Page 1

19" LCD Color Monitor I-INC AH191D

Service

Service

Service

Horizontal Frequency

31-80 kHz

TABLE OF CONTENTS

Description Page Description Page

Table Of Contents.......…….................……..........…........1

Revision List.…........................………................……......2

Important Safety Notice.………….…...............……......3

1. Monitor Specification.................................………........4

2.LCD Monitor Description…………………………….......5

3. Operation Instruction………….........……………...........7

3.1 General Instructions.....................................…...........7

3.2 Control Button…………………………………………...7

3.3 Adjusting the Picture...........................…............9

4. Input/Output Specification............……………............14

4.1 Input Signal Connector............………….................14

4.2 Factory Preset Display Modes..................................15

4.3 Panel Specification.....………………........................16

5.Block Diagram…….…................……..…..............19

5.1Software Flow Chart…………………...............19

5.2 Electrical Block Diagram………....………..………....21

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING ELECTRONIC

EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFOMER FOR THIS UNIT WHEN SERVICING

http://www.wjel.net

SAFETY NOTICE

6. Schematic…………………….…..............................23

6.1 Main Board…………..............................................23

6.2 Power Board....……………....................................28

6.3 Key Board ……………………………..…………….30

6.4 Audio Board....……...............................................31

7. PCB Layout..………….......................................32

7.1. Main Board………........................................32

7.2 Power Board….......................................34

7.3 Audio Board....…….......................................36

7.4 Keypad Board……….............................................36

8. Maintainability………...............................................37

8.1. Equipments and Tools Requirement.....................37

8.2. Trouble Shooting…………....................................38

9. White-Balance, Luminance adjustment...................44

10.Monitor Exploded View……..………………............45

11. BOM List....…….....................................................46

1

Page 2

19" LCD Color Monitor I-INC AH191D

Revision List

Revision Date Revision History TPV Model

A00 Nov-02-2006 Initial release T96HM6DTWEHZAE

http://www.wjel.net

2

Page 3

19" LCD Color Monitor I-INC AH191D

Important Safety Notice

Proper service and repair is important to the safe, reliable operation of all AOC Company Equipment. The service

procedures recommended by AOC and described in this service manual are effective methods of performing service

operations. Some of these service operations require the use of tools specially designed for the purpose. The special

tools should be used when and as recommended.

It is important to note that this manual contains various CAUTIONS and NOTICES which should be carefully read in

order to minimize the risk of personal injury to service personnel. The possibility exists that improper service methods

may damage the equipment. It is also important to understand that these CAUTIONS and NOTICES ARE NOT

EXHAUSTIVE. AOC could not possibly know, evaluate and advise the service trade of all conceivable ways in which

service might be done or of the possible hazardous consequences of each way. Consequently, AOC has not undertaken

any such broad evaluation. Accordingly, a servicer who uses a service procedure or tool which is not recommended by

AOC must first satisfy himself thoroughly that neither his safety nor the safe operation of the equipment will be

jeopardized by the service method selected.

Hereafter throughout this manual, AOC Company will be referred to as AOC.

WARNING

Use of substitute replacement parts, which do not have the same, specified safety characteristics may create shock, fire,

or other hazards.

Under no circumstances should the original design be modified or altered without written permission from AOC. AOC

assumes no liability, express or implied, arising out of any unauthorized modification of design.

Servicer assumes all liability.

FOR PRODUCTS CONTAINING LASER:

DANGER-Invisible laser radiation when open AVOID DIRECT EXPOSURE TO BEAM.

CAUTION-Use of controls or adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

CAUTION -The use of optical instruments with this product will increase eye hazard.

TO ENSURE THE CONTINUED RELIABILITY OF THIS PRODUCT, USE ONLY ORIGINAL MANUFACTURER'S

REPLACEMENT PARTS, WHICH ARE LISTED WITH THEIR PART NUMBERS IN THE PARTS LIST SECTION OF

THIS SERVICE MANUAL.

Take care during handling the LCD module with backlight unit

-Must mount the module using mounting holes arranged in four corners.

-Do not press on the panel, edge of the frame strongly or electric shock as this will result in damage to the screen.

-Do not scratch or press on the panel with any sharp objects, such as pencil or pen as this may result in damage to the

panel.

-Protect the module from the ESD as it may damage the electronic circuit (C-MOS).

-Make certain that treatment person’s body is grounded through wristband.

-Do not leave the module in high temperature and in areas of high humidity for a long time.

-Avoid contact with water as it may a short circuit within the module.

-If the surface of panel becomes dirty, please wipe it off with a soft material. (Cleaning with a dirty or rough cloth may

damage the panel.)

http://www.wjel.net

3

Page 4

19" LCD Color Monitor I-INC AH191D

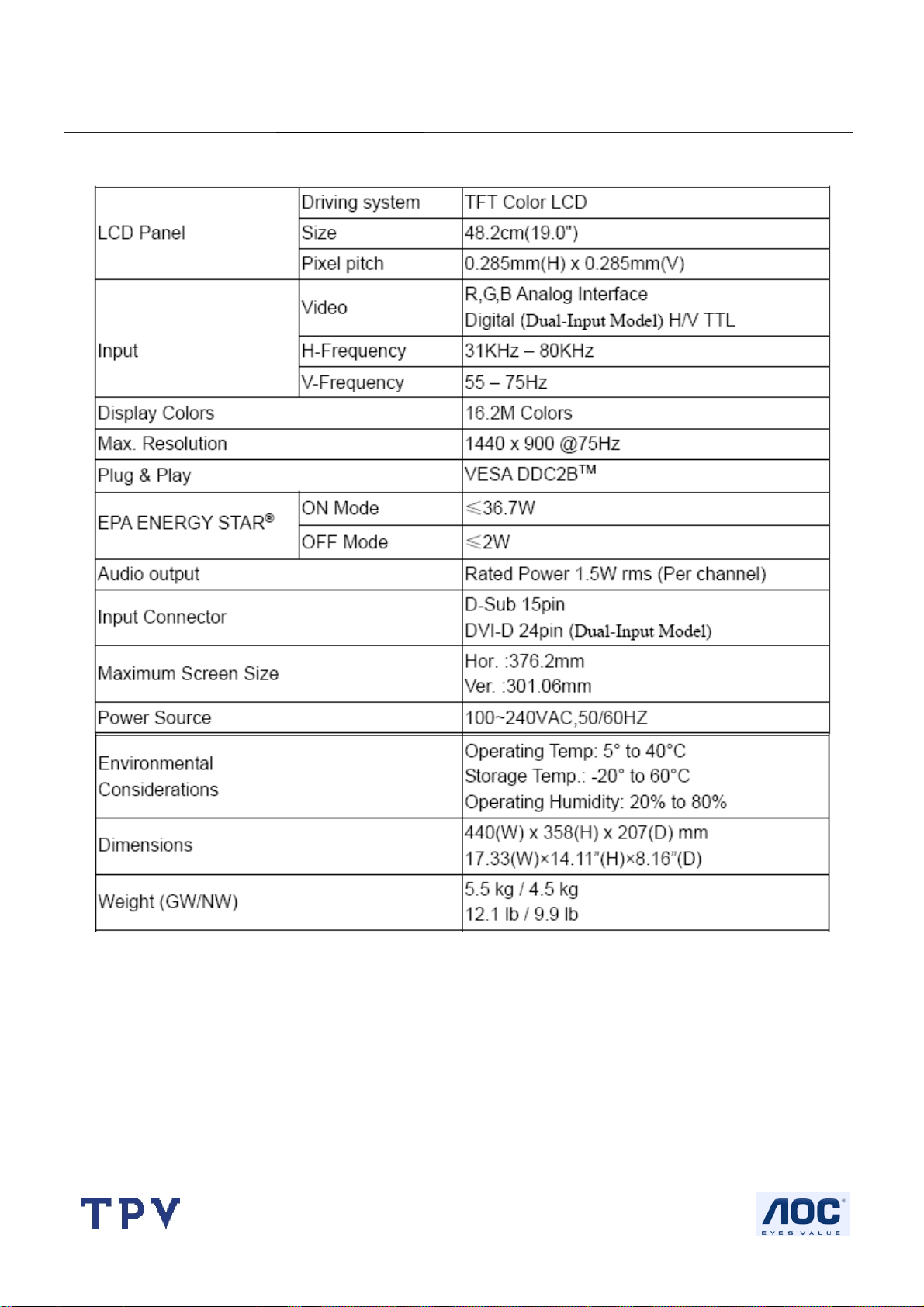

1. Monitor Specifications

http://www.wjel.net

4

Page 5

19" LCD Color Monitor I-INC AH191D

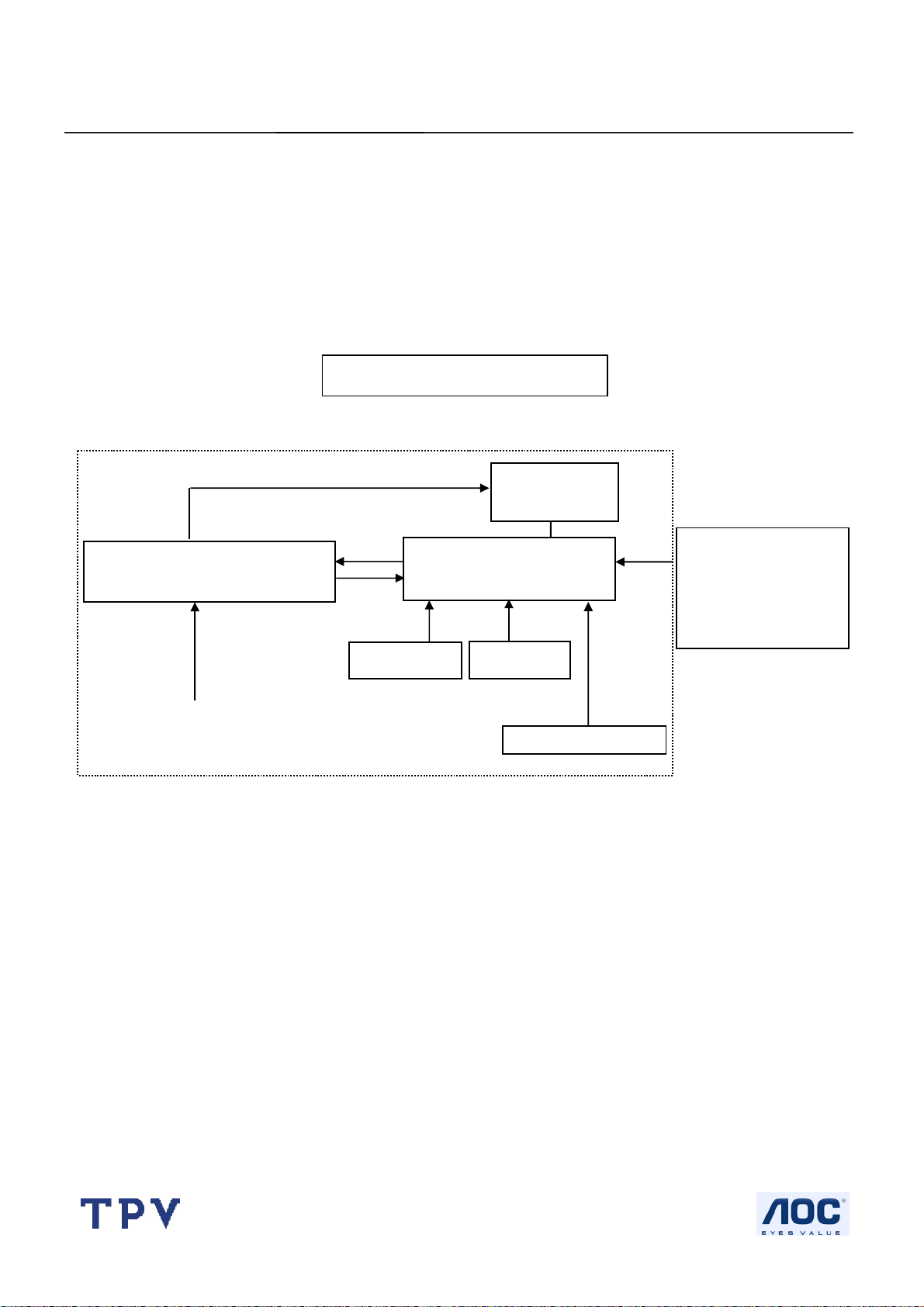

2. LCD Monitor Description

The LCD MONITOR will contain a main board, a power board, an audio board and a key board which house the flat

panel control logic, brightness control logic and DDC.

The power board will provide AC to DC Inverter voltage to drive the backlight of panel and the main board chips each

voltage.

Power board

(Include: adapter, inverter)

CCFL Drive.

Monitor Block Diagram

Flat Panel and

CCFL backlight

Main board

Audio board

Key board

RS232 Connector

For white balance

adjustment in factory

mode

Video signal, DDC

AC-IN

100V-240V

HOST Computer

http://www.wjel.net

5

Page 6

19" LCD Color Monitor I-INC AH191D

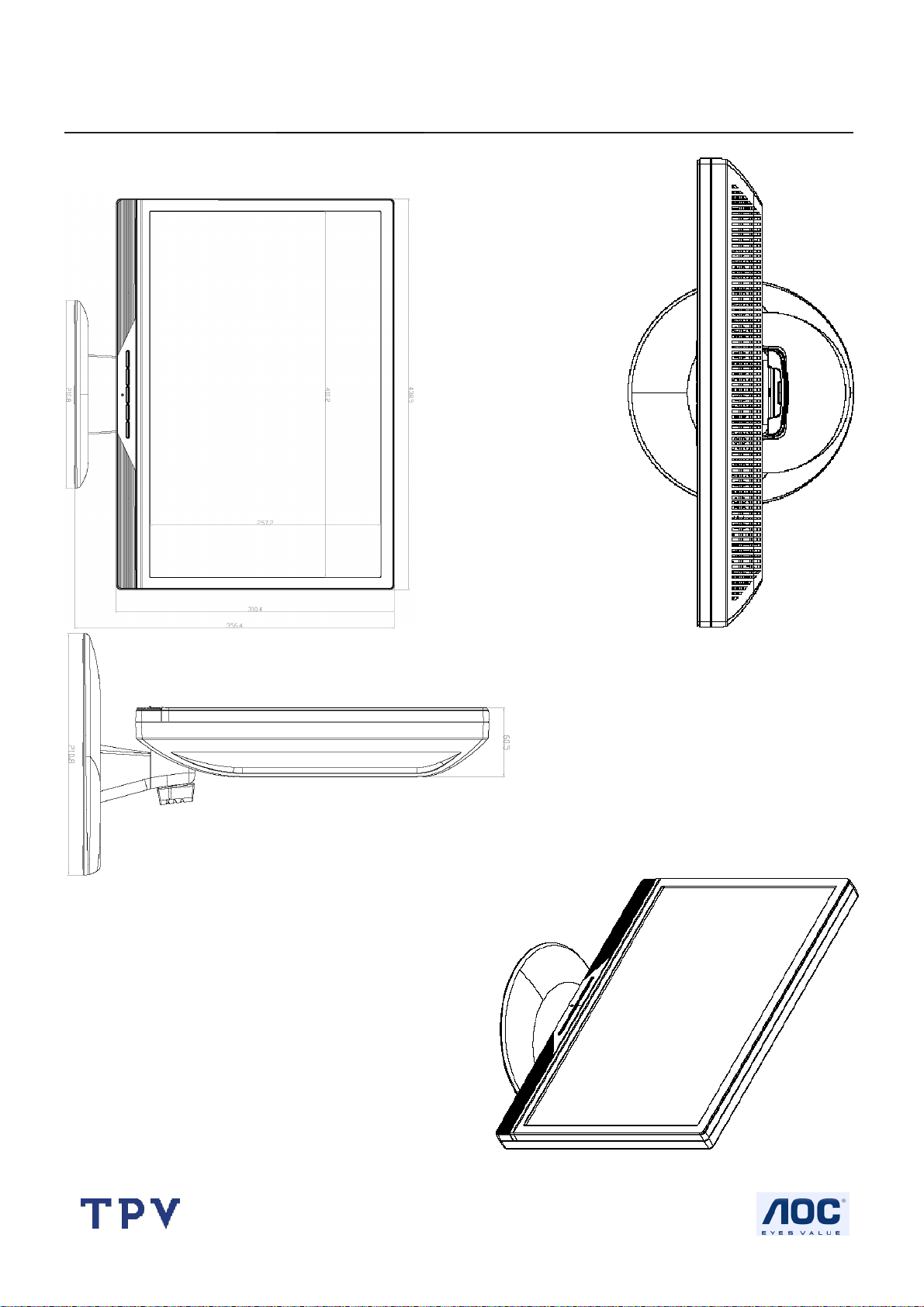

Dimensions

http://www.wjel.net

6

Page 7

19" LCD Color Monitor I-INC AH191D

3. Operating Instructions

3.1 General Instructions

Press the power button to turn the monitor on or off. The control buttons are located in the front of the monitor.

By changing these settings, the picture can be adjusted to your personal preferences.

The power cord should be connected.

-

Connect the video cable from the monitor to the video card.

-

Press the power button to turn on the monitor, the power indicator will light up.

