Page 1

Place this chapter in the Bun Toaster section

of your Equipment Manual.

MANUFACTURED

EXCLUSIVELY FOR

McDONALD'S® BY

A.J. ANTUNES & CO. 1025 NATIONAL

AVE. ADDISON, ILLINOIS 60101,

U.S.A. PHONE: 1 (630)543-8650 TOLL

FREE: 1-800-253-2991

FAX: 1 (630) 543-0359

THIS OWNER'S MANUAL IS FOR THE FOLLOWING

MANUFACTURING NUMBERS: 9200265,9200266, 9200272

& 9200273

Equipment manufactured by Roundup Food Equipment Division of A. J. Antunes & Co. has been constructed of the finest materials available and

manufactured to high quality standards. These units are warranted to be free from mechanical and electrical defects for a period of one year from

date of purchase under normal use and service, and when installed in accordance with manufacturer's recommendations. To insure continued

proper operation of the units, follow the maintenance procedure outlined in the Owner's Manual.

1. This warranty does not cover cost of installation, defects caused by improper storage or handling prior to placing of the Equipment. This warranty

does not include overtime charges or work done by unauthorized service agencies or personnel. This warranty does not cover normal

maintenance, calibration, or regular adjustments as specified in operating instructions, or manuals (see Owner's Manual of specific product): and/or

labor involved in moving adjacent objects to gain access to the Equipment. This warranty does not cover consumable items such as grill covers,

gaskets, O-rings and bulbs. This warranty does not pay travel, mileage, or any other charges for a service to reach the equipment's location (unless

stated in the Owner's Manual).

2. Roundup reserves the right to make changes in design or add any improvements on any product. The right is always reserved to modify equipment

because of factors beyond our control and government regulations. Charges to update equipment do not constitute a warranty charge.

3. If shipment is damaged in transit the purchaser should make his claim directly upon the carrier. Careful inspection should be made of the

shipment as soon as it arrives and visible damage should be noted upon the carrier's receipt. Damage should be reported to the carrier. This

damage is not covered under this warranty.

4. Warranty charges do not include freight or foreign, excise, municipal or other sales or use taxes. All such freight and taxes are the responsibility of

the purchaser.

5. THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, EACH OF WHICH IS HEREBY EXPRESSLY

DISCLAIMED. THE REMEDIES DESCRIBED ABOVE ARE EXCLUSIVE AND IN NO EVENT SHALL ROUNDUP BE LIABLE FOR SPECIAL

CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE BREACH OR DELAY IN PERFORMANCE OF THIS WARRANTY.

1010691 5/97

This manual is for the exclusive use of licensees and employees of McDonald's Systems, Inc.

© 1997 McDonald's Corporation Printed in

All Rights Reserved The United States of America

Page 2

INTRODUCTION

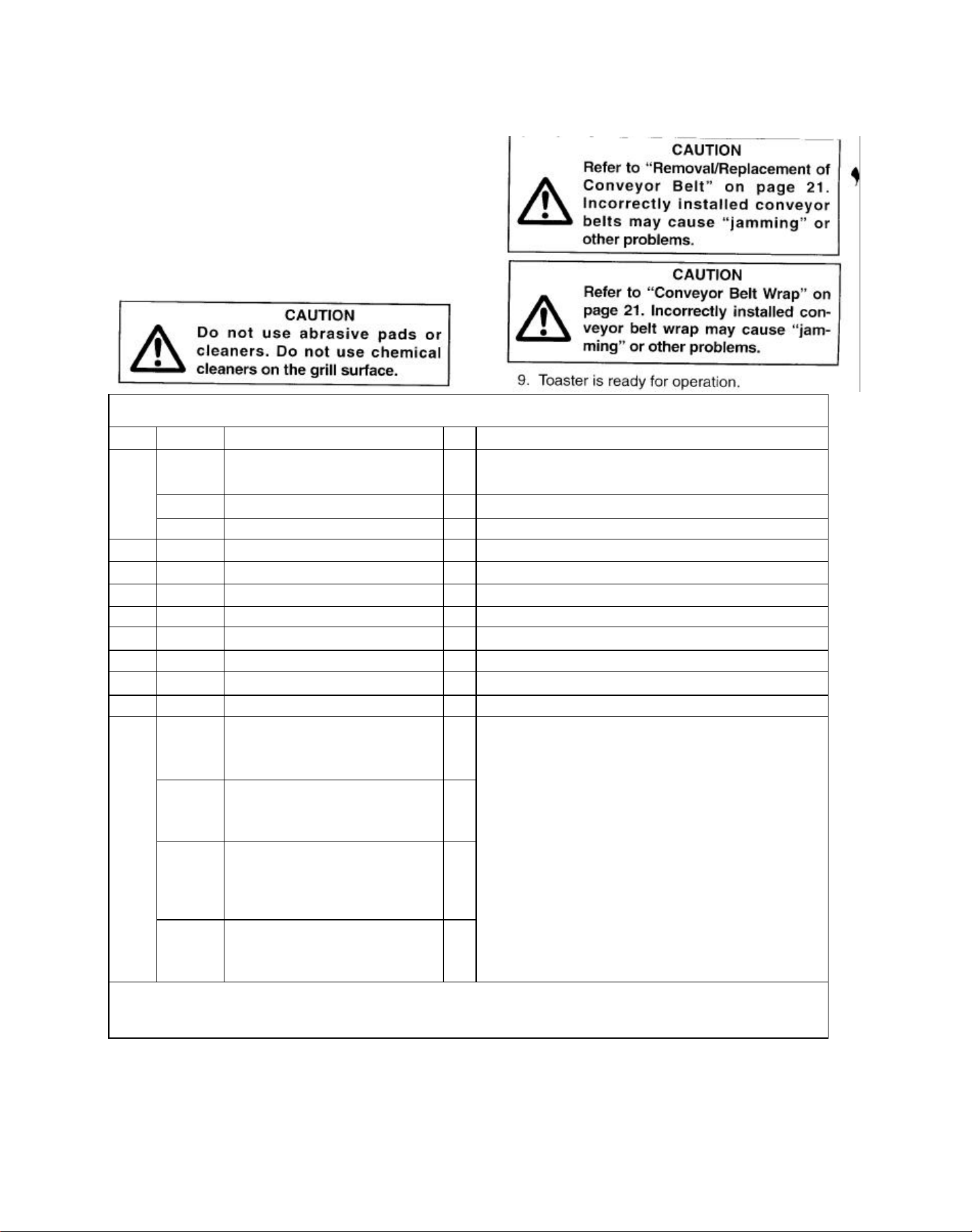

The Antunes Vertical Contact Toaster, Model VCT-22

is designed for contact toasting of buns. The toaster is

designed to allow the operator to place the buns on

both sides of the heated platen at the same time. Buns

are placed into the bun feeder on the top of the

toaster. Uniform golden-brown, warm buns are

retrieved at the base of the toaster.

