Page 1

Anybus®CompactCom™40

SOFTWARE DESIGN GUIDE

HMSI-216-125 4.0 en-US ENGLISH

Page 2

Important User Information

Disclaimer

The information in this document is for informational purposes only. Please inform HMS Industrial Networks of any

inaccuracies or omissions found in this document. HMS Industrial Networks disclaims any responsibility or liability

for any errors that may appear in this document.

HMS Industrial Networks reserves the right to modify its products in line with its policy of continuous product

development. The information in this document shall therefore not be construed as a commitment on the part of

HMS Industrial Networks and is subject to change without notice. HMS Industrial Networks makes no commitment

to update or keep current the information in this document.

The data, examples and illustrations found in this document are included for illustrative purposes and are only

intended to help improve understanding of the functionality and handling of the product. In view of the wide range

of possible applications of the product, and because of the many variables and requirements associated with any

particular implementation, HMS Industrial Networks cannot assume responsibility or liability for actual use based on

the data, examples or illustrations included in this document nor for any damages incurred during installation of the

product. Those responsible for the use of the product must acquire sufficient knowledge in order to ensure that the

product is used correctly in their specific application and that the application meets all performance and safety

requirements including any applicable laws, regulations, codes and standards. Further, HMS Industrial Networks will

under no circumstances assume liability or responsibility for any problems that may arise as a result from the use of

undocumented features or functional side effects found outside the documented scope of the product. The effects

caused by any direct or indirect use of such aspects of the product are undefined and may include e.g. compatibility

issues and stability issues.

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 3

Table of Contents

Page

1 Preface ................................................................................................................................. 5

1.1 About this Document....... .................................. ................. ................. ............................. 5

1.2 Related Documents ........... .............. ................. ................. .................................. ............. 5

1.3 Document History .. ................. ................. .................................. ................. ................. .... 5

1.4 Document Conventions .................... ................. ............................... .................... ............. 7

1.5 Document Specific Conventions................ ................. ................. .................................. ...... 7

1.6 Trademarks................................ .............. ................. ................................................... ... 8

2 About the Anybus CompactCom 40 ................................................................................... 9

2.1 General Information .............................. ................. .................... ............................... ....... 9

2.2 Features ............... ................. ................. .................................. ................. ................. .... 9

3 Software Introduction....................................................................................................... 10

3.1 Background.................... ..................................... ............................... ........................... 10

3.2 The Object Model ........ ................. .................... ............................... ................. ............. 12

3.3 Network Data Exchange ............................. ................. ................................................... . 15

3.4 Diagnostics ................ .................... ................. .............. ................. .................... ........... 16

3.5 File System ... ............................... .................... ................. ............................... ............. 17

3.6 Modular Device ............... ................. ..................................... .............. ................. ......... 19

3.7 SYNC...... .............. ................. ................. .................................. ................. ................. .. 19

3.8 Multilingual Support ......... ................. .............. .................... ................. ................. ......... 24

3.9 Firmware Download ......... ................. .................................. ................. ................. ......... 25

4 Host Communication Layer............................................................................................... 28

4.1 General Information .............................. ................. .................... ............................... ..... 28

4.2 Memory Map ........... ................. ................................................... ................. ................ 29

4.3 Communications Registers.............................. .............. ................. .................................. 30

5 Parallel Host Communication ........................................................................................... 35

5.1 Flow Control .............. .................... ................. .............. ................. .................... ........... 35

5.2 Anybus Event Driven Watchdog .................... ............................... ................. .................... 35

5.3 Application Event Driven Watchdog .......... ................. .............. ................. .................... .... 36

6 SPI Host Communication .................................................................................................. 37

6.1 General Information .............................. ................. .................... ............................... ..... 37

6.2 SPI Frame Format.............. ................. .............. ................. ............................................. 37

6.3 Interrupts ........ ................................................... ................. ......................................... 38

6.4 Message Fragmentation . ................. .............. ................. .................... ................. ............ 38

6.5 SPI Error Handling .................................. ............................... ................. .................... .... 39

6.6 Application Event Driven Watchdog .......... ................. .............. ................. .................... .... 40

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 4

7 Shift Register Host Communication ................................................................................. 41

7.1 General Information .............................. ................. .................... ............................... ..... 41

7.2 Reset ... ................................................... ................. ................................................... . 41

8 Serial Host Communication (UART).................................................................................. 42

8.1 General Information .............................. ................. .................... ............................... ..... 42

9 The Anybus State Machine ............................................................................................... 43

9.1 General Information .............................. ................. .................... ............................... ..... 43

9.2 State Dependent Actions ................................ ............................... .................................. 44

10 Object Messaging .............................................................................................................. 45

10.1 General Information .............................. ................. .................... ............................... ..... 45

10.2 Message Layout.............. .............. .................... ................. ................. .............. ............. 46

10.3 Message Segmentation ............. ................. ................. .................................. ................. . 46

10.4 Data Format........................ ................. ................. .................................. ................. ..... 49

10.5 Command Specification............ ................. ................................................... ................. .. 51

11 Initialization and Startup .................................................................................................. 57

11.1 General Information .............................. ................. .................... ............................... ..... 57

11.2 Startup Procedure.................................. ................. ............................... .................... .... 57

11.3 Anybus Setup (SETUP State).............. ................. ................. .............. .................... ........... 59

11.4 Network Initialization (NW_INIT State)...... ................. .................... .............. ................. ..... 60

12 Anybus Module Objects.................................................................................................... 61

12.1 General Information .............................. ................. .................... ............................... ..... 61

12.2 Object Revisions ......................... ................. ................................................... ............... 61

12.3 Anybus Object (01h) ............. ................. ................................................... ................. ..... 62

12.4 Diagnostic Object (02h) . ................. .................... ............................... ................. ............. 69

12.5 Network Object (03h) ........................ ..................................... .............. ................. ......... 74

12.6 Network Configuration Object (04h) . .................... ................. ................. .............. ............. 81

12.7 Anybus File System Interface Object (0Ah). ................. .................... .............. ................. ..... 83

12.8 Functional Safety Module Object (11h) ............. ............................... .................................. 98

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 5

13 Host Application Objects ................................................................................................ 105

13.1 General Information .............................. ................. .................... ............................... ... 105

13.2 Implementation Guidelines...................... ................. ................. .............. .................... .. 105

13.3 Functional Safety Object (E8h)................................ ................. ....................................... 107

13.4 Application Data Object (FEh).......... .................... ................. .............. ................. ........... 109

13.5 Application Object (FFh) .... ................. ..................................... .............. ................. ....... 118

13.6 Application File System Interface Object (EAh) ................. ................. ................................ 130

13.7 Assembly Mapping Object (EBh) .... ................. ................. .................... .............. ............. 133

13.8 Modular Device Object (ECh) ................................. .............. ................. ......................... 136

13.9 Sync Object (EEh) . .................... ................. ................. .............. .................... ................ 138

13.10 Host Application Specific Object (80h) ........... .............. ................. ................. .................. 140

A Categorization of Functionality ...................................................................................... 141

A.1 Basic........ ................. .................... ................. .............. ................. .................... ......... 141

A.2 Extended ............ .................................. ................. ................. .............. .................... .. 141

B Network Comparison ...................................................................................................... 142

B.1 Network Specific Comments . ................. .................................. ................. ................. .... 144

C Industrial Ethernet Network Comparison...................................................................... 145

D Object Overview.............................................................................................................. 147

D.1 Anybus Module Objects ....... ................. .................................. ................. ................. .... 147

D.2 Host Application Objects ... ................. .............. .................... ................. ................. ....... 148

E Conformance Test Information ...................................................................................... 149

E.1 EtherCAT .............. ................. ................. .................................. ................. ................. 149

E.2 CC-Link................ ................. .............. .................... ................. ................. .............. .... 150

E.3 Ethernet POWERLINK............... .............. ................. .................... ............................... ... 151

E.4 EtherNet/IP................................ ............................... ..................................... ............. 152

E.5 DeviceNet..... .............. ................. .................... ................. .............. ................. ........... 152

E.6 Modbus-TCP ............................. ..................................... ............................... .............. 152

F Runtime Remapping of Process Data............................................................................. 154

F.1 SPI Mode ............ .................... ................. ................. .............. .................... ................ 154

F.2 Parallel Mode, 8/16 Bits, Event Driven ................ .............. .................... ................. .......... 156

F.3 Backwards Compatible Modes................. ................................................... ................. ... 157

F.4 Example: Remap_ADI_Write_Area ........... ................. .................... .............. ................. ... 161

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 6

G CRC Calculation (16–bit) ................................................................................................. 162

G.1 General................................................ ................. ............................... .................... .. 162

G.2 Example .......... ..................................... ............................... ................. .................... .. 162

G.3 Code Example .. ................................................... ................. ................. ...................... 163

H CRC Calculation (32–bit) ................................................................................................. 165

H.1 Example .................................... .............. ................. ..................................... ............. 165

H.2 Code Example ......................... ................. ................. .................................. ................ 165

I Timing & Performance .................................................................................................... 166

I.1 General Information .............................. ................. .................... ............................... ... 166

I.2 Internal Timing ................. ................. ................. ................................................... ...... 166

J Backward Compatibility.................................................................................................. 168

J.1 Initial Considerations ........... ................. .................................. ................. ................. .... 168

J.2 Hardware Compatibility ........................................ ................. ................. ...................... 168

J.3 General Software ..................... ................. ................. .................................. ................ 173

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 7

Preface 5 (176)

1 Preface

1.1 About this Document

This document is intended to provide a good understanding of the Anybus CompactCom

platform. It does not cover any of the network specific features offered by the Anybus

CompactCom 40 products; this information is available in the appropriate Network Guide.

The reader of this document is expected to be familiar with high level software design and

industrial network communication systems in general. For additional information,

documentation, support etc., please visit the support website at www.anybus.com/support.

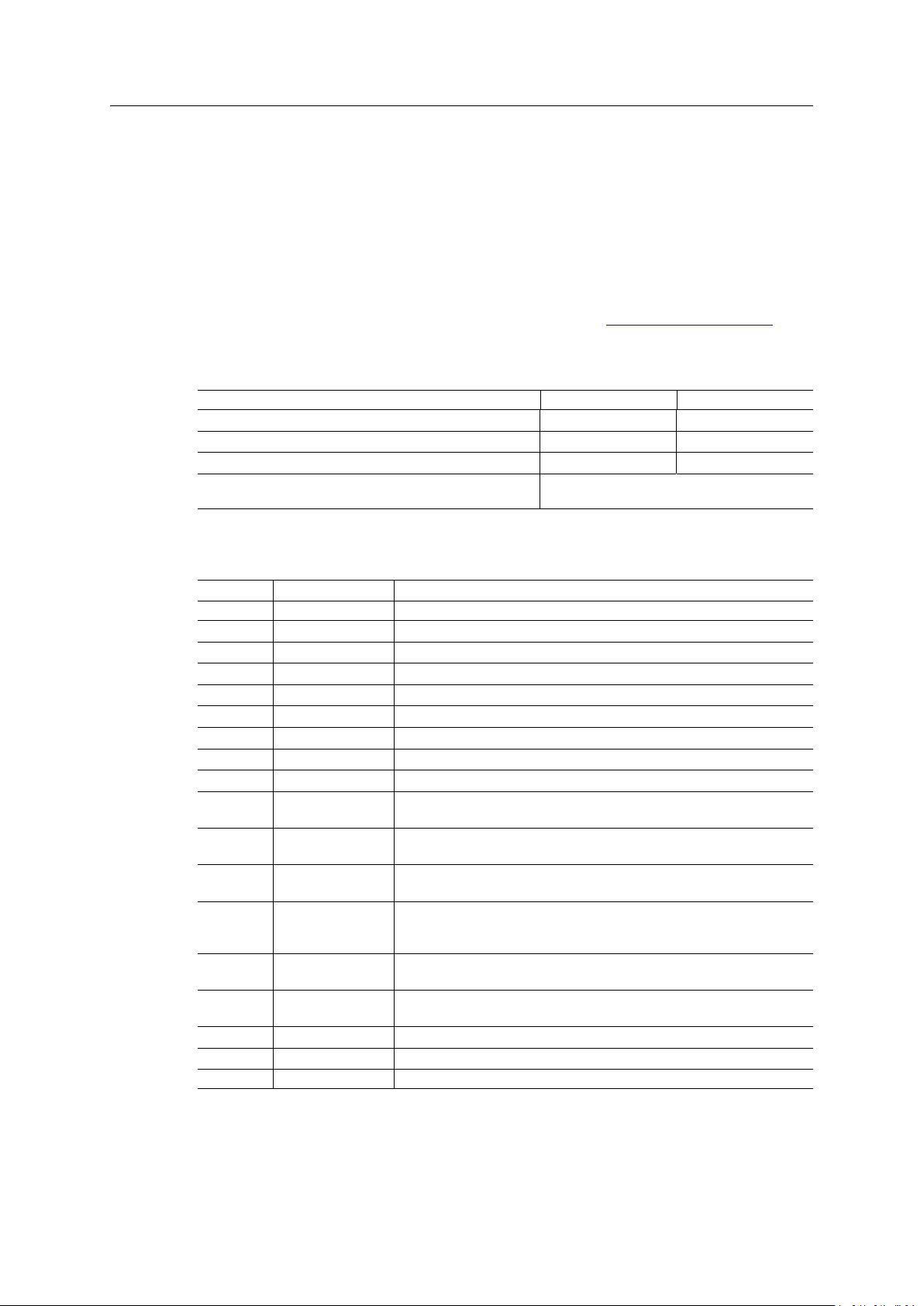

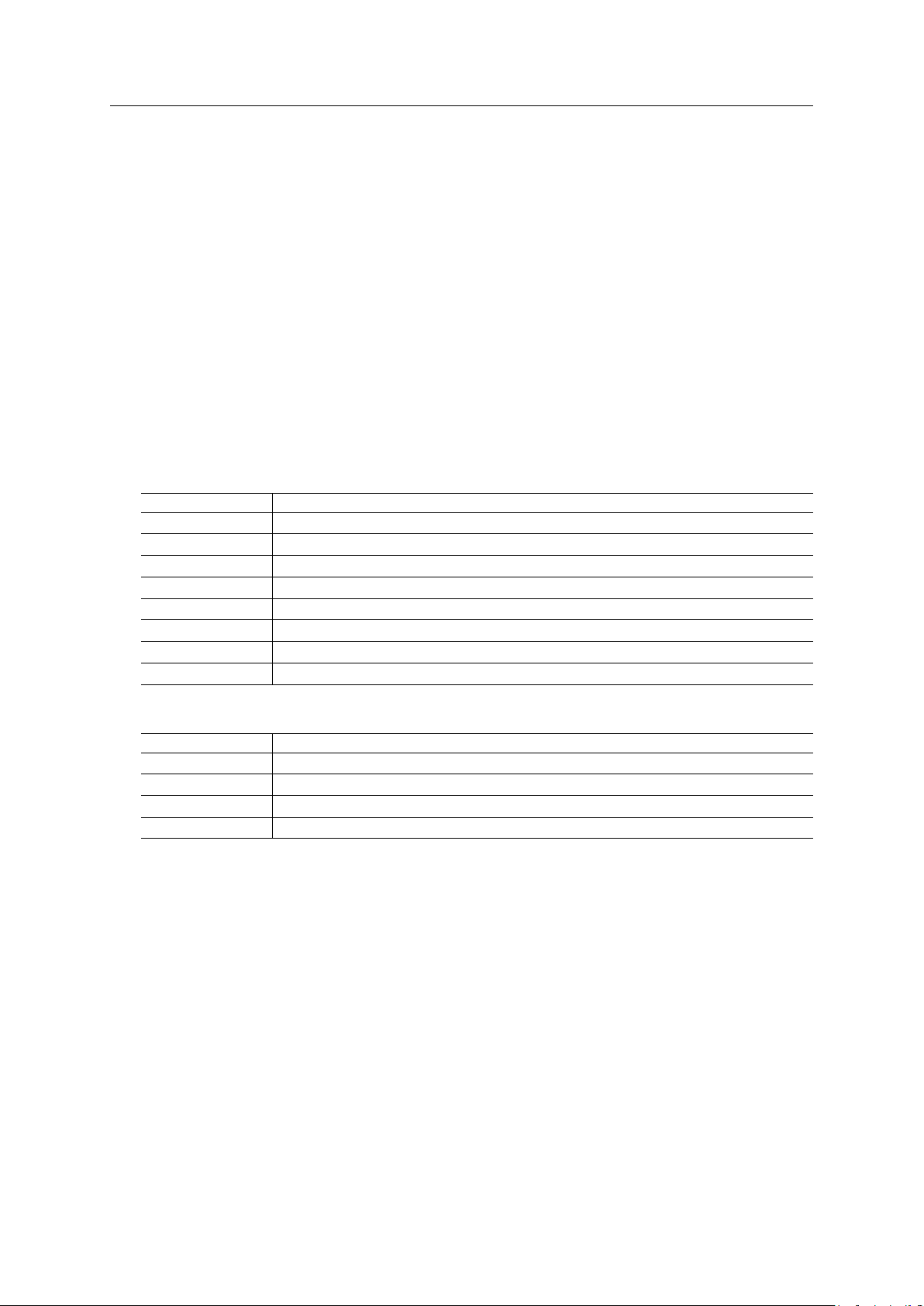

1.2 Related Documents

Document

Anybus CompactCom M40 Hardware Design Guide

Anybus CompactCom B40 Design Guide

Anybus CompactCom Host Application Implementation Guide

Anybus CompactCom 40 Network Guides (separate document for

each supported fieldbus or network system)

