Page 1

Burger King

US

Vertical Contact Toaster

Owner’s Manual

Manufacturing Number:

9210130

A

T

T

I

I

O

N

N

A

S

www.antunes.com

L

I

D

S

E

T

C

CM

L

I

D

S

E

T

P/N 1011495 Rev B 04/19

Page 2

Table of Contents

Overview 2

Before Use 2

In Case of Damage 2

Website 2

Service/Technical Assistance 2

In Case of Damage 2

Equipment Information to Save 2

Authorized Service Agency 2

Safety Information 3

Installation 3

Maintenance 3

Service 3

Specications 4

Unpacking 5

Operating Instructions 6

Startup 6

System Cooldown 6

Toasting 6

Adjusting Toasting Settings 6

Adjusting Bun Compression 6

Status Menu 7

Error Log 7

Program Menu 7

Reset Menu 7

Daily Maintenance 8

Cleaning Accessories &Toaster 8

Cleaning the Release Sheet 8

Cleaning the Conveyor Belts 8

Quarterly Maintenance 9

Clean Cooling Fan 9

Checking Conveyor Chains 9

Error Messages 10

Replacement Parts 11

Exploded Diagram 1 12

Exploded Diagram 2 13

Exploded Diagram 3 14

Exploded Diagram 4 15

Wiring Diagram 16

Notes 17

Limited Warranty 18

Overview

This unit is intended to be used

for commercial applications, for

example: in kitchens of restaurants,

canteens, hospitals and in

commercial enterprises such as

bakeries, butcheries, etc., but not for

continuous mass production of food.

Before Use

This manual contains safety,

installation, and operating

procedures for the unit. Read and

understand it completely before

installing or operating the unit. Keep

this document for reference. If the

unit changes ownership, this manual

must accompany it.

In Case of Damage

If the unit arrives damaged, le a

claim with the carrier immediately.

Save all packing materials when

ling a claim. Freight damage

claims are the responsibility of the

purchaser and are not covered under

warranty.

Website

www.antunes.com

Service/Technical

Assistance

In Case of Damage

If any parts are missing or damaged,

problems with the installation or

operation of this product contact

Antunes Customer Service

immediately at +1-877-392-7856 (toll

free).

Fill in the information in the next

section and have it ready when

calling for assistance. The serial

number is on the specication sticker

located on the system.

Equipment Information to Save

Purchased from:

Date of purchase:

Model number:

Serial number:

Manufacturing number:

Authorized Service Agency

Name:

Phone No:

Address:

2

P/N 1011495 Rev. B 04/19

Page 3

Safety Information

Installation

y Read and understand all instructions

before installing or using the unit.

y Install this unit to comply with the

basic plumbing code of the Building

Ofcials and Code Administrators,

Inc. (BOCA) and the Food Service

Sanitation Manual of the Food

and Drug Administration (FDA).

y Install and locate the equipment

only for its intended use as

described in this manual.

WARNING

ELECTRICAL SHOCK HAZARD.

Failure to follow the instructions

in this manual could result in

serious injury or death.

Do not modify the power supply

cord plug. If it does not t the outlet,

have a proper outlet installed by a

qualied electrician.

Electrical ground is required on

this appliance.

Checkwithaqualiedelectrician

if you are unsure if the appliance

is properly grounded.

Operation

y The unit is furnished with

a properly grounded cord

connector. Do not attempt to

defeat the grounded connector.

y Do not operate the unit if it has

been damaged or dropped, if it

has a damaged cord or plug, or

if it is not working properly.

y Do not block or cover any

openings on the equipment.

y Do not immerse the cord,

unit, or plug in water.

y Keep the cord away from

heated surfaces.

y Do not allow the cord to hang over

the edge of a table or counter.

This appliance is not to be used

by persons (including children)

with reduced physical, sensory

or mental capabilities, or lack

of experience and knowledge

unless they have been given

supervision or instruction.

y Children being supervised are

not to play with the appliance.

y Bread may burn. Therefore toasters

must not be used near or below

curtains or other combustible walls

and materials. Failure to maintain

safe operating distances may cause

discoloration or combustion.

Service

y Inspection, testing, and

repair of electrical equipment

must be performed only by

qualied service personnel.

y To avoid possible personal injury

and/or damage to the unit, all

inspections, tests, and repair of

electrical equipment should be

performed by qualied personnel

ONLY. Contact Antunes Technical

Service for adjustment or repair.

y Turn the power off, unplug the power

cord, and allow unit to cool to room

temperature before performing

any service or maintenance.

y If the supply cord is damaged,

it must be replaced by the

manufacturer, its service agent, or

a similarly qualied person in order

to avoid an electrical hazard.

y Cleaning and user maintenance

shall not be made by children

without supervision.

Do NOT use an extension cord

with this product.

The unit should be grounded

according to local electrical

codes to prevent the possibility

of electrical shock. It requires

a grounded receptacle with

separate electrical lines,

protected by fuses or circuit

breaker of the proper rating.

NEVER unplug the power cord

while the unit is running. Use

the proper shutdown procedure

before unplugging the power

cord.

