Page 1

+$/067$'&+,&$*2.$5/658+(72.<2%(,-,1*0,/$1208/+286(&29(175<381(&23(1+$*(1

HMS Industrial Networks

Mailing address: Box 4126, 300 04 Halmstad, Sweden

Visiting address: Stationsgatan 37, Halmstad, Sweden

Connecting Devices

TM

E-mail: info@hms-networks.com

Web: www.anybus.com

User Manual

Anybus® Communicator™

for EtherNet/IP™ / Modbus-TCP

Doc. Id. HMSI-27-314

Rev. 3.10

Page 2

Important User Information

This document contains a general introduction as well as a description of the technical features provided by the

Anybus Communicator, including the PC-based configuration software.

The reader of this document is expected to be familiar with PLC and software design, as well as communication

systems in general. The reader is also expected to be familiar with the Microsoft® Windows® operating system.

Liability

Every care has been taken in the preparation of this manual. Please inform HMS Industrial Networks AB of any

inaccuracies or omissions. The data and illustrations found in this document are not binding. We, HMS Industrial

Networks AB, reserve the right to modify our products in line with our policy of continuous product development.

The information in this document is subject to change without notice and should not be considered as a commitment by HMS Industrial Networks AB. HMS Industrial Networks AB assumes no responsibility for any errors that

may appear in this document.

There are many applications of this product. Those responsible for the use of this device must ensure that all the

necessary steps have been taken to verify that the applications meet all performance and safety requirements including any applicable laws, regulations, codes, and standards.

HMS Industrial Networks AB will under no circumstances assume liability or responsibility for any problems that

may arise as a result from the use of undocumented features, timing, or functional side effects found outside the

documented scope of this product. The effects caused by any direct or indirect use of such aspects of the product

are undefined, and may include e.g. compatibility issues and stability issues.

The examples and illustrations in this document are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular implementation, HMS Industrial Networks AB cannot

assume responsibility for actual use based on these examples and illustrations.

Intellectual Property Rights

HMS Industrial Networks AB has intellectual property rights relating to technology embodied in the product described in this document. These intellectual property rights may include patents and pending patent applications

in the US and other countries.

Trademark Acknowledgements

Anybus® is a registered trademark of HMS Industrial Networks AB. Microsoft® and Windows® are registered

trademarks of Microsoft, Inc. EtherNet/IP™ and ODVA™ are trademarks of ODVA, Inc. All other trademarks are

the property of their respective holders.

Warning: This is a class A product. in a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

ESD Note: This product contains ESD (Electrostatic Discharge) sensitive parts that may be damaged if ESD

control procedures are not followed. Static control precautions are required when handling the

product. Failure to observe this may cause damage to the product.

Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Copyright© HMS Industrial Networks AB

Doc: HMSI-27-314

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 3

Table of Contents

Preface About This Document

Related Documents ..................................................................................................................... 9

Document History ...................................................................................................................... 9

Conventions & Terminology ................................................................................................... 10

Glossary............................................................................................................................ 10

Sales and Support ...................................................................................................................... 10

Chapter 1 About the Anybus Communicator for

EtherNet/IP

External View............................................................................................................................. 12

Status LEDs ............................................................................................................................... 13

Configuration Switches ............................................................................................................ 14

Table of Contents

Hardware Installation................................................................................................................ 15

Software Installation .................................................................................................................16

Anybus Configuration Manager ........................................................................................ 16

Chapter 2 Basic Operation

General........................................................................................................................................ 17

Data Exchange Model .............................................................................................................. 18

Memory Map.................................................................................................................... 18

Data Exchange Example................................................................................................. 19

Sub-network Protocol............................................................................................................... 20

Protocol Modes.................................................................................................................. 20

Protocol Building Blocks.................................................................................................... 20

Master Mode..................................................................................................................... 21

Generic Data Mode .......................................................................................................... 22

DF1 Master Mode ........................................................................................................... 22

EtherNet/IP............................................................................................................................... 23

General............................................................................................................................. 23

Data Types....................................................................................................................... 23

Memory Layout ................................................................................................................ 24

Modbus-TCP.............................................................................................................................. 25

General............................................................................................................................. 25

Addressing Modes ............................................................................................................. 25

Supported Exception Codes ............................................................................................... 25

Modbus Addressing Mode................................................................................................. 26

Anybus Addressing Mode ................................................................................................. 27

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 4

Chapter 3 File System

General........................................................................................................................................ 28

File System Overview ............................................................................................................... 29

System Files................................................................................................................................ 29

Chapter 4 FTP Server

General........................................................................................................................................ 30

FTP Connection Example (Windows Explorer).................................................................. 31

Chapter 5 Telnet Server

General........................................................................................................................................ 32

General Commands .................................................................................................................. 33

Diagnostic Commands .............................................................................................................34

File System Operations............................................................................................................. 34

Chapter 6 Basic Network Configuration

IV

General Information ................................................................................................................. 37

Ethernet Configuration File (‘ethcfg.cfg’) ............................................................................. 38

General............................................................................................................................. 38

IP Access Control ..................................................................................................................... 39

On/Offline Configuration....................................................................................................... 40

Anybus IPconfig (HICP) ......................................................................................................... 41

Chapter 7 Web Server

General........................................................................................................................................ 42

Authorization .............................................................................................................................43

Content Types............................................................................................................................ 44

Chapter 8 Server Side Include (SSI)

Functions .................................................................................................................................... 46

Changing SSI output................................................................................................................. 55

SSI Output String File..................................................................................................... 55

Temporary SSI Output change .......................................................................................... 56

Chapter 9 E-mail Client

General........................................................................................................................................ 57

E-mail Definitions..................................................................................................................... 58

Chapter 10 Navigating ACM

Main Window............................................................................................................................. 59

Drop-down Menus ............................................................................................................ 60

Toolbar Icons .................................................................................................................... 63

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 5

Chapter 11 Basic Settings

Fieldbus Settings........................................................................................................................ 64

Communicator Parameters ...................................................................................................... 65

Sub-network Parameters ..........................................................................................................66

Chapter 12 Nodes

General........................................................................................................................................ 67

Adding & Managing Nodes ..................................................................................................... 67

Node Parameters ....................................................................................................................... 67

Master Mode and Generic Data Mode.............................................................................. 67

Chapter 13 Transactions

General........................................................................................................................................ 68

Adding & Managing Transactions .......................................................................................... 69

Transaction Parameters (Master Mode)................................................................................. 70

Parameters (Query & Broadcast)...................................................................................... 70

Parameters (Response)....................................................................................................... 71

Transaction Parameters (Generic Data Mode) ..................................................................... 72

Produce Transactions......................................................................................................... 72

Consume Transactions ...................................................................................................... 73

V

Transaction Editor .................................................................................................................... 74

Chapter 14 Frame Objects

General........................................................................................................................................ 75

Adding and Editing Frame Objects ....................................................................................... 75

Constant Objects (Byte, Word, Dword) ................................................................................ 76

Limit Objects (Byte, Word, Dword) ...................................................................................... 77

Data Object ................................................................................................................................ 78

Variable Data Object ................................................................................................................ 78

Checksum Object ...................................................................................................................... 80

Chapter 15 Commands

General........................................................................................................................................ 81

Adding & Managing Commands ............................................................................................ 81

Drop-down Menu ............................................................................................................ 82

Toolbar Icons .................................................................................................................... 82

The Command Editor ..............................................................................................................83

General............................................................................................................................. 83

Basic Navigation............................................................................................................... 83

Drop-down Menu ............................................................................................................ 84

Editing a Command ......................................................................................................... 84

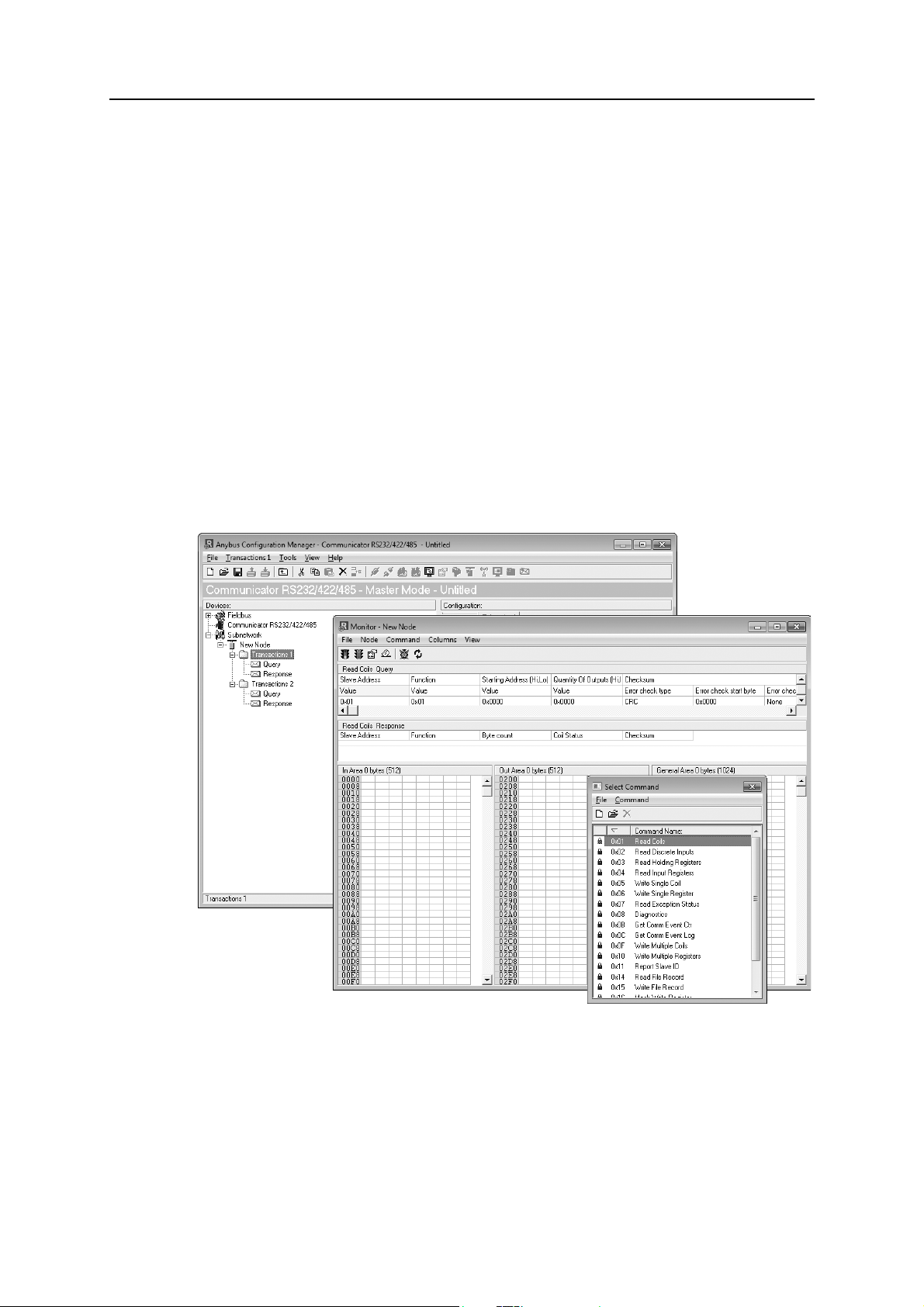

Example: Specifying a Modbus-RTU Command in Master Mode .................................... 85

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 6

Chapter 16 DF1 Protocol Mode

General........................................................................................................................................ 86

Communicator Parameters ...................................................................................................... 87

Sub-network Parameters ..........................................................................................................88