Author

HMS HMSI-216-126

HMS HMSI-27-230

HMS HMSI-27-334

HMS

Document ID

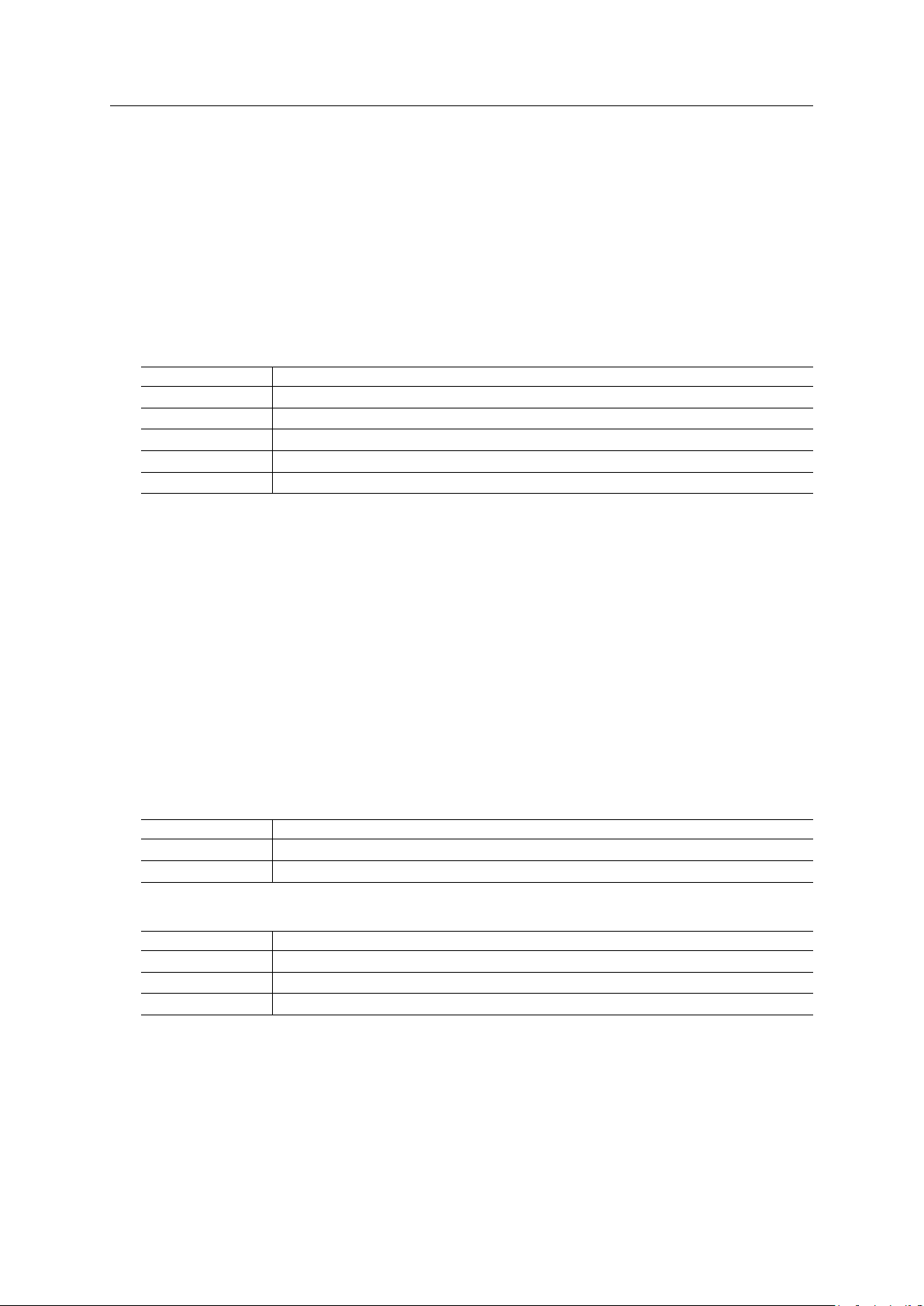

1.3 Document History

Version

0.50 2013-07-02

0.60 2013-12-20

1.00 2014-03-28

1.10 2014-05-26

1.20 2014-08-15

1.21 2014-08-26

1.20 2014-11-10

1.31 2015-02-06

2.00 2015-09-24

3.0 2016-08-31

3.1 2017-04-03

3.2 2017-06-15

3.3 2017-07-10

3.4 2017-11-28

3.5 2018-03-09

3.6 2018-05-28

3.7 2018-09-19

3.8 2018-10-23 Minor corrections

Date

Description

New document

General update

Major update

Major update

Major update

Major update

Major update

Minor update

Major update

Moved from FM to DOX

Major update

CC-Link IE Field added

Misc. updates and corrections

BACnet/IP added

Misc. updates and corrections

Added attr #7 to Application Object (FFh)

Updated information on LED status register

Added appendix on backward compatibility

Added attr #8 - #11 to Application Object (FFh)

Minor updates

Misc. updates

Comparison tables updated for EPL and ECT

Misc. updates

Updates for MQTT support

®

Anybus

CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 8

Preface 6 (176)

Version

Date

3.9 2019-03-01

4.0 2019-11-11

Description

Corrections to Module Device object description

Added info on CANopen module

Minor updates

Rebranded

Updated Anybus Ojbect (01h)

Minor updates

Changed disclaimer

®

Anybus

CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 9

Preface 7 (176)

1.4 Document Conventions

Numbered lists indicate tasks that should be carried out in sequence:

1. First do this

2. Then do this

Bulleted lists are used for:

• Tasks that can be carried out in any order

• Itemized information

► An action

→ and a result

User interaction elements (buttons etc.) are indicated with bold text.

Program code and script examples

Cross-reference within this document: Document Conventions, p. 7

External link (URL): www.hms-networks.com

WARNING

Instruction that must be followed to avoid a risk of death or serious injury.

Caution

Instruction that must be followed to avoid a risk of personal injury.

Instruction that must be followed to avoid a risk of reduced functionality and/or damage

to the equipment, or to avoid a network security risk.

Additional information which may facilitate installation and/or operation.

1.5 Document Specific Conventions

• The terms “Anybus” or “module” refers to the Anybus CompactCom module.

• The terms “host” or “host application” refer to the device that hosts the Anybus.

• Hexadecimal values are written in the format NNNNh or 0xNNNN, where NNNN is the

hexadecimal value.

• Intel byte order is assumed unless otherwise stated.

• Object Instance equals Instance #0.

• Object Attributes resides in the Object Instance.

• The terms “Anybus implementation” and “Anybus version” generally refers to the

implementation in the Anybus module, i.e. network type and internal firmware revision.

• Unless something is clearly stated to be optional, it shall be considered mandatory.

• When writing, fields declared as “reserved” shall be set to zero.

• When reading, fields bits declared as “reserved” shall be ignored.

• Fields which are declared as “reserved” must not be used for undocumented purposes.

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 10

Preface 8 (176)

• A byte always consists of 8 bits.

• A word always consists of 16 bits.

1.6 Trademarks

• Anybus®is a registered trademark of HMS Industrial Networks.

• EtherNet/IP is a trademark of ODVA, Inc.

• DeviceNet is a trademark of ODVA, Inc.

•

EtherCAT®is a registered trademark and

patented technology, licensed by Beckhoff Automation GmbH, Germany.

All other trademarks are the property of their respective holders.

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 11

About the Anybus CompactCom 40 9 (176)

2 About the Anybus CompactCom 40

2.1 General Information

The Anybus CompactCom 40 network communication module is a powerful communication

solution for demanding industrial applications. It is ideal for high performance, synchronized

applications such as servo drive systems. Typical applications are PLCs, HMIs, robotics, AC/DC

and servo drives.

The Anybus CompactCom software interface is designed to be network protocol independent,

allowing the host application to support all major networking systems using the same software

driver, without loss of functionality.

To provide flexibility and room for expansion, an object oriented addressing scheme is used

between the host application and the Anybus module. This allows for a very high level of

integration, since the host communication protocol enables the Anybus module to retrieve

information directly from the host application using explicit object requests rather than memory

mapped data.

The Anybus CompactCom 40 series is backward compatible with the Anybus

CompactCom 30 series though the 40 series has significantly better performance and

include more functionality than the 30 series. The 40 series is backward compatible with

the 30 series in the sense that an application developed for the 30 series should be

possible to use with the 40 series products, even though minor application code changes

may be necessary.

The 40 series products can thus not replace 30 series products as is.

2.2 Features

• Hardware support for triple buffered process data

• Black channel interface, offering a transparent channel for safety communication

• Host interface is network protocol independent

• Multilingual support

• High level of integration

• Synchronization support

• 8-bit and 16-bit parallel modes

• SPI mode

• Stand-alone shift register mode

• Serial interface mode (UART)

• Optional support for advanced network specific features

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 12

Software Introduction 10 (176)

0101101101010110010011

0000101010110100111011

1000010101100000100010

0100110010111000000001

0010001101000100001010

Data from Fieldbus

Network Interface

0101101101010110010011

0000101010110100111011

1000010101100000100010

0100110010111000000001

0010001101000100001010

Data to Fieldbus

Network

3 Software Introduction

3.1 Background

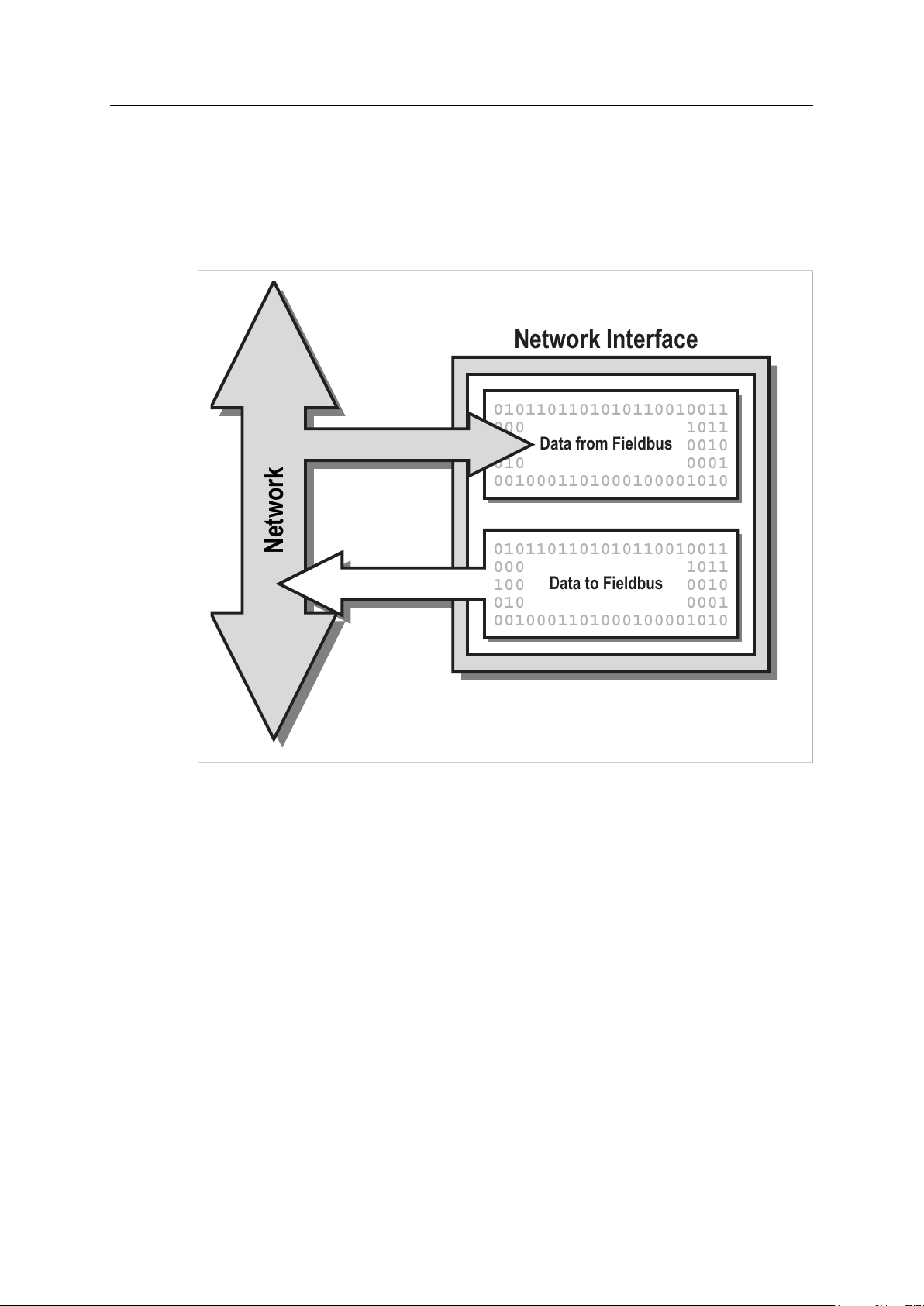

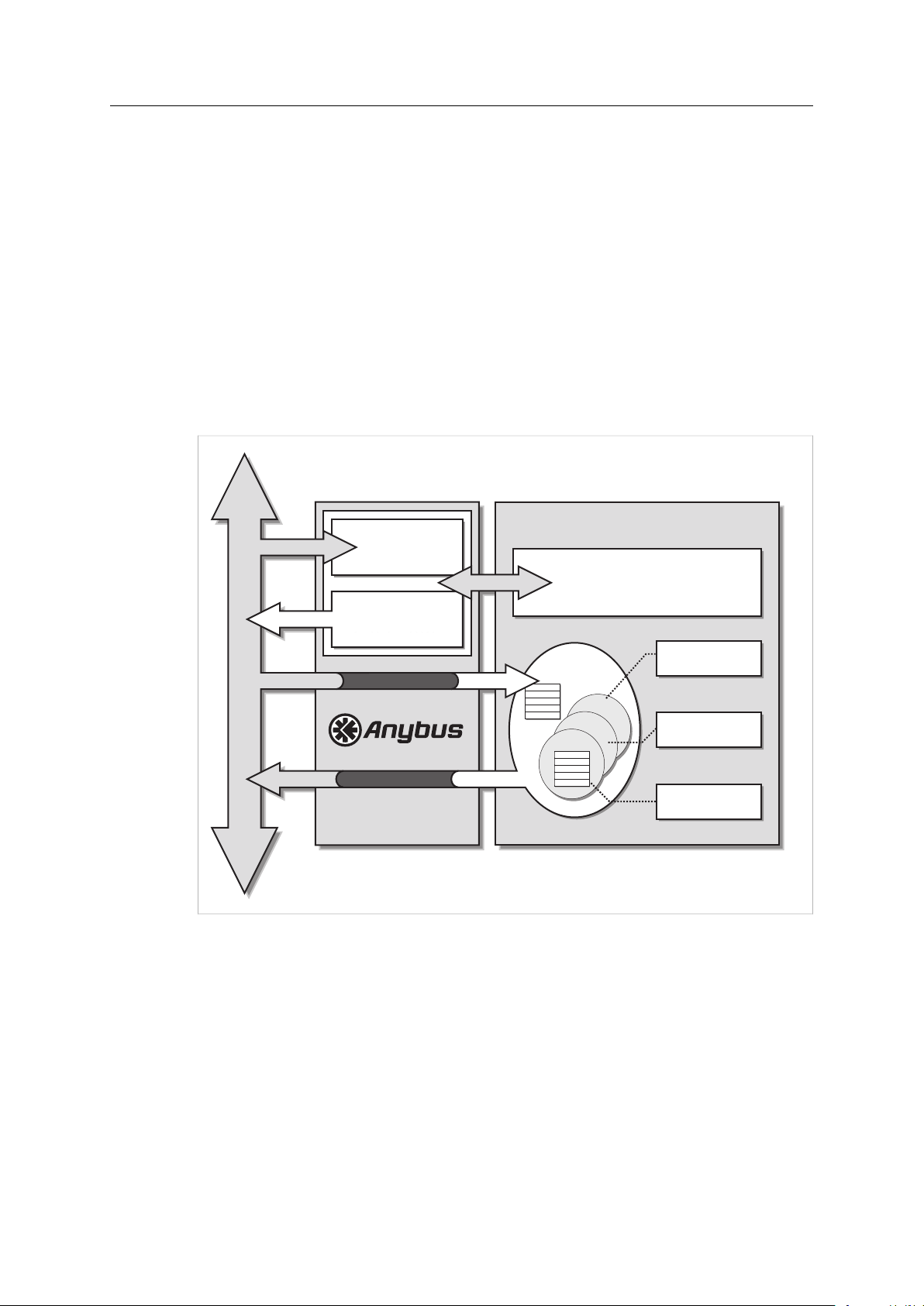

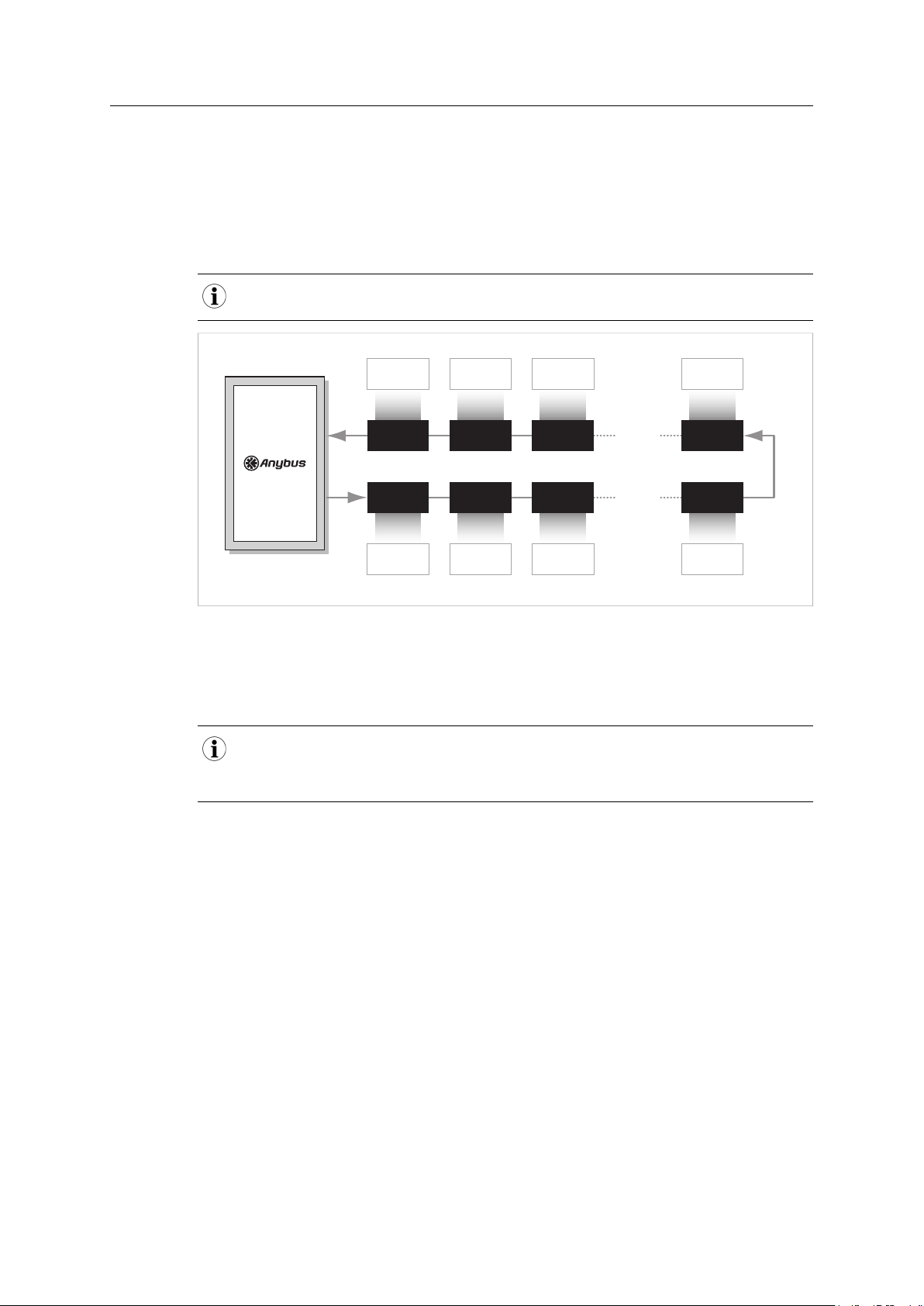

The primary function of an industrial network interface is to exchange information with other

devices on the network. Traditionally, this has mostly been a matter of exchanging cyclic I/O and

making it available to the host device via two memory buffers.

