Page 1

POWER

USE R.O. WATER SUPPLY ONLY

READY

STEAMING

CYCLE

START

CM-100

cheese melter

owner’s manual

Manufacturing Numbers:

9100416

www.ajantunes.com

P/N 1011175 Rev. A 01/12

Page 2

Table of Contents

General .................................................. 2

Warranty Information ............................. 2

Service/Technical Assistance ...................2

Important Safety Information ................. 3

Warnings ................................................ 3

Specifications ......................................... 4

Installation ............................................. 5

Plumbing ................................................ 5

Operating Instructions ............................ 6

Hi-Limit Thermostat ................................ 6

Daily Cleaning ........................................ 7

Monthly Cleaning ................................... 7

Calibration ............................................. 8

Troubleshooting...................................... 9

Wiring Diagram ...................................... 11

Replacement Parts ..................................12

Notes ...................................................... 14

Limited Warranty .................................... 16

GENERAL

The Taco Bell CM-100 Cheese Melter produces

steam to quickly heat and melt cheese for a

variety of products. Simple push-button action

delivers a single-shot of super-heated steam.

Because the amount of steam is always consistent, this unit removes the guesswork and

produces a uniform finished product from one

operator to another.

This manual provides the safety, installation,

and operating procedures for the Cheese

Melter. We recommend that all information

contained in this manual be read prior to

installing and operating the unit.

Your Cheese Melter is manufactured from the

finest materials available and is assembled

to Roundup’s strict quality standards. This

unit has been tested at the factory to ensure

dependable trouble-free operation.

SERVICE/TECHNICAL

ASSISTANCE

If you experience any problems with the

installation or operation of your unit, contact

your local Roundup Authorized Service Agency.

Fill in the information below and have it

handy when calling your Authorized Service

Agency for assistance. The serial number is on

the specification plate located on the rear of

the unit.

Purchased From

Date of Purchase

IMPORTANT

A.J. Antunes & Co. reserves the right

to change specifications and product

design without notice. Such revisions do

not entitle the buyer to corresponding

changes, improvements, additions or

replacements for previously purchased

equipment.

IMPORTANT

Keep these instructions for future reference. If the unit changes ownership,

be sure this manual accompanies the

equipment.

WARRANTY INFORMATION

Please read the full text of the Limited

Warranty in this manual.

If the unit arrives damaged, contact the carrier immediately and file a damage claim with

them. Save all packing materials when filing a

claim. Freight damage claims are the responsibility of the purchaser and are not covered

under warranty.

The warranty does not extend to:

• Damages caused in shipment or damage as result of improper use.

• Installation of electrical service.

• Normal maintenance as outlined in

this manual.

• Malfunction resulting from improper

maintenance.

• Damage caused by abuse or careless

handling.

• Damage from moisture into electrical

components.

• Damage from tampering with, removal

of, or changing any preset control or

safety device.

Model Number

Serial Number

Manufacturing Number

Use only genuine Roundup replacement parts

in this unit. Use of replacement parts other

than those supplied by the manufacturer will

void the warranty. Your Authorized Service

Agency has been factory trained and has a

complete supply of parts for this unit.

Visit www.ajantunes.com or contact the factory at 1-630-784-1000 to locate your nearest

Authorized Service Agency.

Refer to the service agency directory packaged

with your manual and fill in the information

below.

Authorized Service Agency

Name

Phone Number

Address

2

P/N 1011175 Rev. A 01/12

Page 3

IMPORTANT SAFETY

INFORMATION

Use the following guidelines for safe operation of the unit.

• Read all instructions before using

equipment.

• For your safety, the equipment is furnished with a properly grounded cord

connector. Do not attempt to defeat

the grounded connector.

• Install or locate the equipment only

for its intended use as described in

this manual. Do not use corrosive

chemicals in this equipment.

• Do not operate this equipment if it

has a damaged cord or plug, if it is

not working properly, or if it has been

damaged or dropped.

• This equipment should be serviced by

qualified personnel only. Contact your

nearest Authorized Service Agency for

adjustment or repair.

• Do not block or cover any openings on

the unit.

• Do not immerse cord or plug in water.

• Keep cord away from heated surfaces.

• Do not allow cord to hang over edge

of table or counter.

• Turn the power off, unplug the power

cord, and allow unit to cool down

before performing any service or

maintenance on the unit.

• The procedures in this manual may

include the use of chemical products.

These chemical products will be

highlighted with bold face letters followed by the abbreviated HCS (Hazard

Communication Standard). See Hazard

Communication Standard manual for

the appropriated Material Safety Data

Sheets (MSDS).

• The equipment should be grounded

according to local electrical codes to

prevent the possibility of electrical

shock. It requires a grounded receptacle with separate electrical lines,

protected by fuses or circuit breaker of

the proper rating.