Hazard Communication Standard (HCS) — The

procedures in this chapter include the use of

chemical products. These chemical products will

be highlighted with bold face letters followed by

the abbreviation (HCS). See Hazard

Communication Standard (HCS) Manual for the

appropriate Material Safety Data Sheet(s) (MSDS).

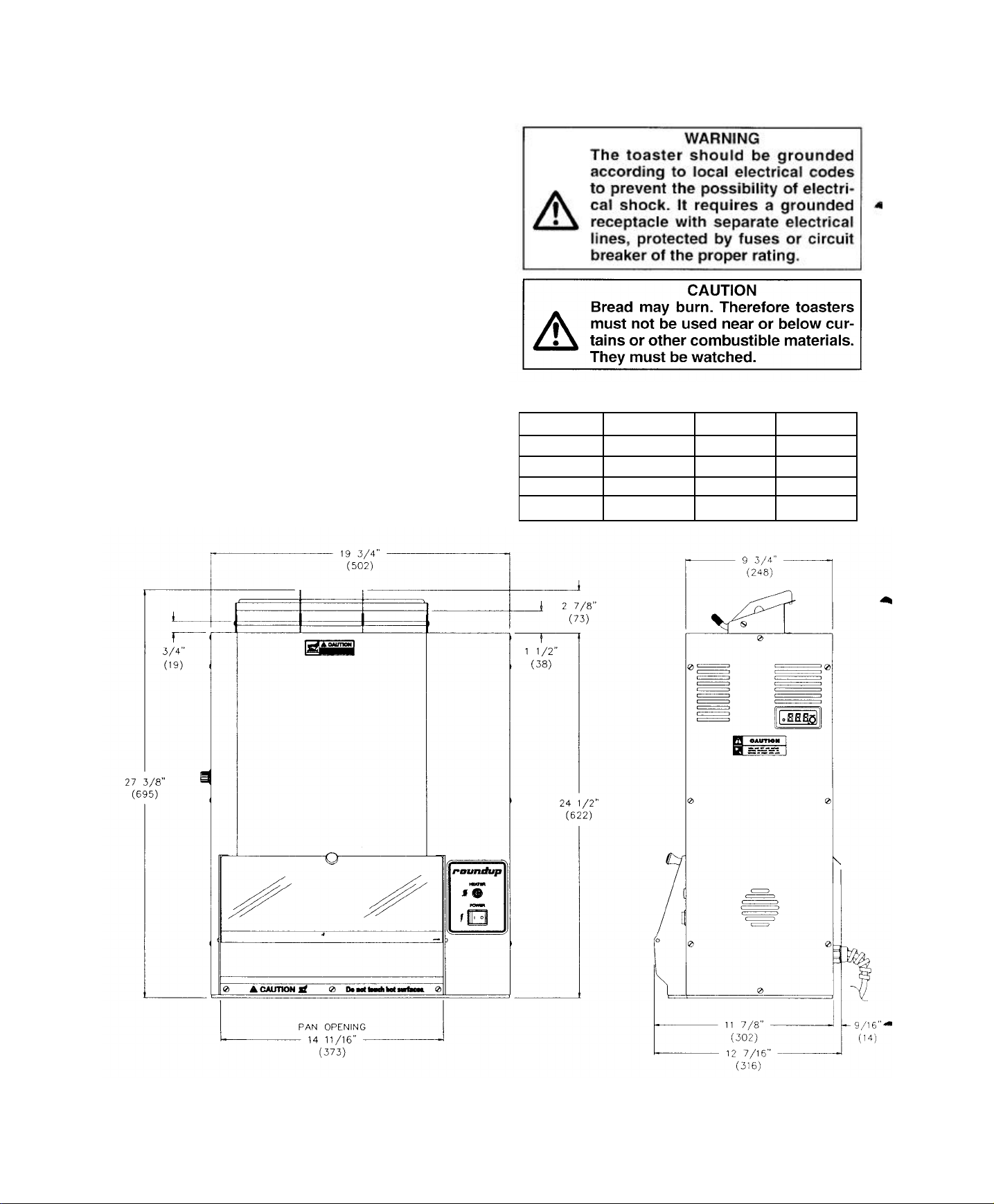

DIMENSIONS

19 1/2 inches (495 mm) wide 12 7/16

inches (316 mm) deep 27 3/8 inches

(695 mm) high

ELECTRICAL RATINGS:

VOLTAGE WATTS AMPS HERTZ

208 2750 13.22 50/60

220 3077 13.99 50/60

230 3363 14.62 50/60

240 3662 15.26 50/60

Page 3

ORDERING/SERVICE INFORMATION

Use only genuine Antunes replacement parts in this

unit. Use of replacement parts other than those

supplied by the manufacturer voids the warranty and

U.L. status.

Your Authorized Service Agency has a parts price list

and inform you of the cost of parts.

Parts Location - To find items you want to order from

the Parts List, proceed as follows:

1. Look at the parts drawing to locate the correct

part needed.

2. Use the item number from the parts drawing to

locate the correct parts in the Parts List. This

section will have the Antunes part number and a

description of the part.

Ordering Information - After finding the parts you want

to order on the Parts List, write down the following

information.

Commonly replaced items are stocked by your

Authorized Service Agency and will be sent out when

your order is received. Other parts will be ordered by

your Authorized Service Agency from A.J. Antunes &

Co.

If technical help is needed, contact the factory service

department. Please have the following information

ready when you call our factory service department:

*Fill in for your records. AUTHORIZED

RETURN POLICY:

No product may be returned without Antunes' prior

written approval. Transportation charges are to be

prepaid by Buyer. Returned goods are subject to

Antunes' inspection and acceptance. Antunes may, at

its discretion, replace any or all returned items within a

reasonable time after Antunes determines that the

returned goods are not in accordance herewith; and in

such event Antunes shall not be liable for any

damages arising from the defective delivery or delay

caused thereby. When expressly authorized by

Antunes in writing, unused products may be returned

to Antunes, subject to service handling, restocking and

rebuilding charges to "as new" condition.