-

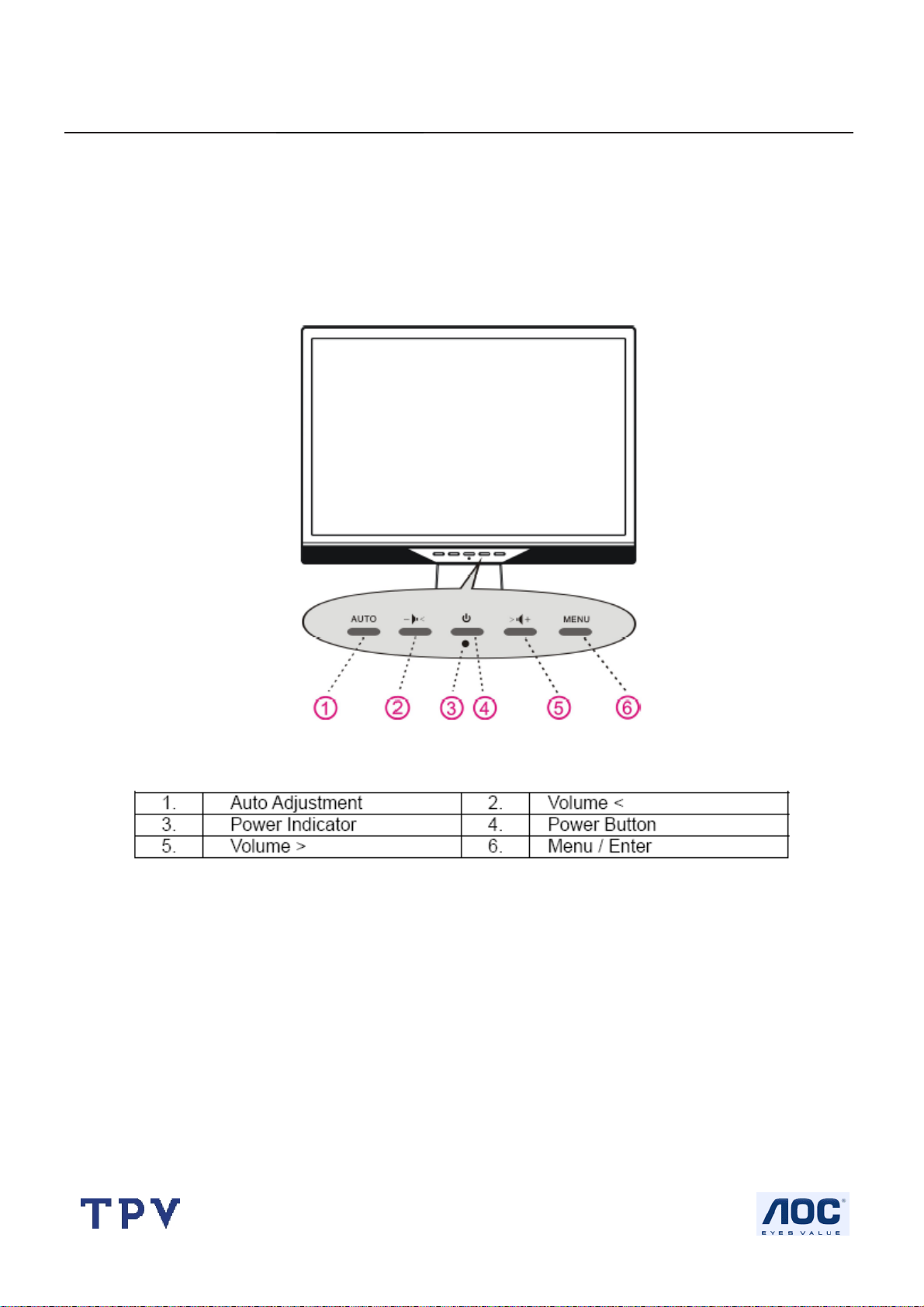

3.2 Control Buttons

http://www.wjel.net

7

Page 8

19" LCD Color Monitor I-INC AH191D

FRONT PANEL CONTROL

• Power Button:

Press this button to switch ON/OFF of monitor’s power.

• Power Indicator:

Green — Power On mode.

Orange — Off mode.

• MENU / ENTER:

1. Activate the OSD menu or adjust the function settings and confirmation or

2. Exit OSD menu when in volume OSD status.

• Volume < >:

1. Activates the volume control when the OSD is OFF.

2. Navigate through adjustment icons when OSD is ON or adjust a function when function is activated.

• Auto Adjust button:

When OSD menu is in off status, press this button to activate the Auto Adjustment function.

(The Auto Adjustment function is used to optimized the H-Position, V-Position, Clock and Focus.)

NOTES:

• Do not install the monitor in a location near heat sources such as radiators or air dusts, or in a place subject to direct

sunlight, or excessive dust or mechanical vibration or shock.

• Save the original shipping box and packing materials, as they will come in handy if you ever have to ship your monitor.

• For maximum protection, repackage your monitor as it was originally packed at the factory.

• To keep the monitor looking new, periodically clean it with a soft cloth. Stubborn stains may be removed with a cloth

lightly dampened with a mild detergent solution. Never use strong solvents such as thinner, benzene, or abrasive

cleaners, since these will damage the cabinet. As a safety precaution, always unplug the monitor before cleaning it.