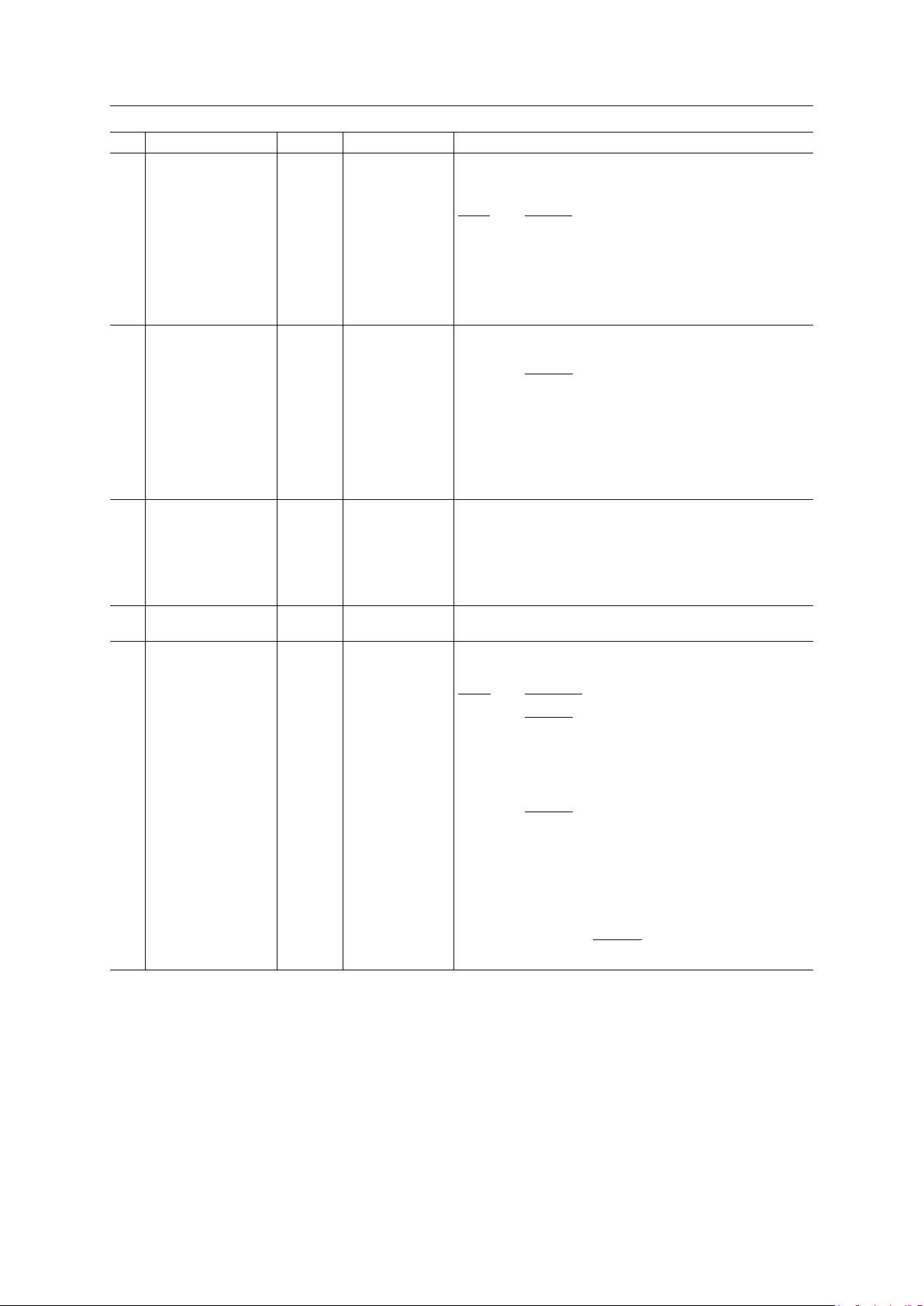

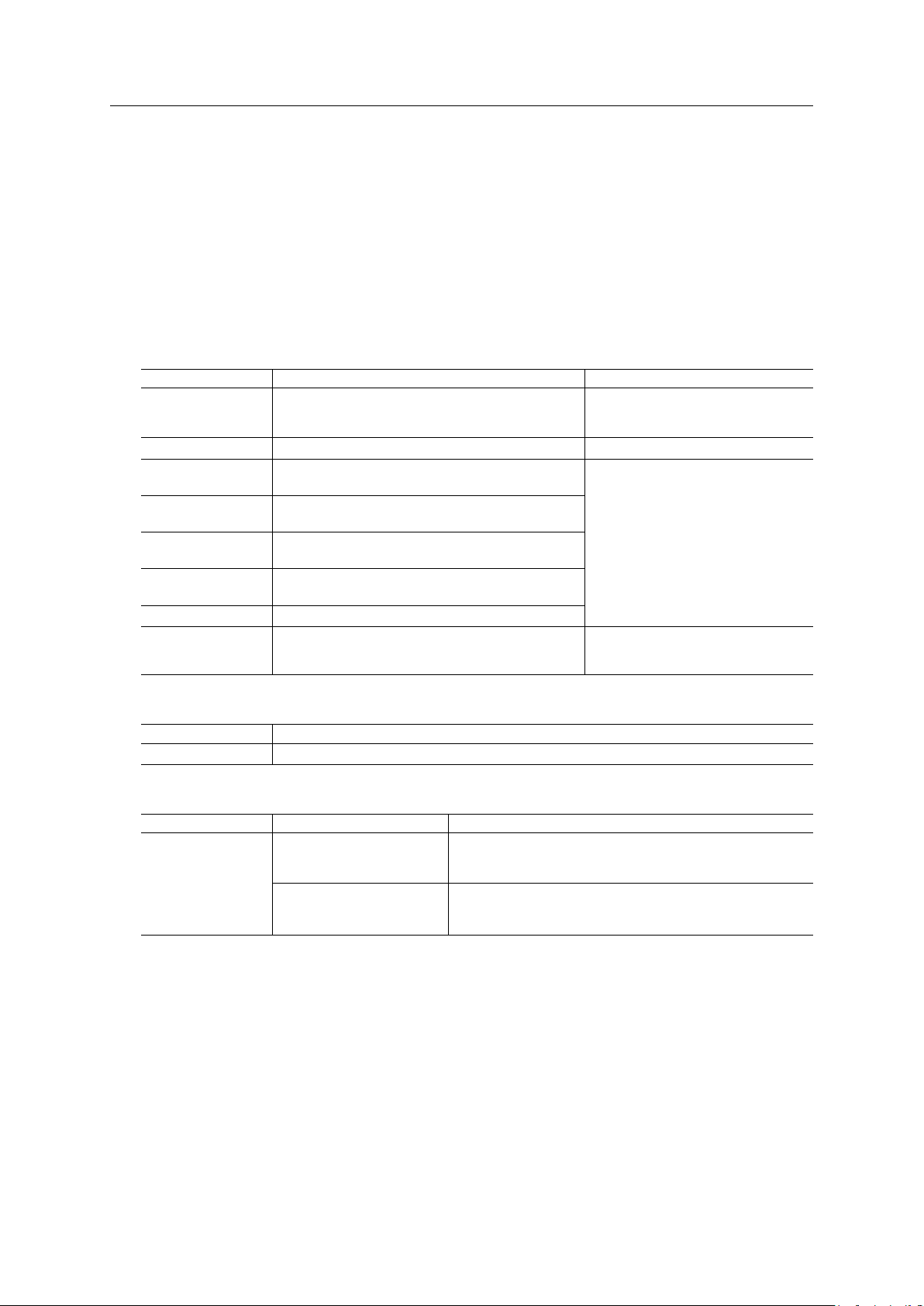

Fig. 1

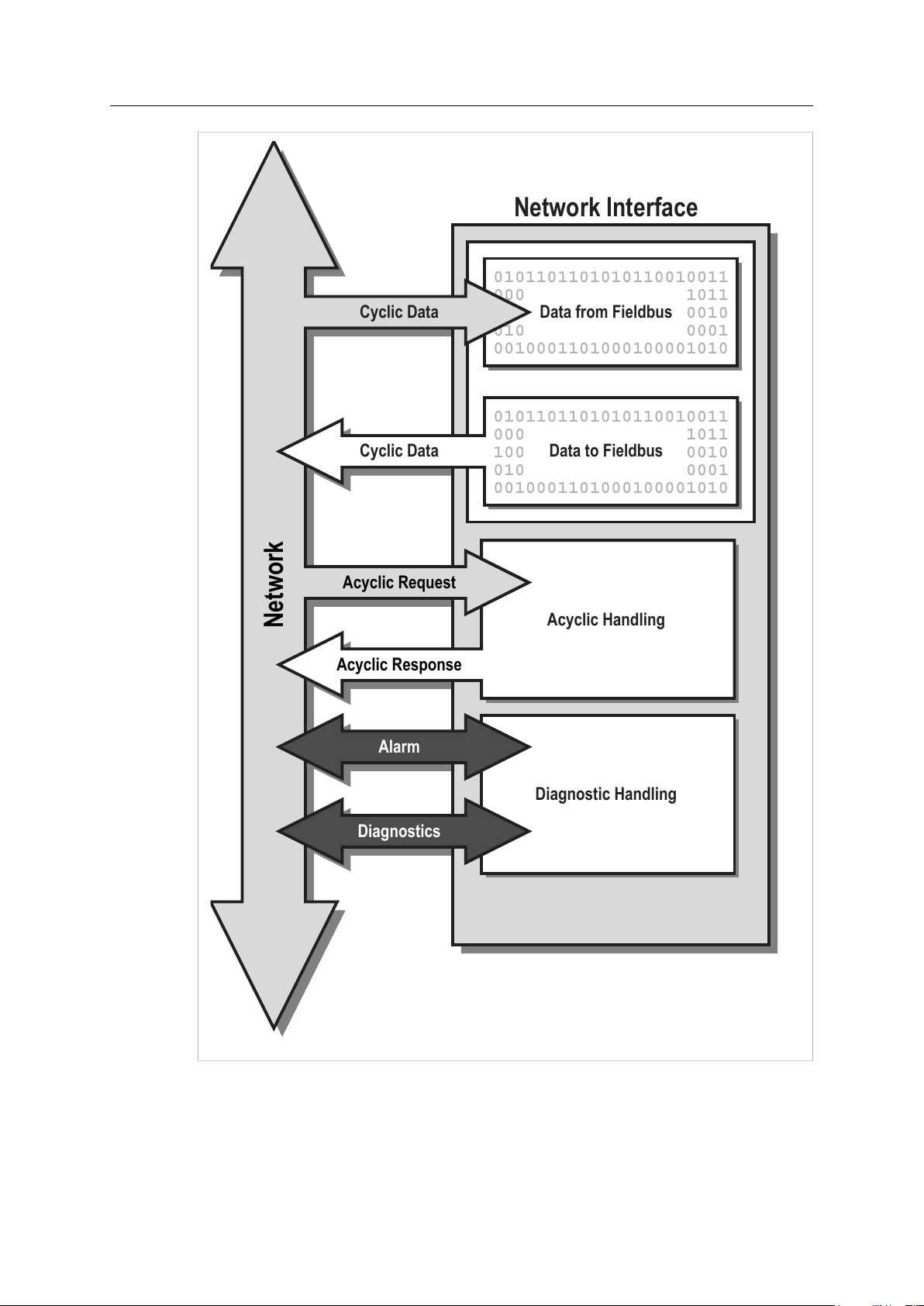

As demand for higher level network functionality increases, the typical role of a network

interface has evolved towards including acyclical data management, alarm handling, diagnostics

etc.

Generally, the way this is implemented differs fundamentally between different networking

systems. This means that supporting and actually taking advantage of this new functionality is

becoming increasingly complex, if not impossible, without implementing dedicated software

support for each network.

By utilizing modern object oriented technology, the Anybus CompactCom provides a simple and

effective way of supporting most networking systems, as well as taking advantage of advanced

network functionality, without having to write separate software drivers for each network.

Acyclic requests are translated in a uniform manner, and dedicated objects provide diagnostic

and alarm handling according to each network standard.

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 13

Software Introduction 11 (176)

0101101101010110010011

0000101010110100111011

1000010101100000100010

0100110010111000000001

0010001101000100001010

Data from Fieldbus

Network Interface

0101101101010110010011

0000101010110100111011

1000010101100000100010

0100110010111000000001

0010001101000100001010

Data to Fieldbus

Diagnostic Handling

Cyclic Data

Cyclic Data

Alarm

Diagnostics

Network

Acyclic Request

Acyclic Response

Acyclic Handling

Fig. 2

®

Anybus

CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 14

Software Introduction 12 (176)

#1

Attributes:

#2

#3

#4

#5

Instance #1

Instance #2

Instance #3

#1

Attributes:

#2

#3

#4

#5

Object #1

(Instance #0)

