Page 1

HMS Industrial Networks

Mailing address: Box 4126, 300 04 Halmstad, Sweden

Visiting address: Stationsgatan 37, Halmstad, Sweden

E-mail: info@hms-networks.com

Web: www.anybus.com

User Manual

Anybus® M-Bus to Modbus-TCP Gateway

Doc: HMSI-27-300

Rev. 1.10

Page 2

Table of Contents

About This Document

Related Documents ..................................................................................................................................1

Document History ...................................................................................................................................1

Conventions & Terminology .................................................................................................................. 1

Notes and warnings.......................................................................................................................... 1

Font conventions............................................................................................................................... 1

Glossary........................................................................................................................................... 2

Support....................................................................................................................................................... 2

Intellectual Property Rights............................................................................................................... 1

Trademark Acknowledgements......................................................................................................... 1

General Information

Introduction .............................................................................................................................................. 2

Description ................................................................................................................................................3

Connections...................................................................................................................................... 3

Table of Contents

Installation

Startup ........................................................................................................................................................ 4

Network configuration ............................................................................................................................ 4

CHIPtool ........................................................................................................................................ 5

Configuration

The web interface ..................................................................................................................................... 7

General tab...................................................................................................................................... 8

Meter tab......................................................................................................................................... 9

Configuration tab ........................................................................................................................... 12

Server tab.......................................................................................................................................14

Security tab .................................................................................................................................... 14

User tab......................................................................................................................................... 15

Service tab...................................................................................................................................... 17

Print page ......................................................................................................................................17

Modbus TCP specification

Function codes........................................................................................................................................18

Data format ............................................................................................................................................. 19

Dummy data.................................................................................................................................. 19

Acquiring and processing meter data

Meter configuration................................................................................................................................20

Scanning for meters......................................................................................................................... 20

Adding meters manually................................................................................................................. 21

Meter data format ................................................................................................................................... 22

Predefined Media ID Values ......................................................................................................... 22

Predefined measurement value types................................................................................................. 23

Predefined units ............................................................................................................................. 25

Modbus register layout.................................................................................................................... 26

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 3

Troubleshooting

Hardware errors ......................................................................................................................................28

Gateway does not respond............................................................................................................... 28

Current consumption too high ......................................................................................................... 28

Network errors........................................................................................................................................29

Web interface and FTP server not accessible.................................................................................... 29

No network connection ................................................................................................................... 29

No write access to the web interface ................................................................................................. 30

Web session is unexpectedly terminated........................................................................................... 30

FTP login failure ........................................................................................................................... 30

Meter reading errors ............................................................................................................................... 31

No meters are detected .................................................................................................................... 31

Some meters are not detected............................................................................................................ 31

Meters are detected but have no data............................................................................................... 32

Scanning takes too long .................................................................................................................. 32

Gateway restarts occasionally during scan........................................................................................ 32

Webserver capacity error message..................................................................................................... 33

Meter data transmit error ......................................................................................................................33

Meter data not transmitted via Modbus.......................................................................................... 33

1-2

Advanced features

Software update ......................................................................................................................................34

Updating the operating system (RTOS) .......................................................................................... 35

Updating application software (firmware)........................................................................................ 36

Telnet connection................................................................................................................................... 37

FTP connection ......................................................................................................................................37

Configuration files ..................................................................................................................................38

System configuration file.................................................................................................................. 38

Meter configuration file ................................................................................................................... 41

Technical Specifications

General..................................................................................................................................................... 42

Dimensions and weight................................................................................................................... 42

Installation..................................................................................................................................... 42

Customs declaration........................................................................................................................ 42

Electrical ..................................................................................................................................................43

Power supply ..................................................................................................................................43

Meter interfaces .............................................................................................................................. 43

Communication interfaces ............................................................................................................... 43

Galvanic isolation........................................................................................................................... 43

Processing unit................................................................................................................................43

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 4

P. About This Document

For more information, related documentation, etc., please visit the HMS website www.anybus.com.

P.1 Related Documents

Document Author

- -

P.2 Document History

Revision List

Revision Date Author(s) Chapter(s) Description

1.00 2015-02-26 ThN All First official release

1.10 2016-04-08 ThN 1, 6, A Added model with max 80 loads

Preface

P.3 Conventions & Terminology

The following conventions are used throughout this manual:

1. Numbered lists provide sequential steps.

• Bulleted lists provide information, not procedure steps.

P.3.1 Notes and warnings

This indicates additional important information.

This indicates important instructions that must be followed to avoid

equipment failure or damage.

P.3.2 Font conventions

Reboot system Menu command or button in graphical user interface.

MBUS_MAXRETRY Parameter entry in a source file.

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 5

P.3.3 Glossary

Abbreviation Explanation

CSV Character-Separated Values

DNS Domain Name System

DI Digital Input

DO Digital Output

DIN Deutsches Institut für Normung, German standardization body

DLDE Direct Local Data Exchange (EN 62056-21, IEC 1107)

DLDERS DLDE communication via RS-232 or RS-485

DLMS Gateway Language Message Specification

I/O In- / Output

ESD ElectroStatic Discharge

FNN Forum Netztechnik/Netzbetrieb

Forum for network technology / network operation (committee of VDE)

FTP File-Transfer Protocol

GPRS General Packet Radio Service

GSM Global System for Mobile Communications

HTTP Hypertext Transfer Protocol

ID Identification, Identifier

IP Internet Protocol or. IP address

LED Light-Emitting Diode

M-Bus Meter-Bus (EN 13757-2/3)

MAC Medium Access Control or MAC address

MUC Multi Utility Communication, MUC-Controller

OEM Original Equipment Manufacturer

PEM Privacy Enhanced Mail

PPP Point-to-Point Protocol

PPPoE Point-to-Point Protocol over Ethernet

RFC Requests For Comments

RSSI Received Signal Strength Indicator

RTC Real Time Clock

RTOS Real Time Operating System

S0 S0 interface (pulse interface, EN 62053-31)

SIM Subscriber Identity Module

SML Smart Message Language

SMTP Simple Mail Transfer Protocol

SNTP Simple Network Time Protocol

TCP Transmission Control Protocol

TLS Transport Layer Security

UTC Coordinated Universal Time

VDE Verband der Elektrotechnik Elektronik Informationstechnik e.V.

(association for electrical, electronic & information technologies)

WAN Wide Area Network

wM-Bus Wireless Meter-Bus (EN 13757-3/4)

XML eXtensible Markup Language

About This Document 2

P.4 Support

For general contact information and support, please refer to the HMS website www.anybus.com.

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 6

Important User Information

This document contains a general introduction as well as a description of the technical features provided by the

Anybus M-Bus to Modbus-TCP Gateway, including the PC-based configuration software.The document only describes the features that are specific to this product.

The reader of this document is expected to be familiar with PLC technology and communication systems in general. The reader is also expected to be familiar with the Microsoft® Windows® operating system.

Liability

Every care has been taken in the preparation of this manual. Please inform HMS Industrial Networks AB of any

inaccuracies or omissions. The data and illustrations found in this document are not binding. We, HMS Industrial

Networks AB, reserve the right to modify our products in line with our policy of continuous product development.

The information in this document is subject to change without notice and should not be considered as a commitment by HMS Industrial Networks AB. HMS Industrial Networks AB assumes no responsibility for any errors that

may appear in this document.

There are many applications of this product. Those responsible for the use of this gateway must ensure that all

the necessary steps have been taken to verify that the applications meet all performance and safety requirements

including any applicable laws, regulations, codes, and standards.

HMS Industrial Networks AB will under no circumstances assume liability or responsibility for any problems that

may arise as a result from the use of undocumented features, timing, or functional side effects found outside the

documented scope of this product. The effects caused by any direct or indirect use of such aspects of the product

are undefined, and may include e.g. compatibility issues and stability issues.

The examples and illustrations in this document are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular implementation, HMS Industrial Networks AB cannot

assume responsibility for actual use based on these examples and illustrations.

Intellectual Property Rights

HMS Industrial Networks AB has intellectual property rights relating to technology embodied in the product described in this document. These intellectual property rights may include patents and pending patent applications

in the US and other countries.

Trademark Acknowledgements

Anybus ® is a registered trademark of HMS Industrial Networks AB. All other trademarks are the property of their

respective holders.

Warning: This is a class A product. in a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

ESD Note: This product contains ESD (Electrostatic Discharge) sensitive parts that may be damaged if ESD

control procedures are not followed. Static control precautions are required when handling the product. Failure to observe this may cause damage to the product.

Anybus M-Bus to Modbus-TCP Gateway User Manual

Copyright© HMS Industrial Networks AB

Doc: HMSI-27-300

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 7

1. General Information

1.1 Introduction

The M-Bus (Meter-Bus) is defined in the standard EN 13757, and is an established and well known interface for automated meter reading. Ease of installation (simple two-wire system with powering by the

bus) and robustness are the most important features. M-Bus has its own physical layer and protocol, so

a translation is necessary to connect it to other systems.

In the field of automation, Modbus TCP is one of the most common communication standards. The

Anybus M-Bus to Modbus-TCP Gateway allows the direct transmission of meter data to a control system (PLC, DDC etc.) using Modbus TCP.

The Anybus M-Bus to Modbus-TCP Gateway supports operating up to either 20 or 80 meters (standard

loads) on the M-Bus depending on the selected gateway version. A powerful protocol stack is implemented. It handles the complete data handling on the Anybus M-Bus to Modbus-TCP Gateway compliant to the standard. All available meters on the market can be read out and processed without further

manual configuration. The meter data is available for other systems without effort.

The Anybus M-Bus to Modbus-TCP Gateway serves as a Modbus TCP slave gateway (Modbus TCP

server) via its Ethernet port. The PLC as a Modbus master (Modbus TCP client) can access meter data

via a network connection. The data is available in different Modbus registers.

Chapter 1

The Anybus M-Bus to Modbus-TCP Gateway reads out the meters autonomously, which is why an initial configuration of the gateway is necessary. A built-in web interface simplifies this process. Via this

web interface all the functionality of the gateway is available to the user. In addition to basic system configuration values can be selected to be available via Modbus, M-Bus scans can be performed, and the

current data is reported. Remote control or remote service is also facilitated through the web interface.

The Anybus M-Bus to Modbus-TCP Gateway comes in a 2U enclosure and is intended for standard

35 mm DIN rail mounting.