Maintenance

y Do not use abrasive materials;

they can damage the unit’s

stainless steel nish.

y Do not use corrosive chemicals

in this equipment.

y Chlorides or phosphates in cleaning

agents (e.g., bleach, sanitizers,

degreasers, and detergents) can

permanently damage stainless

steel equipment. The damage is

usually in the form of discoloration,

dulling of the metal surface nish,

pits, voids, holes, or cracks.

This damage is permanent and

is not covered by warranty.

y Always use a soft, damp cloth for

cleaning. Rinse with clear water and

wipe dry. When required, always rub

in the direction of metal polish lines.

y Routine cleaning should be

performed daily with soap and water.

y Rub off nger marks and smears

using soap and water.

y Do not clean the unit with a

water jet or steam cleaner.

P/N 1011495 Rev B 04/19

3

Page 4

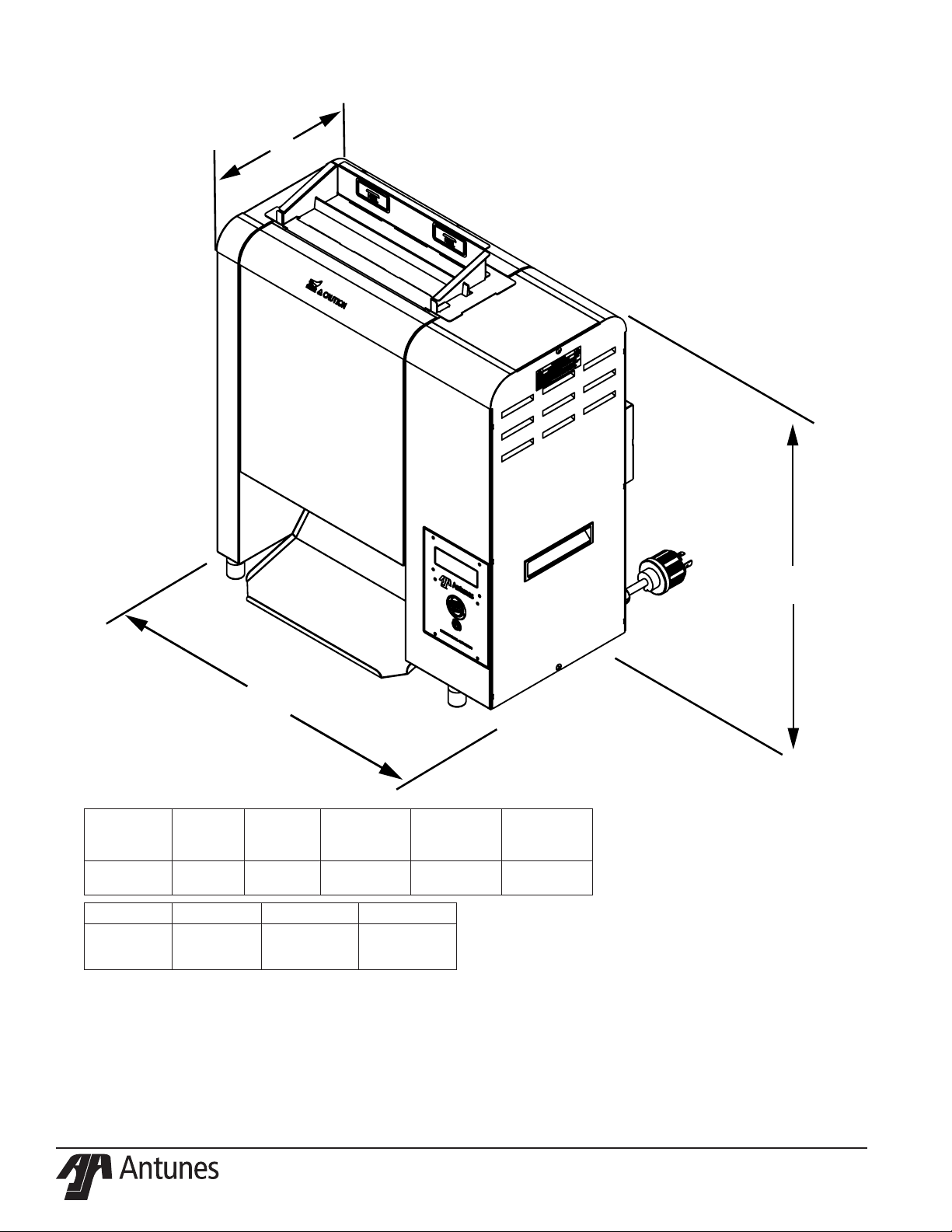

Specications

B

A

Model &

Mfg. No.