• All electrical connections must be in

accordance with local electrical codes

and any other applicable codes.

• Do not clean this appliance with a

water jet.

WARNINGS

Be advised of the following warnings when

operating and performing maintenance on

this unit.

• If the supply cord is damaged, it must

be replaced by an authorized service

agent or a similarly qualified person in

order to avoid a hazard.

• Do not modify the power supply cord

plug. If it does not fit the outlet, have

a proper outlet installed by a qualified

electrician.

• Do not use an extension cord with this

appliance.

• Electrical ground is required on this

appliance.

• Check with a qualified electrician if

you are in doubt as to whether the

appliance is properly grounded.

• If a chemical cleaner is used, be sure

it is safe to use on cast aluminum.

Observe all precautions and warnings

on product label.

• Inspection, testing, and repair of electrical equipment should only be performed by qualified service personnel.

• This equipment is to be installed to

comply with the basic plumbing code

of the Building Officials and Code

Administrators, Inc. (BOCA) and the

Food Service Sanitation Manual of the

Food and Drug Administration (FDA).

• Water pressure must not exceed 25

psi (1.7 kg/cm2 or 172 kPa). Higher

water pressures may cause poor performance or flooding. To reduce water

pressure, install a water pressure regulator and set water pressure to 20–25

psi (1.4–1.7 kg/cm2 or 138–172 kPa).

To order a water pressure regulator

from our Authorized Service Agency,

order P/N 7000314 for one unit or P/N

7000235 for two units.

• To ensure proper steaming characteristics, some calcium/mineral deposits

must be present on the generator

surface. If during cleaning, the surface

does become free of calcium/mineral

deposits, mix one cup tap water with

2 tablespoons of baking soda and

slowly pour 1/4 cup of the solution

onto the generator surface. This may

have to be repeated several times to

ensure proper steaming characteristics

by creating a thin layer of deposits on

the surface. See the Maintenance section of this manual.

• Do not use a sanitizing solution or

abrasive materials. The use of these

may cause damage to the stainless

steel finish.

• Chlorides or phosphates in cleaning agents (e.g. bleach, sanitizers,

degreasers or detergents) could cause

permanent damage to stainless steel

equipment. The damage is usually in

the form of discoloration, dulling of

metal surface finish, pits, voids, holes,

or cracks. This damage is permanent

and not covered by warranty.

• The following tips are recommended

for maintenance of your stainless steel

equipment:

• Always use soft, damp cloth for

cleaning, rinse with clear water

and wipe dry. When required,

always rub in direction of metal

polish lines.

• Routine cleaning should be done

daily with soap, ammonia detergent, and water.

• Stains and spots should be

sponged using a vinegar solution.

• Finger marks and smears should be

rubbed off using soap and water.

• Hard water spots should be

removed using a vinegar solution.

