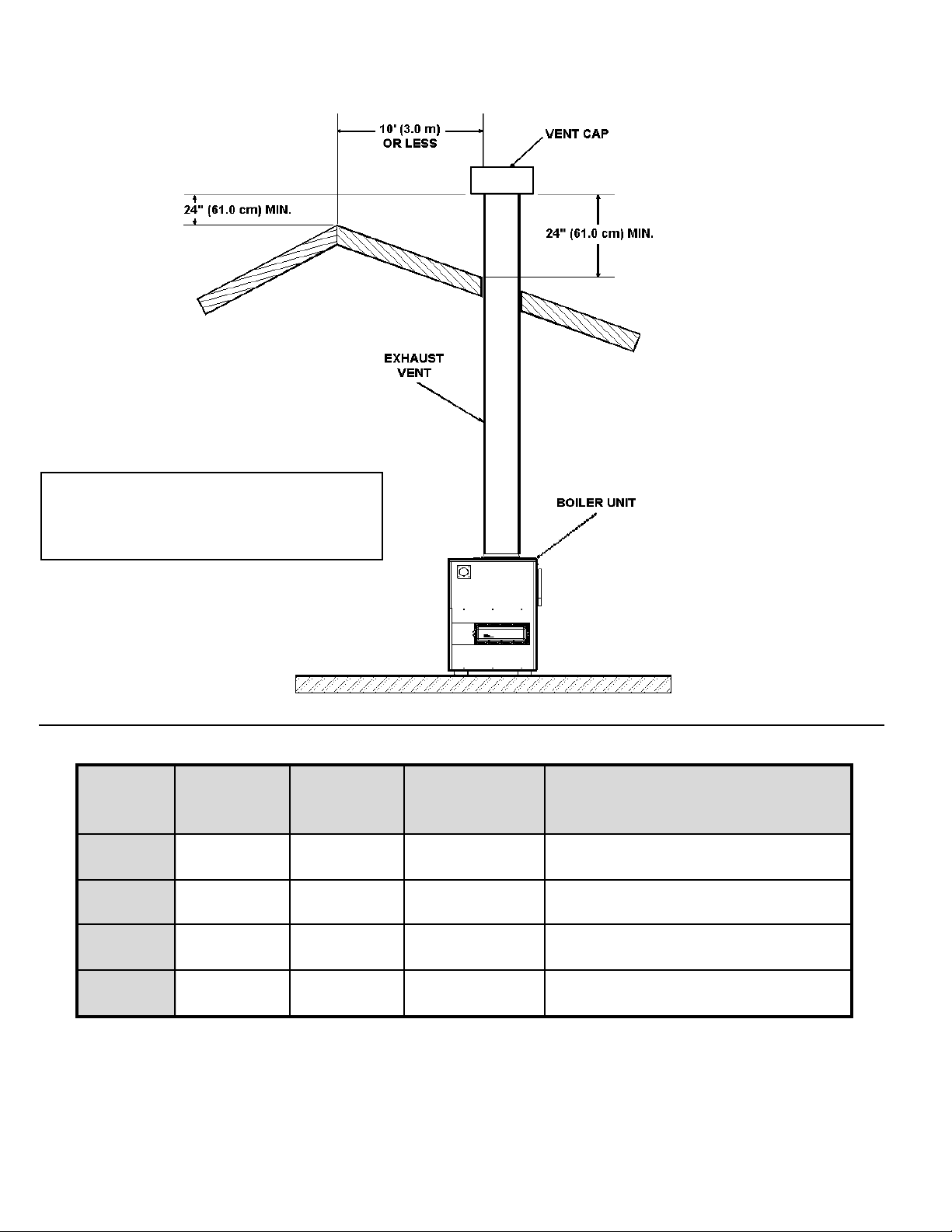

STANDARD VENT - VERTICAL (CATEGORY I)

IMPORT ANT!

VENT PRESSURE MUST BE MAINT AINED

BETWEEN -0.02" W.C. AND -0.04" W.C. AT 24"

(61.0 cm) ABOVE BOILER COLLAR.

Figure 6.

T ABLE 10. STANDARD VERTICAL VENTING (CA TEGOR Y I)

APPLIANCE CERTIFIED EXHAUST MAXIMUM LENGTH

MODEL CA TEGOR Y VENTING VENT SIZE WITHOUT BAROMETRIC DAMPER

MATERIAL INCHES (cm) FEET (m)

I000

1300 TYPE B OR 35 Feet (10.7 m) without damper

1500 EQUIVALENT 12" (30.5 cm) *70 Feet (21.3 m) max. with damper

1850 TYPE B OR 14"(35.6 cm) 35 Feet (10.7 m) without damper

2100 EQUIVALENT *70 Feet (21.3 m) max. with damper

2500

* Extending venting over 70 feet (21.3 m) may require special considerations.