Node Parameters ....................................................................................................................... 89

Services........................................................................................................................................ 89

Available Services ............................................................................................................. 90

Integrity Check .......................................................................................................................... 91

Read Diagnostics ....................................................................................................................... 91

Read Data ................................................................................................................................... 92

Write Data .................................................................................................................................. 92

Chapter 17 Sub-network Monitor

General........................................................................................................................................ 93

Operation.................................................................................................................................... 93

VI

Chapter 18 Node Monitor

General........................................................................................................................................ 94

Navigating the Node Monitor ................................................................................................. 95

Drop-down Menu ............................................................................................................ 96

Toolbar Icons .................................................................................................................... 97

Chapter 19 Data Logger

General........................................................................................................................................ 98

Operation.................................................................................................................................... 98

Configuration ............................................................................................................................. 99

Chapter 20 Configuration Wizards

General...................................................................................................................................... 100

Selecting a Wizard Profile ...................................................................................................... 100

Wizard - Modbus RTU Master ............................................................................................. 101

Chapter 21 Control and Status Registers

General...................................................................................................................................... 102

Handshaking Procedure .................................................................................................. 102

Data Consistency ............................................................................................................ 103

Status Register Contents (Gateway to Control System) .................................................... 104

General Information........................................................................................................ 104

Status Codes in Master Mode and DF1 Master Mode.................................................... 104

Status Code in Generic Data Mode................................................................................. 105

Control Register Contents (Control System to Gateway)................................................. 106

General Information........................................................................................................ 106

Control Codes in Master Mode and DF1 Master Mode.................................................. 106

Control Codes in Generic Data Mode ............................................................................. 106

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 7

Chapter 22 CIP Object Implementation

General...................................................................................................................................... 107

Identity Object, Class 01h...................................................................................................... 108

General Information........................................................................................................ 108

Class Attributes.............................................................................................................. 108

Instance Attributes.......................................................................................................... 108

Message Router, Class 02h..................................................................................................... 109

General Information........................................................................................................ 109

Class Attributes.............................................................................................................. 109

Instance Attributes.......................................................................................................... 109

Assembly Object, Class 04h .................................................................................................. 110

General Information........................................................................................................ 110

Class Attributes.............................................................................................................. 110

Instance 64h (100) Attributes ........................................................................................ 110

Instance 96h (150) Attributes ........................................................................................ 110

Instance C6h (198) Attributes (Heartbeat Input-Only) .................................................. 111

Instance C7h (199) Attributes (Heartbeat, Listen-Only)................................................ 111

Diagnostic Object, Class AAh............................................................................................... 111

General Information........................................................................................................ 111

Class Attributes.............................................................................................................. 111

Instance Attributes, Instance 01h.................................................................................... 111

Parameter Data Input Mapping Object, Class B0h ........................................................... 112

General Information........................................................................................................ 112

Class Attributes.............................................................................................................. 112

Instance Attributes, Instance 01h.................................................................................... 112

Parameter Data Output Mapping Object, Class B1h ........................................................ 113

General Information........................................................................................................ 113

Class Attributes.............................................................................................................. 113

Instance Attributes, Instance 01h.................................................................................... 113

Port Object, Class F4h ........................................................................................................... 114

General Information........................................................................................................ 114

Class Attributes.............................................................................................................. 114

Instance Attributes, Instance 02h.................................................................................... 114

VII

TCP/IP Interface Object, Class F5h ................................................................................... 115

General Information........................................................................................................ 115

Class Attributes.............................................................................................................. 115

Instance Attributes.......................................................................................................... 115

Ethernet Link Object, Class F6h .......................................................................................... 116

General Information........................................................................................................ 116

Class Attributes.............................................................................................................. 116

Instance Attributes.......................................................................................................... 117

Chapter 23 Advanced Fieldbus Configuration

General...................................................................................................................................... 118

Mailbox Editor......................................................................................................................... 118

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 8

Appendix A Parameter Data Initialization (Explicit Data)

General...................................................................................................................................... 119

Add a Mailbox Message.......................................................................................................... 119

Mapping Input Parameter Data to EtherNet/IP ............................................................... 120

Mapping Output Parameter Data to EtherNet/IP............................................................ 122

Appendix B Connector Pin Assignments

Ethernet Connector ................................................................................................................ 124

Power Connector .................................................................................................................... 124

PC Connector .......................................................................................................................... 125

Sub-network Interface ............................................................................................................ 126

General Information........................................................................................................ 126

Bias Resistors (RS485 Only).......................................................................................... 126

Termination (RS485 & RS422 Only) .......................................................................... 126

Connector Pinout (DB9F) .............................................................................................. 126

Typical Connection (RS485)........................................................................................... 127

Typical Connection (RS422 & 4-Wire RS485) ............................................................ 127

Typical Connection (RS232)........................................................................................... 127

VIII

Appendix C Technical Specification

Mechanical Properties............................................................................................................. 128

Electrical Characteristics ........................................................................................................ 128

Environmental Characteristics .............................................................................................. 128

Regulatory Compliance .......................................................................................................... 129

Appendix D Troubleshooting

Appendix E ASCII Table

Appendix F Copyright Notices

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 9

P. About This Document

For more information, documentation etc., please visit the HMS website www.anybus.com.

P.1 Related Documents

Document name Author

ABC-EIP Installation Leaflet HMS

DF1 Protocol and Command Set - Reference Manual, 1770-6.5.16, October 1996 Allen-Bradley

Open Modbus-TCP Specification, Release 1.0 Schneider Electric

RFC 821 Network Working Group

RFC 1918 Network Working Group

ENIP Specifications ODVA

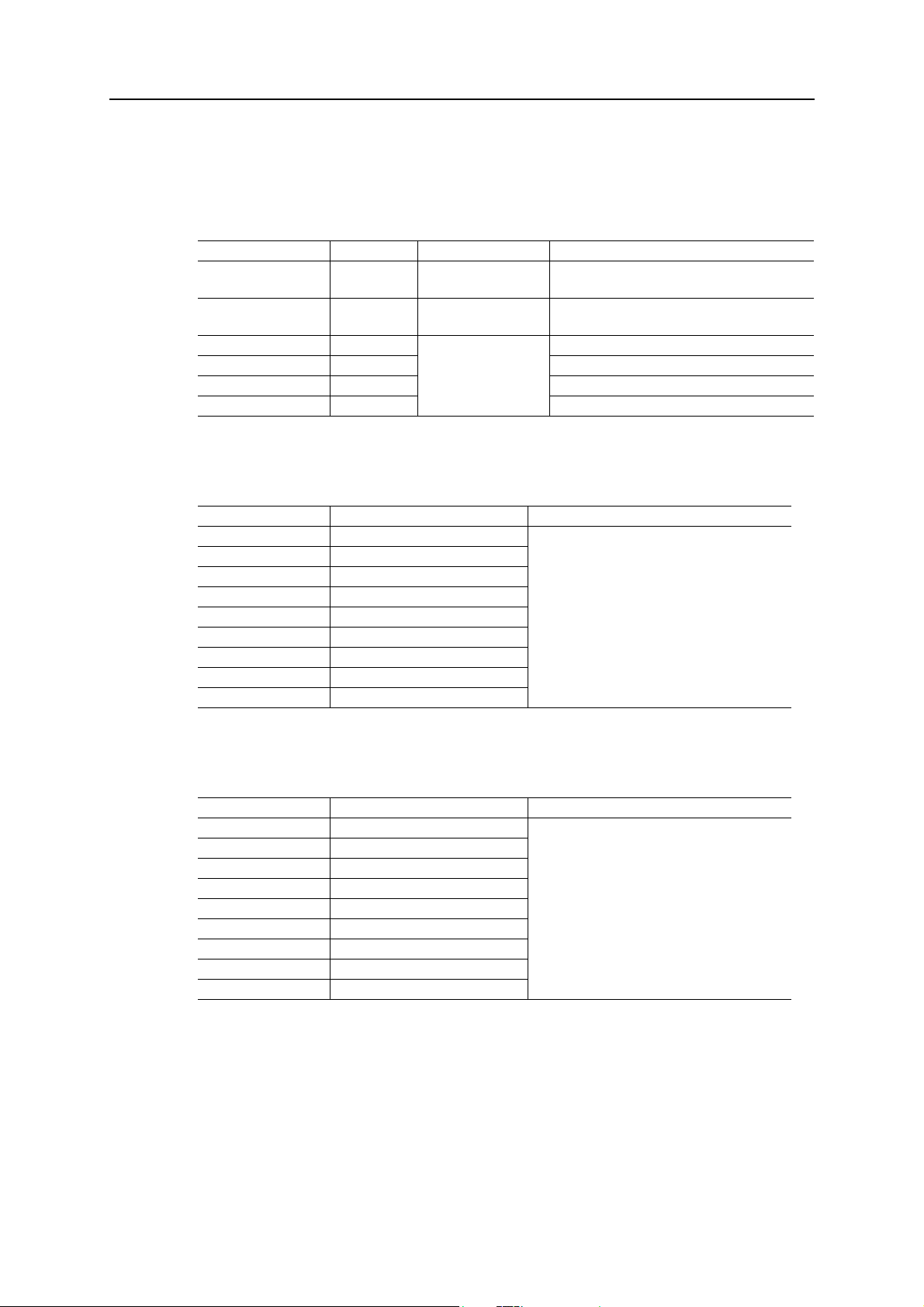

P.2 Document History

Preface

Summary of Recent Changes (3.03... 3.10)

Change Page(s)

Screenshots and descriptions of ABC Tool updated for Anybus Configuration Manager Multiple

Changed “ABC” to “Communicator RS232/422/485” Multiple

Amended description of “Update time” parameter 71, 72

Added description for Consume/Response to “Object Delimiter” parameter 79

Changed “Maximum Data Length” limit 79

Removed obsolete “Start Bits” parameter 88

Removed obsolete “ABCC ExtLink Wizard” entry 100

Replaced “Sales and Support” info with link to website 8

Added parameters to checksum object description 80

Minor text edits, typo corrections Multiple

Updated screenshots in examples 120, 122

Revision List

Revision Date Author Chapter Description

2.00 2006-03-27 PeP All 1st release

2.01 2006-12-22 PeP All Misc. minor corrections

2.02 2008-02-08 PeP 2, 8, A Minor update

2.03 2008-11-03 HeS 1 Minor update

2.04 2009-04-24 KeL All Misc. minor corrections and updates

3.00 2011-02-01 KaD All Misc. corrections, new template and DF1 functionality

3.01 2011-09-30 KaD All Misc corrections and updates, new Anybus Configuration

Manager name

3.02 2011-11-15 KaD P, 2, 3, 6, 8 Minor corrections and updates

3.03 2012-06-08 KaD P, 8, 22 Minor updates

3.10 March 2015 ThN All Misc. corrections and updates, new Doc. ID.

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 10

P.3 Conventions & Terminology

The following conventions are used throughout this document:

• Numbered lists provide sequential steps

• Bulleted lists provide information, not procedural steps

• The term ‘user’ refers to the person or persons responsible for installing the Anybus Communicator in a network.

• The term ‘ABC’ refers to the Anybus Communicator.

• Hexadecimal values are written in the format 0xNNNN, where NNNN is the hexadecimal value.

• Decimal values are represented as NNNN where NNNN is the decimal value

• As in all communication systems, the terms “input” and “output” can be ambiguous, because

their meaning depend on which end of the link is being referenced. The convention in this document is that “input” and “output” are always being referenced to the master/scanner end of the

link.

P.3.1 Glossary

Term Meaning

ABC Anybus Communicator

ACM Anybus Configuration Manager

EIP EtherNet/IP

Broadcaster A protocol specific node in the sub-network scan that hold transactions destined to all nodes

Command A protocol specific transaction.

