Page 1

AAnnyybbuuss®®WWiirreelleessss BBoolltt

USER MANUAL

SCM-1202-007 2.6 en-US ENGLISH

™™

Page 2

Important User Information

Liability

Every care has been taken in the preparation of this document. Please inform HMS Industrial Networks AB of any

inaccuracies or omissions. The data and illustrations found in this document are not binding. We, HMS Industrial

Networks AB, reserve the right to modify our products in line with our policy of continuous product development.

The information in this document is subject to change without notice and should not be considered as a

commitment by HMS Industrial Networks AB. HMS Industrial Networks AB assumes no responsibility for any errors

that may appear in this document.

There are many applications of this product. Those responsible for the use of this device must ensure that all the

necessary steps have been taken to verify that the applications meet all performance and safety requirements

including any applicable laws, regulations, codes, and standards.

HMS Industrial Networks AB will under no circumstances assume liability or responsibility for any problems that may

arise as a result from the use of undocumented features, timing, or functional side effects found outside the

documented scope of this product. The effects caused by any direct or indirect use of such aspects of the product

are undefined, and may include e.g. compatibility issues and stability issues.

The examples and illustrations in this document are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular implementation, HMS Industrial Networks AB cannot

assume responsibility for actual use based on these examples and illustrations.

Intellectual Property Rights

HMS Industrial Networks AB has intellectual property rights relating to technology embodied in the product

described in this document. These intellectual property rights may include patents and pending patent applications

in the USA and other countries.

®

Anybus

trademarks mentioned in this document are the property of their respective holders.

is a registered trademark and Wireless Bolt™is a trademark of HMS Industrial Networks AB. All other

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 3

Table of Contents

Page

1 Preface ................................................................................................................................. 3

1.1 About This Document ...................... ............. .................. .......................... ........................ 3

1.2 Document History ......................................... ............................... .......................... ..........3

1.3 Document Conventions ........ .......................... .................. ............. .................. ..................4

2 Description .......................................................................................................................... 5

2.1 Product Description....... ............................... ............................................ ........................ 5

2.2 Bluetooth or WLAN?.............................. .......................... ............................... .................. 5

2.3 Model Name – Certification Identifier...................... ............................... ............................. 6

3 Installation........................................................................................................................... 7

3.1 Safety ......................... ............................... ............................................ ........................ 7

3.2 General Information .. ............................... ............................................ ............................7

3.3 Mechanical Installation .... .......................... ............................... ........................................ 8

3.4 Connector....................... .......................... ..... .......................... .................. ............. ........ 9

3.5 Ethernet Cabling ............................... .................. .......................... ............................... .. 10

3.6 Digital Input ....................... .......................... ............................... .................. ................ 10

3.7 RESET Button ... .................. .......................... ............................... .................................. 11

4 Configuration..................................................................................................................... 12

4.1 General .... .......................... ............................... ............................................ ............... 12

4.2 Web Interface .......... ............................... .......................... .................. ............. ............. 13

4.3 Factory Restore .......................... .................. ............................... .......................... ........ 28

A Configuration Examples .................................................................................................... 29

A.1 Ethernet Bridge via WLAN or Bluetooth®.... .......................... .................. ............................. 29

A.2 PROFINET networking via Bluetooth

™

A.3 EtherNet/IP

A.4 Ethernet network to existing WLAN........................... ............. ............................... ............ 32

A.5 Adding single Ethernet node to WLAN ........... ............................... .......................... ..... ...... 33

A.6 Accessing PLC via WLAN from Handheld Device.............................. .......................... ..... ...... 34

Networking via Bluetooth®.... .......................... .................. ............................. 31

®

.... .......................... .................. ............................... .. 30

B Wireless Technology Basics .............................................................................................. 36

C Technical Data ................................................................................................................... 37

C.1 Hardware Specifications ..... ............................... .......................... ..... .......................... ..... 37

C.2 Communication ..... ..... ............. ............. .................. .......................... ..... ........................ 38

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 4

This page intentionally left blank

Page 5

Preface 3 (40)

1 Preface

1.1 About This Document

This manual describes how to install and configure Anybus Wireless Bolt.

For additional documentation and software downloads, FAQs, troubleshooting guides and

technical support, please visit www.anybus.com/support.

1.2 Document History

Version

1.0 2016-09-15

1.1 2016-11-23

1.2 2017-12-14

2.0 2017-04-19

2.1 2017-07-06

2.2 2017-10-04

2.3 2017-10-18

2.4 2017-12-21

2.5 2018-02-02

2.6 2018-09-05

Date

Description

First release

Minor additions and updates

Added configuration example

Updated for SP1

Added Bluetooth bridge mode

Updated for SP2

Updated compliance info

Updated for FW 1.3.9

Minor update

Updated for FW 1.6.3

®

Anybus

Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 6

Preface 4 (40)

1.3 Document Conventions

Ordered lists are used for instructions that must be carried out in sequence:

1. First do this

2. Then do this

Unordered (bulleted) lists are used for:

• Itemized information

• Instructions that can be carried out in any order

...and for action-result type instructions:

► This action...

→ leads to this result

Bold typeface indicates interactive parts such as connectors and switches on the hardware, or

menus and buttons in a graphical user interface.

Monospaced text is used to indicate program code and other

kinds of data input/output such as configuration scripts.

This is a cross-reference within this document: Document Conventions, p. 4

This is an external link (URL): www.hms-networks.com

This is additional information which may facilitate installation and/or operation.

This instruction must be followed to avoid a risk of reduced functionality and/or damage

to the equipment, or to avoid a network security risk.

Caution

This instruction must be followed to avoid a risk of personal injury.

WARNING

This instruction must be followed to avoid a risk of death or serious injury.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 7

Description

2 Description

2.1 Product Description

Anybus Wireless Bolt provides wireless communication over WLAN and/or Bluetooth®to wired

networks.

Typical applications for Anybus Wireless Bolt include:

• Adding wireless cloud connectivity to industrial devices

• Accessing devices from a laptop, smartphone or tablet

• Ethernet cable replacement between devices

Note:

Bluetooth PAN (Personal Area Network) may not work with some devices due to different

implementations of Bluetooth by different manufacturers.

WLAN 5 GHz cannot be used at the same time as WLAN 2.4 GHz or Bluetooth.

2.2 Bluetooth or WLAN?

5 (40)

Use Bluetooth when...

• ...the wireless link has an Anybus Wireless Bridge II or Anybus Wireless Bolt at both ends.

• ...an interruption-free connection is more important than data throughput speed.

• ...interference robustness is important – e.g. in an industrial environment.

• ...a Profinet I/O cycle time or EtherNet/IP RPI of 64 ms or more is acceptable.

Use WLAN when...

• ...connecting to other types of wireless devices or a WLAN infrastructure.

• ...high data throughput speed is more important than connection reliability.

• ...large file transfers are expected.

• ...WLAN channel frequency planning is possible.

• ...a low Profinet I/O cycle time or EtherNet/IP RPI is desired.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 8

Description

2.3 Model Name – Certification Identifier

The model name consists of a model prefix followed by two designators for interface

configuration and functionality.

6 (40)

Prefix

Interface configuration

Functionality

AWB2

A

B

A

B

C

Anybus Wireless Bolt

Interface 18-pin socket

Interface RJ45 and 3-pin power socket

Ethernet

Ethernet and RS232/485

Ethernet and CAN

Example: AWB2AA = Anybus Wireless Bolt with18-pin plug connector and Ethernet networking

only.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 9

Installation 7 (40)

3 Installation

3.1 Safety

Caution

This equipment emits RF energy in the ISM (Industrial, Scientific, Medical) band. Make

sure that all medical devices used in proximity to this device meet appropriate

susceptibility specifications for this type of RF energy.