P/N 1011175 Rev. A 01/12

3

Page 4

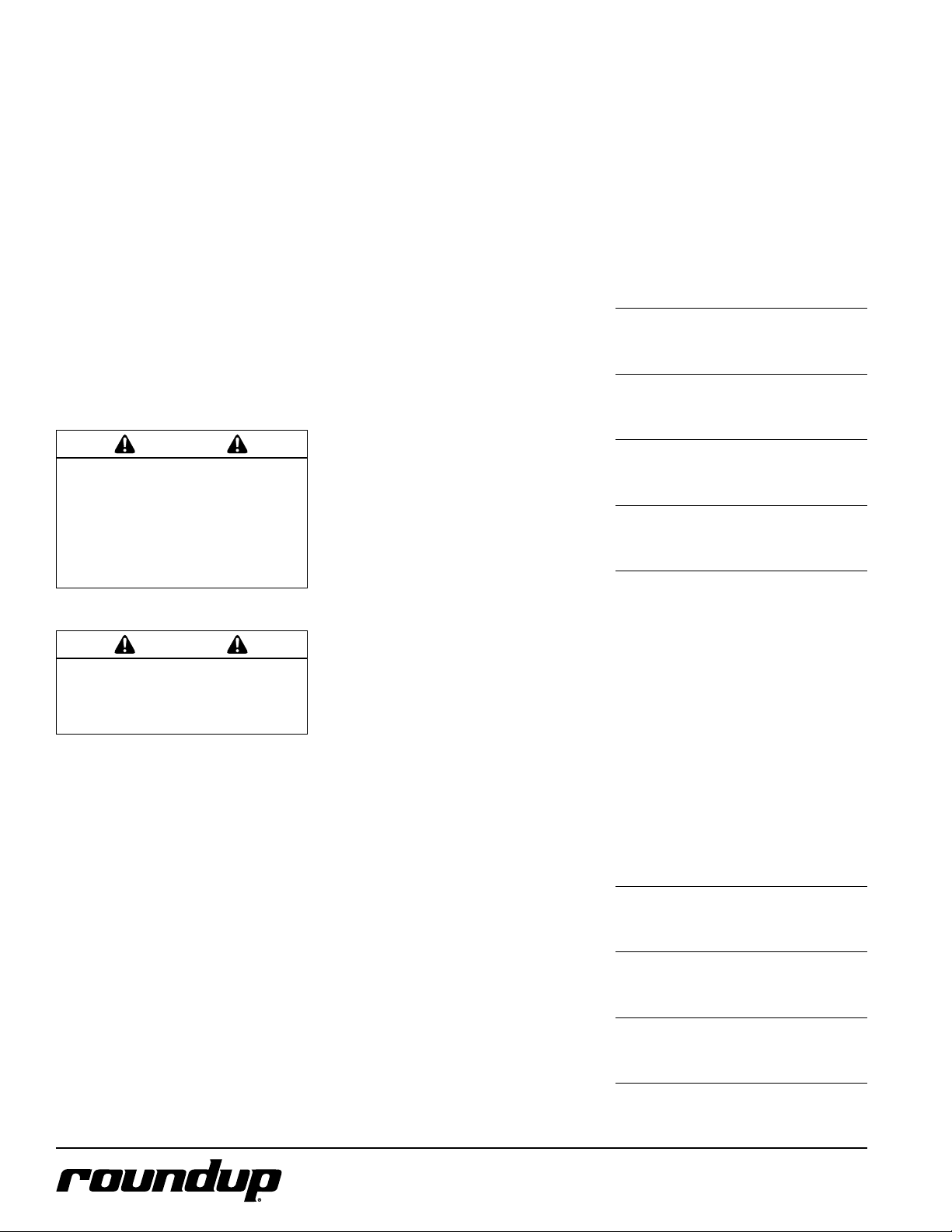

SPECIFICATIONS

A

C

USE R.O. WATER SUPPLY ONLY

B

Model &

Mfg No.

CM-100

9100416

Model &

Mfg No.

CM-100

9100416

Width

(A)

17 3/8”

(441 mm)

Volts Watts Amps Hertz Plug Description

208 3300 16 50/60 NEMA 6-20P

Depth

(B)

17 5/8”

(448 mm)

Height

(C)

8 3/8”

(213 mm)

4

P/N 1011175 Rev. A 01/12

Page 5

Liner

Spatula

Figure 1. CM-100 Spatula Figure 2. Quick Disconnect

INSTALLATION

1. Remove unit and all packing materials

from the shipping carton.

2. The unit should come with the items

listed below:

• Owner’s Manual

• Authorized Service Agency Directory

• Handle and Handle Guard

• Water Quick Disconnect Kit

NOTE: If any parts are missing or damaged, contact Antunes Technical Service

IMMEDIATELY at 1-877-392-7854 or

1-630-784-1000.

3. Remove all packing materials and

protective coverings from the unit.

4. Remove and wash the Spatula and

Liner (Figure 1) in soap and water

by hand. Rinse with clean water and

allow to air dry.

NOTE: Do NOT wash in a power washer.

5. Wipe all surfaces of the unit with a

hot damp cloth.

NOTE: Do NOT use a dripping wet cloth.

Wring out before use.

6. Assemble the Handle and Handle

Guard to the Spatula (Figure 1).

7. Re-install the Spatula.

Handle

Guard

Handle

When placing the Cheese Melter into service,

pay attention to the following guidelines.

• Make sure the power switch is off and

the unit is at room temperature before

plugging in the power cord.

• Do not block or cover any openings on

the unit.

• Do not immerse the power cord or

plug in water.

• Keep the power cord away from

heated surfaces.

• Do not allow the power cord to hang

over edge of table or counter.

Plug the power cord into the appropriate

power outlet. Refer to the specification

plate for the proper voltage.

1. Place the unit on a sturdy, level table

or other work surface..

2. Turn off the power.

3. Ensure the line voltage corresponds to

the stated voltage on the specification

label and power cord warning tag.

4. Connect the unit to the power supply.

USE R.O. WATER SUPPLY ONLY

PLUMBING

The CM-100 requires installation of a reverse

osmosis filtration system for supplying water

to this equipment. To purchase the filtration

system, contact the approved equipment

distributor.

Flexible water line (not supplied) for water

hookup should be 1/4" (6.5 mm) I.D to fit the

quick disconnect (supplied).

NOTE: It is recommended to install an

in-line water strainer (P/N 7000333) to

prevent debris from entering the solenoid

valve. Debris in the solenoid valve will

cause a leaking condition that is not

covered by warranty.