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 8

1.2 Description

24VDC

GND

MBUS+

MBUS-

MBUS+

MBUS-

1.2.1 Connections

The Anybus M-Bus to Modbus-TCP Gateway has the following connections:

General Information 3

Connector Pin assignment Note

Power supply 24 VDC: positive power supply

GND: negative power supply

M-Bus connectors MBUS+: positive bus line (2x)

MBUS-: negative bus line (2x)

Ethernet interface 1: TX+

2: TX−

3: RX+

4: Termination

5: Termination

6: RX−

7: Termination

8: Termination

24 VDC (±5%), Screw clamp

Cross sectional area 2.5 mm²

Screw clamp

Cross sectional area 2.5 mm²

MBUS+ and MBUS- are shorted each

According to TIA-568A/B

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 9

2. Installation

2.1 Startup

After connecting the supply voltage the gateway will boot up automatically.

The following calls are made on system startup:

• Configuration of the network interface (Ethernet) via DHCP or static configuration

• Providing a RAM drive as drive C:

• Obtaining the system time via SNTP

• Starting the main program

The main program provides the entire functionality including the web interface of the gateway.

2.2 Network configuration

The gateway is configured through the built-in web interface, see 3. Configuration.

Chapter 2

To be able to access the web interface, the IP address of the gateway must be in the same subnet (IP

address range) as your local network. If you are unsure about the configuration of your network, please

consult your network administrator.

Default network configuration of Anybus M-Bus to Modbus-TCP Gateway

Static IP address 192.168.1.101

Subnet mask 255.255.255.0

Gateway 192.168.1.254

If the default IP address of the gateway (192.168.1.101) is not within your subnet range, you can change

the IP address using CHIPtool, a free Windows®-based application which can be downloaded here

If the link above does not work, go to the main Beck IPC GmbH download web page

http://www.beck-ipc.com/en/download/index.asp

Changing the network configuration may restrict accessibility. If the

network parameters have been correctly set by an administrator you

should not change them.

and search for “CHIPtool”.

.

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 10

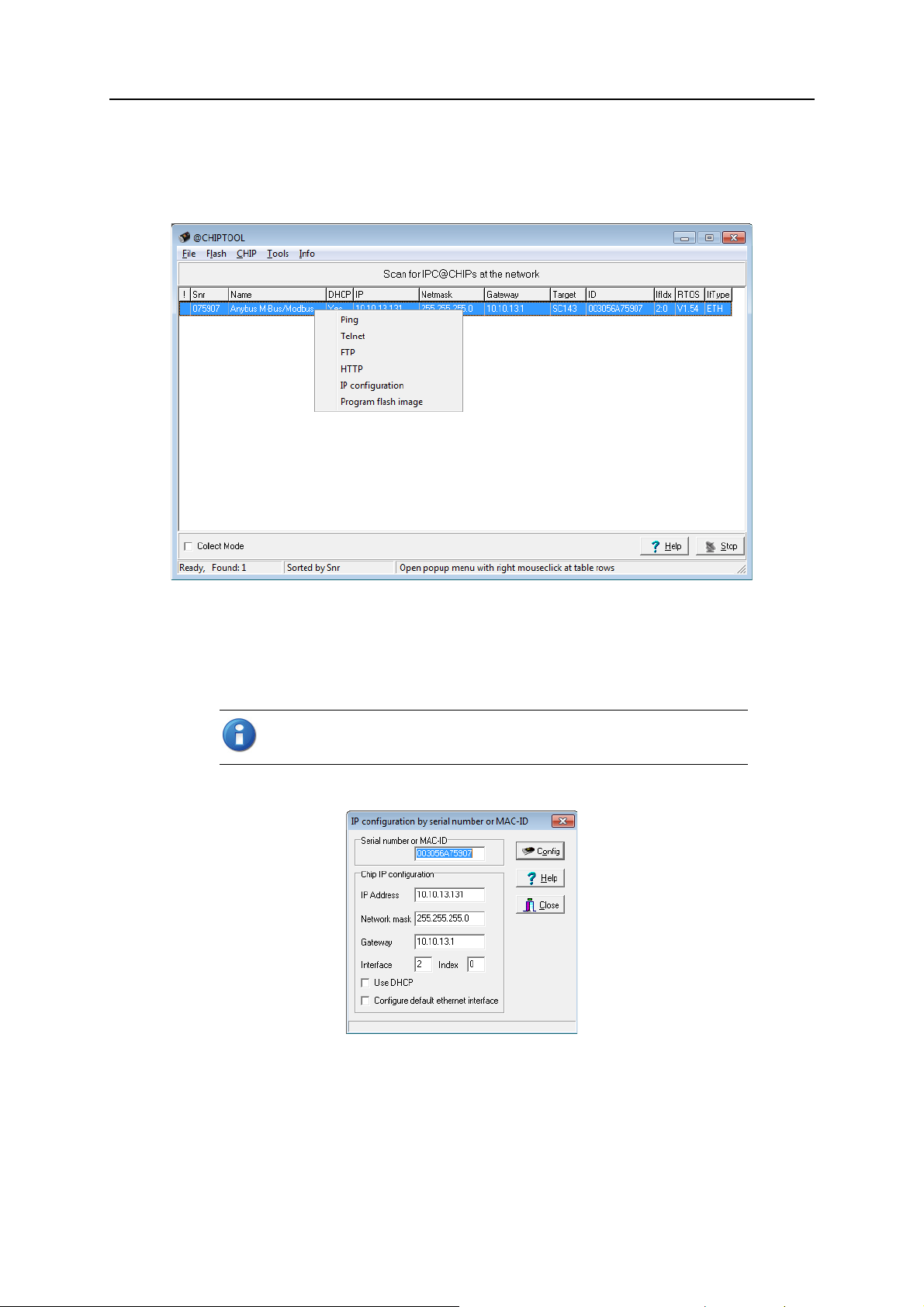

2.2.1 CHIPtool

1. Download and install CHIPtool, then start it using the link in the Windows Start Menu.

The first window will show a list of all detected devices in the local network.

Installation 5

2. Right-click on the gateway that you wish to configure, then select

context menu.

3. If your network has a DHCP server, check

If your network does not have a DHCP server, change the

Gateway settings manually to match your network.

If Use DHCP is checked but the gateway is not able to obtain an IP address dynamically, it will choose a random IP address in the range 169.254.xxx.xxx.

4. Press

Config to save the IP configuration to the gateway.

Use DHCP for automatic configuration.

IP Address, Network mask and

IP configuration from the

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 11

Installation 6

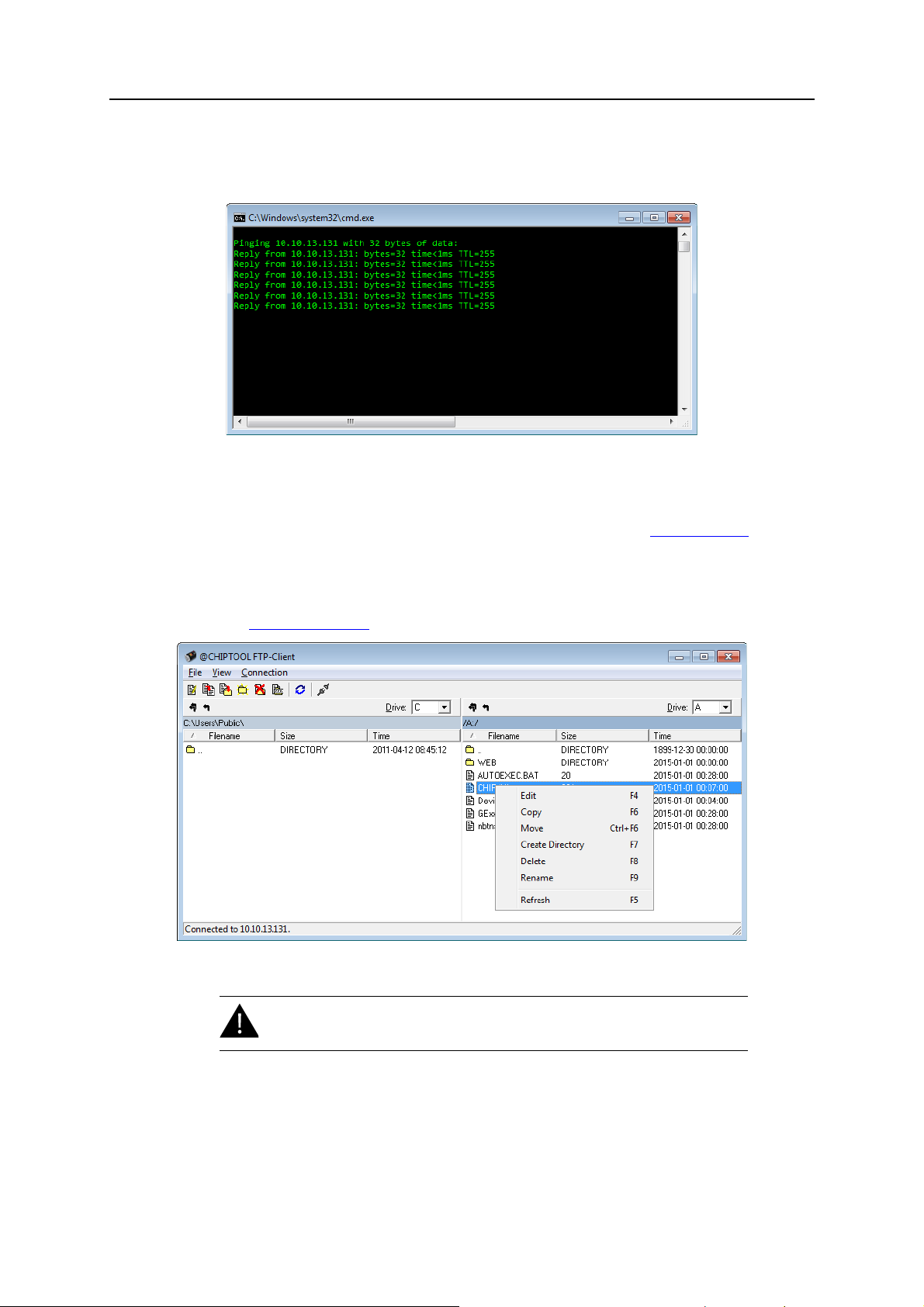

Connection test (ping)

The

Ping command in the CHIPtool context menu can be used for testing the connection. It will open

a Windows command line window and run a standard ping command.

