Page 1

STARTUP GUIDE

Anybus-E300-MBTCP

E300 Communication Module for Modbus TCP

Important User Information

Disclaimer

The information in this document is for informational purposes only.

Please inform HMS Networks of any inaccuracies or omissions found

in this document. HMS Networks disclaims any responsibility or

liability for any errors that may appear in this document.

HMS Networks reserves the right to modify its products in line with

its policy of continuous product development. The information in this

document shall therefore not be construed as a commitment on the

part of HMS Networks and is subject to change without notice. HMS

Networks makes no commitment to update or keep current the

information in this document.

The data, examples and illustrations found in this document are

included for illustrative purposes and are only intended to help

improve understanding of the functionality and handling of the

Preface

About This Document

This manual describes the installation of the Anybus-E300-MBTCP.

For information on how to configure the Anybus-E300-MBTCP, refer

to the user manuals for the Anybus-E300-MBTCP and the E300

Electronic Overload Relay.

Please visit www.anybus.com/support and

www.rockwellautomation.com/support.

Document Conventions

Numbered lists indicate tasks that should be carried out in sequence:

1. First do this

2. Then do this

Bulleted lists are used for:

• Tasks that can be carried out in any order

• Itemized information

► An action

→ and a result

User interaction elements (buttons etc.) are indicated with bold text.

Program code and script examples

Cross-reference within this document: Document Conventions, p. 1

Safety

Intended Use

The intended use of this equipment is as a communication interface.

The communication module allows an E300 Relay to be integrated

into an automation system.

The communication module has two RJ45 connectors that function

as a switch.

If this equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

impaired.

General Safety

WARNING

To prevent electrical shock, disconnect from power source

before installing or servicing. Follow NFPA 70E requirements.

Install in suitable enclosure. Keep free from contaminants.

WARNING

Installation, adjustments, putting into service, use, assembly,

disassembly, and maintenance shall be carried out by suitably

trained personnel in accordance with applicable code of

practice.

Preparation

Support and Resources

For additional documentation and technical support, please visit

www.anybus.com/support and

www.rockwellautomation.com/support.

Recommended Ethernet Cables

1585J-M8TBJM-2

1585J-M8TBJM-2

Custom lengths available up to 99 meters.

RJ45 Straight Male to RJ45 Straight Male, Teal

Robotic TPE, Weld Splatter, Flex Rated, 2 m

RJ45 Straight Male to RJ45 Straight Male, Teal PVC,

600V Rated, 2 m

product. In view of the wide range of possible applications of the

product, and because of the many variables and requirements

associated with any particular implementation, HMS Networks

cannot assume responsibility or liability for actual use based on the

data, examples or illustrations included in this document nor for any

damages incurred during installation of the product. Those

responsible for the use of the product must acquire sufficient

knowledge in order to ensure that the product is used correctly in

their specific application and that the application meets all

performance and safety requirements including any applicable laws,

regulations, codes and standards. Further, HMS Networks will under

no circumstances assume liability or responsibility for any problems

that may arise as a result from the use of undocumented features or

functional side effects found outside the documented scope of the

product. The effects caused by any direct or indirect use of such

aspects of the product are undefined and may include e.g.

compatibility issues and stability issues.

© 2020 HMS Industrial Networks

Box 4126, 300 04 Halmstad, Sweden

SP2873 1.0 / 2020-11-16 / 20639

External link (URL): www.hms-networks.com

WARNING

Instruction that must be followed to avoid a risk of death or

serious injury.

Caution

Instruction that must be followed to avoid a risk of personal

injury.

Instruction that must be followed to avoid a risk of reduced

functionality and/or damage to the equipment, or to avoid a

network security risk.

Additional information which may facilitate installation and/

or operation.

Trademarks

Anybus®is a registered trademark of HMS Networks AB.

All other trademarks are the property of their respective holders.

WARNING

In case of malfunction or damage, no attempts at repair

should be made. The product should be returned to the

manufacturer for repair. Do not dismantle the product.

E300 Communication Module Network Information

Label with Network Information: MAC Id, Serial Number and

Firmware Revision.