1. Connect the Flexible Tubing to the

Quick Disconnect Insert using the supplied hose clamp.

2. Push the Quick Disconnect Insert into

the female fitting on the back of the

unit until it clicks.

CAUTION

Water pressure must not exceed 25 psi (1.7

kg/cm2 or 172 kPa). Higher water pressures

may cause poor performance or flooding.

To reduce water pressure, install a water

pressure regulator, and set water pressure to

20–25 psi (1.4–1.7 kg/cm2 or 138–172 kPa).

P/N 1011175 Rev. A 01/12

CAUTION

Connect this unit to a cold water supply line

only. Connecting this unit to a hot water

supply line will void the warranty.

5

Page 6

POWER

USE R.O. WATER SUPPLY ONLY

CYCLE

START

READY

STEAMING

CYCLE

START

Figure 3. Operating Controls

OPERATING INSTRUCTIONS

1. Turn the power on and allow the unit

to preheat for approximately 20–30

minutes.

NOTE: The green Ready Light will flash

during warm-up. The flashing light will

become steady when the unit is up to

temperature. If the Ready Light continues

to flash after warmup, or starts to flash

during operation, see the Troubleshooting

section in this manual.

NOTE: Do NOT push the CYCLE/START button during warmup. The flashing green

Ready Light indicates the unit is not up to

temperature. If the CYCLE/START button is

pressed while the green light is flashing,

nothing will happen.

2. Pull out the Spatula and place the

product to be steamed onto the

Spatula.

3. Push the Spatula fully into the unit.

NOTE: Spatula must be fully inserted in

order to start a steam cycle.

Reset

Button

Reset Cap

Figure 4. Hi-Limit Thermostat

4. Press and release the CYCLE/START

button. The green Ready Light will turn

off and the yellow Steaming Light will

come on and remain lit for the entire

steaming cycle.

5. At the end of the steaming cycle

(approximately 7 seconds), an audible

signal will sound until the spatula is

removed from the unit and the green

Ready Light will turn back on, indicating the product is ready to be served.

6. Carefully remove the steamed product

and insert the Spatula back into the

unit.

WARNING

To avoid injury, be careful when removing the

Spatula. Be sure to allow steam to escape

before putting hands or face over the

steamer.

