Page 1

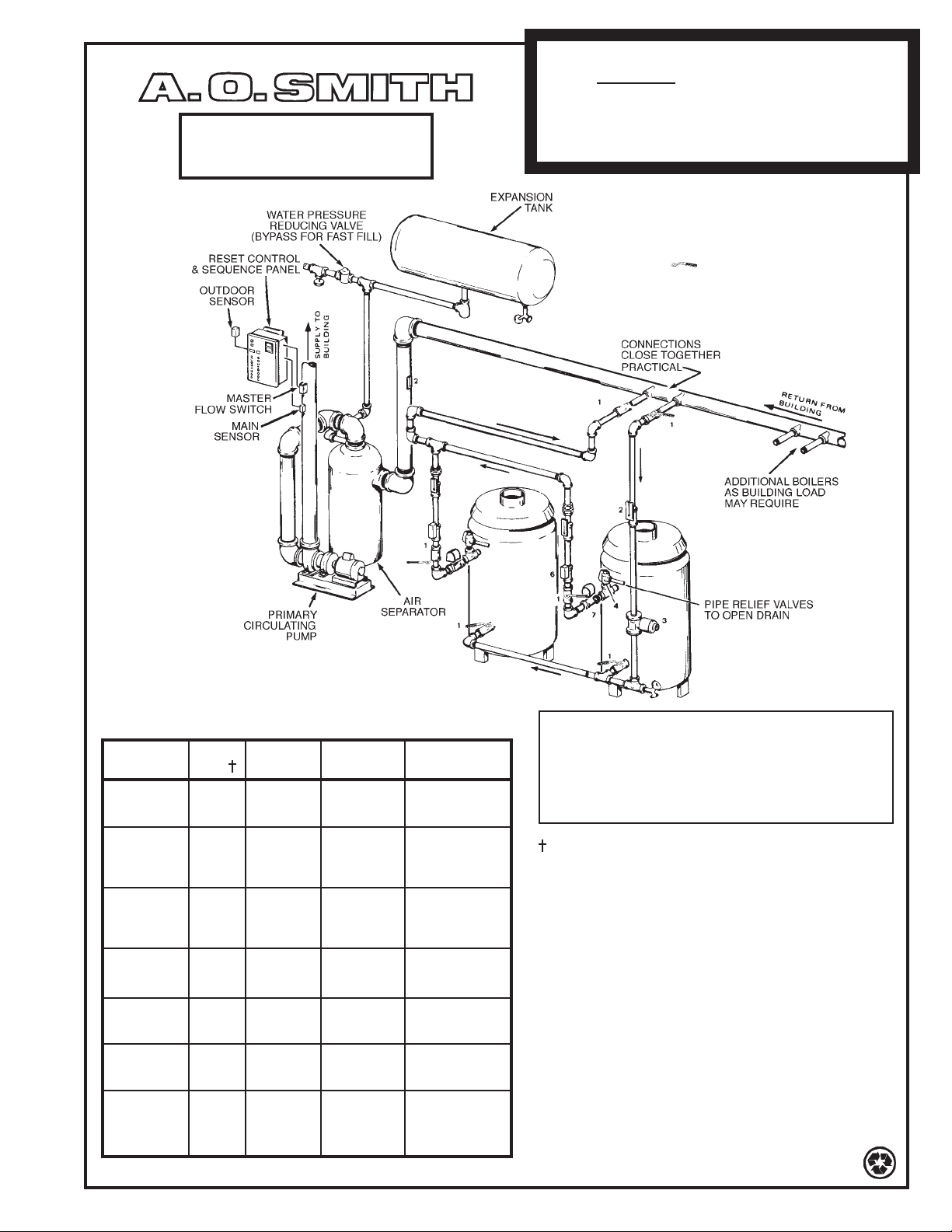

LINEAR-TEMP* SYSTEM

APPLICATION TYPE DIAGRAM

SEE INSTALLATION MANUAL FOR

COMPLETE INSTRUCTIONS

INSTALL IN ACCORDANCE WITH LOCAL CODES.