Page 4

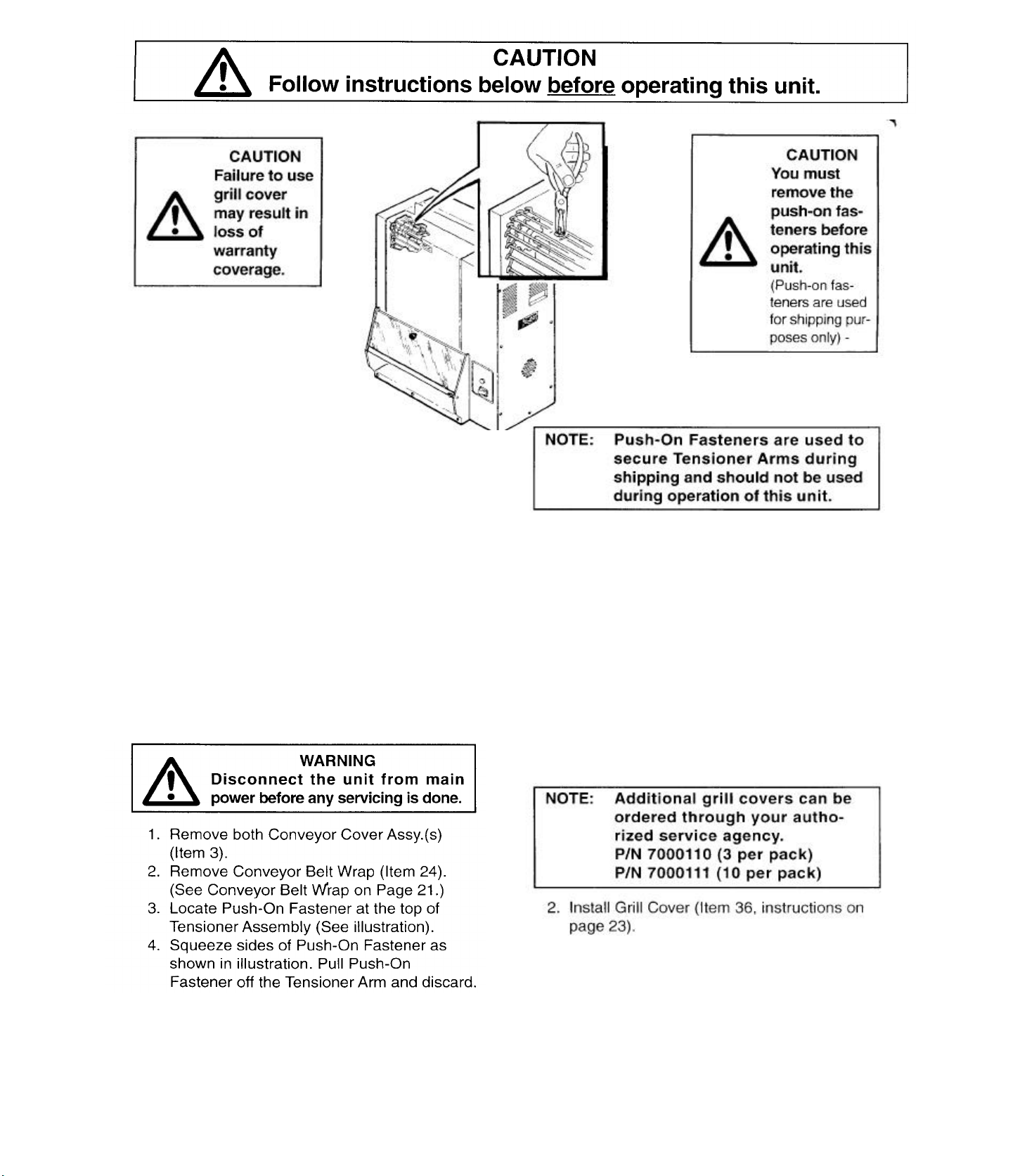

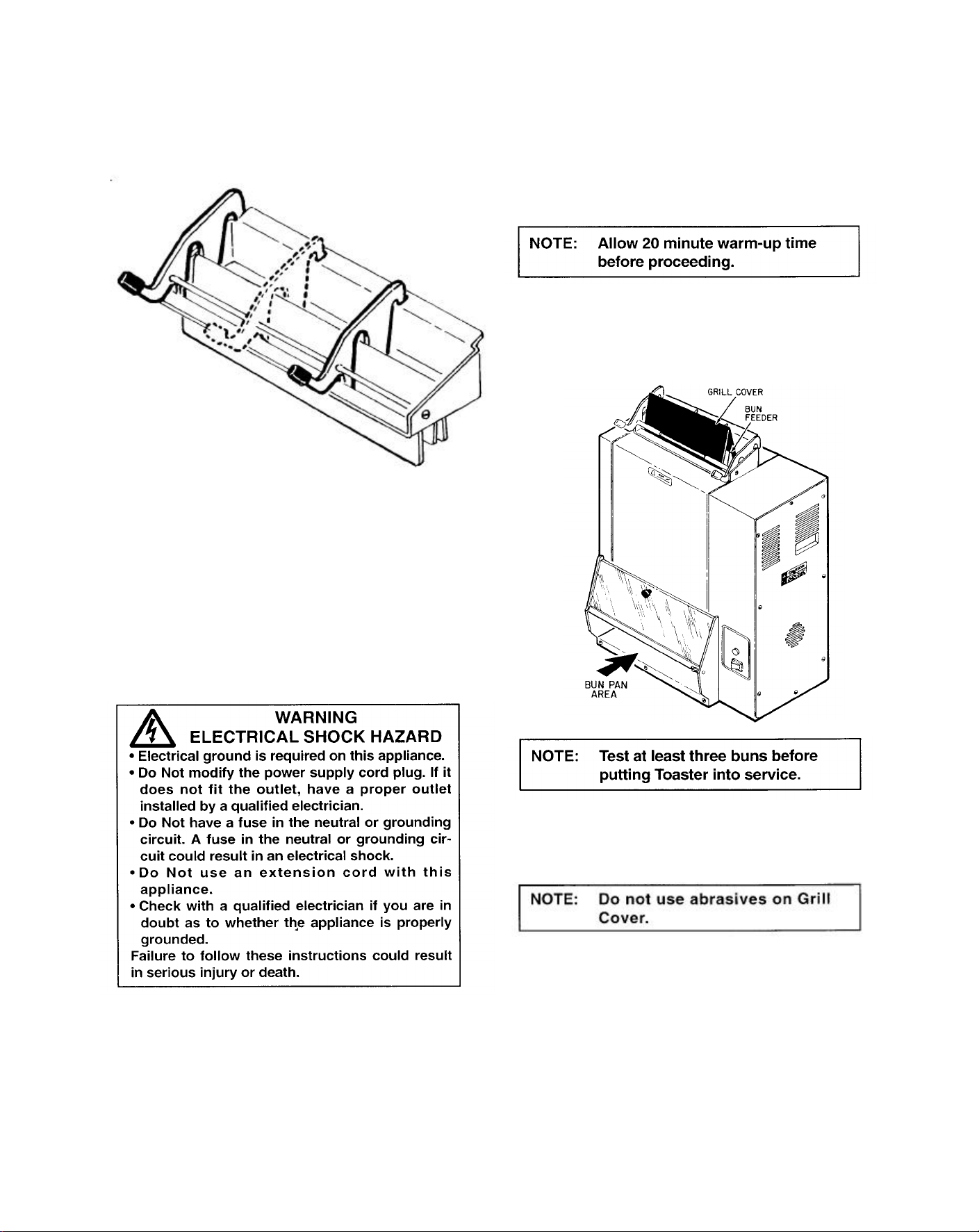

REMOVE PUSH-ON FASTENERS FROM

INSTALLATION

THE TENSIONERS ON MODEL VCT-22

• This procedure removes the Push-On Fasteners

from the Tensioners on your VCT-22. The PushOn Fasteners are needed for shipping only and

are not required for operation.

• This Toaster has four (4) Tensioner Assemblies,

two (2) on each side. Each Tensioner Assembly

has four (4) Push-On Fasteners, two at the top

and two at the bottom. This is a total of sixteen

(16) Push-On Fasteners. We recommend

removing ALL the Push-On Fasteners during

this procedure.

5. Locate and remove the remaining Push-On

Fasteners.

6. Install Conveyor Belt Wrap.

7. Reattach the Conveyor Cover Assy.(s).

8. Test operation of Toaster before returning to

service.

The toaster is shipped completely wired and ready

to connect to a grounded power supply.

To set up the toaster for operation: 1.

Install Bun Feeder (Item 26).

Page 5

3. Adjust Divider Weldment(s) on Bun Feeder to fit

buns being toasted.

Set bun adjustment knobs found on left side (Item

30) of unit: Back should be set to 11/16", (#5) for

bun crowns (top) and the front should be set to

1/2", (#2) for bun heels (bottom).

OPERATION

1. Connect Unit to power supply.

2. Turn bun adjustment knobs (Item 30) to

desired setting.

3. Move Rocker Switch (Item 20) to "ON"

position.

4. Drop buns into Toaster. Cut sides of heel

and crown must face each other (heel in

front, crown in back).

5. Toasted heel and crown will drop into the Bun

Pan (Not included).

5. Connect Toaster to power supply (See

Specification Plate for proper voltage).

6. Unit is now ready for operation.

DAILY MAINTENANCE

When the toaster is cool, remove the Grill Cover

and Bun Feeder. Clean with soap and water and

allow to air dry.

Re-install all parts after drying.

MONTHLY MAINTENANCE

1. Move Rocker Switch (Item 20) to "OFF"