• Connection for the appliance exhaust vent to the stack must be as direct as possible. Maximum and minimum venting length

for Category I appliances shall be determined per the latest edition of the National Fuel Code (U.S.) and CAN/CSA-B149.1

Installation Code (Canada).

• The horizontal breaching of a vent must have an upward slope of not less than 1/4 inch per linear foot (2 cm/m) from the boiler

to the vent terminal. The horizontal portion of the vent shall be supported to maintain clearances and to prevent physical damage

or separation of joints.

I

I

I

I

TYPE B OR 10”(25.4 cm) 35 Feet (10.7 m) without damper

EQUIV ALENT *70 Feet (21.3 m) max. with damper

TYPE B OR 16" (40.6 cm) 35 Feet (10.7 m) without damper

EQUIV ALENT *70 Feet (21.3 m) max. with damper

12

Page 13

ST ANDARD VENT - HORIZONTAL (CA TEGOR Y III)

Figure 7.

T ABLE 11. ST ANDARD HORIZONT AL VENTING (CA TEGOR Y III)

APPLIANCE CERTIFIED EXHAUST MAXIMUM

MODEL CATEGORY VENTING VENT SIZE VENT LENGTH

MA TERIAL INCHES (cm) FEET (m)

I000

1300 STAINLESS

1500 STEEL

1850 STAINLESS

2100 STEEL

2500

WARNING: No substitutions of flue pipe or vent cap material are allowed. Such substitutions would jeopardize the

safety and health of inhabitants.

• A maximum of two elbows can be used on inlet and outlet vent piping respectively. Each elbow is equal to 10 feet (3 m) of

straight pipe.

III

III

III

III

STAINLESS

STEEL

STAINLESS

STEEL

10”(25.4 cm)

12" (30.5 cm)

14"(35.6 cm)

16" (40.6 cm)

70' (21.3 m)

70' (21.3 m)

35' (10.7 m)

35' (10.7 m)

• Use only special gas vent pipes listed for use with Category III gas burning heaters, such as stainless steel Saf-T-Vent

by Heat Fab, Inc., available from A.O. Smith, 500 T ennessee W altz Parkway , Ashland City , TN 37015 Phone: 1-800-433-2545

or Fax: 1-800-433-2515. Pipe joints must be positively sealed.

13

Page 14

DIRECT VENT - VERTICAL (CATEGORY I)

Figure 8.

T ABLE 12. DIRECT VENT (VERTICAL EXHAUST CONFIGURA TIONS)

APPLIANCE CERTIFIED EXHAUST VENT MAXIMUM AIR INTAKE AIR INT AKE MAXIMUM

MODEL CATEGORY EXHAUST VENT SIZE EXHAUST VENT MATERIAL SIZE AIR INTAKE

MATERIAL INCHES (cm) LENGTH FT (m) INCHES (cm) LENGTH FT (m)

GAL. STEEL

CPVC

GAL.STEEL

CPVC

GAL. STEEL

CPVC

GAL. STEEL

CPVC

GAL. STEEL

CPVC

8"

(20.3 cm)

10"

(25.4 cm)

10"

(25.4 cm)

12"

(30.5 cm)

12"

(30.5 cm)

(10.7 m)

(10.7 m)

I000

1300

1500

1850

2100

2500

I PVC, ABS OR

I PVC, ABS CR

I PVC, ABS OR

I PVC, ABS OR

I PVC, ABS OR

TYPE B OR

EQUIVALENT

TYPE B OR

EQUIV ALENT

TYPE B OR

EQUIV ALENT

TYPE B OR

EQUIVALENT

TYPE B OR

EQUIV ALENT

10"

(25.4 cm)

12"

(30.5 cm)

14"

(35.6 cm)

14"

(35.6 cm)

16"

(40.6 cm)

35'

(10.7 m)

35'

(10.7 m)

20'

(6.1 m)

20'

(6.1 m)

20'

(6.1 m)

35'

35'

20'

(6.1 m)

20'

(6.1 m)

20'

(6.1 m)

• Connection for the appliance exhaust vent to the stack must be as direct as possible. Maximum and minimum venting length

for Category I appliances shall be determined per the latest edition of the National Fuel Code (U.S.) and CAN/CSA-B149.1

Installation Code (Canada).

• The vent should be installed so as to prevent the accumulation of condensate and, where necessary , have means provided for

drainage of condensate. The horizontal breaching of a vent must have an upward slope of not less than 1/4 inch per linear foot

(2 cm/m) from the boiler to the vent terminal. The horizontal portion of the vent shall be supported to maintain clearances and to

prevent physical damage or separation of joints.