9210130 200-240 1 Phase 50/60 1900W 10

Model # (A) Width (B) Depth (C) Height

9210130

Volts Phase Hertz Power Current

23”

(584.2mm)

10 3/4”

(273.05mm)

24 3/4”

(628.65mm)

C

4

P/N 1011495 Rev. B 04/19

Page 5

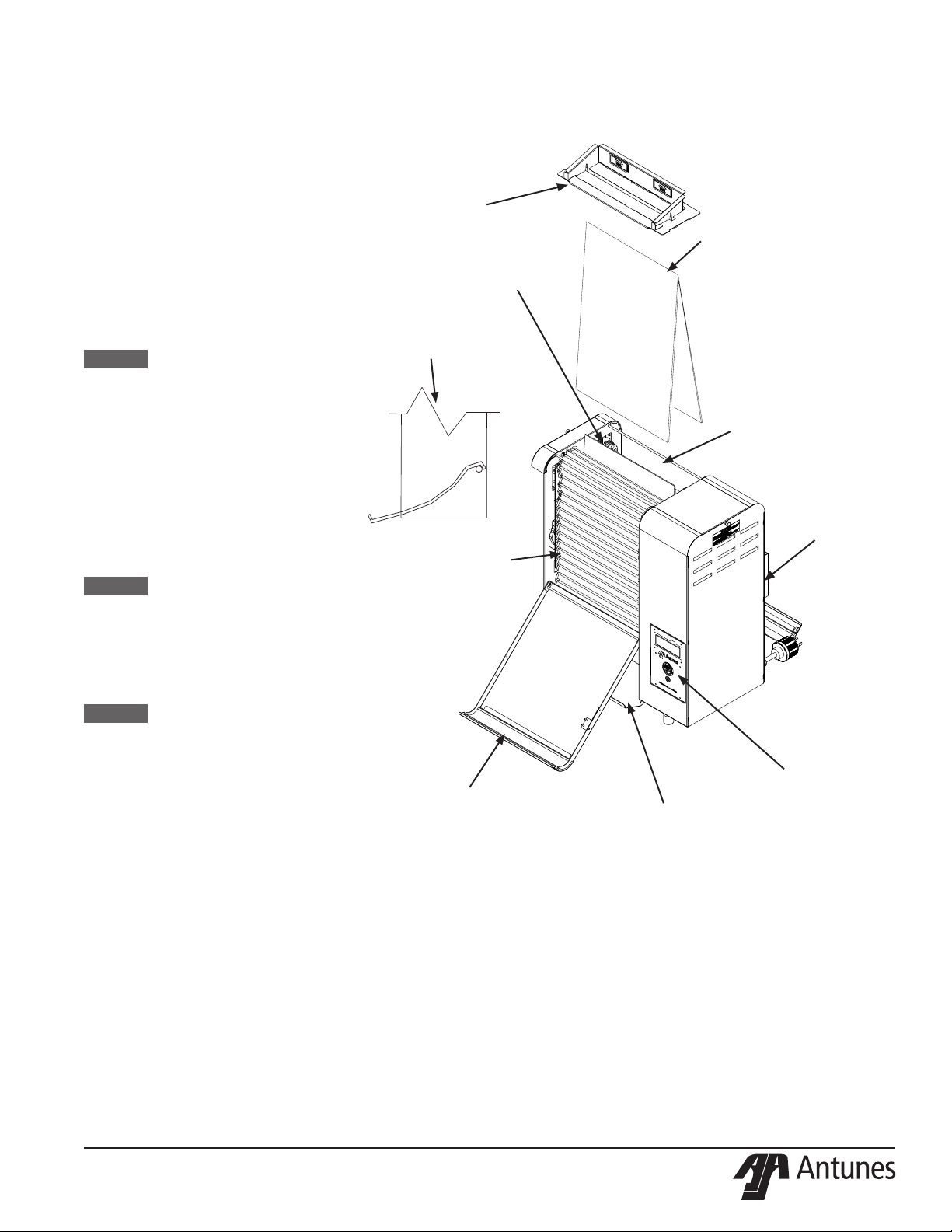

Unpacking

1. Remove toaster and all packing

materials from the shipping

pallet.

2. Remove all shipping tape and

protective coverings from the

toaster and parts.

3. Open the Accessories Box. It

should contain the following:

y Bun Chute

y Bun Feeder

y Two Release Sheets

y Owner’s Manual

NOTICE: If any parts are missing or

damaged, contact Antunes

IMMEDIATELY at 1-800-2532991 (toll free in the U.S. and

Canada) or at 630-784-1000.

4. Wipe the entire exterior of the

toaster and the accessories

mentioned above with a hot

damp cloth. Allow to air dry

completely.

NOTICE: Do NOT use a dripping wet

cloth. Wring out before use.

Bun

Feeder

Bun Chute Assembly

connected over the

bottom rear support

rod

Front

Conveyor

Belt Chain

Release

Sheet

Platen

Rear

Conveyor

Belt Chain

Fan Baffle

5. Install the Bun Chute, Release

Sheet, and Bun Feeder as

shown in Figure 1.

NOTICE: Ensure both Conveyor

Covers are closed before

turning on the toaster. Failure

to do so will trigger an OPEN

COVER Warning. Close the

covers to cancel the warning.

Front

Conveyor

Cover

Assembly

Bun

Chute

Figure 1. Components

Graphical User

Interface and

Power Switch

P/N 1011495 Rev B 04/19

5

Page 6

Operating Instructions

Startup

1. Press and hold the Power button

for two (2) seconds. The splash

screen will appear, followed by

the software version screen. The

toaster will begin its warm-up.