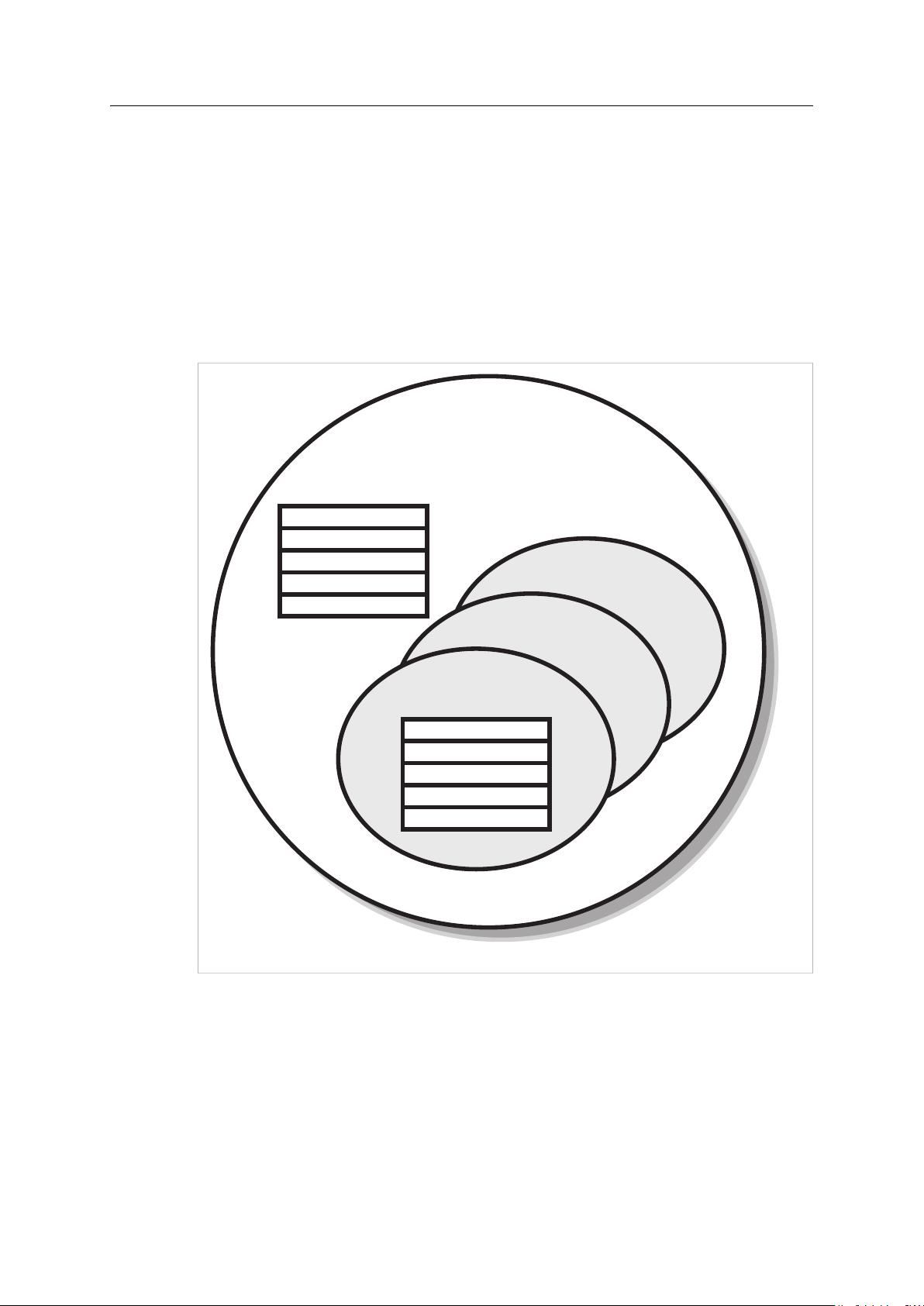

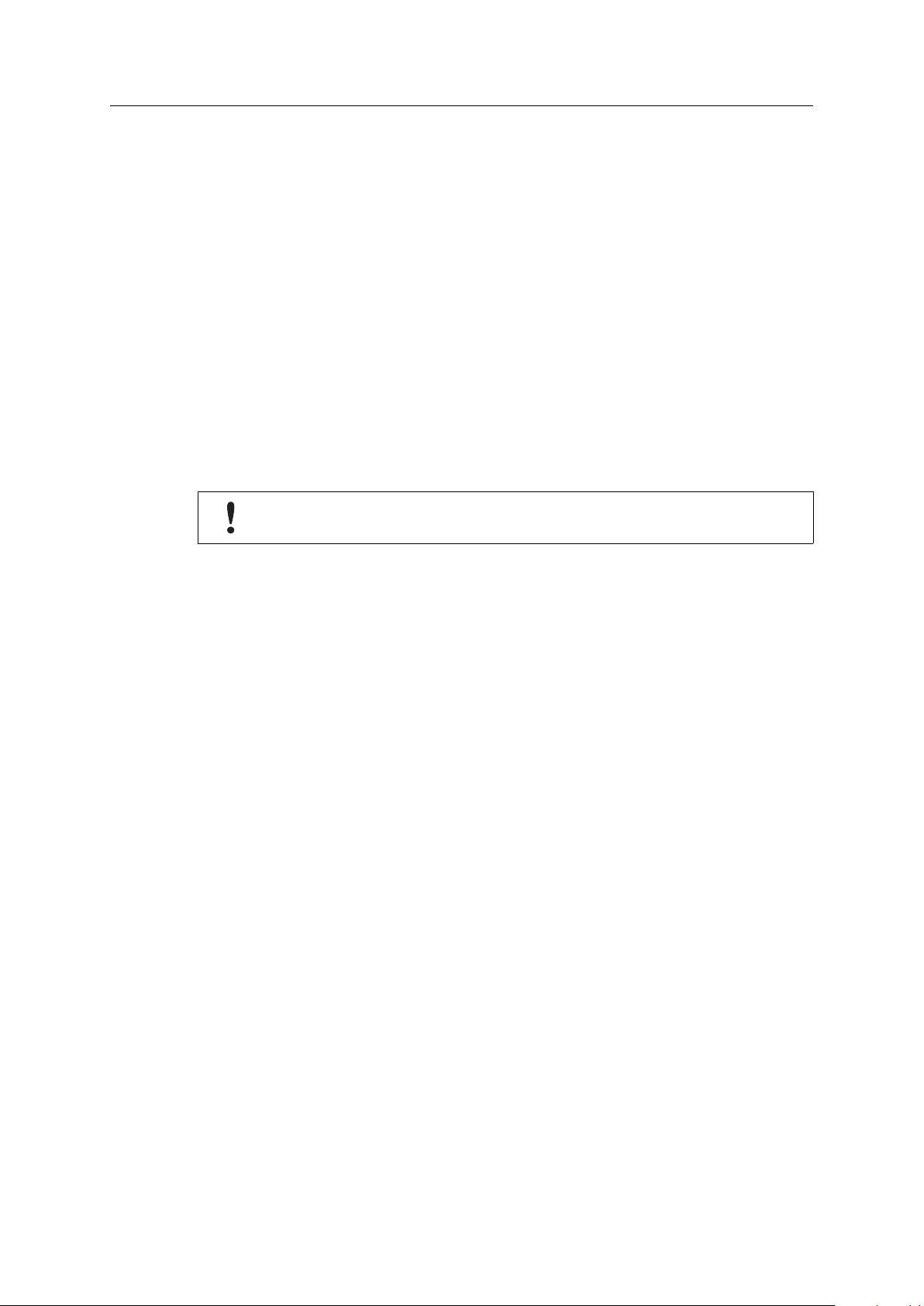

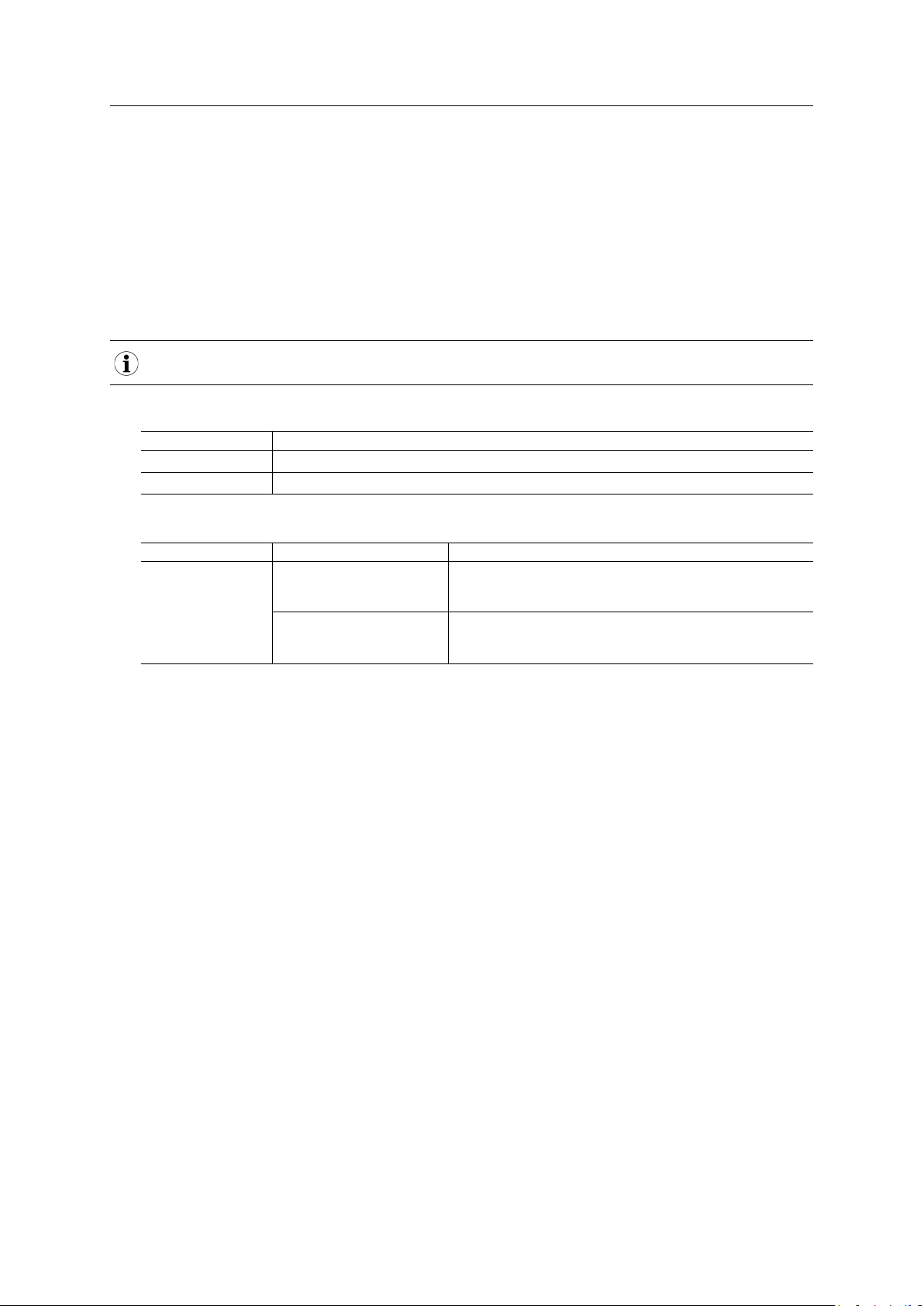

3.2 The Object Model

3.2.1 Basics

To provide a flexible and logical addressing scheme for both the host application and the Anybus

module, the software interface is structured in an object structured manner. While this approach

may appear confusing at first, it is nothing more than a way of categorizing and addressing

information.

Related information and services are grouped into entities called ‘Objects’. Each object can hold

subentities called ‘Instances’, which in turn may contain a number of fields called ‘Attributes’.

Attributes typically represents information or settings associated with the Object. Depending on

the object in question, Instances may either be static or created dynamically during runtime.

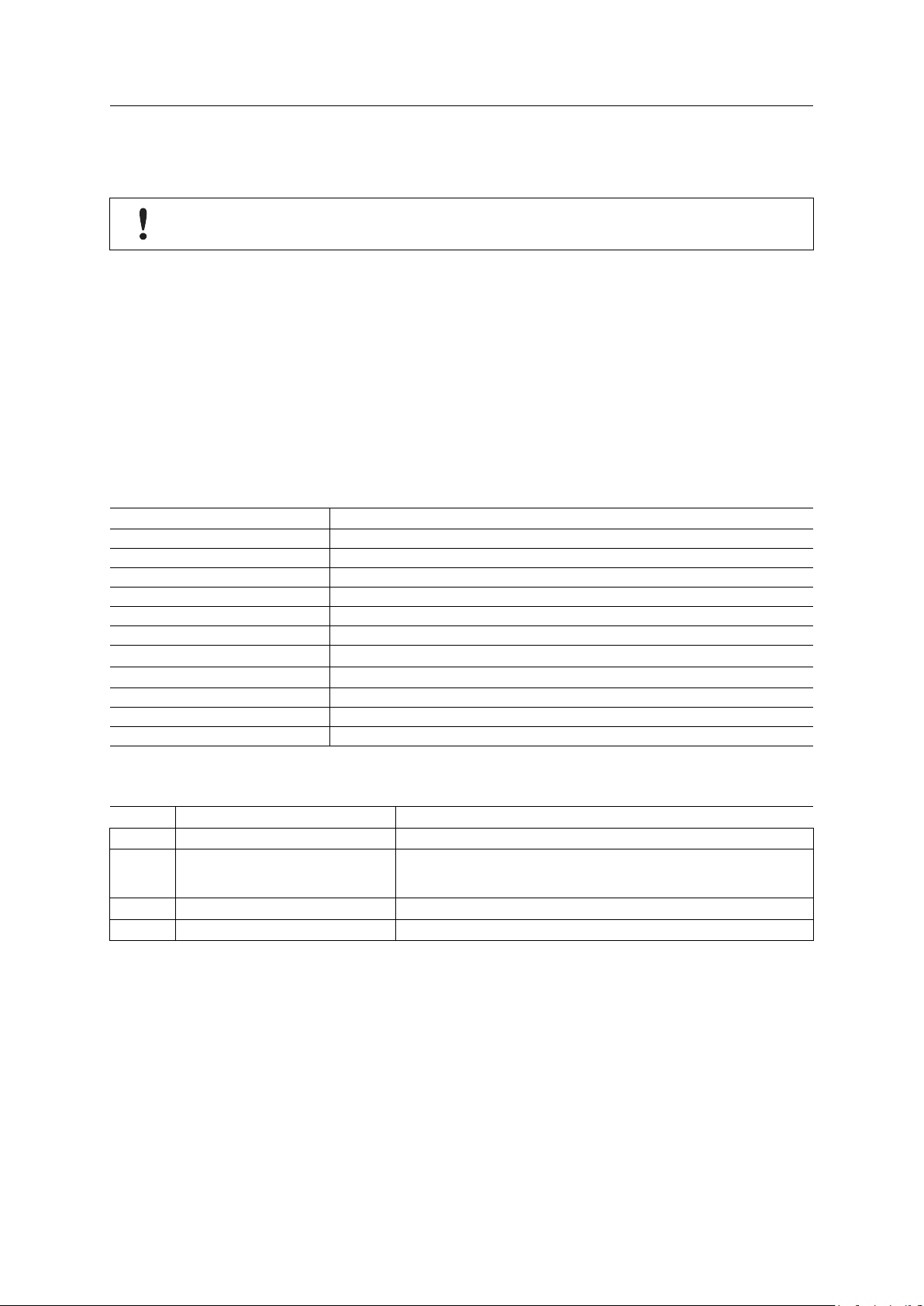

Fig. 3

®

Anybus

CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 15

Software Introduction 13 (176)

3.2.2 Addressing Scheme

Objects, and their contents, are accessed using Object Messaging. Each object message is tagged

with an object number, instance, and attribute, specifying the location of the data or setting

associated with the message.

This addressing scheme applies to both directions; i.e. just like the Anybus module, the

host application must be capable of interpreting incoming object requests and route

them to the appropriate software routines.

Example:

The module features an object called the “Anybus Object”, which groups common settings

relating the Anybus module itself.

In this object, instance #1 contains an attribute called ‘“Firmware version”’ (attribute #2). To

retrieve the firmware revision of the module, the host simply issues a Get Attribute request to

object #1 (Anybus Object), Instance #1, Attribute #2 (Firmware version).

3.2.3 Object Categories

Based on their physical location, objects are grouped into two distinct categories:

Anybus Module Objects These objects are part of the Anybus firmware, and typically controls the behavior of the

Host Application Objects These objects are located in the host application firmware, and may be accessed by the

module and its actions on the network.

Anybus module. This means that the host application must implement proper handling

of incoming object requests.

3.2.4 Standard Object Implementation

The standard object implementation has been designed to cover the needs of all major

networking systems, which means that it is generally enough to implement support for these

objects in order to get sufficient functionality regardless of network type.

Optionally, support for network specific objects can be implemented to gain access to advanced

network specific functionality. Such objects are described separately in each network guide.

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 16

Software Introduction 14 (176)

Anybus Module Objects

The following objects are implemented in the standard Anybus CompactCom 40 firmware:

• Anybus Object

• Diagnostic Object

• Network Object

• Network Configuration Object

• File System Interface Object

• Functional Safety Module Object

• Network Specific Objects

Exactly how much support that needs to be implemented for these objects depends on the

requirements of the host application.

See also...

Anybus Module Objects, p. 61

Host Application Objects

The following objects can be implemented in the host application.

• Application Data Object (Mandatory)

• Application Object (Mandatory)

• Sync Object (Optional)

• Modular Device Object (Optional)

• Assembly Mapping Object (Optional)

• File System Interface Object (Optional)

• Energy Control Object (Optional)

• Functional Safety Object (Optional)

• Network Specific Objects (Optional)

It is mandatory to implement the Application Data Object and the Application Object. The exact

implementation however depends heavily on the requirements of the host application.

See also...

Host Application Objects, p. 105

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 17

Software Introduction 15 (176)

Translation

Application Parameter

Application Parameter

Process Data Handling

Translation

Host Application

0101101101010110010011

0000101010110100111011

1000010101100000100010

0100110010111000000001

0010001101000100001010

Process Data Buffer*

(Read)

Object Response

*) These buffers holds data from ADI's that are mapped to Process Data.

Network

Acyclic Request

Cyclic Data

Acyclic Response

0101101101010110010011

0000101010110100111011

1000010101100000100010

0100110010111000000001

0010001101000100001010

Process Data Buffer*

(Write)

Cyclic Data

(Dedicated Channel)

Application Data

Object

ADI 1

ADI 2

ADI 3

Application Parameter

Object Request

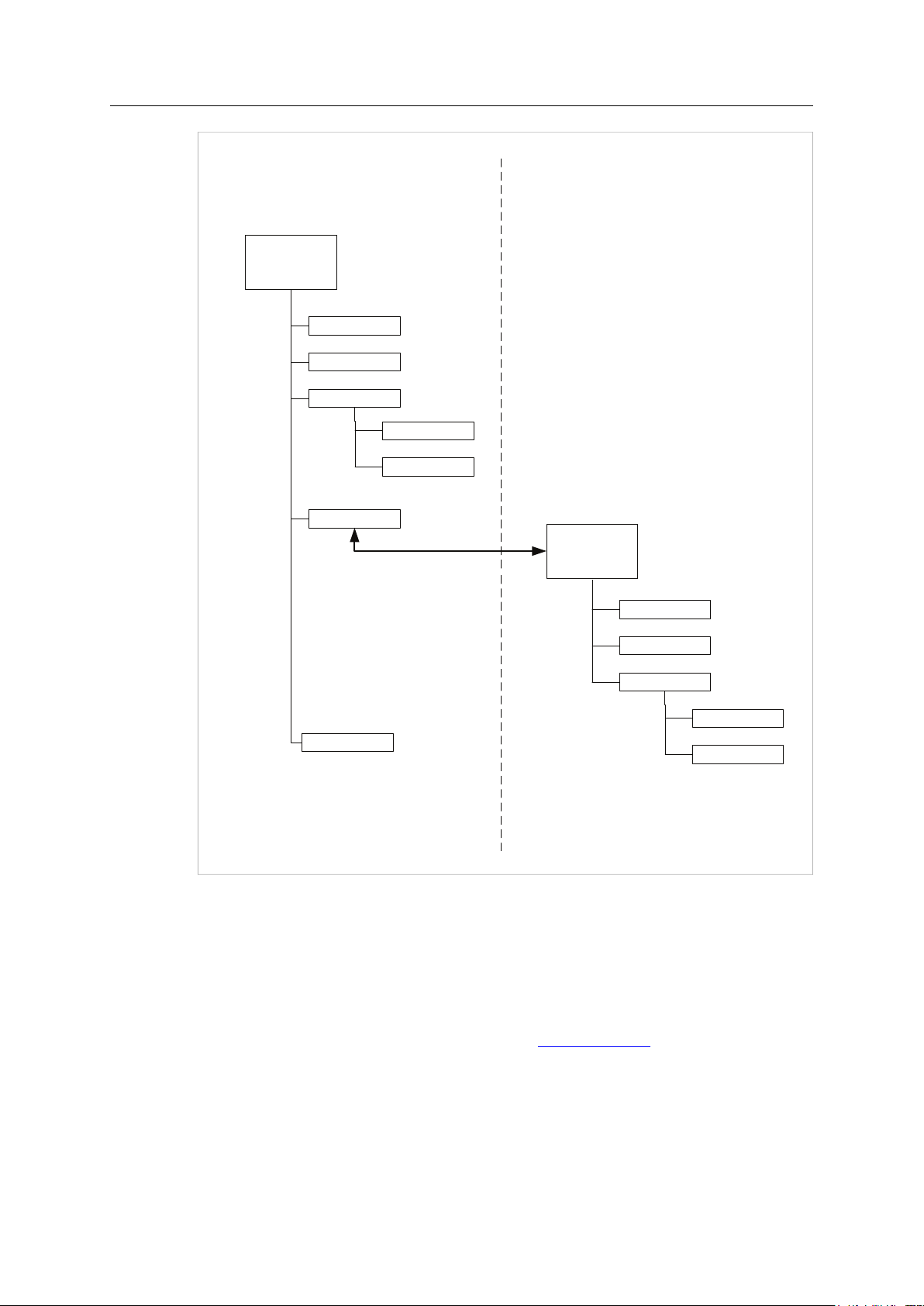

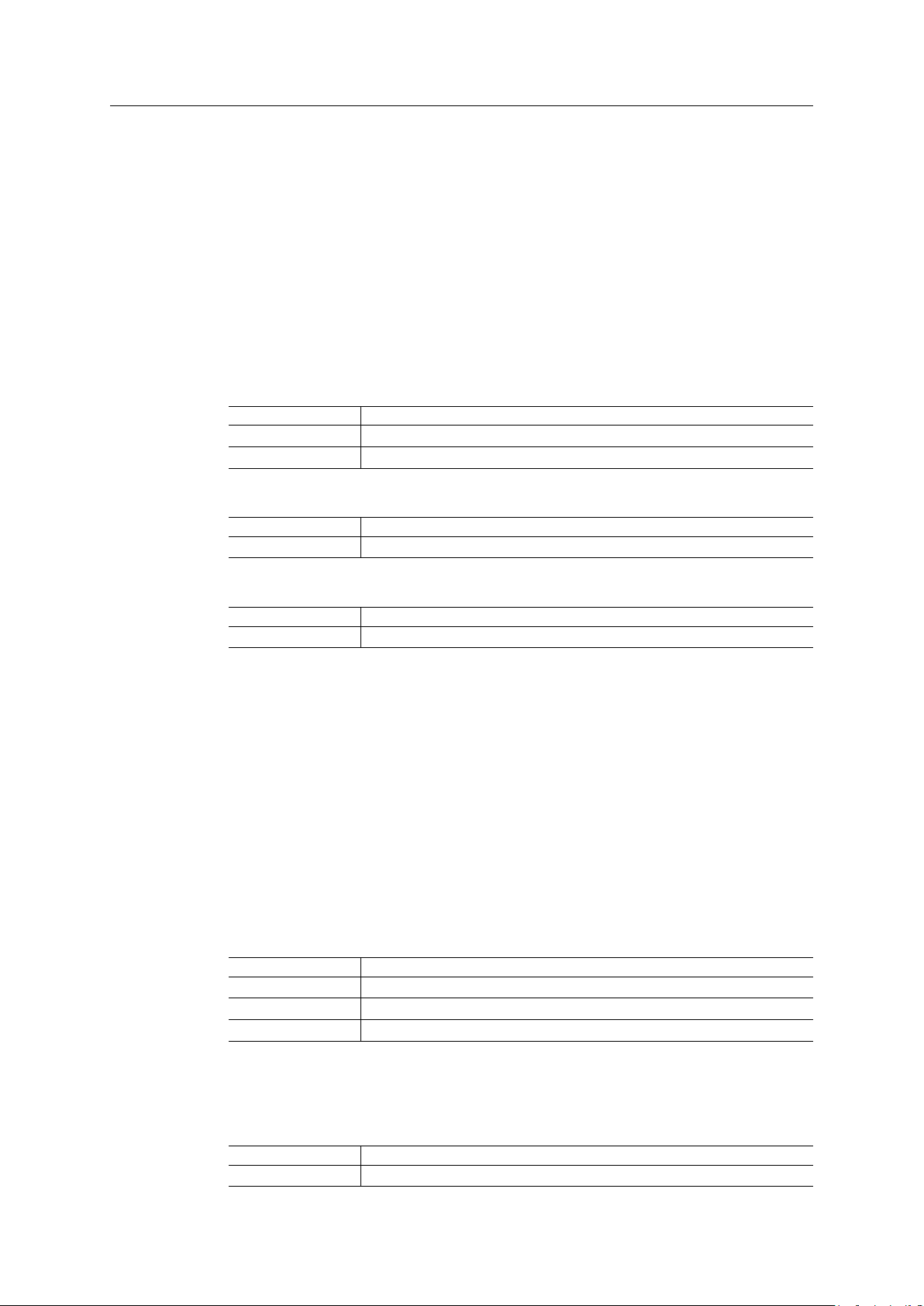

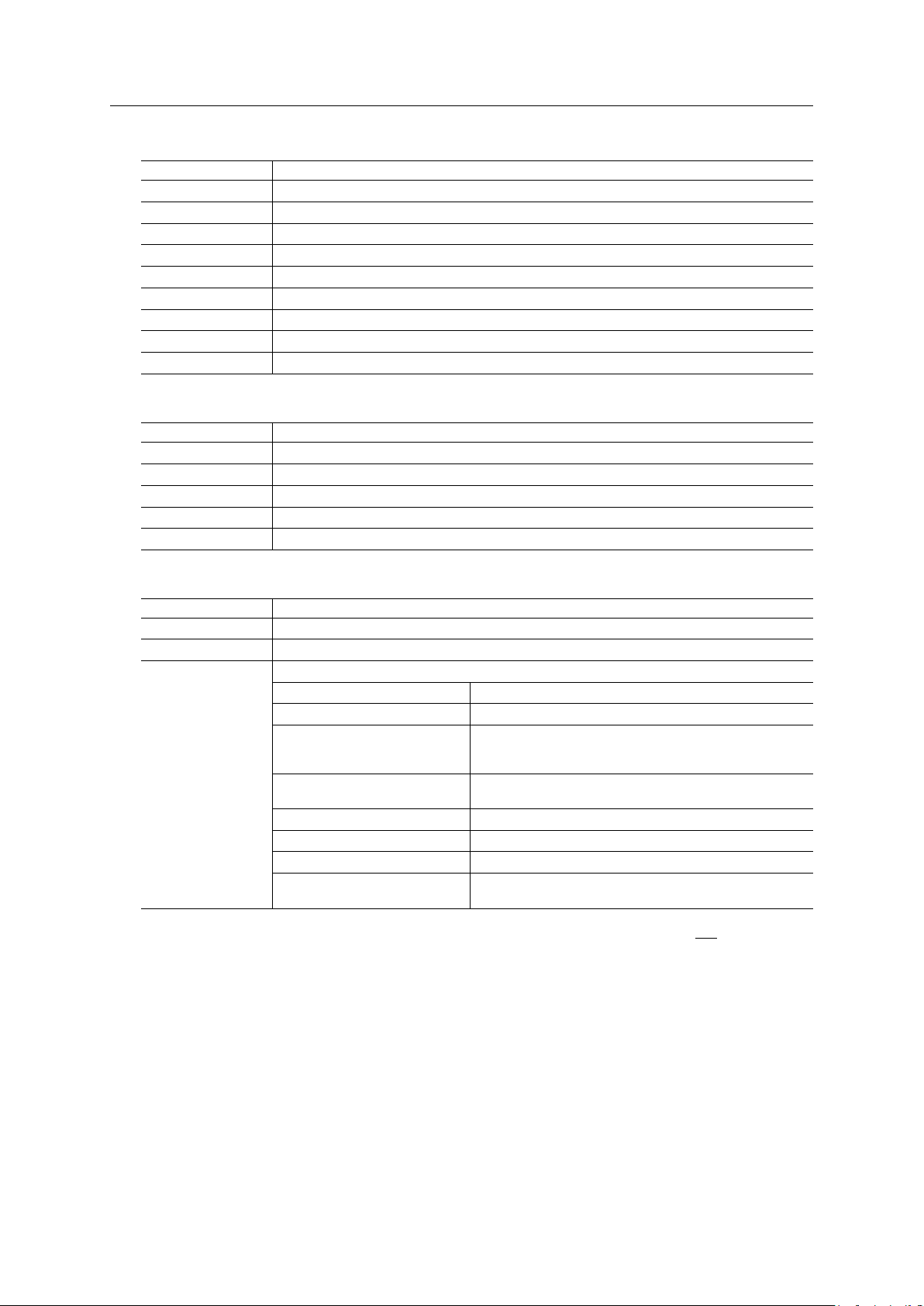

3.3 Network Data Exchange

Data that is to be exchanged on the network is grouped in the Application Data Object. This

object shall be implemented in the host application firmware, and each instance within it (from

now on referred to as “ADI”, i.e. Application Data Instance) represents a block of network data.