14

Page 15

DIRECT VENT - HORIZONT AL (CATEGORY III)

Figure 9.

T ABLE 13. DIRECT VENT (HORIZONT AL EXHAUST CONFIGURA TIONS)

APPLIANCE CERTIFIED EXHAUST MAXIMUM AIR INTAKE AIR INT AKE MAXIMUM

MODEL CATEGOR Y EXHAUST VENT VENT SIZE EXHAUST VENT MA TERIAL SIZE AIR INTAKE

MATERIAL INCHES (cm) LENGTH FT (m) INCHES (m) LENGTH FT (m)

GAL. STEEL

CPVC

GAL.STEEL

CPVC

GAL. STEEL

CPVC

GAL. STEEL

CPVC

GAL. STEEL

CPVC

8"

(20.3 cm)

10"

(25.4 cm)

10"

(25.4 cm)

12"

(30.5 cm)

12"

(30.5 cm)

I000

1300

1500

1850

2100

2500

III PVC, ABS OR

III PVC, ABS CR

III PVC, ABS OR

III PVC, ABS OR

III PVC, ABS OR

STAINLESS

(SEALED)

STAINLESS

(SEALED)

STAINLESS

(SEALED)

STAINLESS

(SEALED)

STAINLESS

(SEALED)

10"

(25.4 cm)

12"

(30.5 cm)

14"

(35.6 cm)

14"

(35.6 cm)

16"

(40.6 cm)

35'

(10.7 m)

35'

(10.7 m)

20'

(6.1 m)

20'

(6.1 m)

20'

(6.1 m)

35'

(10.7 m)

35'

(10.7 m)

20'

(6.1 m)

20'

(6.1 m)

20'

(6.1 m)

WARNING: No substitutions of flue pipe or vent cap material are allowed. Such substitutions would jeopardize the

safety and health of inhabitants.

• A maximum of two elbows can be used on inlet and outlet vent piping respectively. Each elbow is equal to 10 feet (3 m) of

straight pipe.

• Use only special gas vent pipes listed for use with Category III gas burning heaters, such as stainless steel Saf-T -Vent by Heat

Fab, Inc. Inc., available from A.O. Smith, 500 Tennessee Waltz Parkway, Ashland City, TN 37015 Phone: 1-800-433-2545 or

Fax: 1-800-433-2515. Pipe joints must be positively sealed.

15

Page 16

volume may result in condensation within the boiler on cold starts.

This condensing of water vapor in the combustion area can be

prevented if a portion of the system water flow is diverted past the

boiler to cause an increase in boiler temperature.

BYP ASS BALANCING

HYDRONIC INST ALLA TION

The following is a brief description of the equipment required for

installations noted in Figure 10. All installations must comply with

local codes.

With systems where water temperature can be expected to drop

appreciably due to long standby periods, or heavy draw down, a

bypass pipe of at least 1" size with a balancing cock should be

installed between the boiler inlet and outlet. See Figure 10. When

the system first starts, the valve should be slowly opened until the

condensing ceases. This adjustment remains at a permanent

setting to establish required temperature rise across the boiler.

AIR SEPARA T OR

An air separator as shown in the piping diagram is recommended

especially for modern commercial hydronic systems.

VENT V AL VES

It is recommended that automatic, loose key or screwdriver type

vent valves be installed at each convector or radiator.

SYSTEM HEADERS

Split systems with individual supply and return lines from the boiler

room should normally have this piping connected to supply and

return manifold headers near the boiler. To achieve good water

distribution with minimum pressure drop for several circuits,

manifolds should be larger than system loops.

The circuits should be spaced on the header at a minimum of

3" (7.6 cm) center to center. Install a balancing c ock in each return line.

T ABLE 14: INSTALLA TION ITEMS

NO. SUGGESTED ITEMS FOR INSTALLA TION

1. PAIR OF SHOR T PIPE NIPPLES, P AIR OF BOILER

LOOP TEES AND BALL V AL VE BETWEEN SYSTEM

SUPPL Y AND RETURN - ONE SET PER EACH BOILER

2. BOILER PIPE LOOP (See Table 5.)

3. BOILER CIRCULATING PUMP (See Table 5.)

4. THERMOMETER

5. PRESSURE GAUGE

6. LOW WATER CUTOFF (If Required By Local Code.)

7. FLOW SWITCH (Factory-Installed)

8. PRESSURE RELIEF VALVE (Factory-Installed)

9. BOILER INLET - OUTLET

10. SYSTEM SUPPLY TEMPERA TURE THERMOMETER

11. DRAIN or BLOW-DOWN V AL VE

WA TER SUPPL Y LINE

These boilers can be used ONLY in a forced circulation hot water

heating system. The pump must be interlocked with the boiler to

prevent boiler operation without water circulation. See maximum

and minimum flow rate information. Since most forced circulation

systems will be of the closed type, install the water supply line as

shown on piping diagram. See Figure 10. Severe damage will

occur if the boiler is operated without proper water flow

circulation.