Warm up time is less than 30

minutes.

During the warm-up, the current

platen temperature is displayed.

When initial Warm-up completes, the

toaster displays the Main Menu.

The warm-up screen can be

bypassed by touching FOOD.

Toasting

To begin start on the main screen:

BURGWHPR SOUR

MENU

1. Use the arrow key to cycle

through the menu items and

select an option to open the

Toasting Screen.

To choose a different menu item, tap

the highlighted menu item button to

be returned to the previous screen.

M

WHPR

WAIT

---10s

Adjusting Toasting Settings

From the Toasting Screen:

M

WHPR

READY

1. Press and hold for one (1)

second then release the toast

time button.

This opens the timer settings screen

for that darkness preset. The current

setting is shown in the top right

corner in # of seconds.

L

---10s

8s

OK

Wait.. 282F

Toasters are HOT and

can cause severe burns. Keep

hands and objects out of the

toaster. Failure to do so may

result in serious injury. Turn the

toaster off, unplug it, and check

that the toaster is completely

cool before touching or

servicing.

FOOD

NOTICE: After 20 seconds of

inactivity the toaster will time

out. If the toaster is not up to

the operating temperature,

the display will default to

the Warm-Up screen until

operating temperature is

reached. While at operating

temperature, the toaster

will default to the Toasting

Screen.

System Cooldown

Pressing and holding the power

button for two (2) seconds will power

off the toaster. It will then go into

Cooldown Mode. The unit is off but

will continue to show the temperature

of the platen during this time. Wait till

the toaster is completely cooled and

unplug before servicing or moving it.

Cooling.. 458F

NOTICE: If the initial Warm-Up

Screen is bypassed the

toaster may not be at

operating temperature.

In this case, the Toasting

Screen may say WAIT.

If this happens, wait until

the Toasting Screen reads

READY before inserting

product.

M

WHPR

READY

---10s

2. You may change the toasting

speed at any time by touching

the toast time button to cycle

through the three (3) preset

values: Light, Medium, & Dark.

3. When the screen reads READY

you may begin toasting product.

4. Insert product into the toaster

with the CUT SIDE facing the

PLATEN.

NOTICE: If SOUR is selected, the

display will automatically

default to WHPR after 20

seconds.

6

2. Using the left and right arrow

keys, adjust the time to the

setting desired.

3. Touch OK to save the adjusted

setting and return to the Toasting

Screen.

