Page 1

R

30”/36”/48” wide Adjusta Unit

Assembly Instructions

Hello! Thank you for choosing Anthro.

Before beginning assembly of your Adjusta Unit, take a moment to review the parts listed on the next page

to verify that your shipment is complete. Please review the assembly instructions of all Anthro products you

purchased and are planning to include in this installation, prior to beginning this assembly.

To make the assembly of your Adjusta Unit even easier, we have included all of the required tools. The handy

Hex Driver Bit can be used in your electric drill in place of the Hex Driver. Your Adjusta Unit is heavy! A second

person will make this assembly procedure much easier.

Hex Driver 5/32” ............................................................ 375-5000-00

Hex Driver Bit 5/32” ..................................................... 375-5003-00

Hex Key 5/32” ................................................................. 375-5016-00

Hex Key 3/16” ................................................................. 375-5028-00

3-Way Wrench .............................................................225-5196-03

8 oz. Rubber Mallet ..................................................... 375-5022-00

Thank you for buying our Products!

Please return the enclosed Registration Card to receive our product

updates, new catalogs, and sale flyers.

Anthro Corporation Technology Furniture®

10450 SW Manhasset Drive

Tualatin, Oregon 97062

anthro.com

Questions? 1-800-325-3841

Anthro Corporation Technology Furniture® 10450 SW Manhasset Drive Tualatin, Oregon 97062 anthro.com

1-800-325-3841

SAVE THESE INSTRUCTIONS!