Configuration List of configured nodes with transactions on the sub-network

Fieldbus The network to which the communicator is connected.

Frame Higher level series of bytes forming a complete telegram on the sub-network

Monitor A tool for debugging the Anybus Communicator and the network connections

Node A device in the scan-list that defines the communication with a slave on the sub-network

Scan list List of configured slaves with transactions on the sub-network

sub-network

Transaction

Fieldbus Control System Fieldbus master

Higher Level Network In this case, Ethernet (including EtherNet/IP and Modbus-TCP)

Network

Fieldbus

The network that logically is located on a subsidiary level with respect to the fieldbus and to

which the Anybus Communicator acts as a gateway

A generic building block that is used in the sub-network scan-list and defines the data that is

sent out the sub-network

About This Document 10

P.4 Sales and Support

For general contact information and support, please refer to the contact and support pages at

www.anybus.com

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 11

1. About the Anybus Communicator for

PC configuration

and monitoring

Serial communication devices

INVERTER

HMI

Multi-drop up to 31 nodes

Multi-Node Serial Sub NetworkSingle-Node Serial Sub Network

PC configuration

and monitoring

EtherNet/IP Scanner

(e.g a PLC)

EtherNet/IP Scanner

(e.g a PLC)

Serial communication

device

INVERTER

HMI

(Ethernet)

(Ethernet)

PC / web / SCADA

C/ eb/SC

PC / web / SCADA

C/ eb/SC

EtherNet/IP

The Anybus Communicator for EtherNet/IP acts as a gateway between virtually any serial application

protocol and an EtherNet/IP-based network. Integration of industrial devices is enabled with no loss

of functionality, control and reliability, both when retro-fitting to existing equipment as well as when

setting up new installations.

Chapter 1

Sub-network

The Anybus Communicator can address up to 31 nodes, and supports the following physical standards:

•RS-232

•RS-422

•RS-485

Ethernet Interface

Ethernet connectivity is provided through the patented Anybus technology; a proven industrial communication solution used all over the world by leading manufacturers of industrial automation products.

• EtherNet/IP group 2 and 3 server

• Modbus-TCP slave functionality

• Server Side Include (SSI) functionality

• Web server and E-mail client capabilities

• FTP & Telnet servers

• 10/100 Mbit/s, twisted pair

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 12

About the Anybus Communicator for EtherNet/IP 12

G

A

B

C

D

E

F

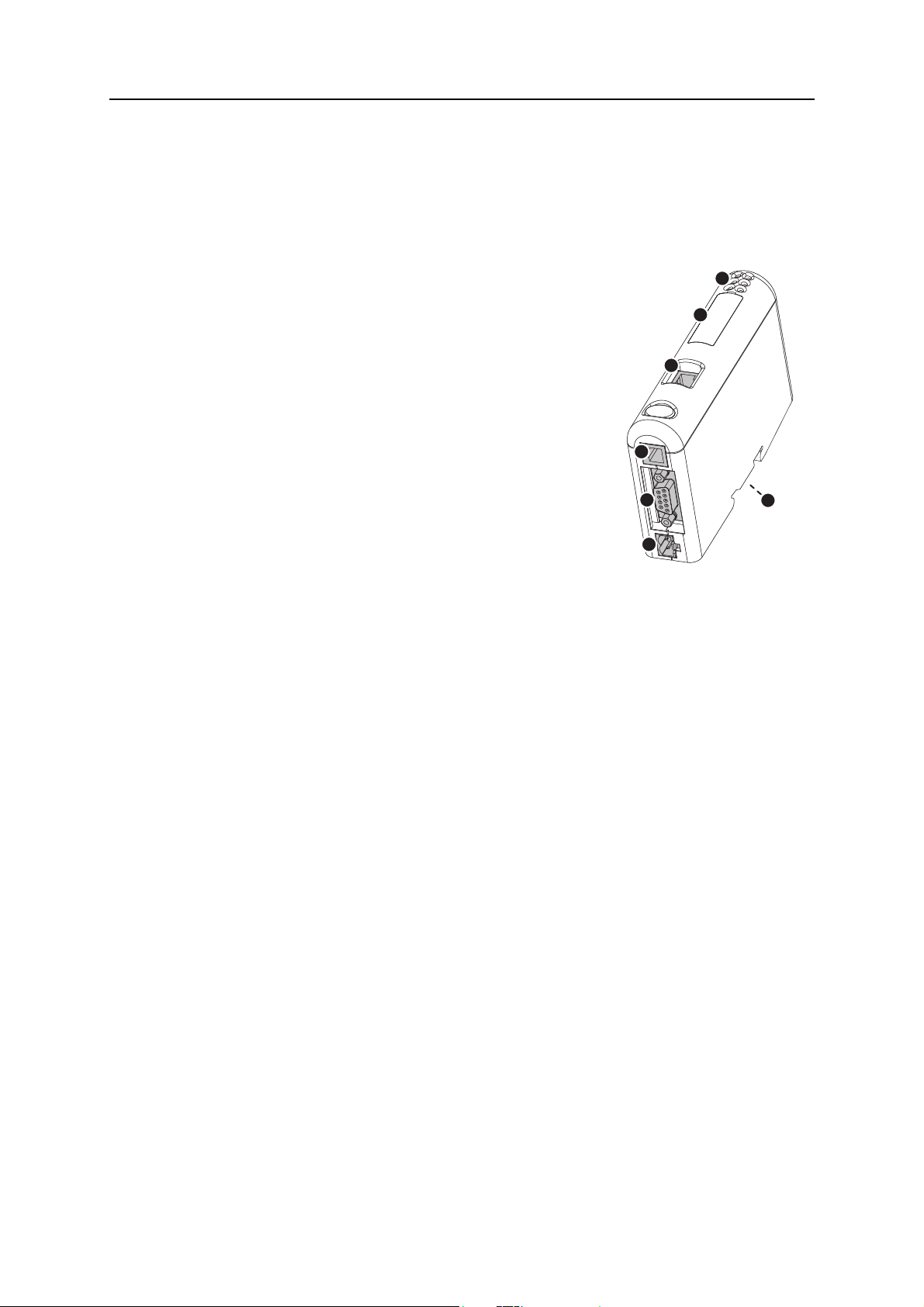

1.1 External View

For wiring and pin assignments, see “Connector Pin Assignments” on page 124.

A: Ethernet Connectors

These connectors are used to connect the Anybus Communicator to the network.

See also...

- “Ethernet Connector” on page 124

B: Configuration Switches

See also...

- “Configuration Switches” on page 14

C: Status LEDs

See also...

- “Status LEDs” on page 13

D: PC-connector

This connector is used to connect the gateway to a PC for

configuration and monitoring purposes.

See also...

- “PC Connector” on page 125

E: Sub-network Connector

This connector is used to connect the gateway to the serial sub-network.

See also...

- “Sub-network Interface” on page 126

F: Power Connector

This connector is used to apply power to the gateway.

See also...

- “Power Connector” on page 124

G: DIN-rail Connector

The DIN-rail mechanism connects the gateway to PE (Protective Earth).

See also...

- “Configuration Switches” on page 14

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 13

1.2 Status LEDs

1

3

5

2

4

6

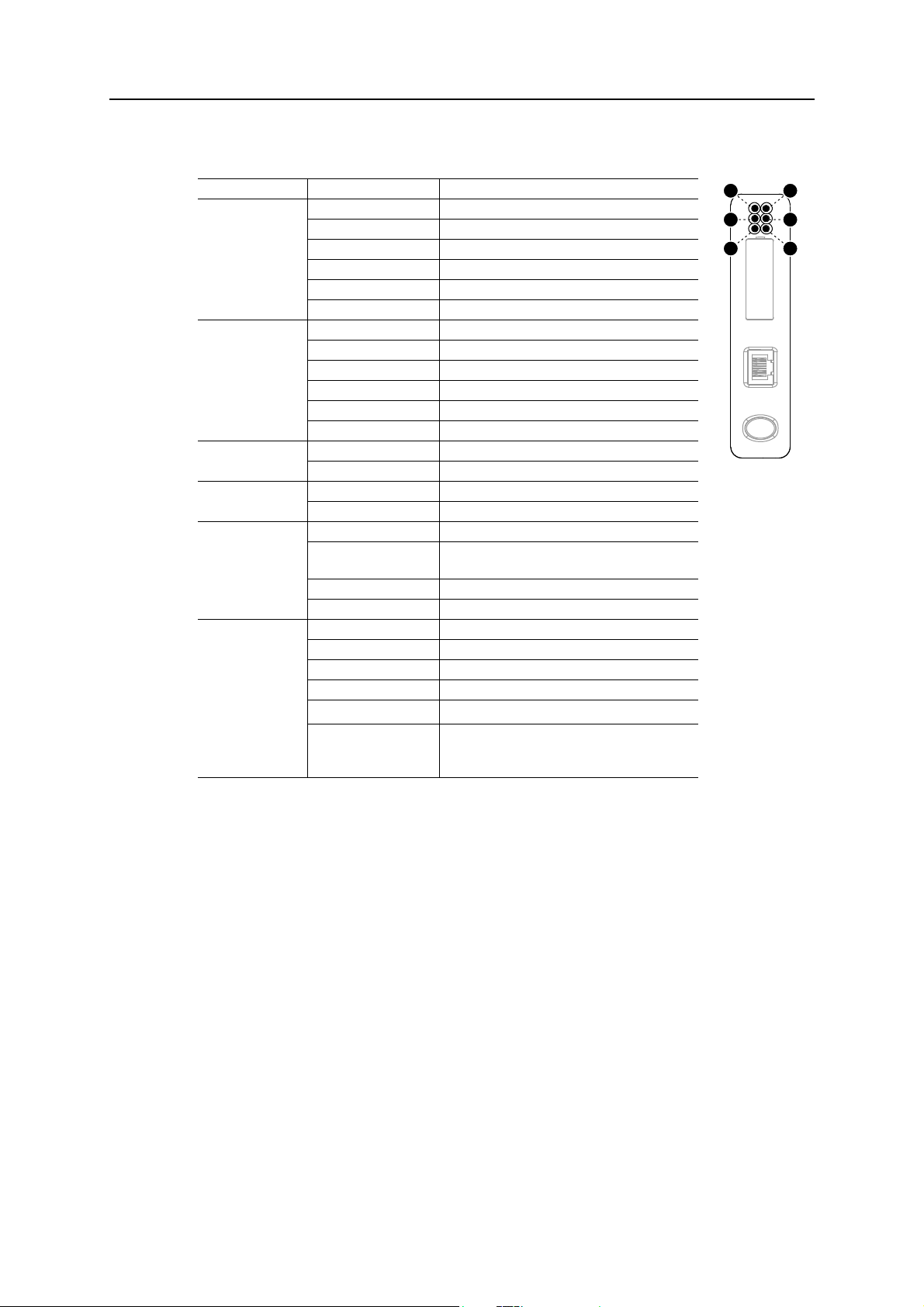

# State Status

1 - Module Status

(EtherNet/IP only)

2 - Network Status

(EtherNet/IP only)

3 - Link Off No link (or no power)

4 - Activity Off No ethernet activity (or no power)

5 - Subnet Status

6 - Device Status Off (no power)

a. This LED shows green when all transactions have been active at least once. This includes

any transactions using “change of state” or “change of state on trigger”. If a timeout occurs

on a transaction, this LED will show red.

b. The gateway is in bootloader mode, and firmware must be restored in order for it to work

properly. Start up the Anybus Configuration Manager and connect to the Anybus Communicator. Select Tools/Options/Module. Click Factory Restore to restore firmware. See

“Tools” on page 61.

