Page 1

Instruction Manual

XP BOILER

MODELS: XB/XW

1000, 1300, 1700

2000, 2600, 3400

SERIES 100/101

25589 Highway 1

McBee, SC 29101

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury or death.

MAINTENANCE - LIMITED WARRANTY

INSTALLATION - OPERATION -

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

•

Do not touch any electrical switch; do

•

not use any phone in your building.

Immediately call your gas supplier

•

from a neighbor’s phone. Follow the

gas supplier’s instructions.

If you cannot reach your gas supplier,

•

call the fire department.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

Thank you for buying this energy efcient boiler.

We appreciate your condence in our products.

PRINTED IN THE U.S.A. 0711 320741-002

Page 2

TABLE OF CONTENTS

TABLE OF CONTENTS ..........................................................................2

SAFE INSTALLATION, USE AND SERVICE.......................................... 3

GENERAL SAFETY................................................................................ 4

INTRODUCTION .................................................................................... 5

Model Identication ............................................................................ 5

Abbreviations Used ........................................................................... 5

Qualications ..................................................................................... 5

DIMENSIONS AND CAPACITY DATA .................................................... 6

FEATURES AND COMPONENTS ....................................................... 10

Component Description ................................................................... 12

CONTROL COMPONENTS ................................................................. 13

BOILER INSTALLATION CONSIDERATIONS ..................................... 15

Hydronic System ............................................................................. 15

Hot water boiler system - general water line connections ............... 16

GENERAL REQUIREMENTS .............................................................. 21

Location ........................................................................................... 21

Fresh air openings for conned spaces ........................................... 23

VENTING .............................................................................................. 25

Vent Installation Considerations ...................................................... 25

Venting Supports ............................................................................. 27

CONDENSATE DISPOSAL .................................................................. 37

GAS SUPPLY CONNECTIONS ........................................................... 38

BOILER START UP AND OPERATIONS ............................................. 40

LIGHTING AND OPERATING INSTRUCTIONS .................................. 42

CONTROL SYSTEM ............................................................................ 45

Burner Control System .................................................................... 45

Burner control operation .................................................................. 46

General operational sequence ........................................................ 47

Local operator interface: display system ......................................... 49

Installation instructions (S7999B OI Display) .................................. 50

Starting up the S7999B OI Display .................................................. 51

Page Navigation .............................................................................. 51

TROUBLESHOOTING ......................................................................... 61

MAINTENANCE PROCEDURES ......................................................... 76

Maintenance schedules ................................................................... 76

General maintenance ...................................................................... 76

Burner maintenance ........................................................................ 77

Venting maintenance ....................................................................... 78

Heat exchanger maintenance .......................................................... 78

Handling ceramic ber materials ..................................................... 79

Replacement parts .......................................................................... 79

PIPING DIAGRAMS ............................................................................. 80

LIMITED WARRANTY .......................................................................... 82

2

Page 3

SAFE INSTALLATION, USE AND SERVICE

The proper installation, use and servicing of this boiler is extremely important to your safety and the safety of others.

Many safety-related messages and instructions have been provided in this manual and on your boiler to warn you and others of a

potential injury hazard. Read and obey all safety messages and instructions throughout this manual. It is very important that the

meaning of each safety message is understood by you and others who install, use, or service this boiler.

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently

DANGER

WARNING

CAUTION

hazardous situation which, if not avoided,

will result in injury or death.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result

in injury or death.

CAUTION indicates a potentially hazardous

situation which, if not avoided, could result in

minor or moderate injury.

CAUTION used without the safety alert

CAUTION

All safety messages will generally tell you about the type of hazard, what can happen if you do not follow the safety message, and

how to avoid the risk of injury.

The California Safe Drinking Water and Toxic Enforcement Act requires the Governor of California to publish a list of substances

known to the State of California to cause cancer, birth defects, or other reproductive harm, and requires businesses to warn of

potential exposure to such substances.

This product contains a chemical known to the State of California to cause cancer, birth defects, or other reproductive harm. This

boiler can cause low level exposure to some of the substances listed in the Act.

symbol indicates a potentially hazardous

situation which, if not avoided, could result in

property damage.

IMPORTANT DEFINITIONS

Gas Supplier: The Natural Gas or Propane Utility or service who supplies gas for utilization by the gas burning

appliances within this application. The gas supplier typically has responsibility for the inspection and code approval of

gas piping up to and including the Natural Gas meter or Propane storage tank of a building. Many gas suppliers also

offer service and inspection of appliances within the building.

APPROVALS

3

Page 4

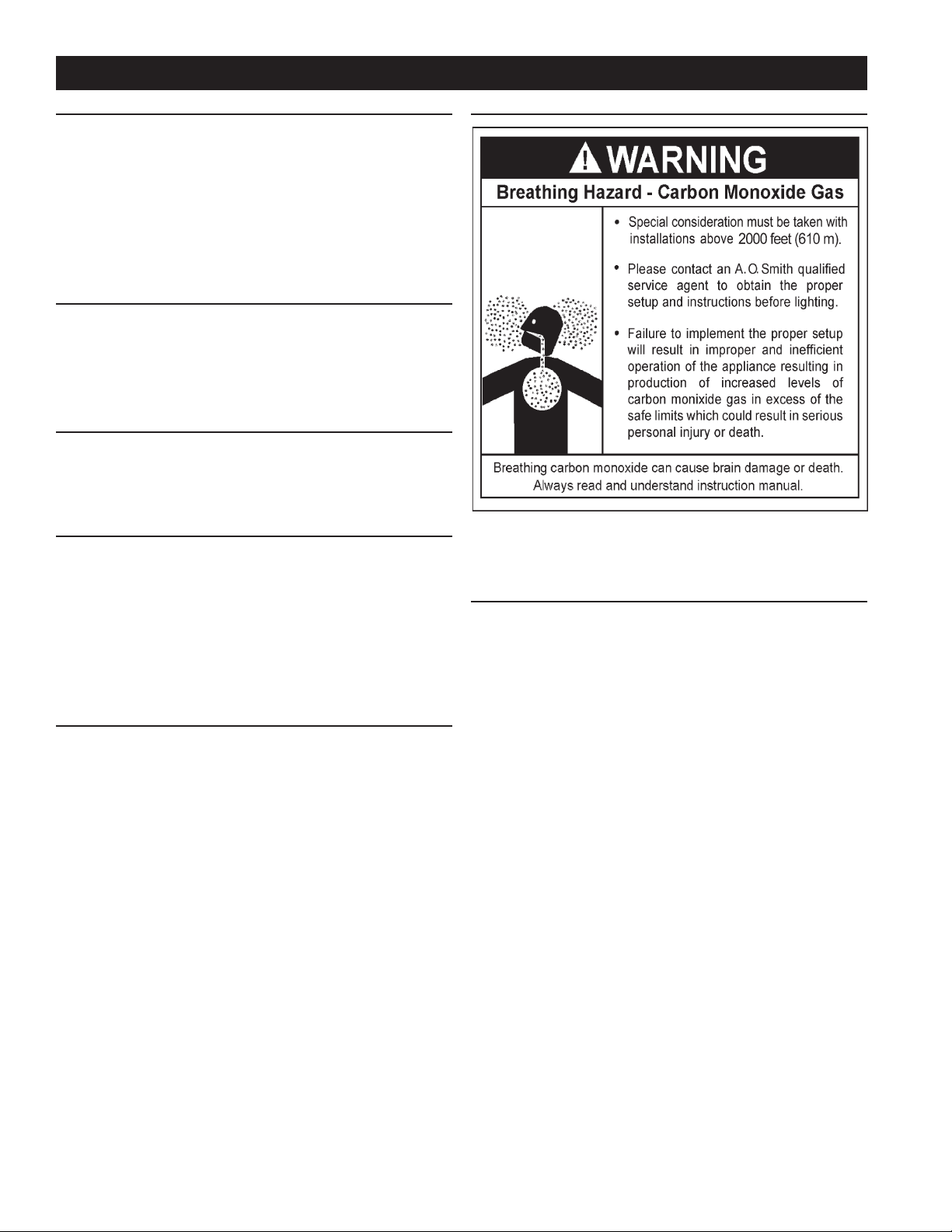

GENERAL SAFETY

GROUNDING INSTRUCTIONS

This boiler must be grounded in accordance with the National

Electrical Code, Canadian Electrical Code and/or local codes.

Boiler is polarity sensitive; correct wiring is imperative for proper

operation.

This boiler must be connected to a grounded metal, permanent

wiring system, or an equipment grounding conductor must be

run with the circuit conductors and connected to the equipment

grounding terminal or lead on the boiler.

INLET WATER CONSIDERATIONS

Circulating water through the boiler and to the remote storage

tank (if applica ble) is accomplished by a pump on XW models

only. For hot water heating systems using the XB model, the

circulating pump is NOT provided on standard models (optional)

and must be eld installed.

CORRECT GAS

Make sure the gas on which the boiler will operate is the same as

that speci ed on the boiler rating plate. Do not install the boiler if

equipped for a different type of gas; con sult your supplier.

PRECAUTIONS

If the unit is exposed to the following, do not operate until all

corrective steps have been made by a qualied service agent:

1. Exposure to re.

2. If damaged.

3. Firing without water.

4. Sooting.

If the boiler has been exposed to ooding, it must be replaced.

LIQUEFIED PETROLEUM GAS MODELS

HIGH ALTITUDE INSTALLATIONS

Rated inputs are suitable up to 2000 feet (610 m) elevation. Consult

the factory for installation at altitudes over 2000 feet (610 m).

FIELD INSTALLED COMPONENTS

When installing the boiler, the follow ing compo nents must be

installed:

• Circulating Pump (Hyd ronic)

• Remote Temperature Sensor/Header Sensor

• Storage Tank (Temperature & Pressure Relief Valve)

Boilers for propane or liqueed petroleum gas (LPG) are different

from natural gas models. A natural gas boiler will not function safely

on LP gas and no attempt should be made to convert a boiler from

natural gas to LP gas.

LP gas must be used with great caution. It is highly explosive

and heavier than air. It collects rst in the low areas making its

odor difcult to detect at nose level. If LP gas is present or even

suspected, do not attempt to nd the cause yourself. Leave

the building, leaving doors open to ventilate, then call your gas

supplier or service agent. Keep area clear until a service call

has been made.

At times you may not be able to smell an LP gas leak. One

cause is odor fade, which is a loss of the chemical odorant that

gives LP gas its distinctive smell. Another cause can be your

physical condition, such as having a cold or diminishing sense

of smell with age. For these reasons, the use of a propane gas

detector is recommended.

If you experience an out of gas situation, do not try to relight

appliances yourself. Call your local service agent. Only trained

LP professionals should conduct the required safety checks in

accordance with industry standards.

4

Page 5

INTRODUCTION

This Instruction Manual covers XP Boiler models XB/XW 1000,

1300, 1700, 2000, 2600, 3400 - Series 100/101. The instructions

and illustrations contained in this Instruction manual will provide

you with troubleshooting procedures to diagnose and repair

common problems and verify proper operation.

MODEL IDENTIFICATION

Check the rating plate afxed to the Boiler. The following

information describes the model number structure:

SERIES-100/101 DESIGNATION:

• XP = Extreme Performance

MODEL (APPLICATION):

• XB = Hydronic Heating Boiler

• XW = Domestic Hot Water Supply Boiler

SIZE:

• 1000 = 920,000 Btu/hr input

• 1300 = 1,300,000 Btu/hr input

• 1700 = 1,700,000 Btu/hr input

• 2000 = 2,000,000 Btu/hr input

• 2600 = 2,600,000 Btu/hr input

• 3400 = 3,400,000 Btu/hr input

FUEL:

N = Natural gas

P = Propane

NOTE:

XB models are equipped with 50 psi pressure relief valve. (pump

is optionally installed)

XW models are factory installed circulating pump (standard),

with 125 psi pressure relief valve.

XB models can be special ordered with a factory installed pump

and XW models can be special ordered without the factory

installed pump. These factory congurations can also be

changed in the eld by installing circulation pumps and changing

pressure relief valves to accommodate domestic and hydronic

hot water system requirements.

Properly installed and maintained, it should give you years of

trouble free service.

ABBREVIATIONS USED

QUALIFICATIONS

QUALIFIED INSTALLER OR SERVICE AGENCY

Installation and service of this boiler requires ability equivalent

to that of a Qualied Agency, as dened by ANSI below. In the

eld involved. Installation skills such as plumbing, air supply,

venting, gas supply and electrical supply are required in addition

to electrical testing skills when performing service.

ANSI Z21.13 - CSA 4.9: “Qualied Agency” - “Any individual,

rm, corporation or company that either in person or through

a representative is engaged in and is responsible for (a) the

installation, testing or replacement of gas piping or (b) the

connection, installation, testing, repair or servicing of appliances

and equipment; that is experienced in such work; that is familiar

with all precautions required; and that has complied with all the

requirements of the authority having jurisdiction.”

If you are not qualied (as dened by ANSI above) and licensed

or certied as required by the authority having jurisdiction

to perform a given task do not attempt to perform any of the

procedures described in this manual. If you do not understand

the instructions given in this manual do not attempt to perform

any procedures outlined in this manual.

This product requires a formal Start-Up by an authorized service/

start-up provider that has been approved by the manufacturer for

this specic product. Call 1-800-527-1953 to locate the nearest

authorized start-up provider and arrange a factory start-up.

Please provide as much notice as possible, preferably 2 weeks.

Please have the model and serial number ready when you call.

This start-up is required to activate the warranty and ensure safe,

efcient operation.

Warranty on this product is limited and could be void in the event

the unit is not installed per the instructions in this manual and/or

not started up by an authorized factory trained service/start-up

provider.