Manifold headers are recommended for split systems with or

without zone valves and also those installations with zone

circulators. If the system is to be split at remote points, good practice

requires special attention be given to main pipe sizing to allow

balancing of water flow.

COOLING PIPING

When the boiler is used in conjunction with a refrigeration system

it must be installed so that the chilled medium is piped in parallel

with the boiler. Appropriate valves, manual or motorized, must be

provided to prevent the chilled medium from entering the boiler.

Water temperature in the heating system must be reduced to less

than 100°F (38°C) before cooling system is started, or damage to

the chiller unit may occur.

If the boiler is connected to chilled water piping or heating coils

exposed to refrigerated air, the boiler piping system must be

equipped with flow control valves or other automatic means to

prevent gravity circulation through the boiler during the cooling cycle.

Primary/secondary pumping of both the chiller(s) and the boiler(s)

is an excellent winter-summer change-over method, because

cooling flow rates are much more than heating flow rates. In this

way each system (heating or cooling) is circulated independently.

EXP ANSION TANK

Install an expansion tank as shown in Figures 10, 11, and 13. The

sizing of the expansion tank is very important and is directly related

to the total water volume of the system. Refer to ASME or other

reliable specifications for sizing.

Fast filling of large pipe, old radiator installations (where high

pressures are not available) requires bypassing of the pressure

reducing valve. Generally, pressure purging is not possible with a

well pump system. High point air venting is essential. For details,

refer to OPERATION section of this manual. If the system is of the

open type, a pressure reducing valve will not be required as the

water supply to the system will be controlled by a manually operated

valve. An overhead surge tank is required.

OF 15 PSI (100 kPa) MUST BE MAINT AINED ON THE BOILER AT

ALL TIMES to avoid potential damage to the boiler that may not be

covered by the warranty.

A MINIMUM PRESSURE

CONVENTIONAL SP ACE HEATING INST ALLA TION

Modern copper-finned tube type boilers are exceptionally fast heating

units. The low water volumes in relation to firing rates require special

attention to water flow rates for smooth, efficient operation. These

considerations for the A. O. Smith copper heat exchanger boilers

are covered below.

Refer to Table 5 showing flow rate vs. pressure drop and

temperature rise.

Figure 10 shows a typical installation of the boiler.

A system with several flow controlled zones, or with a 3-way mixing

valve system could present a flow rate to the boiler of less than

required for a maximum of 50°F (28°C) temperature rise. Design

system with compensating bypasses to the boiler.

A system bypass should be installed as shown in Figure 10 to

prevent boiler circulation starvation when the system zones call for

reduced flow.

16

Page 17

This bypass may also be used with multiple boilers manifolded for

reverse-return flow. The system byp ass would be installed from boiler

outlet to suction side of pump.

Large systems with multiple boilers should include main water

temperature controls (with or without outdoor reset) to sequence the

boiler on and off, in relation to the load on the system.

The boiler piping system of a hot water heating boiler connected to

heating coils located in air handling units where they may be

exposed to circulating refrigerated air, must be equipped with flow

control valves or other automatic means to prevent gravity circulation

of the boiler water during the cooling cycle. It is highly recommended

that the piping be insulated.

SP ACE HEA TING APPLICA TIONS

Controlling of these systems is decided mainly by the type of

building system controlling that is desired. A single boiler installation

might be controlled directly from space temperature thermostat(s).

Multiple boiler installations are more effective when the boilers are

sequenced in and out of operation by some form of main water

temperature controller. With one or two boilers, individual control

settings at progressive temperature may be used. For more than

two boilers, electronic sequencing controlling is recommended.

Individual controls, or the separate stages of a step controller, should

start the boiler loop circulator and fire the boiler. Some large

installations may require the firing of more than one boiler per stage.

The system or primary circulator may or may not be controlled

by the boiler sequencer. When this pump is operated through

the first switch of any type of step controller, care should be

taken to determine if a motor starter is needed due to

insufficient switch capacity.

Multiple boiler installations are especially adapted to the use of

outdoor reset for main water temperatures. This feature is not

mandatory but offers smooth, efficient operation of a modern

system.