http://www.wjel.net

8

Page 9

19" LCD Color Monitor I-INC AH191D

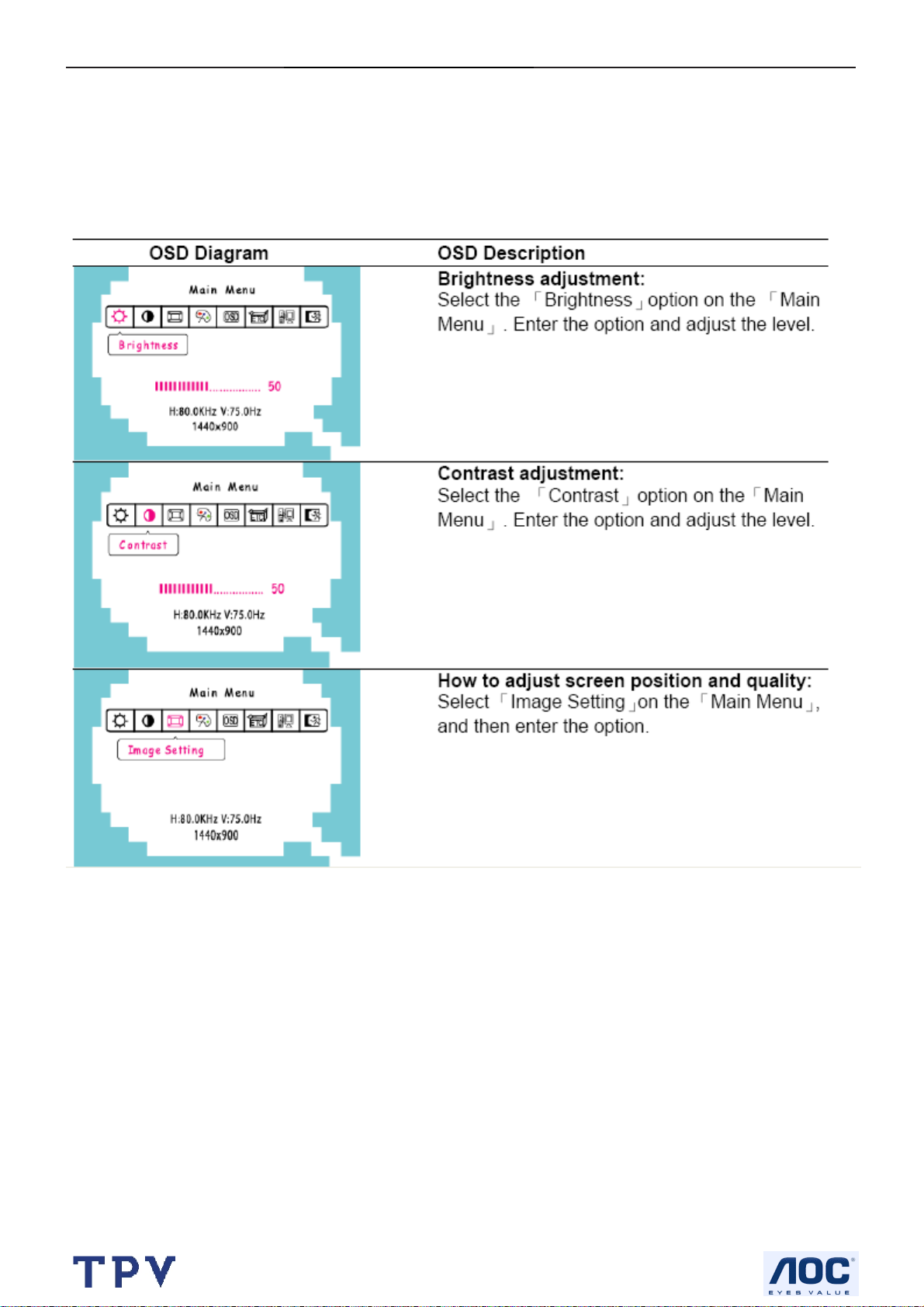

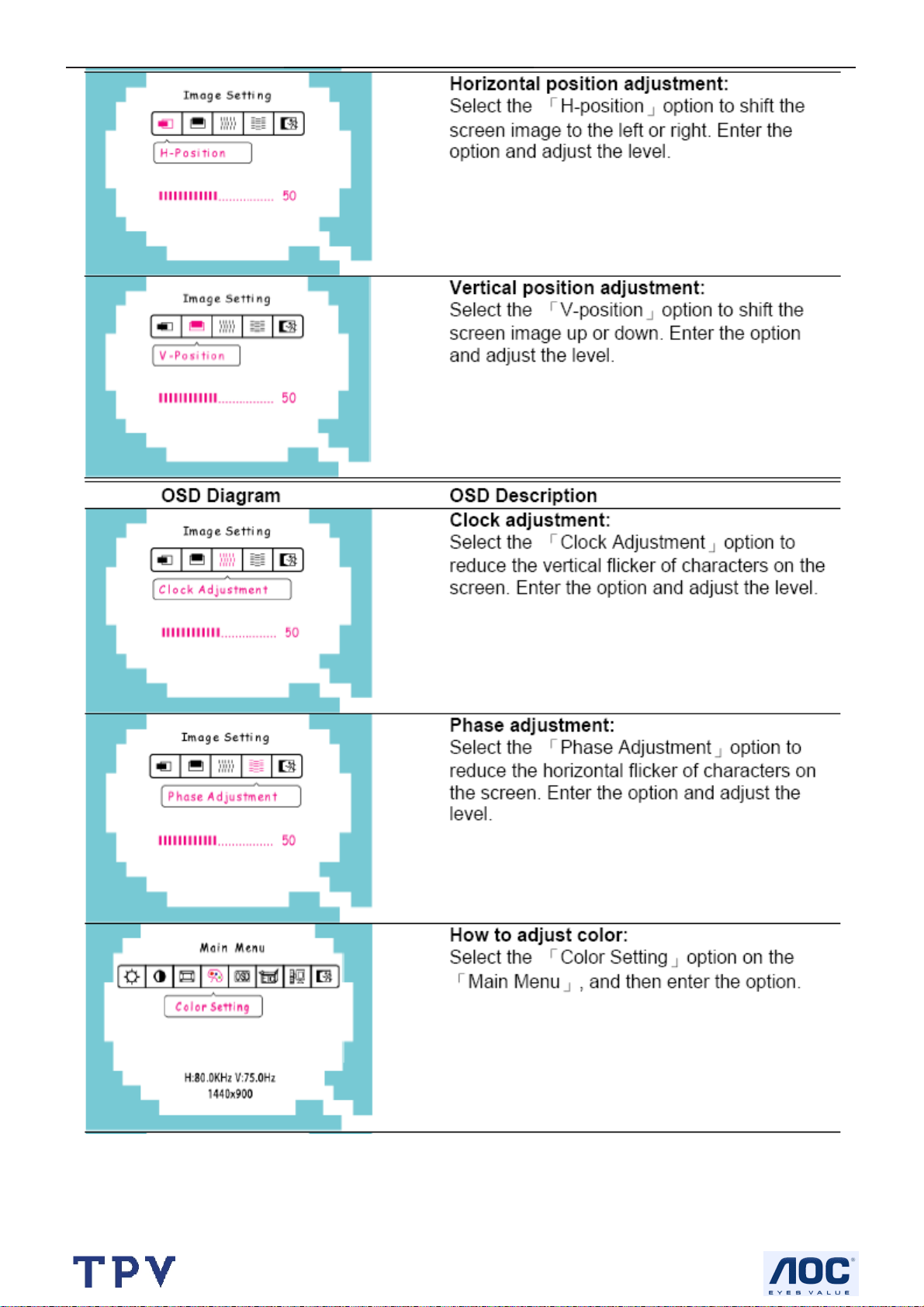

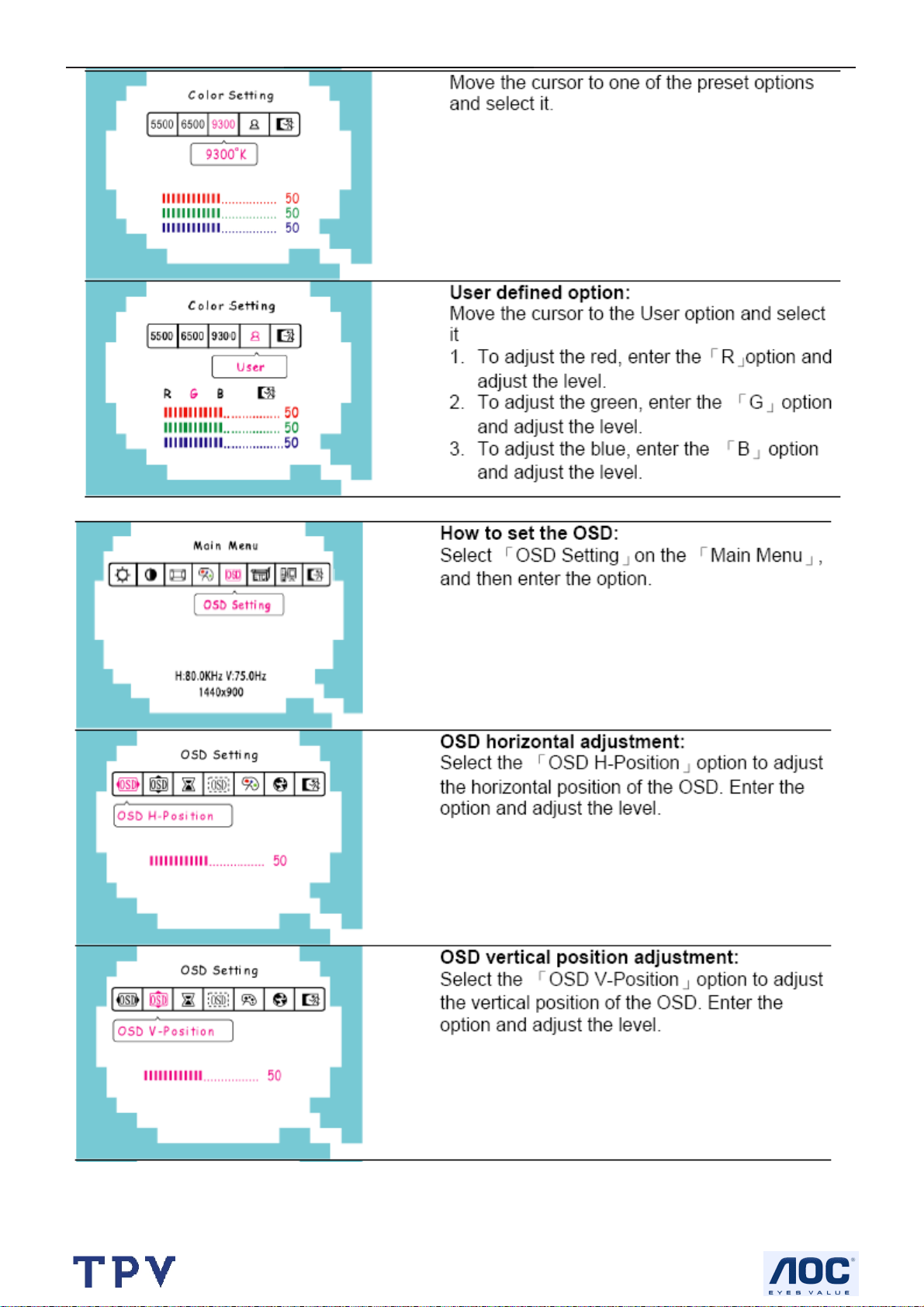

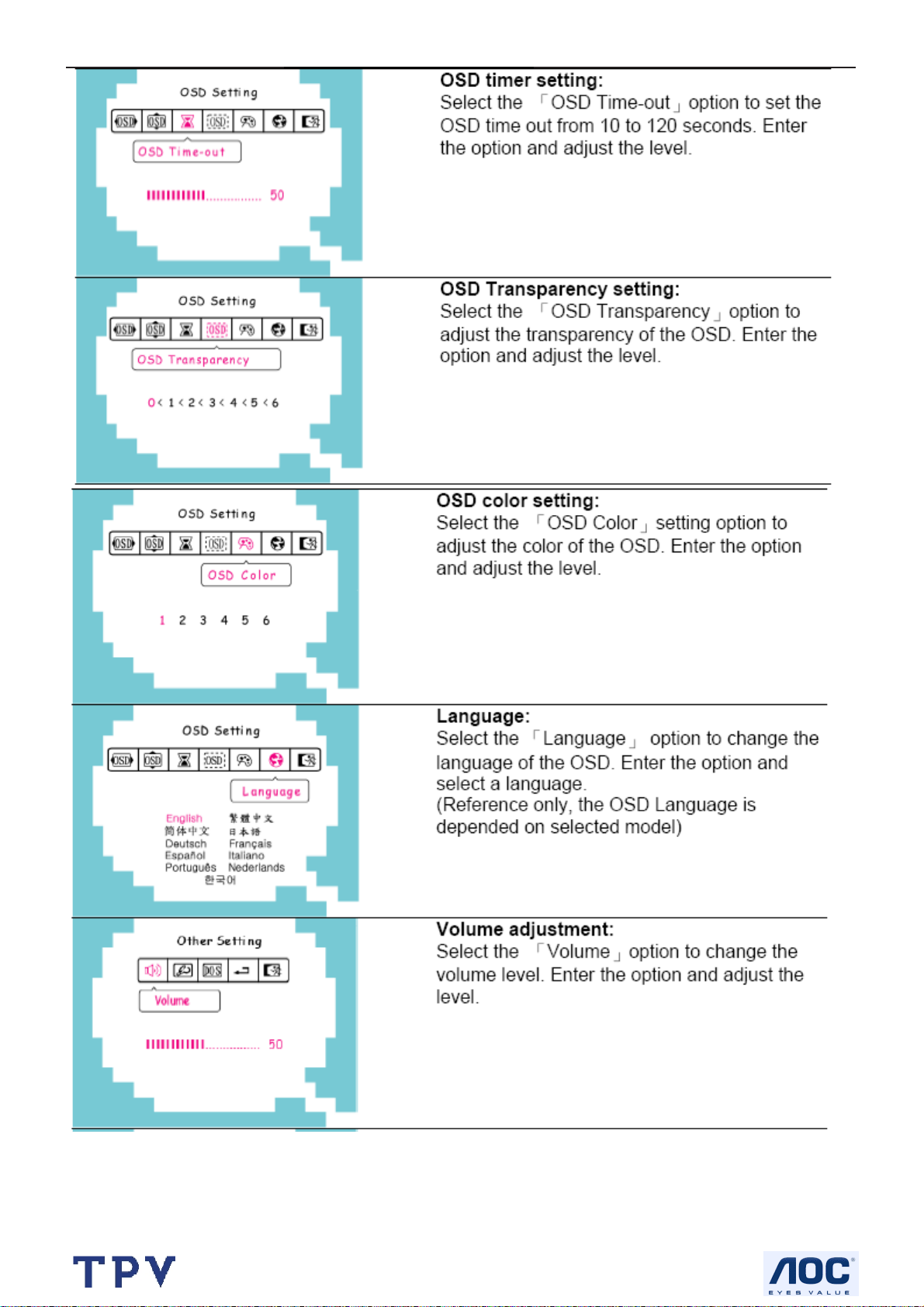

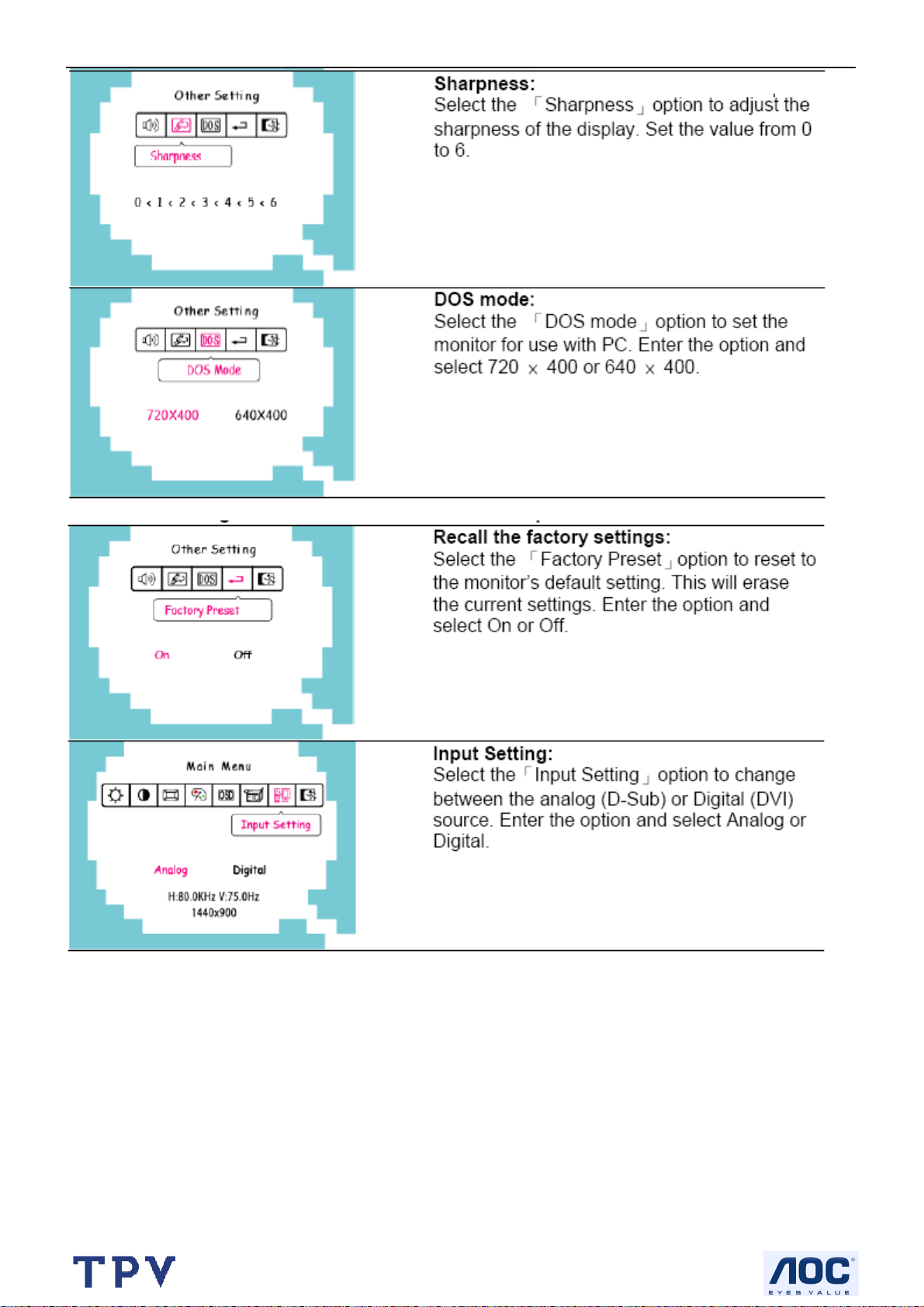

3.3 Adjusting the Picture

Adjustment steps:

1. Press the MENU-button to activate the OSD window.

2. Press < or > to select the desired function.

3. Press the MENU-button to select the function that you want to adjust.

4. Press < or > to change the settings of the current function.

5. To exit and save, select the exit function, or leave the monitor alone for 10 seconds. If you want to adjust any

other function, repeat steps 2-4.

http://www.wjel.net

9

Page 10

19" LCD Color Monitor I-INC AH191D

http://www.wjel.net

10

Page 11

19" LCD Color Monitor I-INC AH191D

http://www.wjel.net

11

Page 12

19" LCD Color Monitor I-INC AH191D

http://www.wjel.net

12

Page 13

19" LCD Color Monitor I-INC AH191D

http://www.wjel.net

13

Page 14

19" LCD Color Monitor I-INC AH191D

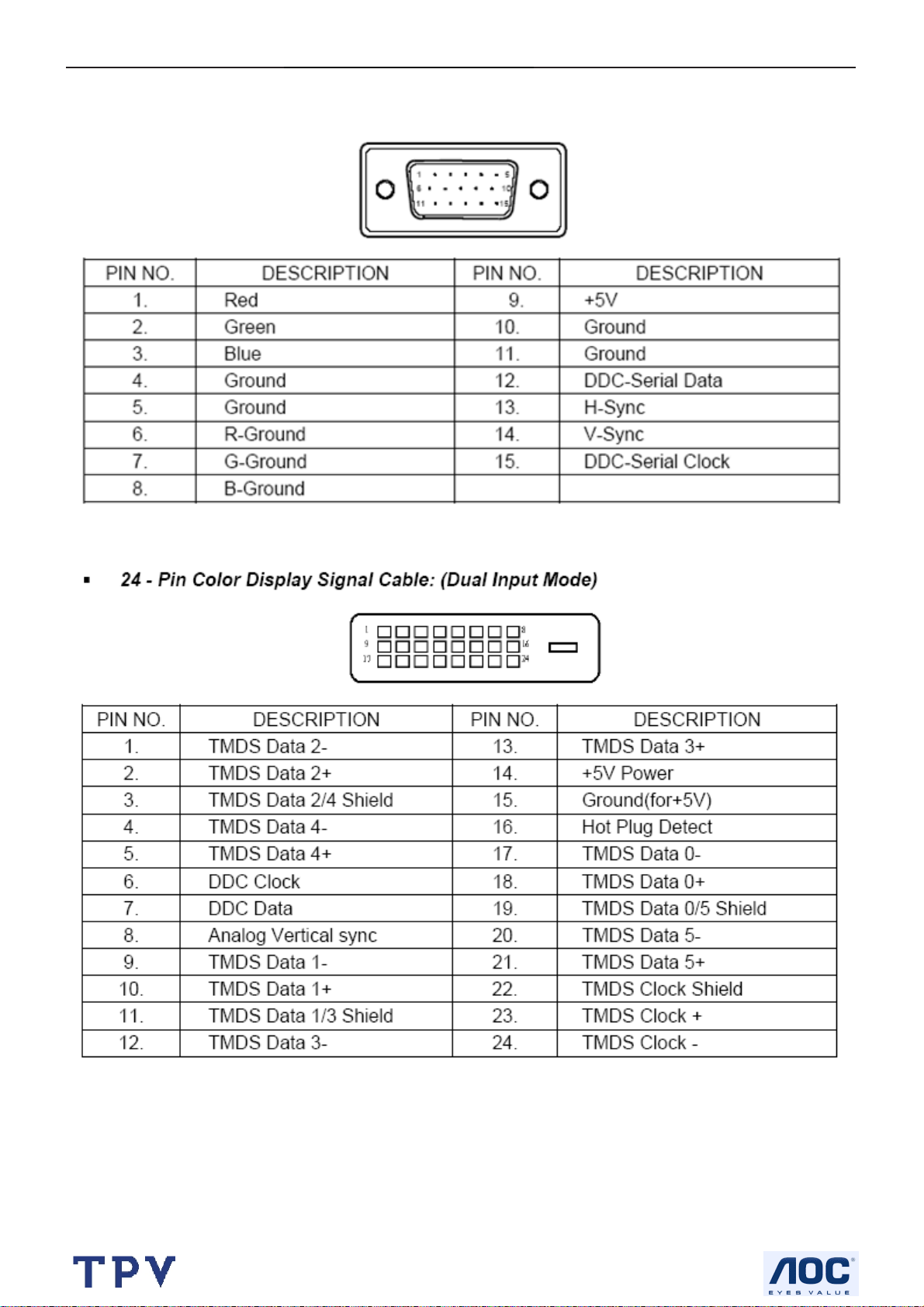

4. Input/Output Specification

4.1 Input Signal Connector

http://www.wjel.net

14

Page 15

19" LCD Color Monitor I-INC AH191D

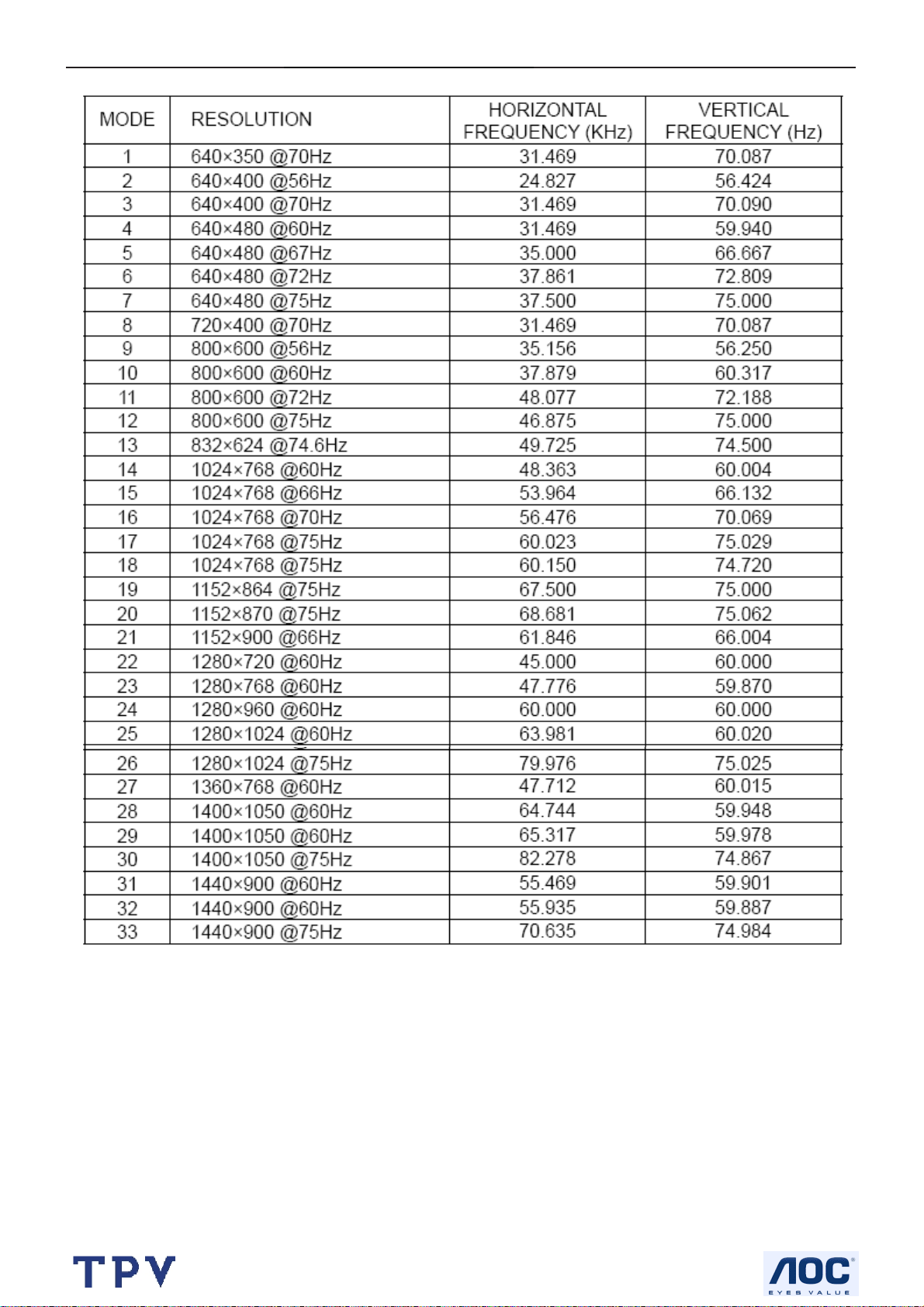

4.2 Factory Preset Display Modes

http://www.wjel.net

15

Page 16

19" LCD Color Monitor I-INC AH191D

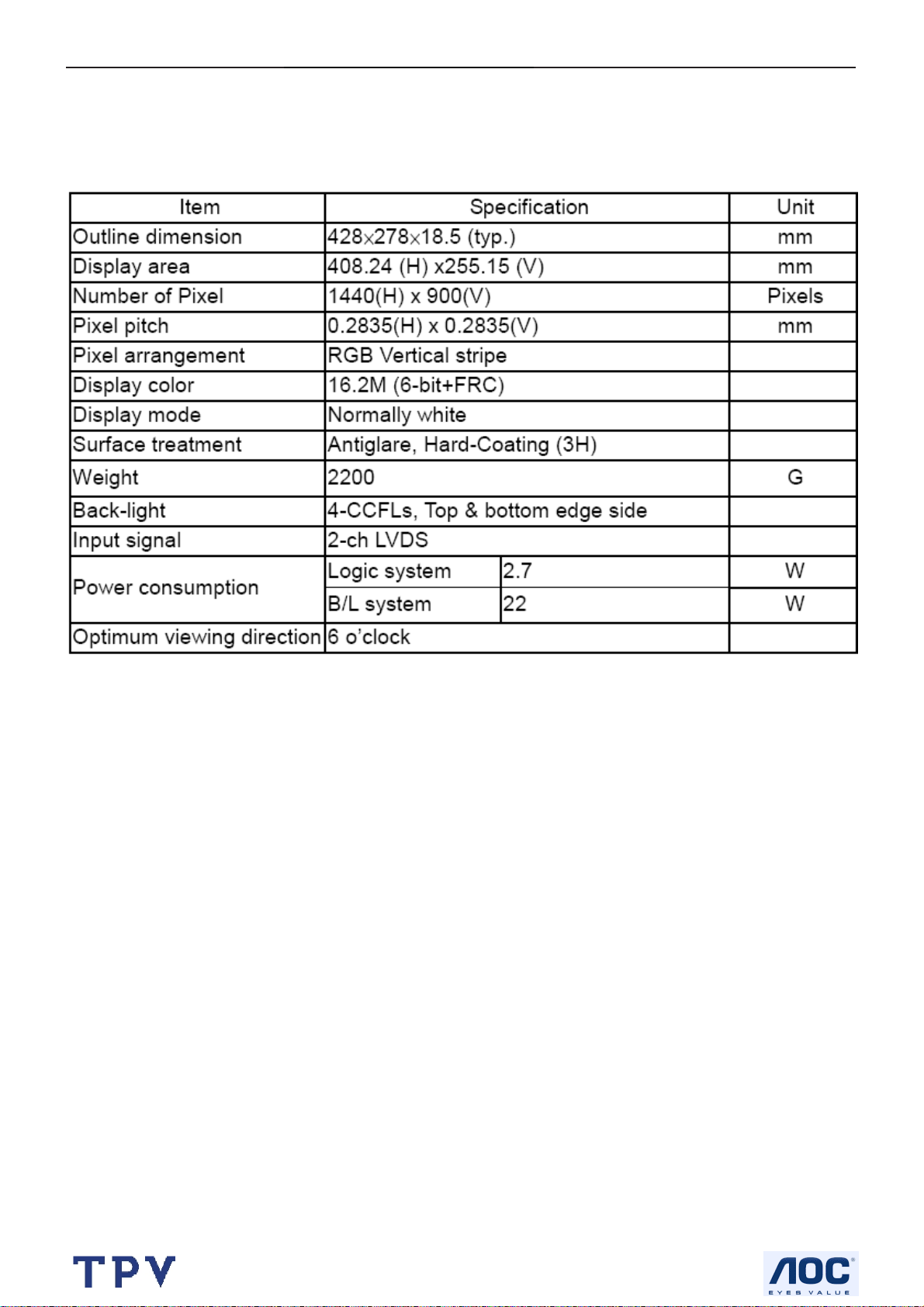

4.4 Panel Specification

HannStar Display model HSD190MGW1-A00 is a color active matrix thin film transistor (TFT) liquid crystal display

(LCD) that uses amorphous silicon TFT as a switching device. This model is composed of a TFT LCD panel, the

voltage reference, common voltage, DC-DC converter, column, and row driver circuit. This TFT LCD has a 19-inch

diagonally measured active display area with WXGA+ resolution (900 vertical by 1440 horizontal pixel array).