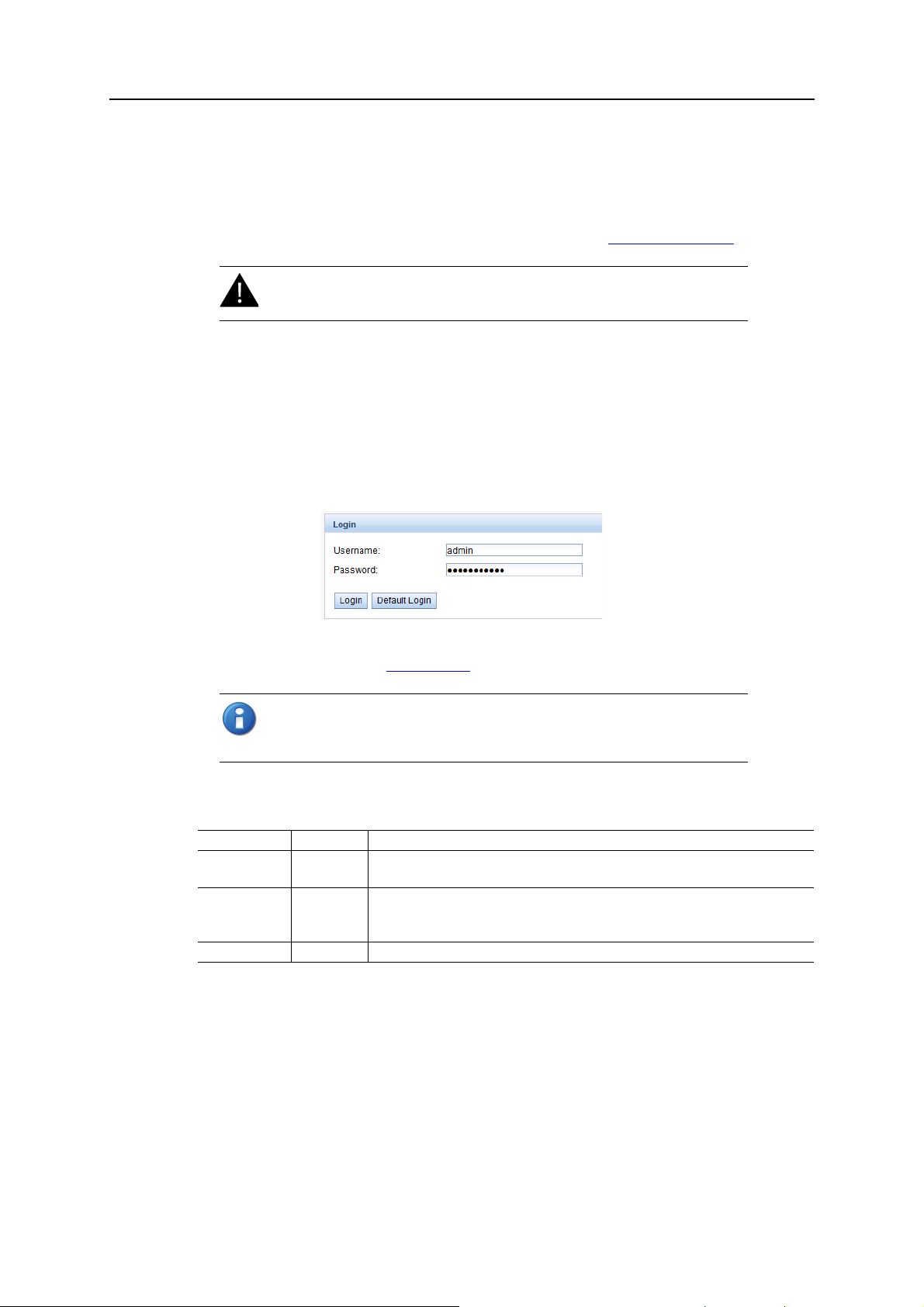

File access (FTP)

The

FTP command in the CHIPtool context menu opens a built-in FTP client, allowing access to the

file system in the gateway. FTP access is restricted to certain users, see also 3.

Configuration.

After logging in, the FTP client will open a file manager window where the left half shows the file system

in your computer, and the right half the the file system in the gateway. Right-clicking on a file or folder

will open a context menu with file commands.

See also 7.3

FTP connection.

Changes to the files and file system should only be carried out by trained

personnel as it may restrict the functionality of the gateway.

Web access (HTTP)

The

HTTP command in the CHIPtool context menu will open the web interface of the gateway in the

default browser.

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 12

3. Configuration

The Anybus M-Bus to Modbus-TCP Gateway is normally configured via the web interface, which gives

access to all gateway parameters, meter configuration and services. The gateway can also be configured

by uploading configuration files directly to the gateway via FTP, see 7.

Changes to the files and file system should only be carried out by trained

personnel as it may restrict the functionality of the gateway.

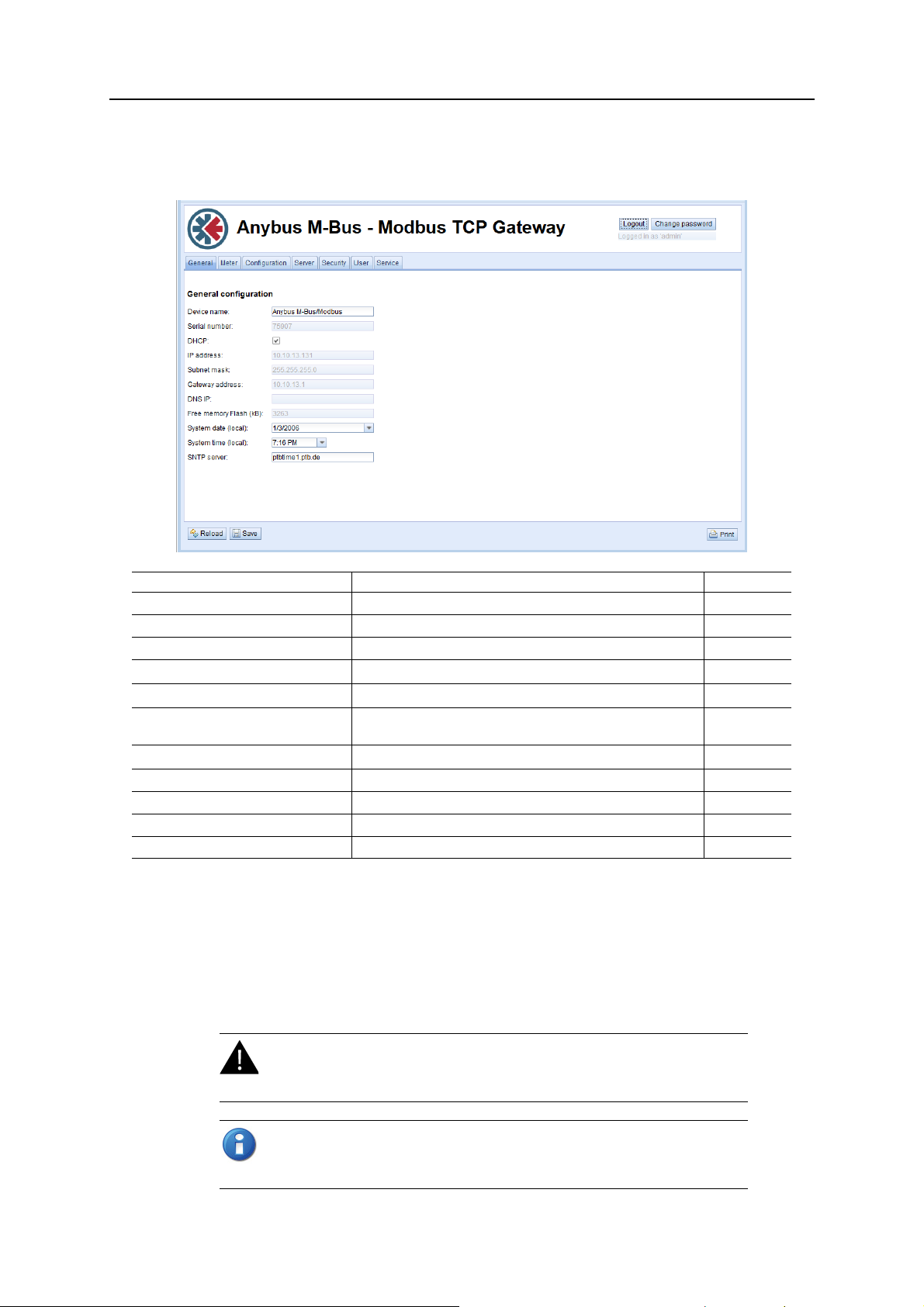

3.1 The web interface

Auto login

The first time you access the web interface you will be automatically logged in with the default username

and password. You can also log in as the default user manually by clicking

screen. The default user only has read access.

Advanced features.

Default Login on the login

Chapter 3

If the default user has been disabled in the configuration, you need to enter a valid username and password and click

Default users and passwords

User Password Description

admin admin Administrator user with root access, allows full access to all services

web web Default user for the web interface. Allows write access to the web interface.

ftp ftp User for FTP access to the log directory (C:/log/)

Login. See also 3.1.6 User tab.

If you are logged in with write access you should always log out after finishing the

configuration, as only one user with write access can be logged in at a time. If

your session stays active, other users will not be able to log in with write access.

(HTTP, FTP, flash update, IP configuration).

If a user with this name and password exists, the web server will automatically log in

with these credentials when accessed.

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 13

3.1.1 General tab

The General tab shows an overview of the current gateway configuration..

Configuration 8

Field Description Write access

Gateway name Name of the gateway (displayed in CHIPtool) Yes

Serial number Serial number of the gateway No

DHCP Enable automatic network configuration Yes

IP address

Subnet mask

Gateway address

DNS IP

Free Memory Flash (kB) Free storage space on internal memory of the controller No

System date (local) Current local system date Yes

System time (local) Current local system time Yes

SNTP Server Address of time server Yes

a. If DHCP is checked, the network parameter fields will be disabled

a

a

a

a

Reload discards the changes made on the page and reloads the currently active settings.

Save saves the changes and reinitializes the gateway.