This product is recommended for use in both industrial and domestic environments. For

industrial environments it is mandatory to use the functional earth connection to comply

with immunity requirements. For domestic environments the functional earth must be

used if a shielded Ethernet cable is used, in order to meet emission requirements.

This product contains parts that can be damaged by electrostatic discharge (ESD). Use

ESD prevention measures to avoid damage.

See also additional safety instructions in the included compliance information.

3.2 General Information

Make sure that you have all the necessary information about the capabilities and restrictions of

your local network environment before installation.

The characteristics of the internal antenna should be considered when choosing the placement

and orientation of the unit.

For optimal reception, wireless devices require a zone between them clear of objects that could

otherwise obstruct or reflect the signal. A minimum distance of 50 cm between the devices

should also be observed to avoid interference.

See also Wireless Technology Basics, p. 36.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 10

Installation 8 (40)

3.3 Mechanical Installation

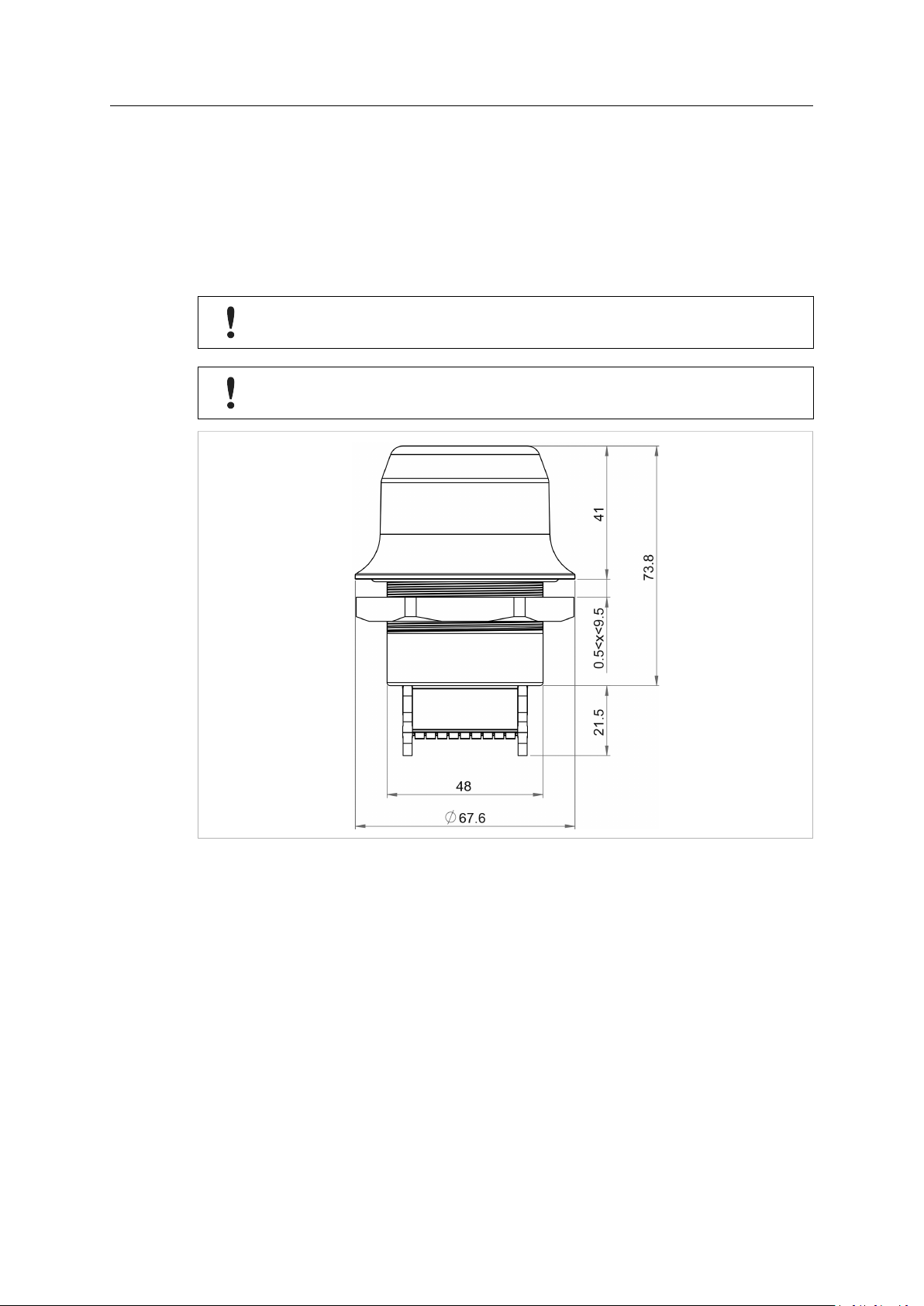

The device is intended to be mounted on top of a machine or cabinet through an M50 (50.5 mm)

hole using the included sealing ring and nut.

The top mounting surface (in contact with the sealing) must be flat with a finish equivalent to

Ra 3.2 or finer and cleaned and free from oils and greases.

Tightening torque: 5 Nm ±10 %.

Make sure that the sealing ring is correctly placed in the circular groove in the top part of

the housing before tightening the nut.

Always hold the BOTTOM part of the unit when untightening the nut, not the top part

(the cap).

Fig. 1 Installation drawing

All measurements are in mm.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 11

Installation 9 (40)