position and unplug power cord.

2. Perform daily maintenance.

3. Remove Conveyor Belt Wrap. (See "Conveyor

Belt Wrap", Page 21).

Page 6

8. Reverse above procedures to assemble the

4. Remove Conveyor Belts (See "Conveyor Belt",

Page 21).

5. Remove both Tensioner assemblies (Item 4) by

pressing down lightly on the rods until they are

free from the Rod Brackets (Item 27). Lift both

tensioners up and out of the unit.

6. Clean Belts and Tensioners with soap and water,

and allow to air dry.

7. Clean the grill surface with a clean, damp cloth

and allow to air dry.

PARTS IDENTIFICATION AND FUNCTION

ITEM PART NO. DESCRIPTION QTY FUNCTION

toaster.

1 0010190 CONVEYOR BELT 2 FLEXIBLE ASSEMBLY USED TO MOVE BUNS THROUGH THE

0800204 1/2" PITCH LINK (SMALL) 3 SMALLER COMPONENT OF CONVEYOR BELT.

0800121 3/4" PITCH LINK (LARGE) 38 LARGER COMPONENT OF CONVEYOR BELT.

2 2150117 IDLER SHAFT 2 SERVES AS UPPER AXLE FOR CONVEYOR BELT.

3 0011189 CONVEYOR COVER ASSY 2 SHEET METAL PART COVERING MOVING PARTS.

4 0011135 TENSIONER ASSY 4 GUIDES CONVEYOR BELT.

5 0800332 ROD, CONVEYOR COVER 2 BOTTOM SUPPORT FOR CONVEYOR COVER ASSY.

6 215K111 SPROCKET 8 USED TO MOVE CONVEYOR BELT.

7 212K103 SPACER KIT 1 METAL RING USED TO CORRECTLY POSITION DRIVE SHAFT.

8 0021107 CONTROL COVER WELDMENT 1 SHEET METAL PART COVERING ELECTRICAL PARTS.

9 2150118 DRIVE SHAFT 2 SERVES AS LOWER AXLE FOR CONVEYOR BELT.

10 0700535 POWER CORD/PLUG ASSY

20A/#320P6W PIN AND SLEEVE PLUG,

(VCT-22 CD, #9200261)

0700552 POWER CORD/PLUG ASSY 20A, L6-20P

TWIST-LOCK PLUG -STRAIGHT (VCT22CS, #9200263)

0700437 POWER-CORD/PLUG ASSY 16A/ICE309

#316P6W PIN AND SLEEVE PLUG, (VCT

22 HI, #9200270)

TOASTER.

1 TRANSFERS ELECTRIC POWER TO THE UNIT.

1

1

0700453 HARMONIZED POWER CORD WITH 16A,

CEE 7/7 SCHUKO PLUG (VCT 22 HC,

#9200271)

6

1

Page 7

ITEM PART NO. DESCRIPTION QTY FUNCTION

11 0011131 TEMPERATURE CONTROL 1 MAINTAINS AND CONTROLS HEAT TO GRILL.

ASSY.