USE R.O. WATER SUPPLY ONLY

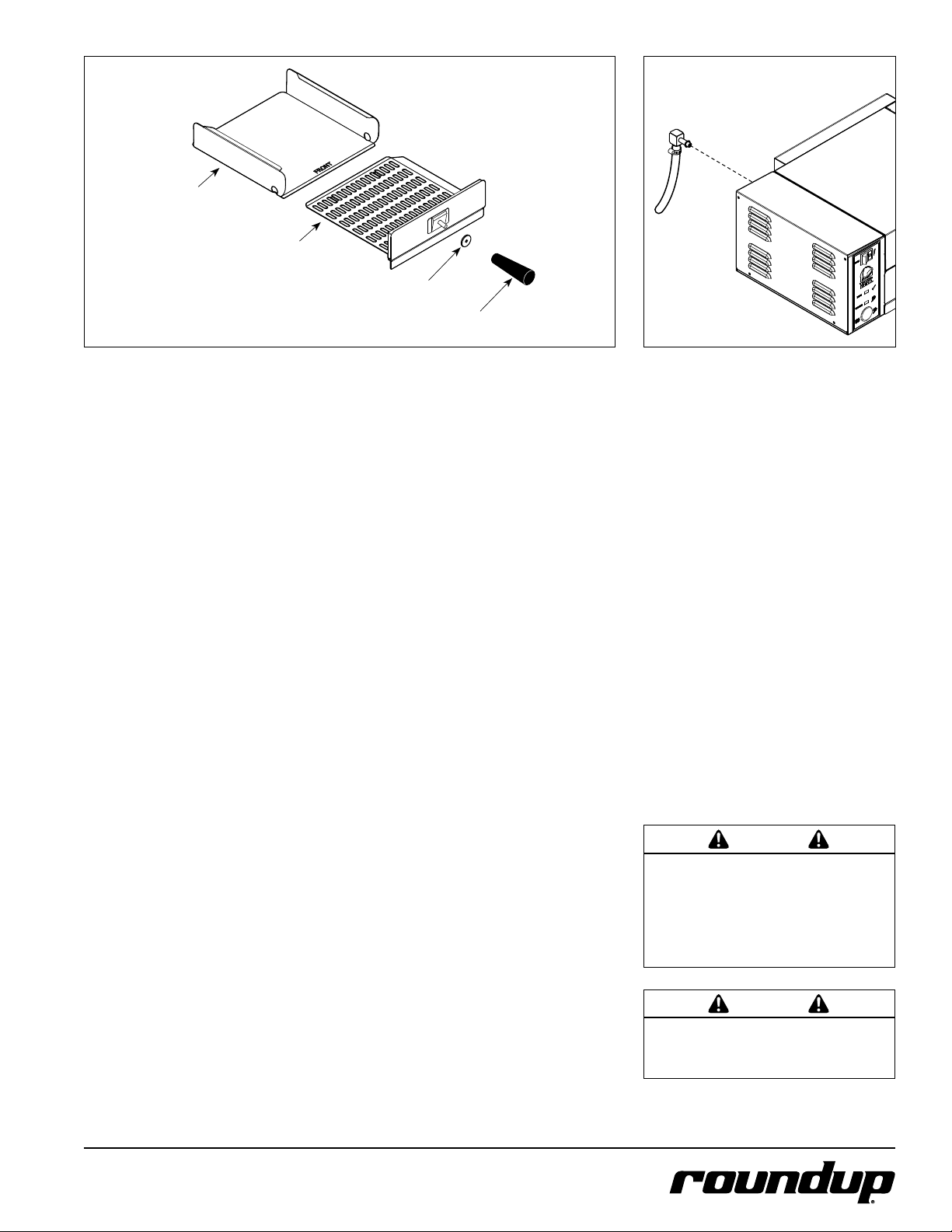

HI-LIMIT THERMOSTAT

A hi-limit thermostat will turn off electrical

power to the Generator and transformer circuits if the unit overheats. To reset the Hi-Limit

Thermostat, allow the unit to cool down

(approximately 45 minutes). Then remove the

cap located on the bottom of the unit (Figure

4) and press the reset button.

If the unit continues to shut off due to overheating, contact your Roundup Authorized

Service Agency.

6

P/N 1011175 Rev. A 01/12

Page 7

CAUTION

Do not use a sanitizing solution or abrasive

materials. The use of these may cause damage to the stainless steel finish.

Chimney

CAUTION

If a chemical cleaner is used, be sure it is

safe to use on cast aluminum. Observe all

precautions and warnings on product label.

CAUTION

Turn the power off, unplug the power cord,

and allow the unit to cool before performing

any service or maintenance.

DAILY CLEANING

NOTE: Frequency of cleaning is determined by water conditions, usage, and

water filter systems.

1. Turn the power off, unplug the power

cord, and allow the unit to cool down.

2. Check the Water Quick Disconnect

Fitting and all hose clamp connections

for leakage. If leakage is apparent,

tighten all clamps or replace part if

required.

3. Remove the Top Cover, Spatula, and

Liner (Figure 6).

4. Remove Chimney (Figure 6)from rear

of unit by sliding upward and away

from the unit.

5. Clean the Top Cover, Spatula, Liner, and

Chimney in hot, soapy water by hand.

Rinse in clear water and wipe dry.

NOTE: Do NOT wash in a power washer.

6. Clean the chamber of any product

spills.

7. Clean entire unit with a clean, hot,

damp cloth (not dripping wet) and

wipe dry.

8. Re-install Chimney, Liner, Spatula, and

Top Cover.

9. Plug in the power cord and test the

unit before returning it to service.

Wing Nut

Generator

Cover

Diffuser

Steam Ports

Figure 6. CM-100 Components

MONTHLY CLEANING

This unit utilizes an open steam generator.

Water sprayed onto the Generator surface

flashes into steam immediately, but the minerals in the water do not steam; they stay on the

Generator surface. A small amount of mineral

deposits are needed for proper operation, but

a buildup of excessive mineral deposits causes

poor steaming efficiency and excessive moisture (wet steam) and will eventually severely

hinder the steaming action.

CLEANING STEAM GENERATOR

1. Turn the power off, unplug the power

cord, and allow the unit to cool down.

2. Remove the Top Cover (Figure 6).

3. Remove the Wing Nut and Generator

Cover (Figure 6).

4. Remove the Diffuser (Figure 6).

5. Examine all steam ports. If mineral

deposits have formed, place a flat

blade screwdriver or wire brush into

the openings. Use a twisting motion to

scrape the openings clean.

NOTE: If the mineral deposits come off in

flakes or layers, buildup is excessive.

6. Use a brass or stainless steel wire

brush and small scraper to loosen and

remove excessive deposits from the

Generator surface. If deposits are still

excessive and/or difficult to remove,

proceed to Step 7.

7. Pour food safe delimer solution (not

supplied) or white vinegar onto the

Generator surface. Be sure to follow

the delimer manufacturer’s directions

Top Cover

Spatula

Handle

Guard

Handle

Liner

for proper mixture and use. It must be

safe for use on aluminum.