ADIs are normally associated with acyclic parameters on the network side. For example, on

DeviceNet and EtherNet/IP, ADIs are represented through a dedicated vendor specific CIP object,

while on PROFIBUS, ADIs are accessed through acyclic DP-V1 read/write services. On EtherCAT

and other protocols that are based on the CANopen Object Dictionary, ADIs are mapped to PDOs,

defined in the object dictionary.

ADIs can also be mapped as Process Data, either by the host application or from the network

(where applicable). Process Data is exchanged through a dedicated data channel in the Anybus

CompactCom host protocol, and is normally associated with fast cyclical network I/O. The exact

representation of Process Data is highly network specific; for example on PROFIBUS, Process

Data correlates to IO data.

Fig. 4

Each ADI may be tagged with a name, data type, range and default value, all of which may be

accessed from the network (if supported by the network in question). This allows higher level

network devices (e.g. network masters, configuration tools etc.) to recognize acyclic parameters

by their actual name and type (when applicable), simplifying the network configuration process.

Some networking systems allows both cyclic and acyclic access to the same parameter. In the

case of the Anybus CompactCom 40, this means that an ADI may be accessed via explicit object

requests and Process Data simultaneously. The Anybus module makes no attempt to synchronize

this data in any way; if necessary, the host application must implement the necessary

mechanisms to handle this scenario.

The Anybus interface uses little endian memory addressing. This means that the byte order is

from the least significant byte (LSB) to the most significant byte (MSB). The Anybus will however

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 18

Software Introduction 16 (176)

Host Application

Network

Diagnostics

Application Diagnostic & Status Handling

Diagnostic

Object

Event

Event

Event

handle ADI values transparently according to the actual network representation (indicated to the

application during initialization). The application driver is responsible for byte swap if required.

Use of this approach is decided because of the following reasons:

• The Anybus can not hold information about the data type of all ADIs due to memory

limitations and start-up time demands.

• The alternative to read the data type prior to every parameter write or read request would

be too time consuming.

See also...

The Anybus State Machine, p. 43

Network Object (03h), p. 74

Functional Safety Object (E8h), p. 107

3.4 Diagnostics

The Anybus CompactCom 40 features a dedicated object for host related diagnostics. To report a

diagnostic event, the host application shall create an instance within this object. When the event

has been resolved, the host simply removes the diagnostic instance again.

Each event is tagged with an Event Code, which specifies the nature of the event, and a Severity

Code, which specifies the severity of the event. The actual representation of this information is

highly network specific.

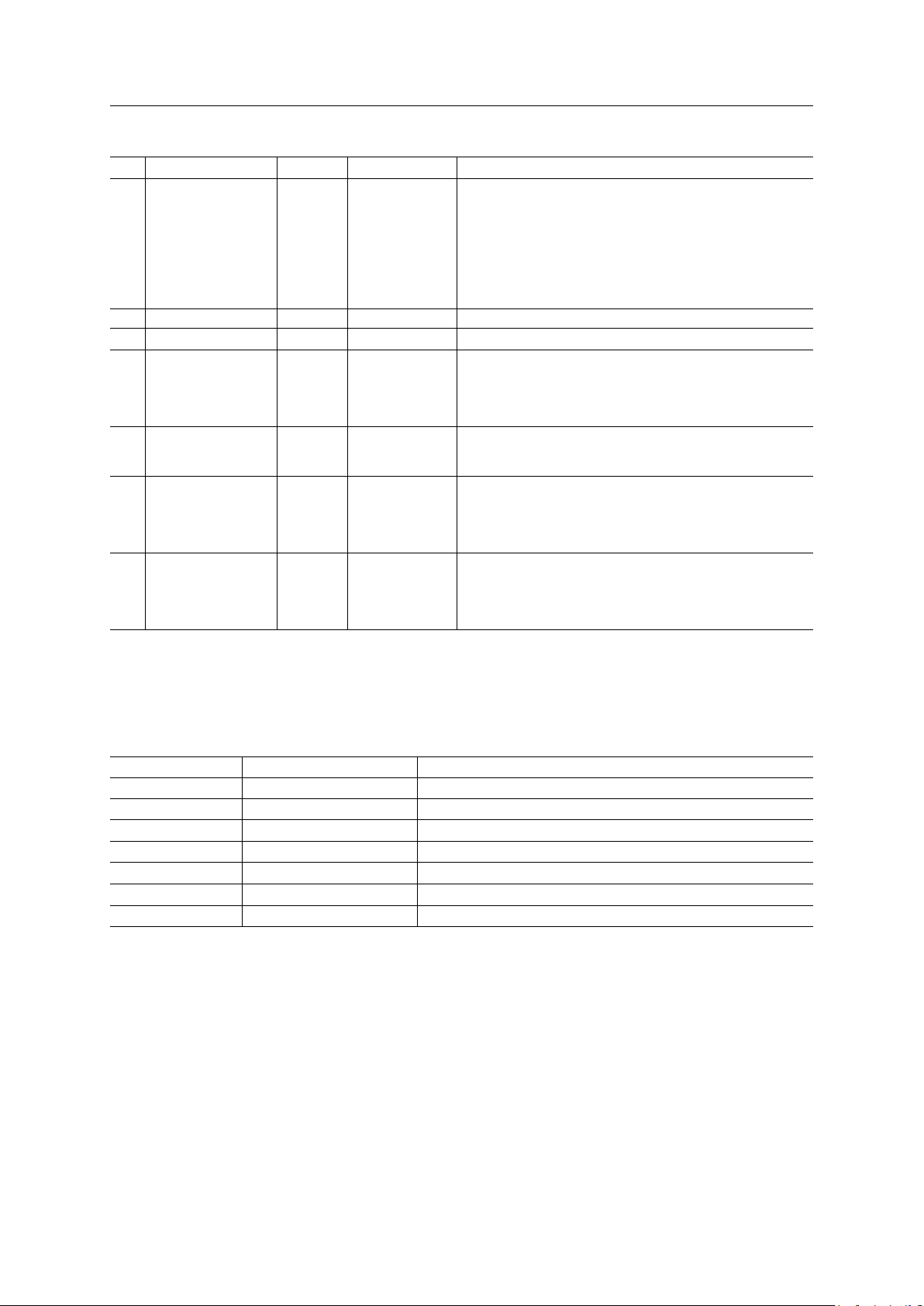

Fig. 5

See also...

Diagnostic Object (02h), p. 69

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 19

Software Introduction 17 (176)

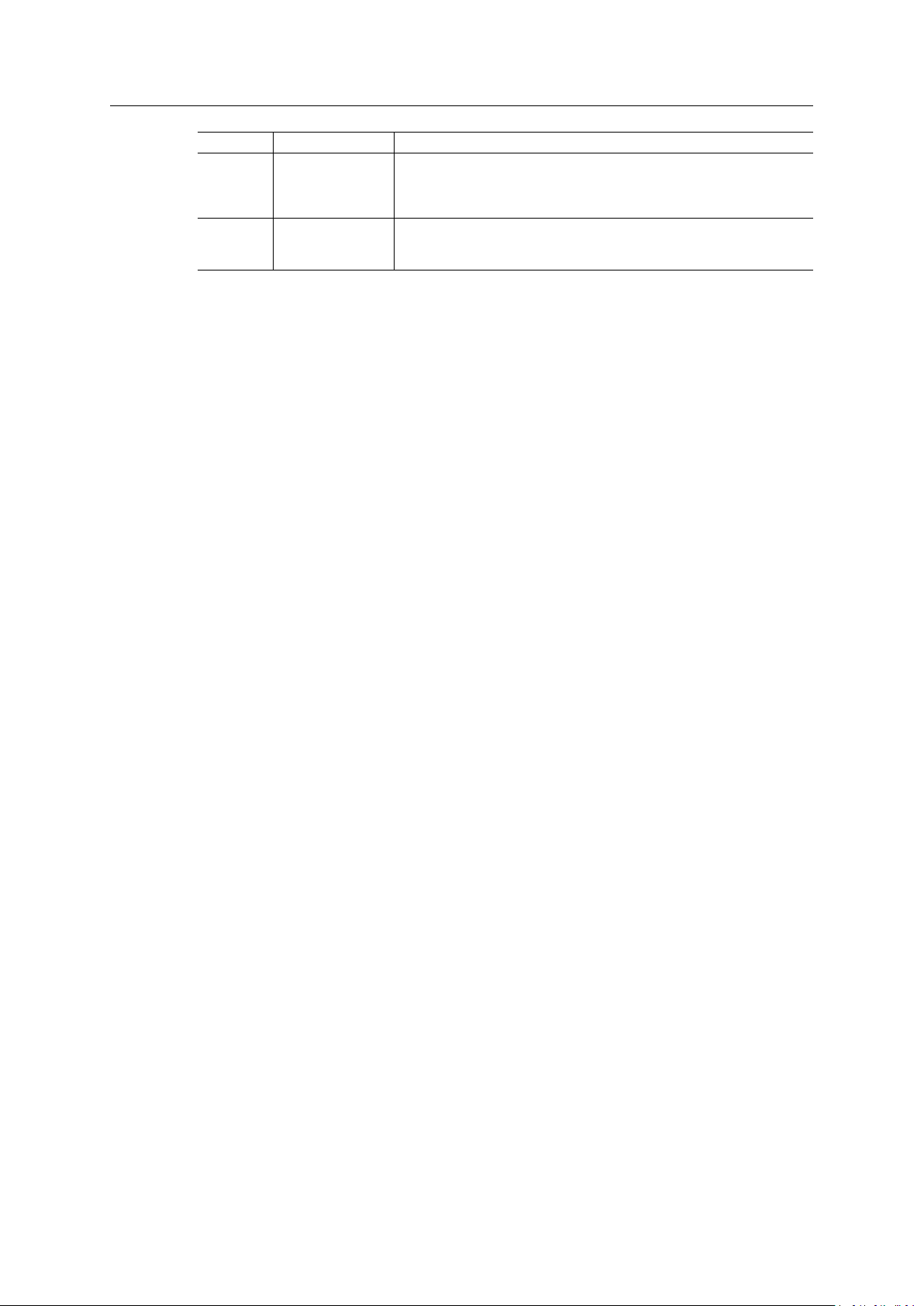

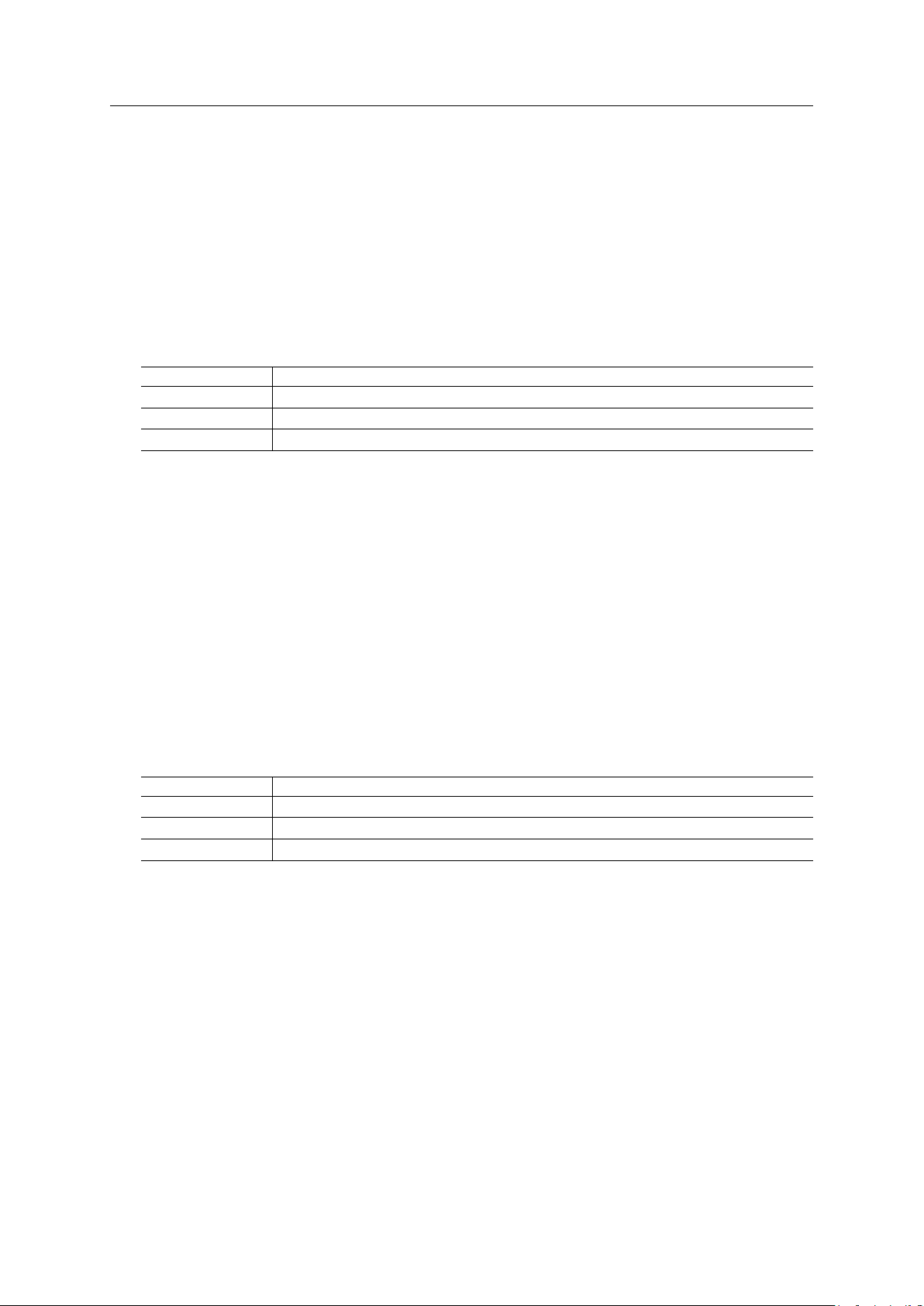

3.5 File System

The modules in the Anybus CompactCom 40 series have a built-in file system.

For modules not supporting FTP, this makes it possible to store firmware files in the firmware

directory using the File System Interface Object (0Ah). No other access to or use of the file

system is possible for these modules.

For modules supporting FTP, the in-built file system can be accessed from the application and

from the network. The file system can not be deleted.

Three directories are predefined:

VFS

Application This directory provides access to the application file system through the Application File

Firmware

The virtual file system that e.g. holds the web pages of the module.

System Interface Object (EAh) (optional). The directory can not be accessed from the

application, only from the network.

Firmware updates are stored in this directory.

In the firmware folder, it is not possible to use append mode when writing a file. Use

write mode only.

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 20

Software Introduction 18 (176)

Anybus

CompactCom

File system

File 1

File 2

VFS

File 1

File 2

Application

Application

File system

File A1

File A2

Directory A1

File A1:1

File A1:2

The Anybus CompactCom accesses

the application file system through the

Application File System Interface Object.

Anybus CompactCom

Application

Firmware*

* The firmware folder is available to the application

for firmware download in all modules.

Fig. 6

See also...

Anybus File System Interface Object (0Ah), p. 83

Application File System Interface Object (EAh), p. 130

Firmware Download, p. 25

Anybus CompactCom 40 Network Guides, available at www.anybus.com

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 21

Software Introduction 19 (176)

3.6 Modular Device

The modular device functionality makes it possible to model a structure of the process data on

to a number of modules of different types within an application, e.g. for handling digital input or

output, analog input or output, or drives. The ADIs are distributed among the modules and the

number of ADIs per module is configurable. The modules are physically connected to a

backplane, with a number of slots. The first slot is occupied by the coupler, which contains the

Anybus CompactCom module. All other slots may be empty or occupied by modules. When

mapping ADIs to process data, the application shall map the process data of each module in slot

order.

See also:

• Modular Device Object (ECh), p. 136

• Anybus CompactCom 40 Network Guides

3.7 SYNC

3.7.1 General Information

Automation systems involving many devices often require a way to synchronize events. To

achieve this, the devices in the system can share a common timing signal. The Anybus

CompactCom 40 supports a SYNC mechanism via the SYNC object, that is optional to implement

in the application.

The following Anybus CompactCom 40 modules support the SYNC functionality:

• Ethernet POWERLINK

• PROFINET-IRT

• EtherCAT

See also:

• Sync Object (EEh), p. 138.

• Application Status Register, p. 30

• The Anybus State Machine, p. 43 for information of the different states of the Anybus

CompactCom module.

3.7.2 Functionality

For a successful SYNC implementation, there are a number of things to implement and consider.

The network master will configure attributes #1-3 and #7 of the SYNC object through the Anybus

CompactCom module before entering state IDLE or PROCESS_ACTIVE. If the module attempts to

set attributes #1-3 in state IDLE or PROCESS_ACTIVE, the application must respond with error

code 0Dh (Invalid state). For unsupported values for the attributes, the application must respond

with a suitable error code (11h (Value too high), 12h (Value too low) or 0Ch (Value out of range)).