Off No power

Green Controlled by a scanner in run state

Green, flashing Not configured, or scanner in idle state

Red Major fault (unrecoverable)

Red, flashing Minor fault (recoverable)

Alternating Red/Green Self-test

Off No IP address (or no power)

Green Online, EtherNet/IP connection(s) established

Green, flashing Online, no EtherNet/IP connections established

Red Duplicate IP address detected, fatal error

Red, flashing One or more connections timed out

Alternating Red/Green Self-test

Green Connected to an ethernet network

Green Receiving or transmitting ethernet packet

a

Off (no power)

Green, flashing Running correctly, but one or more transaction

Green Running

Red Transaction error/timeout or subnet stopped

Alternating Red/Green Invalid or missing configuration

Green Initializing

Green, flashing Running

Red

Red, flashing If the Device Status LED is flashing in a sequence

About the Anybus Communicator for EtherNet/IP 13

error(s) have occurred

Bootloader mode

b

starting with one or more red flashes, please note

the sequence pattern and contact HMS support.

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 14

About the Anybus Communicator for EtherNet/IP 14

1.3 Configuration Switches

If set to a nonzero value, the configuration switches forces the Anybus Communicator to use an IP address in the range 192.168.0.1 - 192.168.0.255.

If set to zero, these settings are specified by the system file ‘ethcfg.cfg’, or by settings

in Anybus Configuration Manager.

Note that the switches are read once during startup; any changes require a reset in

order to have effect.

See also...

• “Basic Network Configuration” on page 37

• “Basic Settings” on page 64

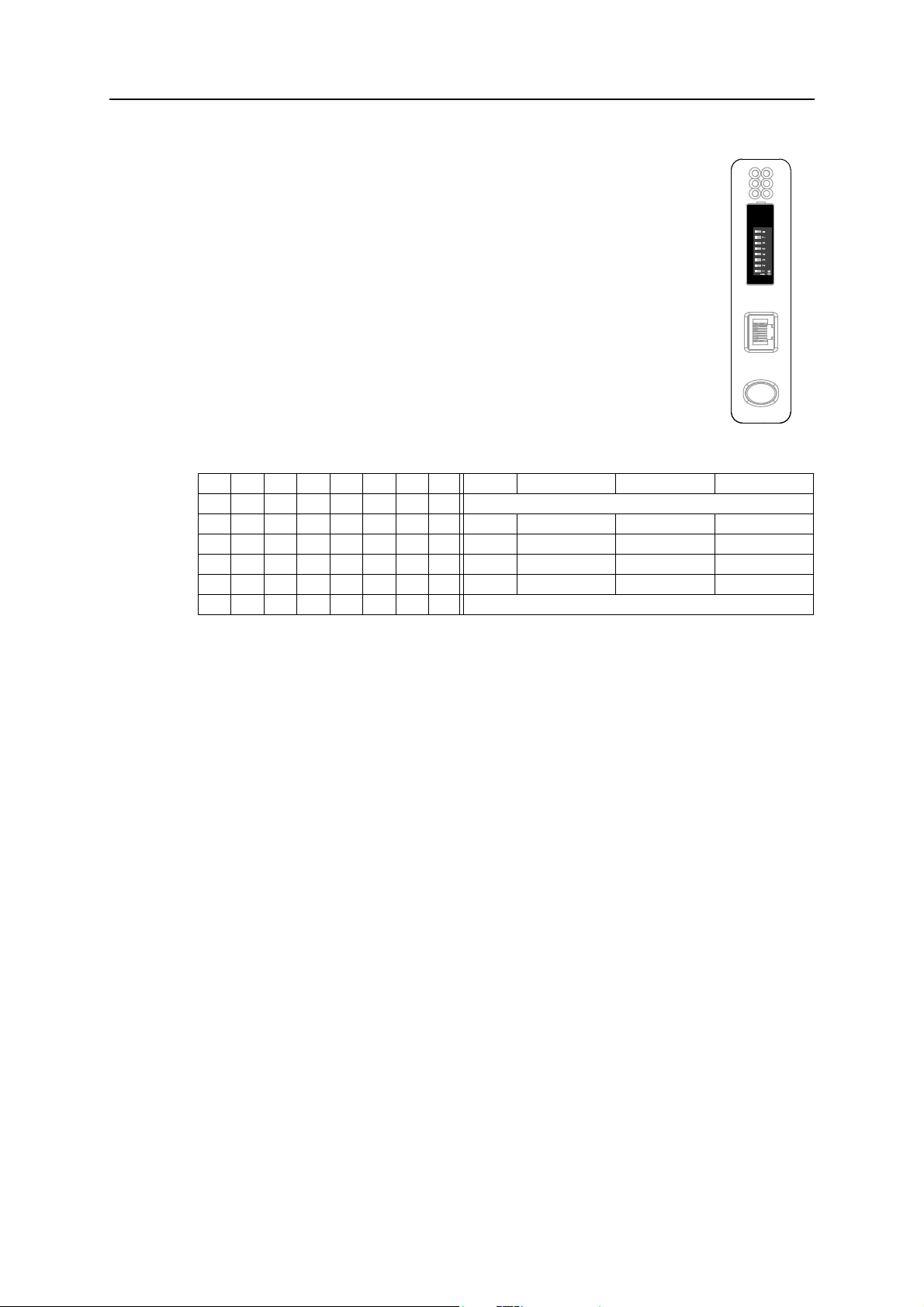

SW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8 DHCP Subnet Gateway IP

OFF OFF OFF OFF OFF OFF OFF OFF (settings determined by ‘ethcfg.cfg’)

OFF OFF OFF OFF OFF OFF OFF ON OFF 255.255.255.0 192.168.0.255 192.168.0.1

OFF OFF OFF OFF OFF OFF ON OFF OFF 255.255.255.0 192.168.0.255 192.168.0.2

... ... ... ... ... ... ... ... ... ... ... ...

ON ON ON ON ON ON ON OFF OFF 255.255.255.0 192.168.0.255 192.168.0.254

ON ON ON ON ON ON ON ON (invalid setting)

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 15

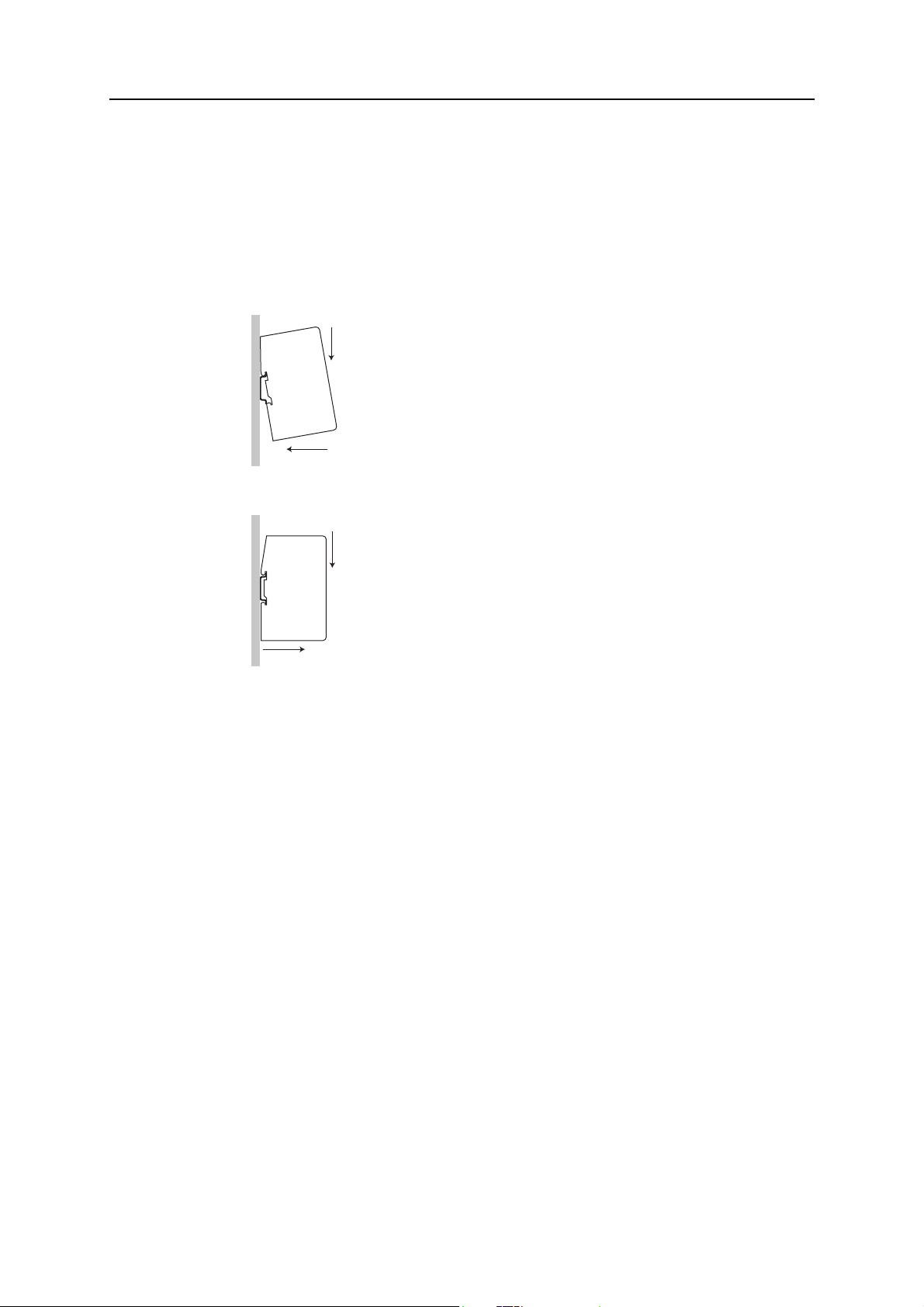

1.4 Hardware Installation

1

2

1

2

Perform the following steps to install the Anybus Communicator module:

1. Snap the gateway on to the DIN-rail.

The DIN-rail mechanism works as follows:

To snap the ABC on, first press it downwards (1) to compress the spring

in the DIN-rail mechanism, then push it against the DIN-rail as to make

it snap on (2)

About the Anybus Communicator for EtherNet/IP 15

To snap the ABC off, push it downwards (1) and pull it out from the DINrail (2), as to make it snap off from the DIN-rail

2. Connect the gateway to an Ethernet network.

3. Connect the gateway to the serial sub-network.

4. Connect the gateway to the PC via the configuration cable.

5. Connect the power cable and apply power.

6. Start the Anybus Configuration Manager program on the PC.

(The Anybus Configuration Manager software will automatically attempt to detect the serial port.

If unsuccessful, select the correct port manually in the “Port”-menu)

7. Configure the gateway using the Anybus Configuration Manager and download the

configuration.

8. Set up the EtherNet/IP communication according to the gateway configuration.

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 16

1.5 Software Installation

1.5.1 Anybus Configuration Manager

System requirements

• Pentium 133 MHz or higher

• 650 MB of free space on the hard drive

•32 MB RAM

• Screen resolution 800 x 600 (16 bit color) or higher

• Microsoft Windows® 2000 / XP / Vista / 7 (32- or 64-bit)

• Internet Explorer 4.01 SP1 or newer (or any equivalent browser)

Installation

• Anybus Communicator resource CD

- Insert the CD and follow the on-screen instructions.

- If the installation does not start automatically: right-click on the CD drive icon and select

“Explore” to show the contents of the CD. Locate the installation executable and doubleclick on it to start the installation, then follow the on-screen instructions.