8. Remove the delimer solution from the

Generator and rinse with clear water

to remove all traces of solution.

9. Clean the Spatula, Liner, Chimney,

Diffuser, Top Cover, and Generator

Cover in hot detergent water. Then

rinse in clear water and wipe dry.

10. Clean steam chamber of any product

spills.

11. Clean the surface of the unit with a

hot, clean, damp cloth (not dripping

wet) and wipe dry.

12. Re-install all parts and fasten the

Generator Cover.

13. Plug in the power cord and water line.

To ensure proper steaming characteristics,

some mineral deposits must be present on

the Generator surface. If during cleaning, the

surface does become free of mineral deposits

(bare aluminum), add plain tap water to surface and allow to boil off.

In soft water areas, it may be necessary to

add a small amount of calcium/minerals to the

generator surface to season it. This will ensure

proper steaming characteristics by producing a

thin coating of mineral deposits on the surface.

Seasoning mixture consists of 2 tablespoons

baking soda, and 1 cup water. Pour 1/4 cup of

seasoning mixture onto hot generator. After

mixture is converted to steam, the remaining loose powder can be removed. Repeat

as needed until there is a thin, white mineral

coating on the surface of the generator.

P/N 1011175 Rev. A 01/12

7

Page 8

CALIBRATION

CYCLE

START

I

N

C

R

E

A

S

E

D

E

C

R

E

A

S

E

0

9

8

7

6

5

4

3

2

1

I

N

C

R

E

A

S

E

D

E

C

R

E

A

S

E

0

9

8

7

6

5

4

3

2

1

If the unit does not steam properly and the

water pressure is 20–25 psi, use the steps

below to calibrate the water volume.

1. With the unit positioned at the edge

of its location surface (counter, table,

etc.), slide the unit forward approximately 3" to expose the Water Volume

Control on the bottom left side of the

unit (Figure 5).

2. Use a small screwdriver to carefully

and slowly adjust the control. Turning

the control clockwise increases the

amount of water volume used per

cycle and counterclockwise decreases

the amount.

NOTE: The Water Volume Control is numbered 0-9 and is preset to 6. With each

turn, the unit will beep.

3. Plug in the power cord and test the

unit before returning it to service.

NOTE: If the steamer does not steam

properly after calibration, refer to the

Troubleshooting section of this manual.

Figure 5. Water Volume Control

CAUTION

Excessive force will damage the Water

Volume Control. Do NOT turn past the builtin stops on the control or the unit will be

damaged and void the warranty.

8

P/N 1011175 Rev. A 01/12

Page 9

TROUBLESHOOTING

WARNING

To avoid possible personal injury and/or damage to the unit, inspection, test, and repair of electrical equipment should be performed by qualified

service personnel. The unit should be unplugged when servicing, except when electrical tests are required. Use extreme care during electrical circuit

tests. Live circuits will be exposed. If the troubleshooting steps listed below do not solve your machine’s problem, contact an Authorized Service

Agency for further assistance.

Problem Possible Cause Corrective Action

Unit steams, but requires two or more

cycles to melt cheese.

Unit heats but does not steam. Low or no water pressure in water line. Remove the quick disconnect insert from the rear of

Excessive condensation in food compartment.

Generator Surface temperature is too low. Verify generator surface temperature to be 380–

420°F.

Insufficient or excessive calcium deposits on

Generator Surface.

Generator Cover is warped or loose. Verify the Wing Nut is tight. If noticeable steam

Low water pressure. Verify water pressure regulator is set to 20–25 psi.

Water volume adjustment is set too low. Calibrate the unit for proper water volume. Refer to

Generator steam ports are restricted. Verify the steam ports are not restricted. Clean

Generator Surface is bare. Generator Surface must have a thin calcium coating

Damaged or worn Quick Disconnect. Remove the Quick Disconnect from the rear of

Solenoid valve coil is defective. Contact your local Authorized Service Agency.

Control Board inoperable or problematic.

Quick Disconnect is not fully engaged at rear of unit

or is damaged.

CYCLE/START button is inoperable. Contact your local Authorized Service Agency.

Optical Switch is not activated. Ensure the Spatula is fully inserted and engages the

Optical Switch is inoperable. Contact your local Authorized Service Agency.

Water pressure is too high. Verify water pressure regulator is set to 20–25 psi.

Water volume adjustment is set too high. Calibrate unit for proper water volume. Refer to the

Verify generator surface has a thin calcium coating

for proper steaming. Refer to the Maintenance section of this manual.

escapes around the Generator Cover, replace the

cover.