If there is a problem with the configuration as a whole, the application must indicate this in the

application status register. See Application Status Register, p. 30.

The application must indicate its minimum supported cycle time and the required input/output

processing times in attributes #4-6 of the SYNC object at all times. The value of these attributes

can be constant or vary, reflecting the timing required for the current process data mapping.

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 22

Software Introduction 20 (176)

3.7.3 Synchronization Lock

If the application needs time to lock on the SYNC signal, it must write 0001h (“Application not

yet synchronized”) to the application status register. When synchronization lock has been

achieved, and there are no configuration errors, the application must write 0000h to the

application status register and then accept a transition to PROCESS_ACTIVE.

Whenever the application is not locked on the SYNC signal, and attribute #7 “Sync mode” in the

SYNC object is set to “1”, the application must write the most accurate nonzero status code to

the application status register.

See also

Application Status Register, p. 30

3.7.4 SYNC Pulse

The SYNC signal, available from the module’s application connector, indicates the synchronization

event to the application by a positive pulse once every cycle. The positive edge of the SYNC pulse

indicates the synchronization event.

The width of the SYNC pulse is at least 5 µs, with a maximum width of 50% of the cycle time.

The SYNC event is also available to the application as a maskable interrupt. See Interrupt Status

Register, p. 32.

3.7.5 Network Translation

Ethernet POWERLINK does not in itself support synchronization functionality. The SYNC signal

from the module is sent once for each cycle, and can as such be used by the application.

In Anybus CompactCom 40 EtherCAT, parameters and settings are stored in CoE objects 1C32h

and 1C33h.

The Anybus CompactCom 40 PROFINET IRT supports both isochronous and non-isochronous

modes.

For more information, please consult the respective network guides.

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 23

Software Introduction 21 (176)

Cycle time

MI0/SYNC Signal

Input Capture

Output Valid

Min: “Output

Processing”

Max: “Input

Processing”

WRPD (Write Process Data)

Written to Anybus

Input Capture

Point

Output Valid

Point

RDPDI

(Read Process

Data Interrupt

From Anybus)

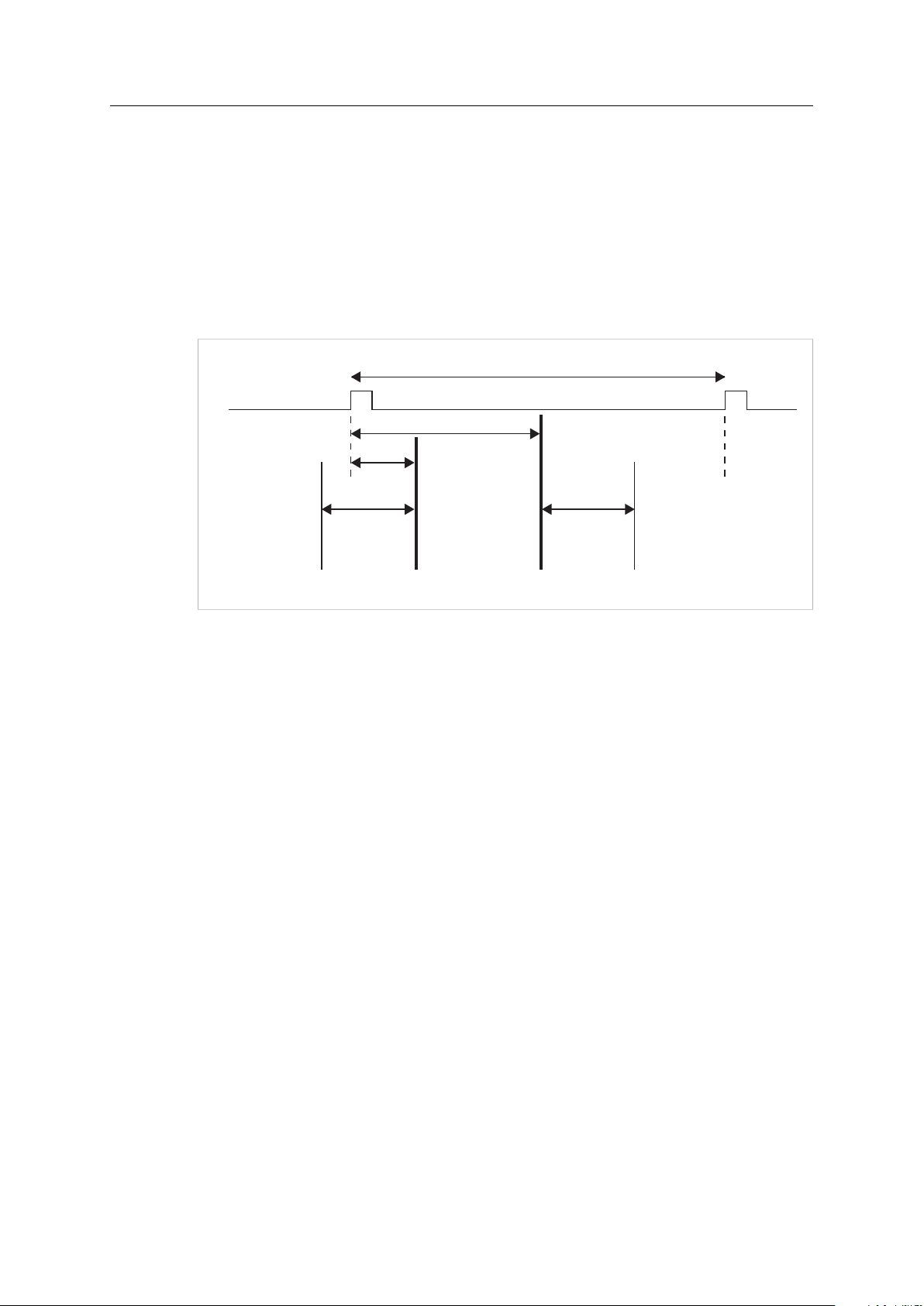

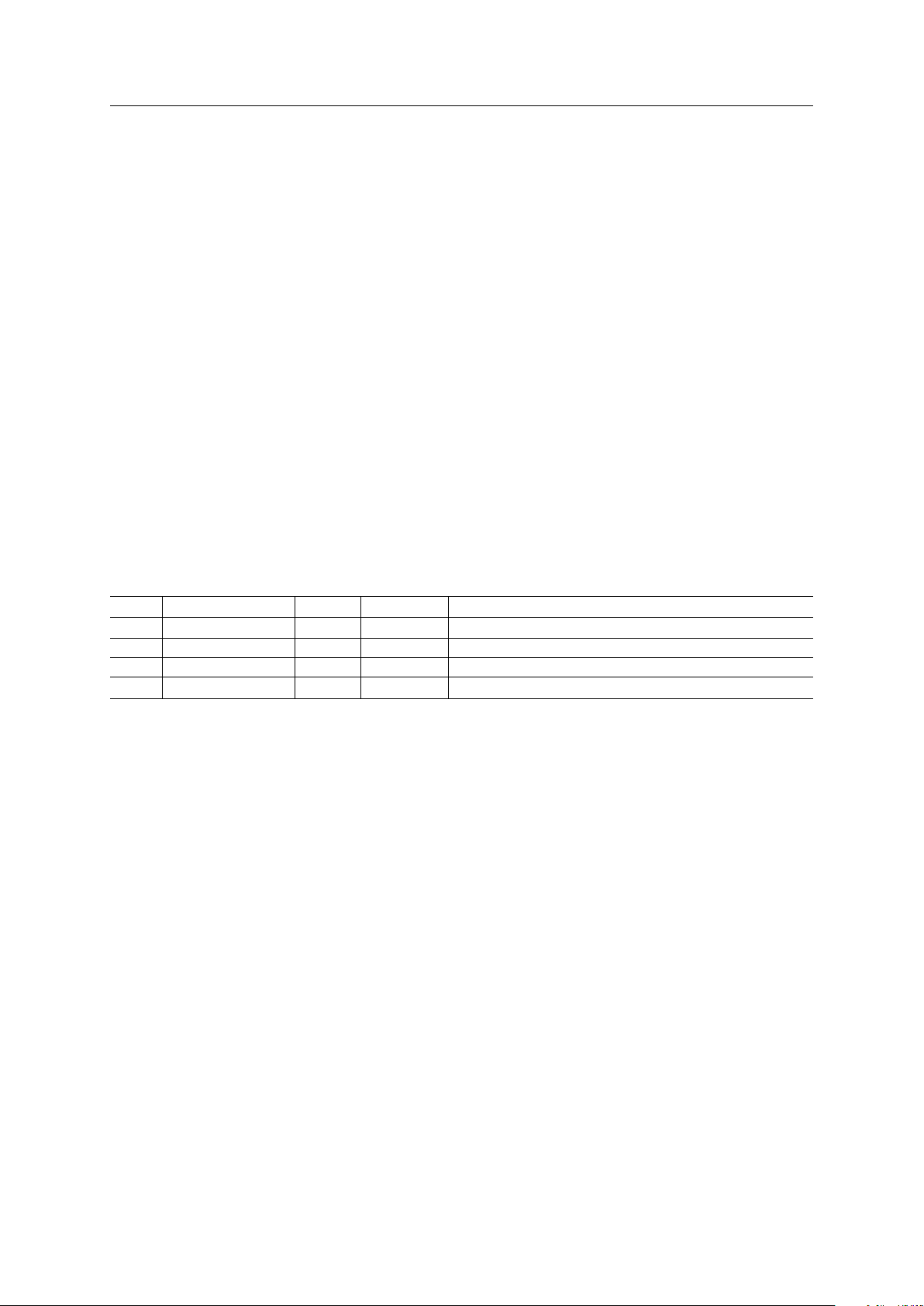

3.7.6 Anybus CompactCom 40 SYNC Implementation

The Goal of SYNC

To set output data to

different devices

simultaneously.

To capture input data from

different devices

simultaneously.

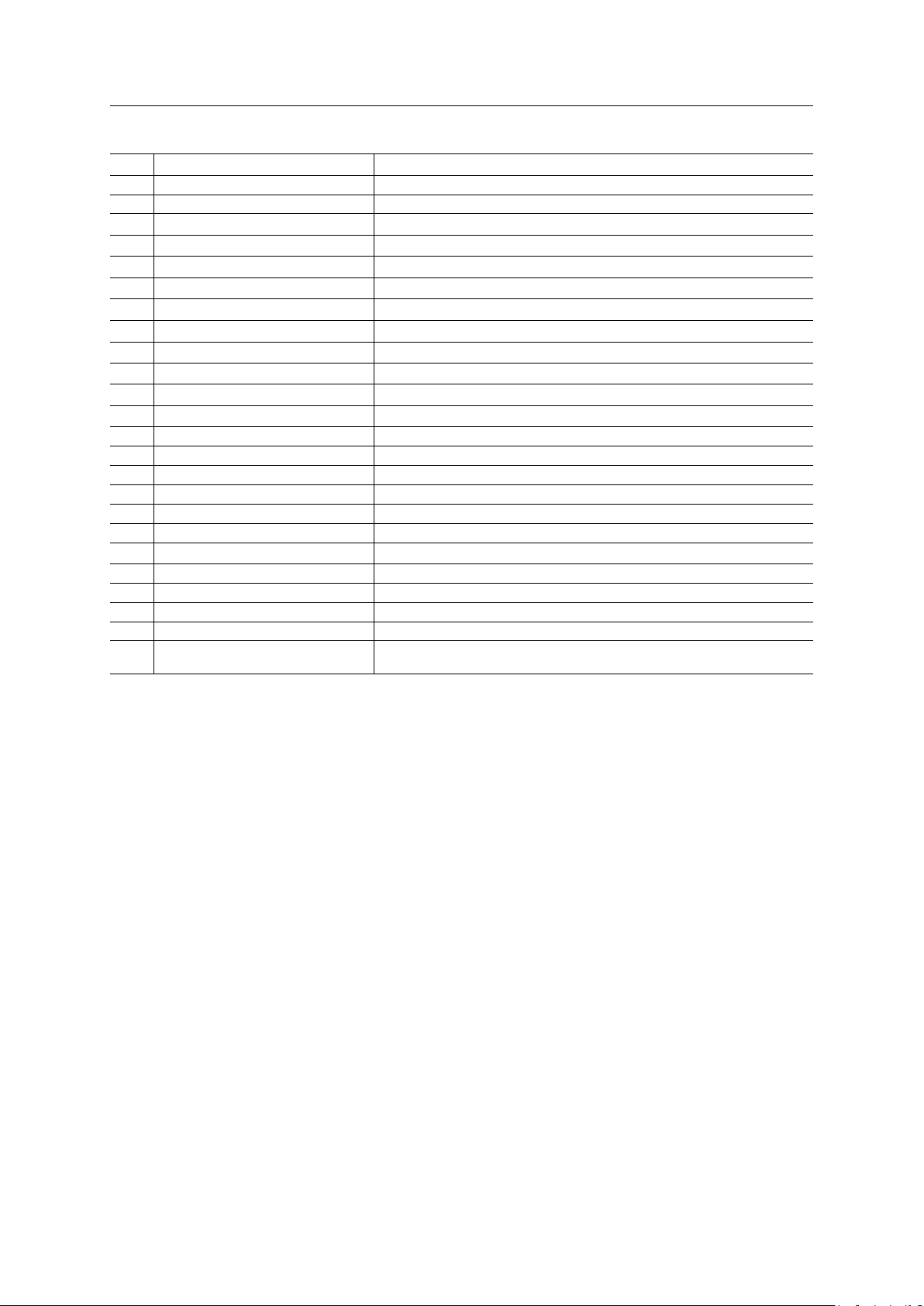

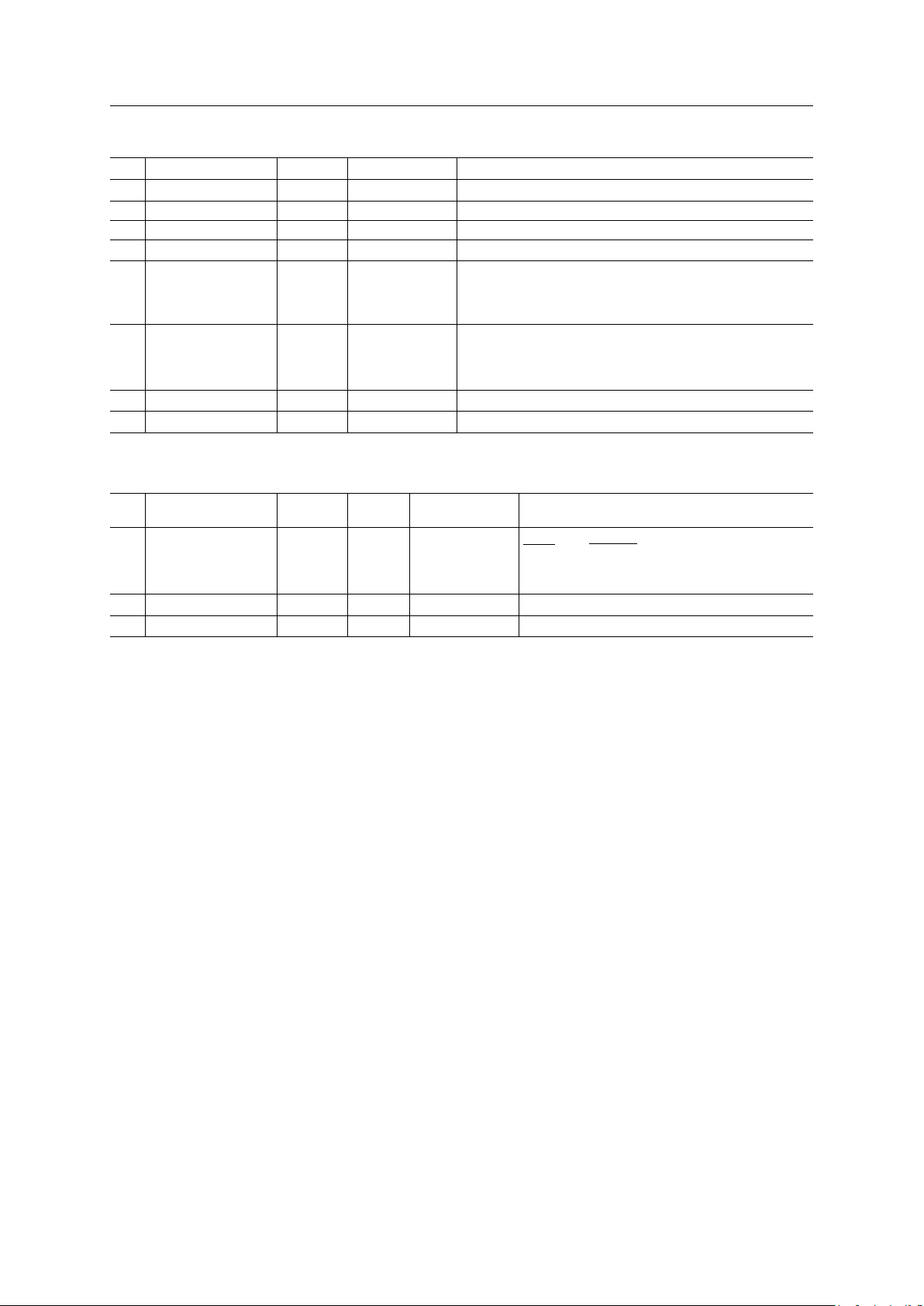

Fig. 7

The PLC will tell all devices in the network to set the next set of available output data at

the application, when the SYNC signal is sent.

The time when the output data is set at the application is called the Output Valid Point.

The time when the input data is available is called the Input Capture Point.

Handling of Output Data

Each device needs time to handle the new output data before it can be set in the application.

This time is not constant.

The device has to follow these steps:

1. Wait for indication of new output data (indicated by the Anybus CompactCom 40 through

the RDPDI (Read Process Data Interrupt).

2. Read the output data from the Anybus CompactCom 40 when receiving the RDPDI.

3. Process the new output data so that it can be used by the host application

– copy data

– process output variables

– do calculations

– etc

4. Wait for the SYNC signal.

5. When the SYNC signal arrives:

– If “Output Valid” = 0, activate the outputs to the host application.

– If “Output Valid” > 0, start a hardware or a software timer on the positive edge of the

SYNC signal. Activate the outputs to the host application when the timer has reached

“Output Valid”.

See Buffer Control Register, p. 31 and Interrupt Status Register, p. 32 for more information on

RDPD (Read Process Data) and RPDPI (Read Process Data Interrupt)

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 24

Software Introduction 22 (176)

Handling of Input Data

Each device needs time to capture, prepare and send new input data. This time is not constant.

The device has to follow these steps:

1. Wait for the SYNC signal.

2. When the SYNC signal arrives (“Input Capture” point):

– If “Input Valid” = 0, capture the current input process variables of the host application.

– If “Input Valid” > 0, start a hardware or a software timer on the positive edge of the

SYNC signal. Capture the current input process data when the timer has reached “Input

Valid”.

3. Prepare the new input process data so that it can be written to theAnybus CompactCom 40.

4. Write the new process input data to theAnybus CompactCom 40.

Host Application Programming Guidelines

See Sync Object (EEh), p. 138 for more information.