IP address of gateway Yes

Subnet mask of gateway Yes

IP address of your local network gateway (not to be confused with

the Anybus M-Bus to Modbus-TCP Gateway)

IP address of DNS server Yes

Yes

If the network configuration is changed, the gateway will be available under the new IP address after you

click

Save. All established network connections to the gateway will be terminated and logged in users

will be logged out automatically.

Changing the network configuration may restrict accessibility. If the

network parameters have been correctly set by an administrator you

should not change them.

Date and time are processed internally as UTC time (without time zone shift).

The web browser will then convert the date and time according to the local time

zone of the computer.

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 14

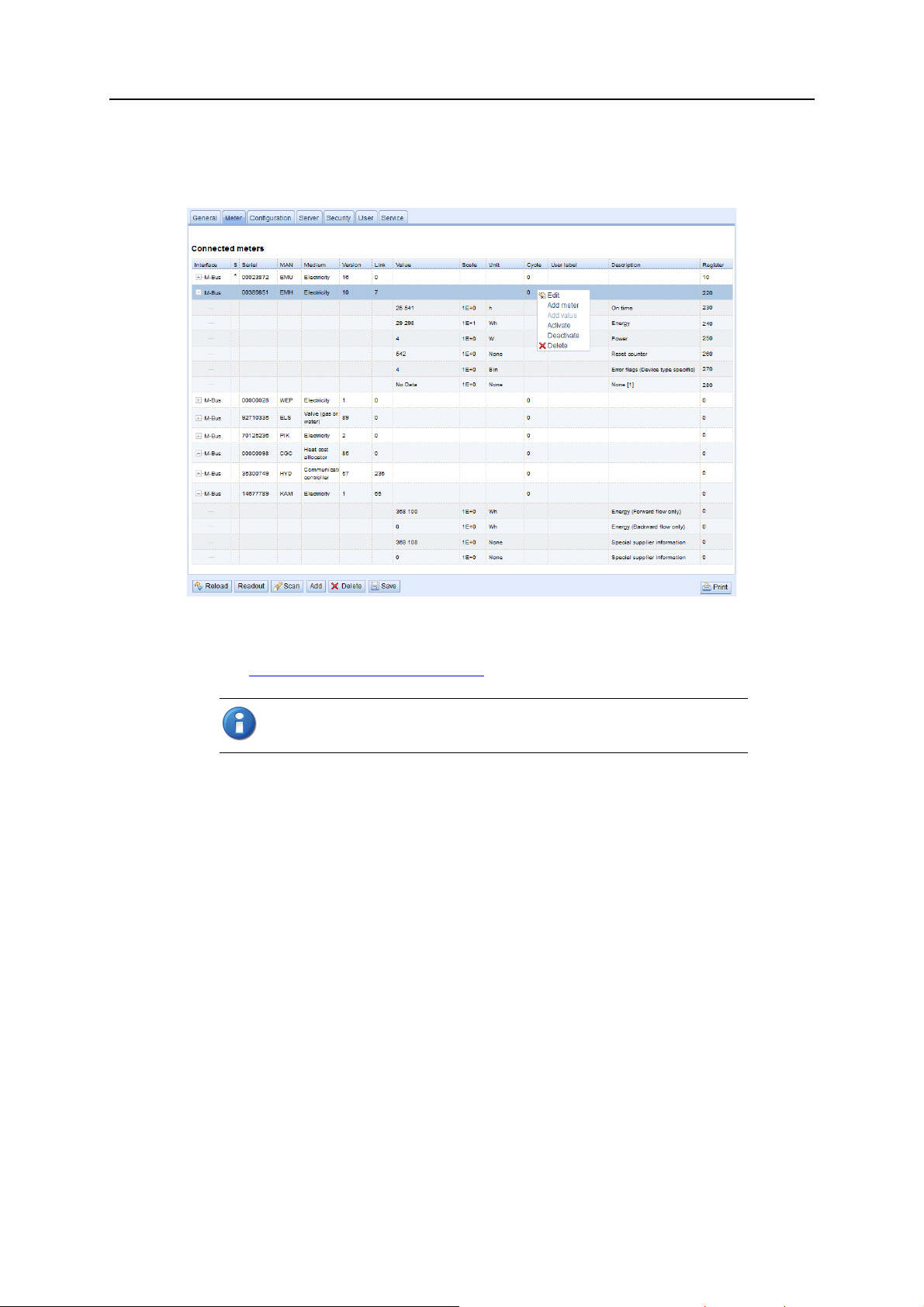

3.1.2 Meter tab

The Meter tab displays a list of connected meters and allows you to search, add and edit entries.

Configuration 9

The meter list is initially empty. After connecting one or several meters to the gateway, click

start populating the list. The scan is configured on the

See also 5.

The default configuration for each meter is applied immediately after scanning. Additional changes to

the configuration must be saved manually.

The list is additively expanded with each scan, and existing meters will not be deleted even if they are

not available anymore.

The meter configuration can be changed with the buttons in the bottom area of the page, or by rightclicking a meter entry. Meters entries and meter value entries can – within the limitations of the used

interface – be automatically searched, created, deleted or edited.

Meter entries and meter value entries can be selected with a single mouse click. Multiple selections are

possible by holding the SHIFT or CTRL keys.

When activating or deactivating a meter, its meter values are automatically enabled or disabled according

to the hierarchy. If a meter is inactive, it is activated by enabling one of its meter values.

Acquiring and processing meter data.

Scanning can take a long time, depending on the mode and number of connected

meters. The scan process cannot be interrupted.

Configuration tab.

Scan to

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 15

Configuration 10

Meter tab fields

Field Description Write access

Interface Interface of meter (M-Bus) No

S Entry status – E indicates that value has been edited Yes

Serial Serial number of meter No

MAN Manufacturer of meter (abbreviation) No

Medium Medium of meter (see 5.2.1

Version Version number of meter No

Value Meter reading or measurement value No

Scale Scale factor (scientific notation) No

Unit Unit (see 5.2.1

Cycle Readout interval in seconds (entering 0 means using the general readout interval) Yes

User label User specific description of meter or value.

Included in export of CSV data, allows application specific mapping.

Description Description of meter value (see 5.2.1

Register Modbus register address, in steps of 10 (see 5.2.4

Active Activates the transfer of meter or meter value via Modbus TCP Yes

Predefined Media ID Values)No

Predefined Media ID Values)No

Yes

Predefined Media ID Values)No

Modbus register layout)Yes

The arrangement of data in the meter list corresponds to the order of the data in the M-Bus protocol.

The meaning of the values can thus be compared directly with the data sheet of the meter. It is also possible to assign the meter values to the raw data of the meter (see 3.1.3

Configuration tab).

Timestamps transmitted within the M-Bus protocol are automatically assigned to the other meter values

where possible. Therefore, some of these may not appear in the list.

The configuration parameter MUC_SHOWTIMESTAMPENTRIES offers the possibility to manually

enable the display of all time stamps (see 7.4.1

System configuration file).

If a scan or a change in the meter list is terminated with the error message “Webserver capacity exceeded”, see 6.3.6

Webserver capacity error message.

Meters that are not found during a scan, or that do not support an automated scan, can be added manually to the meter list using the button

See also 5.1.2 Adding meters manually

Add or the context menu entry Add meter.

.

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 16

Editing meter and value entries

Configuration 11

Meter and value entries can be configured by right-clicking the entry and selecting

menu, or by double-clicking the entry. The fields in the Edit dialog correlate with the fields in the meter

list. Depending on the used interface some fields may be disabled for editing.

The readout interval in seconds can be set independently for each meter in the field

is entered the global readout interval is used, see 3.1.3

Each meter or value entry can be assigned a

consist of a maximumof 50 characters including spaces.

User label for application-specific use. The User label can

Configuration tab.

Edit in the context

Cycle. If no value

Valid characters in User Label:

Unvalid characters:

Modbus address allocation

The Modbus register address can be assigned or reset for a single meter or all meters via the context

menu choices

checked for duplicates. If duplicate addresses are detected an error message will be shown.

Buttons at bottom of page

Readout will update all values regardless of their normal readout interval. This momentary readout may

take some time to create depending on the number of meters that are connected. The normal readout

cycle is not affected by a momentary readout.

Delete will delete the selected entry in the meter list. Individual meter value entries can not be deleted.

Reload discards the changes made on the page and reloads the currently active settings.

Save saves the changes and reinitializes the gateway.

Allocate and Deallocate. When the configuration is saved, the Modbus addresses will be

A-Z, a-z , 0-9

! § $ % & / ( ) = ? + , . *

< > “ ”

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 17

3.1.3 Configuration tab

The Configuration tab provides global meter settings.

Configuration 12

Reload discards the changes made on the page and reloads the currently active settings.

Save saves the changes and reinitializes the gateway.

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 18

Configuration 13

Configuration tab fields

Field Description Write access

Readout interval (s) Standard readout cycle of meters (in seconds). Value might be overwritten for each

meter by parameter Cycle in tab Meter

Description mode Mode of displaying the meter value description on the website:

None: No display of description

Standard: Display of common value description

Extended: Extended display of value description (parameters will be displayed if they differ from 0):

Notation:Description [Memory No.] <Tariff> {min|max|error}

Example:Energy [2] <1> {max}

Extended with DIF/VIF: Extended display including DIF and VIF raw data

Notation:Description [Memory No.] <Tariff> {Value Type} # XX XX XX …

Example:Energy [2] <1> # 8C 11 04

Extended with raw data: Extended display including the raw data oft he complete meter

value entry.

Notation corresponds to Extended with DIF/VIF:

Example:Energy [2] <1> # 8C 11 04 96 47 06 00

DIF/VIF:

Display of DIF/VIF raw data

Raw data:

Displays the raw data oft he complete meter value entry

After changing this parameter a readout is needed to update the meter list and to display

the relevant data.

Maximum gateway count Limitation of the number of meters to scan. (0: no limitation).

Already configured meters are not limitated by this parameter.

Maximum value count Limitation of the number of meter value entries to read during a readout (0: no limitation).

Already configured meter value entries are not limitated by this parameter.