Adjust accordingly.

the maintenance section of this manual.

accordingly.

for proper steaming. Refer to the Maintenance section of this manual.

the unit. The white plastic piece should protrude

approximately 1/8" from the metal.

the unit. While holding into an empty cup, press the

white plastic tip for 5 continuous seconds. A strong,

steady water flow should be noted. If so, re-engage

firmly into the unit. If not present, or low pressure,

contact your maintenance person or plumber.

Remove and re-engage the quick disconnection

firmly until a click is heard. Replace if damaged.

Optical Switch. Replace the Spatula if it is bent or

damaged.

Adjust accordingly.

Installation section of this manual.

P/N 1011175 Rev. A 01/12

9

Page 10

TROUBLESHOOTING (continued)

Problem Possible Cause Corrective Action

Unit only leaks water when powered

off.

Unit only leaks water when powered

on.

Solenoid Valve is leaking due to debris trapped

within its plunger and seat.

Control Board inoperable or problematic. Contact your local Authorized Service Agency.

CYCLE/START button shorted.

Contact your local Authorized Service Agency.

NOTE: This condition is not covered by warranty. To

prevent debris from entering a solenoid, an in-water

strainer must be used.

No heat and the green Ready Light

flashes continuously.

Unit does not operate, power switch is

on, but light is off.

Green Ready Light and yellow

Steaming Light turn on and off intermittently.

Generator is open. Contact your local Authorized Service Agency.

Solid State Relay not closing.

Control Board inoperable or problematic.

Loose, burnt, or broken wires in heater circuit.

Circuit is wired incorrectly.

Unit unplugged. Plug power cord into the appropriate outlet.

Circuit breaker is off. Reset the circuit breaker.

Power cord defective or inoperable. Contact your local Authorized Service Agency.

Power switch defective or inoperable.

Hi-Limit Thermostat is tripping because of an overheating Generator.

Hi-Limit Thermostat is tripping prematurely. If the Hi-Limit Thermostat trips within 380–420°F,

Verify the Generator Surface temperature is 380–

420°F. If temperature is above 420°F, contact your

maintenance person or Authorized Service Agency.

contact your local Authorized Service Agency.

10

P/N 1011175 Rev. A 01/12

Page 11

WIRING DIAGRAM

P/N 1011175 Rev. A 01/12

11

Page 12

REPLACEMENT PARTS

57

45

47

39

35

38

65

14

42

46

13

37

44

34

62

59

4

12

8

51

71

31

28

30

41

36

29

22

55

20

11

21

61

40

49

USE R.O. WATER SUPPLY ONLY

16

15

51

50

34

34

17

67

18

34

43

19

56

53

54

52

34

58

1

69

3

2

12

P/N 1011175 Rev. A 01/12

Page 13

REPLACEMENT PARTS (continued)

Item Part No. Description Qty. Item Part No. Description Qty. Item Part No. Description Qty.

1 0506007 Cavity Liner 1

2 2100107 Spatula Handle 1

3 2100249 Spatula Handle Guard 1

4 0700452 Power Cord 1

5 3010116 Weld Nut #8-32 4

6 3010146 Weld Stud #4-40 x 7/8" 4

7 3040125 PEM Stud #4-40 x 5/8" 2

8 0400251 Strain Relief 1

9 0400138 Locknut Conduit 1

10 3060153 Self-Clinching Stud 1

#6-32 x 3/8"

11 7000652 Solid State Relay, 50A 1

12 4050180 Heat Sink 1

13 308P104* Mach. Screw #8-32 x 3/8" 14 7000245 Generator, 208V, 3800W 1

(Incl. #14, 37, 38, 39 & 65)

15 7000319 Transformer 1

16 300P102* Speed Nut, #8-32 17 1001433 Control Label 1

18 7000841 Momentary Switch Assy. 1

19 4010231 Rocker Switch, 25A 1

20 4070156 Varistor Board 1

21 4050135 Thermocouple, Type J 1

22 0011123 Solenoid Valve Assy. 1

24 VAC

23 2080117 Quick Disconnect, 1

1/8" NPT

24 0503171 Quick Disconnect Plate 1

25 362P102* Lockwasher -

26 2140159 Tape Pipe Tread 2

27 2040103 Male Connector, 1

1/4" x 1/8" NPT

28 2040146 Female Tee Fitting 1

1/4" x 1/8" NPT

29 2040145 Female Elbow Fitting 1

1/4" x 1/8" NPT

30 2000203 Restrictor Tube 1

31 2000236 Inlet Tube 1

32 308P124* Mach. Screw #8-32 33 308P143* KEPS Hex Nut #8-32 34 308P103* Tap Screw, #8-32 x 1/4" 35 0503433 Generator Cover 1

36 0400421 Insulator 1

37 325P170* Wing Nut, 1/4"-20 38 0300129 Stud Cover 1

39 306P134* Mach. Screw #6-32 x 3/8" 40 0503472 Hi-Limit Support Bracket 1

41 7000846 Water Fitting Kit 1

(Incl. #28, 29, 30 & 31)