Abbreviations found in this Instruction Manual include :

• ANSI - American National Standards Institute

• ASME - American Society of Mechanical Engineers

• NEC - National Electrical Code

• NFPA - National Fire Protection Association

• UL - Underwriters Laboratory

• CSA - Canadian Standards Association

• AHRI - Air-Conditioning, Heating and Refrigeration Institute

5

Page 6

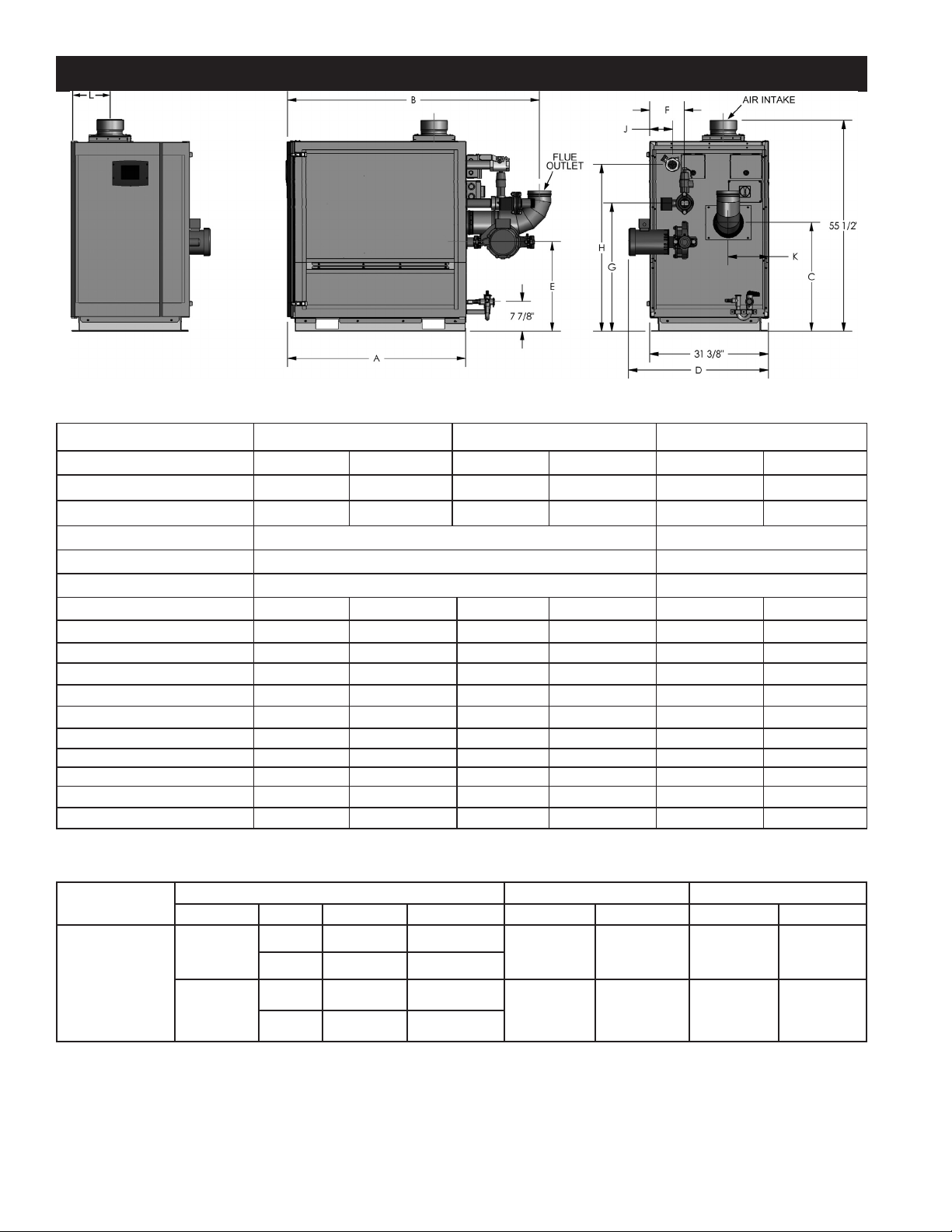

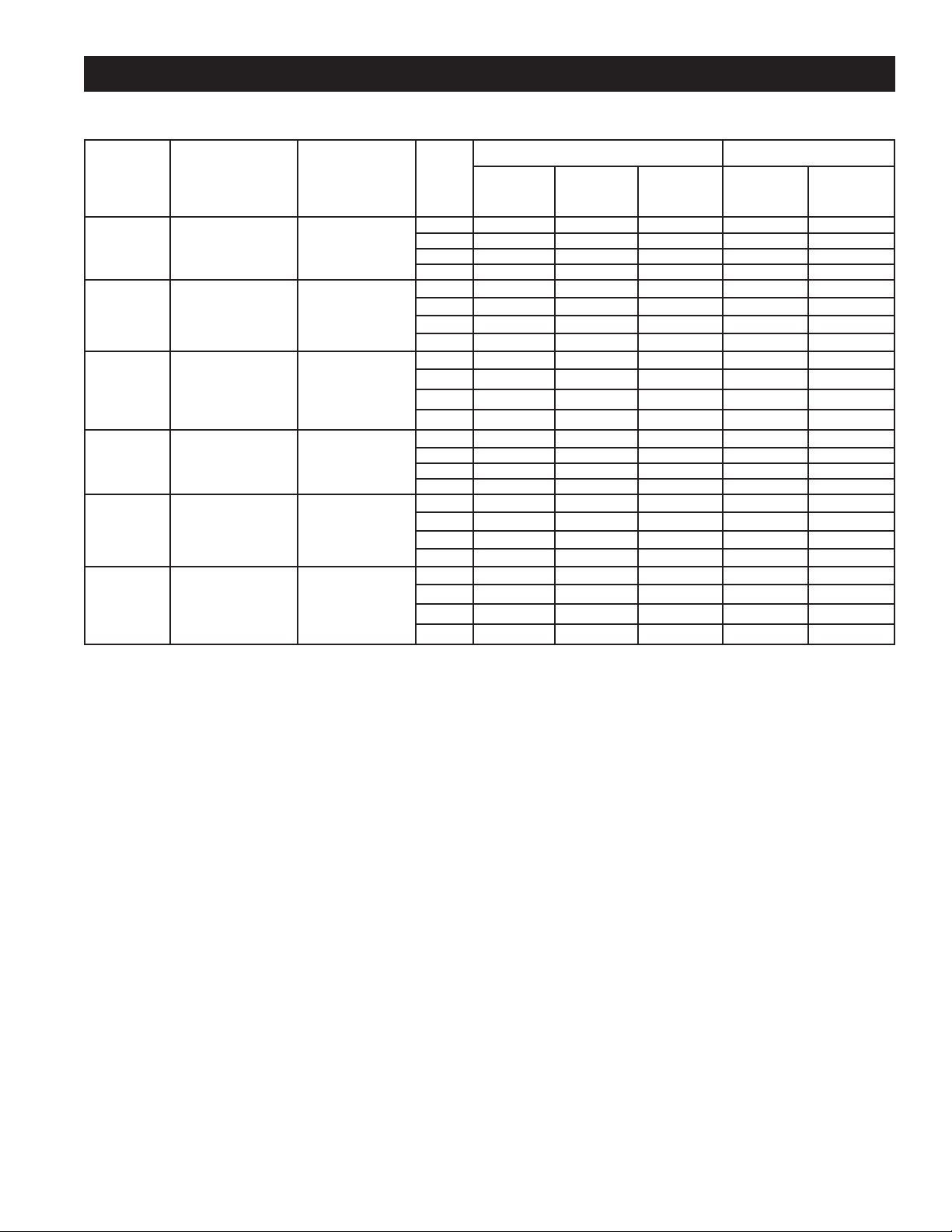

DIMENSIONS AND CAPACITY DATA

FIGURE 1. SINGLE HEAT EXCHANGER BOILER

TABLE 1. ROUGH IN DIMENSIONS (SINGLE)

Models XB/XW-1000 XB/XW-1300 XB/XW-1700

Dimensions inches mm inches mm inches mm

Flue Outlet Diameter 6 152 8 152 8 203

Air Intake Diameter 6 152 6 152 8 203

Water Inlet 2 inch NPT 2 1/2 inch NPT

Water Outlet 2 inch NPT 2 1/2 inch NPT

Gas Inlet 2 inch NPT 2 inch NPT

A 47 1199 49 1245 57 1448

B 67 1702 68 1727 76 1930

C 29 737 29 737 29 737

D 37 940 38 965 37 940

E 23 584 23 584 24 610

F 9 229 9 229 9 229

G 34 864 34 864 34 864

H 44 111 8 45 1143 45 1143

J 6 152 6 152 6 152

K 11 279 11 279 11 279

L 12 305 11 279 12 305

TABLE 2. OPERATING CHARACTERISTICS

Models

(XB/XW)

1000, 1300, 1700

2000, 2600, 3400

Type of Gas Inches W.C. kPa Inches W.C. kPa Inches W.C. kPa

Natural

Propane

Manifold Pressure Maximum Supply Pressure Minimum Supply Pressure

Min Fire -0.2 to - 0.3 -0.05 to - 0.07

14.0 3.49 4.0 1.0

Max Fire -3.0 to -3.9 -0.75 to -0.97

Min Fire -0.1 to - 0.3 -0.025 to -0.07

14.0 3.49 4.0 2.0

Max Fire -3.6 to -4.9 -0.90 to -1.22

6

Page 7

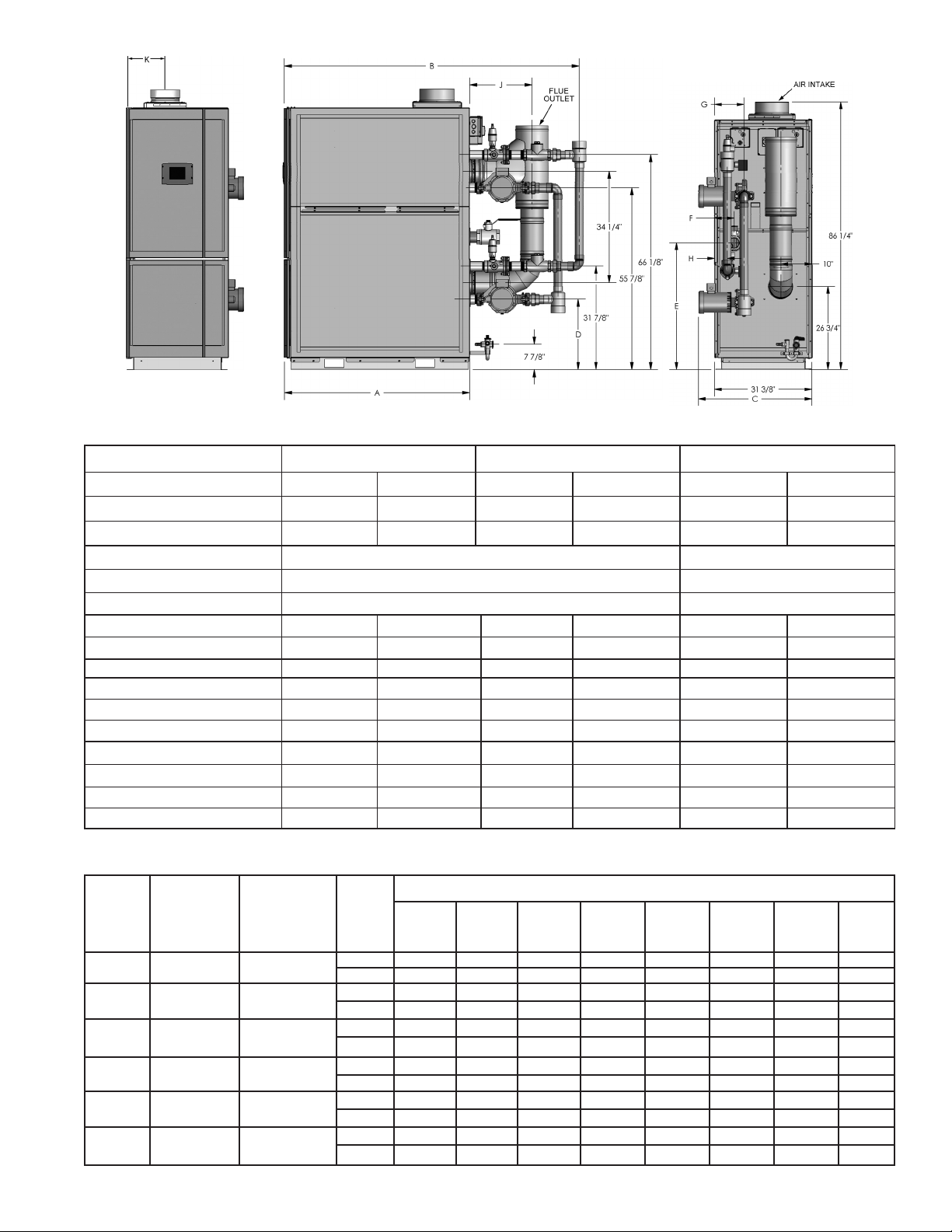

FIGURE 2. DOUBLE HEAT EXCHANGER BOILER

TABLE 3. ROUGH IN DIMENSIONS (DOUBLE)

Models XB/XW-2000 XB/XW-2600 XB/XW-3400

Dimensions inches mm inches mm inches mm

Flue Outlet Diameter 8 203 8 203 10 254

Air Intake Diameter 8 203 8 203 10 254

Water Inlet 3 inch NPT 4 inch NPT

Water Outlet 3 inch NPT 4 inch NPT

Gas Inlet 2 inch NPT 3 inch NPT

A 47 1194 49 1245 57 1448

B 78 1981 80 2032 91 2311

C 36 914 37 940 37 940

D 22 559 22 559 22 559

E 40 1016 41 1041 41 1041

F 7 178 6 152 6 152

G 10 254 10 254 10 254

H 4 102 4 102 4 102

J 20 508 19 483 19 483

K 12 305 12 305 13 330

TABLE 4. RECOVERY CAPACITIES

Models

XW-1000 920,000 854,680

XW-1300 1,300,000 1,207,700

XW-1700 1,700,000 1,579,300

XW-2000 2,000,000 1,858,000

XW-2600 2,600,000 2,415,400

XW-3400 3,400,000 3,158,600

Input Rating

(Btu/hr)