4.4.1 Display Characteristics

http://www.wjel.net

16

Page 17

19" LCD Color Monitor I-INC AH191D

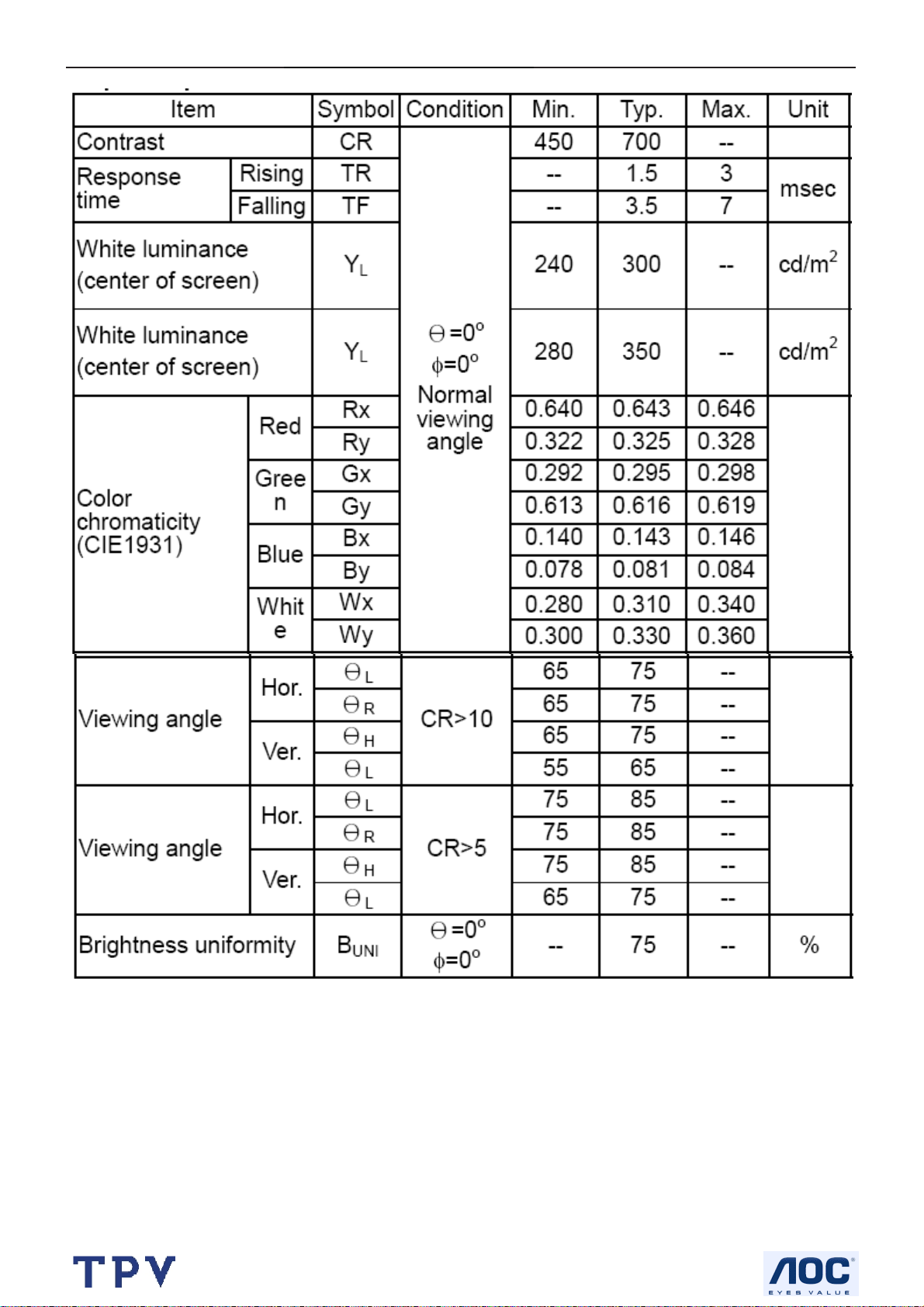

4.4.2 Optical Characteristics

http://www.wjel.net

17

Page 18

19" LCD Color Monitor I-INC AH191D

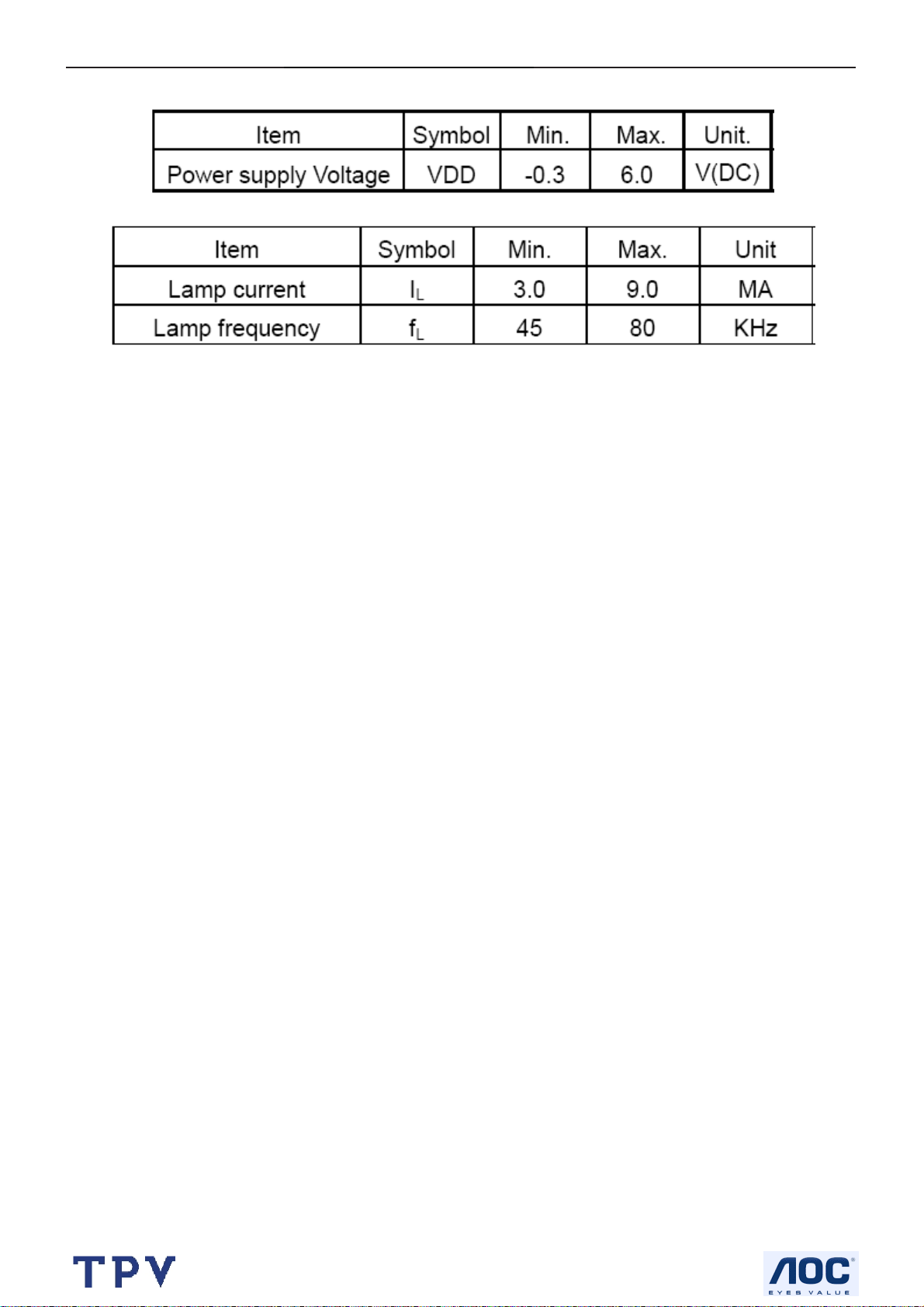

4.4.3 Parameter guide line for CCFL Inverter

TFT LCD Module:

Back Light Unit:

http://www.wjel.net

18

Page 19

19" LCD Color Monitor I-INC AH191D

5. Block Diagram

5.1 Software Flow Chat

1

2

N

4

5

Y

6

7

Y

N

N

3

9

10

Y

N

12

Y

http://www.wjel.net

14

18

N

19

N

11

13

15

17

N

Y

N

Y

16

Y

19

Page 20

19" LCD Color Monitor I-INC AH191D

1) MCU initialize.

2) Is the EPROM blank?

3) Program the EPROM by default values.

4) Get the PWM value of brightness from EPROM.

5) Is the power key pressed?

6) Clear all global flags.

7) Are the AUTO and SELECT keys pressed?

8) Enter factory mode.

9) Save the power key status into EPROM.

Turn on the LED and set it to green color.

Scalar initializes.

10) In standby mode?

11) Update the lifetime of back light.

12) Check the analog port, are there any signals coming?

13) Does the scalar send out an interrupt request?

14) Wake up the scalar.

15) Are there any signals coming from analog port?

16) Display "No connection Check Signal Cable" message. And go into standby mode after the message

disappear.

17) Program the scalar to be able to show the coming mode.

18) Process the OSD display.

19) Read the keyboard. Is the power key pressed?

http://www.wjel.net

20

Page 21

19" LCD Color Monitor I-INC AH191D

5.2 Electric Block Diagram

5.2.1 Main Board

Crystal (14.318MHz)

(X401)

EEPROM

M24C16

(U403)

Scalar TSUM56AK

(Include MCU, ADC, OSD)

(U401)

LCD interface

(CN101)

H sync

V sync

RGB

Digital

Video

Signal

D-Sub

Connector

(CN405)

DVI

Connector

(CN406)

EEPROM

M24C02

(U404)

EEPROM

M24C02

(U405)

http://www.wjel.net

21

Page 22

19" LCD Color Monitor I-INC AH191D

5.2.2 Inverter / Power Board

AC inlet Filter

Rectifier and

filter

Start circuit R904, R931, R938

Switching circuit

PWM control

IC&MOSFET

On/off control

Start circuit

PWM control IC

Transform

er

OVP/OCP circuit

Push-pull

circuit

Rectifier and

filter D908,

D909

To main board

Feedback

circuit IC902,

IC903

LC resonant

12V/5V

12V

Lamp

Dimming control

Feedback circuit

http://www.wjel.net

22

Page 23

19" LCD Color Monitor I-INC AH191D

6. Schematic

6.1 Main Board

TSUM16AWK SCHEMATIC

VCC3.3

XGA/SXGA

B3

+5V

+5V

RIN

GNDR

GIN

GNDG

SOG

BIN

GNDB

HSYNC

VSYN C

DDCA_SDA

DDCA_SCL

DET_VGA

DDC_WP

CLK+

CLK-

DDCD_SDA

DDCD_SCL

DET_DVI

R+

R-

G+

GB+

B-

B4

RIN

GNDR

GIN

GNDG

SOG

BIN

GNDB

HSYNC

VSYN C

DDCA_SDA

DDCA_SCL

DET_VGA

DDC_WP

R+

RG+

GB+

BCLK+

CLKDDCD_SDA

DDCD_SCL

DET_DVI

LVDS OUTPUT

VCC3. 3

VCC1.8

VCC1.8

Vcc3. 3

+5V

+12V

+5V

+12V

3.INP UT

B5

PA[0.. 7]

PA[8.. 13]

PA[14..19]

+12V

+3V3

VCC1.8

+5V

B2

+12V

+3V3

VCC1.8

+5V

VCC3.3

on_BACKLIGHT

on_Panel

on_PANEL_12V

VCTRL

Adj_BACKLIGHT

VLCD

VLCD_12V

VLCD VLCD_12V

http://www.wjel.net

on_BACKLIGHT

on_Panel

on_PANEL_12V

VCTRL

Adj_BACKLIGHT

4.SCALER

PB[0.. 5]

PB[6.. 11]

PB[12..23]

GPO[0.. 4]

ESP

OSP

2.POW ER

PA[0.. 7]

PA[8.. 13]

PA[14.. 19]

PB[0.. 5]

PB[6.. 11]

PB[12.. 23]

GPO[0.. 4]

PA[0.. 7]

PA[8.. 13]

PA[14.. 19]

PB[0.. 5]

PB[6.. 11]

PB[12.. 23]

GPO[0.. 4]

ESP

OSP

VLCD_12V

VLCD

VLCD

VLCD_12V

5.PANEL INTERFACE

Tit le

Size Document Number Rev

B

Date: Sheet

715G1558-C-BJ.DSN

TOP

15Friday , July 21, 2006

A

of

23

Page 24

19" LCD Color Monitor I-INC AH191D

+12V

U701

+5V

C701

NC

L701

+12V

4

1 2

120 OHM

C706

C707

+

0.1uF

+5V

+5V3,4

1 2

C709

0.1uF

adj_BACKLIGH T

100uF/25V

L702

120 OHM

NC/ LT1117-18

3 2

VI VO

GND

GND

GND

GND

C710

+

100uF/25V

R706

4

R707

4.7K 1/16W

SOT-223

4

VO

GND

1

BL_ADJ(DC)

R31

0V ~ 3.3V

4.7K

0V ~ 5V

4.7K

C32

R31

BL_ADJ

47

P W M

D C

N.C

4K7

1uF

CN701

1

3

5

7

9

11

CONN

+5V

NC

C51

1UF

1UF

2

4

6

8

10

12

R701

1K 1/16W

Q701

PMBS3904

BL_ON

BL_ADJ

GND

GND

R705

+

R32

0

X

4.7K 1/16W

C703

+3V3

+3V3

+

C704

NC

22uF/50V

C708

R33

X

4.7K

1uF

MMBT3904

1K 1/10W

R740

NC

+

Q4

X

R739

C723

22uF/50V

+5V

R708

10K 1/16W

C711

0.1uF

Q703

PMBS3904

D704(SSM12L) Vf=0.38V and If=1A.

So when system power on, the

system loading is about 400mA

(3.3V is about 200mA and 1.8V is

about 200mA), So D35 changed

from 1N4148(or BAT42) to

SSM12L(schottky diode).

P.S: The 1N4148 Vf=0.7V~1V can't meet

LDO spec. The BAT42, Vf is OK but the

If=200mA(forward current) can not

meet current spec.