About the Anybus Communicator for EtherNet/IP 16

• From HMS website

- Download the latest version of Anybus Configuration Manager from www.anybus.com

- Unzip the archive on your computer and double-click on the installation executable.

.

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 17

2. Basic Operation

2.1 General

The Anybus Communicator is designed to exchange data between a serial sub-network and a higher level

network. Unlike most other similar devices, the Anybus Communicator has no fixed protocol for the

sub-network, and consequently can be configured to handle almost any form of serial communication.

The gateway can issue serial telegrams cyclically, on change of state, or based on trigger events issued by

the control system in the higher level network (i.e. the fieldbus master or PLC). It can also monitor certain aspects of the sub-network communication and notify the higher level network when data has

changed.

An essential part of the Anybus Communicator package is Anybus Configuration Manager (ACM), a

Windows-based application used to supply the gateway with a description of the sub-network protocol.

No programming skills are required; instead, a visual protocol description-system is used to specify the

different parts of the serial communication.

Chapter 2

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 18

2.2 Data Exchange Model

General Data

ABC Internal Memory

Input Data

(512 bytes)

Subnetwork

Output Data

(512 bytes)

Higher Level Network

Input Data Output Data General Data

Subnetwork:

Fieldbus:

E-mail Client:

SSI:

Subnetwork:

Fieldbus:

E-mail Client:

SSI:

Subnetwork:

Fieldbus:

E-mail Client:

SSI:

Read/Write

Read Only

Read Only

Read Only

Read Only

Read/Write

Read Only

Read/Write

Read/Write

-

-

-

0x000 0x200

0x1FF 0x3FF

0x400

0x???

Internally, data exchanged on the sub-network and on

the higher level network all resides in the same memory.

This means that in order to exchange data with the subnetwork, the higher level network simply reads and

writes data to the memory locations specified using the

Anybus Configuration Manager. The very same memory locations can then be exchanged on the sub-network.

The internal memory buffer is divided into three areas,

based on function:

• Input Data (512 bytes)

This area can be read by the higher level network, the web server and the E-mail client.

(Data representation on the higher level network is described later in this chapter).

Basic Operation 18

• Output Data (512 bytes)

This area can be read/written to by the higher

level network, the web server and the E-mail client.

(Data representation on the higher level network is described later in this chapter).

• General Data (up to 1024 bytes)

This area cannot be accessed from the higher level network, but can be used for transfers

between individual nodes on the sub-network, or as a general “scratch pad” for data. The actual

size of this area depends on the amount of data that is exchanged on the sub-network. The gateway can handle up to 1024 bytes of general data.

2.2.1 Memory Map

When building the sub-network configuration using the Anybus Configuration Manager, the different

areas described above are mapped to the memory locations (addresses) specified below.

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 19

Basic Operation 19

The Temperature Regulator has two

registers, holding the Setpoint Temperature

and the Actual Temperature respectively.

The PLC exchange data between the internal

PLC memory and the slaves (in this case the

ABC) on the EtherNet/IP network.

The ABC copies the Output Register of

the Temperature Regulator to the InputData area.

The ABC copies the Temperature-

Setpoint from the Output Data area to

the Input Register in the Temperature-

Regulator.

The PLC Memory associated with

the ABC is exchanged;

Data from the Input Data area is copied to

PLC Input Memory, and PLC Output

Memory is copied to the Output Data

area.

Input Data

ABC

Serial Device - Temperature Regulator

PLC (EtherNet/IP Scanner)

Output Data General Data

0x000 0x200

0x1FF 0x3FF

0x400

0x???

Output Register Input Register

Temperature Setpoint

Temperature Setpoint

Actual Temperature

Actual Temperature

PLC Memory (Inputs) PLC Memory (Outputs)

Temperature Setpoint

Actual Temperature

(not used in this example)

EtherNet/IPSubnetwork

2.2.2 Data Exchange Example

In the following example, a temperature regulator on the sub-network exchanges information with a

PLC on the higher level network, via the internal memory buffers in the Anybus Communicator.

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 20

Basic Operation 20

2.3 Sub-network Protocol

2.3.1 Protocol Modes

The Anybus Communicator features three distinct operating modes for sub-network communication:

‘Master Mode’, ‘DF1 Master Mode’ and ‘Generic Data Mode’. Note that the protocol mode only specifies the basic communication model, not the actual sub-network protocol.

•Master Mode

In this mode, the gateway acts as a master on the sub-network, and the serial communication is

query-response based. The nodes on the network are not permitted to issue messages unless first

addressed by the gateway .

For more information about this mode, see “Master Mode” on page 21.

• DF1 Master Mode

In this mode, the gateway acts as a master on the sub-network, using the DF1 protocol. The serial

communication is query-response based. For more information about this mode, see “DF1 Protocol Mode” on page 86.

• Generic Data Mode

In this mode, there is no master-slave relationship between the sub-network nodes and the gateway; any node on the sub-network, including the gateway, may spontaneously produce or consume messages.

For more information about this mode, see “Generic Data Mode” on page 22.

2.3.2 Protocol Building Blocks

The following building blocks are used in Anybus Configuration Manager to describe the sub-network

communication. How these blocks apply to the three protocol modes is described later in this document.

•Node

A ‘node’ represents a single device on the sub-network. Each node can be associated with a number of transactions, see below.

•Transaction

A ‘transaction’ represents a complete serial telegram, and consists of a number of frame objects

(see below). Each transaction is associated with a set of parameters controlling how and when to

use it on the sub-network.

• Commands

A ‘command’ is simply a predefined transaction stored in a list in the Anybus Configuration Manager. This simplifies common operations by allowing transactions to be stored and reused.

• Frame Object

‘Frame objects’ are low level entities used to compose a transaction (see above). A frame object

can represent a fixed value (a constant), a range of values (limit objects), a block of data or a calculated checksum.

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 21

Basic Operation 21

Subnetwork Devices

Gateway

Control System

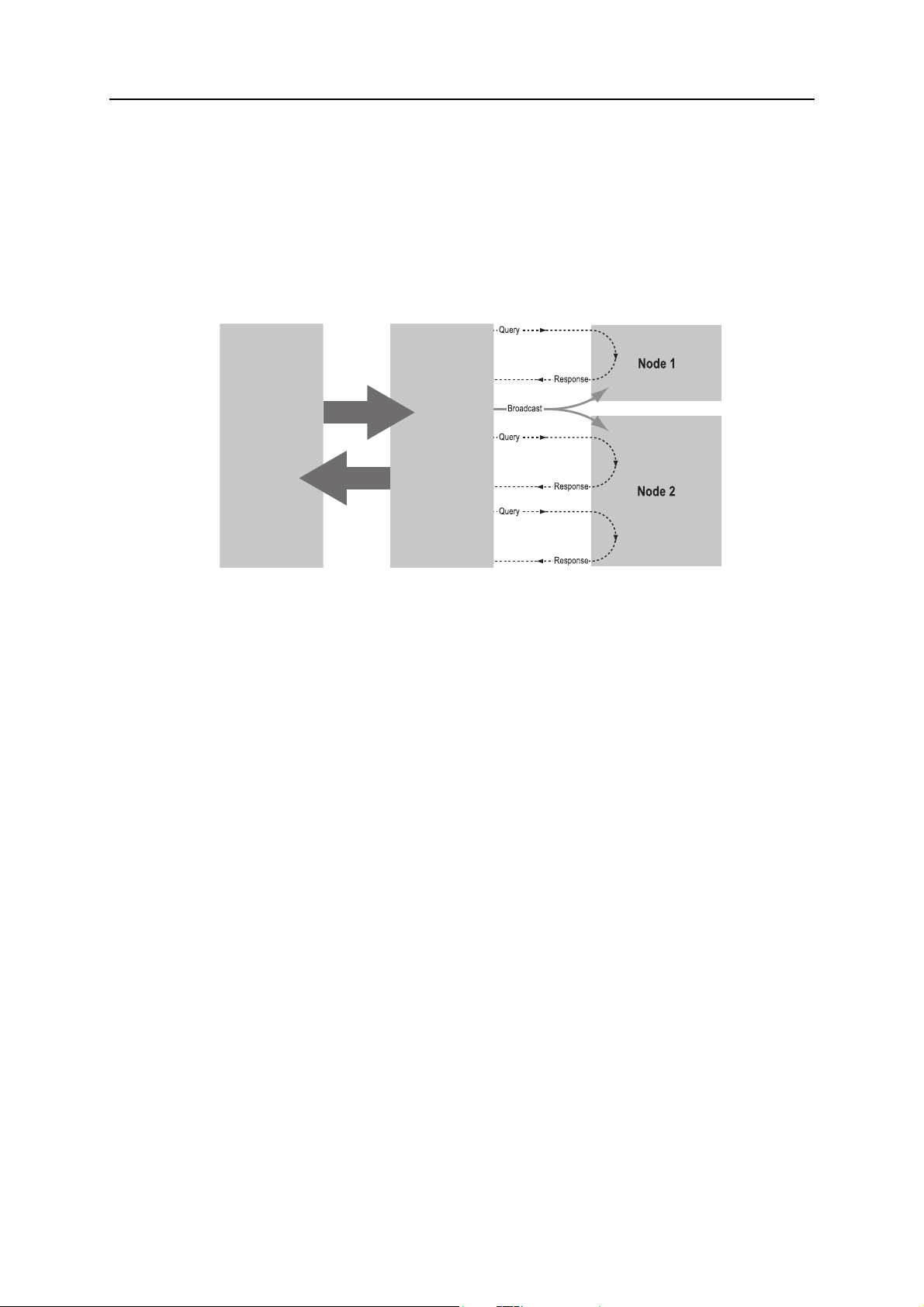

2.3.3 Master Mode

In this mode, the communication is based on a query-response scheme; when the gateway issues a query

on the sub-network, the addressed node is expected to issue a response. Nodes are not permitted to issue

responses/messages spontaneously, i.e. without first receiving a query.

There is, however, one exception to this rule; the broadcaster. Most protocols offer some way of broadcasting messages to all nodes on the network, without expecting them to respond to the broadcasted

message. This is also reflected in the gateway, which features a dedicated broadcaster node.

In Master Mode, Anybus Configuration Manager comes pre-loaded with the most commonly used

Modbus RTU commands, which can be conveniently reached by right-clicking on a node in the Anybus

Configuration Manager and selecting ‘Insert New Command’. Note, however, that this in no way

prevents other protocols based on the same query-response message-scheme from also being implemented.