Output Rating

(Btu/hr)

Temperature Rise - ΔT °F (°C)

Water

Flow

GPH 2,593 1,728 1,482 1,296 1,152 1,037 864 741

LPH 9,815 6,543 5,608 4,907 4,362 3,926 3,272 2,804

GPH 3,664 2,442 2,094 1,832 1,628 1,465 1,221 1,047

LPH 13,868 9,246 7,925 6,934 6,164 5,547 4,623 3,962

GPH 4,791 3,194 2,738 2,395 2,129 1,916 1,597 1,369

LPH 18,136 12,090 10,363 9,068 8,060 7,254 6,045 5,182

GPH 5,636 3,758 3,221 2,818 2,505 2,255 1,879 1,610

LPH 21,336 14,224 12,192 10,668 9,483 8,534 7,112 6,096

GPH 7,327 4,885 4,187 3,664 3,257 2,931 2,442 2,094

LPH 27,737 18,491 15,850 13,868 12,327 11,095 9,246 7,925

GPH 9,582 6,388 5,475 4,791 4,259 3,833 3,194 2,738

LPH 36,271 24,181 20,726 18,136 16,121 14,508 12,090 10,363

40

(22)

60

(33)

7

70

(39)

80

(44)

90

(50)

100

(56)

120

(67)

140

(78)

Page 8

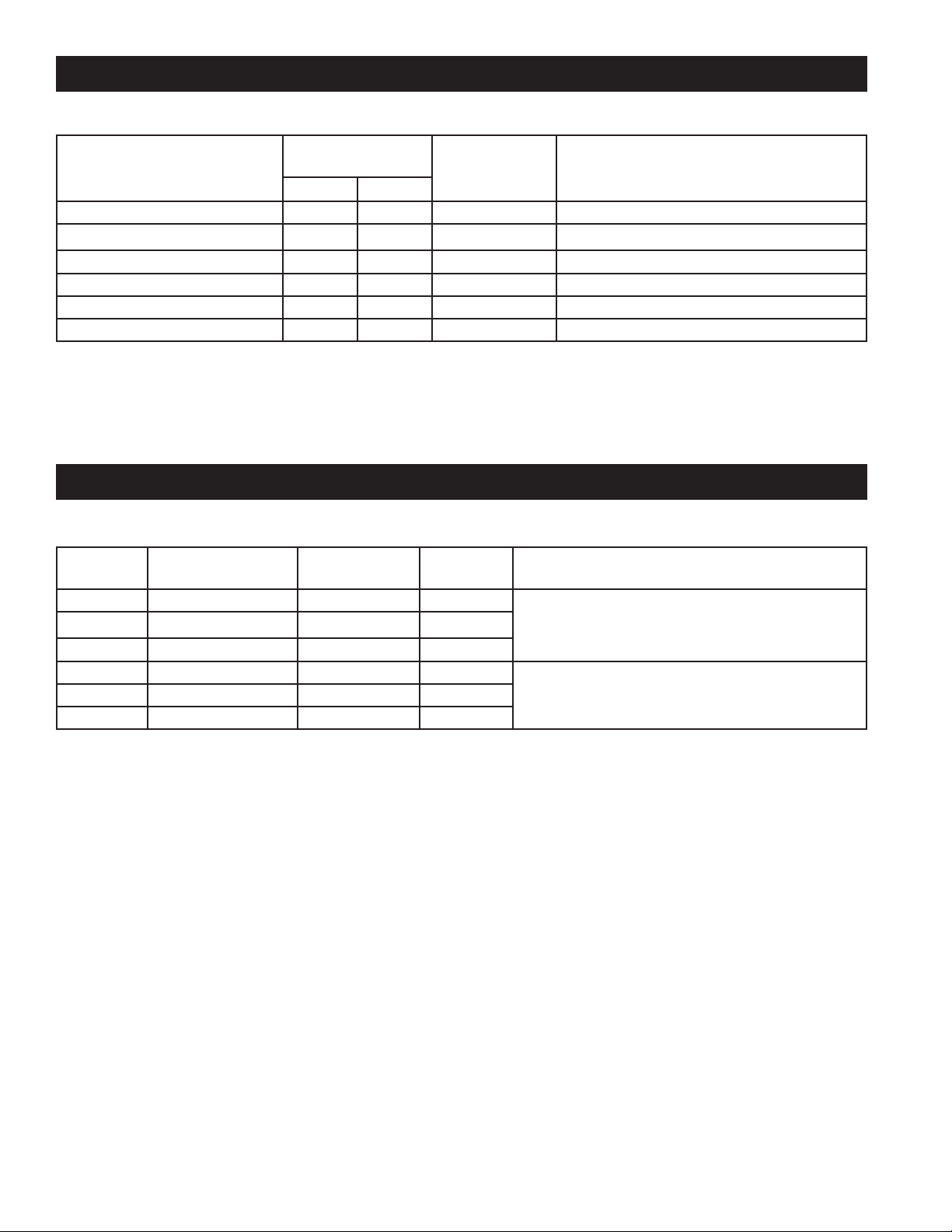

RATINGS

TABLE 5. IBR RATINGS

MODELS

(XB/XW)

1000 920 100 856 744

1300 1300 130 1209 1051

1700 1700 170 1581 1375

2000 2000 100 1860 1617

2600 2600 130 2418 2103

3400 3400 212 3162 2750

Notes:

1. The ratings are based on standard test procedures prescribed by the United States Department of Energy.

2. Net I=B=R ratings are based on net installed radiation of sufcient quantity for the requirements of the building and nothing need

be added for normal piping and pickup. Ratings are based on a piping and pickup allowance of 1.15.

3. Ratings have been conrmed by the Hydronics Institute, Section of AHRI.

INPUT

MBH

MAX MIN

GROSS

OUTPUT MBH

(NOTE 1)

NET I=B=R RATINGS WATER MBH

(NOTE 2)

ELECTRICAL REQUIREMENTS

TABLE 6. ELECTRICAL REQUIREMENTS

MODELS

(XB/XW)

1000 120 60 30 A dedicated, single phase, 30/60 amp circuit breaker

1300 120 60 30

1700 120 60 30

2000 120 60 60 A dedicated, single phase, 60/60 amp circuit breaker

2600 120 60 60

3400 120 60 60

SUPPLY VOLTAGE

(VOLTS)

FREQUENCY

(HZ)

CURRENT

(AMPS)

ELECTRICAL NOTES

with a grounded neutral should be provided to supply

power to the boiler.

with a grounded neutral should be provided to supply

power to the boiler.

8

Page 9

FLOW, HEAD AND TEMPERATURE RISE

TABLE 7. XB MODELS - FLOW, HEAD AND TEMPERATURE RISE

Models

XB-1000 920,000 855,600

XB-1300 1,300,000 1,209,000

XB-1700 1,700,000 1,581,000

XB-2000 2,000,000 1,860,000

XB-2600 2,600,000 2,418,000

XB-3400 3,400,000 3,162,000

Input

(Btu/hr)

Output

(Btu/hr)

Temperature Rise - ΔT °F Flow Rate

Water

Flow

GPM 86 56 43 86 43

LPM 325 211 162 325 162

ΔP FT 26 12 7 26 7

ΔP M 7.9 3.7 2.1 7.9 2.1

GPM 120 80 60 120 60

LPM 453 302 226 453 226

ΔP FT 32.5 15 8 32.5 8

ΔP M 9.9 4.6 2.4 9.9 2.4

GPM 156 104 78 156 78

LPM 592 395 296 592 296

ΔP FT 35 14 8 35 8

ΔP M 10.7 4.3 2.4 10.7 2.4

GPM 184 123 92 184 92

LPM 696 464 348 696 348

ΔP FT 26 12 7 26 7

ΔP M 7.9 3.7 2.1 7.9 2.1

GPM 239 159 120 239 120

LPM 905 604 453 905 453

ΔP FT 32.5 15 8 32.5 8

ΔP M 9.9 4.6 2.4 9.9 2.4

GPM 313 209 156 313 156

LPM 1184 789 592 1184 592

ΔP FT 35 14 8 35 8

ΔP M 10.7 4.3 2.4 10.7 2.4

20 30 40 Maximum Minimum

Note: Head Loss shown is through the boiler only and allows for no additional piping.

9

Page 10

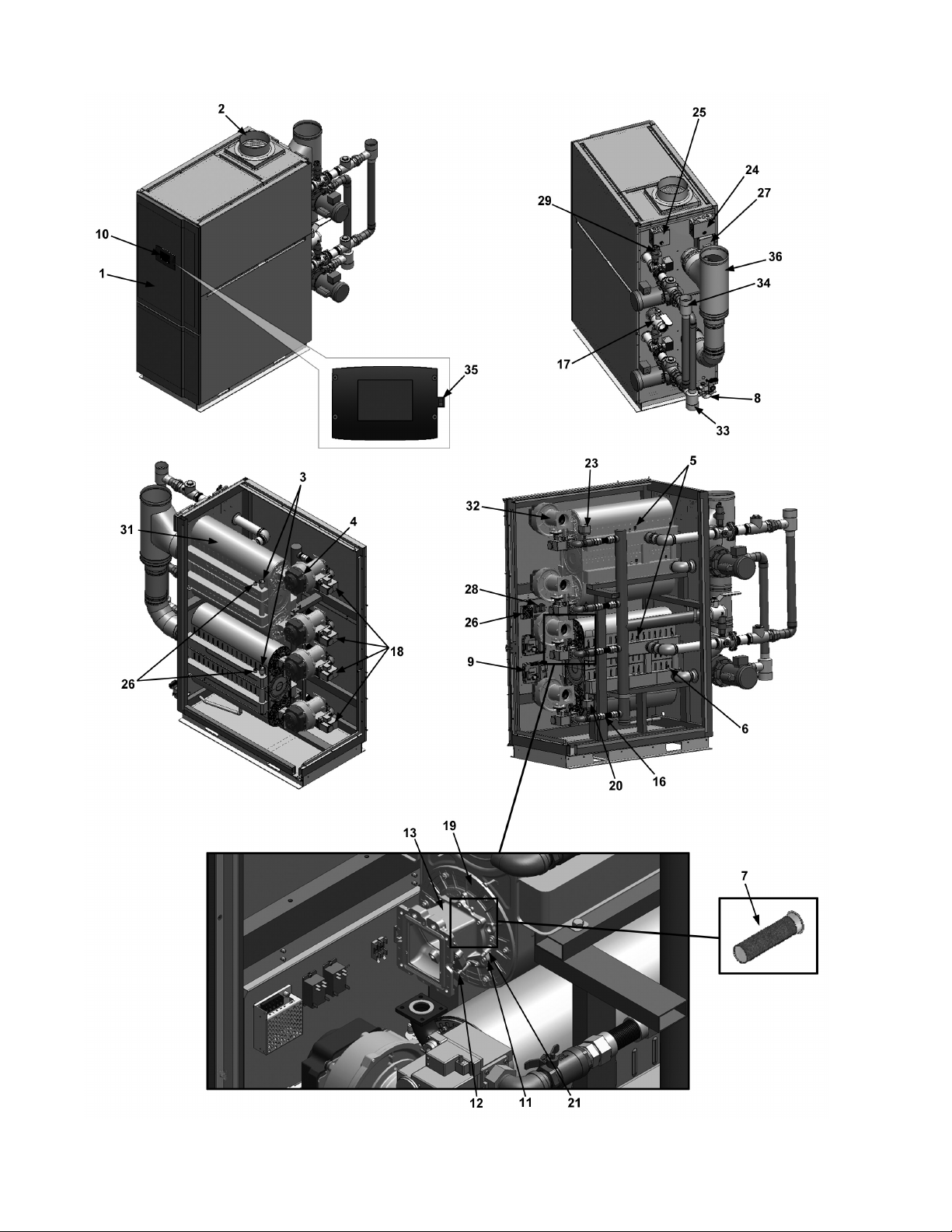

FEATURES AND COMPONENTS

FIGURE 3. SINGLE HEAT EXCHANGER BOILER COMPONENTS

10

Page 11

FIGURE 4. DOUBLE HEAT EXCHANGER BOILER COMPONENTS

11

Page 12

COMPONENT DESCRIPTION

1. Front access door:

Provides access to the gas train, burner controllers and the heat

exchanger.

2. Air Filter Box:

Allows for the connection of the PVC air intake pipe to the boiler

through a standard PVC adapter. It uses a lter to prevent dust

and debris from entering the boiler.

3. Automatic air vents:

Designed to remove trapped air from the heat exchanger coils.

4. Blowers:

The blowers pull in air and gas through the venturis. Air and gas

mix inside the venturi and are pushed into the burners, where

they burn inside the combustion chamber.

5. Boiler inlet temperature sensors

These sensors monitor system return water temperature.

6. Boiler outlet temperature sensors/High Limits

These sensors monitor boiler outlet water temperature. The boiler

modulates based on the Lead Lag Sensor connected to the tank.

7. Burners

Made with metal ber and stainless steel construction, the

burners use pre-mixed air and gas and provide a wide range of

ring rates.

8. Condensate Trap

Disposes the condensate produced from heat exchanger and

houses a switch that detects in case of blockage.

9. Control modules

The control modules respond to internal and external signals and

control the blowers, gas valves, and pumps to meet the heating

demand.