11A 407K025 TEMPERATURE CONTROL 1

DISPLAY

11B 407K024 CONTROL BOARD, 1

TRANSFORMER/RELAY

12 2150158 BALL BEARING 2 ALLOWS SMOOTH ROTATION OF DRIVE SHAFTS.

13 050K115 BEARING RETAINER KIT 1 POSITIONS AND HOLDS BALL BEARING.

14 2150109 DRIVE SPROCKET-16 TOOTH 1 TOOTHED METAL PART THAT TRANSFERS POWER TO

DRIVE SHAFTS FROM DRIVE CHAIN.

15 2150178 DRIVE CHAIN (VCT -22) 1 USED TO TRANSFER POWER FROM MOTOR SPROCKET

TO DRIVE SPROCKET.

16 0011193 IDLER SPROCKET ASSY 1 REVERSES DRIVE CHAIN MOTION.

17 0500538 MOTOR MOUNTING BRKT. 1 METAL SUPPORT USED TO SECURE MOTOR BRACKET

TO TOASTER.

18 400K153 DRIVE MOTOR KIT 1 ELECTRICAL PART USED TO MOVE DRIVE CHAIN.

19 2150110 MOTOR SPROCKET (25B20/60HZ) 1 USED TO MOVE DRIVE CHAIN.

2150177 MOTOR SPROCKET (25B24/50HZ) 1

20 4010137 SWITCH, ROCKER (250 VAC) 1 CONTROLS ELECTRICAL POWER TO THE UNIT.

LIGHTS UP WHEN POWER IS ON.

21 4060304 TERMINAL BLOCK 1 PROVIDES CONNECTION POINT FOR ELECTRICAL WIRES.

22 0503156 TEMPERATURE CONTROL 1 METAL SUPPORT USED TO SECURE COMPONENTS OF

BRACKET TEMPERATURE CONTROL ASSEMBLY.

23 4060229 INDICATOR LIGHT (230 VAC) 1 COMES ON WHEN HEATING ELEMENT IS HEATING,

CONTROLLED BY THE THERMOSTAT.

24 0400304 CONVEYOR BELT WRAP 2 SILICONE COVER THAT PREVENTS DAMAGE TO BUNS

AND HOLDS TO HEAT THE BUNS.

25 0011191 ROLLER TENSIONER ASSY 2 METAL PART THAT KEEPS CONVEYOR BELT AT PROPER

TENSION.

26 7000116 BUN FEEDER 1 SHEET METAL PART THAT HOLDS BUNS AND GUIDES

THEM INTO THE TOASTER.

27 050K114 ROD BRACKET KIT 2 METAL PART THAT HOLDS TENSIONER AND ALLOWS IT

TO MOVE DURING ADJUSTMENT.

28 1000982 CONTROL PANEL LABEL 1 IDEN TIFIES CONTROLS.

29 100P983 DIAL LABEL (PKG. OF 10) 1 IDENTIFIES BUN THICKNESS SETTINGS.

30 2100123 KNOB (W / SETSCREWS) 2 MOVES CONVEYOR CAM TO PROVIDE THICKNESS

ADJUSTMENT.

31 0503195 COVER. END HOUSING 1 SHEET METAL PART THAT COVERS MECHANICAL

COMPONENTS.

32 4050212 THERMOCOUPLE ASSY. 1 SENSES TEMPERATURE.

33 215K158 BEARING RETAINER KIT 6 POSITIONS AND HOLDS BALL BEARING.

34 0021103 END HOUSING WELDMENT 1 PROTECTIVE METAL SIDE, SUPPORTS INTERNAL PARTS.

7

Page 8

ITEM 35 PART NO.

0500543

36 7000110 GRILL COVER (PKG. OF 3) TEFLON PART THAT COVERS GRILL, CREATES

7000111 GRILL COVER (PKG. OF 10) - SMOOTH TOASTING SURFACE.

37 38 0100213

0021102

DESCRIPTION SEPARATOR CONE QTY 1 FUNCTION METAL PART THAT GUIDES BUN ONTO GRILL.

GRILL (208 VOLT) CONTROL HOUSING 1 1 HEATED ALUMINUM CASTING. PROTECTIVE METAL SIDE,

SUPPORTS INTERNAL COMPONENTS.

39 7000121 SLIDE RAIL KIT (INCLUDES 2 SLIDE

40 41 0021116

0021111

42 0021114 DIVIDER WELDMENT (LH) 1 MOVABLE PART THAT ADJUSTS FROM SIDE TO SIDE AND GUIDES

43 2000200 TUBE 1 SUPPORTS DIVIDER WELDMENTS.

44 0021113 DIVIDER WELDMENT (RH) 1 MOVABLE PART THAT ADJUSTS FROM SIDE TO SIDE AND GUIDES

45 7000119 THERMOCOUPLE RETAINER KIT 1 HOLDS THERMOCOUPLE IN PLACE.

46 0503200 PANEL, REAR 1 SHEET METAL PART - COVERS BACK OF BUN PAN AREA.

47 4030162 HIGH LIMIT THERMOSTAT 1 RESETTABLE SAFETY SWITCH WHICH TURNS THE POWER OFF

48 0400258 STRAIN RELIEF 1 HOLDS POWER CORD SET TO CABINET.

49 0503212 STOP, PAN 1 POSITIONS REAR OF BUN PAN.

50 0503210 LOCATOR, BUN PAN 2 POSITIONS AND HOLDS BUN PAN.

" 0011196 FLOOR ASSEMBLY 1 SHEET METAL PART - CREATES SPACE FOR BUN PAN.

52 53 0503131

0503135

RAILS FOR TENSIONERS)

CONVEYOR CAM BUN FEEDER

WELDMENT

PLATEN EXTENSION O UTER PLATEN

EXTENSION INNER

2 PREVENTS METAL-TO-METAL CONTACT AND LIMITS NOISE.

2 1 POSITIONS CONVEYOR BELT TO TOAST DIFFERENT THICKNESS

OF BUN. SHEET METAL PART THAT HOLDS COMPONENTS OF

BUN FEEDER.

BUNS INTO TOASTER.

BUNS INTO TOASTER.

TO THE STEAM GENERATOR WHEN THE THERMOSTAT IS NOT

CONTROLLING MAXIMUM TEMP.

1 1 OUTSIDE HALF OF COMPONENT THAT GUIDES BUNS TO BUN

PAN. INSIDE HALF OF COMPONENT THAT GUIDES BUNS TO BUN

PAN.