RAW log active Activates the raw data log. Yes

M-Bus mode M-Bus scan mode (secondary, reverse secondary or primary search) Yes

Primary start address First address for primary search Yes

Primary final address Last address for primary search Yes

Secondary address mask Search mask for secondary search, 8 numerical characters; „F“ defines a wildcard; miss-

ing characters will be filled up with leading zeros

M-Bus baud rate Baudrate for M-Bus communication (300-19200 baud) Yes

M-Bus timeout M-Bus timeout until reception of first data (in ms) Yes

M-Bus idle timeout M-Bus timeout until end of reception (in ms) Yes

M-Bus full timeout M-Bus timeout (complete) for reception of a whole data packet (in ms) Yes

M-Bus request mode Mode of the M-Bus readout (REQ_UD2):

Standard: Readout with REQ_UD2

Extended 1: Readout with Get-All-Data (DIF/VIF 7F 7E) and REQ_UD2

Extended 2: Readout with Get-All-Data (DIF 7F) and REQ_UD2

M-Bus reset mode Mode of the M-Bus Reset (before scan and readout):

None: no reset

Standard: Send SND_NKE to primary address of the meter or broadcast address when

using secondary adressing

Extended 1:

Send SND_NKE to primary address FD and SND_NKE to primary address of the meter

or broadcast address when using secondary addressing

Extended 2: Send SND_NKE and an Application Reset to primary address FD and a

SND_NKE to the primary address of the meter or to broadcast address when using sec-

ondary addressing.

M-Bus max. multipage Limits the count of multipage requests Yes

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 19

Configuration 14

3.1.4 Server tab

The Server tab provides settings for the Modbus TCP interface.

Field Description Write access

Modbus Mode Select Modbus TCP (normal mode) or dummy data (see 4.2.1

Modbus Port Port number to which the Modbus TCP client (master) should connect Yes

Reload discards the changes made on the page and reloads the currently active settings.

Dummy data)Yes

Save saves the changes and reinitializes the gateway.

3.1.5 Security tab

The Security tab allows enabling/disabling of FTP and Telnet access to the gateway.

Field Description Write access

FTP server active Enable/disable FTP access Yes

Telnet server active Enable/disable Telnet access Yes

Reload discards the changes made on the page and reloads the currently active settings.

Save saves the changes and reinitializes the gateway.

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 20

Configuration 15

3.1.6 User tab

The User tab allows you to create and manage users and assign them specific access rights. The following users are pre-configured on delivery:

User Password Description

admin admin Administrator user with root access, allows full access to all services

(HTTP, FTP, flash update, IP configuration).

web web Default user for the web interface. Allows full access to the web interface.

If a user with this name and password exists, the web server will automatically log in

with these credentials when accessed.

ftp ftp User for FTP access to the log directory (C:/log/)

Access rights to the different tabs of the web interface and to the FTP server can be set individually for

each user by ticking the check boxes. Most of the choices are self-explanatory.

Change password means that the user is allowed to change his/her password.

Sessions indicates the currently active sessions for this user.

Maximum sessions indicates the maximum number of simultaneous sessions allowed for the user,

where -1 means unlimited.

To edit the password and the max session setting, either double-click on a user entry or right-click on

the user entry and select

the new password in the

Edit. To change the password, tick the Set password checkbox, then enter

Password field.

The admin user can not be edited this way. To change the admin password, log

in as admin and click

Change password at the top of the web page.

If you lose the admin password the unit must be reset. Please contact

Anybus support for assistance.

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 21

Configuration 16

User tab fields

Field Description Write access

Name Username No

Overwrite password Not used Yes

Change password User is allowed to change his/her password Yes

Sessions Number of currently open session with this user account No

Maximum sessions Maximum number of simultaneous sessions for this user (-1 = unlimited) Yes

Read General Read access for tab General Yes

Write General Write access for tab General Yes

Read Meter Read access for tab Meter Yes

Write Meter Write access for tab Meter Yes

Read Config Read access for tab Configuration Yes

Write Config Write access for tab Configuration Yes

Read Server Read access for tab Server Yes

Write Server Write access for tab Server Yes

Read Security Read access for tab Security Yes

Write Security Write access for tab Security Yes

Read Service Read access for tab Service Yes

Write Service Write access for tab Service Yes

Write User Read/Write access for tab User Yes

FTP User is allowed to access the FTP server (maximum 2 users) No

New users can be added by clicking the

selecting

Username cannot be changed once the user has been saved.

FTP Access will only allow access to the log data directory (C:\log). Only the admin user will have full

Add from the context menu.

Add button, or by right-clicking anywhere in the user list and

access to the file system via FTP. This means that you can grant access to logged data from a remote

client without exposing any other data or services of the gateway.

Delete deletes the selected user.

Reload discards the changes made on the page and reloads the currently active settings.

Save saves the changes and reinitializes the gateway.

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 22

Configuration 17

3.1.7 Service tab

The Service tab provides information about the hardware and software for maintenance use. The values

on this tab are read-only.

Reload will refresh the information.

Reboot will restart the gateway. All internal processes will be reinitialized after the reboot.

3.1.8 Print page

Clicking the Print button (bottom right) will export the complete configuration as a print-formatted

HTML page in a new browser tab or window.

Meter Configuration section of the print page is output in a table format that can be copied and

The

pasted directly into a spreadsheet.

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 23

4. Modbus TCP specification

The Modbus protocol was originally developed by the company Modicon (now Schneider Electric) for

the communication with their controllers. Data is transmitted in the terms of 16 Bit registers (integer

format) or as status information in terms of data bytes. Over the years, the protocol has been continuously expanded. Modbus TCP is a variant of Modbus and part of the standard IEC 61158.

A full specification for Modbus can be found here: www.modbus.org

The Modbus protocol is a single master protocol. The master controls the entire communication and monitors timeouts (no response from the addressed gateway). The connected gateways are only allowed to

respond to requests by the master.

The Anybus M-Bus to Modbus-TCP Gateway is a type of Modbus TCP server, a Modbus TCP slave.

Modbus TCP communication requires an established connection between a client (e.g. a PC or PLC)

and the gateway over a specified TCP port. The default port number is 502. See also 3.1.4

If a firewall is installed between the gateway and the client, make sure that the configured TCP port is

open in the firewall.

4.1 Function codes

Chapter 4

Server tab.

The following Modbus function codes are supported by the gateway:

Code Name Description

0x01 Read Coil Not used

0x03 Read Holding Register Reading of meter data

0x05 Write Single Coil Not used

0x06 Write Single Register Not used

0x10 Write Multiple Register Not used

0x0F Force Multiple Coil Not used

0x2B Read Gateway Identification Reading of gateway data by MEI = 0x0E

Function codes marked “Not used” are replied with ILLEGAL DATA ADDRESS (0x02); other unsupported codes are replied with ILLEGAL FUNCTION (0x01).

If the function code 0x2B (Read Gateway Identification) is used with MEI=0x03, the gateway will respond with identification data. The values 0x01 and 0x02 are supported as Gateway ID code, allowing

to retrieve basic and regular gateway identification data:

Code Name Data type Example Type

0x00 VendorName String HMS Basic

0x01 ProductCode String 1036 Basic

0x02 MajorMinorRevision String 001 Basic

0x03 VendorUrl String www.anybus.com Regular

0x04 ProductName String Anybus M-Bus to Modbus-TCP Gateway Regular

0x05 ModelName String Standard Regular

0x06 UserApplicationName String Modbus TCP Gateway Regular

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 24

Modbus TCP specification 19

4.2 Data format

The arrangement of data in the Modbus registers corresponds to the usual structure. It uses big endian

representation. For the 16 bit registers, the higher byte is sent first, then the lower byte.

Example:value: 0x1234 transmission order: 0x12, 0x34

If number and data ranges go beyond 16 bits, representation is similar. Again, the most significant 16 bit

register is sent first and is addressed with the lowest register address.

Example:value: 0x12345678 transmission order: 0x12, 0x34, 0x56, 0x78

The word order of 32 bit and 64 bit values can be changed within the system configuration file by setting

the parameter MODBUS_SWAP, see 7.4.1

4.2.1 Dummy data

For checking the data layout on the Modbus master side the gateway can be configured to generate dummy data (see 3.1.4

to the register layout described in 5.2.4

Address Value Description Decoded value

0 0x0002 Serial number of gateway, upper word 0x2993A

1 0x993A Serial number of gateway, lower word

2 0x0001 Version of the communication protocol 1

3 0x006F Firmware version of gateway 0x6F = 111: Version 1.11

4 0x519C Timestamp of gateway system time, upper word 0x519CC16D = 1369227629:

5 0xC16D Timestamp of gateway system time, lower word

6 0x0000 Empty field

7 0x0100 Type field of register set in upper byte 0x01: Gateway entry

8 0x0000 Empty field

9 0x0000 Empty field

10 0x00BC Serial No. of meter, upper word 0xBC614E = 12345678

11 0x614E Serial No. of meter, lower word

12 0x0443 3-letter manufacturer Code 0x0443: ABC

13 0x0102 Version (upper byte) and medium (lower byte) of the meter 0x0102: Version 1, medium 2 (electricity)

14 0x519C Timestamp of the meter, upper word 0x519CC164 = 1369227620:

15 0xC164 Timestamp of the meter, lower word

16 0x0000 Empty field

17 0x0200 Type field of register set in upper byte 0x02: Meter entry

18 0x0000 Empty field

19 0x0000 Empty field

20 0x0000 Meter value (integer), highest word 0xBC614E = 12345678

21 0x0000 Meter value (integer)

22 0x00BC Meter value (integer)

23 0x614E Meter value (integer), lowest word

24 0x449A Meter value (float), upper word 0x449A522B = 1234.567800

25 0x522B Mater value (float), lower word

26 0xFFFC Scaling factor (exponent to base 10) 0xFFFC = -4: Factor = 10^-4

27 0x0005 Type field of register set in upper byte

and unit of value in lower byte

28 0x519C Timestamp of meter value, upper word 0x519CBBB3 = 1369226163:

29 0xBBB3 Timestamp of meter value, lower word

Server tab). The following data will be represented via the Modbus interface according

System configuration file.

Modbus register layout:

Wednesday, May 22nd 2013, 15:00:29 GMT+2

Wednesday, May 22nd 2013, 15:00:20 GMT+2

Calculation:

12345678 * 10^-4 = 1234.5678 Wh

0x00: Meter value entry

0x05: Wh

Wednesday, May 22nd 2013, 14:36:03 GMT+2

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 25

5. Acquiring and processing meter data

The main task of the Anybus M-Bus to Modbus-TCP Gateway is the processing and transmission of

meter data. For proper operation, the following issues must be considered:

• The available meters must be configured correctly. Required meters or meter values must be enabled by the checkbox

• The read out meter data must be transmittable from the gateway to a PLC via Modbus TCP.