24 VAC System Controller (Optional)

GB models require a field supplied 24VAC operating control to be

installed in the system such as: loop thermostat, indoor/outdoor reset

control, sequencing panel, or energy management system. The

connection for such devices is located in the 24 VAC junction box at

the rear of the unit. A 24 V AC thermostat/aquastat can only be used as

an "On/Off" switch for the unit. The actual controlling of the staging will

be through either the inlet or tank probe.

INTERNAL CONT AMINANTS

The system must be internally cleaned and flushed after a new or

replacement unit has been installed to remove contaminants that

may have accumulated during installation. This is doubly important

when a replacement unit is installed into an existing system where

Stop Leak or other boiler additives have been used.

All systems should be completely flushed with a grease removing

solution to assure trouble-free operation. Pipe joint compounds, soldering

paste, grease on tubing and pipe all tend to contaminate a system.

Failure to clean and flush the system can cause solids to form on

the inside of the heat exchanger, can produce acid concentrations

that become corrosive, can allow excessive amounts of air or other

gases to form which could block circulation, foul system

accessories and damage circulator seals and impellers.

Normal use of flow control valves is required to prevent cross

circulation of zones as with any multiple pump system.

It is recommended that after installation, the boiler and system

when filled should include the proper percentage of cleaning solution

Figure 10. Single or Multiple Boiler Installation Diagram

17

Page 18

related to approximate water volume of the system. The system

should be turned on to circulate water mix for about one hour and

then flush clean with fresh water.

Before operating the boiler, the entire system must be filled with

water, purged of air and checked for leaks. Do not use Stop Leak or

other boiler compounds.

THE WA TER HEA TER SHOULD BE LOCA TED IN AN AREA WHERE

THE GENERAL PUBLIC DOES NOT HAVE ACCESS TO BOILER

CONTROLS.

limit the maximum tank probe temperature for GW applications.

Failure to do this will void the warranty. If the tank probe is not

designated as the controlling probe, the staging of the unit will be

controlled by the inlet probe and will not use the desired tank

temperature as its base.

Refer to "Connection Diagram" in order to connect the tank probe

to the boiler. See Figures 12 and 15.

See section titled "Temperature Setpoints" for instructions on how

to set the temperature.

HOT WATER SUPPLY

BOILER INST ALLATION

WATER LINE CONNECTIONS

Where excessive heat exchanger condensation exists due to

continued low inlet water temperatures below 120°F (49°C), a

bypass balance loop must be installed. See Figures 10 and 12.

HARD WA TER CONDITIONS

Where hard water conditions exist, water softening or the threshold

type of water treatment is recommended. This will protect the

dishwashers, coffee urns, water heaters, water piping and other

equipment. When water softening or water treatment is not practical,

a comparatively easy method of periodic lime removal from the unit

must be employed.

WARNING

LIME ACCUMULATION CAN REDUCE THE LIFE OF THE

EQUIPMENT , REDUCE EFFICIENCY AND WASTE FUEL. BOILER

FAILURE DUE TO LIME OR SCALE BUILDUP VOIDS THE

WARRANTY.

Tank Probe (Optional)

In addition to the Inlet and Outlet/ECO Probes, units can be

optionally equipped with a tank probe. The connection for the tank

probe is located in the 24VAC junction box at the rear of the unit.

The tank probe can be configured to control the staging of the unit.

See "Tank Probe Installation Procedure" section below for

additional information.

T ANK PROBE INSTALLA TION PROCEDURE

A tank probe is supplied with each hot water supply boiler (GW). To

connect the tank probe to the boiler, remove the cover from the

24VAC junction box at the rear of the unit. Connect the probe wires

across terminals 1 & 2. (The wires leading to the terminals will be

yellow.) Check the field connection diagram located on this cover of

the junction box to assure proper wiring.

Once the tank probe has been connected to the boiler, it must be

designated as the controlling probe for the system. This is

accomplished by changing two Dip Switch settings on the Central

Control Board. First, Dip Switch “SW1-4” must be set to the “ON”

position to designate the tank probe as the controlling probe.

Second, Dip Switch “SW1-1” must be set to the “OFF” position to

GAS CONNECTIONS

WARNING

THIS BOILER IS NOT INTENDED TO OPERATE AT GAS SUPPLY

PRESSURE OTHER THAN SHOWN ON THE RATING PLATE.