10. Touch Screen Display

Digital controls with touch screen technology and full color

display.

11. Sight glass

The quartz sight glass provides a view of the ame for inspection

purposes.

12. Flame sensors

Used by the control module to detect the presence of burner

ame.

13. Flap valves

Prevents recirculation of ue products when only one burner is

running.

14. Flue gas sensors (not visible)

These sensors monitor the ue gas exit temperature. The control

modules will modulate and shut down the boiler if the ue gas

temperature gets too hot. This protects the ue pipe from

overheating.

15. Flue pipe adapter (not visible)

Allows for the connection of the PVC vent pipe system to the

boiler.

16. Gas shutoff valves (Internal unit)

Manual valves used to isolate the gas valves from the burners.

17. Main gas shutoff valve (External unit)

Manual valve used to isolate the boiler from the gas supply.

18. Automatic modulating gas valve

The gas valve with the addition of venturi and blower are used for

modulating premix appliances.

19. Heat exchanger access covers

Allows access to the combustion side of the heat exchanger

coils.

20. High gas pressure switch

Switch provided to detect excessive supply gas pressure.

21. Spark Igniter

Provides direct spark for igniting the burners.

22. Boiler power supply terminals (not visible)

The main power to the boiler is supplied through the terminals

housed inside the high voltage junction box.

23. Low gas pressure switch

Switch provided to detect low gas supply pressure.

24. High voltage connection box

This box has terminals for connecting the main power supply

(120V) to the boiler and outputs power supply (120V) for the

pumps from the boiler control. This box has terminals for low

voltage devices such as condensate trap and ow switch.

25. Sensors/Communication Box

Connects sensors to tank sensor/header sensor and external

connections to building managements systems through MODBUS.

26. Low water cutoff board and sensor probe (LWCO)

Device used to ensure adequate water is supplied to the boiler.

In the event of inadequate water levels, LWCO will ensure boiler

shut down. LWCO board is connected to the electronic panel,

whereas the sensor probe is connected to the heat exchanger.

27. Main power supply switch

Turns 120 VAC ON/OFF to the boiler.

28. Pump relay

The pump relays are used tfor providing power to the XW Boiler

models.

29. Pressure relief valve

Protects the heat exchangers from an over pressure condition.

The relief valve will be set at particular PSI, depending on models.

30. Reset switch (optional) (not visible)

Reset switch for the low water cutoff.

31. Stainless steel heat exchangers

Allows system water to ow through specially designed coils.

32. Venturi

The venturi is a gas/air mixing unit that allows modulation of a

premix burner with constant gas/air ratio.

33. Water inlet

Water connection that return water from the system to the heat

exchangers.

34. Water outlets

A NPT water connection that supplies hot water to the system.

35. Enable/Disable Switch

This is an emergency boiler turn off switch which disconnects

the interlock voltage to the control board, hence turning off the

power supply to the gas valves. Do not use this switch for

turning off the boiler, this should be done from the touch

screen display, using the Operational Switch on the Lead

Lag screen.

36. Vent outlet

Provides an outlet for combustion gases to outdoor.

12

Page 13

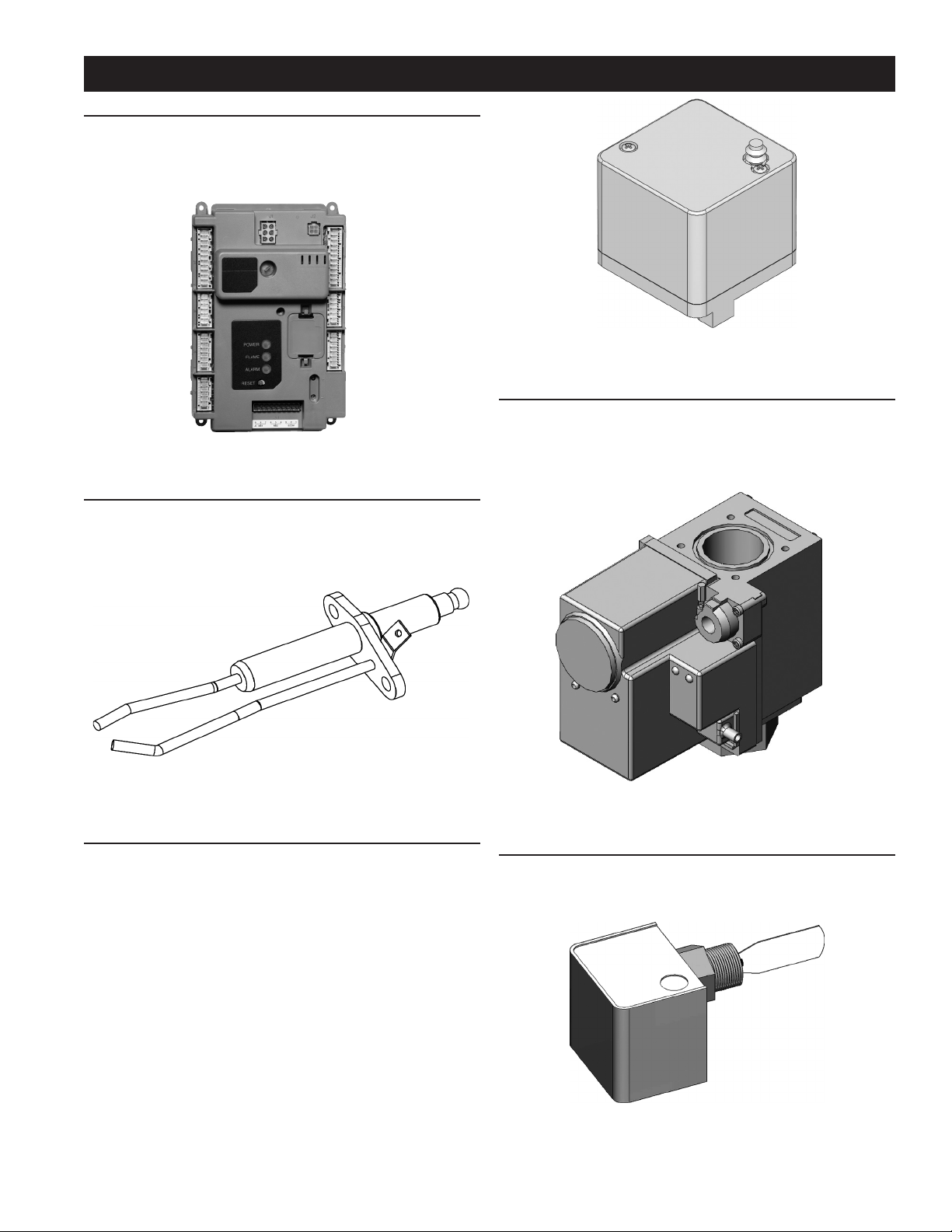

CONTROL COMPONENTS

THE CONTROL SYSTEM

The R7910A1138 is a burner control system that provides heat

control, ame supervision, circulation pump control, fan control,

boiler control sequencing, and electric ignition function. It will

also provide status and error reporting.

FIGURE 5. BURNER CONTROL SYSTEM

SPARK IGNITER

The spark igniter is a device that ignites the main burner. When

power is supplied to the igniter electrode, an electric arc is

created between the electrode and the ground terminal which

ignites the main burner.

FIGURE 7. LOW/HIGH GAS PRESSURE SWITCH

GAS VALVE

The gas valve is a normally closed servo regulated gas valve.

The valve opens only when energized by the burner control and

closes when the power is removed. The burner control supplies

24 volts to the gas valve during operation.

FIGURE 6. SPARK IGNITER

LOW/HIGH GAS PRESSURE SWITCH

This XP boiler is equipped with a low gas pressure switch which

meets the CSD-1 code requirements.

The Low Gas Pressure Switch is normally open and remains

open unless the pressure falls below the preset pressure.

The High Gas Pressure Switch is normally closed and is used to

detect excessive gas pressure.

FIGURE 8. GAS VALVE

WATER FLOW SWITCH

The water ow switch activates when sufcient water ow has

been established. Switch will not close when water ow is not

present.

FIGURE 9. WATER FLOW SWITCH

13

Page 14

FLAME SENSOR

Each burner is equipped with a ame sensor to detect the

presence of the burner ames at high and low re conditions. If

no ame is sensed, the gas valve will close automatically. The

voltage sensed by the ame sensor will also be displayed on the

Burner Screen.

FIGURE 10. FLAME SENSOR

WATER TEMPERATURE LIMIT CONTROLS

The “XB/XW” models incorporate an outlet water sensor having

dual sensors, that are factory set at 210°F (99°C).

MAIN POWER SUPPLY SWITCH

The main power supply switch is a padlockable switch. This switch

pro vides 120V from the power supply to the boiler.

This switch needs to be turned off when servicing the boiler.

Note: The Enable/Disable Switch on the front of the boiler

does not interrupt electrical power to the boiler.

WATER TEMPERATURE SENSORS

FIGURE 12. WATER TEMPERATURE SENSORS

Temperature sensors are threaded immersion probes.

Temperature probes have embedded temperature sensors

(thermistors). The boiler’s control system monitors these sensors

to determine water temperature at various points in the system.

INLET AND OUTLET TEMPERATURE SENSORS

All models have two inlet and two outlet temperature sensors

for each heat exchanger, factory installed to monitor the water

temperature entering and leaving the boiler. The Inlet Probe is

a temperature sensor only and has two leads. The Outlet probe

also contains the manual reset high temperature limit switch

and has four leads. The control system displays the Inlet and

Outlet water temperatures sensed from these two sensors on the

default Temperatures screen.

REMOTE SENSORS

All models are supplied from the factory with a remote sensor.

The remote sensor is used to control system water temperature

for a single boiler in a domestic hot water storage tank or in the

return line from a primary/secondary hydronic heating system.

The boiler will modulate its ring rate in response to the

actual system temperature and load conditions. The control

system displays the temperature sensed from the remote sensor

as the “Lead Lag” temperature on the default Temperatures

screen.

FIGURE 11. MAIN POWER SUPPLY SWITCH

LOW WATER CUTOFF DEVICE (LWCO)

Low water cutoff device is normally a closed switch that opens

when water drops below a preset level. Each model is equipped

with a factory installed LWCO. LWCO board is connected to the

electronic panel, whereas the sensor probe is connected to the

heat exchanger.

FIGURE 13. LWCO BOARD AND PROBE

14

Page 15

BOILER INSTALLATION CONSIDERATIONS

GENERAL

If the system is to be lled with water for testing or other purposes

during cold weather and before actual operation, care must be taken

to prevent freezing of water in the system. Failure to do so may cause

the water in the system to freeze with resulting damage to the system.

Damage due to freezing is not covered by the warranty.

Figure 78 on Page 80 shows a typical primary, secondary piping

method. This is the preferred piping method for most stainless steel

boilers. Other piping methods, however, may provide good system

operation. A prime concern when designing heating systems is the

maintenance of proper ow through the unit during boiler operation.

The secondary pump should be sized per the recommended ow

rate of the boiler, see Dimension and Capacity Data section in this

manual.

Before locating the boiler:

1. Check for nearby connection to:

• System water piping

• Venting connections

• Gas supply piping

• Electrical power

2. Locate the boiler so that if water connections should leak,

water damage will not occur. When such locations cannot

be avoided, it is recommended that a suitable drain pan,

adequately drained, be installed under the appliance.

The pan must not restrict combustion air ow. Under no

circumstances is the manufacturer to be held responsible

for water damage in connection with this appliance, or any

of its components.

3. Check area around the boiler. Remove any combustible

materials, gasoline and other ammable liquids.

4. Make sure the gas control system components are protected

from dripping or spraying water or rain during operation or

service.

5. If a new boiler will replace an existing boiler, check for and

correct system problems, such as:

• System leaks causing oxygen corrosion or heat

exchanger cracks from hard water deposits.

• Lack of freeze protection in boiler water causing system

and boiler to freeze and leak.

HYDRONIC SYSTEM

The following is a brief description of the equipment required

for the installations noted in this manual. All installations must

comply with local code.

WATER SUPPLY LINE

These boilers can be used only in a forced circulation hot water

heating system. Since most forced circulation systems will be of

the closed type, install the water supply line as shown on piping

diagram.

Fast lling of large pipe, old radiator installations and pressure

purging of series loop systems (where high pressures are not

available) requires bypassing of the pressure reducing valve.

Gener ally, pressure purging is not possible with a well pump

system. High point air venting is essential.

If the system is of the open type, a pressure reducing valve will not

be required as the water supply to the system will be controlled by

a manu ally operated valve. An overhead surge tank is required. A

minimum pressure of 15 psi (100 kPa) must be maintained on the

boiler at all times to ensure avoidance of potential damage to the

boiler which may not be covered by the warranty.

EXPANSION TANK

If the system is of the closed type, install an expansion tank. The

sizing of the expansion tank for a closed system is very important and

is directly related to the total water volume of the system.

An air separator as shown in the piping diagrams is recommended

especially for modern commercial hydronic systems. See Figure 78

on Page 80.

VENT VALVES

It is recommended that automatic, loose key or screw-driver type

vent valves be installed at each convector or radiator.

SYSTEM HEADERS

Split systems with individual supply and return lines from the

boiler room should normally have this piping connected to

supply and return manifold headers near the boiler. To achieve

good water distribution with maximum pressure drop for sever al

circuits, manifolds should be larger than system mains.

The circuits should be spaced on the heater at a minimum of 3”

(76 mm) center to center. Install a balancing cock in each return

line.

Manifold headers are recommended for split systems with

or without zone valves and also those installations with zone

circulators. If the system is to be split at remote points, good

practice requires special attention be given to main pipe sizing to

allow balancing of water ow.