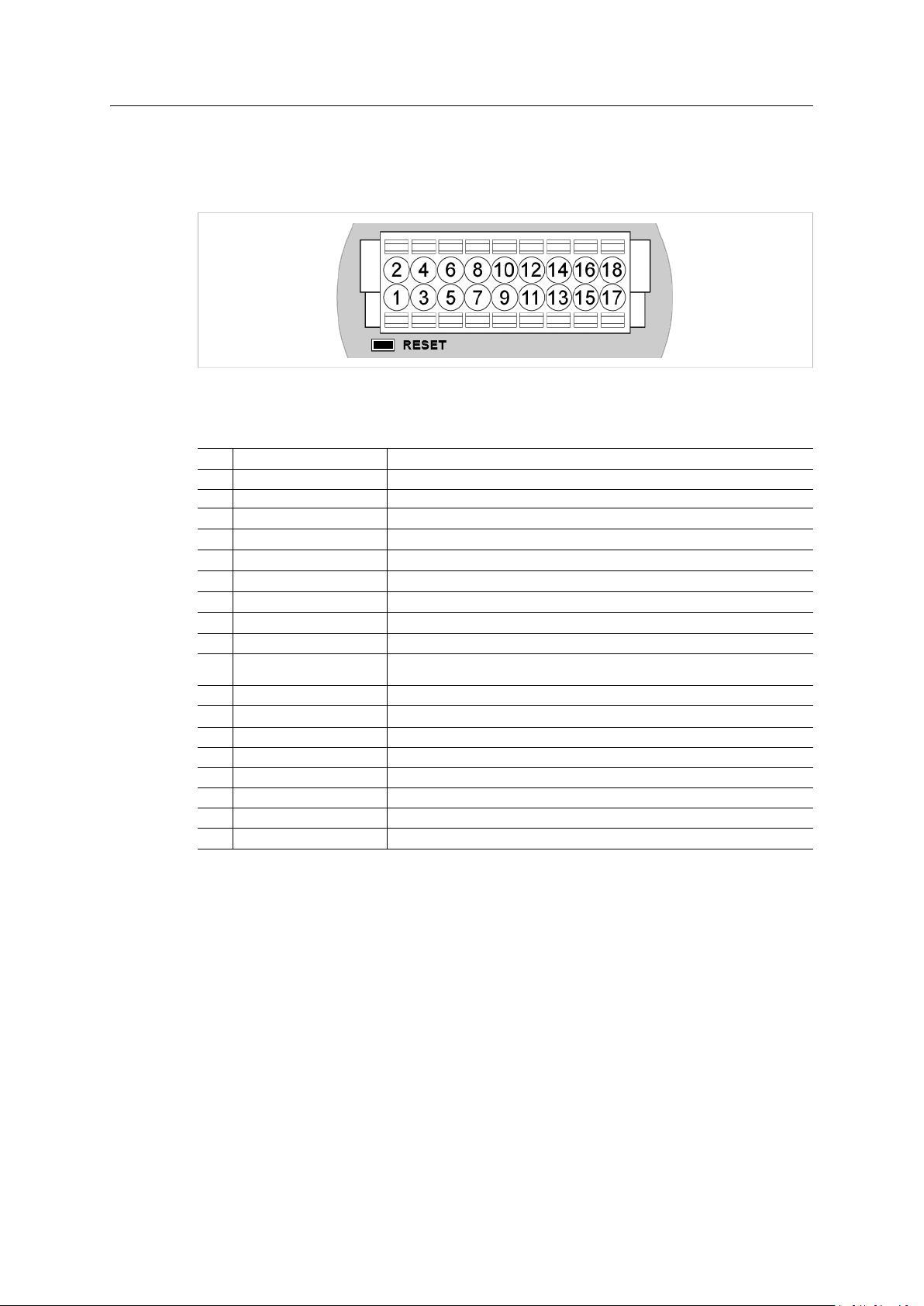

3.4 Connector

The 18-pin connector is common for all models of the Anybus Wireless Bolt. Some pins may have

a different function depending on model. Unused pins should not be connected.

Fig. 2 Connector

The location of the RESET button can be used as a reference for the pin numbering when the

connector is attached to the Wireless Bolt. Pin 1 will be the pin closest to the button.

Name

Pin

1 VIN

2 GND Power Ground

3 DI

DI_GND

4

ETN_RD+

5

ETN_RD-

6

ETN_TD-

7

ETN_TD+

8

RS485_B

9

FE/Shield

10

RS232_TXD

11

RS485_A/RS232_RXD

12

RS232_RTS RS-232 Request To Send

13

RS232_CTS

14

ISO_5V

15

ISO_GND

16

CAN_L

17

CAN_H

18

Description

Power + (9–30 V)

Digital input + (9–30 V)

Digital input ground

Ethernet receive + (white/orange)

Ethernet receive - (orange)

Ethernet transmit - (green)

Ethernet transmit + (white/green)

RS-485 B Line

Ethernet:

Serial:

RS-232 Transmit

RS-485 A Line / RS-232 Receive

RS-232 Clear To Send

Isolated 5 V for serial interface

Isolated Ground for serial interface

CAN Low

CAN High

Functional Earth

Functional Earth and Shield

Note:

• The Ethernet wire colors refer to the T568A standard.

• If using a shielded Ethernet cable the shield must be unconnected.

• RS-232 and RS-485 cannot be used at the same time.

• Use termination for RS-485 and CAN when required.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 12

Installation 10 (40)

3.5 Ethernet Cabling

To make an Ethernet connector cable for Anybus Wireless Bolt:

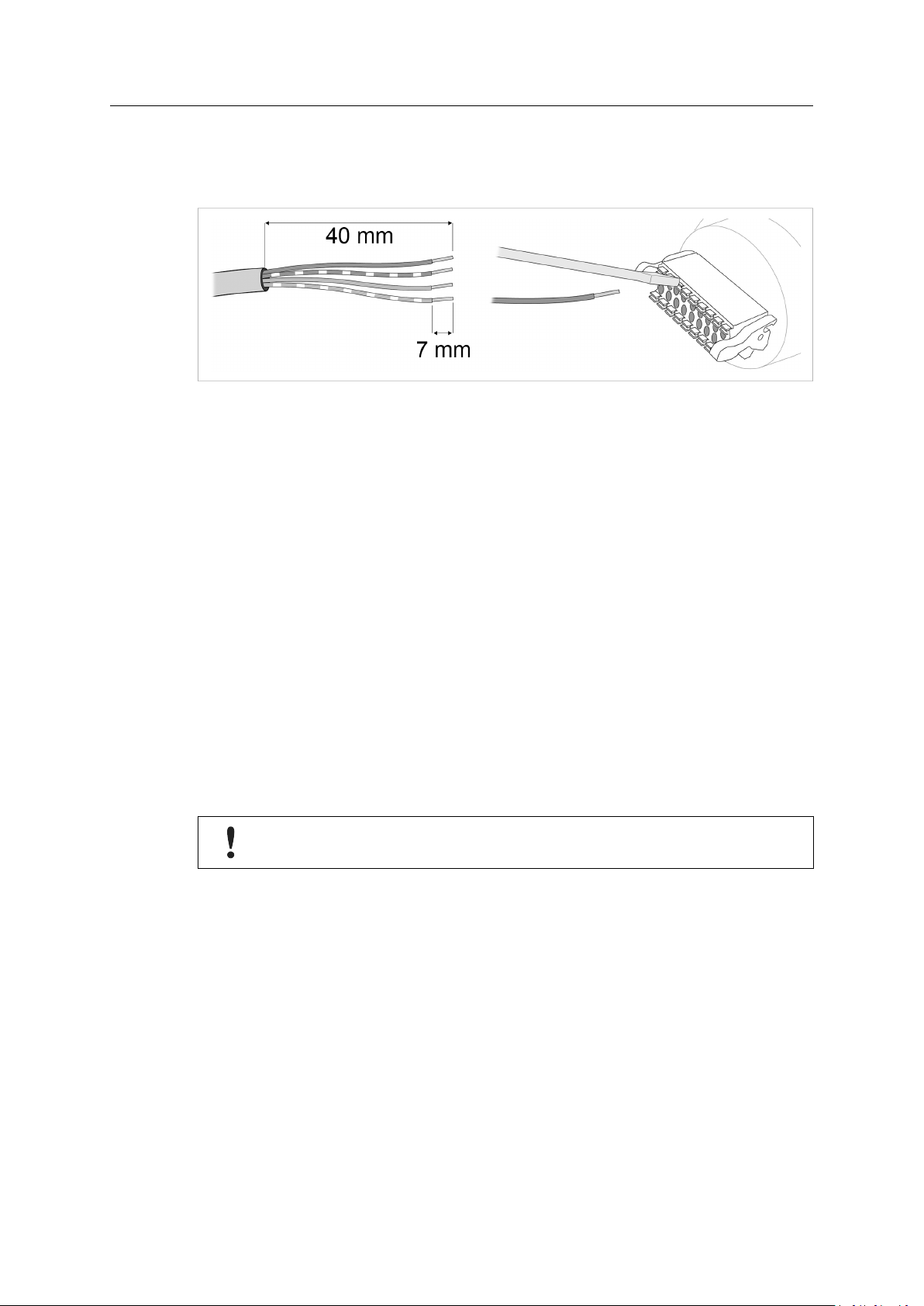

Fig. 3

1. Cut off one of the connectors on a standard Cat5e or Cat6 Ethernet cable.

2. Strip off about 40 mm (1½ inch) of the cable jacket and untwist the orange, orange/white,

green and green/white wires. The other wires will not be used.