EXPOSURE TO HIGHER GAS SUPPLY PRESSURE MAY CAUSE

DAMAGE TO GAS VALVES WHICH CAN RESULT IN FIRE OR

EXPLOSION. IF OVERPRESSURE HAS OCCURRED SUCH AS

THROUGH IMPROPER TESTING OF GAS LINES OR EMERGENCY

MALFUNCTION OF THE SUPPL Y SYSTEM, THE GAS VAL VES MUST BE

CHECKED FOR SAFE OPERA TION. MAKE SURE THAT THE OUTSIDE

VENTS ON THE SUPPL Y REGULATORS AND THE SAFETY VENT V ALVES

ARE PROTECTED AGAINST BLOCKAGE. THESE ARE P AR TS OF

THE GAS SUPPLY SYSTEM, NOT THE BOILER. VENT BLOCKAGE

MA Y OCCUR DURING ICE BUILD-UP OR SNOW STORMS.

WHEN LOCAL CODES REQUIRE A MAIN MANUAL SHUT-OFF

VALVE OUTSIDE THE BOILER JACKET, A SUITABLE MAIN

MANUAL SHUT -OFF V ALVE MUST BE INSTALLED IN A LOCA TION

COMPL YING WITH THOSE CODES.

IT IS IMPORT ANT TO GUARD AGAINST GAS VAL VE FOULING

FROM CONTAMINANTS IN THE GAS WAYS. SUCH FOULING

MA Y CAUSE IMPROPER OPERA TION, FIRE OR EXPLOSION. IF

COPPER SUPPLY LINES ARE USED THEY MUST BE

APPROVED FOR GAS SERVICE.

BEFORE AT TACHING THE GAS LINE BE SURE THAT ALL GAS

PIPE IS CLEAN ON THE INSIDE.

TO TRAP ANY DIRT OR FOREIGN MATERIAL IN THE GAS

SUPPLY LINE, A DIRT LEG (SOMETIMES CALLED DRIP LEG)

MUST BE INCORPORATED IN THE PIPING. THE DIRT LEG

MUST BE READILY ACCESSIBLE AND NOT SUBJECT TO

FREEZING CONDITIONS. INSTALL IN ACCORDANCE WITH

RECOMMENDATIONS OF SER VING GAS SUPPLIERS. REFER TO

NATIONAL FUEL GAS CODE, ANSI Z223.1 OR CAN/CSA -B149.1

(current edition).

THE BOILER AND ITS INDIVIDUAL SHUTOFF VALVE MUST BE

DISCONNECTED FROM THE GAS SUPPLY PIPING SYSTEM

DURING ANY PRESSURE TESTING OF THAT SYSTEM AT TEST

PRESSURES IN EXCESS OF 1/2 PSI (3.5 KPA).

THE BOILER MUST BE ISOLATED FROM THE GAS SUPPLY

PIPING SYSTEM BY CLOSING ITS INDIVIDUAL MANUAL

SHUTOFF VALVE DURING ANY PRESSURE TESTING OF THE

GAS SUPPLY PIPING SYSTEM AT TEST PRESSURES EQUAL TO

OR LESS THAN 1/2 PSI (3.5KPA).

18

Page 19

ONE GENESIS (MODEL GW) HOT WATER SUPPLY BOILER WITH HORIZONTAL TANK

INSTALL THERMAL EXPANSION

TANK ON COLD WATER

SUPPLY LINE, IF CHECK VALVE

OR PRESSURE REDUCING

VALVE IS USED IN SUPPLY.

DANGER

TEMPERATURE SETTING SHOULD NOT EXCEED

SAFE USE TEMPERATURE AT FIXTURES.

SEE WATER TEMPERATURE CONTROL

WARNING ON P AGE 26. IF HIGHER PREHEA T

TEMPERA TURES ARE NECESSARY TO OBTAIN

ADEQUATE BOOSTER OUTPUT, ADD AN

ANTI-SCALD VALVE FOR HOT WATER

SUPPLIED TO FIXTURES.

PRESSURE RELIEF VALVE RATING SHOULD

NOT EXCEED PRESSURE CAPACITY OF ANY

COMPONENT IN THE SYSTEM.

PIPING SHOULD CONFORM TO LOCAL CODES.

BALL VALVES ARE SHOWN FOR SERVICING

BOILER. HOWEVER, LOCAL CODES SHALL

GOVERN THEIR USAGE.

IMPORTAN T

WATER FLOW SWITCH PROTECTS THE

BOILER IN CASE OF WATER SERVICE

INTERRUPTION OR CIRCULATOR FAILURE.

• PIPE TO OPEN DRAIN

X FACTORY-INSTALLED ON UNIT

== SUPPLIED WITH UNIT

= FIELD-INSTALLED

THE WA TER MANIFOLD IS NOT DESIGNED T O

WARNING

SUPPORT THE WEIGHT OF THE WA TER PIPING

SYSTEM. SPECIAL CARE MUST BE TAKEN T O

ENSURE PROPER SUPPORT .

