Anybus AWB1, Wireless Bolt IoT, AWB1000, AWB1001 SAFETY AND COMPLIANCE INFORMATION [ml]

SAFETY AND COMPLIANCE

INFORMATION

Anybus®Wireless Bolt IoT

AWB1

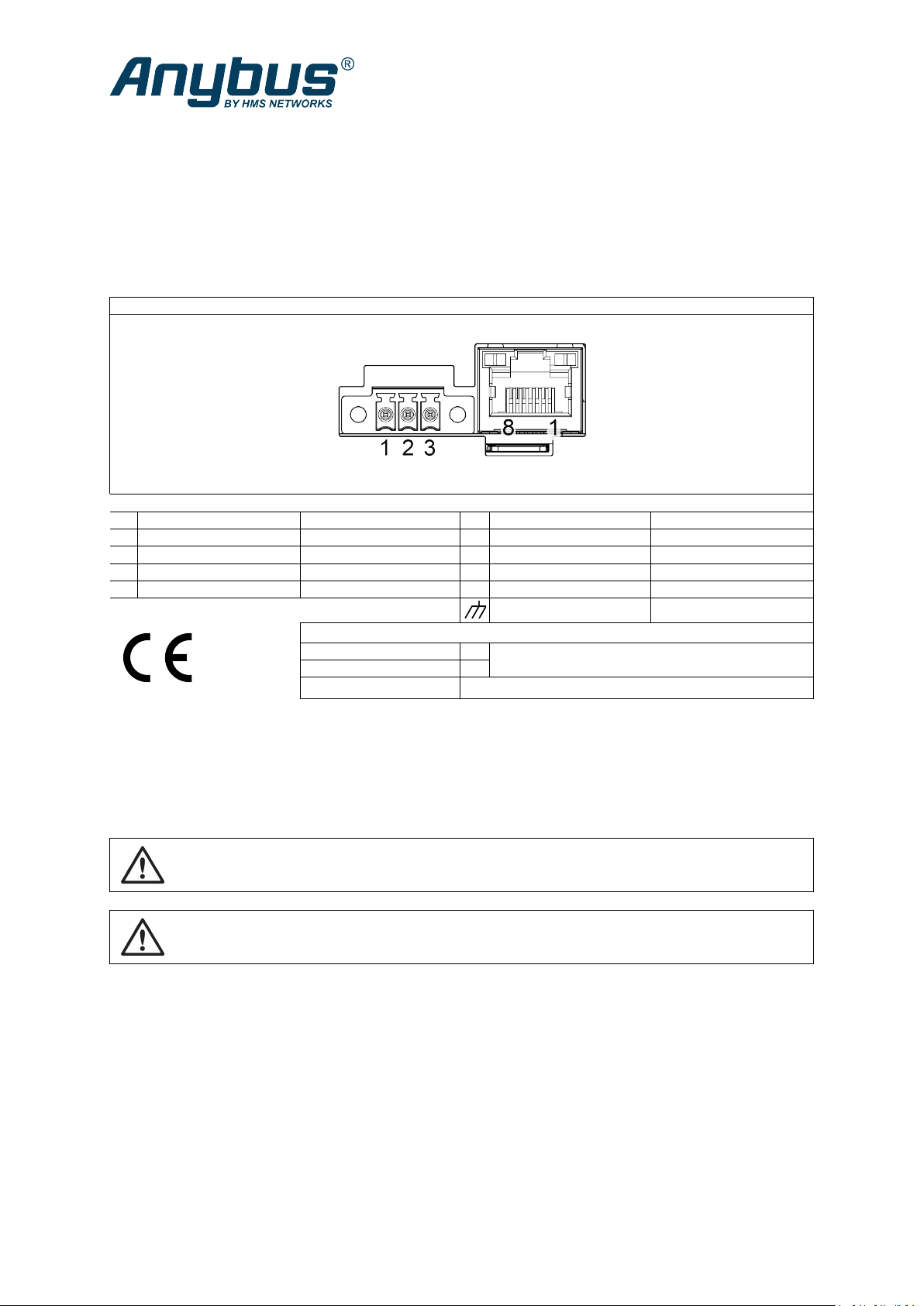

Ethernet Connector RJ45 PoE

Data PoE

Pin

1 TD+ A+ 5 B+

2 TD- A+ 6 RD- A3 RD+ A- 7 B4 B+ 8 B-

Power Connector 3-pin

1

2

3

™

Data PoE

Pin

Shield

+

11–33 VDC

-

Functional Earth (FE)

FE

Safety and Compliance Information

Warning Levels

WARNING

Instruction that must be followed to avoid a risk of death or serious injury.

Caution

Instruction that must be followed to avoid a risk of personal injury.

© 2020 HMS Industrial Networks

SP2728 1.1 mul / 2020-12-16 / 21110

Anybus®Wireless Bolt IoT™Safety and Compliance Information 2 (4)

General Safety Instructions

Caution

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the

equipment may be impaired.

Caution

This product contains parts that can be damaged by electrostatic discharge (ESD). Use ESD prevention

measures to avoid damage.

Intended Use

The intended use of this equipment is as a communication interface and router. The equipment receives and

transmits data over Ethernet and Cellular standard networks.

Type Identification

The type name consists of a type prefix followed by two designators for interface configuration and

functionality.

Prefix

Interface configuration

Functionality

AWB1

A

A

Anybus Wireless Bolt IoT

RJ45 and 3-pin power socket, LTE-NB

Ethernet

Example: AWB1AA = RJ45, 3pin power socket, LTE-NB and Ethernet functionality.

Installation

Make sure that the sealing ring is correctly placed in the circular groove in the top part of the housing

before tightening the nut.

Always hold the BOTTOM part of the unit when untightening the nut, not the top part (the cap).

• Make sure that you have all the necessary information about the capabilities and restrictions of your local

network environment before installation.

• The device is intended to be mounted on top of a machine or cabinet through an M50 (50.5 mm) hole

using the included sealing ring and nut. The top mounting surface (in contact with the sealing) must be

flat with a finish equivalent to Ra 3.2 or finer and cleaned and free from oils and greases.

• Tightening torque: 5 Nm ±10 %

• Transient protection shall be provided if the Ethernet cables are to be exposed in an outdoor environment.

• Use minimum 90 °C copper (Cu) wire only.

• Use in Overvoltage Category II Pollution Degree 2 Environment conforming to EN 60664-1.

• This equipment is designed to comply as Class III equipment according to

61010-2-201.

© 2020 HMS Industrial Networks

SP2728 1.1 mul / 2020-12-16 / 21110

Loading...

Loading...