Rev. C January 2006

Page 2

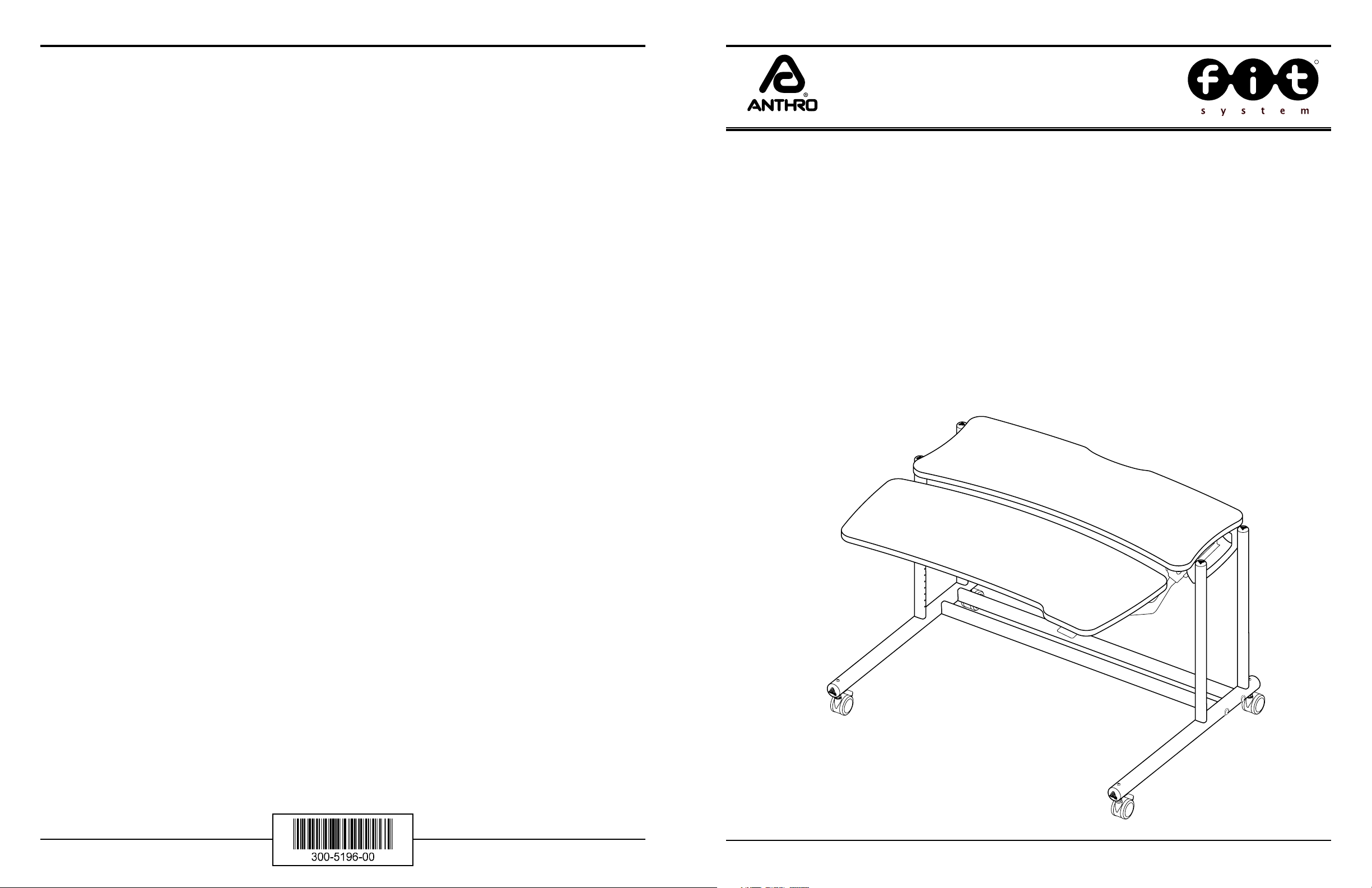

Component list for part #’s FAJ30zz/xx3, FAJ36zz/xx3 & FAJ48zz/xx3

02

06

03

04

05

01

07

15

16

17

18

19

20

19

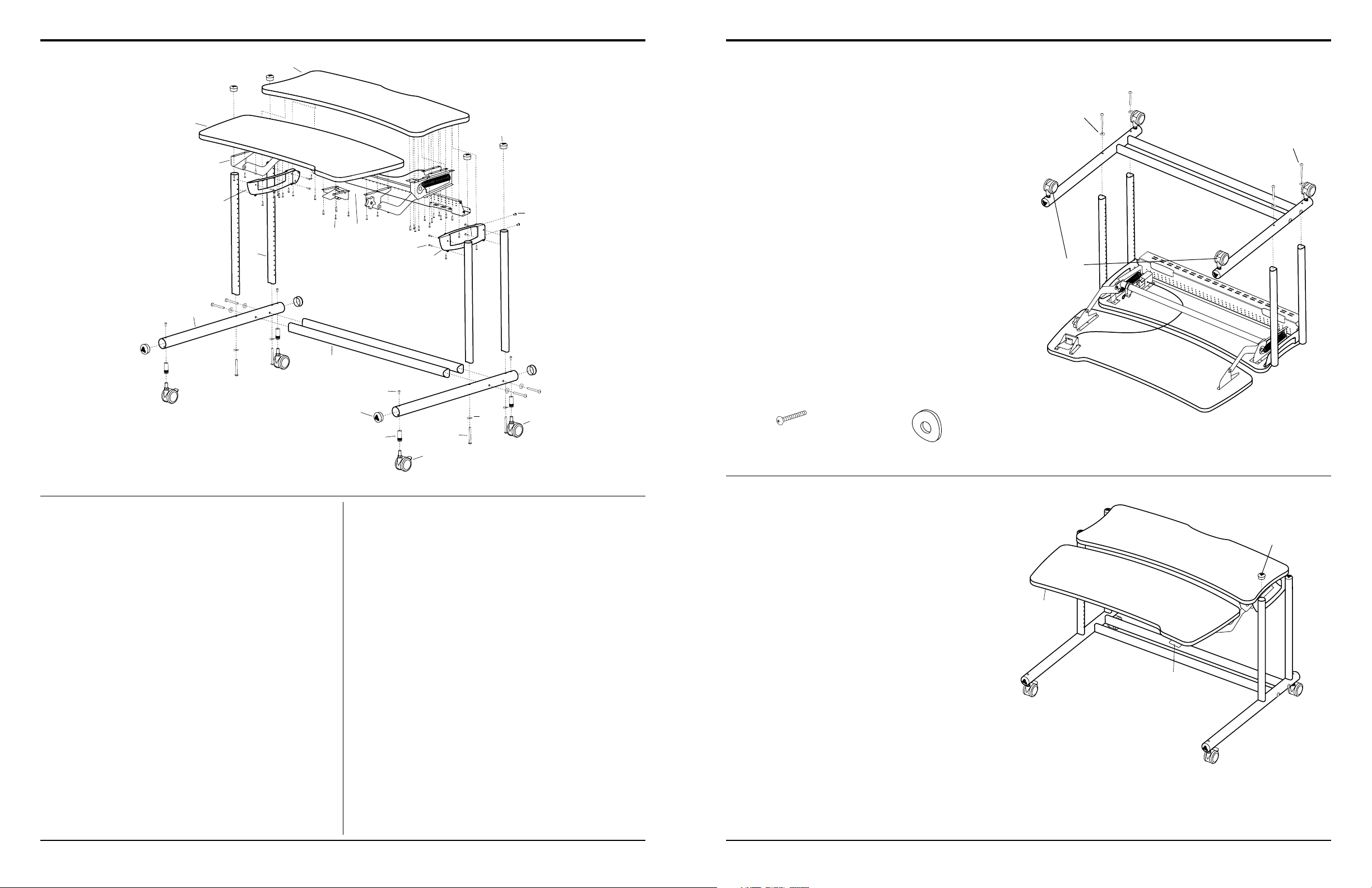

Step 12

Align the Base Assembly on the Vertical Tubes as shown.

Secure the Base Assembly by inserting a fit Bolt through a

Tube Washer. Then insert the Bolt through the Base Tube

and carefully thread it into the Vertical Tubes.

Repeat for the remaining three Bolts and tighten all Bolts.

fit Tube

Washer

fit Bolt

Locking Casters

09

NOTE: Detailed views of all Hardware are provided with each Assembly Step.

01–fit Adjusta Fixed Worksurface Qty. 1 ....................... (see below)

30” Wide Fixed Worksurface (FAJ30zz/xx3) ....100-6454-00

36” Wide Fixed Worksurface (FAJ36zz/xx3) ....100-6455-00

48” Wide Fixed Worksurface (FAJ48zz/xx3) ....100-6456-00

02–fit Adjusta Caddy Worksurface Qty. 1 ....................... (see below)

30” Wide Caddy Worksurface (FAJ30zz/xx3)..100-6458-00

36” Wide Caddy Worksurface (FAJ36zz/xx3) ..100-6459-00

48” Wide Caddy Worksurface (FAJ48zz/xx3) ..100-6460-00

03– fit Adjusta Mechanism...............Qty. 1 ....................... (see below)

(The Adjusta Mechanism is packaged separately & requires assembly)

30” Wide Adjusta Mechanism (FAJ30zz/xx3) ...225-5545-00

36” Wide Adjusta Mechanism (FAJ36zz/xx3) ...225-5546-00

48” Wide Adjusta Mechanism (FAJ48zz/xx3) ...225-5547-00

04– Small Support Bracket X .............Qty. 1 ...................225-2014-00

05– 24.875” Vertical Legs .................Qty. 4 ...................125-5230-00

06– Adjusta Base Tubes ......................Qty. 2 ..................125-5276-00