TWO TEMPERA TURE WA TER

MIXING VALVE APPLICATION

CIRCULATING RETURN

LINE CONNECTIONS

• TEMPERED WATER LOOP, IF USED,

CONNECT TO POINT R.

• STORED TEMPERA TURE WATER LOOP ,

IF USED, CONNECT TO ANY OPENING

NEAR BOTTOM OF T ANK.

MINIMUM

MODELS

MODELS INCHES

GW-1000

THRU 2 1/2"

2500 NPT

FACTOR Y PUMP SIZING

BASED ON 50 EQUIVALENT

FEET (15.2 m) OF PIPE.

PIPE SIZE

Figure 11. Single boiler with horizontal tank.

Encase field-supplied wires

between tank probe and junction

box with 1/2" field supplied

conduit. "Pigtails" of fieldsupplied wires should be spliced

to "pigtails" of tank probe and

connected to 24 VAC junction box.

See figure 15. This conduit and

wiring should be separate from

any other conduit/wiring to guard

against EMI (electromagnetic

interference).

Figure 12. Tank probe installation.

19

Page 20

ONE GENESIS (MODEL GW) HOT WATER SUPPLY BOILER WITH VERTICAL TANK

PRESSURE RELIEF VALVE RATING SHOULD NOT EXCEED PRESSURE CAPACITY OF ANY COMPONENT IN THE SYSTEM.

PIPING SHOULD CONFORM TO LOCAL CODES.

BALL VALVES ARE SHOWN FOR SERVICING BOILER. HOWEVER, LOCAL CODES SHALL GOVERN THEIR USAGE.

IMPORTANT

WATER FLOW SWITCH PROTECTS THE BOILER IN CASE OF WATER SERVICE INTERRUPTION OR CIRCULATOR FAILURE.

• PIPE TO OPEN DRAIN

X FACTORY INSTALLED ON UNIT

== SUPPLIED WITH UNIT

= FIELD-INSTALLED

INSTALL THERMAL EXPANSION

TANK ON COLD WATER SUPPLY

LINE, IF CHECK VALVE OR

PRESSURE REDUCING VALVE

IS USED IN SUPPLY.

Figure 13. Single boiler with vertical tank.

MINIMUM

MODELS

PIPE SIZE

MODELS INCHES

GW-1000

THRU 2 1/2"

2500 NPT

FACTORY PUMP SIZING BASED

ON 50 EQUIVALENT FEET

(15.2 m) OF PIPE.

20

DANGER

TEMPERATURE SETTING SHOULD NOT EXCEED SAFE USE

TEMPERATURE A T FIXTURES. SEE W A TER TEMPERA TURE

CONTROL WARNING ON P AGE 26. IF HIGHER PREHEA T TEMPERATURES ARE NECESSARY TO OBTAIN ADEQUATE

BOOSTER OUTPUT, ADD AN ANTI-SCALD V AL VE FOR HOT

WA TER SUPPLIED TO FIXTURES.

TWO TEMPERATURE WATER

MIXING VALVE APPLICATION

CIRCULATING RETURN

LINE CONNECTIONS

• TEMPERED WATER LOOP, IF USED,

CONNECT TO POINT R.

• STORED TEMPERATURE W ATER LOOP ,

IF USED, CONNECT TO ANY OPENING

NEAR BOTTOM OF T ANK.

Page 21

4" BTU/hr 35,880,000 24,648,000 19,968,000 17,004,000 15,132,000 13,728,000 12,636,000 11,700,000 11,232,000 10,452,000 9,360,000 8,580,000 7,800,000 7,176,000

kW 10,508 7,219 5,848 4,980 4,432 4,021 3,701 3,427 3,290 3,061 2,741 2,513 2,284 2,102

3" BTU/hr 17,160,000 12,012,000 9,750,000 8,268,000 7,410,000 6,708,000 6,084,000 5,772,000 5,382,000 5,070,000 4,602,000 4,134,000 3,822,000 3,556,800

kW 5,026 3,518 2,856 2,421 2,170 1,965 1,782 1,690 1,576 1,485 1,348 1,211 1,1 1 9 1,042

kW 2,878 1,987 1,608 1,371 1,211 1,097 1,028 937 891 845 754 685 626 585

2 1/2" BTU/hr 9,828,000 6,786,000 5,491,200 4,680,000 4,134,000 3,744,000 3,510,000 3,198,000 3,042,000 2,886,000 2,574,000 2,340,000 2,137,200 1,999,800

kW 1,805 1,256 1,005 868 768 694 640 594 557 525 466 43 4 388 366

1 1/2" BTU/hr 3,276,000 2,277,600 1,840,800 1,544,400 1,404,000 1,263,600 1,170,000 1,076,400 1,014,000 - - - - - - - - - - - - - - -

