Anybus Communicator - EtherNet/IP Interface Installation Sheet

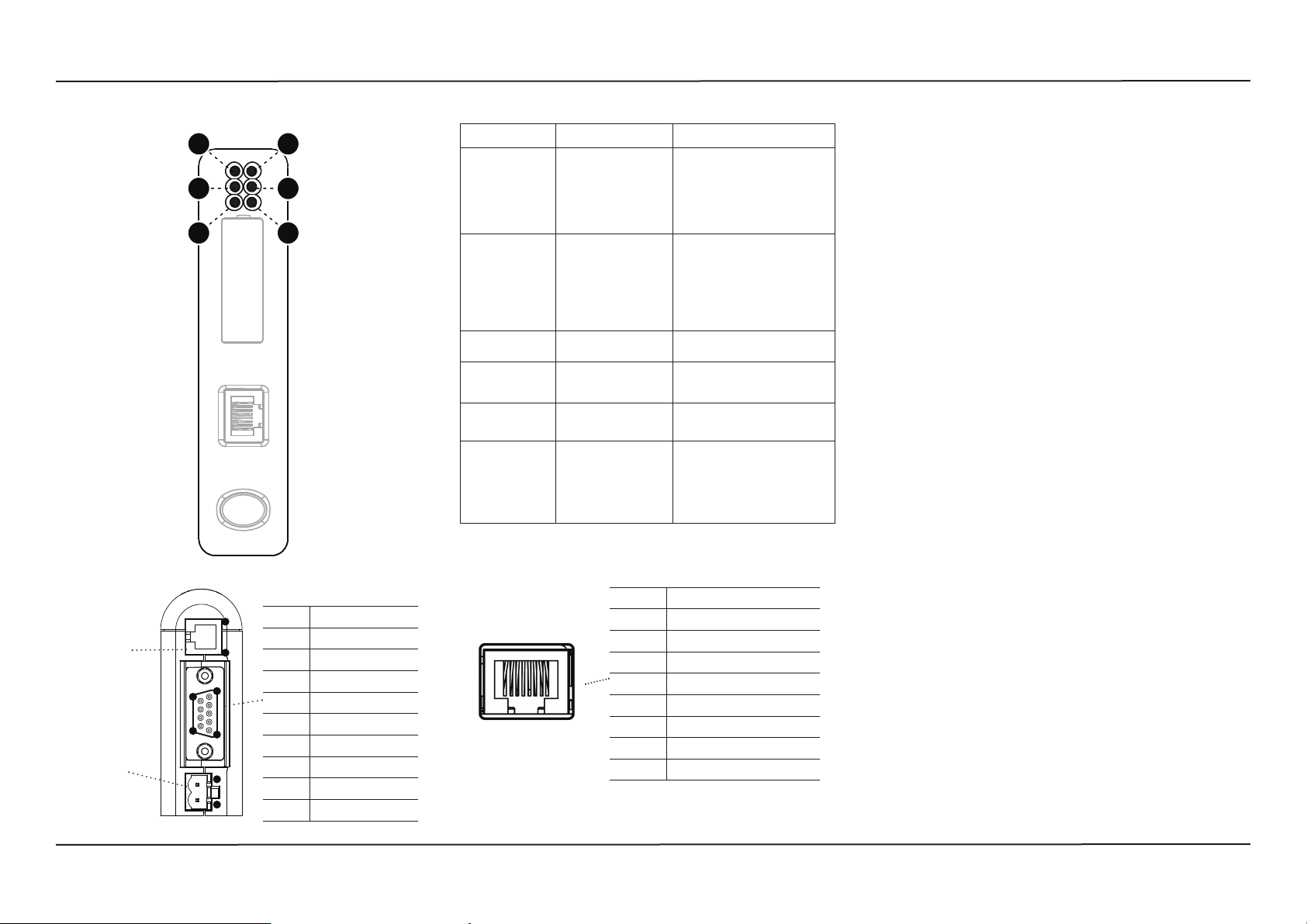

Module Front

LED Indicators

1

3

5

2

4

6

LED Indication Description

1 (Module Status) Off

2 (Network Status) Off

3 (Link) Off

4 (Activity) Off

5 (Subnet Status) Flashing green

6 (Device Status) Off

Green

Flashing Green

Flashing Red

Red

Flashing Green/Red

Green

Flashing Green

Red

Flashing Red

Flashing Green/Red

Green

Flashing Green

Green

Red

Alternating red/green

Green

Flashing green

Red

Flashing red

No power

Controlled by a scanner in run state

Not confi gured, or scanner in idle state

Minor fault (recoverable)

Major fault (unrecoverable)

Self-test in progress

No IP address, or no power

Online, one or more EtherNet/IP connections established

Online, no connections established

Duplicate IP address detected. Fatal error.