300-2, 399-2, 420-2, 520-2 OR 670-2

SECONDARY PUMP AND PIPE SELECTION DATA FOR

CONNECTIONS TO EACH PAIR OF BOILERS

Boiler Temp. Secondary Boiler Pump Boiler

Model Rise Piping Selection Inlet & Outlet

2"

2"

SH-1

60-13

2-1/2"

2"

60-13"

2-1/2"

60-14

2-1/2"

2"

60-14

2-1/2"

2"

60-14

2-1/2"

2"

60-19

60-14

60-13

2-1/2"

HW-300 1-1/4"

HW-399 1-1/2"

HW-300 1-1/4"

HW-420 1-1/2"

(2) HW-300

(1) HW-300

with

(1) HW-399

**

(1) HW-300

with

(1) HW-420

**

(2) HW-399

(2) HW-420

(2) HW-520

(2) HW-670

20°

30°

40°

20°

30°

40°

20°

30°

20°

30°

40°

20°

30°

40°

20°

30°

40°

20°

30°

35°

40°

2"

1-1/2"

1-1/4"

2-1/2"

2"

1-1/2"

2-1/2"

2"

2"

2"

1-1/2"

2"

2"

1-1/2"

2-1/2"

2"

2"

3"

2-1/2"

2-1/2"

2-1/2"

1-1/4"

1-1/2"

1-1/2"

2"

2"

1. BALL VALVE

2. THERMOMETER

3. BOILER CIRCULATING PUMP

4. RELIEF VALVE

5. SAFETY LIMIT CONTROL (If Required)

6. SAFETY FLOW SWITCH

NOTE: Make most economical selection of secondary

pump and piping to provide a temperature rise compatible

with system design temperature and highest expected

boiler inlet temperature Example system design at:

220° use 20° temp. rise

210° use 30° temp. rise

200° or less use 40° temp. rise

ASSUMING THAT PRIMARY PUMPING IS SIZED

FOR A 20° TEMPERATURE DROP!

Secondary flow rate should not create a

temperature rise that will force boiler temperatures

up to the 240° maximum setting of limit controls.

** Flow rates through unequal models must be

adjusted to establish equal temperature rise.