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 22

Basic Operation 22

Subnetwork Devices

Control System

Gateway

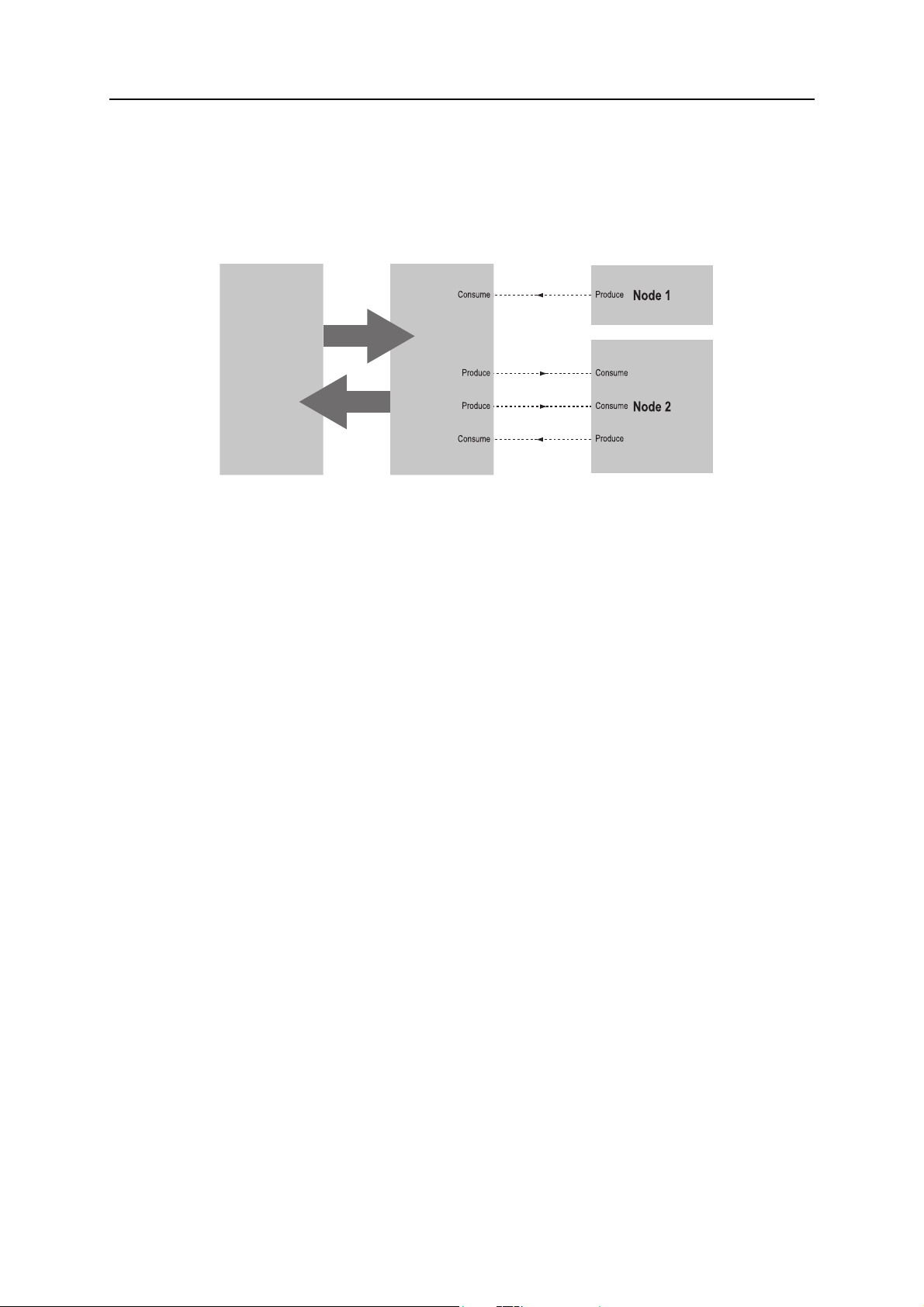

2.3.4 Generic Data Mode

In this mode, there is no master-slave relationship between the nodes on the sub-network and the gateway. Any node (including the gateway) may spontaneously produce or consume a message. Nodes are

not obliged to respond to messages, nor do they need to wait for a query in order to send a message.

In the figure above, the Anybus Communicator ‘consumes’ data ‘produced’ by a node on the sub-network. This ‘consumed’ data can then be accessed from the higher level network. This also works the

other way around; the data received from the higher level network is used to ‘produce’ a message on the

sub-network, for ‘consumtion’ by a node.

2.3.5 DF1 Master Mode

Please refer to “DF1 Protocol Mode” on page 86.

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 23

Basic Operation 23

2.4 EtherNet/IP

2.4.1 General

EtherNet/IP is based on the Control and Information Protocol (CIP), which is also the application layer

for DeviceNet and ControlNet. The Anybus Communicator acts as a Group 2 or 3 server on the

EtherNet/IP network.

Input and output data is accessed using I/O connections or explicit messages towards the assembly object and the parameter input/output mapping objects.

See also...

• “CIP Object Implementation” on page 107

2.4.2 Data Types

The input and output data hold two types of data; I/O data and parameter data. I/O data is exchanged

on change of value, and can be accessed using I/O connections towards the assembly object.

Parameter data can be accessed acyclically via the parameter input and output mapping objects. Note,

however, that each instance attribute within these objects must be created manually using the Anybus

Configuration Manager.

For more information see “Parameter Data Initialization (Explicit Data)” on page 119.

See also...

• “Assembly Object, Class 04h” on page 110

• “Parameter Data Input Mapping Object, Class B0h” on page 112

• “Parameter Data Output Mapping Object, Class B1h” on page 113

• “Fieldbus Settings” on page 64

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 24

Basic Operation 24

Input Data Output Data General Data

0x000 0x200

0x1FF 0x3FF

0x400

0x???

0x0FF

0x100

0x27F

0x280

I/O Data (Input)

I/O Data (Output)

(Cannot be accessed

from EtherNet/IP)

Parameter Data (Input)

Parameter Data (Output)

2.4.3 Memory Layout

I/O sizes are specified using the Anybus Configuration Manager and correlate to the Anybus Communicator memory as follows:

Example:

I/O Sizes for the gateway set to the following values:

IO Size In= 256 bytes (0x0100)

IO Size Out= 128 bytes (0x0080)

Resulting memory layout:

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 25

Basic Operation 25

2.5 Modbus-TCP

2.5.1 General

The Modbus-TCP protocol is an implementation of the standard Modbus protocol running on top of

TCP/IP. The built-in Modbus-TCP server provides access to the input and output data areas via a subset of the functions defined in the Modbus-TCP specification.

The server supports up to 8 simultaneous connections and communicates over TCP port 502. For detailed information regarding the Modbus-TCP protocol, consult the Open Modbus Specification.

2.5.2 Addressing Modes

The Anybus Communicator features two different modes of operation regarding the Modbus communication:

• Modbus Addressing Mode (Default)

In this mode, the input and output data areas are mapped to different function codes.

Note that coil addressing is not possible in this mode.

See also...

- “Modbus Addressing Mode” on page 26

• Anybus Addressing Mode

Compared to Modbus Addressing Mode, this mode allows data to be addressed in a more flexible

way. Note however that several function codes can be used to access the same data in the gateway. While this may appear confusing at first, it allows data to be manipulated in ways not possible in Modbus Addressing Mode (e.g. it is possible to manipulate individual bits of a register by

accessing coils associated with the same memory location).

See also...

- “Anybus Addressing Mode” on page 27

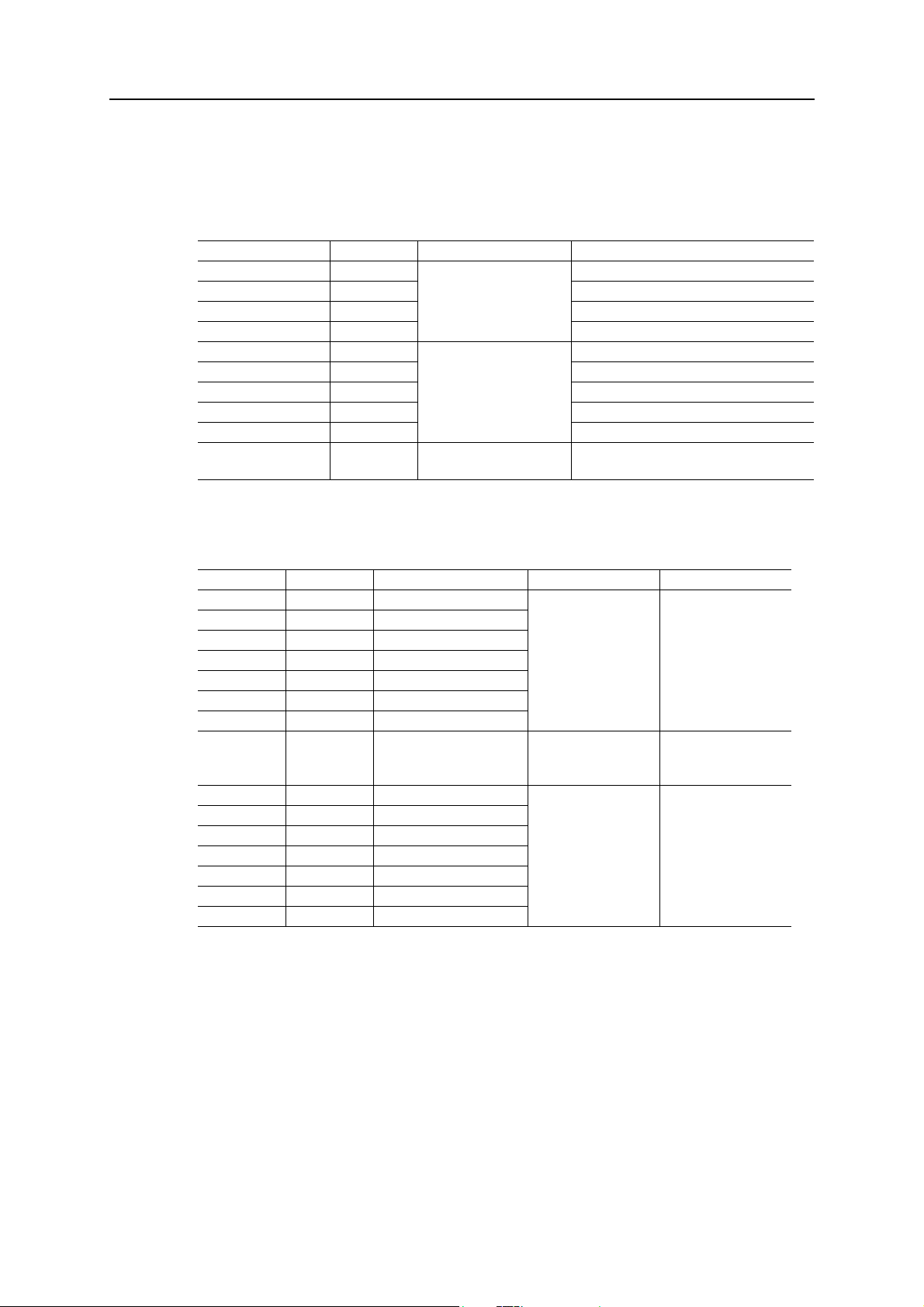

2.5.3 Supported Exception Codes

Code Name Description

0x01 Illegal function The function code in the query is not supported

0x02 Illegal data address The data address received in the query is outside the initialized memory area

0x03 Illegal data value The data in the request is illegal

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 26

Basic Operation 26

2.5.4 Modbus Addressing Mode

Supported Function Codes

The following function codes can be used in this mode:

Modbus Function Function Code Associated with Area No. of I/Os or Data Points per Command

Read Holding Registers 3 Output Data area

(0x200...0x3FF)

Read Input Registers 4 Input Data area

(0x000....0x1FF)

Write Single Register 6 Output Data area

Force Multiple Registers 16 1 - 800 registers

Mask Write Register 22 1 register

Read/Write Registers 23 125 registers read / 100 registers write

(0x200...0x3FF)

Input Register Map

The input data area is mapped to input registers as follows:

Register # Memory Location in the gateway Comments

1 0x000... 0x001 Each register corresponds to two bytes in the input

2 0x002... 0x003

3 0x004... 0x005

4 0x006... 0x007

5 0x008... 0x009

6 0x00A... 0x00B

... ...

255 0x1FC... 0x1FD

256 0x1FE... 0x1FF

1 - 125 registers

1 - 125 registers

1 register

data area.

Holding Register Map

The output data area is mapped to holding registers as follows:

Register # Memory Location in the gateway Comments

1 0x200... 0x201 Each register corresponds to two bytes in the out2 0x202... 0x203

3 0x204... 0x205

4 0x206... 0x207

5 0x208... 0x209

6 0x20A... 0x20B

... ...