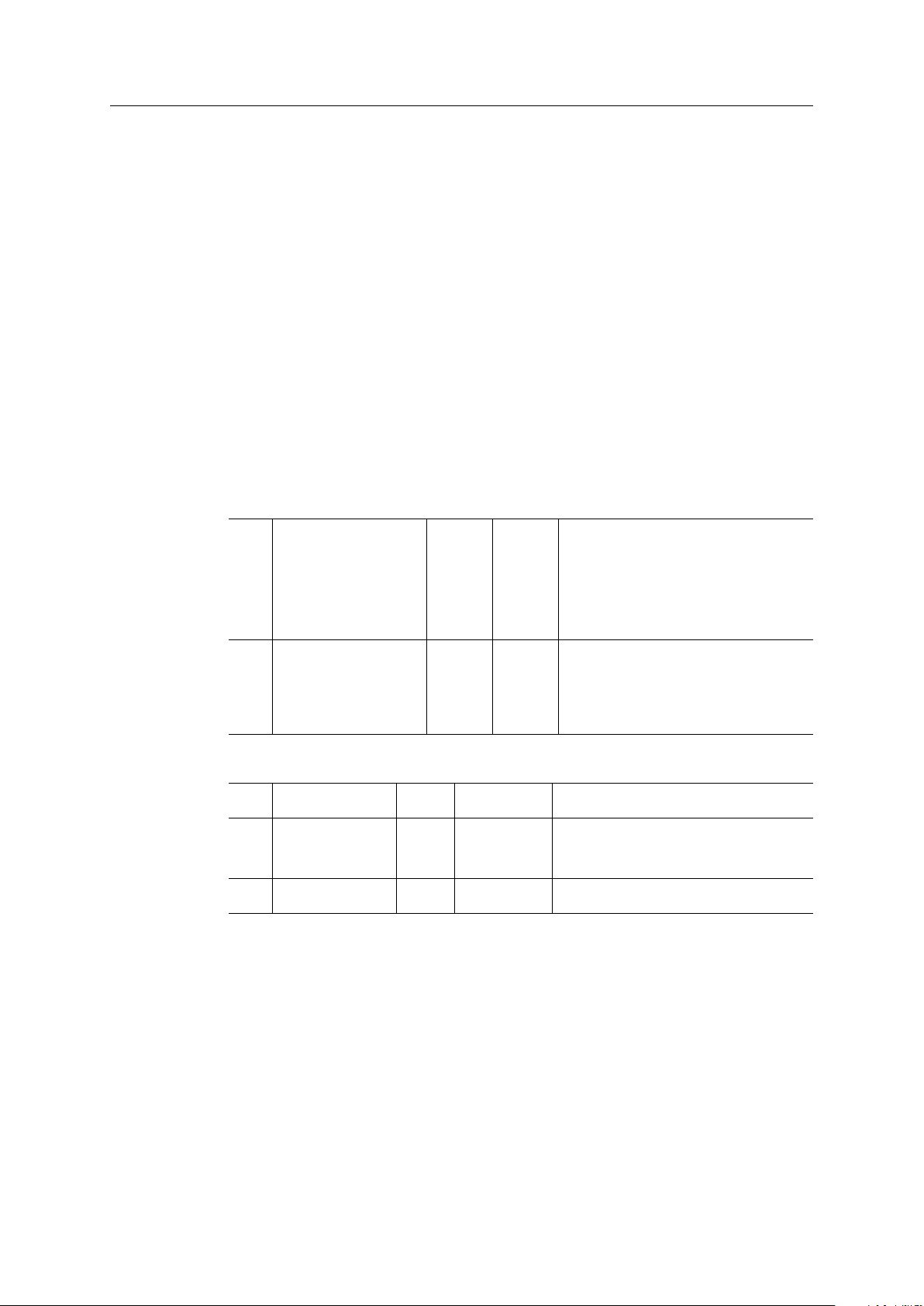

1. Implement the SYNC Object (part 1)

7

Sync mode

8

Supported sync modes

Get/Set

Get UINT16

UINT16

This attribute is used to select synchronization

mode. It enumerates the bits in attribute 8

0: Non synchronous operation. (Default value if

non synchronous operation is supported)

1: Synchronous operation

2 - 65535: Reserved. Any attempt to set sync

mode to an unsupported value shall generate

an error response

A list of the synchronization modes the

application supports. Each bit corresponds to a

mode in attribute 7

Bit 0: 1 = Non synchronous mode supported

Bit 1: 1 = Synchronous mode supported

Bit 2 - 15: Reserved (0)

2. Implement the SYNC Object (part 2)

4 Output processing Get UINT32

5

Input processing Get UINT32

6

Min cycle time

Get UINT32

Minimum required time, in nanoseconds,

between RDPDI interrupt and “Output valid”

Maximum required time, in nanoseconds, from

“Input capture” until write process data has been

completely written to the Anybus CompactCom

40

Minimum cycle time supported by the

application (in nanoseconds)

The time elapsed between receiving an RDPDI interrupt and when the process output

variables have been taken over by the application has to be measured. The maximum time

must be provided by the application when the Anybus CompactCom 40 asks for attribute #4

“Output processing”. The network master has to make sure that the minimum output

processing time is longer than the maximum time measured.

The time elapsed between capturing the input process variables and when the input process

data is written to the CompactCom 40 must be measured. The maximum time must be

provided by the application when the Anybus CompactCom 40 asks for attribute #5 “Input

processing”.

The host application must measure the maximum time needed to handle all process data

(the time from receiving the RDPDI interrupt until the write process data has been written

to the Anybus CompactCom 40). This value must be provided by the application when the

Anybus CompactCom 40 asks for attribute #6 “Min cycle time”.

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 25

Software Introduction 23 (176)

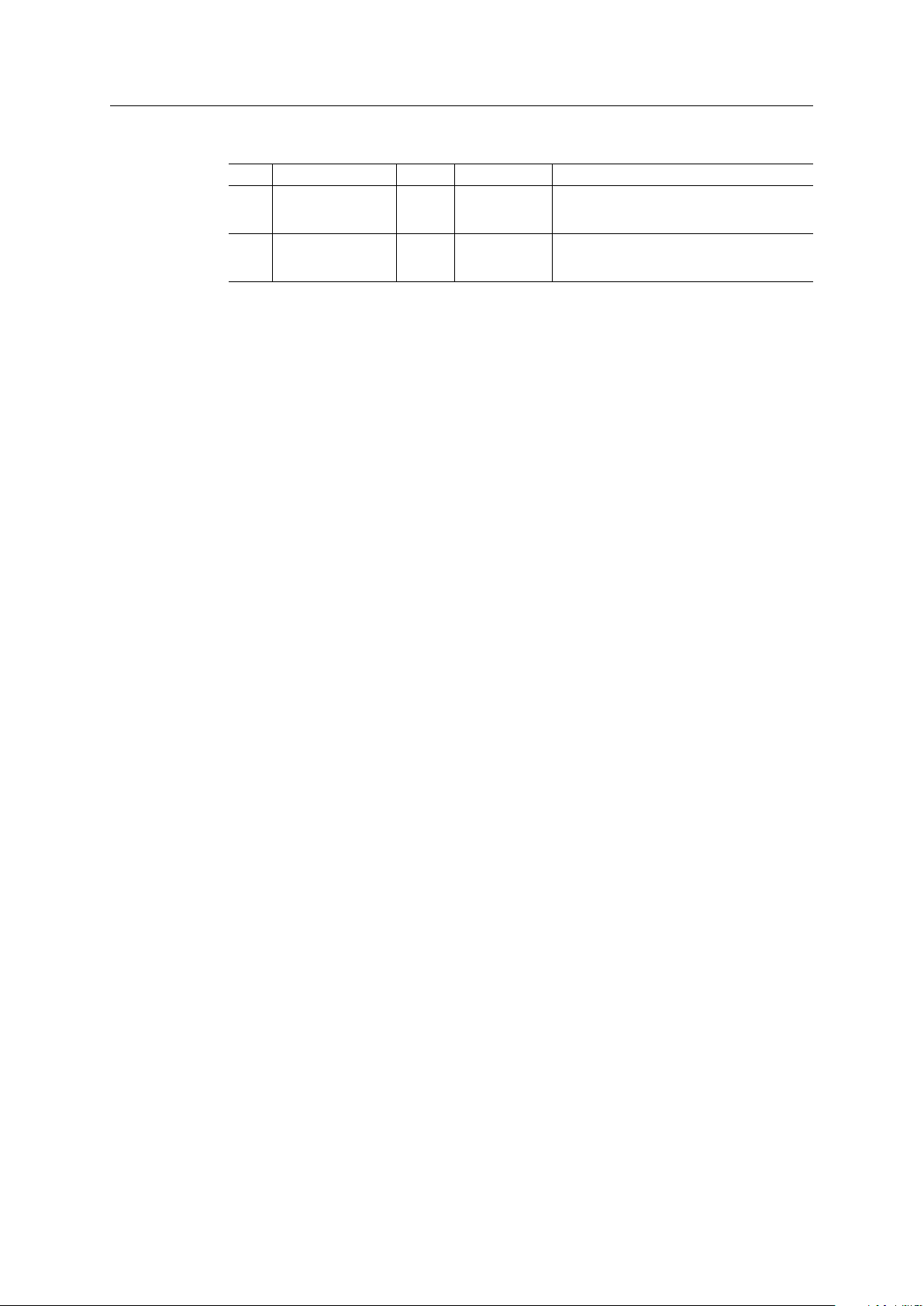

3. Implement the SYNC Object (part 3)

1

Cycle time

2

Output valid

3 Input capture

Get/Set

Get/Set

Get/Set

UINT32

UINT32

UINT32

Application cycle time in nanoseconds

Output valid point relative to SYNC events, in

nanoseconds

Default value: 0

Input capture point relative to SYNC events, in

nanoseconds

Default value: 0

These three attributes can all be set by the Anybus CompactCom 40.

Using attribute #1, “Cycle time”, theAnybus CompactCom 40 informs the host application

about the real used cycle time (by the Set_Attribute command). This value must be

evaluated by the host application and refused if not acceptable (not suitable, e.g. in conflict

with other cyclic tasks of the host application or not within the defined range). If refused,

the Anybus CompactCom 40 will report this to the PLC.

Attributes #2 and #3 reflect functionality present on some networks (e.g. EtherCAT, SERCOS

and PROFINET), where the input capture and output valid points can be fine-tuned. This can

be used to offset one device relative to another by a small amount of time. To support

values other than zero (0), timers will have to be implemented in the application.

4. Implement the Application Status Register

See Application Status Register, p. 30 for more information.

5. Act upon receiving an RDPDI and a SYNC signal

When receiving an RDPDI interrupt, read the output process data from the Anybus

CompactCom 40, prepare it (handle and assign it to process output variables) so that it can

be activated when receiving a SYNC signal.

When receiving a SYNC signal, do the following:

a. Transfer the output process variables to the application immediately.

b. Capture all input process variables immediately.

c. Prepare and assign the input process variables to the input process data.

d. Write the input process data to the CompactCom.

Steps b, c and d must be done within the time specified by attribute #5 “Input processing”.

Steps a and b assumes Output Valid and Input Capture to be zero (0).

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 26

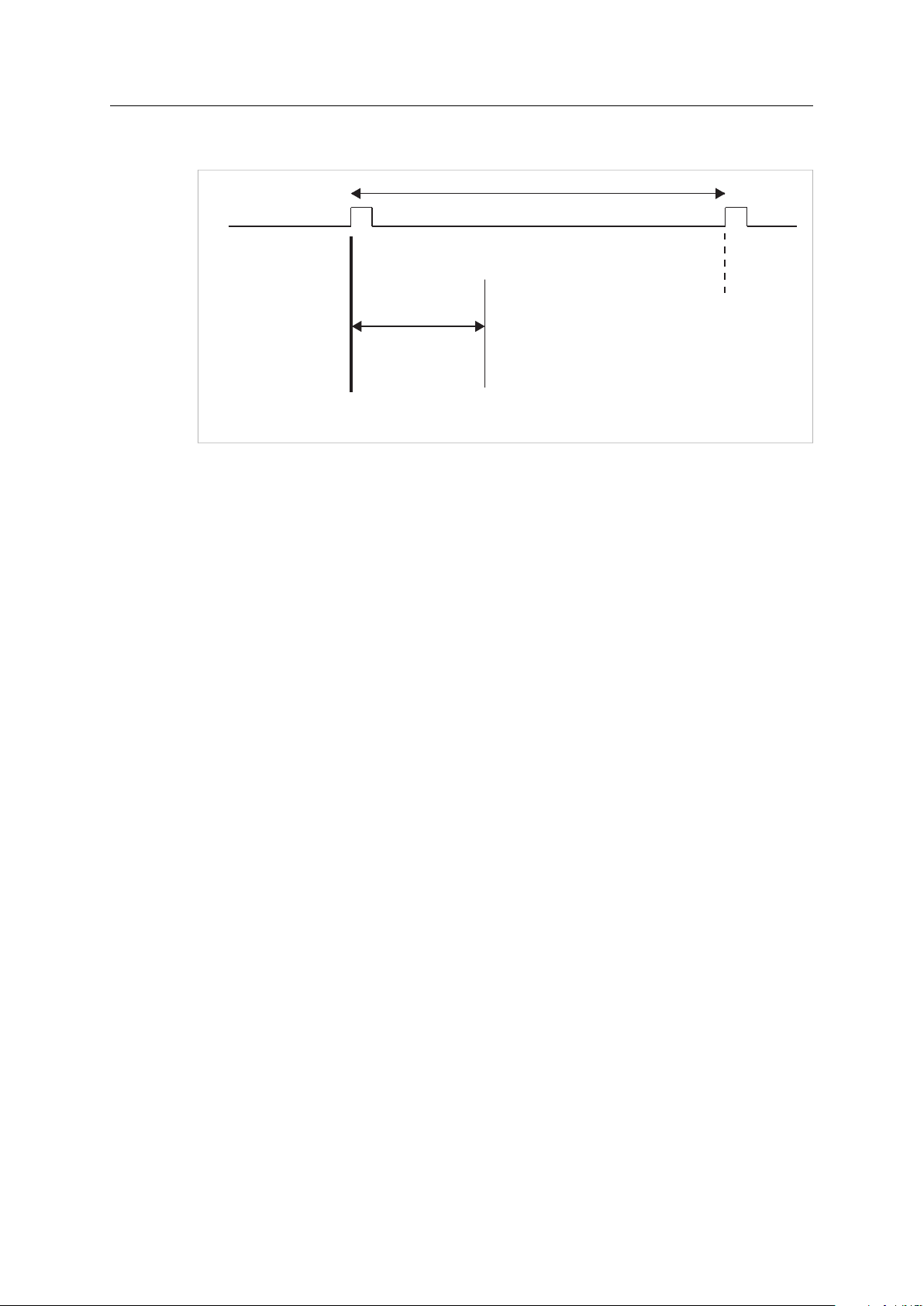

Software Introduction 24 (176)

Cycle time

MI0/SYNC Signal

Max: “Input

Processing”

WRPD Written to

Anybus

Output Valid Point

and

Input Capture Point

The Easiest Realization of a Synchronous Application

Fig. 8

The following steps show how to create a very simple synchronous application.

1. Set up an interrupt routine triggered by the positive SYNC edge. Disable the RDPDI interrupt.

2. In the SYNC interrupt routine:

– Sample the input data and write it to the Anybus CompactCom 40.

– Read the output data from the Anybus CompactCom 40 and start using it immediately.

3. For this application, attribute #4 “Output processing” in the SYNC object should be set to

zero (0). No measurement needed.

4. Attribute #5 “Input processing” must be determined. It can probably be hard coded to a

fixed value, but this is application specific and depend on the complexity of the SYNC

interrupt routine and the application processor performance.

5. For attributes #2 “Output valid” and #3 “Input capture”, only the value zero (0) will be

accepted by the application.

This simple step-by-step method will work in all applications where the process data handling

can be made fast and simple.

3.8 Multilingual Support

Where applicable, the Anybus CompactCom 40 supports multiple languages. This mainly affects

instance names and enumeration strings, and is based on the current language setting in the

Anybus Object. Note that this also applies to Host Application Objects, which means that the

host application should be capable of changing the language of enumeration strings etc.

accordingly.

When applicable, the Anybus CompactCom 40 forwards change-of-language-requests from the

network to the Application Object. It is then up to the host application to grant or reject the

request, either causing the module to change its language settings or to reject the original

network request.

Supported languages:

• English (default)

• German

• Spanish

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 27

Software Introduction 25 (176)

• Italian

• French

See also...

Application Object (FFh), p. 118

3.9 Firmware Download

Download and upgrade of network communication firmware for a specific fieldbus or industrial

network can be performed in different ways, depending on which Anybus CompactCom 40 that

is to be upgraded.

3.9.1 Important

When the Anybus CompactCom 40 is restarted after a firmware download, the application must

wait for the installation to finish before initialization is started. The Anybus CompactCom 40 is

protected against power failure during download and/or installation and will recover upon

restart.

• If download through e.g. Firmware Manager or FTP, is interrupted, please restart the

firmware download process from the beginning.

• To install the new firmware after download is completed, reset the Anybus CompactCom 40.

If the installation of the new firmware is interrupted, e.g. due to power loss, please restart

the Anybus CompactCom 40. The installation process will automatically start from the

beginning and the new firmware will be installed without any further action.

For more information see, Startup Procedure, p. 57

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 28

Software Introduction 26 (176)

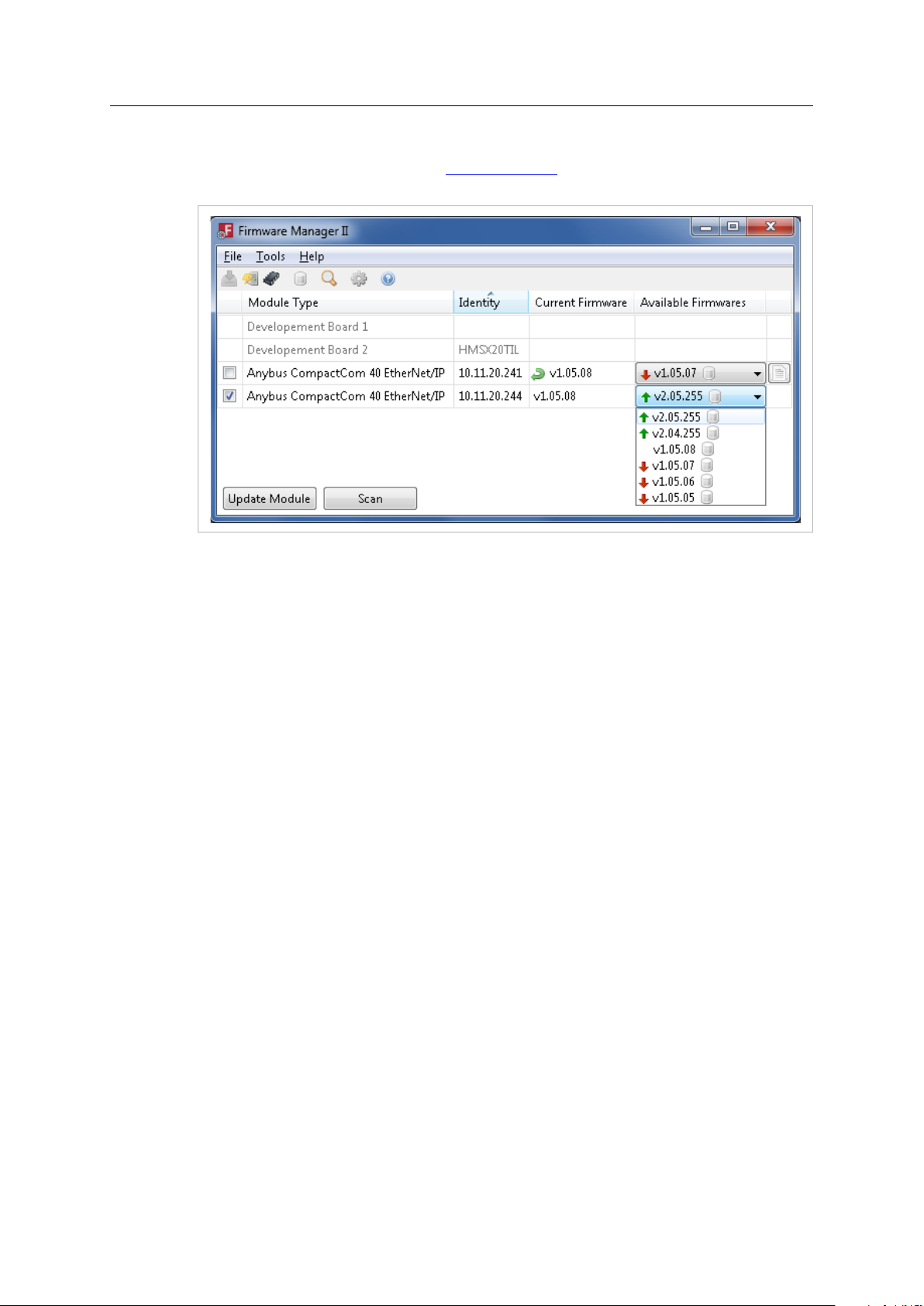

3.9.2 Using Firmware Manager II

This tool is available without cost from www.anybus.com. It can be used to download new

firmware for any Anybus CompactCom 40.