R29

X

1K

H1

9

9

123

123

R710 NC

R712 4.7K 1/16W

H2

678

5

678

5

4

4

TP

+5V

9

9

123

123

R711

10K 1/ 16W

678

678

5

4

TP

on_BACKLIGH T 4

H3

5

4

678

5

9

678

9

5

4

4

123

TP

123

D702

SMAL140

R704

100 1/16W

del

+5V

+5V3,4

D704

SMAL140

C713

0.1uF

U702

3

1

AIC1084-33PM

Q702

PZT2907A

TO-263

VIN

VOUT

ADJ

del

D701

SMAL140

Recommond to used "Blue" parts circuit

for VCC1.8V if you want to suppoert DDC

function when system power off

2

R702

51 1/16W

C702

+

22uF/50V

R703

2K 1/16W

VCTRL 4

VCC3. 3

C712

+

100uF/25V

VCC1.8

VCC1. 8 4

VCC3.3 4

VCC3. 3

VCC3.3 4

C714

0.1uF

For LVDS PANEL

R733

NC

on_PANEL

4

R734

10K 1/16W

R735

4.7K 1/16W

C721

0.1uF

R716

NC

+3V3

+5V

Q708

PMBS3904

R717

10K 1/16W

R723 51K 1/16W

C715

0.022uF

Q706

PMBS3906

0.1uF

C727

C724

NC

1

VLCD_12V

32

Q705

NC

+

NC

C719

+5V

VLCD_12V 5

+12V

R730

NC

R728

NC

R731

NC

Tit le

Size Docum ent Number Rev

Custom

Date: Sheet

Power

715G1558-C-BJ.DSN

VLCD

Q704

AO3401L

+

C717

22uF/50V

VLCD 5

+5V

+3V3

R722

R721

NC

0 1/16W

R727

NC

on_PANEL_12V

For RSDS and Panel VCC=12V

+5V

+12V

R720

R736

NC

NC

R737 NC/ 4K7

C722

NC

4

PMBS3904

Q709

+5V

+12V

R719

R729

NC

NC

R724 51K

C716

NC

Q707

NC

http://www.wjel.net

24

35Friday , July 21, 2006

A

of

Page 25

19" LCD Color Monitor I-INC AH191D

CN406

RGB GND

HSYNC

VSYN C

SYNC GND

DDC SCL

DDC SDA

1/3shield

2/4shield

0/5shield

clk shield

DAT0+

DAT0-

DAT1+

DAT1-

DAT2+

DAT2-

DAT3+

DAT3-

DAT4+

DAT4-

DAT5+

DAT5-

JACK DVI

1716

11

12

13

14

15

HSI

VSI

D408

MLL5232B 5.6V

25

R

26

G

27

B

29

28

8

15

6

7

14

+5V

16

HPD

11

3

19

22

18

17

10

9

2

1

13

12

5

4

21

20

23

clk+

24

clk-

CN405

DB15

RED+

1

6

REDGREEN+

2

GREEN-

7

BLUE+

3

8

BLUE-

4

VGA5V

9

5

VGA_CON

10

MLL5232B 5.6V

SCL_DVI

SDA_DVI

DVI5V

HPD

DAT0+

DAT0DAT1+

DAT1DAT2+

DAT2-

DCLK+

DCLK-

R491

10K 1/ 16W

D406

FB409 430 OHM

D409

MLL5232B 5.6V

R472

NC

3

D417

BAV99

C447

1

2

0.1uF

2

3

D403

BAV99

C439 0.1uF

2

+5V

R471

10K 1/ 16W

R458 100 1/ 16W

D426

LL5232B 5.6V 5%

3

D418

BAV99

C448

1

0.1uF

PC5V

1

2

3

C440 0.1uF

2

3

D419

BAV99

C449

1

0.1uF

D404

BAV99

C441 0.1uF

1

2

R448

2.2K 1/16W

D414

LL5232B 5.6V 5%

3

D420

BAV99

C450

2

0.1uF

FB410 0 1/ 16W

FB411 0 1/ 16W

FB412 0 1/ 16W

R438

75 1/ 16W

3

D405

BAV99

ESD 5V

1

R446 1K 1/ 16W

C442

R449

22pF

2.2K 1/16W

DET_DVI 4

R455 100 1/ 16W

R456 100 1/ 16W

D415

LL5232B 5.6V 5%

3

3

D421

BAV99

http://www.wjel.net

C451

1

2

0.1uF

C452

2

1

0.1uF

D422

BAV99

ESD5V

1

R439

75 1/ 16W

R447 1K 1/ 16W

C443

22pF

D416

LL5232B 5.6V 5%

3

D423

BAV99

C453

1

2

0.1uF

R440

75 1/ 16W

D411

MLL5232B 5.6V

DVI5V

C445

0.1uF

R462 10 1/ 16W

R463 10 1/ 16W

R464 10 1/ 16W

R465 10 1/ 16W

R466 10 1/ 16W

R467 10 1/ 16W

R468 10 1/ 16W

R469 10 1/ 16W

3

D424

BAV99

C454

1

2

0.1uF

R434 56 1/ 16W

R435 56 1/ 16W

R436 56 1/ 16W

R437 470 1/ 16W

R441 100 1/ 16W

R442 100 1/ 16W

R443 100 1/ 16W

+5V

R444

10K 1/ 16W

D410

MLL5232B 5.6V

D412

MLL5232B 5.6V

R457

10K 1/ 16W

+5V 2,4

R445 100 1/ 16W

B+ 4

B- 4

G+ 4

G- 4

R+ 4

R- 4

CLK+ 4

CLK- 4

ESD 5V

C432 0.047uF

C433 0.047uF

C434 0.047uF

C435 0.047uF

C436 0.047uF

C437 0.047uF

C438 0.047uF

SCL_VGA

SDA_VGA

+5V

R470

D425

1 2

DDCA_SDA4

DDCA_SCL4

DDCD_SDA4

DDCD_SCL4

10K 1/10W

RLZ36B

RIN 4

GIN 4

BIN 4

SOG 4

GNDR 4

GNDG 4

GNDB 4

DET_VGA 4

HSYNC 4

VSYN C 4

R450

10K 1/ 16W

R453 100 1/ 16W

R454 100 1/ 16W

R459

10K 1/ 16W

+5V

PC5V

1

2

D407

BAV70

R451

10K 1/ 16W

R460

10K 1/ 16W

3

R452

10K

+5V

R461

10K

Tit le

Size Docum ent Num ber Rev

B

Date: Sheet

U404

8

7

6

DVI5V

1

2

3

R473

NC

VCC

WP

SCL

M24C02

D413

BAV70

U405

8

7

6

M24C02

VCC

WP

SCL

A0

A1

A2

GNDSDA

A0

A1

A2

GNDSDA

C444

1

0.22uF

2

3

45

DDC_WP 4

C446

1

0.22uF

2

3

45

DDC_WP 4

Input

715G1558-C-BJ.DSN

45Friday , July 21, 2006

of

A

25

Page 26

19" LCD Color Monitor I-INC AH191D

VCC3.3

R403 390 1%

C401

2

SDO

1

CE#

6

SCK

R492

20

R493

20

R415

59

58

56

55

57

54

53

63

64

65

66

39

40

42

43

45

46

48

49

36

37

51

62

0.1uF

61

70

71

72

73

19

32

33

102

104

R416

10K 1/16W

+5V

R430

1K 1/16W

Q404

PMBS3904

DDCA_SDA3

DDCA_SCL3

+5V

+

C418

10uF/50V

R404

10K 1/16W NC

+5V

Reset

Circuit

C417

0.22uF

10K 1/16W

U406

R489

10K 1/16W

VCC3.3

R486

NC

R487

10K 1/16W

23

RSTVCC

GND

ASM810MEURF-T

1

R490

GNDR3

GNDG3

GNDB3

HSYNC3

VSYNC3

DDCD_SDA3

DDCD_SCL3

AVDD

U402

8

VDD

7

HOLD#

3

WP#

4 5

VSS SD I

WP

C421 22pF

X401

14.318MHz

C423 22pF

VCC3.3

R407 NC

R410 NC

RIN3

GIN3

SOG3

BIN3

R+3

R-3

G+3

G-3

B+3

B-3

CLK+3

CLK-3

SST25VF010-20-4C-SAE

10K 1/16W

R431 NC

R433 4.7K 1/16W

VDVI

VMPLL

44

50

AVDD_DVI

AVDD_DVI

RIN0P

RIN0M

GIN0P

GIN0M

SOGIN0

BIN0P

BIN0M

HSYNC0

VSYNC0

DDCA_SDA

DDCA_SCL

R+

RG+

GB+

BCK+

CKDDCD_SDA

DDCD_SCL

REXT

REFP

REFM

SDO

CSZ

SCK

SDI

RST

XIN

XOU T

MODE [0]

MODE [1]

R432 10K 1/16W

VPLL

AVDD

52344

60

BYPASS

AVDD_PLL

AVDD_ADC

AVDD_MPLL

RSDS/LVDS/TTL

GND

GND

GND

GND

41

47

3896116

13

C431

1uF/25V

VDDP

67

14

95

103

VDDP

VDDP

VDDP

VDDP

GND

GND

OUT-L+

OUT-L-Volume

VDDC

12

68

97

115

117

VDDP

VDDC

VDDC

VDDC

VDDC

NC/LVACKP/NC

NC/LVACKM/NC

RA1P/LVA2P/RA2

RA1N/ LVA2M/RA3

RA2P/LVA1P/RA4

RA2N/ LVA1M/RA5

RA3P/LVA0P/RA6

RA3N/ LVA0M/RA7

GA3P/LVA3P/GA6

GA3N/LV A3M/GA7

RB1P/NC/RB2

RB1N/NC/RB3

RB2P/NC/RB4

RB2N/NC/RB5

RB3P/NC/RB6

RB3N/NC/RB7

GB1P/NC/GB2

GB1N/NC/ GB3

GB2P/NC/GB4

GB2N/NC/ GB5

GB3P/NC/GB6

GB3N/NC/ GB7

CLKAP/LVB3P/ LHSYN C

CLKAN/LVB3M/LVSYNC

CLKBP/LVBC KP/LCK_ODD

CLKBN/L VBCKM/LDE

NC/LVB2 P/NC

NC/LVB2M/NC

BB1P/LVB1P/BB2

BB1N/LVB1M/BB3

BB2P/LVB0P/BB4

BB2N/LVB0M/BB5

BB3P/NC/BB6

BB3N/NC/BB7

GPIO_P22

GPIO_P23

GPIO_P03

GPIO_P16/PWM2

GPIO_P15/PWM0

PWM2/GPIO_P24

GPIO_P27/PWM1

GPIO_P12

PWM1/GPIO_P25

GPIO_P00/SAR1

GPIO_P01/SAR2

GPIO_P02/SAR3

GPIO_P06

GPIO_P07

PWM0/GPIO_P26

GPIO_P13

GPIO_P14

GPIO_P10/I2C_MCL

GPIO_P11/I2C_MDA

FB407

600 OHM

FB408

600 OHM

CN404

1

3

5

7

9

11

13

CONN

VDDC

FB401

VCC1.8

VCC1.82

11

VCTRL

107

PA0

108

PA1

109

PA2

110

PA3

PA4

111

PA5

112

PA6

113

PA7

114

PA8

98

NC

99

PA9

NC

100

PA10

NC

PA11

101

NC

105

PA12

106

PA13

89

PA14

NC

PA15

90

NC

PA16

91

NC

92

PA17

NC

PA18

93

NC

94

PA19

NC

9

PB0

10

PB1

15

PB2

PB3

16

17

PB4

PB5

18

2

PB6

3

PB7

5

PB8

PB9

6

7

PB10

8

PB11

118

PB12

PB13

119

120

PB14

121

PB15

122

PB16

PB17

123

124

PB18

PB19

125

PB20

126

127

PB21

128

PB22

PB23

1

80

ESP

NC

OSP

81

NC

88

GPO0

NC

GPO1

87

NC

86

GPO2

NC

85

GPO3

NC

84

GPO4

NC

83

NC

82

NC

75

74

26

35

69

R488 100R 1/10W

78

79

20

21

22

RSTN

R418 100 1/16W

23

R420 100 1/16W

24

R411 100 1/16W

25

27

R422 4.7K 1/16W

R423 4.7K 1/16W

28

29

30

31

VCC3.3

77

76

R424

10K 1/16W

+12V

+12V 2

+5V

+5V 2,3

R484

10K 1/16W

2

4

6

http://www.wjel.net

8

10

12

OUT-R+

OUT-R-

14

R425

10K 1/16W

R428 100 1/16W

R429 100 1/16W

+5V

R485

10K 1/16W

AUDIO_STBY

AUDIO_MUTE

VCTRL 2

P[0..7]

PA[8..13]

PA[14..19]

PB[0..5]

PB[6..11]

PB[12..23]

GPO[0..4]

WP

KEY1

KEY2

POWER

Volume

AUDIO_MUTE

AUDIO_STBY

R426

10K 1/16W

R427 100 1/16W

Option

PA[0..7] 5

PA[8..13] 5

PA[14..19] 5

PB[0..5] 5

PB[6..11] 5

PB[12..23] 5

ESP 5

OSP 5

GPO[0..4] 5

R405

22K 1/16W

10K 1/16W

on_PANEL_12V 2

DET_DVI 3

DET_VGA 3

on_PANEL 2

on_BACKLIGHT 2

adj_BACKLI GHT 2

U403

8

VCC

7

WP

6

SCL

AT24C16N-10SC-2.7

KEY_B

LED_G

KEY_AUTO

KEY_RI GHT

POWER

OUT-L+

OUT-L-

VCC3.32

DDC_WP 3

Q402

PMBS3904

C422

0.1uF

R406

C425

0.22uF

1

A0

2

A1

3

A2

45

GNDSDA

CN403

1

3

5

7

9

11

13

15

CONN

VCC3.3

R481

R482

NC

NC

Q405

NC

KEY_A

2

LED_A

4

6

KEY_MENU

KEY_LEFT

8

10

12

KEY_C

OUT-R+

14

16

OUT-R-

R483

NC

KEY2

KEY1

LED_G

LED_A

POWER

C426

KEY A

C616

NC

C429

C427

C428

0.1uF

0.1uF

0.1uF

0.1uF

+5V

R412

10K 1/16W

R417 20K 1/16W

C424 0.1uF

3.9K 1/16W

C430

D401

0.1uF

RLZ36B

1 2

VCC3.3

VCC3.32

VCC3.32

+5V 2,3

10K 1/16W

600 OHM

600 OHM

R474

22uF/50V

FB403

R413

VCC3.3

D402

1 2

C403

RLZ36B

+

C404

0.1uF

C408

22uF/50V

VCC3.3

VCC3.3

+5V

R475

3.9K 1/16W

C405

0.1uF

VDDP

+

FB404

600 OHM

FB406

600 OHM

R414

240 1/16W

Q401

PMBS3906

R421 0 1/16W

C406

0.1uF

C409

C411

C410

0.1uF

0.1uF

0.1uF

VDVI

C415

C414

0.1uF

0.1uF

VMPLL

C419

C420

0.1uF

0.1uF

10K 1/16W

LED_G

R476 1K 1/16W

R477 1K 1/16W

Title

Size Document Number Rev

C

Date: Sheet

VCC3.32

C412

0.1uF

R408

C413

0.1uF

VCC3.32

R478 1K 1/16W

R479 1K 1/16W

VCC3.3

+5V

R409

75 1/16W

Q403

PMBS3906

R480 1.5K 1/16W

Scaler

715G1558-C-BJ.DSN

FB402

600 OHM

VCC3.3

R419 0 1/16W

AVDD

FB405

600 OHM

LED_A

KEY_AUTO

KEY_RI GHT

KEY_MENU

KEY_LEFT

C407

0.1uF

VPLL

C416

0.1uF

KEY_A

KEY_B

KEY_C

A

25Friday, July 21, 2006

of

26

Page 27

19" LCD Color Monitor I-INC AH191D

VLCD

R89

PB[0. .5]

PB0

RB1P

RB1N

PB1

RB2P

PB2

PB3

RB2N

PB4

RB3P

PB5

RB3N

PB[6.. 11]

PB6

GB1P

GB1N

PB7

PB8

GB2P

PB9

GB2N

PB10

GB3P

GB3N

PB11

PB[12.. 23]

CLKBP

PB14

CLKBN

PB15

PB18

BB1P

BB1N

PB19

BB2P

PB20

PB21

BB2N

BB3P

PB22

PB23

BB3N

R101 NC/0

OSP

ESP

R102 NC/0

C106

NC

R91

Table 1

X

X

X

V

V

V

Table 1

AU 17

QDI 17

CPT 17

INNOLUX 15

HannStar 15

CPT 15

LG 15

Innolux 17"

R90

3.3V

3.3V

3.3V

3.3V

NC

0R

0R

0R

0R

NC

C107

NC

R103 NC

R104 NC

R105 NC

R106 NC

R107 NC

R108 NC

R109 NC

R92

NC

12V

0R

NC

NC

NC

NC

RA3N

RA3P

RA2N

RA2P

RA1N

RA1P

GA3N

GA3P

GA2N

GA2P

GA1N

GA1P

CLKAN

CLKAP

BA3N

BA3P

BA2P

BA1N

BA1P

GPOO1

GPOO0

GPOO3

GPOO2

GPOO4

R93

3.3V

3.3V

3.3V

3.3V

FB0N

FB0P

FB1N

FB1P

FB2N

FB2P

FG0N

FG0P

FG1N

FG1P

FG2N

FG2P

FCLKN

FCLKP

FR0N

FR0P

FR1N

FR1P

FR2N

FR2P

STH

LP

POL

STV2

CLKV

STV1

OE

R94

5V

0R

NC

0R

0R

0R

3.3V

0R

R95

5V

0R

NC

NC

NC

NC

0R

CN102

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

IL-FHR -B50S-HF (JAE)

R97

R96

5V

NC

0R

12V

0R

NC

NC

NC

12V

0R

NC

NC

NC

3.3V

0R

NC

CN103

RXO0RXO1RXO2RXOCRXO3RXE0RXE1RXE2RXECRXE3-

R738

VLCD

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

IL-FH R-B30S-HF (JAE)