255 0x3FC... 0x3FD

256 0x3FE... 0x3FF

put data area.

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 27

Basic Operation 27

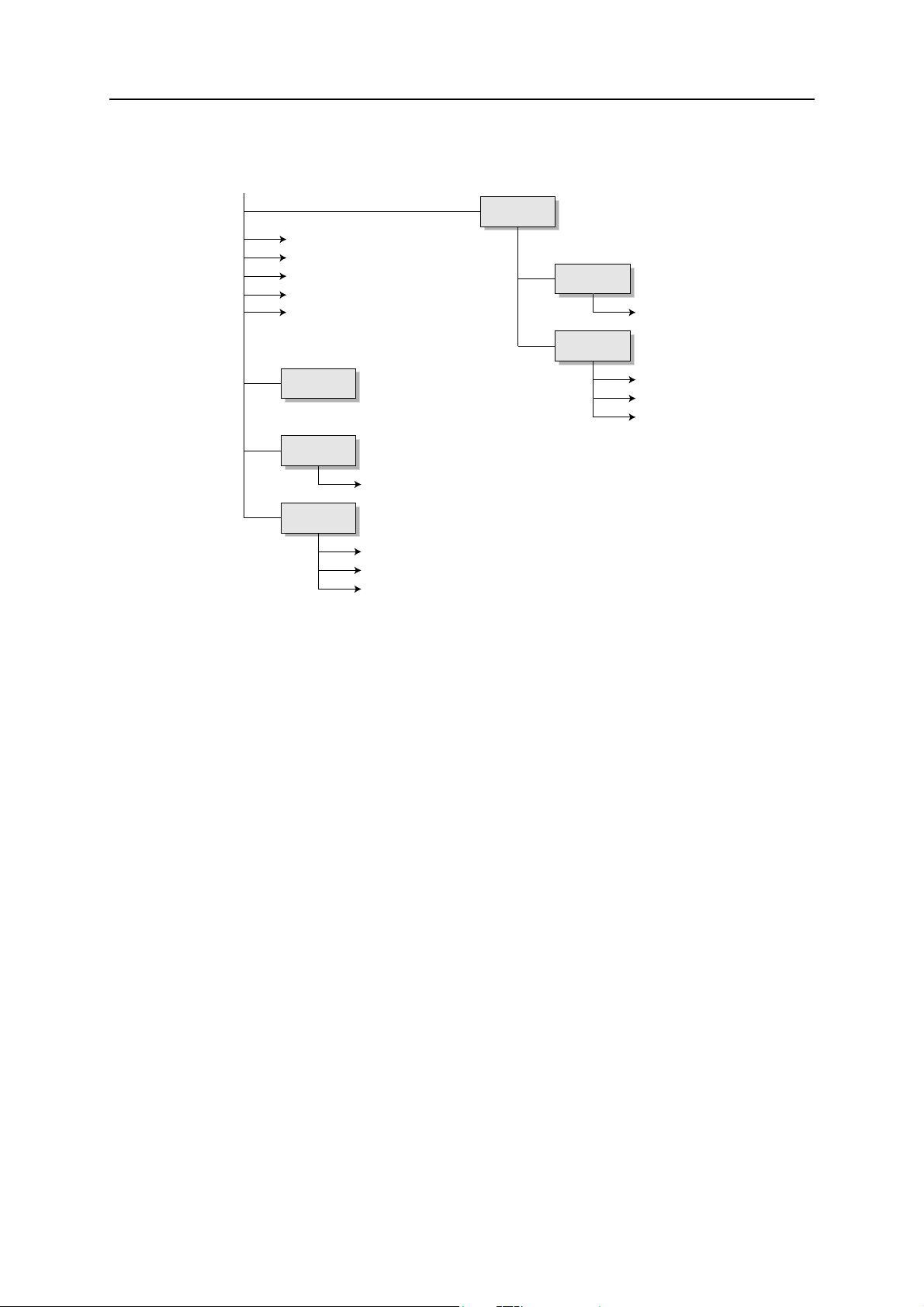

2.5.5 Anybus Addressing Mode

Supported Function Codes

The following function codes can be used in this mode:

Modbus Function Function Code Associated with Area(s) No. of I/Os or Data Points per Command

Read Coil 1 Input and Output Data Area

Read Input Discretes 2 1 - 2000 bits

Read Holding Registers 3 1 - 125 registers

Read Input Registers 4 1 - 125 registers

Write Coil 5 Output Data Area (0x200...

Write Single Register 6 1 register

Force Multiple Coils 15 1 - 800 bits

Force Multiple Registers 16 1 - 100 registers

Mask Write Register 22 1 register

Read/Write Registers 23 Input and Output Data Area

(0x000... 0x3FF)

0x3FF)

(0x000... 0x3FF)

Coil & Register Map

1 - 2000 bits

1 bit

125 registers read/100 registers write

The input and output data areas are mapped to coils and registers as follows:

Register # Coil # Memory Location in ABC Area Comments

1 1... 16 0x000... 0x001 Input Data area 2 17... 32 0x002... 0x003

3 33... 48 0x004... 0x005

4 49... 64 0x006... 0x007

... ... ...

255 4065... 4080 0x1FC... 0x1FD

256 4081... 4096 0x1FE... 0x1FF

257

...

1024

1025 16385... 16400 0x200... 0x201 Output Data area 1026 16401... 16416 0x202... 0x203

1027 16417... 16432 0x204... 0x205

1028 16433... 16448 0x206... 0x207

... ... ...

1279 20449... 20464 0x3FC... 0x3FD

1280 20465... 20480 0x3FE... 0x3FF

4097... 4112

...

16369... 16384

- - (reserved)

Note 1: The table above applies to all function codes.

Note 2: Coils are mapped MSB first, i.e. coil 0 corresponds to bit 15 of register 0.

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 28

3. File System

3.1 General

General

The Anybus Communicator features a built-in file system, which is used to store information such as

web files, network communication settings, e-mail messages etc.

Storage Areas

The file system consists of the different storage areas:

• Non-volatile area (approx. 1.4 Mb)

This section is intended for static files such as web files, configurations files etc.

• Volatile area (approx. 1 Mb)

This area is intended for temporary storage; data placed here will be lost in case of power loss or

reset.

Chapter 3

Conventions

• ‘\’ (backslash) is used as a path separator

• A ‘path’ originates from the system root and as such must begin with a ‘\’

• A ‘path’ must not end with a ‘\’

• Names may contain spaces (‘ ‘) but must not begin or end with one.

• Names may not contain the following characters: ‘\ / : * ? “ < > |’

• Names cannot be longer than 48 characters (plus null termination)

• A path cannot be longer than 256 characters (filename included)

• The maximum number of simultaneously open files is 40

• The maximum number of simultaneously open directories is 40

Important Note:

The non-volatile storage is located in FLASH memory. Each FLASH segment can be erased approximately 100 000 times.

The following operations will erase one or more FLASH segments:

• Deleting, moving or renaming a file or directory

• Writing or appending data to an existing file

• Formatting the file system

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 29

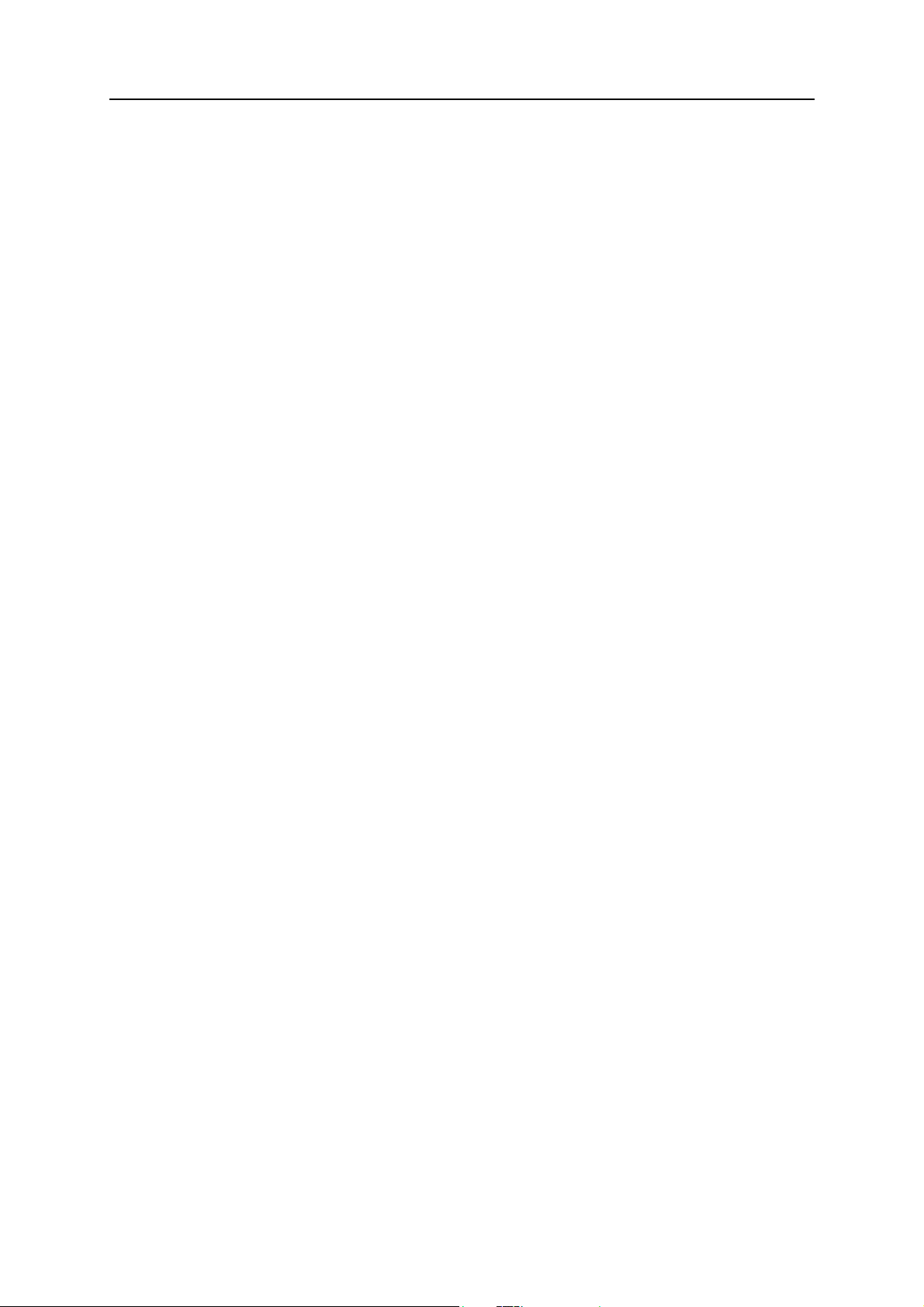

3.2 File System Overview

user

pswd

email

pswd

email

sys_pswd.cfg

ad_pswd.cfg

ethcfg.cfg

email_1.cfg

email_10.cfg

.

.

.

.

.

.

email_1.cfg

email_10.cfg

RAM

http.cfg

ssi_str.cfg

(admin root)

(user root)

(volatile, optional)

(protected)

(protected)

ip_accs.cfg

onoffln.cfg

File System 29

3.3 System Files

The file system contains a set of files used for system configuration. These files, known as “system files”,

are regular ASCII files that can be altered using a standard text editor (such as the Notepad in Microsoft

Windows™). Note that some of these files may also be altered by the gateway itself, e.g. when using SSI

(see “Server Side Include (SSI)” on page 45).