CHECK VALVES

Check valves must be installed to isolate each boiler in

installations where multiple boilers/pumps are installed in the

same zone.

COOLING PIPING

When the boiler is used in conjunction with a refrigeration system

it must be installed so that the chilled medium is piped in parallel

with the boiler. Appropriate ow control valves, manual or

motorized, must be provided to prevent the chilled medium from

entering the boiler.

If the boiler is connected to chilled water piping or its heating coils

are exposed to refrigerated air, the boiler piping system must be

equipped with ow valves or other automatic means to prevent

gravity circulation through the boiler during the cooling cycle.

Primary/secondary pumping of both the chiller(s) and the boiler(s) is

an excellent winter-summer change-over method, because cooling

ow rates are so much more than heating ow rates. In this way each

system (heating or cooling) is circulated independently.

15

Page 16

CIRCULATING PUMP

A circulating pump is used when a system requires a circulating

loop or there is a storage tank used in conjunction with the boiler.

Install in accordance with the current edition of the National

Electrical Code, NFPA 70 or the Canadian Electrical Code,

CSA C22.1. All bronze circulating pumps are recommended

for use with commercial boilers. Some circulating pumps are

manufactured with sealed bearings and do not require further

lubrication. Some circulating pumps must be periodically oiled.

Refer to the pump manufacturer’s instructions for lubrication

requirements.

XB HYDRONIC BOILERS: The circulating pump is not provided

on standard models (optional) and must be obtained and installed

in the eld.

XW HOT WATER BOILERS: The circulating pump is integral to

the XW models. This pump has been lubricated at the factory,

and future lubrication should be in accordance with the motor

manufacturer’s instructions provided as a supplement to this

manual.

PRIMARY SYSTEM CONTROL

All XP boiler installations require a “Primary System Control” that

senses and reacts to water temperature inside the storage tank

on domestic water applications or in the return line on primary/

secondary hydronic heating systems. The Primary System

Control will activate and deactivate boiler heating cycles based

on its setpoint and current system water temperature. There are

three suitable methods to congure a Primary System Control.

One of these three methods must be used.

1. The Primary System Control can be the boiler’s

control system working with the factory supplied Header

Sensor, installed inside the storage tank on domestic water

applications or in the return line on primary/secondary

hydronic heating systems.

2. Alternatively, the Burner Control system can be used

as a Primary System Control. It will also provide boiler status

and error reporting. Multiple boilers can be joined together

to heat a system instead of a single, larger burner or boiler.

Using boilers in parallel is more efcient, costs less, reduces

emissions, improves load control, and is more exible than

the traditional large boiler.

3. MB2 and COM2 ports can be used for Building

Management Systems.

INTERNAL CONTAMINANTS

The hydronic system must be internally cleaned and ushed

after a new or replacement boiler has been installed, to remove

contaminants that may have accumulated during installation.

This is extremely important when a replacement boiler is installed

into an existing system where Stop Leak or other boiler additives

have been used.

Failure to clean and ush the system can produce acid

concentrations that become corrosive, and leads to heat

exchanger failure.

All hot water heating systems should be completely ushed with

a grease removing solution to assure trouble-free opera tion. Pipe

joint compounds, soldering paste, grease on tubing and pipe all

tend to contaminate a system

Failure to ush contaminants from a system can cause solids

to form on the inside of boiler exchangers, create excessive

blockage of water circulation, deterioration of the pump seals

and impellers.

HOT WATER BOILER SYSTEM - GENERAL WATER LINE CONNECTIONS

Piping diagrams will serve to provide the installer with a

reference for the materials and methods of piping necessary for

installation. It is essential that all water piping be installed and

connected as shown on the diagrams. Check the diagrams to

be used thoroughly before starting installation to avoid possible

errors and to minimize time and material cost. It is essential that

all water piping be installed and connected as shown on the

diagrams. See Figure 78 on Page 80 and Figure 79 on Page 81.

CLOSED WATER SYSTEMS

Water supply systems may, because of code requirements

or such conditions as high line pressure, among others, have

installed devices such as pressure reducing valves, check

valves, and back ow preventers. Devices such as these cause

the water system to be a closed system.

THERMAL EXPANSION

As water is heated, it expands (thermal expansion). In a closed

system the volume of water will increase when it is heated. As the

volume of water increases there will be a corresponding increase

in water pressure due to thermal expansion. Thermal expansion

can cause premature failure (leakage). This type of failure is not

covered under the limited warranty. Thermal expansion can also

cause intermittent Temperature-Pressure Relief Valve operation:

water discharged from the valve due to excessive pressure build

up. This condition is not covered under the limited warranty.

The Temperature-Pressure Relief Valve is not intended for the

constant relief of thermal expansion.

A properly sized thermal expansion tank must be installed on

all closed systems to control the harmful effects of thermal

expansion. Contact a local plumbing service agency to have a

thermal expansion tank installed.

PRESSURE RELIEF VALVE

An ASME rated pressure relief valve is furnished with the boiler.

A tting for the relief valve is provided in the top of the boiler.

Never operate the heating elements without being certain the

boiler is lled with water and a properly sized pressure relief

valve is installed in the relief valve opening provided.

The pressure rating of the relief valve should be equal to or less

than the rated pressure capacity of any component in the system

including the boiler. Should the valve need to be replaced, call

the toll free phone number listed on the back of this manual for

further technical assistance

16

Page 17

CAUTION

•

Pressure Relief Valve discharge pipe must

terminate at adequate drain.

Water Damage Hazard

Explosion Hazard

Relief Valve must comply with

ASME code.

Properly sized Relief Valve must

be installed in opening provided.

Can result in overheating and

excessive tank pressure.

Can cause serious injury or death.

A discharge pipe from the relief valve should terminate at an

adequate oor drain. Do not thread, plug, or cap the end of

drain line.

In addition, a CSA design-certied and ASME-rated tempera ture

and pressure (T&P) relief valve must be installed on each and

every water storage tank in hot water supply system. The T&P

relief valve must comply with appli cable construction provisions

of Standard for Relief Valves for Hot Water Supply Systems, ANSI

Z21.22 or CSA 4.4. T&P re lief valve must be of automatic reset

type and not embody a single-use type fusible plug, cartridge or

linkage.

T&P relief valve should have a temperature rating of 210°F

(99°C), a pressure rating not exceeding lowest rated working

pressure of any system compo nent, and a discharge capacity

exceeding total input of water boilers supply ing water to storage

tank.

Locate the T&P relief valve (a) in the top of the tank, or (b) in

the side of the tank on a centerline within the upper 6 inches

(152 mm) of the top of the tank, see Figure 78 and Figure 79.

The tapping should be threaded in accordance with the current

edition of the Standard for Pipe Threads, General Purpose

(inch), ANSI/A SME B1.20.1. The location of, or in tended location

for, the T&P relief valve should be readily accessible for servicing

or replacement.

GAS CONNECTIONS

The Discharge Pipe:

• Shall not be smaller in size than the outlet pipe size of the

valve, or have any reducing couplings or other restrictions.

• Shall not be plugged or blocked.

• Shall not be exposed to freezing temperatures.

• Shall be of material listed for hot water distribution.

• Shall be installed so as to allow complete drainage of both

the relief valve and the discharge pipe.

• Must terminate a maximum of six inches above a oor

drain or external to the building. In cold climates, it is

recommended that the discharge pipe be terminated at an

adequate drain inside the building.

• Shall not have any valve or other obstruction between the

relief valve and the drain.

Once the boiler is installed and lled with water and the system

is pressurized, manually test the operation of the pressure relief

valve. See the Maintenance Procedures section of this manual

for instructions.

Your local code authority may have other specic safety relief

valve requirements not covered below. If any pressure relief

valve is re placed, the replace ment valve must com ply with the

current version of the ASME Boiler and Pressure Vessel Code,

Section IV (“HEATING BOILERS”).

XB HYDRONIC BOILERS, are shipped with a 50 psi (345 kPa)

pressure relief valve. This relief valve must be in stalled in the

water outlet as near to the boiler as possi ble.

XW HOT WATER BOILERS, are shipped with a 125 psi (860

kPa) pressure relief valve that must be in stalled in the water outlet as near to the boil er as possi ble.

This ASME-rated valve has a discharge capacity that exceeds

maximum boiler input rating and a pres sure rating that does not

exceed maxi mum working pres sure shown on boiler rating plate.

Make sure the gas on which boiler is to operate is same as that

specied on the rating plate. Do not install boiler if equipped for a

different type of gas. Consult your gas supplier.

This boiler is not intended to operate at gas supply pressure

other than shown on the rating plate. A lock-up or positive shutoff type regulator must be installed in gas supply line. For proper

gas regulation the lock-up style regulators must be installed no

closer than a minimum of 3 feet from the boiler and a maximum

of 8 feet away from the boiler. Exposure to higher gas supply

pressure may cause damage to gas valves which can result in

re or explosion. If overpressure has occurred such as through

improper testing of gas lines or emergency malfunction of supply

system, the gas valves must be checked for safe operation.

Make sure that the outside vents on supply regulators and the

safety vent valves are protected against blockage. These are

parts of the gas supply system, not boiler. Vent blockage may

occur during ice build-up or snowstorms.

The boiler must be isolated from the gas supply piping system by

closing its main manual gas shut off valve during any pressure

testing of the gas supply piping system at test pressures equal

to or less than 1/2 psig.

Disconnect the boiler and its main manual gas shut-off valve

from the gas supply piping during any pressure testing of the

gas supply system over 1/2 psig. The gas supply line must be

capped when not connected to the boiler.

17

Page 18

It is important to guard against gas valve fouling from

contaminants in the gas ways. Such fouling may cause improper

operation, re or explosion. If copper supply lines are used they

must be approved for gas service.

When local codes require a main manual shut-off valve outside

the boiler jacket, a suitable main manual shut-off valve must be

installed in a location complying with those codes.

Before attaching gas line be sure that all gas pipe is clean

on inside. To trap any dirt or foreign material in the gas supply

line, a drip leg (or sediment trap) must be incorporated in piping.

The drip leg must be readily accessible and not subject to

freezing conditions. Install in accordance with recommendations

of serving gas supplier. Refer to the current edition of the National

Fuel Gas Code, ANSI Z223.1/NFPA 54 or the Natural Gas and

Propane Installation Code, CAN/CSA B149.1

Size of gas supply piping may be larger than heater connection

on installations where a signicant run of piping is required.

To prevent damage, care must be taken not to apply too much

torque when attaching gas supply pipe to boiler gas inlet. When

installing and tightening gas piping use a second wrench to hold

the gas valve to keep the valve from turning. To prevent damage

to the gas valve do not use pipe wrench on the valve body.

Fittings and unions in gas line must be of metal to metal type.

Apply joint compounds (pipe dope) sparingly and only to the

male threads of pipe joints. Do not apply compound to the rst

two threads. Use compounds resistant to the action of liqueed

petroleum gases. The boiler and its gas connection must be leak

tested before placing the boiler in operation.

GAS SUPPLY LINE SIZING

The gas piping installation must be capable of supplying the

maximum probable gas demand without excessive pressure loss.

Depending on local practices, the ALLOWABLE PRESSURE

LOSS between the gas meter, or service regulator and each

appliance is generally 0.3 or 0.5 inches of water column (0.075

or 0.124 kPa).

For single boiler installation, refer to Table 8 and Table 9 to size

iron pipe or equivalent gas supply line size to be used with single

unit.

For multiple boiler installation or installations of a single boiler

with other gas appliances, please refer to Table 10 and Table 11

on Page 20 to size iron pipe or equivalent gas supply line. These

tables are taken from the current edition of the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 or the Natural Gas and Propane

Installation Code, CAN/CSA B149.1.

• Table 10 is based on a pressure drop of 0.5 inches water

column (0.124 kPa), and a gas with a specic gravity of

0.60 and a heating value of 1,000 BTU/ft3, approximately

that of Natural Gas.

• Table 11 is based on a pressure drop of 0.5 inches water

column (0.124 kPa), and a gas with a specic gravity of

1.53 and a heating value of 2,500 BTU/ft3, approximately

that of Propane Gas.

Where it is necessary to use more than the average number of

ttings (i.e., elbows, tees and valves in gas supply line) use a

pipe larger than specied to compensate for increased pressure

drop.

Table 8 and Table 9 shows the maximum equivalent gas pipe

length for a single unit installation. It does not take into account

other appliances that may be connected to the gas line.

For installation of multiple units, or instances where several

appliances are connected to the same line, use Table 10 and

Table 11 for proper sizing.