08– Insert Screws ................................. Qty. 4 ...................325-5052-00

09– 2.0” Large End Caps ...................Qty. 4 ...................175-5157-00

10– Caster Inserts ............................... Qty. 4 ...................525-5032-00

11– 3” Locking Casters ......................Qty. 2 ...................150-5053-00

12– 5/16-18 fit Bolts ..............................Qty. 8 ...................325-5194-00

13– fit Tube Washers .........................Qty. 8 ..225-2050-00 or 225-3522-00

14– 3” Non-Locking Casters ........... Qty. 2 ...................150-5052-00

15– 3/4” Wood Screws ........................Qty. 42 ................325-5106-00

16– Back Trough .................................... Qty. 1 ....................... (see below)

30” Wide Back Trough (F3029zz/xx3) ................225-2290-00

36” Wide Back Trough (F3629zz/xx3) ................225-2291-00

48” Wide Back Trough (F4829zz/xx3) ................225-2292-00

17– Support Screws ............................ Qty. 8 ...................325-5010-00

18– Small Support Bracket Y ............Qty. 1 ...................225-2015-00

19– 1/4-20 Button Head Screws ...... Qty. 4 ...................325-5003-00

20– 1.5” Small Caps .............................Qty. 4 ...................175-5156-00

07– Cross Tubes .................................... Qty. 2 ....................... (see below)

30” Wide Cross Tube (FAJ30zz/xx3) ...................125-5219-00

36” Wide Cross Tube (FAJ36zz/xx3) ...................125-5220-00

48” Wide Cross Tube (FAJ48zz/xx3) ...................125-5214-00

All Fastener quantities listed here are the minimum needed

for your Adjusta Unit assembly. There may be a few extra

Fasteners included, which are not counted in the Parts List.