• The PLC must be able to interpret the meter data format.

5.1 Meter configuration

5.1.1 Scanning for meters

It is possible to search for meters automatically on the M-Bus interface. The meters primary or secondary addresses are used in an iterative scan process. When the scan process has been completed all detected meters will appear in the meter list.

Active and must have a valid register address.

Chapter 5

Scan mode (primary or secondary) is selected on the

The scan process itself is started from the

The M-Bus interface allows mixed configurations, i. e. it is possible to scan for primary addresses first

and then for secondary addresses in a second run. Newly detected meters are appended to the existing

list. Meters found in both runs stay in the list and remain unchanged if already configured. If a meter is

found for the first time during the primary search, the primary address is used for all further requests.

This applies also to secondary search and secondary addressing.

M-bus supports both primary and secondary addressing when accessing a meter. Secondary addressing

is recommended if the meters should be recognized and read out without additional configuration.

However, the read-out process is slower than with primary addressing. If all meters are pre-configured

with a unique primary address it is recommended to use primary addressing, narrowed down to the limits

for the primary addresses according to the expected values. The big advantage of primary addressing is

that meters of the exact same type and configuration (although with different serial numbers) can be

swapped without reconfiguring the gateway.

Automated allocation of the primary addresses or setting of parameters and registers of meters by the

gateway is available on request.

Meter tab (see 3.1.2 Meter tab).

Configuration tab (see 3.1.3 Configuration tab).

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 26

Acquiring and processing meter data 21

5.1.2 Adding meters manually

Meters that are connected to the M-Bus interface of the gateway but not found automatically during a

scan can be added manually from the

must be known to be able to add it manually.

Meter tab, see 3.1.2 Meter tab. The configuration of the meter

The fields in the

the interface to which the meter is connected, the serial number of the meter, the 3-letter manufacturer

code (see www.dlms.com

add a custom

The parameter

with the same configuration.

Click

OK to save the configuration. The new meter(s) will now appear in the list.

Add meter dialog correspond to the fields in the meter list. It is possible to configure

), the medium, the version number, and the desired update cycle . You can also

User label for identification purposes. The fields are explained in 3.1.2 Meter tab.

Number of meters makes it possible to create more than one meter at the same time

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 27

5.2 Meter data format

The media and value types and units used in meter data are pre-defined in the standard EN 13757-3.

Custom types and units may also be defined depending on the meter interface.

5.2.1 Predefined Media ID Values

Index Description

0Other

1Oil

2Electricity

3Gas

4 Heat (outlet)

5 Steam

6Warm water

7 Water

8 Heat cost allocator

9 Compressed air

10 Cooling (outlet)

11 Cooling (inlet)

12 Heat (inlet)

13 Combined heat / cooling

14 Bus / System component

15 Unknown medium

16 - 19 Reserved

20 Calorific value

21 Hot water

22 Cold water

23 Dual register (hot/cold) water

24 Pressure

25 A/D Converter

26 Smoke detector

27 Room sensor

28 Gas detector

29 - 31 Reserved

32 Breaker (electricity)

33 Valve (gas or water)

34 - 36 Reserved

37 Customer unit

38 - 39 Reserved

40 Waste water

41 Waste

42 Carbon dioxide

43 - 48 Reserved

49 Communication controller

50 Unidirectional repeater

51 Bidirectional repeater

52 - 53 Reserved

54 Radio converter (system side)

55 Radio converter (meter side)

56 - 255 Reserved

Acquiring and processing meter data 22

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 28

Acquiring and processing meter data 23

5.2.2 Predefined measurement value types

Index Description

0None

1 Error flags (Gateway type specific)

2 Digital output

3 Special supplier information

4Credit

5Debit

6Volts

7 Ampere

8Reserved

9 Energy

10 Volume

11 Ma ss

12 Operating time

13 On time

14 Power

15 Volume flow

16 Volume flow ext

17 Mass flow

18 Return temperature

19 Flow temperature

20 Temperature difference

21 External temperature

22 Pressure

23 Timestamp

24 Time

25 Units for H. C. A.

26 Averaging duration

27 Actuality duration

28 Identification

29 Fabrication

30 Address

31 Meter specific description - can be used to specify custom value types (text based)

32 Digital input

33 Software version

34 Access number

35 Gateway type

36 Manufacturer

37 Parameter set identification

38 Model / Version

39 Hardware version

40 Metrology (firmware) version

41 Customer location

42 Customer

43 Access code user

44 Access code operator

45 Access code system operator

46 Access code developer

47 Password

48 Error mask

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 29

Index Description

49 Baud rate

50 Response delay time

51 Retry

52 Remote control (gateway specific)

53 First storagenum. for cyclic storage

54 Last storagenum. for cyclic storage

55 Size of storage block

56 Storage interval

57 Vendor specific data

58 Time point

59 Duration since last readout

60 Start of tariff

61 Duration of tariff

62 Period of tariff

63 No VIF

64 wM-Bus data container

65 Data transmit interval

66 Reset counter

67 Cumulation counter

68 Control signal

69 Day of week

70 Week number

71 Time point of day change

72 State of parameter activation

73 Duration since last cumulation

74 Operating time battery

75 Battery change

76 RSSI

77 Day light saving

78 Listening window management

79 Remaining battery life time

80 Stop counter

81 Vendor specific data container

82 Reactive energy

83 Reactive power

84 Relative humidity

85 Phase voltage to voltage

86 Phase voltage to current

87 Frequency

88 Cold/Warm Temperature limit

89 Cumulative count max. power

90 - 255 Reserved

Acquiring and processing meter data 24

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 30

Acquiring and processing meter data 25

5.2.3 Predefined units

Index Unit Description

0NoneNone

1BinBinary

2 Cur Local currency units

3VVolt

4AAmpere

5 Wh Watt hour

6 J Joule

7m^3Cubic meter

8 kg Kilogram

9 s Second

10 min Minute

11 h Hou r

12 d Day

13 W Watt

14 J/h Joule per Hour

15 m^3/h Cubic meter per hour

16 m^3/min Cubic meter per minute

17 m^3/s Cubic meter per second

18 kg/h Kilogram per hour

19 Degree C Degree celsius

20 K Kelvin

21 Bar Bar

22 Dimensionless

23 - 24 Res Reserved

25 UTC UTC

26 bd Baud

27 bt Bit time

28 mon Month

29 y Year

30 Day of week

31 dBm dBm

32 Bin Bin

33 Bin Bin

34 kVARh Kilo voltampere reactive hour

35 kVAR Kilo voltampere reactive

36 cal Calorie

37 % Percent

38 ft^3 Cubic feet

39 Degree Degree

40 Hz Hertz

41 kBTU Kilo british thermal unit

42 mBTU/s Milli british thermal unit per second

43 US gal US gallon

44 US gal/s US gallon per second

45 US gal/min US gallon per minute

46 US gal/h US gallon per hour

47 Degree F Degree Fahrenheit

48 - 255 Res Reserved

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 31

Acquiring and processing meter data 26

5.2.4 Modbus register layout

The Anybus M-Bus to Modbus-TCP Gateway uses a fixed address structure of 10 Modbus registers per

address. Addresses are enumerated starting with 0.

• Data types using more than one register are encoded with the most significant word at the lowest

address.

• The function code 0x03 (Read Holding Register) is used for reading the data.

Within the Modbus protocol, data is formatted as either integer or float. Other data types (like BCD) are

converted to integer values before transmission.

The first 10 Modbus register, starting at address 0, are status registers of the gateway:

Address Name Data length Description

0 - 1 Serial number 32 Bit Serial number of the gateway in hexadecimal format

2 Protocol version 16 Bit Protocol version for the Modbus interface (value = 1)

3 Version 16 Bit Software version of the gateway (as integer)

4 - 5 Time stamp 32 Bit Unix timestamp of last read-out

Gateway system time must be set correctly (manually or via SNTP)

6 Reserved Reserved

7 Type field / reserved 16 Bit Type field for register set in the upper Byte (value=1 for gateway entry), lower byte is

reserved

8 - 9 Reserved Reserved

Each meter is characterized by 10 Modbus registers. Their offset has to be added to the starting register

address for each meter. They are defined as follows:

Offset Name Data length Description

0 - 1 Serial number 32 Bit Serial number of meter as integer value (not BCD), only decimal numbers allowed

2 Manufacturer ID 16 Bit Encoding of manufacturer by using different blocks of Bits: Bits 10 - 14: first character,

Bits 5 - 9: second character and Bits 0 - 4: third character, the particular values point to

the three letters, counting from “A” with value 1

3 Version / medium 16 Bit Version of meter in the upper Byte and the medium ID in the lower Byte

4 - 5 Time stamp 32 Bit Unix timestamp of last meter read-out, system time of the gateway shall be set correctly

(manually or via SNTP)

6 Reserved Reserved

7 Type field / reserved 16 Bit Type field for register set in the upper Byte (value=2 for meter entry), lower byte is

reserved

8 Flags 16 Bit Bit 0: Value 1: Meter could not be read, Value 0: Meter could be read correctly

Bit 1: Value1: Not all meter values are updated, Value 0: All meter values updated

Bit 2-15: Reserved

9 Reserved Reserved

Each meter value is characterized by 10 Modbus registers. Their offset has to be added to the starting

register address for each meter value. They are defined as follows:

Offset Name Data length Description

0 - 3 Meter value 64 Bit Signed integer value (not scaled)

4 - 5 Meter value 32 Bit Floating point value (scaled to unit in register 7), IEEE 754

6 Scale factor 16 Bit Signed scale factor (exponent to the power of 10)

7 Type field / unit 16 Bit Type field for register set in the upper Byte (value=0 for meter value entry), the lower byte

is the unit index (see above).