SINGLE UNIT INSTALLATION, SUGGESTED GAS PIPE

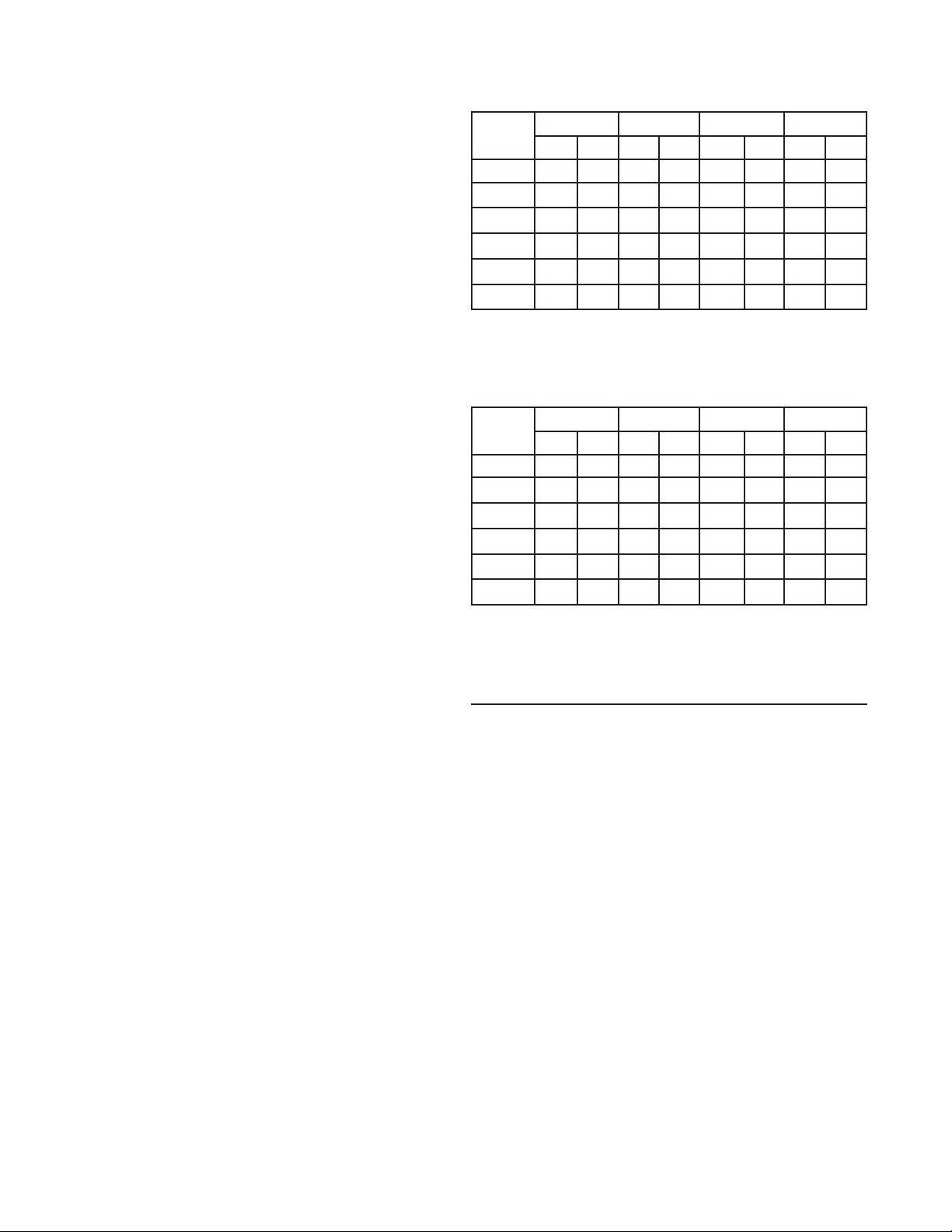

TABLE 8.

SIZING. MAXIMUM EQUIVALENT PIPE LENGTH (IN FEET).

BTU

Input

920,000 70 150 175 ----- ----- ----- ----- -----

1,300,000 40 100 100 200 ----- ----- ----- -----

1,700,000 20 60 70 150 200 ----- ----- -----

2,000,000 20 50 50 100 150 ----- ----- -----

2,600,000 10 30 30 70 90 200 ----- -----

3,400,000 ----- ----- 20 40 50 125 200 -----

Natural gas 1000 Btu/ft^3, 0.60 specic gravity @ 0.3 in. w.c. pressure drop.

Propane gas 2500 Btu/ft^3, 1.50 specic gravity @ 0.3 in. w.c. pressure drop.

2” 2-1/2” 3” 4”

Nat Pro Nat Pro Nat Pro Nat Pro

TABLE 9.

SINGLE UNIT INSTALLATION, SUGGESTED GAS PIPE

SIZING. MAXIMUM EQUIVALENT PIPE LENGTH (IN FEET).

BTU

Input

920,000 125 200 200 ----- ----- ----- ----- -----

1,300,000 80 175 175 ----- ----- ----- ----- -----

1,700,000 40 100 100 ----- ----- ----- ----- -----

2,000,000 30 80 80 200 200 ----- ----- -----

2,600,000 20 50 50 125 150 ----- ----- -----

3,400,000 10 30 30 70 90 200 ----- -----

Natural gas 1000 Btu/ft^3, 0.63 specic gravity @ 0.5 in. w.c. pressure drop.

Propane gas 2500 Btu/ft^3, 1.50 specic gravity @ 0.5 in. w.c. pressure drop.

2” 2-1/2” 3” 4”

Nat Pro Nat Pro Nat Pro Nat Pro

CORROSIVE MATERIALS AND CONTAMINATION

SOURCES

Products to avoid:

• Spray cans containing chloro/uorocarbons

• Permanent wave solutions

• Chlorinated waxes/cleaners

• Chlorine-based swimming pool chemicals

• Calcium chloride used for thawing

• Sodium chloride used for water softening

• Refrigerant leaks

• Paint or varnish removers

• Hydrochloric acid/muriatic acid

• Cements and glues

• Antistatic fabric softeners used in clothes dryers

• Chlorine-type bleaches, detergents, and cleaning

solvents found in household laundry rooms

• Adhesives used to fasten building products and other

similar products

Areas likely to have contaminants:

• Dry cleaning/laundry areas and establishments

• Swimming pools

• Metal fabrication plants

• Beauty shops

• Refrigeration repair shops

• Photo processing plants

18

Page 19

• Auto body shops

• Plastic manufacturing plants

• Furniture renishing areas and establishments

• New building construction

• Remodeling areas

Common household products, pool and laundry products may

contain uorine or chlorine compounds. When these chemicals

come in contact with the boiler, they react and can form strong

acids. The acid can spoil the boiler wall, causing serious damage

and may result in ue gas spillage or boiler water leakage into

the building.

If the above mentioned contaminants and corrosive materials

chemicals are present near the location of the boiler, make sure

to remove the boiler permanently or relocate air inlet and vent

terminations to other areas.

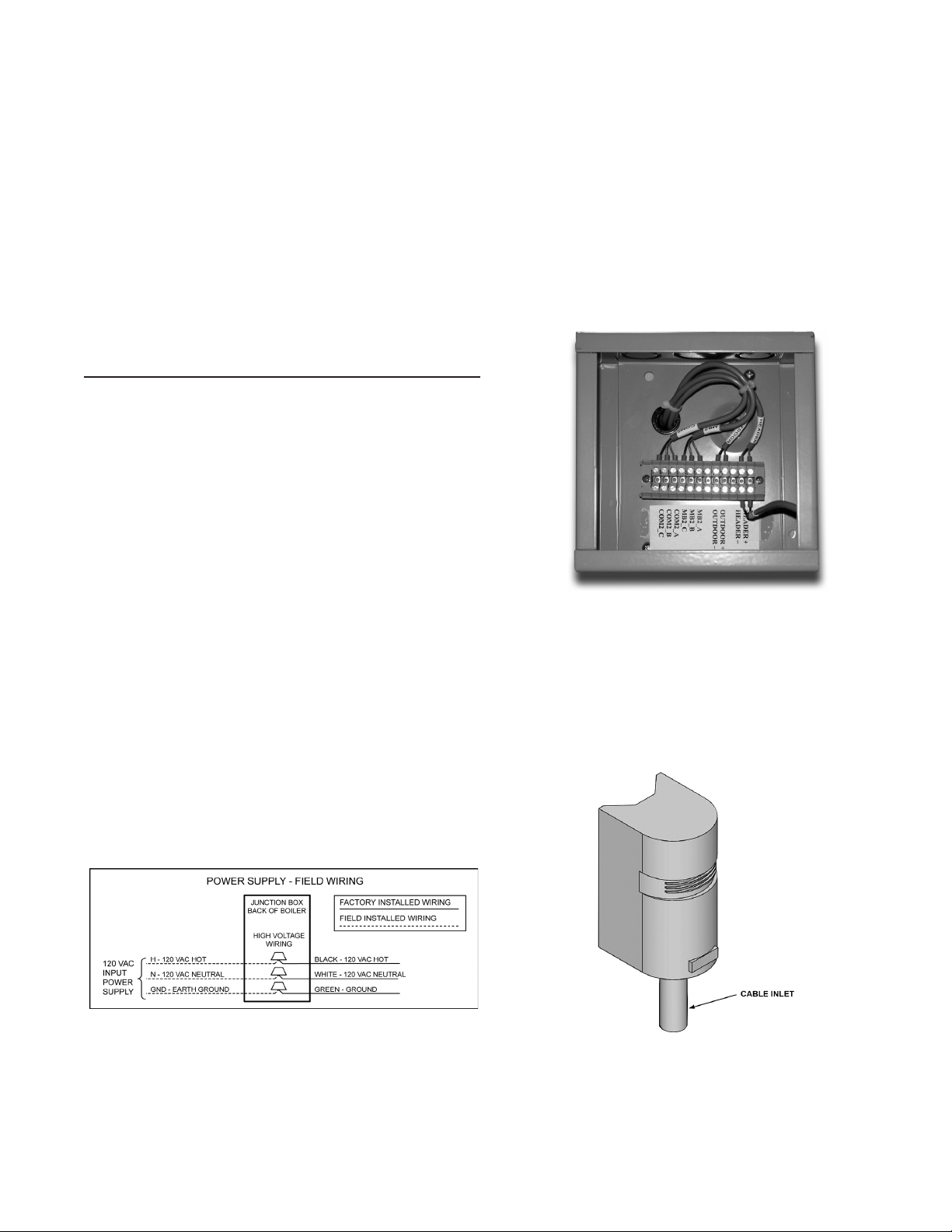

FIELD WIRING

120 VAC POWER SUPPLY WIRING

A dedicated, single phase, 30-60 amp (refer to Table 6 on Page

8) circuit breaker with a grounded neutral should be provided to

supply power to the boilers. Use #10 AWG wire for the 120 VAC

power supply to the boiler. All 120 VAC power supply connections

must be made as shown in Figure 14. These connections

should be made at the rear of the unit where a wiring junction

box is provided. Field installed power supply wiring to the boiler

should be installed in conduit. This conduit and wiring should

be separate from any other conduit/wiring to guard against EMI

(electromagnetic interference).

POWER SUPPLY CHECK

To reduce the possibility of electrical interference with the boiler’s

control system the power supply voltage, polarity and ground must

be checked. Using an AC volt meter check the 120 VAC power

supply wiring from the breaker prior to making power supply

connections at the boiler. Conrm the power supply voltage &

polarity are correct and that an adequate ground connection is

present by performing the three voltage tests below. See Figure

14 for wiring references.

Conrm RMS voltage between:

• H and GND = 108 VAC minimum, 132 VAC maximum.

• N and H = 108 VAC minimum, 132 VAC maximum.

• N and GND = < 1 VAC maximum.

LOW VOLTAGE CONTROL WIRING

1. Header Terminals: In case of Hydronic Boilers, the header

terminals are connected to the hydronic loop header sensor.

Whereas in case of Hot water Boilers the header terminals

are connected to the tank sensor where the temperature can

be sensed. See Figure 15.

2. Outdoor Terminals: In case of Hydronic Boilers, they are

connected to the outdoor sensors. But in case of Hot water

Boilers, they are not connected. See Figure 15. The outdoor

sensors must be mounted with cable inlet facing down

as shown in Figure 16. The maximum length of the wire

connecting from the boiler to the outdoor sensor must be no

more than 50 feet.

3. MB2 and COM2 terminals are meant for building

management systems.

FIGURE 15. LOW VOLTAGE CONTROL WIRING

All low voltage control wiring connections must be made as

shown in Figure 14. These connections should be made at the

rear of the unit where a wiring junction box is provided. Field

installed wiring inside 1/2 inch conduit is installed between the

junction box on the back of the boiler and the temperature probe

and/or eld supplied external control being used. This conduit

and wiring should be separate from any other conduit/wiring to

guard against EMI (electromagnetic interference).

FIGURE 14. FIELD WIRING

FIGURE 16. OUTDOOR SENSOR

The outdoor sensor must be mounted in a shaded location, to

avoid direct sunlight. It must be atleast 3 feet away from any

exhaust, dryer, bathroom or other building vents. It must be

located on the north side of th building, above the expected snow

line where ice and debris cannot cover it.