3. Strip off about 7 mm (¼ inch) of the isolation on each wire.

4. Push the pin spring release next to each socket on the connector and insert the correct wire

end according to Connector, p. 9.

Connect the wires from the power supply to the connector in the same way as the Ethernet

wiring. Make sure that polarity is not reversed.

RJ-45 Adapter

An Ethernet adapter with an RJ45 female connector can be ordered as an accessory. Please

contact your sales representative for more information.

3.6 Digital Input

The digital input can be used for additional functionality with advanced configurations and to

reset the unit. For more information please refer to the Anybus Wireless Bolt/Bridge II AT

Reference Guide.

If voltage is applied to the digital input for more that 10 seconds the unit will be reset to

factory defaults.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 13

Installation 11 (40)

3.7 RESET Button

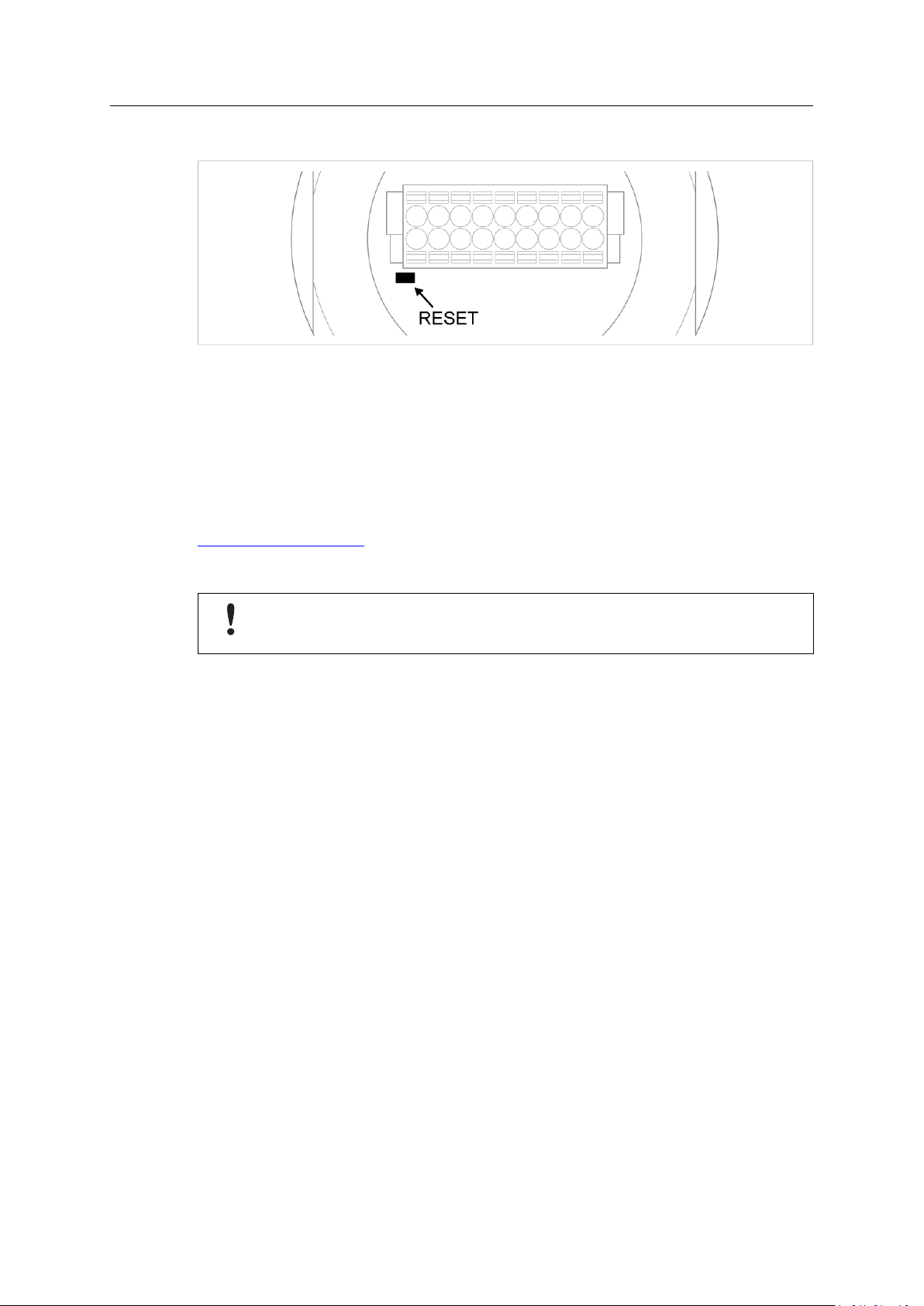

Fig. 4 RESET button

The RESET button is located on the bottom of the unit.

When the unit is powered on, press and hold RESET for >10 seconds and then release it to reset

to the factory default settings.

Recovery Mode

If the web interface cannot be accessed, the unit can be reset by starting in Recovery Mode and

reinstalling the firmware using Anybus Firmware Manager II, which can be downloaded from

www.anybus.com/support.

To enter Recovery Mode, press and hold RESET during startup.

Firmware updates should normally be carried out through the web interface. Recovery

Mode should only be used if the unit is unresponsive and the web interface cannot be

accessed.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 14

Configuration 12 (40)

4 Configuration

4.1 General

Anybus Wireless Bolt should normally be configured via the web interface. Parameters can be set

individually or using one of the pre-configured Easy Config modes.

The web interface is accessed by pointing a web browser to the IP address of the Wireless Bolt.

The default address is 192.168.0.99. The computer accessing the web interface must be in the

same IP subnet as the Wireless Bolt.

Fig. 5 Web interface

Advanced configuration can be carried out by issuing AT (modem) commands through the web

interface or over a Telnet or RAW TCP connection to port 8080. See the AT Commands Reference

Guide or the Help page in the web interface for more information.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 15

Configuration 13 (40)