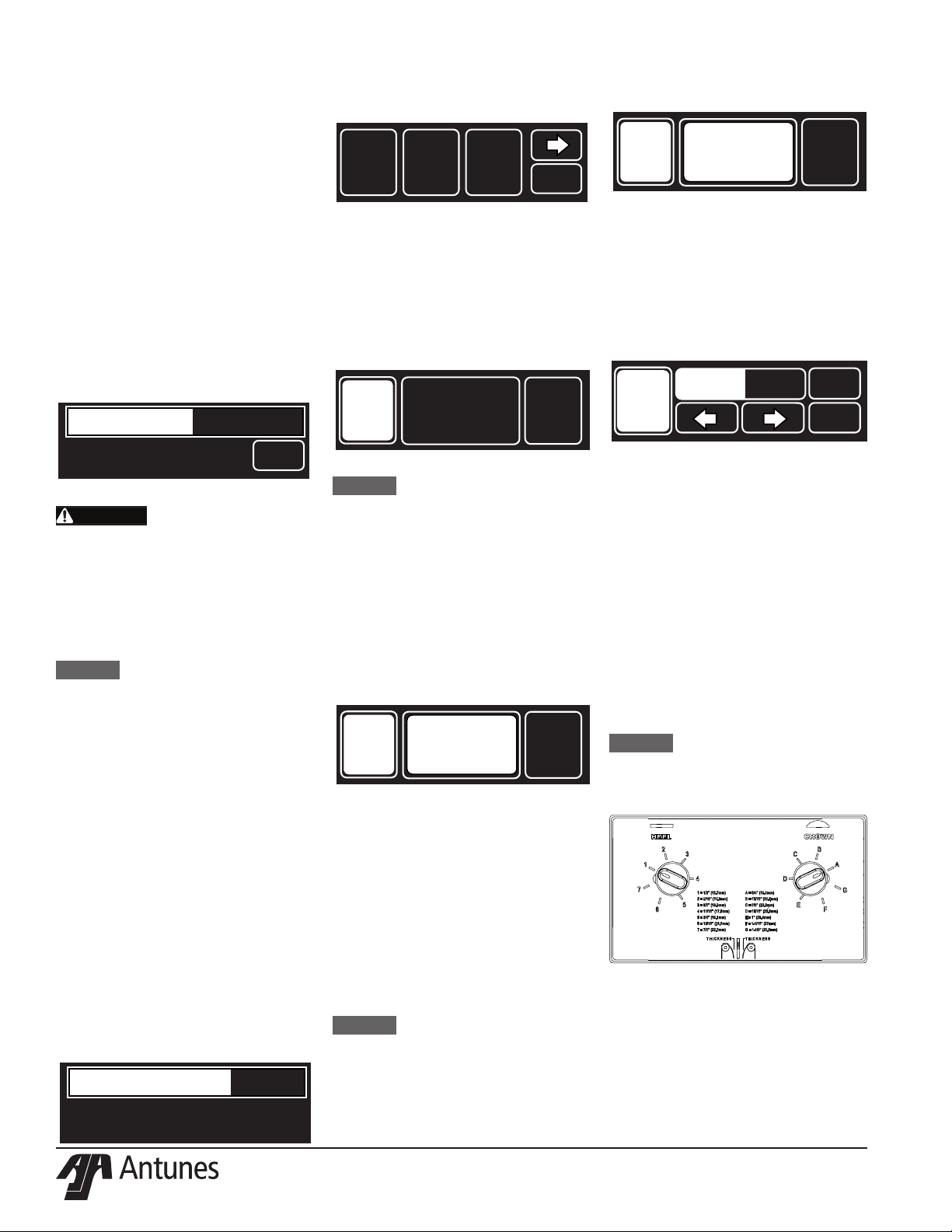

Adjusting Bun Compression

This toaster features compression

knobs that are adjustable for different

bun thickness.

Increase the compression setting

for buns that are taller in height and

decrease for buns that are shorter.

NOTICE: For darker toast decrease the

compression setting. For lighter

toast increase the compression

setting.

Figure 2. Bun Thickness

Compression Control

Crown - Rotate knob

Counterclockwise to increase

and clockwise to decrease the

compression setting

Heel - Rotate the knob clockwise to

increase the and counterclockwise to

decrease the compression setting.

P/N 1011495 Rev. B 04/19

Page 7

Manager Menu

Touching MENU from the main menu

will open up the Manager Menu. You

can access the options for Status,

Errors, Programming, and Resetting.

BURGWHPR SOUR

MENU

Touch MENU to return to the main

screen to exit.

MENU

ERRSSTAT

Status Menu:

Touch STAT from the Manager Menu

to open the Status Menu.

PLATEN TEMP

STAT

CURR: 72

SET: 610°F

Use the up and down arrow buttons

to view the statuses for:

y Platen Temperature

y Power

y Board Temperature

y Motor Speed

y Total Run Time (Total time

the toaster has been ON)

Touch STAT again to be returned to

the Manager Menu.

°F

Program Menu:

Touch PRGM from the Manager

Menu to open the Program Menu.

PRGM

There are several options to adjust in

the Program Menu: Set Platen Point,

Units, Beeper Volume.

Selecting SETP will open the Platen

Set Point Temperature Menu:

SETP

SETP UNIT

565

OK

Use the arrow keys to show the

different Manager menu options.

Error Log:

Touch ERRS from the Manager

Menu to open the Error Log.

25) 0D+03:03

ERRS

Errors are listed in reverse order

with the most recent error listed rst.

Up to 30 errors can be stored in the

system. Use the up and down arrow

buttons to view the logged errors.

Error time is displayed as time

elapsed since the error occurred. If

the error occurred less than 100 days

before, then it will be displayed in the

following format:

Days, Hours: Minutes.

The above example shows that the

error occurred 0 Days, 3 hours and 3

minutes ago.

After 100 days, the error will be

displayed in number of days only.

Touch ERRS again to be returned to

the Manager Menu.

Open Probe

(E117)

The default set-point temperature is

565F.

Adjust the Set Point Temperature

using the arrow keys. Touch OK to

save your changes or SETP to return

to the Program Menu without saving.

The temperature is shown in

Fahrenheit by default. To change

units, select UNIT to change the

display unit (Fahrenheit or Celsius)

Select VOL to change the beeper

volume (Off, Low or High)

Reset Menu:

Touch RSET from the Manager Menu

to open the Reset Menu.

RSET

There are several options for

resetting: All, Options (All Options

in the Program Menu), Food (All

darkness for food items), and Errors

(to clear the Error Log).

Use the arrow keys to navigate.

Touch the desired menu item to reset

it.

OPTALL

P/N 1011495 Rev B 04/19

Touch RSET again to be returned to

the Manager Menu.

7

Page 8

Daily Maintenance

The toaster requires a minimal

amount of maintenance. Daily

maintenance helps keep the toaster

running smoothly and free of any

excess buildup that comes from daily

use and wear. These steps should

be completed at the end of every day

to ensure that the toaster maintains

optimum efciency.

The toaster will remain

hot to the touch while it is cooling

down. Personal injury and burns

may result from touching the toaster

before it is finished cooling down.

Wear Heat Resistant Gloves during

all cleaning processes.

Cleaning the Accessories and

the Toaster

1. Push the Power Button to turn

the toaster off.

2. The toaster will enter the

cool down mode. The fan will

continue to run. This cool down

mode will shut the toaster down

automatically when complete.