CN101

2

1

4

3

6

5

8

7

10

9

CONN

L703

BEAD 120OHM

1 2

R741

150R 1/4W

12

14

16

18

20

22

24

26

28

30

VLCD 2

C726

0.1uF/ 16V

11

13

15

17

19

21

23

25

27

29

RXO0+

RXO1+

RXO2+

RXOC+

RXO3+

RXE0+

RXE1+

RXE2+

RXEC+

RXE3+

LVB0P

LVB1P

LVB2P

LVBCKP

LVB3P

LVA0P

LVA1P

LVA2P

LVACKP

LVA3PC101

RB3N

B0N

B0P

RB3P

B1N

RB2N

B1P

RB2P

RB1N

B2N

B2P

RB1P

BG0N

GB3N

GB3P

BG0P

BG1N

GB2N

GB2P

BG1P

GB1N

BG2N

BG2P

GB1P

BCLKN

CLKBN

BCLKP

CLKBP

BR0N

BB3N

BR0P

BB3P

BB2N

BR1NBA2N

BB2N

BR1P

BB2P

BR2N

BB1N

BR2P

BB1P

LVB0M

LVB1M

LVB2MGPOO3

LVBCKM

LVB3M

LVA0M

LVA1M

LVA2M

LVACKM

LVA3M

NC

12V

0R

NC

NC

NC

NC

C725

22uF/50V

+

150R 1/4W

CN8

PB[0..5]4

PB[6.. 11]4

PB[12.. 23]4

OSP4

ESP4

VLCD2

VLCD_12V

VLCD_12V2

R88

RP1

CN9

X

X

X

V

V

V

X

V

PA[0..7]

PA0

LVACKP

PA1

LVACKM

PA2

LVA2P

PA3

LVA2M

PA4

LVA1P

PA5

LVA1M

PA6

LVA0P

PA7

LVA0M

PA12

LVA3P

LVA3M

PA13

PB[12.. 23]

PB12

LVB3P

PB13

LVB3M

PB14

LVBCKP

PB15

LVBCKM

LVB2P

PB16

PB17

LVB2M

LVB1P

PB18

LVB1M

PB19

LVB0P

PB20

PB21

LVB0M

C104

NC

LVDS Panel

RSDS Panel

C105

NC

GPOO0

GPOO1

GPOO2

GPOO4

CN7

X

V

8

7

6

C103

C102

NC

NC

NC

PA2

PA3

PA4

PA5

PA6

PA7

PA8

PA9

PA10

PA11

PA12

PA13

PA14

PA15

PA16

PA17

PA18

PA19

PB12

PB13

GPO0

GPO1

GPO2

GPO3

GPO4

PA[0. .7]4

RA1P

RA1N

RA2P

RA2N

RA3P

RA3N

GA1P

GA1N

GA2P

GA2N

GA3P

GA3N

PB[12..23]4

BA1P

BA1N

BA2P

BA2N

BA3P

BA3N

CLKAP

CLKAN

RP101 NC

1

2

3

4 5

R110 NC

PA[0..7]4

PA[8..13]4

PA[14.. 19]4

GPO[0.. 4]4

PA[0..7]

PA[8..13]

GPO[0.. 4]

Tit le

http://www.wjel.net

Size Document Number Rev

B

Date: Sheet

PANEL INTERFACE

715G1558-C-BJ.DSN

55Friday , July 21, 2006

27

of

A

Page 28

19" LCD Color Monitor I-INC AH191D

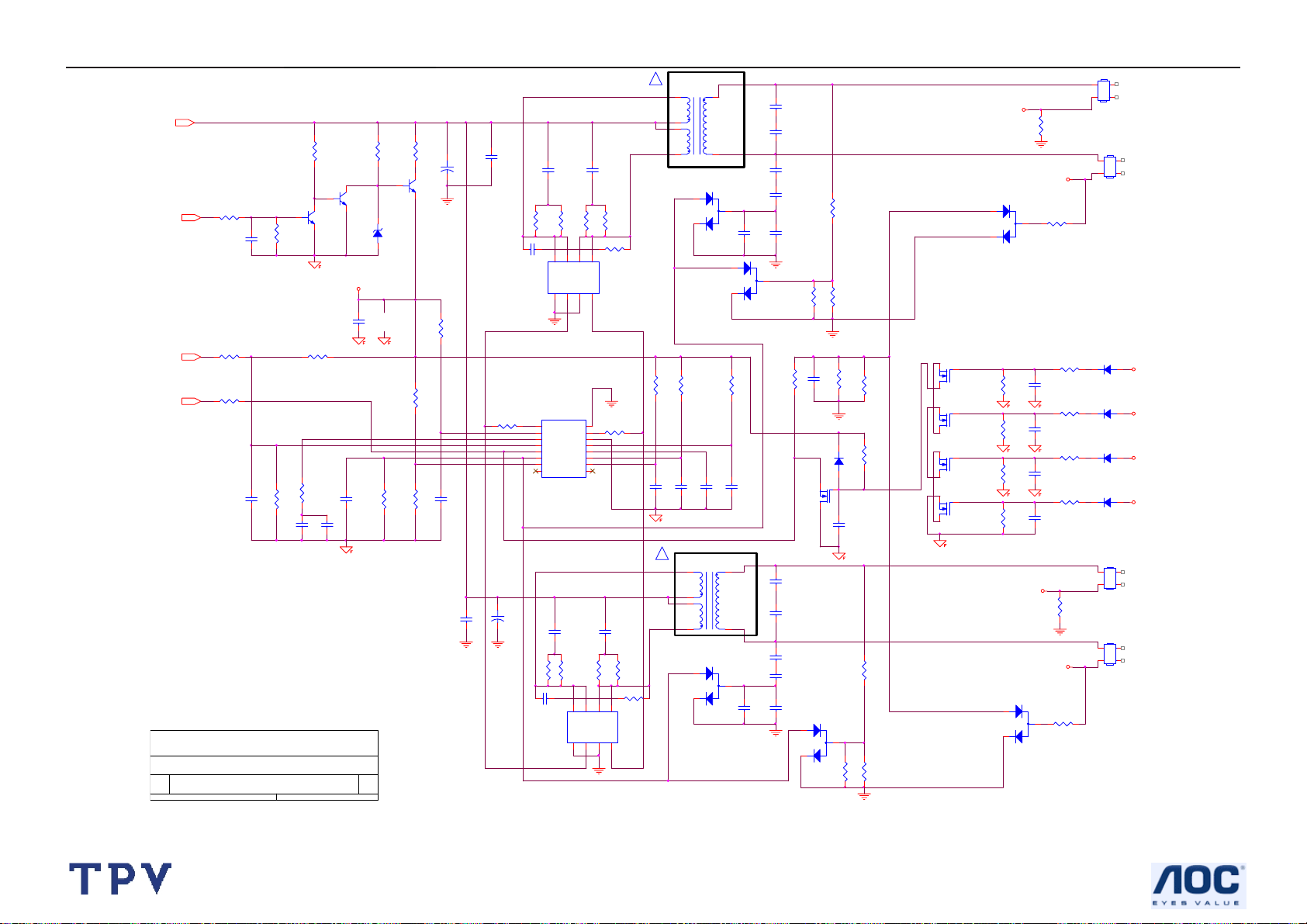

6.2 Power Board

D908

SP20150

2

D909

SP20100

2

C932

0.0015uF/2KV

C933

0.0015uF/2KV

R920

1K 0805

C918

0.1uF

R921

1K 0805

R934

47 1206

R935

47 1206

C934

JUMP

C936

470uF/25V

C935

470uF/25V

R937

100 1206

R936

100 1206

R916

100 1206

Over voltage protection

ZD901

RLZ13B

1 2

R926

2K 0805

C931

1000PF/5 00V

+

+

1 2

+

ZD902

RLZ5.6B

+

C912

470uF/25V

C904

470uF/25V

R927

10KΩ 1/4W

3.6K 0805 1%

C919

0.1uF

R922

1K 0805

L903

3.5UH

+

C937

470UF/25V

L904

3.5UH

R925

R923

33K 0805 1%

R924

2.4K 0805 1%

AOC (Top Victory) Electronics Co., Ltd.

Titl e

1.POWER OUTPUT 12V & 5 V

Size Document Number Rev

G1899-1-HP-X-1-060720

Date: Sheet

Friday , July 21, 2006

+

C911

470UF/25V

1 2

PTZ9.1B

ZD903

ON/OFF

C916

0.1uF

F903

FUSE

F902

FUSE

DIM

12

11

10

9

8

7

6

5

4

3

2

1

C917

0.1uF

11

+12V

+5V

CN902

of

ON/OFF

DIM

NC

GND

GND

GND

GND

GND

+5V

+5V

+12V

+12V

1

1

-+

2

3

2

3

L902

1

4

VAR901

NC

2

3

L901

2.0MH

1

4

C903

0.47uF/ 275V

R902

R901

680KΩ 1/4W

680KΩ 1/4W

3

CN901

SOCKET

BD901

4A 800V

4

73L 174-65-LS

R903

680KΩ 1/4W

NR901

NTCR

12

C905

100uF/4 50V

C901

1000PF/2 50V

C902

1000PF/2 50V

12

t

F901

FUSE

!

+

1 2

Over voltage protection

ZD906

R941

NC

NC

C913

NC

C908

0.1uF

IC901

LD7575

R913

100K 0805

8

LD7575

7

N.C

RT1CS

R906

6

4

2

1

IC902

T901

C900

0.0022UF

!

47 1206

R919

470Ω 1/4W

12

IC903

KIA431A-AT/P

3

1

95

10

7

3

8

11

12

1

43

R931

100KΩ 1/4W

R904

100KΩ 1/4W

R938

100KΩ 1/4W

6

HV

OUT

GND

COMP

4

2

ZD907

NC

R939

NC

NC

IC904

R905

100K 2W

C930

0.0015uF /2KV

D903

0Ω 1/4W

C907

+

R910

22Ω 1/4W

RLZ18B

TO PI N3

D904

ZD904

C909

220pF

NC

1N4148W

1 2

R911

1KΩ 1/4W

C910

470pF/50V

ZD905

NC

1 2

TO PI N3

VCC

5

3

1 2

R912

12

10K 0805

D901

FR107

Q903

STP10NK70ZFP

R914

0.47 2W

D902

R909

5.1Ω 1/4W

FR103

C906

+

22UF/50V

FB901

BEAD

Over current protection

80GL17T 37 L GP

http://www.wjel.net

28

Page 29

19" LCD Color Monitor I-INC AH191D

PT801

!

80GL19T 8 DN GP

5

+12V

R804

R802

300KΩ 1/8W

10K 0805

ON/OFF

R803

10K 0805

C801

R806

10K 0805

0.1uF

R808

200K 0805

DIM

PID

R801

NC

C803

0.01uF

R811

47K 0805

C804

1uF/25V

10K 0805

Q801

PMBS3904

C840

1uF/25V

R809

180KΩ 1/8W

R812

C814

0.22uF/25V

Q802

PMBS3904

VCC

AOC (Top Victory) Electronics Co., Ltd.

Titl e

HP W19 series 17" 19'' 4 LAMPS INVERTER

Size Document Number Rev

G1899-1-HP-X-1-060720

Tuesday, February 27, 2007

Date: Sheet

11

of

C805

1000pF

7

3

4

R805

470Ω 1/4W

+

C811

Q803

470UF/25V

PMBS3904

ZD801

RLZ5.6B

1 2

R807

22Ω 1/4W

R810

1MΩ 1/8W

R813

1MΩ 1/8W

R814

750KΩ 1/8W

C829

0.1uF

C806

1uF/25V

http://www.wjel.net

1

C828

0.1uF

5.1Ω 1/4W

R842

+

C815

470UF/25V

?

Q806

AM9945

R828

IC801

1

DRV1

2

VDDA

3

TIMER

4

DIM

5

ISEN

6

VSEN

7

OVPT

NC18NC2

OZ9938

R863

?

AM9945

332/1206

C822

30 1206

30 1206

8

S1N1G1N2S2N3G2N

PGND

DRV2

GNDA

SSTCMP

C813

R818

30 1206

30 1206

Q805

R861

30 1206

D2N5D2N6D1N7D1N

4

16

15

14

13

CT

12

11

LCT

10

ENA

9

332/1206

8

S1N1G1N2S2N3G2N

R829

332/1206

C823

5.1Ω 1/4W

R837

R819

30 1206

D2N5D2N6D1N7D1N

4

R862

30 1206

?

332/1206

C812

1 8

D801

1

3

2

BAV99

1

D806

2

BAV99

R816

1MΩ 1/8W

R815

100K 1/ 8W

C807

C808

0.01uF

0.0068uF

!

5

3

4

1 8

R864

30 1206

?

C809

0.047uF

PT802

80GL19T 8 DN GP

D803

1

2

BAV99

R817

33KΩ 1/8W

7

3

C820

470pF/50V

C810

560PF/50V

C831

470pF/50V

3

82KΩ 1/8W

R825

51KΩ 1/8W

C816

22pF/3KV

C841

22pF/3KV

C825

5pF/3KV

C824

5pF/3KV

C818

0.0033uF/16V

R823

Q804

RK7002

C834

22pF/3KV

C837

22pF/3KV

C826

5pF/3KV

C835

5pF/3KV

C827

0.0033uF/16V

1

2

82KΩ 1/8W

C819

0.047uF

D809

1N4148W

D805

R830

R822

6.2MΩ 1/2W

R827

7.5K /0805

R826

430 0805 1%

open lamp protection

C844

0.1uF

BAV99

3

R841

430 0805 1%

R860

1MΩ 1/8W

R832

6.2MΩ 1/2W

R831

7.5K 0805

Q807

RK7002

1MΩ 1/8W

Q808

RK7002

1MΩ 1/8W

Q809

RK7002

1MΩ 1/8W

Q810

RK7002

1MΩ 1/8W

D802

R846

R847

R848

R849

OPT1

R836

1K 1/ 10W

OPT2

1

2

BAV99

R858

3

750Ω 1/8W

C838

0.1uF

C839

0.1uF

C842

0.1uF

C843

0.1uF

OPT3

OPT4

D804

1

BAV99

R824

3

2

750Ω 1/8W

R853

R852

R850

R851

1K 0805

R843

CONN

4.7KΩ 1/8W

4.7KΩ 1/8W

4.7KΩ 1/8W

4.7KΩ 1/4W

CN801

CONN

CONN

CONN

1342

CN802

D810

1N4148W

D811

1N4148W

D812

1N4148W

D813

1N4148W

CN803

CN804

1342

OPT1

OPT2

OPT3

OPT4

1342

1342

29

Page 30

19" LCD Color Monitor I-INC AH191D

6.3 Key Board

ESD by jc chen

2006/5/11

GND wire

SW001

KEY SEL

CN002

EAR PHONEJACK

SW002

KEY LEFT

1

5

4

3

2

7

8

GND

POWER KEY

BZX79-B5V6

SW003

R101 75

R102 75

ZD102

1 2

GND

SW004

KEY RIGHT

1 2

GND

SPKR_R+

SPKR_L+

ZD101

BZX79-B5V6

SW005

GREEN

KEY MANU

1

2

GND

1

2

GND

ESD by jc chen

2006/5/11

KEY_SEL

KEY_LEFT

POWER_ KEY

KEY RIGHT

KEY_MANU

LED_ORANGE

1

3

DP101

ORANGE

LED

2

CN003

SPK-R

CN004

SPK-L

ESD by jc chen

2006/5/11

GND wire

LED_ORANGE

KEY_SEL

KEY_RIGHT

POWER_ KEY

GND

SPKR_L+

11

1

3

5

7

9

CN001

CONN

2

4

6

8

10

12

LED_GRN

KEY_MANU

KEY_LEFT

GNDLED_GRN

SPKR_R+

GND

GND

AOC (Top Victory) Electronics Co., Ltd.

Title

http://www.wjel.net

Size Document Number Rev

A

Date: Sheet

715G2127-1

11Tuesday, June 13, 2006

of

c

30

Page 31

19" LCD Color Monitor I-INC AH191D

6.4 Audio Board

OUT_L

MUTE

15

16

VS

VS

OUTR

VAROUT_R

VAROUT_L

GND

GND

GND

13

181920

+12V

OUTL

SVR

GND

+

C201

470uF/16V

U201

E-TDA7496L

17

14

10

7

5

C208

470uF/16V

+

C202

470uF/16V

+

R202

200K

GND

C205

470uF/16V

R207

1K

C203

0.1uF

+

470uF/16V

R208

1K

OUT_R

+

C207

CN204

1

2

3

CONN

CN201

AUDIO INPUT JACK

1

5

4

3

2

GND

GND

ZD201

BZX79-B5V6

12V

CN202

14

12

GND

C210

+

1uF/50V

10

8

6

4

2

CONN

STANDBY

C213

0.1uF

VOLUME

R201

R203 18K

ZD202

BZX79-B5V6

1 2

1 2

18K

C211

100pF

R210

20K

R211

20K

R212

220K

C212

100pF

C214

NC

+12V

C209

+

1uF/50V

C204

0.47uF/100V

C206

0.47uF/100V

4

9

6

11

12

13

11

9

7

5

3

1

INL

INR

VOLUME

STBY

MUTE

123

8

GND

NC

GND

GND

GND

GND

GND

http://www.wjel.net

GND

Title

Size Document Number Rev

Date: Sheet

GND

<Doc> 1A

GND

715G2128-1

11Tuesday, June 13, 2006

of

31

Page 32

19" LCD Color Monitor I-INC AH191D

7. PCB Layout

7.1 Main Board

http://www.wjel.net

32

Page 33

19" LCD Color Monitor I-INC AH191D

http://www.wjel.net

33

Page 34

19" LCD Color Monitor I-INC AH191D

7.2 Power Board

http://www.wjel.net

34

Page 35

19" LCD Color Monitor I-INC AH191D

http://www.wjel.net

35

Page 36

19" LCD Color Monitor I-INC AH191D

7.3 Key Board

7.4 Audio Board

http://www.wjel.net

36

Page 37

19" LCD Color Monitor I-INC AH191D

8. Maintainability

8.1 Equipments and Tools Requirement

1. Voltmeter.

2. Oscilloscope.

3. Pattern Generator.

4. DDC Tool with an IBM Compatible Computer.

5. Alignment Tool.

6. LCD Color Analyzer.

7. Service Manual.

8. User Manual.

http://www.wjel.net

37

Page 38

19" LCD Color Monitor I-INC AH191D

8.2 Trouble Shooting

8.2.1 Main Board

No Power

Press power key and look

if the picture is normal

Please reinsert and make sure

the AC of 100-240 is normal

Measure U702 Vout=3.3V

Q702 Vc=1.8V

X401 oscillate waveforms

are normal

No power

NG

OK

OK

OK

Replace U401

NG

NG

NG

Reinsert or check the

Adapter/Inverter

section

Check CN701 or replace

U702, Q702

Replace X401

NG

Replace U401

http://www.wjel.net

38

Page 39

19" LCD Color Monitor I-INC AH191D

No Picture (LED orange)

Measure U702 Vout=3.3V

Q702 Vc=1.8V

No picture

The button if under

control

OK

OK

X401 oscillate

waveform is normal

OK

Check HS/VS from

CN405 is normal

OK

Replace U401

NG

NG

NG

X401 oscillate

waveform is normal

OK

Check reset circuit of

U401 is normal

Replace U401

NG

Replace U702, Q702

Replace X401

Check Correspondent

component

OK

NG

Replace X401

NG

Check Correspondent

component

http://www.wjel.net

39

Page 40

19" LCD Color Monitor I-INC AH191D

White Screen

Replace CN101 or

re-solder

Measure C725 (+) =5V

Check CN101 connector or

solder normal?