42 0021654 Chimney 1

43 0012654 Optical Switch Assy. 1

44 2100247 Knob 1

45 2100250 Handle Guard 1

46 1001192 Label, Caution 1

47 0506011 Top Cover 1

48 2140109 Loctite (not shown) 1

49 0506008 Thermocouple Retainer 1

50 4070171 Main Board 1

51 304P105* Hex Nut, #4-40 52 2180145 Bumper Cover 4

53 7000130 Bumper Recess 4

54 310P136* Mach. Screw #10-32 x 1/4"

55 4030314 Hi-Limit Thermostat 1

56 0505999 Bottom Cover 1

57 0505997 Control Housing Cover 1

58 0505998 End Housing Cover 1

59 7000136 Terminal Block 1

60 306P101* Hex Nut #6-32 61 306P123* Mach. Screw #6-32 x 7/8"

62 1000967 Marking Label 1

63 2140156 Adhesive Sealant 1

64 308P120* Mach. Screw #8-32 x 5/8"

65 0503431 Steam Diffuser 1

66 4060107 Cable Tie 1

(not shown)

67 1000402 Label, Increase/Decrease 1

68 1001062 Label, Connections 1

69 0021655 Spatula 1

70 0502199 Spacer 2

71 7000446 Teflon Pipe, 3.625” Lg. 1

(See Note below)

72 0700807 Wire Set 1

(not shown)

73 1001427 Wiring Diagram 1

(not shown)

* Available only in packages of 10.

NOTE: Always use Teflon tape on threads

and tighten until very snug.

P/N 1011175 Rev. A 01/12

13

Page 14

NOTES

14

P/N 1011175 Rev. A 01/12

Page 15

NOTES (continued)

P/N 1011175 Rev. A 01/12

15

Page 16

LIMITED WARRANTY

Equipment manufactured by Roundup Food Equipment Division of A.J. Antunes & Co. has been constructed of the finest materials available and manufactured to high quality standards. These units are warranted to be free from electrical and mechanical

defects for a period of one (1) year from date of purchase under normal use and service, and when installed in accordance with

manufacturer’s recommendations. To insure continued operation of the units, follow the maintenance procedures outlined in the

Owner’s Manual. During the first 12 months, electro-mechanical parts, non-overtime labor, and travel expenses up to 2 hours (100

miles/160 km), round trip from the nearest Authorized Service Center are covered.

1. This warranty does not cover cost of installation, defects caused by improper storage or handling prior to placing of the Equipment.

This warranty does not cover overtime charges or work done by unauthorized service agencies or personnel. This warranty does

not cover normal maintenance, calibration, or regular adjustments as specified in operating and maintenance instructions of this

manual, and/or labor involved in moving adjacent objects to gain access to the equipment. This warranty does not cover consumable/wear items such as Platen Release Sheets, Conveyor Belt Wraps, Gaskets, O-rings, Light Bulbs, Air Bulb Actuators, Rubber Seals,

Rubber Feet, Teflon Egg Rings, Teflon Dampers, Teflon Curtains, Damper Support Springs. This warranty does not cover damage to

the Load Cell or Load Cell Assembly due to abuse, misuse, dropping of unit/shock loads or exceeding maximum weight capacity (4

lbs). This warranty does not cover abuse/improper care of the spatula and liner. This warranty does not cover water contamination

problems such as foreign material in water lines or inside solenoid valves. It does not cover water pressure problems or failures

resulting from improper/incorrect voltage supply. This warranty does not cover Travel Time & Mileage in excess of 2 hours (100

miles/160 km) round trip from the nearest authorized service agency.

2. Roundup reserves the right to make changes in design or add any improvements on any product. The right is always reserved to

modify equipment because of factors beyond our control and government regulations. Changes to update equipment do not constitute a warranty charge.

If shipment is damaged in transit, the purchaser should make a claim directly upon the carrier. Careful inspection should be made of the

3.

shipment as soon as it arrives and visible damage should be noted upon the carrier’s receipt. Damage should be reported to the carrier.

This damage is not covered under this warranty.

4. Warranty charges do not include freight or foreign, excise, municipal or other sales or use taxes. All such freight and taxes are the

responsibility of the purchaser.

5. THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, EACH OF WHICH IS HEREBY EXPRESSLY DISCLAIMED. THE REMEDIES DESCRIBED ABOVE ARE EXCLUSIVE AND IN NO EVENT SHALL ROUNDUP BE LIABLE FOR SPECIAL CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE BREACH OR DELAY IN PERFORMANCE OF THIS WARRANTY.

Loading...

Loading...