3. Wearing Heat Resistant Gloves,

remove the following items from

the toaster (refer to Figure 1):

y Bun Feeder

y Bun Chute

y Release Sheet

4. Wash the Bun Feeder and Bun

Chute in a three compartment

sink. Let air dry.

NOTICE: Do NOT wash any of

the accessories in a Power

Soak Machine or any other

mechanical washer. Damage

to the accessories may result.

Wash all accessories by hand

in the sink

5. Wipe down the outside of the

toaster with a clean, sanitized

towel dampened with noncorrosive cleaning solution.

Cleaning the Release Sheet

1. Remove the Bun Feeder and

Release Sheet and inspect both

sides of the Release sheet.

NOTICE: Replace the Release

Sheet if it is overly worn,

creased, or torn.

2. Lay the release sheet on a

clean, at, dry surface. Spray a

multipurpose cleaner on a clean,

dry towel.

3. Wipe the Release Sheet rmly

from top to bottom over its entire

surface.

4. Immediately repeat this

procedure with a clean, dry towel

dampened with water.

5. Wipe the entire Release Sheet

with a clean towel dampened

with sanitizer solution and allow

to air dry.

6. Turn the Release Sheet over and

repeat Steps 2 through 5 on the

reverse side.

7. Allow Release Sheet to

completely dry before installing.

8. Reinstall the Release Sheet,

checking to make sure it is

draped properly over the Platen.

NOTICE: Rotate the reversible

Release Sheet from side to

side daily to extend the life of

the Release Sheet.

Cleaning the Conveyor Belts

Wear heat resistant gloves during the

belt cleaning process to avoid risk of

burns or cuts while cleaning.

NOTICE: Grill Cleaner is most

effective when used while

the toaster is still warm. Do

NOT wait for the toaster to

cool down completely before

cleaning.

1. Face the front of the toaster.

From the bottom of the Conveyor

Cover Weldment, lift up and tilt

the cover away from the toaster

to expose the Conveyor Belt.

NOTICE: The conveyor belts will

rotate slowly during “Cooling

Mode” when the covers are

open.

2. Spread a light coating of high

temperature grill cleaner or

degreaser on a non-scratch pad

or clean towel.

3. Applying moderate pressure,

scrub the metal slats side to side

until clean.

NOTICE: There is a metal backing

plate behind the conveyor to

provide support for cleaning

the slats. Only clean the

conveyor while it is against

the backing plate in the center

to prevent damage to the unit.

4. Wipe the conveyor belt with

another clean, towel sprayed

with sanitizer solution. Let the

belt air dry.

5. Close the front Conveyor Cover,

making sure it locks into place.

6. Repeat steps 1-5 to clean the

rear conveyor belt.

8

P/N 1011495 Rev. B 04/19

Page 9

Quarterly Maintenance

Clean Cooling Fan

To ensure proper airow and help

prevent the occurrence of fan fault

or error messages the cooling fan

intake vent and/or fan should be

periodically cleaned.

1. Turn the toaster off and allow

the toaster to complete its cool

down.

2. Unplug the power cord.

3. Locate the Fan Bafe on the rear

of the toaster. Pull the pin out

and tilt the bafe up and away

from the toaster to remove. (See

Figure 3)

Checking Conveyor Chains

This unit features an take-up system

that automatically applies tension

to the conveyor chain as it wears/

stretches. Over a period of time

however, the take-up system can

reach it’s maximum level resulting

in the conveyor chain eventually

skipping on the sprockets. This is

easily remedied by removing one or

more conveyor links from each side

of the belt.

1. Turn the toaster off and let it

enter cooldown mode.

2. Open both conveyor covers.

The belts will be rotating slowly

during cooldown mode.

3. Locate the bottom Idler shaft on

the front and rear conveyors. If

the belt is skipping a link(s) will

need to be removed.

4. Close the conveyor covers

and let the unit cool before

proceeding. Unplug the power

cord.

5. Remove the Bun Feeder

Figure 4. Remove Belt Link

9. To shorten a stretched Conveyor

Belt Chain, remove one complete

link from the chain.

NOTICE: The ends of the hooks

must point down (Figure 4).

10. Wrap the Conveyor Belt Chain

around the top and lower

sprockets and connect by

hooking both ends together.

NOTICE: Some pressure may need

to be applied to the top idler

shaft by pressing it down to

provide more slack to the

belt when reinstalling the

conveyor belt chain.

Figure 3. Fan Bafe Removal

4. Wipe away any debris and lint

from the fan bafe and air intake

vent with a clean towel.

5. Reinstall Fan Bafe to toaster

and plug in power cord.

6. Return toaster to use.

NOTICE: It is very important to keep

the cooling fan and electrical

compartment clean and in

top operational mode. Do not

ignore these cleaning steps.

6. Remove the release sheet to

avoid damaging it during the belt

link replacement process.

7. Open both Conveyor Covers.

8. Disconnect the Conveyor Belt

Chain by squeezing any two

links together and unhooking

both ends of one link (Figure 4).

Needle-nose pliers may be used

P/N 1011495 Rev B 04/19

9

Page 10

Error Messages

If the toaster displays any error messages, touch the error button to silence the error beeper.