4.2 Web Interface

4.2.1 System Overview

®

Anybus

Wireless Bolt™User Manual

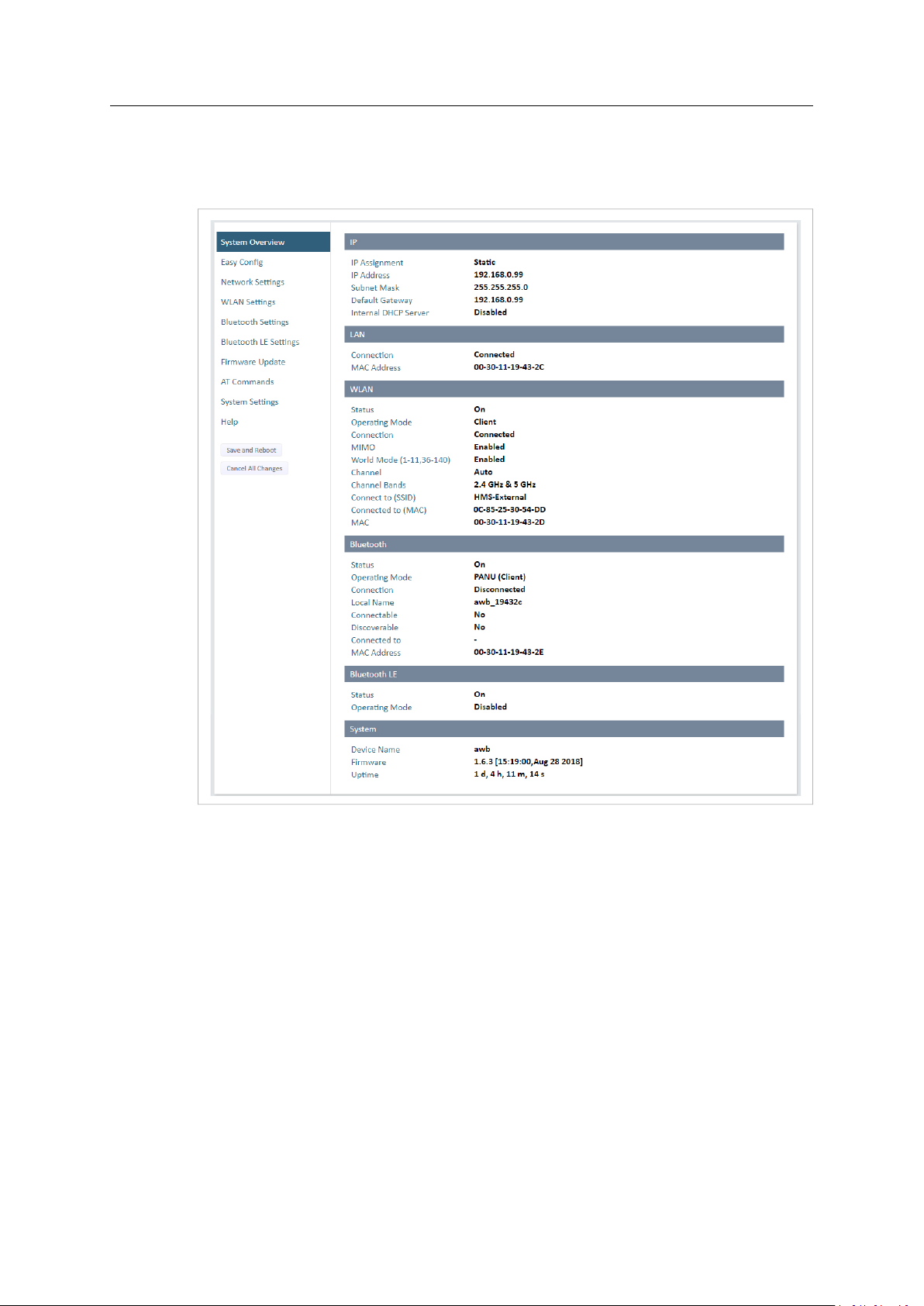

Fig. 6 System Overview page

The System Overview page shows the current settings and connection status for the wired and

wireless interfaces. The different parameters are explained in the descriptions of each settings

page in this manual.

The Help page describes AT commands that can be used for advanced configuration.

Save and Reboot This button will be enabled if the unit must be restarted to apply a change.

Cancel All Changes Resets parameter changes that have not been applied.

SCM-1202-007 2.6 en-US

Page 16

Configuration 14 (40)

4.2.2 Easy Config

Fig. 7 Easy Config page

To activate an Easy Config mode, select it from the dropdown menu and click on Set. The mode

will be activated immediately.

Easy Config Modes

EC

Role

1 Bluetooth PANU

–

2

–

3

4

Client

5 WLAN AP

6

Bluetooth NAP

7 WLAN AP

8

Bluetooth NAP

9 Bluetooth PANU

(any) Apply PROFINET optimization and restart.

10

(any)

11

Description

Configure as Bluetooth client and scan for another client (PANU–PANU).

Reset configuration to factory defaults.

Reset IP settings to factory defaults.

Wait for automatic configuration.

Configure units in mode 4 as clients.

Restart as access point and connect clients.

Configure units in mode 4 as clients.

Restart as access point and connect clients.

Apply PROFINET optimization to all units.

Configure as Bluetooth client and scan for another client (PANU–PANU).

Apply PROFINET optimization to both units.

Enable PROFIsafe mode.

®

Anybus

Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 17

Configuration 15 (40)

Notes:

• Mode 1 will scan for units in mode 4. When a unit in mode 4 is detected, the scanning unit

will configure itself as a Bluetooth PANU client, send a connection configuration to the

detected unit, and restart. The detected unit will also restart and attempt to connect to the

first unit as a PANU client.

• Modes 5, 6, 7 and 8 will scan for units in mode 4. The detected units will be reconfigured as

clients and the scanning unit will restart as an access point. The clients will then restart and

connect to the access point.

• Modes 7 and 8 will additionally apply PROFINET optimization to all the units. PROFINET

messages will then have priority over TCP/IP frames.

• Mode 11 locks the unit in PROFIsafe mode where the configuration cannot be changed

without physical access. To cancel this mode the unit must be restored to factory defaults

by pressing and holding the RESET button.

• Modes 10 and 11 will be added to the configuration without changing any other settings.

• Modes 1 and 9 will listen for 40 seconds or until a configuration is established.

• Modes 4 will listen for 120 seconds or until receiving a configuration.

• Modes 5, 6, 7 and 8 will time out after 120 seconds.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 18

Configuration 16 (40)

4.2.3 Network Settings

Fig. 8 Network Settings page

IP Assignment

IP Address Static IP address for the unit

Subnet Mask Subnet mask when using static IP

Default Gateway Default gateway when using static IP

Internal DHCP Server Disabled: No internal DHCP functionality

Start Address (Y) The internal DHCP server will assign up to 7 IP addresses starting from X.X.X.Y, where X

Select static or dynamic IP addressing (DHCP)

The browser should automatically be redirected to the new address after clicking on

Save and Reboot (not supported by all browsers).

DHCP Relay Enabled: The unit can receive a DHCP request on one interface and resend

it to a DHCP server located on one of the other interfaces.

Only a single DHCP server can be active for all the connected interfaces.

If WLAN is used, the forwarding mode must be set to Layer 3 IP Forward.

DHCP Server Enabled: Activates an internal DHCP server. This option is only available

when IP Assignment is set to Static.

Do not enable this option if there is already a DHCP server on the network!

is taken from the current static IP address setting, and Y is the value in Start Address.

Already allocated addresses will be skipped, including the address of the unit itself. The

subnet mask setting will be ignored.

Examples:

IP Address: 192.168.0.99, Start Address: 101

DHCP range = 192.168.0.101 – 192.168.0.107

IP Address: 192.168.0.103, Start Address: 101

DHCP range = 192.168.0.101 – 192.168.0.108

7 addresses are allocated but the address of the unit is skipped.

®

Anybus

Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 19

Configuration 17 (40)

4.2.4 WLAN Settings - Client

Fig. 9 WLAN Settings - Client

Enable

Operating Mode Choose operation as WLAN Client or Access Point. If Access Point is selected, additional

Channel Bands Choose to scan only the 2.4 GHz or 5 GHz channel band, or both (default).

Enable/disable the WLAN interface.

settings will be available.

The unit can be configured to scan on both the 2.4 GHz and 5 GHz channel bands but can only

communicate on one band at a time.

Scan for Networks Click to scan the selected frequency band(s) for discoverable WLAN networks.

Connect to SSID

Authentication Mode

Passkey

Username, Domain,

Passphrase

Select a network from the dropdown menu to connect to it.

To connect manually to a network, enter its SSID (network name) here. This can be used

if the network does not broadcast its SSID.

Select the authentication/encryption mode required by the network.

Open = No encryption or authentication

Enter the passkey when using WPA/WPA2-PSK or WEP64/128.

Authentication details when using LEAP or PEAP (WPA2 Enterprise).

®

Anybus

Wireless Bolt™User Manual

Channel Select a specific channel to use when scanning for networks.

Auto = all available channels will be scanned (default).