Fig. 9

Using the tool, perform the following steps to download new firmware to the module.

1. Connect a computer with the Firmware Manager II software installed to the network

containing the module.

2. Start the Firmware Manager II tool.

3. Scan the network and find the module.

4. Click the Firmware Repository icon in the menu, to open the Firmware Repository window.

Drag the firmware folder into the window to add the new firmware to the repository. Close

the Firmware Repository window.

5. In the scan window, under the “Available Networks” tab, select the appropriate firmware

for the module. Click the Change Network button. A confirmation window will appear. Click

Yes to start the download of the new firmware. Please make sure that download is

completely finished before continuing.

6. After download, a restart of the module is needed to install the new firmware. If the

application allows it, it is possible to restart the module via the Restart Module button in

the Firmware Manager II tool. If the application does not allow restart from the network, a

manual restart of the module is needed.

For more information, see the help file in the Firmware Manager II software.

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 29

Software Introduction 27 (176)

3.9.3 Using the Internal File System

The internal file system can be accessed via the File System Interface Object. Interfacing this

object from the host application, makes it possible to store the new firmware in the /firmware

directory in the internal file system. The next time the module is started the firmware will be

upgraded. After the firmware is installed, the firmware file is deleted from the /firmware

directory.

In the firmware folder, it is not possible to use append mode when writing a file. Be sure

to use write mode only.

See also ...

• Application File System Interface Object (EAh), p. 130

3.9.4 Using FTP

If the module supports FTP, this can be used to access the file system and upload the new

firmware directly to the /firmware directory. The next time the module is started the firmware

will be upgraded. After the firmware is installed, the firmware file is deleted from the /firmware

directory.

See also ...

• Application File System Interface Object (EAh), p. 130

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 30

Host Communication Layer

4 Host Communication Layer

4.1 General Information

The main communication layer is used by the 8-bit/16-bit parallel modes and the SPI mode. It is

divided into process data read/write areas, message data read/write areas and a number of

control registers.

Below is a detailed description of the memory map and the different control registers.

4.1.1 Communication Basics

The communication between the host and the Anybus CompactCom 40 is simple, fast and

flexible.

The host can read or write process data at any time. It can check for incoming data via the buffer

control register or by enabling appropriate interrupts via the interrupt mask register.

Attempts to access reserved registers will produce unpredictable results. Attempts to

write to a read-only register will produce unpredictable results. Reserved bits shall be

written with zeros (0). Reading reserved bits returns undefined values.

28 (176)

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 31

Host Communication Layer

4.2 Memory Map

The address offset specified below is relative to the base address of the module, i.e. from the

beginning of the area in host application memory space where the interface has been

implemented.

The memory area is not available during reset.

The shaded areas and registers are used for backward compatibility with the Anybus

CompactCom 30 series.

29 (176)

Byte Address Word Address

0000h - 0FFFh 0000h - 07FFh Process data, write

1000h - 1FFFh 0800h - 0FFFh Process data, read area

2000h - 25FFh 1000h - 12FFh Message data, write

2600h - 2FFFh 1300h - 17FFh Reserved

3000h - 35FFh 1800h - 1AFFh Message data, read

3600h - 37FFh 1B00h - 1BFFh Reserved

3800h - 38FFh 1C00h - 1C7Fh Process data, write

3900h - 39FFh 1C80h - 1CFFh Process data, read area

3A00h - 3AFFh 1D00h - 1D7Fh Reserved

3B00h - 3C06h 1D80h - 1E03h Message data, write

3C07h - 3CFFh 1E04h - 1E7Fh Reserved

3D00h - 3E06h 1E80h - 1F03h Message data, read

3E07h - 3FE7h 1F04h - 1FF3h Reserved

3FE8h - 3FEFh 1FF4h - 1FF7h Current network time

3FF0h - 3FF1h 1FF8h Module capability

3FF2h - 3FF3h 1FF9h

3FF4h - 3FF5h 1FFAh Application status

3FF6h - 3FF7h 1FFBh Anybus CompactCom

3FF8h - 3FF9h 1FFCh Buffer control register

3FFAh - 3FFBh 1FFDh Interrupt mask register

3FFCh - 3FFDh 1FFEh

3FFEh 1FFFh Control register

3FFFh

Area Bytes Access,

area

area

area

area

area

area

register

LED status register 2 R

register

module status register

Interrupt status

register

Status register 1 R

4096

4096 R

1536

2560

1536 R

512

256

256 R

256

263

249

263 R

481

8 R

2 R

2

2 R

2

2

2

1

seen from

host

R/W

R/W

-

-

R/W

-

R/W

-

-

R/W

R/W

R/W

R/W

R/W

Notes

This is the total size of the

area. The actual size

depends on the network.

For network specific

process area sizes, see

Network Comparison, p.

142.

Applicable to all protocols

Applicable to all protocols

Applicable to the event

driven protocol.

Applicable to the half

duplex protocol

If an application is to use “current network time”, the network time must first be sampled. This is

performed by writing to this register. The register will be updated with the actual value from the

network, which then can be read by the application.

C-programmers are reminded to declare the entire shared memory area as volatile.

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 32

Host Communication Layer

4.3 Communications Registers

4.3.1 Module Capability Register

The module capability register contains one of the values below, indicating module type. The

application should determine the module type by examining the low byte only. The high byte is

reserved for future use.

30 (176)

Value

0000h Active Anybus CompactCom 30 series module, supporting the half duplex protocol only

000Bh Active Anybus CompactCom 40 series module, supporting the event driven as well as the half

000Ch Active Anybus IP with parallel AXI bus

0101h

0202h

0303h

0404h (reserved)

0505h Passive Bluetooth

0606h - 0909h (reserved)

0A0Ah

0C0Ch - 0F0Fh (reserved)

All passive modules belong to the Anybus CompactCom 30-series. There are no passive modules in the

Anybus CompactCom 40-series.

4.3.2 LED Status Register

The first 8 bits of this register reflect the LED status, as represented by the value of the instance

attribute LED status (#13) in the Anybus Object. See Anybus Object (01h), p. 62 for more

information. The following for bits reflect status of the signals LED5A, LED5B, LED6A and LED6B.

Module Type

8 bit parallel and serial modes

duplex protocol

8 bit/16 bit parallel, shift register, SPI and serial modes

Passive RS232

Passive RS422

Passive USB

Passive RS485

If a bit is set to 1, the status of the corresponding LED is ON.

Bit

0 LED1A

1 LED1B

2 LED2A

3 LED2B

4 LED3A

5 LED3B

6 LED4A

7 LED4B

8 LED5A

9 LED5B

10 LED6A

11 LED6B

12–15

LED Signal

(none)

4.3.3 Application Status Register

The application status register is primarily used in SYNC applications. It is used in applications

where the network in question supports the ability to indicate critical process data errors to the

master. If this is supported, the Anybus CompactCom 40 module will accept and handle the

below listed status codes written by the application.

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 33

Host Communication Layer

This register is optional to use. For networks which do not support indications of critical process

data errors, the module will ignore this register.

The register contains an 8 bit value. When the register is accessed from the parallel interface, the

value is provided as a word aligned value with the upper 8 bits always set to 0. See Memory Map,

p. 29.

31 (176)

Value

00h

01h Not yet synchronized Not ready for transition to state PROCESS_ACTIVE

02h Sync configuration error A problem with the current attribute values in the Sync object

03h Read process data configuration

04h Write process data configuration

05h Synchronization loss The application has lost synchronization lock

06h Excessive data loss The application has detected a significant loss of process data from

07h

Error

No error

error

error

Output error

Description

Ready for transition to state PROCESS_ACTIVE

(Default)

prevents the transition to state PROCESS_ACTIVE

A problem with the current read process data mapping prevents

the transition to state PROCESS_ACTIVE

A problem with the current write process data mapping prevents

the transition to state PROCESS_ACTIVE

If the Anybus CompactCom is in the state PROCESS_ACTIVE, it will

change to a lower state

the network

If the Anybus CompactCom is in the state PROCESS_ACTIVE, it will

change to a lower state

Application malfunction

If the Anybus CompactCom is in the state PROCESS_ACTIVE, it will

change to a lower state

The Anybus state machine is described in The Anybus State Machine, p. 43

4.3.4 Anybus CompactCom Module Status Register

This register contains the current Anybus CompactCom module state, and a supervised bit

indicated by the Anybus CompactCom module. The Anybus state machine is described in The

Anybus State Machine, p. 43

Bit Name

0 - 2

3

4 - 15

S[0..2] The current Anybus CompactCom module state

Supervised bit 1 = Supervised by another network device

-

4.3.5 Buffer Control Register

This register is used by the application to control the event driven communication with the

Anybus CompactCom module.

By writing to this register, it is possible to trigger appropriate events. Write “1” to trigger bits,

and “0” to leave bits unaffected.

Reading this register gives the current status of the different memory areas.

For more information about how to implement and use bits 0–3, seeCommunication Basics, p. 35

Description

0 = Not supervised by another network device

See Supervised Bit (SUP), p. 34.

Reserved (0)

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 34

Host Communication Layer

32 (176)

Bit

0 WRPD

1 RDPD

2 WRMSG

3 RDMSG

4 ANBR

5 APPR

6 APPRCLR

7 - 15

Name

(Write Process Data)

(Read Process Data)

(Write Message Data)

(Read Message Data)

(Anybus Ready)

(Application Ready)

(Application Ready

Clear)

-

Description

The application shall write “1” to this bit when new data has been written.

When the module has updated the read process data, this bit will be read as

“1”.

The application shall write “1” to this bit to request the latest read process

data. By doing this the bit is cleared.

Note: “updated” data does not necessarily mean “changed” data.

This bit is read as “1” when the write message area is occupied.

This bit is cleared by the module when the write message area is available for

a new message.

When the application sends a write message to the module, it shall write “1”

to this bit.

The application is only allowed to write to the write message area while this

bit is “0”.

Note: it is only allowed to write command messages when the ANBR bit is also

set.

This bit will be read as “1” when the module has posted a new read message.

The application writes “1” to this bit to acknowledge the message. By doing

this the bit is cleared.

The application is only allowed to read the read message area while this bit is

“1”.

This bit is set to “1” when the module is ready to receive a new command

message.

The application is only allowed to send command messages while this bit is “1”.

This bit can only change from “1” to “0” while WRMSG is “1”.

It can change from “0” to “1” at any time.

The application writes ‘1’ to this bit when it is ready to receive a new

command message.

The module will only send command messages while this bit is “1”.

Use APPRCLR to set this bit to “0”.

The application can write “1” to this bit to clear the APPR bit. This is only

allowed when RDMSG is “1”.

Reserved

4.3.6 Interrupt Mask Register

This register makes it possible for the application to enable or disable individual interrupts,

according to the table below.

Bit

0 RDPDIEN

1 RDMSGIEN

2 WRMSGIEN

3 ANBRIEN

4 STATUSIEN

5

6 SYNCIEN

7 - 15

Name

-

-

4.3.7 Interrupt Status Register

The module indicates the pending interrupts in this register, according to the table below.

Description

Set this bit to “1” to enable interrupt for when the RDPD bit in the buffer

control register transitions from “0” to “1”.

Set this bit to “1” to enable interrupt for when the RDMSG bit in the buffer

control register transitions from “0” to “1”.

Set this bit to “1” to enable interrupt for when the WRMSG bit in the buffer

control register transitions from “1” to “0”.

Set this bit to “1” to enable interrupt for when the ANBR bit in the buffer

control register transitions from “0” to “1”.

Set this bit to “1” to enable interrupt for an Anybus CompactCom module

status register change.

Reserved

Set this bit to “1” to enable interrupt for a SYNC event.

Reserved

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 35

Host Communication Layer

33 (176)

Bit Name

0 RDPDI

1 RDMSGI

2 WRMSGI

3 ANBRI

4 STATUSI

5 PWRI

6 SYNCI

7 - 15

-

Description

This bit is set to “1” when RDPD in the buffer control register transitions from

“0” to “1”.

The application shall write “1” to this bit to set it to “0”.

This bit is set to “1” when RDMSG in the buffer control register transitions

from “0” to “1”.

The application shall write “1” to this bit to set it to “0”.

This bit is set to “1” when WRMSG in the buffer control register transitions

from “1” to “0”.

The application shall write “1” to this bit to set it to “0”.

This bit is set to “1” when ANBR in the buffer control register transitions from

“0” to “1”.

The application shall write “1” to this bit to set it to “0”.

This bit is set to “1” on an Anybus CompactCom module status register change.

The application shall write “1” to this bit to set it to “0”.

This bit is set to “1” when the module is ready to start communication after a

power-up or a hardware reset.

The application shall write “1” to this bit to set it to “0”.

This bit is set to “1” on each SYNC event.

The application shall write “1” to this bit to set it to “0”.

Reserved

4.3.8 Control Register (Read/Write)

Only used for the half duplex (ping/pong) protocol.

This register controls the communication towards the Anybus CompactCom.

b7 (MSB)

CTRL_T CTRL_M CTRL_R CTRL_AUX

Bit

CTRL_T

CTRL_M

CTRL_R

CTRL_AUX

-

b6 b5 b4 b3 b2 b1

Description

The host application shall toggle this bit when sending a new telegram. CTRL_T must be set to “1” in the

initial telegram sent by the application to the module.

If set, the message subfield in the current telegram is valid.

If set, the host application is ready to receive a new command.

(ignored)

(reserved, set to zero)

4.3.9 Status Register (Read Only)

Only used for the half duplex (ping/pong) protocol.

This register holds the current status of the Anybus CompactCom.

b0 (LSB)

- - - -

b7 (MSB)

STAT_T STAT_M STAT_R STAT_AUX SUP S2 S1 S0

Bit

STAT_T

STAT_M

®

Anybus

CompactCom™40 Software Design Guide

b6 b5 b4 b3 b2 b1

Description

When the module issues new telegrams, this bit will be set to the same value as CTRL_T in the last

telegram received from the host application.

If set, the message subfield in the current telegram is valid.

b0 (LSB)

HMSI-216-125 4.0 en-US

Page 36

Host Communication Layer

34 (176)

Bit

STAT_R

STAT_AUX

SUP

S[0... 2] These bits indicates the current state of the module (see also The Anybus State Machine, p. 43).

Description

If set, the Anybus module is ready to process incoming commands.

See Auxiliary Bit (STAT_AUX, CTRL_AUX), p. 34.

Value:

0:

1:

See Supervised Bit (SUP), p. 34.

S2 S1 S0

0 0 0 SETUP

0 0 1 NW_INIT

0 1 0 WAIT_PROCESS

0 1 1 IDLE

1 0 0 PROCESS_ACTIVE

1 0 1 ERROR

1 1 0

1 1 1 EXCEPTION

Meaning:

Module is not supervised.

Module is supervised by another network device.

Anybus State

(reserved)

The Status Register shall be regarded as cleared at start-up. The first telegram issued by the host

application must therefore not contain a valid message subfield since STAT_R is effectively

cleared (0).

4.3.10 Supervised Bit (SUP)

While the Anybus State Machine reflects the state of the cyclic data exchange, the SUP-bit

indicates the overall status of the network communication, including acyclic communication. For

example, on CIP, this bit indicates that the master has a connection towards the module. This

connection may be an I/O connection, or an acyclic (explicit) connection. In case of the latter, the

communication will be “silent” for extended periods of time, and the state machine will indicate

that the network is Idle. The SUP-bit will however indicate that there still is a connection towards

the module.

Exactly how this functionality should be handled, the offered level of security, and how to

correctly activate it is network specific and often depends on external circumstances, e.g.

configuration of the network as well as other network devices. Whether use of the SUP-bit is

appropriate must therefore be decided for each specific application and network.

4.3.11 Auxiliary Bit (STAT_AUX, CTRL_AUX)

The Anybus CompactCom 40 module ignores the CTRL_AUX bit in the Control Register..

The module will set the STAT_AUX bit in the Status Register if new process data has been

received from the network since the last telegram.

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 37

Parallel Host Communication 35 (176)

5 Parallel Host Communication

5.1 Flow Control

The following only applies to the event driven modes (full duplex modes). For information about

the half duplex mode, see Serial Host Communication (UART), p. 42.

Data can be read or written from either the host or the Anybus CompactCom module, at any

point and in any order. Communication can be fully controlled by writing to and reading from the

buffer control register, or it can be achieved by enabling interrupts for appropriate events using

the interrupt mask register. If enabled, an interrupt is generated each time the module has made

new data available.

See Buffer Control Register, p. 31 and Interrupt Mask Register, p. 32.

5.1.1 Communication Basics

When using the parallel host interface, data is exchanged via the shared memory area. For more

information, see Memory Map, p. 29.

Data Transmission

To write process data :

1. Write data to the write process data memory area. The area currently mapped by ADIs for

process data must be refilled with new data.

2. Finalize the write process by writing “1” to bit 0 (WRPD) in the buffer control register.

To write message data:

1. Read bit 2 (WRMSG) in the buffer control register.

– If it is “0”, the area is available for new message data.

– If it is “1”, the area is occupied and is not yet available to receive new message data.

2. Write data to the write message data memory area.

3. Finalize the write process by writing “1” to bit 2 (WRMSG) in the buffer control register.

Data Reception

For the latest read process data:

1. Write “1” to bit 1 (RDPD) in the buffer control register, to gain access to the process data.

2. Read the latest read process data from the read process data area.

For the latest message data:

1. Read bit 3 (RDMSG) in the buffer control register.

– If it is “0”, no new message data has been posted.

– If it is “1”, there is a new message in the read message data area.

2. Read the latest message data from the read message data area.

3. Write “1” to bit 3 (RDMSG) in the buffer control register.

5.2 Anybus Event Driven Watchdog

It is possible for the host to establish whether or not the Anybus CompactCom module is working

properly by periodically measuring the message response time. If this time exceeds a specified

Anybus®CompactCom™40 Software Design Guide

HMSI-216-125 4.0 en-US

Page 38

Parallel Host Communication 36 (176)

value, the module can be assumed to be malfunctioning. The host can then enter an application

specific safe state, reset the module, or take similar actions.

It is strongly recommended to have at least a rudimentary watchdog mechanism, to be able to

restart the module if needed.

5.3 Application Event Driven Watchdog

If desired by the application, an application watchdog timeout can be enabled within the Anybus