Touch the error button turn the toaster off and restart it. If the error persists, contact Antunes Technical Service: 1-877392-7854 (toll free).

Error

Code

E101 HI-LIMIT

E117 OPEN PROBE

E135 WARMUP

E10 MOTOR

E2 ZERO CROSS Internal control board error.

E6 MEMORY Memory chip error.

E105 OVERTEMP Temperature is 25°F over Set

E111 UNDERTEMP Unit drops 100°F below Set

E305 MOTOR

E300 MOTOR STOP Motor Failure.

E123 BOARD TEMP

OPEN COVER Conveyor cover isn’t locked in

MOTOR LOAD

Error Description Corrective Action

High-Limit is triggered.

Thermocouple connection is

open.

The unit is taking too long to

TIME

COMM

SLOW

Warning Description

warm-up.

Unit cannot communicate with

motor.

Point Temperature.

Point Temperature when in

READY state.

Motor speed drops below 75%.

Control Board is too hot.

place. Check conveyor covers.

Motor speed drops below 90%

for 5 seconds.

Allow sufcient time (10-15 minutes) for the unit to cool

down. Remove the Hi-Limit control cap at the rear of

the unit. Press the Hi-Limit Reset button. Turn the unit

on and test the unit by toasting some product. If the

Hi-Limit continues to trip, contact Antunes Technical

Service at +1-877-392-7854 for assistance.

Re-secure the Platen Thermocouple connection to the

Control Board. If the Control Display still reads “Open

Probe” If message persists, contact Antunes Technical

Support at +1-877-392-7854 (toll free) for assistance.

Cycle Power OFF Unplug unit for 30 seconds Cycle

Power ON . If message persists, contact Antunes

Technical Support at +1-877-392-7854 (toll free) for

assistance.

Check the conveyor belts & surrounding areas for any

obstructions/jams. Contact Antunes Technical Support

at +1-877-392-7854 (toll free) for further assistance.

Inspect the cooling fan on the back for operation and

ensure it is clean. If needed, clean the cooling fan or

replace.

Inspect both conveyor covers and ensure that they are

properly engaged.

Check the conveyor belts & surrounding areas for any

obstructions/jams. Contact Antunes Technical Support

at +1-877-392-7854 (toll free) for further assistance.

CAUTION

Use of any replacement part other than

those supplied by Antunes of their authorized

distributors can cause injury to the operator

and damage to the equipment and will void

all warranties.

10

WARNING

Before replacing any parts, or opening

any side or rear panel from the toaster,

disconnect the toaster from the electrical

power supply.

P/N 1011495 Rev. B 04/19

Page 11

Replacement Parts

Parts list (see Exploded diagrams below)

Note

Use only genuine Antunes replacement parts in this

unit. Use of parts other than those supplied by the

manufacturer will void the warranty.

Item

No.

1a 7001966 Conveyor Belt, Formed 2

1b 7001967 Conveyor Links Kit

2 70P0249 Release Sheet (3 Pack) 1

3 7001991 Bun Feeder 1

4 7001984 Platen, Grill

5 7001985 Rear Conveyor Cover 1

6 7001986 Front Conveyor Cover 1

7 7001988 Compression Label 1

8 7001989 Side Housing Panel kit 1

9 7001990 Control Side Panel Kit 1

10 7001965 Control Label 1

11 7001993 Bun Chute 1

12 7001611 Handle Snap-In 2

13 7001000 Rubber Leg Kit 4

14 7001957 Main Board Kit 1

15 7001958 Display Board Kit 1

16 7001959 Motor Board 1

17 7001960 Capacitor 1

18 7001961 Display Cover 1

19 7001962 USB Cable 1

20 7001528 Varistor Board 1

21 7001968 Fan Bafe 1

22 7000913 Fan 230VAC Kit 1

23 7001969 Drive Chain 1

24 7001970 Drive Shaft 2

25 7001971 Idler Shaft 2

26 7001972 Spring Guide LH/RH 4

27 7001973 Plate Tensioner 4

28 7001974 Spring Bearing Retainer 4

29 7001975 Cam Compression R/L 4

30 7001976 Cam Shaft 2

31 7001977 Motor Sprocket 2

32 7001978 Drive Sprocket 8

33 7001979 Dive Bearing Retainer 2

34 7001980 Idler Bearing Retainer 2

35 7001981 Idler Sprocket Assy 8

Part # Description QTY.

200V/1900W

Item

No.