54 4030319 HEATER, SILICONE 1 PART IS GLUED TO BOTTOM OF FLOOR ASSEMBLY, PROVIDES

55 0503192 BASE 1 SHEET METAL PART - COVERS BOTTOM OF UNIT.

56 . ......

0503155

*57 0700553 WIRE SET 1 PERMITS CONNECTION OF ALL ELECTRICAL PARTS.

58 0200208 GASKET, BASE 1 SEALS UNIT TO COUNTER.

59 0011187 DOOR ASSY. 1 CLEAR PLASTIC - ALLOWS VIEWING OF AND ACCESS TO BUN

60 0503198 BUN CHUTE 1 GUIDES BUNS INTO BUN PAN AFTER TOASTING.

MOTOR BRACKET - METAL SUPPORT USED TO SECURE DRIVE MOTOR TO MOTOR

HEAT IN BUN PAN AREA.

MOUNTING. BRACKET.

PAN.

8

Page 9

ITEM PART NO. DESCRIPTION QTY FUNCTION

35 0500543 SEPARATOR CONE 1 METAL PART THAT GUIDES BUN ONTO GRILL.

36 7000110 GRILL COVER (PKG. OF 3) - TEFLON PART THAT COVERS GRILL, CREATES

7000111 GRILL COVER (PKG. OF 10) - SMOOTH TOASTING SURFACE.

37 0100213 GRILL (208 VOLT) 1 HEATED ALUMINUM CASTING.

38 0021102 CONTROL HOUSING 1 PROTECTIVE METAL SIDE, SUPPORTS INTERNAL COMPONENTS.

39 7000121 SLIDE RAIL KIT (INCLUDES 2 SLIDE

40 41 0021116

0021111

42 0021114 DIVIDER WELDMENT (LH) 1 MOVABLE PART THAT ADJUSTS FROM SIDE TO SIDE AND

43 2000200 TUBE 1 SUPPORTS DIVIDER WELDMENTS.

44 0021113 DIVIDER WELDMENT (RH) 1 MOVABLE PART THAT ADJUSTS FROM SIDE TO SIDE AND

45 7000119 THERMOCOUPLE RETAINER KIT 1 HOLDS THERMOCOUPLE IN PLACE.

46 0503200 PANEL, REAR 1 SHEET METAL PART - COVERS BACK OF BUN PAN AREA.

47 4030162 HIGH LIMIT THERMOSTAT 1 RESETTABLE SAFETY SWITCH WHICH TURNS THE POWER OFF

48 0400258 STRAIN RELIEF 1 HOLDS POWER CORD SET TO CABINET.

49 0503212 STOP, PAN 1 POSITIONS REAR OF BUN PAN.

50 0503210 LOCATOR, BUN PAN 2 POSITIONS AND HOLDS BUN PAN.

51 0011196 FLOOR ASSEMBLY 1 SHEET METAL PART - CREATES SPACE FOR BUN PAN.

52 0503131 PLATEN EXTENSION OUTER 1 -] OUTSIDE HALF OF COMPONENT THAT GUIDES BUNS TO BUN

RAILS FOR TENSIONERS)

CONVEYOR CAM BUN FEEDER

WELDMENT

2 PREVENTS METAL-TO-METAL CONTACT AND LIMITS NOISE.

2 1 POSITIONS CONVEYOR BELT TO TOAST DIFFERENT THICKNESS

OF BUN. SHEET METAL PART THAT HOLDS COMPONENTS OF

BUN FEEDER.

GUIDES BUNS INTO TOASTER.

GUIDES BUNS INTO TOASTER.

TO THE STEAM GENERATOR WHEN THE THERMOSTAT IS NOT

CONTROLLING MAXIMUM TEMP.

PAN.

53 0503135 PLATEN EXTENSION INNER 1 INSIDE HALF OF COMPONENT THAT GUIDES BUNS TO BUN PAN.

54 4030319 HEATER, SILICONE 1 PART IS GLUED TO BOTTOM OF FLOOR ASSEMBLY, PROVIDES

55 0503192 BASE 1 SHEET METAL PART - COVERS BOTTOM OF UNIT.

56 0503155 MOTOR BRACKET 1 METAL SUPPORT USED TO SECURE DRIVE MOTOR TO MOTOR

'57 0700553 . . - WIRE SET 1 PERMITS CONNECTION OF ALL ELECTRICAL PARTS.

58 59 60 0200208

0011187

0503198

NOT SHOWN

GASKET, BASE DOOR ASSY. BUN

CHUTE

HEAT IN BUN PAN AREA.

MOUNTING. BRACKET.

1 1 1 SEALS UNIT TO COUNTER. CLEAR PLASTIC - ALLOWS VIEWING

OF AND ACCESS TO BUN PAN. GUIDES BUNS INTO BUN PAN

AFTER TOASTING.

8

Page 10

PARTS IDENTIFICATION

10

Page 11

EXPLODED VIEW

Page 12

12

Page 13

EXPLODED VIEW

13

Page 14

TROUBLESHOOTING GUIDE

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

No heat and conveyor belts do

not move.

Not enough voltage, defective power cord,

Defective wiring. Check all electrical connections for bums,

No heat and conveyor belts

move.

Toaster is installed incorrectly. Perform Installation and Operating Procedures

defective power switch.

Defective wiring. Check all electrical connections for burns

on Page 4 of this manual.

Check receptacle for correct voltage. (See

Specifications, Page 2). With unit plugged in and

Rocker Switch ON, check for correct voltage into

Rocker Switch. If low or zero voltage, replace

Power Cord. If correct voltage, check for correct

voltage out of Rocker Switch. If low or no

voltage, replace Rocker Switch.

discoloration or arcing. Replace all connections

or components with damaged terminals.

Replace all damaged wiring with the same or a

higher rated wire.

discoloration or arcing. Replace all connections

or components with damaged terminals.

Replace all damaged wiring with t he same or a

higher rated wire.

Defective temperature display control or defective

grill.

High limit thermostat tripped or defective. With power off and unit cool to the touch,

To check temperature display control -Allow unit

to warm up for 20 minutes. A. Check grill

temperature at center of grill (with conveyor belt

wrap, conveyor belt, tensioners, and grill cover

removed)., B. After grill temperature reaches a

maximum of 469° -471°F (242°-244°C) and the

temperature begins to drop, the indicator light

(Item 23) should turn off. If test readings do not

agree with these figures, replace temperature

display control. To check grill -A. Use an Ohm

meter to test resistance of the grill heater

(Disconnect one wire to isolate heater). Correct

cold resistance is: 15.73 Ohms for 208V/2750

watt grills.

remove one wire and check across terminals for

continuity. If continuity, part is good. If no

continuity, press reset and retest. If still no

continuity, replace.