See also WLAN Channels and World Mode (Client Mode only), p. 19

SCM-1202-007 2.6 en-US

Page 20

Configuration 18 (40)

Advanced Settings

Bridge Mode Layer 2 tunnel = All layer 2 data will be bridged over WLAN.

Use when multiple devices on both sides of an Ethernet network bridge must be able to

communicate via WLAN (many-to-many).

Only works between Anybus Wireless Bolt or Wireless Bridge II devices.

Layer 2 cloned MAC only = Layer 2 data from only a single MAC address (specified

below) will be bridged over WLAN (many-to-one).

Layer 3 IP forward (default) = IP data from all devices will be bridged over WLAN.

This mode must be used when using the DHCP Relay function.

Cloned MAC Address The MAC address to use with Layer 2 cloned MAC only (see above).

WLAN Roaming

Anybus Wireless Bolt supports Fast Roaming according to IEEE 802.11r. This enables a WLAN

client to roam quicker between WLAN Access Points that have the same SSID and support IEEE

802.11r. Fast Roaming is enabled as default but can be permanently disabled using AT commands.

When Fast Roaming is disabled the client will be able to roam between all access points that

have been specified with SSID, BSSID and Channel in a connection list (using AT commands).

When Fast Roaming is enabled only the first access point SSID in the list will be used, and the

BSSID and Channel parameters are ignored. If the access point does not support IEEE 802.11r the

client will continue without Fast Roaming.

See the AT Commands Reference Guide or the Help page in the web interface for more

information about how to set up WLAN roaming.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 21

Configuration 19 (40)

WLAN Channels and World Mode (Client Mode only)

Which channels are available for WLAN communication is restricted by the regulatory domain

where the unit is operating. Anybus Wireless Bolt supports regulatory domain detection

according to the IEEE 802.11d specification.

The unit is initially set in World Mode which enables only the universally allowed channels in the

2.4 GHz and 5 GHz bands (see the table below). World Mode can be disabled and additional

channels added using AT commands. The unit will then search for country information during the

scan. If the scan indicates that the unit is operating within either the European (ETSI) or North

American (FCC) regulatory domains, the additional channels will be enabled. A new scan will be

performed every hour to update the regulatory domain.

If no country information or conflicting information is detected, the unit will revert to World

Mode. The unit must then be restarted to update the regulatory domain.

See the AT Commands Reference Guide or the Help page in the web interface for more

information about how to use AT commands.

Regulatory domains and WLAN channels

2.4 GHz 5 GHz

WORLD 1–11 36, 40, 44, 48, 52, 56, 60, 64, 100, 104, 108, 112, 116, 132, 136, 140

ETSI 1–11, 12, 13 36, 40, 44, 48, 52, 56, 60, 64, 100, 104, 108, 112, 116, 120, 124, 128, 132,

FCC 1–11 36, 40, 44, 48, 52, 56, 60, 64, 100, 104, 108, 112, 116, 132, 136, 140

136, 140

Notes

• The maximum output power will be reduced on some channels depending on regulatory

requirements.

• WLAN communication may take a longer time to establish during startup if World Mode is

disabled and additional channels are used.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 22

Configuration 20 (40)

4.2.5 WLAN Settings - Access Point

Fig. 10 WLAN Settings - Access Point

The following settings are specific for Access Point mode:

Network (SSID) Enter an SSID (network name) for the Wireless Bolt.

If this entry is left blank, the unit will generate an SSID which includes the last 6

characters of the MAC ID.

Authentication Mode

WPA2 Passkey Enter a string in plain text or hexadecimal format to use for authentication.

Channel Bands, Channel Select the WLAN channel band and channel to use for the access point.

Select the authentication/encryption mode to use for the access point.

Open = No encryption or authentication

WPA2 = WPA2 PSK authentication with AES/CCMP encryption

Regular (plain text) passwords must be between 8 and 63 characters.

All characters in the ASCII printable range (32–126) are allowed, except

" (double quote) , (comma) and \ (backslash).

Hexadecimal passwords must start with 0x and be exactly 64 characters.

See also the example passwords below.

Valid channels are 1 to 11 for the 2.4 GHz band and 36, 40, 44, 48 for the 5 GHz band.

Password examples

For plain text passwords a combination of upper and lower case letters, numbers, and special

characters is recommended.

Example of a strong plain text password:

uS78_xpa&43

Example of hexadecimal password:

0x000102030405060708090a0b0c0d0e0f101112131415161718191a1b1c1d1e1f

Do not use the example passwords above in a live environment!

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 23

Configuration 21 (40)

4.2.6 Bluetooth Settings – General

Fig. 11 Bluetooth Settings

Enable

Operating Mode PANU (Client) = The unit will operate as a Bluetooth PAN (Personal Area Network) User

Local Name Identifies the unit to other Bluetooth devices. If left blank, the unit will use a default

Connectable Enable to make the unit accept connections initiated by other Bluetooth devices.

Discoverable Enable to make the unit visible to other Bluetooth devices.

Security Mode Disabled = No encryption or authentication.

Paired Devices Lists the currently connected Bluetooth devices.

Enable/disable the Bluetooth interface.

device. It can connect to another single Bluetooth PANU device or to a Bluetooth

Network Access Point.

NAP (Access Point) = The unit will operate as a Bluetooth Network Access Point. It can

connect to up to 7 Bluetooth PANU devices.

name including the last 6 characters of the MAC ID.

PIN = Encrypted connection with PIN code security. This mode only works between two

units of this type and brand (not with third-party devices). PIN codes must consist of 4 to

6 digits.

Just Works = Encrypted connection without PIN code.

®

Anybus

Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 24

Configuration 22 (40)

4.2.7 Bluetooth Settings – PANU Mode

Fig. 12 Bluetooth Settings – PANU

PANU mode only

Scan for Devices Scans the network for discoverable Bluetooth devices. To connect to a device, select it

Connect To

Connection Scheme Choose whether to select a Bluetooth device by MAC address (default) or Name when

MAC/Name

from the dropdown menu when the scan has completed.

Used when connecting manually to a NAP or PANU device.

connecting manually.

Connecting to MAC will lock the connection to a specific hardware while connecting to

Name allows for more flexibility.

MAC address or Name of the Bluetooth device to connect to.

®

Anybus

Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 25

Configuration 23 (40)

4.2.8 Bluetooth Settings – NAP Mode

Fig. 13 Bluetooth settings – NAP

NAP mode only

Bridge Mode Standard = Default mode.

Layer 3 IP forward = IP data will be bridged over Bluetooth.

This mode must be used when connecting to an Android device over Bluetooth. The

network must have an active DHCP server.

List Nearby Devices Scans the network and lists discoverable Bluetooth devices.

Pairing cannot be initiated in NAP mode.

®

Anybus

Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 26

Configuration 24 (40)

4.2.9 Bluetooth LE Settings

Fig. 14 Bluetooth LE settings

Bluetooth LE Settings

Operating Mode Disabled = Bluetooth LE disabled (default)

Central = Bluetooth LE enabled

Please refer to the AT Commands Reference Guide or select Help in the main menu for more

information about using Bluetooth LE.

Bluetooth must be enabled on the Bluetooth Settings page to use Bluetooth LE.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 27

Configuration 25 (40)

4.2.10 Firmware Update

To update the firmware in the unit, click on Browse to select a downloaded firmware file, then

click on Send to send it to the unit.

Fig. 15 Firmware update in progress

Both progress bars will turn green when the firmware update has been completed. The unit will

then reboot automatically.