36 7001982 Support rod 2

37 7001983 Support Cover 2

38 7001987 Spring Compression 8

39 7001964 Door Sensor Board 2

40 7001016 Power Cord -

41 7001144 Thermostat, Hi-Limit

42 7001609 Terminal Block,

43 7001143 Solid State Relay 1

1

44 7001527 Cap-Mp Motor Run 1

45 7000500 Motor 1

46 7001033 Bearing Assy 2

47 7001324 Knob 2

48 7001293 Thermocouple, Type K 1

49 0013862 Conveyor Frame, Front 1

50 0013863 Conveyor Frame, Rear 1

51 0509113 Bracket, Motor Board

52 0509148 Bracket, Conveyor

53 0509365 Bracket, Motor

54 0510017 Bracket, Tensioner 1

55 0600158 Spring, Roller Tension 4

56 1000900 Label - Warning 1

57 1001180 Label - Heel 2

58 1001213 Label - Shock Hazard 1

59 1002774 Label - Wiring Diagram 1

60 3250219 SH Bolt 5/16 Dia X 1”

61 304P105* Nut, Hex “KEPS” #4-40

62 306P130* Nut, Hex “KEPS” #06-

63 308P143* Nut, Hex “KEPS” #8-32 -

64 310P102* Washer, Int. Tooth-

65 310P134* Nut, #10-32 Acorn -

66 310P146* Nut, Hex “KEPS” #10-

67 310P178* Screw, Hex Bolt #10-32

* Indicates that item can only be purchsed in packs of

Part # Description QTY.

1

T/Lock L6-30P

1

700F

1

S-Series

1

Mount

4

Frame Mount

1

Mounting

8

LG 1/4-20

-

Zinc

-

32 Steel; Zinc Plated

-

Lock, #10

-

32

-

X 3/8”

ten (10).

P/N 1011495 Rev B 04/19

11

Page 12

Exploded Diagram 1

5

3

47

7

12

8

3

6

11

13

12

P/N 1011495 Rev. B 04/19

Page 13

Exploded Diagram 2

46

28

38

29

27

27

55

65

52

60

66

60

66

34

P/N 1011495 Rev B 04/19

13

Page 14

Exploded Diagram 3

5

2

50

4

48

49

36

32

25

1

6

1

30

24

37

14

P/N 1011495 Rev. B 04/19

Page 15

ExplodedDiagram4

41

10

18

61

14

15

61

43

44

22

62

29

56

20

35

21

24

19

32

54

46

27

68

55

51

46

63

61

33

64

66

52

42

28

32

67

60

16

66

61

9

58

59

53

45

12

P/N 1011495 Rev B 04/19

15

Page 16

Wiring Diagram

16

P/N 1011495 Rev. B 04/19

Page 17

Notes

P/N 1011495 Rev B 04/19

17

Page 18

Limited Warranty

Equipment manufactured by Antunes has been constructed of the nest materials available and manufactured to high

quality standards. These units are warranted to be free from electrical and mechanical defects for a period of one

(1) year from date of purchase under normal use and service, and when installed in accordance with manufacturer’s

recommendations. To insure continued operation of the units, follow the maintenance procedures outlined in the

Owner’s Manual. During the rst 12 months, electromechanical parts, non-overtime labor, and travel expenses up to 2

hours (100 miles/160 km), round trip from the nearest Authorized Service Center are covered.

This warranty does not cover cost of installation, defects caused by improper storage or handling prior to placing of

the Equipment. This warranty does not cover overtime charges or work done by unauthorized service agencies or

personnel. This warranty does not cover normal maintenance, calibration, or regular adjustments as specied in

operating and maintenance instructions of this manual, and/or labor involved in moving adjacent objects to gain access

to the equipment. This warranty does not cover consumable/wear items. This warranty does not cover damage to the

Load Cell or Load Cell Assembly due to abuse, misuse, dropping of unit/shock loads or exceeding maximum weight

capacity (4 lbs). This warranty does not cover water contamination problems such as foreign material in water lines or

inside solenoid valves. It does not cover water pressure problems or failures resulting from improper/incorrect voltage

supply. This warranty does not cover Travel Time & Mileage in excess of 2 hours (100 miles/160 km) round trip from

the nearest authorized service agency.

Antunes reserves the right to make changes in design or add any improvements on any product. The right is always

reserved to modify equipment because of factors beyond our control and government regulations. Changes to update

equipment do not constitute a warranty charge.

If shipment is damaged in transit, the purchaser should make a claim directly upon the carrier. Careful inspection

should be made of the shipment as soon as it arrives and visible damage should be noted upon the carrier’s receipt.

Damage should be reported to the carrier. This damage is not covered under this warranty.

Warranty charges do not include freight or foreign, excise, municipal or other sales or use taxes. All such freight and

taxes are the responsibility of the purchaser.

This warranty is exclusive and is in lieu of all other warranties, expressed or implied, including any implied warranty

or merchantability or tness for a particular purpose, each of which is hereby expressly disclaimed. The remedies

described above are exclusive and in no event shall Antunes be liable for special consequential or incidental damages

for the breach or delay in performance of this warranty.

The warranty does not extend to:

y Damages caused in shipment or damage as result of improper use.

y Installation of electrical service.

y Installation, calibration, or adjustment.

y Normal maintenance outlined in this manual.

y Malfunction resulting from improper service or maintenance.

y Damage caused by improper installation, abuse, or careless handling.

y Damage from moisture getting into electrical components.

y Damage from tampering with, removal of, or changing any preset control or safety device.

y Damage caused by parts or components not provided by Antunes

+1 (630) 784-1000

®

+1 (800) 253-2991

+86-512-6841-3637

+86-512-6841-3907

Loading...

Loading...