Page 15

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Grill is hot and conveyor

belts do not move.

Toaster is installed incorrectly. Perform Installation and Operating

Procedures on Page 4 of this manual.

Defective wiring. Check all electrical connections for burns,

discoloration or arcing. Replace all

connections or components with damaged

terminals. Replace all damaged wiring with

the same or a higher rated wire.

Defective drive motor or wrong drive motor. To check drive motor -A. Measure

resistance of motor coil. Replace motor if

coil measures either open circuit or zero

resistance. B. Mark the drive motor

sprocket and count the turns per minute.

Correct drive motor speed is three (3) turns

per minute.

Defective drive chain or loose sprocket. Check drive chain for kinks, broken or bent

links or other damage. Check motor

sprocket and drive sprockets (on drive

shaft), tighten setscrew on flat of shaft if

needed. Also check for

broken/damaged/worn sprockets. Replace

as needed.

Conveyor Cover Assy.(s) not installed. Install Conveyor Cover Assy.(s).

Conveyor belts installed incorrectly. Install conveyor belt to match diagram on

Page 21. Be sure that the "hook" faces out

and the point of the hook is down.

Roller Tensioner Assy. or Tensioner bent or

missing.

Replace Roller Tensioner Assy.(s) (Item

25) or Tensioner (Item 4) if damaged or

missing.

Conveyor belt is loose or missing links (41

links required).

Remove conveyor belt by squeezing any

two links together to "unhook" the links. Lay

conveyor belt flat and count links. Correct

amount is forty one (41) links, 38 large and

3 small links. To shorten conveyor belt,

remove one or more small links. Replace

entire conveyor belt if links are damaged.

Product is over-toasted or

grill heat is too high or drop

time is too slow.

Defective wiring. Check all electrical connections for burns,

discoloration or arcing. Replace all

connections or components with damaged

terminals. Replace all damaged wiring with

the same or a higher rated wire.

Defective temperature display control or

defective grill.

To check temperature display control Allow unit to warm up for 20 minutes. A.

Check grill temperature at center of grill

(with conveyor belt wrap, conveyor belt,

tensioners, and grill cover removed),

15

Page 16

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

(Continued) Product is over-

toasted or grill heat is too high

or drop time is too slow.

Defective drive motor or wrong drive motor. To check drive motor -A. Measure resistance of

Defective drive chain or loose sprocket. Check drive chain for kinks, broken or bent links

Conveyor Cover Assy.(s) not installed. Install Conveyor Cover Assy.(s).

(Continued) Defective temperature display

control or defective grill.

B. After grill temperature reaches a maximum of

469°-471°F (242°-244°C) and the temperature

begins to drop, the indicator light (Item 23)

should turn off. If test readings do not agree with

these figures, replace temperature control

display. To check grill -A. Use an Ohm meter to

test resistance of the grill heater (Disconnect

one wire to isolate heater). Correct cold

resistance is: 15.73 Ohms for 208V/2750 watt

grills.

motor coil. Replace motor if coil measures either

open circuit or zero resistance. B. Mark the

drive motor sprocket and count the turns per

minute. Correct drive motor speed is three (3)

turns per minute.

or other damage. Check motor sprocket and

drive sprockets (on drive shaft), tighten

setscrew of flat of shaft if needed. Also check

for broken/damaged/worn sprockets. Replace

as needed.

Conveyor belts installed incorrectly. Install conveyor belt to match diagram on Page

Conveyor belt is loose or missing links (41 links

Roller Tensioner Assy. or Tensioner bent or

Bun adjustment knobs set incorrectly. Measure bun thickness and set bun adjustment

Product is under-toasted or grill

heat is too low or drop time is

too fast.

required).

missing.

Not enough voltage, defective power cord,

defective power switch.

21. Be sure that the "hook" faces out and the

point of the hook is down.

Remove conveyor belt by squeezing any two

links together to "unhook" the links. Lay

conveyor belt flat and count links. Correct

amount is forty one (41) links, 38 large and 3

small links. To shorten conveyor belt, remove

one or more small links. Replace entire

conveyor belt if links are damaged.

Replace Roller Tensioner Assy. (Item 25) or

Tensioner (Item 4) if damaged or missing.

knobs correctly.

Check receptacle for correct voltage. With unit

plugged in and Rocker Switch ON, check for

voltage at bottom of Rocker Switch. If low or

zero voltage, replace Power Cord. If correct

voltage, check at top of power switch for correct

voltage. If low or no voltage, replace Rocker

Switch.

16

Page 17

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

Product is getting "Stuck" or

(Continued) Product is

under-toasted or grill heat is

too low or drop time is too

fast.

Defective wiring. Check all electrical connections for bums,

discoloration or arcing. Replace all

connections or components with damaged

terminals. Replace all damaged wiring with

the same or a higher rated wire.

Defective temperature display control or

defective grill.

To check temperature display control -Allow

unit to warm up for 20 minutes. A. Check

grill temperature at center of grill (with

conveyor belt wrap, conveyor belt,

tensioners, and grill cover removed)., B.

After grill temperature reaches a maximum

of 469°-471°F (242°-244°C) and the

temperature begins to drop, the indicator

light (Item 23) should turn off. If test

readings do not agree with these figures,

replace temperature display control. To

check grill -A. Use an Ohm meter to test

resistance of the grill heater (Disconnect one

wire to isolate heater). Correct cold

resistance is: 15.73 Ohms for 208V/2750

watt grills.

Defective drive motor or wrong drive motor. To check drive motor -A. Measure

resistance of motor coil. Replace motor if

coil measures either open circuit or zero

resistance. B. Mark the drive motor sprocket

and count the turns per minute. Correct

drive motor speed is three (3) turns per

minute.

Bun adjustment knobs set incorrectly. Measure bun thickness and set bun

adjustment knobs correctly.

conveyor belts "Stop" when

product is toasting.

Not enough voltage, defective power cord,

defective power switch.

Check receptacle for correct voltage. With

unit plugged in and Rocker Switch ON,

check for voltage at bottom of Rocker

Switch. If low or zero voltage, replace Power

Cord. If correct voltage, check at top of

power switch for correct voltage. If low or no

voltage, replace Rocker Switch.