White screen

OK

NG

OK

NG

Checks Q704, Q706,

Q708 are broken

NG

OK

Check X401

OK

Replace U401

Replace Q704,

Q706, Q708

NG

Replace X401

Replace PANEL

http://www.wjel.net

40

Page 41

19" LCD Color Monitor I-INC AH191D

8.2.2 Power Board

1. No Power

Check to CN902 Pin1, 2 =12V and Pin3, 4 = 5 V

No power

OK

NG

Check Interface board

Check AC line volt 120V or 220V

OK

NG

Change F901, Check BD901, Q903, IC901

Check the voltage of C905 (+)

OK

NG

Check bridge retified circuit

Check start voltage for the Pin6 of IC901

OK

NG

Change IC901

Check the auxiliary voltage is smaller than 20V

NG

OK

http://www.wjel.net

Check D908, D909, ZD903…

Check IC902,IC903

Check Q903…OLP circuit

41

Page 42

19" LCD Color Monitor I-INC AH191D

2. W/LED No Backlight

Check C811 (+) =12V

OK

NG

Check adapter circuit

Check ON/OFF signal

OK NG

Check Interface board

Check IC801 PIN2=5V

Check the Pin1, Pin15 of IC801 have square wave

NGOK

Check Q801,Q802,Q803

OK

NG

Check IC801

Check Q805,Q806 have the output of

square wave at short time.

OK

Check the resonant wave of Pin7 & Pin8 for PT801/PT802

OK

Check the output of PT801/PT802

NG

NG

Check Q805,Q806,PT801,PT802

Check C816, C841 or C834, C837

http://www.wjel.net

Change PT801 or PT802

Check connecter & lamp

42

Page 43

19" LCD Color Monitor I-INC AH191D

8.2.3 Key Board

OSD is unstable or not working

Is Keypad board connecting normally?

OK

Is Button Switch normally?

OK

Is Keypad board normally?

OK

Check main board

NG

Connect Keypad Board

NG

Replace Button Switch

NG

Replace Keypad Board

http://www.wjel.net

43

Page 44

19" LCD Color Monitor I-INC AH191D

9. White- Balance, Luminance Adjustment

Approximately 30 minutes should be allowed for warm up before proceeding White-Balance adjustment.

1. How to do the Chroma-7120 MEM. Channel setting

A. Reference to chroma 7120 user guide

B. Use “SC” key and “NEXT” key to modify x,y,Y value and use “ID” key to modify the

TEXT description Following is the procedure to do white-balance adjust

2. Setting the color temp. you want

A. MEM.CHANNEL 3 (9300 color):

9300 color temp. parameter is x = 283 ±28, y = 297 ±28,Y=220cd/㎡

B. MEM.CHANNEL 4 (6500 color):

6500 color temp. parameter is x = 313±28, y = 329 ±28, Y=220cd/㎡

C. MEM.CHANNEL 9 (5500 color):

5500 color temp. parameter is x = 333±28, y = 348 ±28, Y=220cd/㎡

3. Enter into factory mode of AH191D

Turn on the power, press simultaneously the MENU and AUTO buttons, then the factory OSD will be at the left top of

the panel.

4. Bias adjustment:

Set the Contrast

5. Gain adjustment:

Move cursor to “-F-” and press MENU key

A. Adjust 9300 color-temperature

1. Switch the Chroma-7120 to RGB-Mode (with press “MODE” button)

2. Switch the MEM. Channel to Channel 3 (with up or down arrow on chroma 7120)

3. The LCD-indicator on chroma 7120 will show x = 283 ±28, y = 297 ±28, Y=220cd/㎡

4. Adjust the RED of color 1 on factory window until chroma 7120 indicator reached the value R=100

5. Adjust the GREEN of color 1 on factory window until chroma 7120 indicator reached the value G=100

6. Adjust the BLUE of color 1 on factory window until chroma 7120 indicator reached the value B=100

7. Repeat above procedure (item 4,5,6) until chroma 7120 RGB value meet the tolerance =100±2

B. Adjust 6500 color-temperature

1. Switch the chroma-7120 to RGB-Mode (with press “MODE” button)

2. Switch the MEM.channel to Channel 4(with up or down arrow on chroma 7120)

3. The LCD-indicator on chroma 7120 will show x = 313 ±28, y = 329 ±28, Y=220cd/㎡

4. Adjust the RED of color 2 on factory window until chroma 7120 indicator reached the value R=100

5. Adjust the GREEN of color 2 on factory window until chroma 7120 indicator reachedthe value G=100

6. Adjust the BLUE of color 2 on factory window until chroma 7120 indicator reached the value B=100

7. Repeat above procedure (item 4,5,6) until chroma 7120 RGB value meet the tolerance =100±2

C. Adjust 5500 color-temperature

1. Switch the chroma-7120 to RGB-Mode (with press “MODE” button)

2. Switch the MEM.channel to Channel 9 (with up or down arrow on chroma 7120)

3. The LCD-indicator on chroma 7120 will show x = 333±28, y = 348 ±28, Y=220cd/㎡

4. Adjust the RED of color 3 on factory window until chroma 7120 indicator reached the value R=100

5. Adjust the GREEN of color 3 on factory window until chroma 7120 indicator reachedthe value G=100

6. Adjust the BLUE of color 3 on factory window until chroma 7120 indicator reached the value B=100

7. Repeat above procedure (item 4,5,6) until chroma 7120 RGB value meet the tolerance =100±2

D. Turn the Power-button off to quit from factory mode.

to 50; Adjust the Brightness to 80.

http://www.wjel.net

44

Page 45

19" LCD Color Monitor I-INC AH191D

10. Monitor Exploded View

http://www.wjel.net

45

Page 46

19" LCD Color Monitor I-INC AH191D

11. BOM List

T96HM6DTWEHZAE

Location Part No. Description

78G 322E02 L SPEAKER

78G 322E02 R SPEAKER

Q1G1030 10128 CR3 SCREW

AUPC6QA5P AUDIO BOARD

CBPC6HM6HCQP CONVERSION BOARD FOR 19

KEPC6QA6P KEY BOARD

PWPC942HT1P POWER BOARD

52G 1186 SMALL TAPE

52G 1207 A TAPE

52G6020 17 PROTECT FILM

89G 173 56 4B AUDIO CABLE

89G 715HAA D2 SIGNAL CABLE

89G1745CAA 9 SIGNAL CABLE

89G420A18N IS POWER CORD

95G8014 16E05 WIRE HARNESS

95G8018 3515 LVDS CABLE

M1G 340 8225 CR3 SCREW 4*8mm

M1G1140 6128 CR3 SCREW

M1G1730 6128 CR3 SCREW M3x6

M1G1730 6128 CR3 SCREW M3x6

M1G1730 6128 CR3 SCREW M3x6

M1G3030 5225 CR3 SCREW

Q1G 330 8120 SCREW 3X8mm

Q1G 330 8120 SCREW 3X8mm

Q1G 330 12 47 CR3 SCREW

705GH9K0F34003 ASS'Y

750GLH90GW111N PANEL LCD 19"MG1 A00

A15G0032 H7 MAIN FRAME

A33G0030 ZT 1L 32 CABLE COVER

A34G0051 ZT 1B REAR COVER

H26G 800850 1A BARCODE

H40G 19N850 2A ID LABEL

H41G7800850 3A QSG FOR AH191

H41G7800850 8B RECYCLE INFORMATION

H44G9030850 1B CARTON

H45G 87 1 4H EPE COVER

H45G 87 4 H PE BAG FOR BASE/MANUAL

H45G 87 4 H PE BAG FOR BASE/MANUAL

H52G 1175 4 MIDDLE TAPE FOR CARTON

H52G 1175 5 BIG TAPE FOR CARTON

H70G1600850 1B CD MANUAL

Q40G 58170931A HI-POT PASS LABEL

Q40G0002850 2A EPA LABEL

Q44G9030 1 EPS

http://www.wjel.net

46

Page 47

19" LCD Color Monitor I-INC AH191D

Q44G9030 2 EPS

Q45G 88606 14 PE BAG

Q52G6025 13 40 MYLAR

AIAUPC6QA5P AUDIO BOARD FOR AI

CN202 33G802414C H 2*7PIN DUAL ROW RIGHT A

U201 56G 616 31 IC TDA7496T 1.2W*2 DIP-

C201 67G215D4713KV LOW ESR EC 470UF 16V

C202 67G215D4713KV LOW ESR EC 470UF 16V

C207 67G215D4713KV LOW ESR EC 470UF 16V

C205 67G215Y4713RV 470UF +-20% 16V

C208 67G215Y4713RV 470UF +-20% 16V

CN201 88G 30210K E PHONE JACK

715G2128 1 AUDIO BOARD PCB

J201 95G 90 23 TINCOATEDCOPPER

R207 61G 60210252T CFR 1K OHM+-5% 1/6W

R208 61G 60210252T CFR 1K OHM+-5% 1/6W

R201 61G 60218352T 18KOHM 5% 1/6

R203 61G 60218352T 18KOHM 5% 1/6

R210 61G 60220352T CFR 20K OHM+-5% 1/6W

R211 61G 60220352T CFR 20K OHM+-5% 1/6W

R202 61G 60220452T 200KOHM 5% 1/6W

R212 61G 60222452T 220KOHM 5% 1/6W

C211 65G 444101 5T 100 PF 10% 50V Y5P

C212 65G 444101 5T 100 PF 10% 50V Y5P

C203 65G 450104 7T 0.1UF +80-20% 50V Y5V

C213 65G 450104 7T 0.1UF +80-20% 50V Y5V

C204 67G 70478 9T 0.47UF +-20% 100V

C206 67G 70478 9T 0.47UF +-20% 100V

C209 67G 309109 7T 1.0UF +-20% 50V

C210 67G 309109 7T 1.0UF +-20% 50V

SMTC6HM6HCQP MAIN BOARD

CN404 33G801714H H WAFER OR PLUG

CN701 33G8027 12 WAFER 2*6P 2.0MM R/A

CN403 33G8027 16 WAFER 16PIN 2.0mm DIP

CN101 33G8027 30 H WAFER 30P 2.0MM RIGHT A

40G 457624 1B CPU LABEL

40G 45762412B CBPC LABEL

44G3231508512 GASKET

C418 67G215V100 7N KY50VB10-M-CC3 5*11.5MM

C717 67G215V100 7N KY50VB10-M-CC3 5*11.5MM

C710 67G215V101 4N KY25VB100M-CC3(6.3*11)

C712 67G215V101 4N KY25VB100M-CC3(6.3*11)