2" BTU/hr 6,162,000 4,290,000 3,432,000 2,964,000 2,620,800 2,371,200 2,184,000 2,028,000 1,903,200 1,794,000 1,591,200 1,482,000 1,326,000 1,248,000

kW 959 667 539 452 411 370 343 315 297 - - - - - - - - - - - - - - -

kW 640 434 352 302 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

kW 410 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

1 1/4" BTU/hr 1,400,000 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

(Inches) (3.05) (6.10) (9.14) (12.19) (15.24) (18.29) (21.34) (24.38) (27.43) (30.48) (38.10) (45.72) (53.34) (60.96)

Size Cap. 10 Ft. 20 Ft. 30 Ft. 40 Ft. 50 Ft. 60 Ft. 70 Ft. 80 Ft. 90 Ft. 100 Ft. 125 Ft. 150 Ft. 175 Ft. 200 Ft.

Iron Pipe

Nominal

T ABLE 15. Suggested Pipe Size For Multiple Gas Appliances (Natural)

(Inches) (3.05) (6.10) (9.14) (12.19) (15.24) (18.29) (21.34) (24.38) (27.43) (30.48) (38.10) (45.72) (53.34) (60.96)

Iron Pipe

1 1/4" BTU/hr 2,184,000 1,482,000 1,201,200 1,029,600 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

1" BTU/hr 1,060,800 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Size Cap . 1 0 Ft. 20 Ft. 30 F t. 40 Ft . 50 F t. 60 Ft. 70 F t. 80 Ft . 90 Ft. 100 Ft. 125 Ft. 150 Ft. 175 Ft. 200 Ft.

Nominal

kW 311 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

TABLE 16. Suggested Pipe Size For Multiple Gas Appliances (Propane Gas)

4" BTU/hr 23,000,000 15,800,000 12,800,000 10,900,000 9,700,000 8,800,000 8,100,000 7,500,000 7,200,000 6,700,000 6,000,000 5,500,000 5,000,000 4,600,000

kW 6,736 4,627 3,749 3,192 2,841 2,577 2,372 2,197 2,109 1,962 1,757 1,61 1 1,464 1,347

kW 3,222 2,255 1,830 1,552 1,391 1,259 1,142 1,084 1,010 952 864 776 718 668

3" BTU/hr 11,000,000 7,700,000 6,250,000 5,300,000 4,750,000 4,300,000 3,900,000 3,700,000 3,450,000 3,250,000 2,950,000 2,650,000 2,450,000 2,280,000

kW 1,845 1,274 1,031 879 776 703 659 600 571 542 483 439 401 375

2 1/2" BTU/hr 6,300,000 4,350,000 3,520,000 3,000,000 2,650,000 2,400,000 2,250,000 2,050,000 1,950,000 1,850,000 1,650,000 1,500,000 1,370,000 1,280,000

kW 1,157 805 644 556 492 445 410 381 357 337 299 - - - - - - - - -

1 1/2" BTU/hr 2,100,000 1,460,000 1,180,000 990,000 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

2" BTU/hr 3,950,000 2,750,000 2,200,000 1,900,000 1,680,000 1,520,000 1,400,000 1,300,000 1,220,000 1,150,000 1,020,000 - - - - - - - - -

kW 615 428 346 290 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Maximum Capacity of Pipe in BTU/hr and kW for Gas Pressures of 14 in. W .C. (0.5 p si) or Less and a Pressure Drop of 0.5 in. W .C.

(based on 1.53 Specific Gravity Gas w/Heating V alue of 2,500 BTU’s/Ft

Length of Pipe in Feet (Metres)

Maximum Capacity of Pipe in BTU/hr and kW for Gas Pressures of 14 in. W .C. (0.5 p si) or Less and a Pressure Drop of 0.5 in. W .C.

(based on 0.60 Specific Gravity Gas w/Heating Value of 1,000 BTU’ s/Ft

Length of Pipe in Feet (Metres)

3

)

3

)

21

Page 22

Gas Pipe sizing may be larger than heater connections on

installations where a significant run of piping is required. To prevent

damage, care must be taken not to apply too much torque when

attaching gas supply pipe to gas inlet.

Fittings and unions in the gas line must be metal to metal type.

Apply joint compounds (pipe dope) sparingly and only to the male

threads of pipe joints. Do not apply compound to the first two

threads. Use compounds resistant to the action of liquefied

petroleum gases.

Where it is necessary to use more than the average number of

pipe fittings i.e. elbows, tees, and valves in gas supply line, use

a pipe larger than specified to compensate for increased