Defective wiring. Check all electrical connections for burns,

discoloration or arcing. Replace all

connections or components with damaged

terminals. Replace all damaged wiring with

the same or a higher rated wire.

17

Page 18

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

(Continued) Product is getting

"Stuck" or conveyor belts

"Stop" when product is

toasting.

Defective drive chain or loose sprocket. Check drive chain for kinks, broken or bent links

Conveyor Cover Assy.(s) not installed. Install Conveyor Cov er Assy.(s).

Conveyor belts installed incorrectly. Install conveyor belt to match diagram on Page

Conveyor belt is loose or missing links (41 links

Defective drive motor or wrong drive motor. To check drive motor -A. Measure resistance of

required).

motor coil. Replace motor if coil measures either

open circuit or zero resistance. B. Mark the

drive motor sprocket and count the turns per

minute. Correct drive motor speed is three (3)

turns per minute.

or other damage. Check motor sprocket and

drive sprockets (on drive shaft), tighten

setscrew on flat of shaft if needed. Also check

for broken/damaged/worn sprockets. Replace

as needed.

21. Besure that the "hook" faces out and the

point of the hook is down.

Remove conveyor belt by squeezing any two

links together to "unhook" the links. Lay

conveyor belt flat and count links. Correct

amount is forty one (41) links, 38 large and 3

small links. To shorten conveyor belt, remove

one or more small links. Replace entire

conveyor belt if links are damaged.

Roller Tensioner Assy.(s) or Tensioner bent or

Bun adjustment knobs set incorrectly. Measure bun thickness and set bun adjustment

Conveyor belt wrap missing or not installed

Conveyor belts are "Jumping"

or "Snapping"

Defective drive motor or wrong drive motor. To check drive motor -A. Measure resistance of

missing.

properly.

Toaster is installed incorrectly. Perform Installation and Operating Procedures

Replace Roller Tensioner Assy. (Item 25) or

Tensioner (Item 4) if damaged or missing.

knobs correctly.

Install Conveyor Belt Wrap (Item 24) properly

(See ''Conveyor Belt Wrap" on Page 21).

on Page 4 of this manual.

motor coil. Replace motor if coil measures either

open circuit or zero resistance. B. Mark the

drive motor sprocket a nd count the turns per

minute. Correct drive motor speed is three (3)

turns per minute.

18

Page 19

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

(Continued) Conveyor belts are

"Jumping" or "Snapping"

Conveyor Cover Assy.(s) not installed. Install Conveyor Cover Assy.(s).

Conveyor belts installed incorrectly. Install conveyor belt to match diagram on Page

Conveyor belt is loose or missing links (41 links

Roller Tensioner Assy.(s) or Tensioner bent or

Bun adjustment knobs set incorrectly. Measure bun thickness and set bun adjustment

Defective drive chain or loose sprocket. Check drive chain for kinks, broken or bent

required).

missing.

links or other damage. Check motor sprocket

and drive sprockets (on drive shaft), tighten

setscrew of flat of shaft if needed. Also check

for broken/damaged/worn sprockets. Replace

as needed.

21. Be sure that the "hook" faces out and the

point of the hook is down.

Remove conveyor belt by squeezing any two

links together to "unhook" the links. Lay

conveyor belt flat and count links. Correct

amount is forty one (41) links, 38 large and 3

small links. To shorten conveyor belt, remove

one or more small links. Replace entire

conveyor belt if links are damaged.

Replace Roller Tensioner Assy. (Item 25) on

inside of face panel) or Tensioner (Item 4) if

damaged or missing.

knobs correctly.

19

Page 20

TEMPERATURE DISPLAY CONTROL/ CONTROL

BOARD TRANSFORMER/RELAY Removal -

1 Remove Control Cover Weldment (Item 8).

2. Remove screws holding Temperature Control

Assy. (Item 11).

3. Remove screw(s) holding the part.

4. Disconnect wires from part. Installation-

1. Connect wires to part.

2. Attach part to Temperature Control Assy.

3. Attach Temperature Control Assy. to Toaster.

4. Test operation before putting unit into service.

5. Installation is complete.

TEMPERATURE ADJUSTMENT

Setting Temperature Adjustment.

1. Turn Power Switch to ON.

2. Push and hold the Display Selector Button and

turn the Set Point Adjustment Knob to the

desired set point. Temperature range is 469°471°F (242°-244°C). Clockwise increases

temperature, counter-clockwise decreases

temperature.

20

Page 21

DRIVE MOTOR

With Power OFF -1. Remove Cover Panel

(Item 8).

^ 2. Remove Drive Motor/Motor Bracket r (Item

18/56).

3. Remove Motor Sprocket (Item 19) with a hex

wrench.

4. Attach Motor Bracket and Sprocket to new Mot or.

2. Move Bun Adjustment Knob to 3/4" (#6) to loosen

Conveyor belt and Conveyor Belt Wrap.

3. Move the Conveyor Belt Wrap until the "flap"

clan be lifted.

4. Lift the flap and remove the pin holding the

Conveyor Belt Wrap by pulling gently. Turn or

spin the pin to make removal easier.

Page 22

3. Disconnect Conveyor Belt by unhooking

both ends of one link, then remove

Conveyor Belt. Replacement -

1. Move Bun Adjustment Knobs to "3/4"(#6) to

loosen conveyor belt.

ROLLER TENSIONER ASSY.

With Power OFF -

1. Remove Conveyor Cover Assy. (Item 3).

2. Remove 8x32 nuts (Item S) from Roller

Tensioner Assy.

3. Remove old Roller Tensioner Assy.

4. Reverse steps 1-3 to complete procedure.

Page 23

INSTALLATION OF GRILL COVER

1 . Turn OFF the power and allow the unit to USE METAL TOOLS TO CREASE THE

cool completely. GRILL COVER!

" 2. Remove Grill Cover (Item 36), if one is in 5. Install Bun Feeder.

place. Remove the Bun Feeder (Item 26) 6. install the Grill Cover by draping it over

and set aside, both sides of the grill surface. Note that

3. Lay a Grill Cover on a clean, flat surface, the crease should be centered directly on

Note that the Grill Cover is longer than it the (black separator cone).

is wide. Fold exactly in half the LONG 7. check Grill Cover to be sure it is not

way caught in conveyor. Unit is now ready for

4. Crease the Grill Cover at the fold by use.

pressing the fold with a finger. DO NOT

Page 24

Loading...

Loading...