19

Page 20

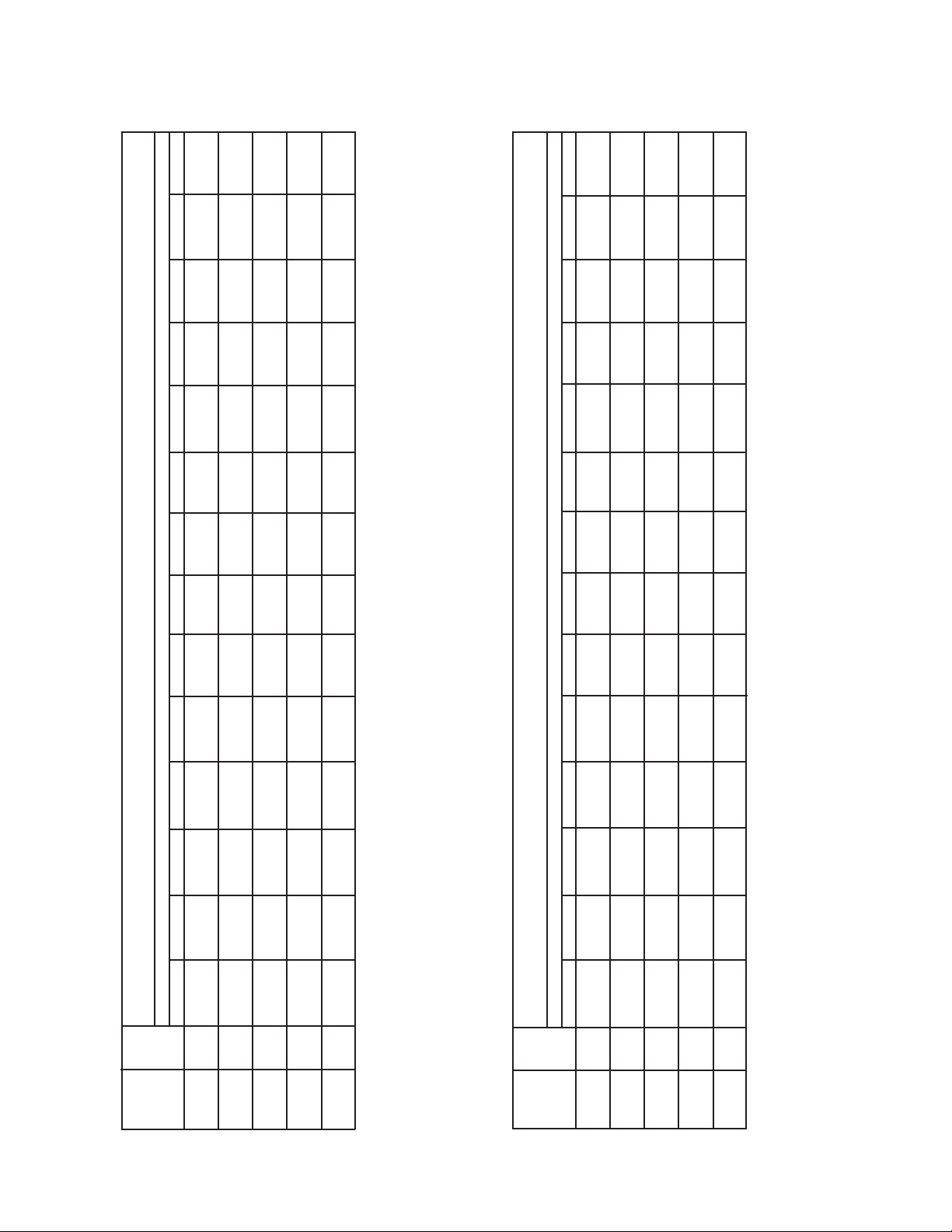

TABLE 10. SUGGESTED PIPE SIZE FOR MULTIPLE GAS APPLIANCES (NATURAL GAS)

Nominal Maximum Capacity of Pipe in BTU/hr and kW for Gas Pressures of 14 in. W.C. (0.5 psi) or Less and

Iron Pipe a Pressure Drop of 0.5 in. W.C. (based on 0.60 Specic Gravity Gas w/Heating Value of 1,000 BTU’s/Ft3)

Size Length of Pipe in Feet (Meters)

(Inches) 10 (3.05) 20 (6.1) 30 (9.14) 40 (12.19) 50 (15.24) 60 (18.29) 70 (21.34) 80 (24.38) 90 (27.43) 100 (30.48) 125 (38.1) 150 175 200

1 1/2 BTU/hr 2,100,000 1,460,000 1,180,000 990,000 900,000 810,000 750,000 690,000 650,000 620,000 550,000 500,000 460,000 —

kW 615 428 346 290 264 237 220 202 190 182 161 146 135 —

2 BTU/hr 3,950,000 2,750,000 2,200,000 1,900,000 1,680,000 1,520,000 1,400,000 1,300,000 1,220,000 1,150,000 1,020,000 950,000 850,000 800,000

kW 1,157 805 644 556 492 445 410 381 357 337 299 278 249 234

2 1/2 BTU/hr 6,300,000 4,350,000 3,520,000 3,000,000 2,650,000 2,400,000 2,250,000 2,050,000 1,950,000 1,850,000 1,650,000 1,500,000 1,370,000 1,280,000

kW 1,845 1,274 1,031 879 776 703 659 600 571 542 483 439 401 375

3 BTU/hr 11,000,000 7,700,000 6,250,000 5,300,000 4,750,000 4,300,000 3,900,000 3,700,000 3,450,000 3,250,000 2,950,000 2,650,000 2,450,000 2,280,000

kW 3,222 2,255 1,830 1,552 1,391 1,259 1,142 1,084 1,010 952 864 776 718 668

4 BTU/hr 23,000,000 15,800,000 12,800,000 10,900,000 9,700,000 8,800,000 8,100,000 7,500,000 7,200,000 6,700,000 6,000,000 5,500,000 5,000,000 4,600,000

kW 6,736 4,627 3,749 3,192 2,841 2,577 2,372 2,197 2,109 1,962 1,757 1,611 1,464 1,347

20

TABLE 11. SUGGESTED PIPE SIZE FOR MULTIPLE GAS APPLIANCES (PROPANE GAS)

Nominal Maximum Capacity of Pipe in BTU/hr and kW for Gas Pressures of 14 in. W.C. (0.5 psi) or Less and

Iron Pipe a Pressure Drop of 0.5 in. W.C. (based on 0.60 Specic Gravity Gas w/Heating Value of 1,000 BTU’s/Ft3)

Size Length of Pipe in Feet (Meters)

(Inches) 10 (3.05) 20 (6.1) 30 (9.14) 40 (12.19) 50 (15.24) 60 (18.29) 70 (21.34) 80 (24.38) 90 (27.43) 100 (30.48) 125 (38.1) 150 175 200

1 1/2 BTU/hr 3,276,000 2,277,600 1,840,800 1,544,400 1,404,000 1,263,600 1,170,000 1,076,400 1,014,000 967,200 858,000 780,000 717,600 670,800

kW 959 667 539 452 411 370 343 315 297 283 251 228 210 196

2 BTU/hr 6,162,000 4,290,000 3,432,000 2,964,000 2,620,800 2,371,200 2,184,000 2,028,000 1,903,200 1,794,000 1,591,200 1,482,000 1,326,000 1,248,000

kW 1,805 1,256 1,005 868 768 694 640 594 557 525 466 434 388 366

2 1/2 BTU/hr 9,828,000 6,786,000 5,491,200 4,680,000 4,134,000 3,744,000 3,510,000 3,198,000 3,042,000 2,886,000 2,574,000 2,340,000 2,137,200 1,999,800

kW 2,878 1,987 1,608 1,371 1,211 1,097 1,028 937 891 845 754 685 626 585

3 BTU/hr 17,160,000 12,012,000 9,750,000 8,268,000 7,410,000 6,708,000 6,084,000 5,772,000 5,382,000 5,070,000 4,602,000 4,134,000 3,822,000 3,556,800

kW 5,026 3,518 2,856 2,421 2,170 1,965 1,782 1,690 1,576 1,485 1,348 1,211 1,119 1,042

4 BTU/hr 35,880,000 24,648,000 19,968,000 17,004,000 15,132,000 13,728,000 12,636,000 11,700,000 11,232,000 10,452,000 9,360,000 8,580,000 7,800,000 7,176,000

kW 10,508 7,219 5,848 4,980 4,432 4,021 3,701 3,427 3,290 3,061 2,741 2,513 2,284 2,102

Page 21

GENERAL REQUIREMENTS

REQUIRED ABILITY

Installation or service of this boiler requires ability equivalent to

that of a licensed trades man in the eld involved. Plumbing, air

supply, venting, gas supply, and electrical work are re quired.

LOCATION

When installing the boiler, consideration must be given to proper

location. The location selected should provide ade quate air

supply and be as centralized with the piping system as possible.

REPLACING EXISTING COMMON VENTED BOILER

NOTE: This section does not describe a method for common

venting XP units. It describes what must be done when a unit

is removed from a common vent system. The XP units require

special vent systems and fans for common vent. Contact the

factory if you have questions about common venting XP units.

When an existing boiler is removed from a common venting

system, the common venting system is likely to be too large

for proper venting of the appliances remaining connected to it.

At the time of removal of an existing boiler, the following steps

should be followed with each appliance remaining connected to

the common venting system placed in operation, while the other

appliances remaining connected to the common venting system

are not in operation.

1. Seal any unused openings in the common venting system.

2. Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion and deciencies which could

cause an unsafe condition.

3. In so far as it is practical, close all building doors and

windows and all doors between the space in which the

appliances remaining connected to the common venting

system are located and other spaces of the building. Turn

on clothes dryers and any appliance not connected to the

common venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they will operate

at maximum speed. Do not operate a summer exhaust fan.

Close replace dampers.

4. Place in operation the appliance being inspected. Follow the

lighting instructions. Adjust thermostat so the appliance will

operate continuously.

5. Test for spillage at the draft hood relief opening after 5

minutes of main burner operation. Use the ame of a match

or candle, or smoke from a cigarette, cigar or pipe.

6. After it has been determined that each appliance remaining

connected to the common venting system properly vents

when tested as outlined above, return doors, windows,

exhaust fans, replace dampers and any other gas-burning

appliance to their previous condition of use.

7. Any improper operation of the common venting system

should be corrected so that the installation conforms with

the National Fuel Gas Code, ANSI Z223.1/NFPA 54 and/

or CSA B149.1, Installation Codes. When resizing any

portion of the common venting system, the common venting

system should be resized to approach the minimum size as

determined using the appropriate tables and guidelines in the

National Fuel Gas Code, ANSI Z223.1/NFPA 54 and/or CSA

B149.1, Installation Codes.

This boiler is intended for Indoor Installation only, and should not

be installed where freezing temperatures or any moisture could

damage the external components of the boiler.

21

Page 22

PANELS AND COVERS

All panels and covers (e.g. control and junction box covers; front,

side and rear panels of boiler) must be in place after service and/

or before opera tion of boiler. This will ensure that all gas ignition

components will be protected from water.

The XP is a low-pressure boiler (Category IV) to be used as

either hot water supply (domestic/commercial water heating) or

hot water heating (hydronic) application. Category IV appli ances

are often termed “High Ef ciency” appliances.

CHEMICAL VAPOR CORROSION

Boiler corrosion and component failure can be caused by the

he a ting an d br eakd own of air b o r ne chemic a l vapors. Spr ay can

propellants, cleaning sol vents, refrigerator and air conditioning

refrig erants, swimming pool chemicals, calcium and sodium

chloride (water softener salt), waxes, and process chemicals

are typical compounds which are potentially corrosive. These

materials are corrosive at very low concentration levels with little

or no odor to reveal their presence.

Products of this sort should not be stored near boiler. Also, air

which is brought in contact with boiler should not contain any

of these chemicals. If necessary, uncontaminated air should be

obtained from remote or outside sources. Failure to observe this

requirement will void warranty.

LEVELING

Because this unit is a Category IV appliance it produces some

amounts of condensation. The unit has a condensation disposal

system that requires this unit to be level to properly drain. Each

unit should be checked to be certain that it is level prior to starting

the unit.

If the unit is not level, obtain and insert shims under the feet at

the frame base to correct this condition.

AIR REQUIREMENTS

Breathing Hazard - Carbon Monoxide Gas

Install appliance in accordance with

the Instruction Manual and NFPA 54 or

CAN/CSA-B149.1.

To avoid injury, combustion and ventilation

air must be taken from outdoors.

Do not place chemical vapor emitting

products near water heater.

Breathing carbon monoxide can cause brain damage or

death. Always read and understand instruction manual.

INSTALLATION CLEARANCES

This boiler is approved for installation in an alcove with minimum

clearances to combustibles.

TABLE 12. INSTALLATION CLEARANCES

RECOMMENDED

SERVICE

CLEARANCES

Front 30" (762 mm) 8" (203 mm)

Rear 36" (610 mm) 24" (610 mm)

Left 24 " (610 mm) 1" (25.4 mm)

Right 24 " (610 mm) 2" (51 mm)

Top 24" (610 mm) 6" (152 mm)

2” (51 mm) clearance is allowable from combustible construction

for hot water pipes.

Sufcient area should be provided at the front and rear of the

unit for prop er servicing. In a utility room installa tion, the door

opening should be wide enough to allow the boiler to enter or

to permit the replacement of another appli ance such as a boiler.

FLOORING AND FOUNDATION:

All models are approved for installation on combustible ooring,

but must never be installed on carpeting. Do not install the boiler

on carpeting even if foundation is used. Fire can result, causing

severe personal injury, death, or substantial property damage.

If ooding is possible, elevate the boiler sufciently to prevent

water from reaching the boiler.

CLEARANCES FROM

COMBUSTIBLE

MATERIALS

For safe operation an adequate supply of fresh uncontaminated

air for combustion and ventilation must be provided.

An insufcient supply of air can cause recirculation of combustion

products resulting in contamination that may be hazardous to

life. Such a condition often will result in a yellow, luminous burner

ame, causing sooting of the combustion chamber, burners and

ue tubes and creates a risk of asphyxiation.

Do not install the boiler in a conned space unless an adequate

supply of air for combustion and ventilation is brought in to that

space using the methods described in the Conned Space

section that follows.

Never obstruct the ow of ventilation air. If you have any doubts

or questions at all, call your gas supplier. Failure to provide the

proper amount of combustion air can result in a re or explosion

and cause property damage, serious bodily injury or death.

UNCONFINED SPACE

An unconned space is one whose volume is not less than 50

cubic feet per 1,000 Btu/hr (4.8 cubic meters per kW) of the

total input rating of all appliances installed in the space. Rooms

communicating directly with the space, in which the appliances

are installed, through openings not furnished with doors, are

considered a part of the unconned space.

Makeup air requirements for the operation of exhaust fans,

kitchen ventilation systems, clothes dryers and replaces shall

also be considered in determining the adequacy of a space to

provide combustion, ventilation and dilution air.

UNUSUALLY TIGHT CONSTRUCTION

In unconned spaces in buildings, inltration may be adequate

to provide air for combustion, ventilation and dilution of ue

gases. However, in buildings of unusually tight construction (for

example, weather stripping, heavily insulated, caulked, vapor

barrier, etc.) additional air must be provided using the methods

described in the Conned Space section that follows.

22

Page 23

CONFINED SPACE

A conned space is one whose volume is less than 50 cubic

feet per 1,000 Btu/hr (4.8 cubic meters per kW) of the total input

rating of all appliances installed in the space.