10

08

11

12

13

14

(5/16-18 X 3.5”) fit Bolt

325-5194-00

fit Tube Washer

225-2050-00 or 225-3522-00

Step 13

Insert the four 1.5” Small End Caps into the Vertical Legs.

Congratulations! Your assembly is complete.

Please return the enclosed Registration Card to receive

our product updates, new catalogs, and sale flyers.

Thank you for choosing Anthro!

Adjust the Caddy Worksurface height by:

1. Squeezing and holding the Paddle.

2. Reposition the Caddy to the desired location.

3. Release the Paddle.

Adjust the Caddy Worksurface angle by:

1. Rotating the Knobs counterclockwise.

2. Reposition the Caddy to the desired angle.

3. Rotate the Knobs clockwise.

1.5” Small

End Cap

Rotate Knobs

to adjust

Caddy angle.

Squeeze Paddle

to adjust Caddy height.

Anthro Corporation Technology Furniture® 10450 SW Manhasset Drive Tualatin, Oregon 97062 1-800-325-3841

anthro.com

Page 3

FAJ30zz/xx3, FAJ36zz/xx3 & FAJ48zz/xx3

Step 9 (requires Worksurface to be 12” from floor)

Rotate the Caddy Worksurface so the predrilled holes face

upward and the Lip faces the front of the Adjusta Unit.

Slide the Caddy under the Mechanism and align

the three holes located on each end of the Caddy and

Mechanism.

Secure the Caddy using a total of six Wood Screws. Then,

secure the Paddle to the Caddy using four Wood Screws.

NOTE: Make certain the Cable for the Paddle is positioned

underneath the Adjusta Bar.

3

/4” Wood Screw

325-5106-00

Step 10

Install two Caster Inserts into each Base Tube and secure with one Insert Screw per Insert.

Insert one Locking and one Non-Locking Caster into

each Insert of a Base Tube as shown.

Insert two End Caps into the ends of both Base Tubes.

Wood Screw

Paddle

(12” high surface shown shaded)

Adjusta Bar

Leave these two side holes open

Step 1a

Your Adjusta Mechanism comes unassembled and is

boxed separately inside the Adjusta Unit package.

Begin to assemble the Mechanism by first locating the Adjusta

Crossbar and Brake/Paddle Assembly, position it as shown at

right. Depress the Paddle once to free the Brake Shaft.

Place the Brake Shaft between the two center Crossbar

Flanges. Insert the Post through both center Crossbar

Flanges and Brake Shaft.

Post

(included with 225-554x-00)

Step 1b

Install the Cotter Pin through the single opening of the

Post to secure into place.

NOTE: included with Adjusta Mechanism is a small bag of

Hardware containing the (1) Post, (1) Cotter Pin, (2) Hex

Nuts, (2) Wood Screws, & (2) Cable Mounts.

Cotter Pin

(included with 225-554x-00)

Crossbar

Center Crossbar Flanges

Cotter Pin

Brake/Paddle Assembly

Brake Shaft

Post

Caster Inserts placed

into the large holes

Insert Screw

(with pink threads)

325-5052-00

Step 11

Attach a Cross Tube to a Base Tube by inserting a fit Bolt

through a Tube Washer, then insert the Bolt through the

Base Tube and carefully thread into the Cross Tube.

Repeat this procedure for other Cross Tube. Then tighten

all fit Bolts.

Locking

Caster

Cross Tube

Non-Locking

Base Assembly

Caster

fit Bolt

fit Tube

Washer

Step 2 (uses the 3-Way Wrench)

Unpack the remaining Adjusta Mechanism components

and arrange them as shown at right.