One or more connections timed out

Self-test in progress

No link

Connected to an Ethernet network

No Ethernet activity

Activity, receiving/transmitting Ethernet

packets

Running, but one or more transaction errors

Running

Transaction error/timeout or subnet stopped

Power off

Invalid or missing confi guration

Initializing

Running

Bootloader mode

Note the fl ash sequence pattern and contact

HMS support

Accessories Checklist

The following items are required for installation:

• Anybus Communicator Resource CD (Includes confi guration

software, manuals and application notes)

• RS232 confi guration cable

• Subnetwork connector

• Ethernet cable and connector (not included)

Installation and Startup Summary

• Mount the Communicator on the DIN-rail.

• Connect the Communicator to the Ethernet/IP network.

• Connect the Communicator to the subnetwork.

• Connect the confi guration cable between the Communicator

and the PC containing the Anybus Confi guration Manager

software (ACM).

• Power on the Communicator (+24 V DC).

• Confi gure the Communicator using ACM.

• Include the Anybus Communicator EDS fi le in the

Ethernet/IP confi guration tool.

• Confi gure and start the Ethernet/IP network.

Bottom View

PC Connector:

1. GND

2. GND

3. RS232 Rx

4. RS232 Tx

Power:

1. +24 V DC

2. GND

Ethernet/IP Connectors

Subnetwork Connector

Pin no. Description

1

1 +5V OUT

4

2 RS232 Rx

5

9

6

1

1

2

3 RS232 Tx

4NC

5 Signal GND

6 RS422 Rx+

7 RS422 Rx-

8 RS485+ / RS422 Tx+

9 RS485- / RS422 Tx-

18

Pin no Description

1 TD+

2 TD-

3 RD+

4 Termination

5 Termination

6 RD-

7 Termination

8 Termination

Further information and documents about this product can be

found at the product pages on www.anybus.com.

www.anybus.comSP0904, rev. 1.10, Mar 2015

Anybus Communicator Installation Sheet

UL Certifi cation

EMC Compliance (CE)Additional installation and operating

IND: CONT. EQ.

FOR HAZ LOC.

CL I, DIV 2

GP A,B,C,D

TEMP

CODE

E203225

Warnings!

• WARNING - EXPLOSION HAZARD - SUBSTITUTION OF

ANY COMPONENTS MAY IMPAIR SUITABILITY FOR

CLASS I, DIVISION 2.

• WARNING - EXPLOSION HAZARD - WHEN IN

HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES.

• WARNING - EXPLOSION HAZARD - DO NOT

DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE

NON-HAZARDOUS.

Attention!

• ATTENTION – RISQUE D’EXPLOSION – LE REMPLACEMENT DE TOUT COMPOSANTS INVALIDE LA

CERTIFICATION CLASS I, DIVISION 2.

• ATTENTION – RISQUE D’EXPLOSION – EN ZONE

EXPLOSIVE, VEUILLEZ COUPER L’ALIMENTATION

ÉLECTRIQUE AVANT LE REMPLACEMENT OU LE

RACCORDEMENT DES MODULES.

instructions

• Max Ambient Temperature: 55°C (for Hazloc environments)

• Field wiring terminal markings (wire type (Cu only, 14-30

AWG)).

• Use 60/75 or 75°C copper (Cu) wire only.

• Terminal tightening torque must be 5-7 lb-in (0.5 - 0.8 Nm).

• Use in overvoltage category 1 pollution degree 2 environment.

• Installed in an enclosure considered representative of the

intended use.

• Secondary circuit intended to be supplied from an isolating source and protected by overcurrent protective devices

installed in the fi eld sized per the following:

Control Circuit Wire Size Maximum Protective Device Rating

AWG (mm2) Amperes

22 (0.32) 3

20 (0.52) 5

18 (0.82) 7

16 (1.3) 10

14 (2.1) 20

12 (3.3) 25

ODVA Conformity

This product is in accordance with the EMC directive 89/336/EEC,

with amendments 92/31/EEC and 93/68/EEC through conformance

with the following standards:

• EN 50082-2 (1993)

EN 55011 (1990) Class A

• EN 61000-6-2 (1999)

EN 61000-4-3 (1996) 10 V/m

EN 61000-4-6 (1996) 10 V/m (all ports)

EN 61000-4-2 (1995) ±8 kV Air Discharge

±4 kV Contact discharge

EN 61000-4-4 (1995) ±2 kV Power port

±1 kV Other ports

EN 61000-4-5 (1995) ±0.5 kV Power ports (DM/CM)

±1 kV Signal ports

• ATTENTION – RISQUE D’EXPLOSION – NE PAS

DÉCONNECTER L’ÉQUIPEMENT TANT QUE

L’ALIMENTATION EST TOUJOURS PRÉSENTE OU

QUE LE PRODUIT EST TOUJOURS EN ZONE EXPLOSIVE ACTIVE.

EtherNet/IP CONFORMANCE TESTED™ is a certifi cation mark

of ODVA.

Further information and documents about this product can be

found at the product pages on www.anybus.com.

www.anybus.com

Loading...

Loading...