8 - 9 Time stamp 32 Bit Unix time stamp transmitted by the meter, if there are no time stamps transmitted by the

meter, this value is set to 0

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 32

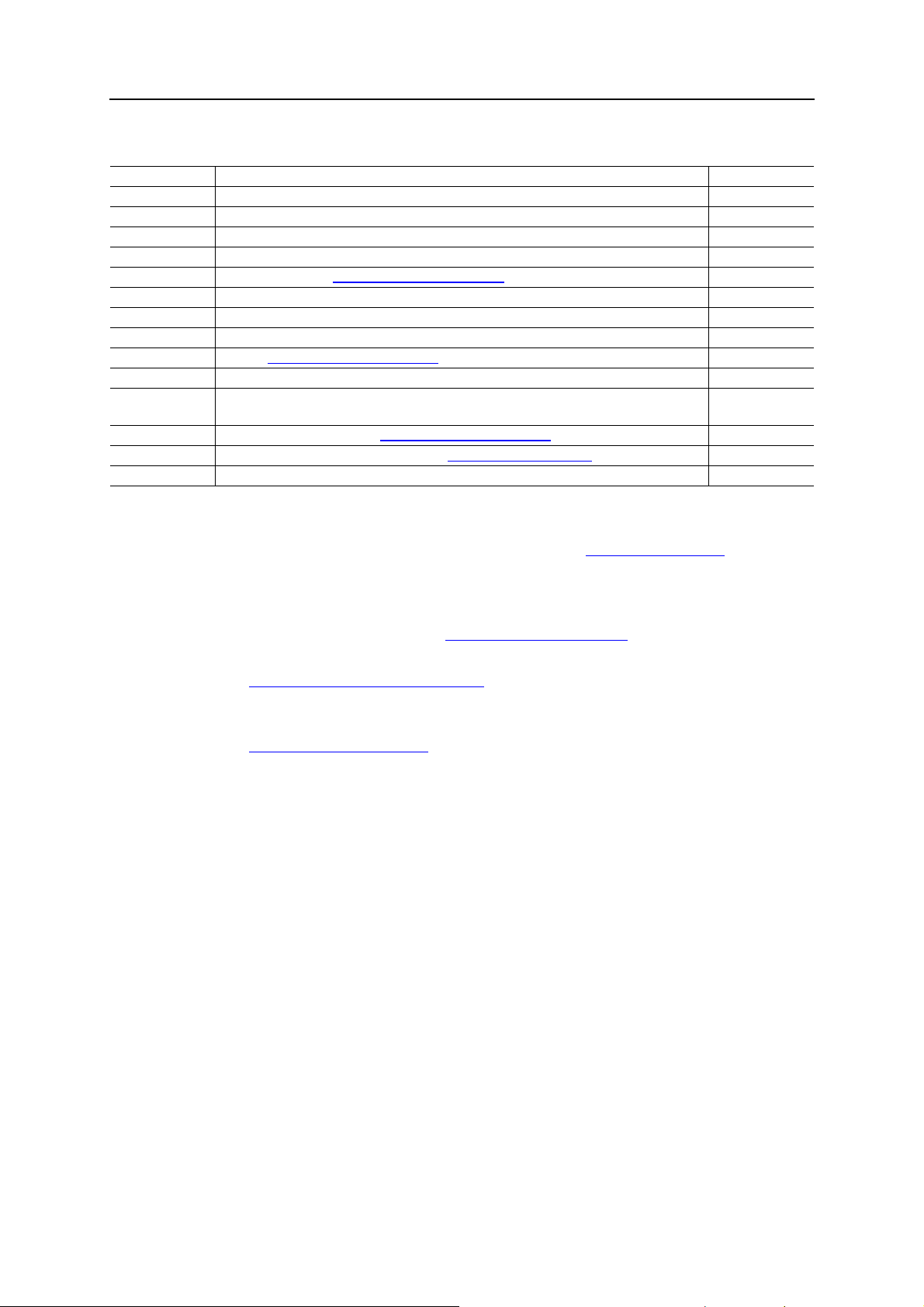

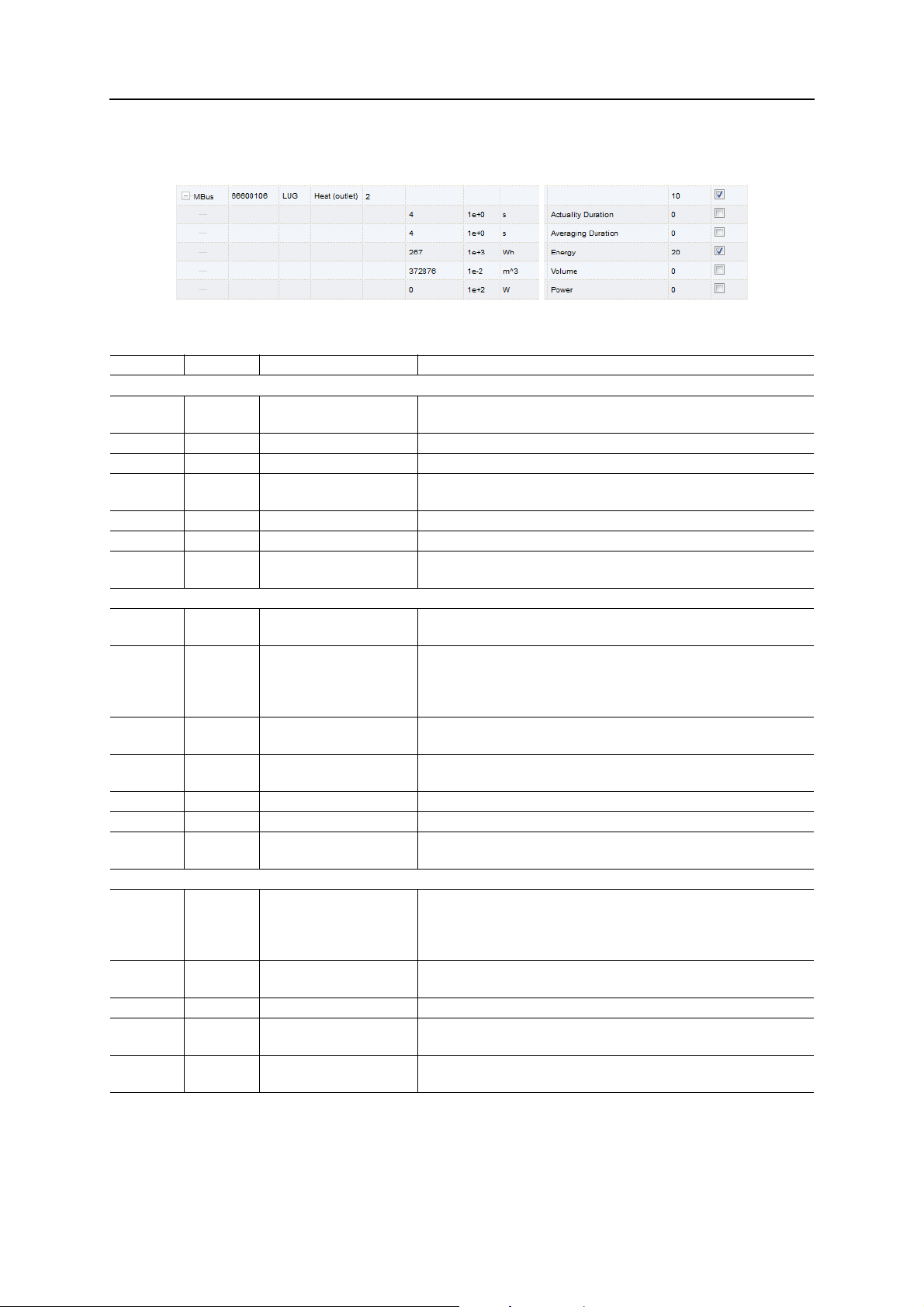

Example

Example configuration of Modbus addresses via the web interface:

In this example, the following data will be transmitted to the Modbus master

Address Value Name Decoded value

Gateway entry

0

1

2 0x0001 Protocol version 1

3 0x006F Version Version = 0x006F = 111 → v1.11

4

5

6 0x0000 Reserved

7 0x0100 Type field / reserved Type = 1 → gateway entry

8

9

Meter entry

10

11

12 0x32A7 Manufacturer ID 0x32A7 =‘0011.0010.1010.0111’

13 0x0204 Version / medium Version = 2

14

15

16 0x0000 Reserved

17 0x0200 Type field / reserved Type = 2 → meter entry

18

19

Meter value entry

20

21

22

23

24

25

26 0x0003 Scale factor Factor = 10^3

27 0x0005 Type field / unit Type = 0 → meter value entry

28

29

0x0002

0x993A

0x519C

0xC16D

0x0000

0x0000

0x03F8

0x3CAA

0x519C

0xC16D

0x0000

0x0000

0x0000

0x0000

0x0000

0x010B

0x4882

0x5F00

0x519C

0xBBB3

Serial number 0x0002993A

Time stamp 0x519CC16D = 1369227629 =

Wednesday, 2013-05-22, 15:00:29 GMT+2

Reserved

Serial number 0x03F83CAA = 66600106

1st letter: ‘_011.00__.____.____’ → 0x0C = 12 → L

2nd letter: ‘____.__10.101_.____’ → 0x15 = 21 → U

3rd letter: ‘____.____.___0.0111’ → 0x07 = 7 → G

Medium = 4 = Heat (outlet)

Time stamp 0x519CC16D = 1369227629 =

Wednesday, 2013-05-22, 15:00:29 GMT+2

Reserved

Meter value (integer) 0x000000000000010B = 267

Resulting value: 267 * 10^3 Wh

Meter value (floating point) 0x48825F00 = 267000.000000 Wh

Unit = 5 → Wh

Time stamp 0x519CBBB3 = 1369226163 =

Wednesday, 2013-05-22, 14:36:03 GMT+2

Acquiring and processing meter data 27

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 33

6. Troubleshooting

This section lists some of the most common problems and suggestions how to solve them.

If you still cannot solve your problem, please contact Anybus support.

6.1 Hardware errors

6.1.1 Gateway does not respond

After powering the gateway it does not operate. Current consumption is about 0 mA and both

Ethernet LEDs are unlit.

1. Check that the power supply is connected with the correct polarity.

2. Check that the power supply voltage is approximately 24 VDC measured between terminals

“24VDC” and “GND”.

6.1.2 Current consumption too high

Chapter 6

After powering the gateway, current consumption rises above 500 mA.

1. Check that the M-Bus connection voltage is approximately 36 VDC measured between terminals

“MBUS+” and “MBUS-”.

2. Disconnect the gateway from the M-Bus.

- Check if the current consumption is back to normal.

- Measure the M-Bus connection voltage again.