Openings must be installed to provide fresh air for combustion,

ventilation and dilution in conned spaces. The required size for

the openings is dependent on the method used to provide fresh

air to the conned space and the total Btu/hr input rating of all

appliances installed in the space.

DIRECT VENT APPLIANCES

Appliances installed in a direct vent conguration that derive all

air for combustion from the outdoor atmosphere through sealed

intake air piping are not factored in the total appliance input Btu/

hr calculations used to determine the size of openings providing

fresh air into conned spaces.

EXHAUST FANS

Where exhaust fans are installed, additional air shall be provided

to replace the exhausted air. When an exhaust fan is installed

in the same space with a water heater, sufcient openings to

provide fresh air must be provided that accommodate the

requirements for all appliances in the room and the exhaust fan.

Undersized openings will cause air to be drawn into the room

through the water heater’s vent system causing poor combustion.

Sooting, serious damage to the water heater and the risk of re

or explosion may result. It can also create a risk of asphyxiation.

LOUVERS AND GRILLES

The free areas of the fresh air openings in the instructions that

follow do not take in to account the presence of louvers, grilles or

screens in the openings.

The required size of openings for combustion, ventilation and

dilution air shall be based on the “net free area” of each opening.

Where the free area through a design of louver or grille or screen

is known, it shall be used in calculating the size of opening

required to provide the free area specied. Where the louver and

grille design and free area are not known, it shall be assumed

that wood louvers will have 25% free area and metal louvers and

grilles will have 75% free area. Non motorized louvers and grilles

shall be xed in the open position.

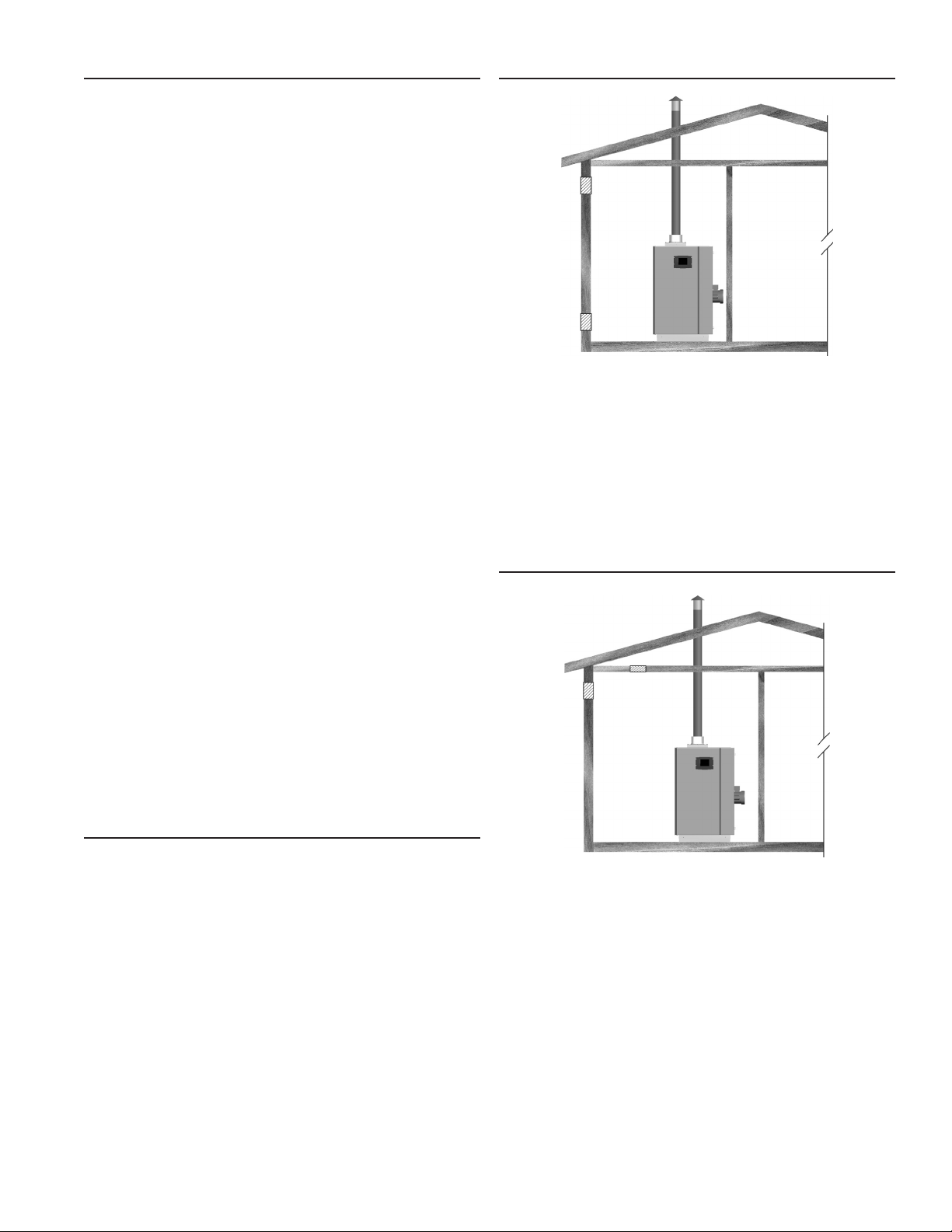

OUTDOOR AIR THROUGH TWO OPENINGS

FIGURE 17. OUTDOOR AIR THROUGH TWO OPENINGS

The conned space shall be provided with two permanent

openings, one commencing within 12 inches (300 mm) of the top

and one commencing within 12 inches (300 mm) of the bottom of

the enclosure. The openings shall communicate directly with the

outdoors. See Figure 17.

Each opening shall have a minimum free area of 1 square inch

per 4,000 Btu/hr (550 mm2 per kW) of the aggregate input rating

of all appliances installed in the enclosure. Each opening shall

not be less than 100 square inches (645 cm2).

OUTDOOR AIR THROUGH ONE OPENING

FRESH AIR OPENINGS FOR CONFINED SPACES

The following instructions shall be used to calculate the size,

number and placement of openings providing fresh air for

combustion, ventilation and dilution in conned spaces. The

illustrations shown in this section of the manual are a reference

for the openings that provide fresh air into conned spaces

only. Do not refer to these illustrations for the purpose of vent

installation. See Venting section on Page 25 for complete venting

installation instructions.

FIGURE 18. OUTDOOR AIR THROUGH ONE OPENING

Alternatively a single permanent opening, commencing within 12

inches (300 mm) of the top of the enclosure, shall be provided.

See Figure 18. The water heater shall have clearances of at

least 1 inch (25 mm) from the sides and back and 6 inches (150

mm) from the front of the appliance. The opening shall directly

communicate with the outdoors or shall communicate through a

vertical or horizontal duct to the outdoors or spaces that freely

communicate with the outdoors and shall have a minimum free

area of the following:

1. 1 square inch per 3000 Btu/hr (700 mm2 per kW) of the total

input rating of all appliances located in the enclosure, and

2. Not less than the sum of the areas of all vent connectors in

the space.

23

Page 24

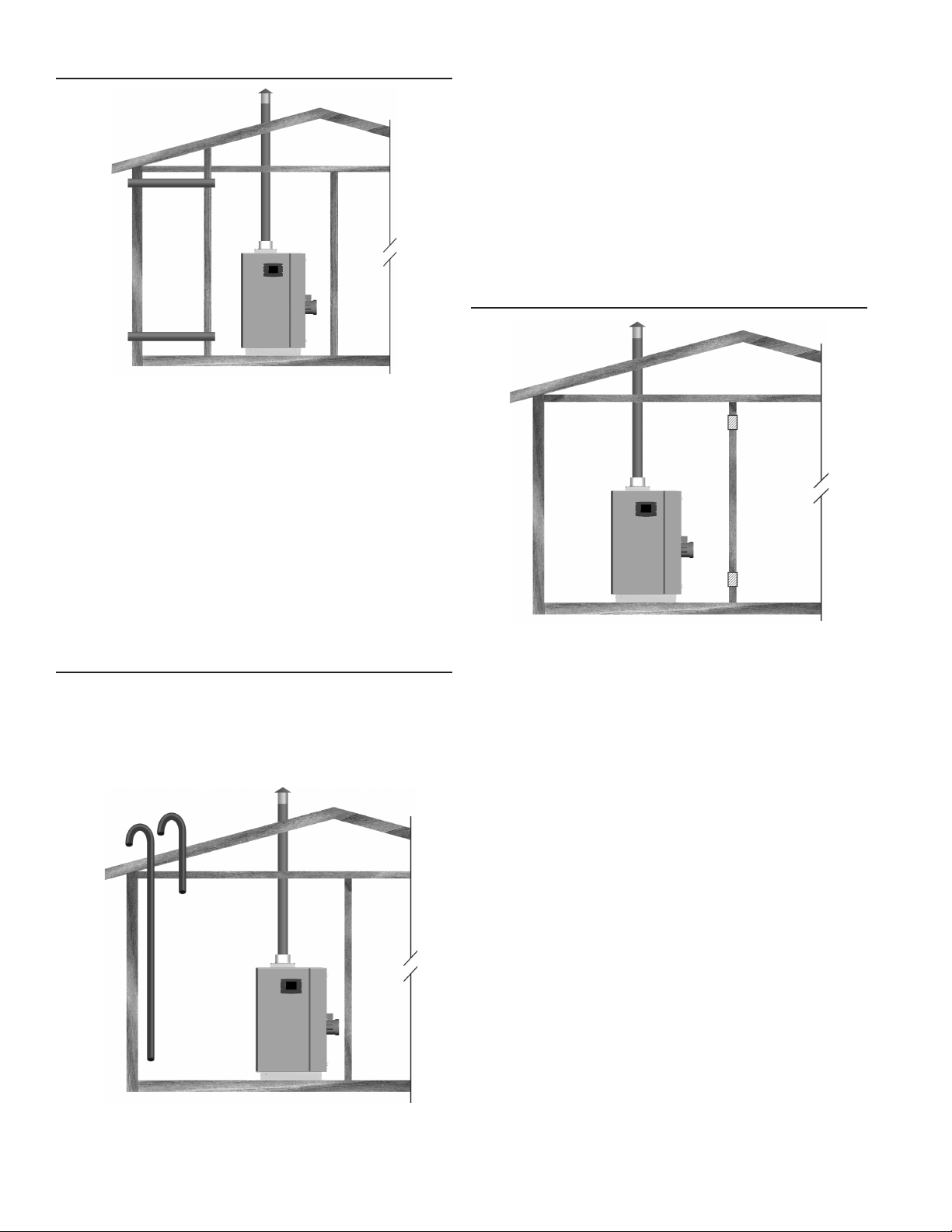

OUTDOOR AIR THROUGH TWO HORIZONTAL DUCTS

FIGURE 19. OUTDOOR AIR THROUGH TWO HORIZONTAL

DUCTS

The conned space shall be provided with two permanent

horizontal ducts, one commencing within 12 inches (300 mm) of

the top and one commencing within 12 inches (300 mm) of the

bottom of the enclosure. The horizontal ducts shall communicate

directly with the outdoors. See Figure 19.

Each duct opening shall have a minimum free area of 1 square

inch per 2,000 Btu/hr (1100 mm2 per kW) of the aggregate input

rating of all appliances installed in the enclosure.

When ducts are used, they shall be of the same cross sectional

area as the free area of the openings to which they connect.

The minimum dimension of rectangular air ducts shall be not less

than 3 inches.

OUTDOOR AIR THROUGH TWO VERTICAL DUCTS

The illustrations shown in this section of the manual are a

reference for the openings that provide fresh air into conned

spaces only.

Do not refer to these illustrations for the purpose of vent

installation.

The conned space shall be provided with two permanent vertical

ducts, one commencing within 12 inches (300 mm) of the top and

one commencing within 12 inches (300 mm) of the bottom of the

enclosure. The vertical ducts shall communicate directly with the

outdoors. See Figure 20.

Each duct opening shall have a minimum free area of 1 square

inch per 4,000 Btu/hr (550 mm2 per kW) of the aggregate input

rating of all appliances installed in the enclosure.

When ducts are used, they shall be of the same cross sectional

area as the free area of the openings to which they connect.

The minimum dimension of rectangular air ducts shall be not less

than 3 inches.

AIR FROM OTHER INDOOR SPACES

FIGURE 21. AIR FROM OTHER INDOOR SPACES

The conned space shall be provided with two permanent

openings, one commencing within 12 inches (300 mm) of the top

and one commencing within 12 inches (300 mm) of the bottom of

the enclosure. See Figure 21.

Each opening shall communicate directly with an additional

room(s) of sufcient volume so that the combined volume of all

spaces meets the criteria for an Unconned Space.

Each opening shall have a minimum free area of 1 square inch

per 1,000 Btu/hr (1100 mm2 per kW) of the aggregate input rating

of all appliances installed in the enclosure. Each opening shall

not be less than 100 square inches (645 cm2).

FIGURE 20. OUTDOOR AIR THROUGH TWO VERTICAL

DUCTS

24

Page 25

VENTING

Vent sizing, installation and termination should be in accordance

with this installation manual. This boiler must be vented using

PVC/CPVC or Stainless Steel materials.

All electrical power and gas must be turned off prior to any

installation of the venting system.

VENT INSTALLATION CONSIDERATIONS

This boiler is a category IV appliance that can be vented using

room air for intake combustion air, or direct vented so that all

intake air for combustion comes from the outside through a

sealed pipe. When installing this appliance as direct vent, special

vent kits are required.

In cold climates any water vapor remaining in the ue gases will

condense into a cloud of vapor at the point where the vent system

exits the building. Special consideration is recommended, before

locating the vent termination near walkways, windows and

building entrances.

Direct venting into dead spaces such as alleys, atriums, and