The format of the system files are based on the concept of ‘keys’, where each ‘key’ can be assigned a

value, see example below.

Example:

[Key1]

value of key1

[Key2]

value of key2

The exact format of each system file is described in detail later in this document.

The contents of the above files can be redirected:

Example:

In this example, the contents will be loaded from the file ‘here.cfg’.

Note: Any directory in the file system can be protected from web access by placing the file web-accs.cfg

in the directory, see “Authorization” on page 43.

[file path]

\i\put\it\over\here.cfg

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 30

4. FTP Server

4.1 General

The built-in FTP server provides a way to access the file system using a standard FTP client.

The following port numbers are used for FTP communication:

• TCP, port 20 (FTP data port)

• TCP, port 21 (FTP command port)

Security Levels

The FTP server features two security levels; admin and normal.

• Normal level users

The root directory will be ‘\user’.

• Admin level users

The root directory will be ‘\’, i.e. the user has unrestricted access to the file system.

Chapter 4

User Accounts

The user accounts are stored in two files, which are protected from web access:

• ‘\user\pswd\sys_pswd.cfg’

This file holds the user accounts for normal level users.

• ‘\pswd\ad_pswd.cfg’

This file holds the user accounts for admin level users.

File Format:

The format of these files are as follows:

Username1:Password1

Username2:Password2

Username3:Password3

Note 1: If no valid user accounts have been defined, the gateway will grant admin level access to all users. In such cases, the FTP accepts any username/password combination, and the root directory will be

‘\’.

Note 2: The FTP server shares user accounts with the Telnet server.

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 31

4.2 FTP Connection Example (Windows Explorer)

The built-in FTP client in Windows Explorer can easily be used to access the file system as follows:

1. Open the Windows Explorer by right-clicking on the ‘Start’ button and selecting ‘Explore’.

2. In the address field, type FTP://<user>:<password>@<address>

- Substitute <address> with the IP address of the Anybus Communicator

- Substitute <user> with the username

- Substitute <password> with the password

3. Press enter. The Explorer will now attempt to connect to the gateway using the specified settings.

If successful, the built in file system is displayed in the Explorer window.

FTP Server 31

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 32

5. Telnet Server

5.1 General

The built-in Telnet server provides a way to access the file system using a standard Telnet client. The

server communicates through TCP port 23.

Security Levels

Just like the FTP server, the Telnet server features two security levels; admin and normal.

• Normal level users

The root directory will be ‘\user’.

• Admin level users

The root directory will be ‘\’, i.e. the user has unrestricted access to the file system.

User Accounts

Chapter 5

The Telnet server shares user accounts with the FTP server. If no valid user accounts have been defined,

the gateway will grant admin level access to all users. In such case, no login is required, and the root directory will be ‘\’.

For more information, see “User Accounts” on page 30

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 33

5.2 General Commands

admin

•Syntax

admin

•Description

Provided that the user can supply a valid admin username/password combination, this command

provides admin access rights to normal level users.

exit

•Syntax

exit

•Description

This command closes the Telnet session.

help

Telnet Server 33

•Syntax

help [general|diagnostic|filesystem]

•Description

If no argument is specified, the following menu will be displayed.

General commands:

help - Help with menus

version - Display version information

exit - Exit station program

Also try ‘help [general|diagnostic|filesystem]’

version

•Syntax

version

•Description

This command will display version information, serial number and MAC ID of the Ethernetmodule, in the Communicator.

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 34

5.3 Diagnostic Commands

arps

•Syntax

arps

•Description

Display ARP stats and table

iface

•Syntax

iface

•Description

Display net interface stats

routes

Telnet Server 34

•Syntax

routes

•Description

Display IP route table

sockets

•Syntax

sockets

•Description

Display socket list

5.4 File System Operations

For commands where filenames, directory names or paths shall be given as an argument the names can

be written directly or within quotes. For names including spaces the filenames must be surrounded by

quotes. It is also possible to use relative pathnames using ‘.’, ‘\’ and ’..’

append

•Syntax

append [file] [“The line to append”]

•Description

Appends a line to a file.

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 35

cd

•Syntax

cd [path]

•Description

Changes current directory.

copy

•Syntax

copy [source] [destination]

•Description

This command creates a copy of the source file at a specified location.

del

•Syntax

del [file]

Telnet Server 35

•Description

Deletes a file.

dir

•Syntax

dir [path]

•Description

Lists the contents of a directory. If no path is given, the contents of the current directory is listed.

df

•Syntax

df

•Description

Displays filesystem info.

format

•Syntax

format

•Description

Formats the filesystem. This is a privileged command and can only be called in administration

mode.

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 36

md

•Syntax

md [directory]

•Description

Creates a directory. If no path is given, the directory is created in the current directory.

mkfile

•Syntax

mkfile [filename]

•Description

Creates an empty file.

move

•Syntax

move [source] [destination]

Telnet Server 36

•Description

This command moves a file or directory from the source location to a specified destination.

rd

•Syntax

rd [directory]

•Description

Removes a directory. The directory can only be removed if it is empty.

ren

•Syntax

ren [old name] [new name]]

•Description

Renames a file or directory.

type

•Syntax

type [filename]

•Description

Types the contents of a file.

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 37

6. Basic Network Configuration

6.1 General Information

The Anybus Communicator offers two modes of operation regarding the network settings:

• Settings specified by Configuration Switches

If the on-board switches are set to a non-zero value, the ABC is locked to the following settings:

IP Address:192.168.0.x(x = switch value)

Gateway:255.255.255.0

Subnet:255.255.255.0

DHCP:OFF

See also...

- “Configuration Switches” on page 14

• Settings specified in Anybus Configuration Manager

When valid settings have been specified in Anybus Configuration Manager

(‘TCP/IP Settings’ = enabled), then these are the settings the gateway will use.

When settings have been specified in Anybus Configuration Manager, the contents of the system

file ‘ethcfg.cfg’ will be ignored completely, causing the following behavior:

- DNS services will not be available

- Domain and Host name cannot be set

- E-mail services will not be available

- Network settings received via HICP or DCP) will be lost in the event of a power loss or a

reset.

Chapter 6

• Settings specified in ‘ethcfg.cfg’

If no settings are specified in Anybus Configuration Manager (i.e. ‘TCP/IP Settings’ = disabled),

the gateway will use the settings stored in the system file ‘ethcfg.cfg’.

If this file is missing, the gateway will attempt to retrieve the settings via DHCP or HICP for 30

seconds. If no configuration has been received within this period, the gateway will halt and indicate an error on the on-board LEDs.

EtherNet/IP

The TCP/IP settings can be accessed from EtherNet/IP through the TCP/IP Interface Object.

See also...

• “TCP/IP Interface Object, Class F5h” on page 115

DHCP/BootP

The Anybus Communicator can retrieve the TCP/IP settings from a DHCP or BootP server. If no

DHCP server is found, the gateway will default to the current settings in ‘\ethcfg.cfg’.

If no current settings are available (‘ethcfg.cfg’ is missing, or contains invalid settings), the gateway will

halt and indicate an error on the on-board status LEDs (the network configuration may however still be

accessed via HICP, see “Anybus IPconfig (HICP)” on page 41.

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 38

Basic Network Configuration 38

File Format:

[IP address]

xxx.xxx.xxx.xxx

[Subnet mask]

xxx.xxx.xxx.xxx

[Gateway address}

xxx.xxx.xxx.xxx

[DHCP/BOOTP]

ON or OFF

[SMTP address]

xxx.xxx.xxx.xxx

[SMTP username]

username

[SMTP password]

password

[DNS1 address]

xxx.xxx.xxx.xxx

[DNS2 address]

xxx.xxx.xxx.xxx

[Domain name]

domain

[Host name]

anybus

[HICP password]

password

• IP address

• Subnet mask

• Gateway address

• DHCP/BootP

ON - Enabled

OFF - Disabled

• SMTP server/login settings

Username and Password is only necessary if required by the

server.

• Primary and Secondary DNS

Needed to be able to resolve host names

• Default domain name for not fully qualified host names

•Host name

•HICP password

6.2 Ethernet Configuration File (‘ethcfg.cfg’)

6.2.1 General

To exist on the network, the Anybus Communicator needs a valid TCP/IP configuration. These settings

are stored in the system file ‘\ethcfg.cfg’. Note that if TCP/IP settings are enabled in Anybus Configuration Manager, then the IP address, gateway and subnet settings in ethcfg.cfg will be overwritten every

time the module is restarted. All other settings are unaffected.

The settings in this file may also be affected by...

See also...

• EtherNet/IP (See “EtherNet/IP” on page 37).

• HICP (See “Anybus IPconfig (HICP)” on page 41)

• SSI (See “Server Side Include (SSI)” on page 45)

• “FTP Server” on page 30

• “Fieldbus Settings” on page 64

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 39

Basic Network Configuration 39

File Format:

[Web]

xxx.xxx.xxx.xxx

[FTP]

xxx.xxx.xxx.xxx

[Modbus-TCP]

xxx.xxx.xxx.xxx

[EtherNet/IP]

xxx.xxx.xxx.xxx

[All]

xxx.xxx.xxx.xxx

• Nodes listed here may access the web server

• Nodes listed here may access the FTP server

• Nodes listed here may access the gateway via Modbus-TCP

• Nodes listed here may access the gateway via EtherNet/IP

• Fallback setting, used by the gateway when one or several of the

keys above are omitted

6.3 IP Access Control

It is possible to specify which IP addresses are permitted to connect to the Anybus Communicator. This

information is stored in the system file ‘\ip_accs.cfg’.

Note: ‘*’ may be used as a wildcard to select IP series.

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 40

Basic Network Configuration 40

•On/Offline trigger source

Values: ‘Link’ (default), ‘EIP’, ‘Modbus’ or a combination

• Timeout Value

Range: 1... 65535 (default = 1).

A value of 10 equals 1000 ms.

• Commands (Optional)

Selects what Modbus commands that must be

received during the timeout period.

If the keyword ‘ALL’ is given (default), the On/

Offline functionality will trigger on all Modbus

commands.

• Online method (Optional)

Defines how to handle data in the OUT I/O area

when going from Offline to Online.

If “1” (default), “old data” is restored

If “2”, “Offline” data is kept until overwritten by

master.

File Format:

[ON/OFF-line trigger]

Modbus

[Timeout]

10

[Commands]

3, 16, 23

[ON-line method]

1

6.4 On/Offline Configuration

By default, the On/Offline indication is triggered by the link status. Other triggering options can however be specified in the optional system file ‘\onoffln.cfg’, which should be placed in the module root

and looks as follows:

The contents of this file can be redirected by placing the line ‘[File path]’ on the first row, and a file path

on the second.

File example:

In this example, the settings described above will be loaded from the file ‘\my_settings\on-off-line_configuration.cfg’.

Note 1: The keys ‘[Timeout]’ and ‘[Commands]’ shall only be given if the On/Offline Trigger value is

set to ‘Modbus’.

Note 2: The settings in this file will be ignored if the application has issued the mailbox message

MB_ON_OFF_LINE_CONFIG. See “Advanced Fieldbus Configuration” on page 118.

[File path]

\my_settings\on-off-line_configuration.cfg

Doc: HMSI-27-314, Rev. 3.10Anybus Communicator EtherNet/IP / Modbus-TCP User Manual

Page 41

Basic Network Configuration 41

6.5 Anybus IPconfig (HICP)

The Anybus Communicator supports the HICP protocol used by the Anybus IPconfig utility from

HMS, which can be downloaded free of charge from the HMS website. This utility may be used to configure the network settings of any Anybus product connected to the network. Note that if successful,