Page 2

Installation

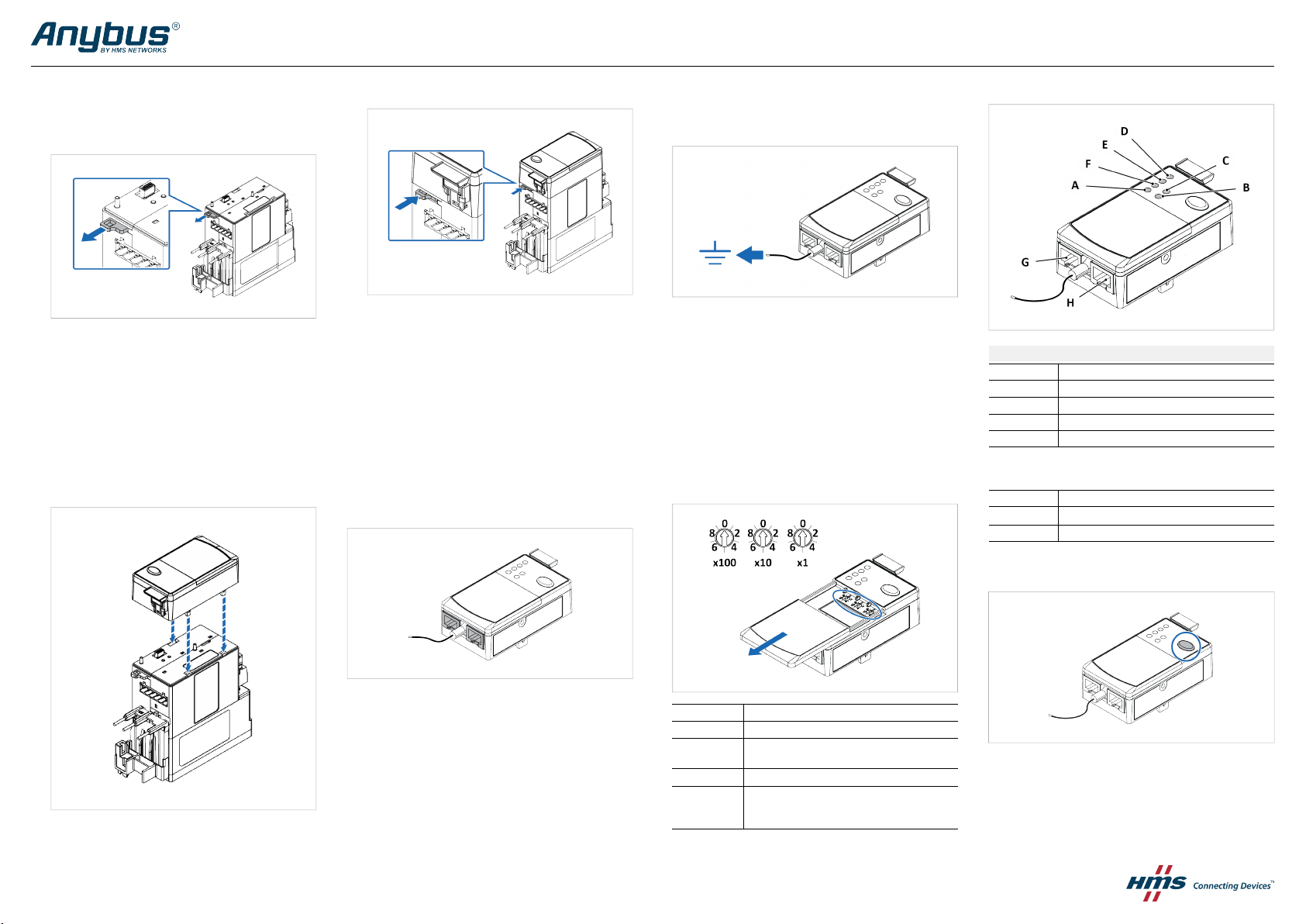

Attach the E300 Communication Module

1. Pull out the locking tab located on the upper left side of

theE300 Relay Control Module.

3. To lock the modules, push in the locking tab located on the

upper left side of the E300 Relay Control Module.

Connecting to Ground

Motor protection function:

Ground Fault – zero sequence method (50 N)

► Connect the Green Wire to Functional Earth (Ground).

LED Guide

E300 Communication Module LED Indicators

Position

A

B

C

D Power

LED Indicator

Link 1 Status and RJ45 Port G status

Link 2 Status and RJ45 Port H status

Network Status

2. Attach the E300 Communication Module to the E300 Relay

Control Module.

© 2020 HMS Industrial Networks

Box 4126, 300 04 Halmstad, Sweden

SP2873 1.0 / 2020-11-16 / 20639

Connecting to Modbus TCP Network

The E300 Communication Module has two RJ45 ports that act as an

Ethernet switch.

The E300 Communication Module listens for incoming Modbus TCP

connections on TCP port 502.

Up to four simultaneous Modbus TCP connections are supported.

IP Address Setting Via Rotary Switches

Node Address

001 - 254

255 - 887

889 - 999

888

000

► A power cycle is required for the changes to take effect.

Function

Set IP Address to 192.168.1.xxx

Configure the module to “Use configured settings”,

values from non volatile storage.

Reset to factory defaults

Configure the module to “Use configured settings”,

values from non volatile storage.

Enter Administration mode

E300 Communication Module LED Indicators (continued)

Position

E

F

LED Indicator

TRIP/WARN

Module Status

Test/Reset

Test: Ensure that the E300 Relay is untripped. To open the trip relay

contact: Press the Test/Reset button for 2 seconds.

Reset: Ensure that the E300 Relay is tripped. To close the trip relay

contact: Press and immediately relese the Test/Reset button.

Loading...

Loading...