* Trademark A.O. Smith Corporation

Revised June 1998 E 117.0

Page 2

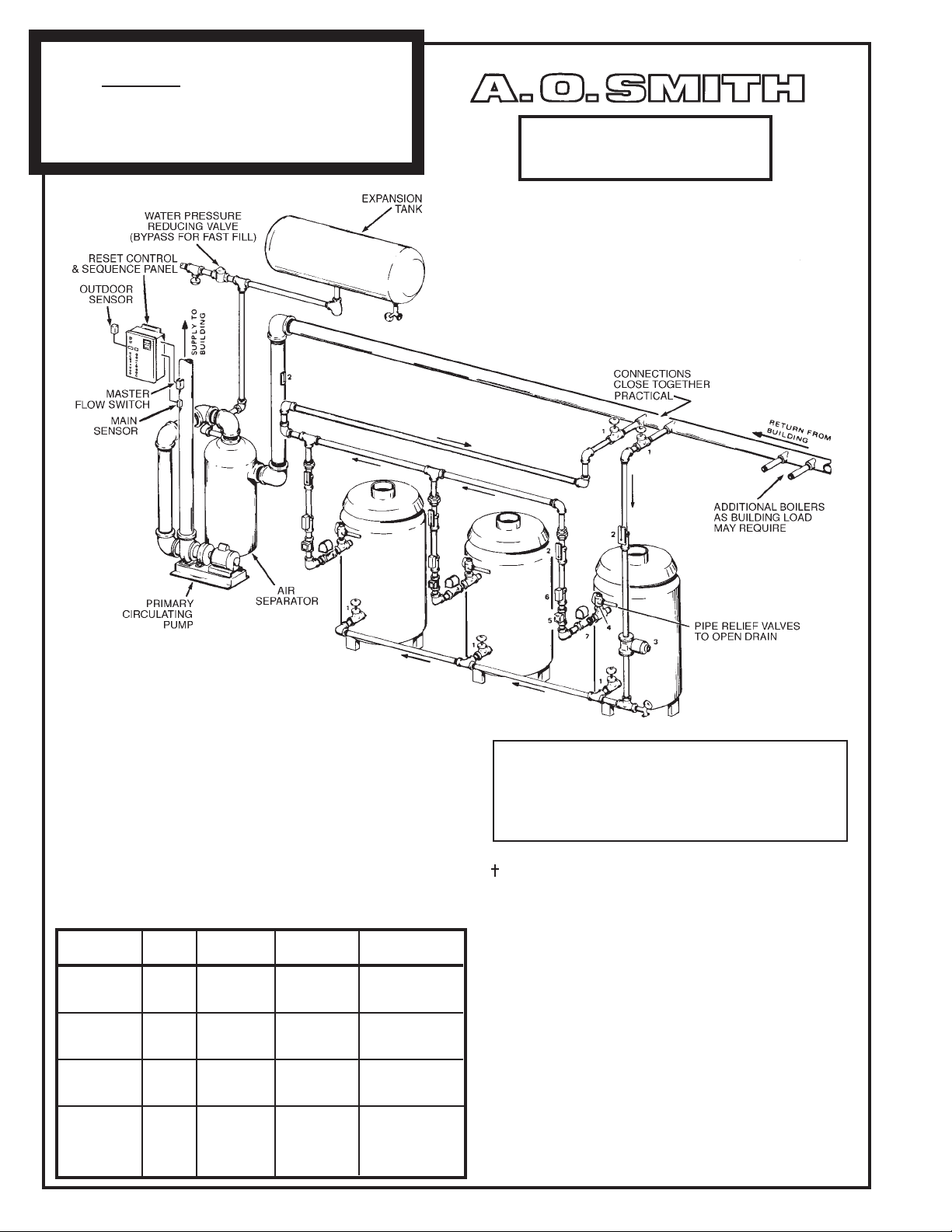

LINEAR-TEMP* SYSTEM

300-2, 399-2, 420-2, 520-2 OR 670-2

APPLICATION TYPE DIAGRAM

SEE INSTALLATION MANUAL FOR

COMPLETE INSTRUCTIONS

INSTALL IN ACCORDANCE WITH LOCAL CODES.

SECONDARY PUMP AND PIPE SELECTION DATA FOR

CONNECTIONS TO EACH PAIR OF BOILERS

Boiler Temp. Secondary Boiler Pump Boiler

Model Rise Piping Selection Inlet & Outlet

(2) HW-399

(2) HW-420

(2) HW-520

(2) HW-670

20°

30°

40°

20°

30°

40°

20°

30°

40°

20°

30°

35°

40°

2"

2"

1-1/2"

2"

2"

1-1/2"

2-1/2"

2"

2"

3"

2-1/2"

2-1/2"

2-1/2"

60-14

2-1/2"

2"

60-14

2-1/2"

2"

60-14

2-1/2"

2"

60-19

60-14

60-13

2-1/2"

1-1/2"

1-1/2"

2"

2"

1. BALL VALVE

2. THERMOMETER

3. BOILER CIRCULATING PUMP

4. RELIEF VALVE

5. SAFETY LIMIT CONTROL (If Required)

6. SAFETY FLOW SWITCH

NOTE: Make most economical selection of secondary

pump and piping to provide a temperature rise compatible

with system design temperature and highest expected

boiler inlet temperature Example system design at:

220° use 20° temp. rise

210° use 30° temp. rise

200° or less use 40° temp. rise

ASSUMING THAT PRIMARY PUMPING IS SIZED

FOR A 20° TEMPERATURE DROP!

Secondary flow rate should not create a

temperature rise that will force boiler temperatures

up to the 240° maximum setting of limit controls.

** Flow rates through unequal models must be

adjusted to establish equal temperature rise.

* Trademark A.O. Smith Corporation

E 118.0 © A. O. SMITH CORP. 1998 Printed in the U.S.A.

Loading...

Loading...