3. Check if the Ethernet LEDs are flashing.

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 34

6.2 Network errors

6.2.1 Web interface and FTP server not accessible

The gateway web interface and the FTP server are not accessible.

Troubleshooting 29

1. Run CHIPtool and check if the gateway appears in the list (see 2.2.1

- If the gateway is not visible in CHIPtool, continue to 6.2.2

- If the gateway is visible in CHIPtool, run a connection test (ping).

- Try to access the FTP server from CHIPtool.

2. If the gateway responds to ping and can be accessed with the FTP client in CHIPtool, but is not

accessible from a browser or an external FTP client, check that the gateway is within your network subnet (see 2.2

If you are unsure, contact your network administrator.

3. If the web interface start page is visible but the default user is not logged in, check if you can log

in using admin credentials. You can also try clearing the web browser cache (see the documentation for your browser).

Network configuration) and that it is not blocked by firewall settings.

CHIPtool).

No network connection.

6.2.2 No network connection

The gateway cannot be accessed and is not visible in CHIPtool.

1. Check the physical connection (cables and connectors).

- Check that the link LED on the Ethernet port of the gateway shows an amber light and the

activity LED is flashing green.

- Check the corresponding LEDs on the remote terminal (PC, switch, etc.).

- If necessary, replace the cables and try again.

2. If the gateway still does not appear in CHIPtool, check that communication is not blocked by a

firewall. If you are unsure, contact your network administrator.

3. If the gateway appears in CHIPtool, run a connection test (ping).

If no ping reply is received and the gateway is connected via a local network, try using a direct

network connection to the PC instead.

A cross-over Ethernet cable may be needed for a direct connection between the

gateway and a PC.

Using a direct connection between the PC and gateway, the following example IP configuration

can be used. No other network gateways must be connected to the PC except the gateway.

PC

IP 192.168.1.10

Subnet mask 255.255.0.0

Anybus M-Bus to Modbus-TCP Gateway

IP 192.168.1.101

Subnet mask 255.255.0.0

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 35

6.2.3 No write access to the web interface

The web interface is accessible but the settings cannot be changed.

Troubleshooting 30

1. Check if you are logged in as a user with write access (see 3.1.6

in as another user with write access.

2. Write access is only allowed for one of the currently logged in users. If another user with write

access is already logged in, they will have to log out before you can log in with write access.

If you are the only logged in user that has write access,

- Check if you have another active session in a different browser or browser tab.

- A previous session may not have been closed properly. Try clearing the web browser cache

(see the documentation for your browser).

3. Log in as admin and edit the access rights for the user.

User tab). If not, log out and log

6.2.4 Web session is unexpectedly terminated

If the web session is unexpectedly terminated, this may be due to a connection timeout. The timeout

limit can be increased from its default value by editing the system parameter WEBCOM_TIMEOUT

(see 7.4.1

A timeout may also occur if the gateway is currently busy with the collection and transmission of meter

data, which takes priority over web communication.

System configuration file).

6.2.5 FTP login failure

FTP login fails, or the file list is empty.

1. Log in to the web interface as admin and check the FTP user password.

2. Try logging in to the FTP server as admin and check the communication log.

3. If the login was successful (no errors in the communication log) but the files in the gateway are

not visible, try using your FTP client in FTP passive mode.

(Passive mode can be selected at login in the CHIPtool FTP client.)

4. Check the network configuration (see 2.2

blocked by firewall settings. If you are unsure, contact your network administrator.

Network configuration) and that the gateway is not

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 36

6.3 Meter reading errors

6.3.1 No meters are detected

A scan has been completed but none of the connected meters appear in the meter list.

1. Check the cable between the gateway and the meter and replace faulty cables.

2. Check that the M-Bus connection voltage is approximately 36 VDC measured between terminals

“MBUS+” and “MBUS-”.

3. Check that the M-Bus interface (M-Bus mode) is enabled in the

(see 3.1.3

4. Check that the connected meters support configured search mode (primary or secondary).

5. Try searching for meters gradually by limiting the address space (

using a search mask (

6. Try different settings of

7. Try a different

8. If possible, disconnect the meters one by one to eliminate a possible source of error.

9. Connect another M-Bus meter (if available) and repeat the communication test with this meter

in order to locate the source of error.

10. Increase the system parameter MBUS_MAXRETRY from the default value.

Meters that do not respond to every request will be found easier by increasing the number of

retries the gateway makes. See 7.4.1

Configuration tab).

Secondary address mask).

M-Bus request mode and M-Bus reset mode.

M-Bus baud rate (300, 2400 or 9600), or a higher M-Bus timeout value.

System configuration file.

Configuration tab

Primary start address) or by

Troubleshooting 31

6.3.2 Some meters are not detected

A scan has been completed but some of the connected meters do not appear in the meter list.

1. Perform the scan both as a primary scan and a secondary scan, as not every meter supports both

methods. See 3.1.3

2. Try search masks or limiting the address space to perform a gradual scan of the M-Bus.

See also 6.3.1

3. If possible, disconnect the detected meters one by one to eliminate a possible source of error.

4. Connect another M-Bus meter (if available) and repeat the communication test with this meter

in order to locate the source of error.

5. Increase the system parameter MBUS_MAXRETRY from the default value.

Meters that do not respond to every request will be found easier by increasing the number of

retries the gateway makes. See 7.4.1

Configuration tab.

No meters are detected.

System configuration file.

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 37

Troubleshooting 32

6.3.3 Meters are detected but have no data

Some meters may contain an erroneous declaration of the secondary address. This is why these meters

are not addressable for meter readouts, although they are visible in the meter list.

The system parameter MBUS_SELECTMASK makes it possible to mask parts of the secondary address

and replace them with a wildcard character. The version field especially is a frequent cause of this problem (MBUS_SELECTMASK=4). See 7.4.1

System configuration file.

6.3.4 Scanning takes too long

Under certain circumstances, performing a scan of the M-Bus can take a very long time (>1 h).

• Try working with search masks or limiting the address space to perform a gradual scan.

See 3.1.3

• Decrease the value of the system parameter MBUS_MAXRETRY

See 7.4.1

• Select a different scan mode, either on the

by setting the system parameter MBUS_SCANMODE.

Reversed secondary scan (SECONDARYSCANREVERSE) is often particularly useful to speed up

scanning of the M-Bus.

Configuration tab.

System configuration file.

Configuration tab (see 3.1.3 Configuration tab), or

6.3.5 Gateway restarts occasionally during scan

The gateway is equipped with an internal watchdog to prevent denial of service (DoS). If a scan takes a

very long time, the watchdog may reboot the gateway.

If the scan usually takes a very long time (due to a large number of connected meters or a slow connection) it may be necessary to increase the value of the system parameter WATCHDOG_SCAN.

See 7.4.1

Under certain circumstances there can be lots of collisions on the M-Bus, for example if all meters are

responding at the same time. These collisions and the resulting high current draw of the M-Bus slaves

can in exceptional cases trigger a reboot of the gateway.

Try working with search masks or limiting the address space to perform a gradual scan.

See 3.1.3

If possible, try to split the bus and scan each bus segment separately.

System configuration file.

Configuration tab.

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 38

Troubleshooting 33

6.3.6 Webserver capacity error message

After a scan or a change in the meter list, the gateway (even after a reboot) may show the following error

message in the meter list:

The meter list exceeds the capacity of the internal webserver

This error message is caused by an internal limitation of the webserver. The meter list will be generated

in the gateway and meter data will be logged and sent via already configured interfaces, but configuration

of the meters via the web interface is not possible.

This can be caused by a large number of configured meters and/or very long parameter lists of single

meters. To be able to display the meter list, the number of displayed meters or the number of values per

meter need to be limited.

The following parameters on the

can be used to set the limitation:

•

Description mode set to Standard or (if not needed) set to None.

•

Maximum gateway count set to the default value of 20 or 80, or to a lower value.

•

Maximum value count set to the default value of 25 or to a lower value.

•

M-Bus request mode set to Standard (deactivates the request of partly extensive additional

data of the meter).

•

M-Bus max. multipage set to the default value of 3 or lower.

Any change of the parameter

rameters need a regeneration of the meter list. This is accomplished by deleting all meters and saving the

now empty meter list, then performing a new scan.

Trying to save a meter list that exceeds the internal limit of the webserver leads

to the deletion of the meter list.

The meter configuration may also be changed manually by editing the meter configuration file, see

7.4.2

Meter configuration file. The gateway needs to be restarted for the changes to take effect.

It is not possible to display the meter list in the web interface when manual editing is used.

Configuration tab of the web interface (see 3.1.3 Configuration tab)

Description Mode will be valid directly after clicking Save. All other pa-

6.4 Meter data transmit error

6.4.1 Meter data not transmitted via Modbus

• Check that the parameters for the Modbus communication (IP and port) are set correctly.

See 3.1.4

• If possible, check the network communication with the remote system using a network analyzer

such as Wireshark

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Server tab.

.

Page 39

7. Advanced features

7.1 Software update

In order to provide new features to the Anybus M-Bus to Modbus-TCP Gateway, the operating system

and gateway software can be updated using CHIPtool (see 2.2

The update consists of two steps. In the first step, the operating system (RTOS) on the controller is updated. In the second step the firmware of the gateway is transferred. In most cases, updating the RTOS

is not necessary.

Network configuration).

Chapter 7

The current version numbers of RTOS and the gateway software can be found in the

web interface. See 3.1.7

Software updates should only be carried out by trained personnel as there

is a risk of restricting functionality or damaging the gateway.

The integrity of the software files must be confirmed before updating.

Corrupted software files may restrict the functionality of the gateway.

A continuous power supply must be ensured during an update. A power

failure during a software update may damage the gateway.

Service tab.

Service tab of the

Anybus M-Bus to Modbus-TCP Gateway User Manual Doc: HMSI-27-300, Rev: 1.10

Page 40

Advanced features 35

7.1.1 Updating the operating system (RTOS)

RTOS is provided as an image file named “SC1x3V0[version]_FULL.hex”, where [version] represents

the RTOS version (e.g. 154).

1. Start CHIPtool and right-click on the gateway that is to be updated.

In the context menu, select

Program flash image.

2. In the dialog that opens, click to browse to and select the RTOS image file on your com-

puter, then click

You will be asked for the administrative password to start the update.

See also 3.1

The gateway will reboot automatically when the update has been completed.

Start in the section Use UDP/IP. Do not change any other settings.

The web interface.