Fig. 16 Firmware update completed

Updating the firmware will not change the configuration settings.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 28

Configuration 26 (40)

4.2.11 AT Commands

Fig. 17 AT Commands

AT commands can be used for setting advanced parameters that are not accessible in the web

interface, to read out parameters in text format, and for batch configuration using command

scripts.

Enter or paste the commands into the text box, then click on Send. The result codes will be

displayed below the text box.

Click on Help for a complete list of supported AT commands.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 29

Configuration 27 (40)

4.2.12 System Settings

Fig. 18 System Settings

Device Info

Device Name

Password Enter a password for accessing the web interface.

Reboot System Reboots the system without applying changes.

Cancel All Changes Restores all parameters in the web interface to the currently active values.

Factory Reset

Enter a descriptive name for the unit.

Resets the unit to the factory default settings and reboots.

Setting a secure password for the unit is strongly recommended.

Settings Backup

Create Settings Backup Click on Generate to save the current configuration to a file on your computer.

Restore Settings Click on Choose file and select a previously saved configuration, then click on Load. The

General Configuration

settings in the saved configuration will be applied and the unit will reboot.

®

Anybus

Wireless Bolt™User Manual

Reboot System Reboots the system without applying changes.

Cancel All Changes Restores all parameters in the web interface to the currently active values.

Factory Reset

Resets the unit to the factory default settings and reboots.

SCM-1202-007 2.6 en-US

Page 30

Configuration 28 (40)

4.3 Factory Restore

Any one of these actions will restore the factory default settings:

• Clicking on Factory Restore on the System Settings page

• Executing Easy Config Mode 2

• Issuing the AT command AT&F and then restarting the unit

• Holding RESET pressed for >10 seconds and then releasing it

• Applying voltage to the digital input for >10 seconds

Default Network Settings

IP Assignment Static

IP Address

Subnet Mask

Default Gateway

Internal DHCP Server Disabled

Default WLAN Settings

Operating Mode Client

Channel Bands

Authentication Mode

Channel

Bridge Mode Layer 3 IP forward

192.168.0.99

255.255.255.0

192.168.0.99

2.4 GHz & 5 GHz

WPA/WPA2–PSK

Auto

Default Bluetooth Settings

Operating Mode PANU (Client)

Local Name [generated from MAC address]

Connectable

Discoverable

Security Mode Just works

Bluetooth LE Disabled

No

No

®

Anybus

Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 31

Appendix A: Configuration Examples 29 (40)

A Configuration Examples

A.1 Ethernet Bridge via WLAN or Bluetooth

Configuration with Easy Config

Fig. 19 Ethernet bridge

This example describes how to connect two Ethernet network segments via WLAN or Bluetooth

using Easy Config.

1. In the web interface of unit 1, activate Easy Config Mode 4. This unit will now be

discoverable and open for automatic configuration.

Fig. 20 Easy Config Mode 4

®

2. In the web interface of unit 2, activate Easy Config Mode 5 for WLAN or 6 for Bluetooth.

This unit should now automatically discover and configure unit 1 as a client, and configure

itself as an access point.

Fig. 21 Easy Config Mode 5

Unit 1 will automatically be assigned the first free IP address within the same Ethernet

subnet as unit 2.

Adding More Devices

Up to 6 additional clients can be added by repeating the procedure. Each new client will be

assigned the next free IP address within the current subnet.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 32

Appendix A: Configuration Examples 30 (40)

A.2 PROFINET networking via Bluetooth

Configuration with Easy Config

Fig. 22 PROFINET wireless network

This example describes how to connect a PROFINET IO device and a PROFINET PLC over

Bluetooth using two Wireless Bolts and Easy Config.

The Wireless Bolts will be configured with PROFINET optimization, which means that PROFINET

messages will have priority over TCP/IP frames.

See the respective documentation for the IO device and PLC on how to configure them for

PROFINET communication.

Configuration

1. Reset both Wireless Bolts to the factory default settings.

®

2. Connect Wireless Bolt 1 to the IO device and Wireless Bolt 2 to the PLC.

3. Set Wireless Bolt 1 to Easy Config Mode 4.

This unit will now be discoverable and open for automatic configuration.

4. Set Wireless Bolt 2 to Easy Config Mode 8

This unit should now automatically discover and configure unit 1 as a Bluetooth client, and

configure itself as an access point. Both units will be optimized for PROFINET.

The IO device should now be able to communicate with the PLC as if using a wired connection.

Adding More Devices

Up to 6 additional clients can be added by repeating the procedure. Each new client will be

assigned the next free IP address within the current subnet.

The IO cycle update time for each IO device must be set to ≥ 64 ms.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 33

Appendix A: Configuration Examples 31 (40)

A.3 EtherNet/IP™Networking via Bluetooth

Configuration with Easy Config

Fig. 23 EtherNet/IP wireless network

This example describes how to connect an EtherNet/IP IO device and an EtherNet/IP PLC over

Bluetooth using two Wireless Bolts and Easy Config.

See the respective documentation for the IO device and PLC on how to configure them for

EtherNet/IP communication.

Configuration

1. Reset both Wireless Bolts to the factory default settings.

2. Connect Wireless Bolt 1 to the IO device and Wireless Bolt 2 to the PLC.

3. Set Wireless Bolt 1 to Easy Config Mode 4.

®

This unit will now be discoverable and open for automatic configuration.

4. Set Wireless Bolt 2 to Easy Config Mode 6

This unit should now automatically discover and configure unit 1 as a Bluetooth client, and

configure itself as an access point.

The IO device should now be able to communicate with the PLC as if using a wired connection.

Adding More Devices

Up to 6 additional clients can be added by repeating the procedure. Each new client will be

assigned the next free IP address within the current subnet.

The Requested Packet Interval (RPI) for each IO device must be set to ≥ 64 ms.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 34

Appendix A: Configuration Examples 32 (40)

A.4 Ethernet network to existing WLAN

Fig. 24 Connecting to a WLAN

This example describes how to connect a machine with an internal Ethernet network to an

existing WLAN.

This setup allows traffic on network layer 3, but not layer 2. This means that TCP/IP based

protocols such as EtherNet/IP, Modbus TCP and BACnet can be used on the WLAN, but not

protocols that use layer 2 traffic, such as PROFINET.

Configuration

1. Reset the Wireless Bolt to the factory default settings.

2. In Network Settings, configure the IP settings as required by the wireless network.

3. If the network uses DHCP, select DHCP Relay Enabled.

4. In WLAN Settings, click on Scan for Networks.

5. When the scan has completed, select the wireless network from the dropdown list.

6. If required, select the authentication mode and enter the passkey for the wireless network.

WLAN Bridge Mode must be set to Layer 3 IP forward (the default setting).

7. Click on Save and Reboot.

The Ethernet network should now be able to access the WLAN access point.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 35

Appendix A: Configuration Examples 33 (40)

A.5 Adding single Ethernet node to WLAN

Fig. 25 Adding WLAN connectivity

This example shows how to connect a PLC with an Ethernet network interface to an existing

WLAN with support for layer 2 and layer 3 traffic. The WLAN interface in the Wireless Bolt will

clone the MAC address of the Ethernet interface in the PLC.

Only a single Ethernet node will be able to communicate via a third-party WLAN access point in

this setup.

Configuration

1. Reset the Wireless Bolt to the factory default settings.

2. In Network Settings, configure the IP settings as required by the wireless network.

3. In WLAN Settings, click on Scan for Networks.

4. When the scan has completed, select the wireless network from the dropdown list.

5. If required, select the authentication mode and enter the passkey for the wireless network.

6. Click on Save and Reboot.

7. Check the System Overview page to confirm that the WLAN connection is established

before continuing.