C707 67G215V470 4R LOW E.S.R 47UF +/-20% 2

C403 67G215Y2207NV KY50VB22M-CC3 5*11

C408 67G215Y2207NV KY50VB22M-CC3 5*11

C702 67G215Y2207NV KY50VB22M-CC3 5*11

C723 67G215Y2207NV KY50VB22M-CC3 5*11

C725 67G215Y2207NV KY50VB22M-CC3 5*11

http://www.wjel.net

47

Page 48

19" LCD Color Monitor I-INC AH191D

CN405 88G 35315F HJ SOC SUBD H 15P F

CN406 88G 35424F HL DVI 24PIN FEMALE

U401 90G6250 1 GP HEAT SINK

X401 93G 22 53 14.31818MHZ HC-49US

U401 56G 562129 IC TSUM56AK-LF-1 PQFP-1

U702 56G 563 7 AIC1084-33PM

U404 56G1133 34 M24C02-WMN6TP

U405 56G1133 34 M24C02-WMN6TP

U403 56G1133 56 M24C16-WMN6TP

U402 56G1133 59 SST25VF010-20-4C-SAE S0

Q402 57G 417 4 PMBS3904/PHILIPS-SMT(04

Q404 57G 417 4 PMBS3904/PHILIPS-SMT(04

Q701 57G 417 4 PMBS3904/PHILIPS-SMT(04

Q703 57G 417 4 PMBS3904/PHILIPS-SMT(04

Q401 57G 417 6 PMBS3906/PHILIPS-SMT(06

Q403 57G 417 6 PMBS3906/PHILIPS-SMT(06

Q706 57G 417 6 PMBS3906/PHILIPS-SMT(06

Q702 57G 417 17 T PZT2907A

Q704 57G 763 1 AO3401L SOT23 BY AOS(A1

FB410 61L0603000 RST SM 0603 JUMP MAX 0R

FB411 61L0603000 RST SM 0603 JUMP MAX 0R

FB412 61L0603000 RST SM 0603 JUMP MAX 0R

R419 61L0603000 RST SM 0603 JUMP MAX 0R

R421 61L0603000 RST SM 0603 JUMP MAX 0R

R721 61L0603000 RST SM 0603 JUMP MAX 0R

R462 61L0603100 RST CHIP 10OHM +-5% 1/1

R463 61L0603100 RST CHIP 10OHM +-5% 1/1

R464 61L0603100 RST CHIP 10OHM +-5% 1/1

R465 61L0603100 RST CHIP 10OHM +-5% 1/1

R466 61L0603100 RST CHIP 10OHM +-5% 1/1

R467 61L0603100 RST CHIP 10OHM +-5% 1/1

R468 61L0603100 RST CHIP 10OHM +-5% 1/1

R469 61L0603100 RST CHIP 10OHM +-5% 1/1

R492 61L0603100 RST CHIP 10OHM +-5% 1/1

R493 61L0603100 RST CHIP 10OHM +-5% 1/1

R478 61L0603100 1F CHIP 1KOHM 1/16W 1%

R479 61L0603100 1F CHIP 1KOHM 1/16W 1%

R411 61L0603101 RST SM 0603 RC0603 100R

R418 61L0603101 RST SM 0603 RC0603 100R

R420 61L0603101 RST SM 0603 RC0603 100R

R427 61L0603101 RST SM 0603 RC0603 100R

R428 61L0603101 RST SM 0603 RC0603 100R

R429 61L0603101 RST SM 0603 RC0603 100R

R441 61L0603101 RST SM 0603 RC0603 100R

R442 61L0603101 RST SM 0603 RC0603 100R

R443 61L0603101 RST SM 0603 RC0603 100R

R445 61L0603101 RST SM 0603 RC0603 100R

R453 61L0603101 RST SM 0603 RC0603 100R

http://www.wjel.net

48

Page 49

19" LCD Color Monitor I-INC AH191D

R454 61L0603101 RST SM 0603 RC0603 100R

R455 61L0603101 RST SM 0603 RC0603 100R

R456 61L0603101 RST SM 0603 RC0603 100R

R458 61L0603101 RST SM 0603 RC0603 100R

R488 61L0603101 RST SM 0603 RC0603 100R

R704 61L0603101 RST SM 0603 RC0603 100R

R430 61L0603102 RST SM 0603 RC0603 1K P

R446 61L0603102 RST SM 0603 RC0603 1K P

R447 61L0603102 RST SM 0603 RC0603 1K P

R476 61L0603102 RST SM 0603 RC0603 1K P

R477 61L0603102 RST SM 0603 RC0603 1K P

R701 61L0603102 RST SM 0603 RC0603 1K P

R739 61L0603102 RST SM 0603 RC0603 1K P

R404 61L0603103 CHIPR 10K OHM +-5% 1/16

R406 61L0603103 CHIPR 10K OHM +-5% 1/16

R408 61L0603103 CHIPR 10K OHM +-5% 1/16

R412 61L0603103 CHIPR 10K OHM +-5% 1/16

R413 61L0603103 CHIPR 10K OHM +-5% 1/16

R415 61L0603103 CHIPR 10K OHM +-5% 1/16

R416 61L0603103 CHIPR 10K OHM +-5% 1/16

R424 61L0603103 CHIPR 10K OHM +-5% 1/16

R425 61L0603103 CHIPR 10K OHM +-5% 1/16

R426 61L0603103 CHIPR 10K OHM +-5% 1/16

R432 61L0603103 CHIPR 10K OHM +-5% 1/16

R444 61L0603103 CHIPR 10K OHM +-5% 1/16

R450 61L0603103 CHIPR 10K OHM +-5% 1/16

R451 61L0603103 CHIPR 10K OHM +-5% 1/16

R452 61L0603103 CHIPR 10K OHM +-5% 1/16

R457 61L0603103 CHIPR 10K OHM +-5% 1/16

R459 61L0603103 CHIPR 10K OHM +-5% 1/16

R460 61L0603103 CHIPR 10K OHM +-5% 1/16

R461 61L0603103 CHIPR 10K OHM +-5% 1/16

R470 61L0603103 CHIPR 10K OHM +-5% 1/16

R471 61L0603103 CHIPR 10K OHM +-5% 1/16

R484 61L0603103 CHIPR 10K OHM +-5% 1/16

R485 61L0603103 CHIPR 10K OHM +-5% 1/16

R487 61L0603103 CHIPR 10K OHM +-5% 1/16

R489 61L0603103 CHIPR 10K OHM +-5% 1/16

R490 61L0603103 CHIPR 10K OHM +-5% 1/16

R491 61L0603103 CHIPR 10K OHM +-5% 1/16

R708 61L0603103 CHIPR 10K OHM +-5% 1/16

R711 61L0603103 CHIPR 10K OHM +-5% 1/16

R717 61L0603103 CHIPR 10K OHM +-5% 1/16

R734 61L0603103 CHIPR 10K OHM +-5% 1/16

R480 61L0603150 1F CHIP 1.5OHM 1/16W 1%

R703 61L0603202 CHIPR 2K OHM+-5% 1/16W

R417 61L0603203 CHIPR 20K OHM+-5% 1/16W

R448 61L0603222 RST SM 0603 RC0603 2K2

http://www.wjel.net

49

Page 50

19" LCD Color Monitor I-INC AH191D

R449 61L0603222 RST SM 0603 RC0603 2K2

R405 61L0603223 CHIPR 22K OHM +-5% 1/16

R414 61L0603241 CHIP 240 OHM 1/16W

R403 61L0603390 0F CHIP 390 OHM 1/10W 1%

R474 61L0603392 CHIP 3.9K OHM 1/16W

R475 61L0603392 CHIP 3.9K OHM 1/16W

R437 61L0603471 CHIPR 470 OHM+-5% 1/16W

R422 61L0603472 RST SM 0603 RC0603 4K7

R423 61L0603472 RST SM 0603 RC0603 4K7

R433 61L0603472 RST SM 0603 RC0603 4K7

R705 61L0603472 RST SM 0603 RC0603 4K7

R707 61L0603472 RST SM 0603 RC0603 4K7

R712 61L0603472 RST SM 0603 RC0603 4K7

R735 61L0603472 RST SM 0603 RC0603 4K7

R702 61L0603510 CHIP 51 OHM 5% 1/16W

R723 61L0603513 CHIP 51K OHM

R434 61L0603560 CHIPR 56 OHM +-5% 1/16W

R435 61L0603560 CHIPR 56 OHM +-5% 1/16W

R436 61L0603560 CHIPR 56 OHM +-5% 1/16W

R409 61L0603750 CHIPR 75 OHM+-5% 1/16W

R438 61L0603750 CHIPR 75 OHM+-5% 1/16W

R439 61L0603750 CHIPR 75 OHM+-5% 1/16W

R440 61L0603750 CHIPR 75 OHM+-5% 1/16W

R741 61L0805222 CHIP 2.2KOHM 5% 0805 1/

R738 61L1206222 RST CHIPR 2.2KOHM +-5%

C401 65G0603104 32 CHIP 0.1UF 50V X7R

C404 65G0603104 32 CHIP 0.1UF 50V X7R

C405 65G0603104 32 CHIP 0.1UF 50V X7R

C406 65G0603104 32 CHIP 0.1UF 50V X7R

C407 65G0603104 32 CHIP 0.1UF 50V X7R

C409 65G0603104 32 CHIP 0.1UF 50V X7R

C410 65G0603104 32 CHIP 0.1UF 50V X7R

C411 65G0603104 32 CHIP 0.1UF 50V X7R

C412 65G0603104 32 CHIP 0.1UF 50V X7R

C413 65G0603104 32 CHIP 0.1UF 50V X7R

C414 65G0603104 32 CHIP 0.1UF 50V X7R

C415 65G0603104 32 CHIP 0.1UF 50V X7R

C416 65G0603104 32 CHIP 0.1UF 50V X7R

C419 65G0603104 32 CHIP 0.1UF 50V X7R

C420 65G0603104 32 CHIP 0.1UF 50V X7R

C422 65G0603104 32 CHIP 0.1UF 50V X7R

C424 65G0603104 32 CHIP 0.1UF 50V X7R

C426 65G0603104 32 CHIP 0.1UF 50V X7R

C427 65G0603104 32 CHIP 0.1UF 50V X7R

C428 65G0603104 32 CHIP 0.1UF 50V X7R

C429 65G0603104 32 CHIP 0.1UF 50V X7R

C430 65G0603104 32 CHIP 0.1UF 50V X7R

C439 65G0603104 32 CHIP 0.1UF 50V X7R

http://www.wjel.net

50

Page 51

19" LCD Color Monitor I-INC AH191D

C440 65G0603104 32 CHIP 0.1UF 50V X7R

C441 65G0603104 32 CHIP 0.1UF 50V X7R

C445 65G0603104 32 CHIP 0.1UF 50V X7R

C447 65G0603104 32 CHIP 0.1UF 50V X7R

C448 65G0603104 32 CHIP 0.1UF 50V X7R

C449 65G0603104 32 CHIP 0.1UF 50V X7R

C450 65G0603104 32 CHIP 0.1UF 50V X7R

C451 65G0603104 32 CHIP 0.1UF 50V X7R

C452 65G0603104 32 CHIP 0.1UF 50V X7R

C453 65G0603104 32 CHIP 0.1UF 50V X7R

C454 65G0603104 32 CHIP 0.1UF 50V X7R

C706 65G0603104 32 CHIP 0.1UF 50V X7R

C709 65G0603104 32 CHIP 0.1UF 50V X7R

C711 65G0603104 32 CHIP 0.1UF 50V X7R

C713 65G0603104 32 CHIP 0.1UF 50V X7R

C714 65G0603104 32 CHIP 0.1UF 50V X7R

C721 65G0603104 32 CHIP 0.1UF 50V X7R

C727 65G0603104 32 CHIP 0.1UF 50V X7R

C421 65G0603220 32 CHIP 22PF 50V X7R

C423 65G0603220 32 CHIP 22PF 50V X7R

C442 65G0603220 32 CHIP 22PF 50V X7R

C443 65G0603220 32 CHIP 22PF 50V X7R

C715 65G0603223 32 CHIP 0.022UF 50V X7R 06

C716 65G0603223 32 CHIP 0.022UF 50V X7R 06

C417 65G0603224 22 CHIP 0.22UF 25V X7R

C425 65G0603224 22 CHIP 0.22UF 25V X7R

C444 65G0603224 22 CHIP 0.22UF 25V X7R

C446 65G0603224 22 CHIP 0.22UF 25V X7R

C432 65G0603473 32 CHIP 0.047UF 50V X7R

C433 65G0603473 32 CHIP 0.047UF 50V X7R

C434 65G0603473 32 CHIP 0.047UF 50V X7R

C435 65G0603473 32 CHIP 0.047UF 50V X7R

C436 65G0603473 32 CHIP 0.047UF 50V X7R

C437 65G0603473 32 CHIP 0.047UF 50V X7R

C438 65G0603473 32 CHIP 0.047UF 50V X7R

C431 65G0805105 22 CHIP 1UF 25V X7R 0805

C708 65G0805105 37 CHIP 1UF 50V Y5V

FB407 71G 56K121 M CHIP BEAD

FB408 71G 56K121 M CHIP BEAD

L701 71G 56K121 M CHIP BEAD

L702 71G 56K121 M CHIP BEAD

L703 71G 56K121 M CHIP BEAD

FB401 71G 56Z601 CHIP BEAD 600 OHM 0805

FB402 71G 56Z601 CHIP BEAD 600 OHM 0805

FB403 71G 56Z601 CHIP BEAD 600 OHM 0805

FB404 71G 56Z601 CHIP BEAD 600 OHM 0805

FB405 71G 56Z601 CHIP BEAD 600 OHM 0805

FB406 71G 56Z601 CHIP BEAD 600 OHM 0805

http://www.wjel.net

51

Page 52

19" LCD Color Monitor I-INC AH191D

FB409 71G 59B431 BK1608 HW 431

D406 93G 39149 MLL5232B BY FULL POWER

D408 93G 39149 MLL5232B BY FULL POWER

D409 93G 39149 MLL5232B BY FULL POWER

D410 93G 39149 MLL5232B BY FULL POWER

D411 93G 39149 MLL5232B BY FULL POWER

D412 93G 39149 MLL5232B BY FULL POWER

D407 93G 64 42 P BAV70 SOT-23

D413 93G 64 42 P BAV70 SOT-23

D403 93G 6433P BAV99

D404 93G 6433P BAV99

D405 93G 6433P BAV99

D417 93G 6433P BAV99

D418 93G 6433P BAV99

D419 93G 6433P BAV99

D420 93G 6433P BAV99

D421 93G 6433P BAV99

D422 93G 6433P BAV99

D423 93G 6433P BAV99

D424 93G 6433P BAV99

D401 93G 39S 45 T RLZ36B BY ROHM

D402 93G 39S 45 T RLZ36B BY ROHM

D425 93G 39S 45 T RLZ36B BY ROHM

D701 93G1004 4 SMAL140

D702 93G1004 4 SMAL140

D704 93G1004 4 SMAL140

715G1558 C BJ MAIN BOARD PCB

SMTKEPC6QA6P KEY BOARD SMT

CN003 33G3802 2H WAFER 2P RIGHT ANGLE

CN004 33G3802 2H WAFER 2P RIGHT ANGLE

CN001 33G8027 12 H PIN HEADER 2*6 R/A

SW001 77G 600 1 CJ TACT SWITCH

SW002 77G 600 1 CJ TACT SWITCH

SW003 77G 600 1 CJ TACT SWITCH

SW004 77G 600 1 CJ TACT SWITCH

SW005 77G 600 1 CJ TACT SWITCH

DP101 81G 12 1F GP LED

CN002 88G 30211K POHNE JACK 5 PIN

GND1 95G 900633 WIRE HARNESS

R101 61L0805681 680 OHM 1/10W

R102 61L0805681 680 OHM 1/10W

C101 65G0603271 31 CHIP 270PF 50V NPO

C102 65G0603271 31 CHIP 270PF 50V NPO

ZD101 93G 64 49 SU EGA10603 V05

ZD102 93G 64 49 SU EGA10603 V05

715G2127 1 KEPC BOARD PCB

PW942HT1SMTP POWER BOARD FOR SMT

L902 S73G17465VW FILTER

http://www.wjel.net

52

Page 53

19" LCD Color Monitor I-INC AH191D

15G8033 1 GP BKT_AC INLET

CN801 33G8021 2E U WAFER

CN802 33G8021 2E U WAFER

CN803 33G8021 2E U WAFER

CN804 33G8021 2E U WAFER

40G 45762420A ID LABEL

51G 6 4503

IC902 56G 139 3A PC123Y22FZOF

NR901 61G 58080 WT 8 OHM NCT

C816 65G 3J2206ET H 22PF 5% SL 3KV TDK

C834 65G 3J2206ET H 22PF 5% SL 3KV TDK

C837 65G 3J2206ET H 22PF 5% SL 3KV TDK

C841 65G 3J2206ET H 22PF 5% SL 3KV TDK

C824 65G 3J5096ET H 5PF 5% 3KV TDK

C825 65G 3J5096ET H 5PF 5% 3KV TDK

C826 65G 3J5096ET H 5PF 5% 3KV TDK

C835 65G 3J5096ET H 5PF 5% 3KV TDK

C901 65G305M1022BP Y2 1000PF M 250VAC Y5P

C902 65G305M1022BP Y2 1000PF M 250VAC Y5P

C900 65G306M2222BP 2200PF +-20% 400VAC

C905 67G215S10115N PAG450VB100-M-L18*35.5M

C811 67G215V471 4K ED 470UF 25V

C815 67G215V471 4K ED 470UF 25V

C904 67G215V471 4K ED 470UF 25V

C911 67G215V471 4K ED 470UF 25V

C912 67G215V471 4K ED 470UF 25V

C935 67G215V471 4K ED 470UF 25V

C936 67G215V471 4K ED 470UF 25V

C937 67G215V471 4K ED 470UF 25V

L903 73G 253 91 LS CHOKE BY LI SHIN

L904 73G 253 91 LS CHOKE BY LI SHIN

L901 73L 174 53 LG GP CHOKE

T901 80GL17T 37 L GP XFMR FOR POWER LITAI

PT801 80GL19T 8DN1 OZ9RR_TRANS

PT802 80GL19T 8DN1 OZ9RR_TRANS

F901 84G 55 7W FUSE 3.15A 250V WICKMAN

BD901 93G 50460900 GBU408

CN902 95G8014 12569 WIRE HARNESS

P1G1730 8128 CR3 SCREW M3x8

705GQ7K0 93003 D909 ASS'Y

705G 780 87 27 CN901 ASS'Y

705G 980 61S01 R905 ASS'Y

705G 980 61S02 R914 ASS'Y

705GQ7K0 57001 D903 ASS'Y

705GQ7K0 93001 D908 ASS'Y

PW942HT1AIP POWER BOARD FOR AI

IC901 56G 379 61 A LD7575PS SOP-8

IC801 56G 608 10 Y OZ9938GN

http://www.wjel.net

RTV 胶

53

Page 54

19" LCD Color Monitor I-INC AH191D

Q801 57G 417 4 PMBS3904/PHILIPS-SMT(04

Q802 57G 417 4 PMBS3904/PHILIPS-SMT(04

Q803 57G 417 4 PMBS3904/PHILIPS-SMT(04

Q804 57G 759 2 RK7002

Q807 57G 759 2 RK7002

Q808 57G 759 2 RK7002

Q809 57G 759 2 RK7002

Q810 57G 759 2 RK7002

Q805 57G 763 14 AM9945N

Q806 57G 763 14 AM9945N

JR804 61L0805000 CHIP O OHM 1/8W

JR805 61L0805000 CHIP O OHM 1/8W

JR807 61L0805000 CHIP O OHM 1/8W

R810 61L0805100 4F CHIPR 1M OHM +-1% 1/8W

R816 61L0805100 4F CHIPR 1M OHM +-1% 1/8W

R836 61L0805102 CHIPR 1K OHM +-5% 1/10W

R843 61L0805102 CHIPR 1K OHM +-5% 1/10W

R920 61L0805102 CHIPR 1K OHM +-5% 1/10W

R921 61L0805102 CHIPR 1K OHM +-5% 1/10W

R922 61L0805102 CHIPR 1K OHM +-5% 1/10W

R926 61L0805102 CHIPR 1K OHM +-5% 1/10W

R803 61L0805103 CHIPR 10K OHM +-5% 1/10

R804 61L0805103 CHIPR 10K OHM +-5% 1/10

R806 61L0805103 CHIPR 10K OHM +-5% 1/10

R812 61L0805103 CHIPR 10K OHM +-5% 1/10

R912 61L0805103 CHIPR 10K OHM +-5% 1/10

R815 61L0805104 CHIPR 100K OHM+-5% 1/10

R913 61L0805104 CHIPR 100K OHM+-5% 1/10

R813 61L0805105 CHIP 1M OHM 5% 1/8W

R846 61L0805105 CHIP 1M OHM 5% 1/8W

R847 61L0805105 CHIP 1M OHM 5% 1/8W

R848 61L0805105 CHIP 1M OHM 5% 1/8W

R849 61L0805105 CHIP 1M OHM 5% 1/8W

R860 61L0805105 CHIP 1M OHM 5% 1/8W

R809 61L0805184 180K OHM 1/8W

R808 61L0805204 200K OHM 1/10W

R924 61L0805240 1F CHIPR 2.4KOHM +-1% 1/8W

R802 61L0805304 300K OM 1/8W

R817 61L0805330 2F CHIP 33KOHM 1/8W 1%

R923 61L0805330 2F CHIP 33KOHM 1/8W 1%

R925 61L0805360 1F CHIP 3.6KOHM 1/8W 1%

R826 61L0805430 0F RST CHIPR 430 OHM +-1%

R841 61L0805430 0F RST CHIPR 430 OHM +-1%

R850 61L0805472 CHIRP 4.7K OHM +-5% 1/1

R852 61L0805472 CHIRP 4.7K OHM +-5% 1/1

R853 61L0805472 CHIRP 4.7K OHM +-5% 1/1

R811 61L0805473 CHIPR 47K OHM +-5% 1/10

R825 61L0805513 CHIP 51KOHM 1/8W

http://www.wjel.net

54

Page 55

19" LCD Color Monitor I-INC AH191D

R824 61L0805751 750 OHM

R858 61L0805751 750 OHM

R827 61L0805752 CHIP 7.5K OHM 1/10W