DO NOT SKIP THIS STEP! After the final steps of the configuration procedure the web

interface may no longer be accessible from the network without doing a factory reset.

8. In WLAN Settings, set Bridge Mode to Layer 2 cloned MAC only.

9. Enter the MAC address of the PLC in the Cloned MAC Address field.

10. Click on Save and Reboot.

The Wireless Bolt will now function as a WLAN interface for the PLC using the MAC address of its

Ethernet interface.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 36

Appendix A: Configuration Examples 34 (40)

A.6 Accessing PLC via WLAN from Handheld Device

Fig. 26 Accessing a PLC from a handheld device using WLAN

This example describes how to use a Wireless Bolt to access the web interface of a PLC on a

wired network from a tablet or smartphone which uses DHCP. The Wireless Bolt will function as

a WLAN access point.

Please refer to the documentation for the handheld device and PLC on how to configure their

respective network settings.

Configuration

1. Reset the Wireless Bolt to the factory default settings.

2. In Network Settings, configure the IP settings as required.

a. If the wired network uses DHCP, select DHCP Relay Enabled. The DHCP server on the

network will now be able to allocate an IP address to the handheld device.

b. If the wired network uses static IP, select DHCP Server Enabled and set a Start Address

for DHCP addressing. Make sure that the address range does not contain any existing

addresses on the network.

The Wireless Bolt will now function as a DHCP server and allocate an IP address to the

handheld device over WLAN.

Do not enable the internal DHCP Server if there is already a DHCP server on the network,

as this may cause IP address conflicts.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 37

Appendix A: Configuration Examples 35 (40)

3. In WLAN Settings, set Operating Mode to Access Point.

Fig. 27 WLAN Settings

4. Enter a unique SSID (network name) for the new wireless network.

5. Set Authentication Mode to WPA2 and enter a passkey.

6. Select a Channel band and a Channel.

7. Click on Save and Reboot.

You should now be able to connect to the SSID of the Wireless Bolt on your handheld device and

access the PLC by by entering its IP address in a browser.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 38

Appendix B: Wireless Technology Basics 36 (40)

B Wireless Technology Basics

Wireless technology is based on the propagation and reception of electromagnetic waves. These

waves respond in different ways in terms of propagation, dispersion, diffraction and reflection

depending on their frequency and the medium in which they are travelling.

To enable communication there should optimally be an unobstructed line of sight between the

antennas of the devices. However, the so called Fresnel Zones should also be kept clear from

obstacles, as radio waves reflected from objects within these zones may reach the receiver out

of phase, reducing the strength of the original signal (also known as phase cancelling).

Fresnel zones can be thought of as ellipsoid three-dimensional shapes between two wireless

devices. The size and shape of the zones depend on the distance between the devices and on the

signal wave length. As a rule of thumb, at least 60 % of the first (innermost) Fresnel zone must

be free of obstacles to maintain good reception.

Fig. 28 Fresnel zones

Area to keep clear of obstacles (first Fresnel zone)

Distance (d)

100 m 1.7 m 1.2 m

200 m 2.5 m 1.7 m

300 m 3.0 m 2.1 m

400 m 3.5 m 2.4 m

2.4 GHz (WLAN or Bluetooth) 5 GHz (WLAN)

Fresnel zone radius (r)

The wireless signal may be adequate even if there are obstacles within the Fresnel zones, as it

always depends on the number and size of the obstacles and where they are located. This is

especially true indoors, where reflections on metal objects may actually help the propagation of

radio waves. To reduce interference and phase cancelling, the transmission power of the unit

may in some cases have to be reduced to limit the range.

It is therefore recommended to use a wireless signal analysis tool for determining the optimal

placement and configuration of a wireless device.

Anybus®Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 39

Appendix C: Technical Data 37 (40)

C Technical Data

C.1 Hardware Specifications

Order code

Color Black White top and black base

Wired interface type Ethernet

Connector

Antenna

Maximum range

Operating temperature

Storage temperature

Humidity EN 600068-2-78: Damp heat, +40°C, 93% humidity for 4 days.

Vibration See datasheet

Dimensions

Weight

Housing material Plastic (see datasheet for details)

Protection class

Mounting

Power supply 9–30 VDC (-5 % +20 %)

Power consumption

AWB2000 AWB2001

Included plug connector

Internal dual-band 2.4 GHz and 5 GHz antenna

100 m (WLAN and Bluetooth)

Shadow: -40 to +65 °C

Direct sunlight: -40 to +45 °C

-40 to +85 °C

Height: 75 mm (95 mm incl. connector, 41 mm outside)

Diameter: 68 mm

81 g

Top (outside of host): IP67 / UL NEMA 4X

Base (inside of host): IP21

M50 screw and nut (50.5 mm hole needed)

Cranking 12 V (ISO 7637-2:2011 pulse 4)

Reverse polarity protection

0.7 W idle, 1.7 W max.

Shadow: -40 to +65 °C

Direct sunlight: -40 to +65 °C

®

Anybus

Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 40

Appendix C: Technical Data 38 (40)

C.2 Communication

Ethernet

Ethernet interface

Ethernet protocols

Wireless LAN

Wireless standards IEEE 802.11 a, b, g, n, d, r

Operation modes Access point or client

Fast roaming

Max. number of clients

for access point

WLAN channels

RF output power

Power consumption 54 mA @ 24 VDC

Net data throughput 20 Mbps.

Link speed Max 65 Mbps (802.11n SISO)

Security

10/100BASE-T with automatic MDI/MDIX auto cross-over detection

IP, TCP, UDP, HTTP, LLDP, ARP, DHCP Client/Server, DNS support

PROFINET IO, EtherNet/IP, Modbus-TCP

IEEE 802.11r (client)

7

2.4 GHz Access Point: 1–11

2.4 GHz Client: 1–11 + 12 & 13 depending on regulatory domain scan

5 GHz Access Point: 36–48 (U-NII-1)

5 GHz Client: 36-48 + 100–116, 132–140, 120–128 depending on regulatory domain scan. (U-

NII-1, U-NII-2, U-NII-2e)

18 dBm EIRP (including max antenna gain 3 dBi)

WEP 64/128, WPA, WPA-PSK and WPA2, TKIP and AES/CCMP, LEAP, PEAP including MS-CHAP

Classic Bluetooth

Wireless standards (profiles) PAN (PANU & NAP)

Operation modes Access point or Client

Max. number of clients

for access point

RF output power

Power consumption 36 mA @ 24 VDC

Net data throughput ~1 Mbps

Bluetooth version support Classic Bluetooth v2.1

Security

7

14 dBm EIRP (including max antenna gain 3 dBi)

Authentication & Authorization, Encryption & Data Protection, Privacy & Confidentiality, NIST

Compliant, FIPS Approved

Bluetooth Low Energy

Wireless standards (profiles)

Operation modes Central or Peripheral (pending)

Max. number of clients

for Central

RF output power

Power consumption 36 mA @ 24 VDC

Net data throughput ~200 kbps

Bluetooth version support Bluetooth 4.0 dual-mode

Security AES-CCM cryptography

GATT

7

10 dBm EIRP (including max antenna gain 3 dBi)

®

Anybus

Wireless Bolt™User Manual

SCM-1202-007 2.6 en-US

Page 41

This page intentionally left blank

Page 42

last page

© 2019 HMS Industrial Networks

Box 4126

300 04 Halmstad, Sweden

info@hms.se SCM-1202-007 2.6 en-US / 2019-03-06 / 12172

Loading...

Loading...