Place one Crossbar end onto the lower Crossbar

Button and Threaded Bolt (located on each of the Arm

Mechanisms). Secure the Crossbar to the Arm Mechanism

using one 5/16” Hex Nut onto the Threaded Bolt.

Repeat for remaining Crossbar end and Arm Mechanism.

Arm Mechanism

NOTE: it is very impor ta nt that you attach the

Crossbar ONLY to the Lower Crossbar Button.

Brake/Paddle As-

sembly

Crossbar

Arm Mechanism

Threaded Bolts

5

/16” Hex

Nut

Paddle

Lower Crossbar

Button

(5/16-18 X 3.5”) fit Bolt

325-5194-00

Anthro Corporation Technology Furniture® 10450 SW Manhasset Drive Tualatin, Oregon 97062 1-800-325-3841

fit Tube Washer

225-2050-00 or 225-3522-00

5

/16” Hex Nut

(included with 225-554x-00)

DETAIL VIEW

anthro.com

Page 4

FAJ30zz/xx3, FAJ36zz/xx3 & FAJ48zz/xx3

300-5196-00

Step 3

Place your Fixed Worksurface onto the floor with the

predrilled holes facing upward.

Position the Small Support Brackets onto the Fixed

Worksurface and align two of the holes on each Support

with the predrilled holes on the Worksurface. Loosely

secure each Small Support to the Worksurface using two

Wood Screws per Support.

3

/4” Wood Screw

325-5106-00

Step 4

Place the Back Trough onto the Fixed Worksurface,

between the installed Support Brackets (from Step 3).

Align the two Threaded holes on each end of the Back

Trough with those on both Support Brackets. Carefully,

thread one Button Head Screw through the Support

Bracket, into the Back Trough. Repeat for remaining three

Button Head Screws.

Insert two Wood Screws through the two remaining Holes

on the Back Trough flange (which should be aligned with two

predrilled holes on the Worksurface) and tighten into place.

Small Support

Bracket Y

SECOND: Install the Wood Screws

Back Trough

Back Trough

Flange

Threaded

holes

Wood Screw

Small Support

Bracket X

NOTE: Make certain

to ins tal l the Back

Trough in front of the

Support Brackets

Step 6

Attach a rear Vertical Leg by installing two Support Screws

through the Small Support Bracket Y into Holes 1 & 3

from the top (non-coped end).

Attach a front Vertical Leg to Holes 1 & 3 using the same

procedure.

Hole 3

Hole 1

Support Screw

325-5010-00

Step 7

Attach the remaining Vertical Legs to the Small Support

Bracket X using the same procedure used in Step 6.

NOTE: Make certain to install the Vertical Legs into the same

holes used in Step 6.

Bottom

(coped)

end

Top

(non-coped)

end

Bottom

(coped)

end

Hole 3

Hole 1=31” Final Worksurface Height

Support Screw

Small Support

Bracket Y

Hole 3

Hole 1

Support Screw

3

/4” Wood Screw

325-5106-00

(1/4-20 X .50”) Button Head Screw

325-5003-00

Step 5

Determine the best height for your Fixed Worksurface.

These instructions will place your Fixed Worksurface 31”

from the floor using the standard 3” Casters.

For a final Fixed Worksurface height that is lower than

31”, adjust one hole down for each inch of variance

desired.

NOTE: Your Fixed Worksurface location may be changed

after your Adjusta Unit has been completely assembled by

repeating Steps 6 and 7.

Small Support

Bracket X

FIRST: Install the Button Head Screws

Adjusta Caddy has

approximately 11”

of travel

31”

Adjusta Fixed

Worksurface

Support Screw

325-5010-00

Step 8 (requires Worksurface to be 12” from floor)

Place the Mechanism onto the Worksurface Assembly.

Align the Mechanism Flanges with the predrilled holes

on the Worksurface underside.

Secure the Mechanism to the Worksurface using a total of

twelve Wood Screws.

Align the six holes of the Brake Assembly with those on

the Worksurface. It may be necessary to depress the

Paddle while manipulating the Brake over the predrilled

Worksurface holes.

Secure the Brake Assembly using a total of six Wood Screws.

3

/4” Wood Screw

325-5106-00

Paddle

Wood Screw

Brake

Mechanism Flanges

Small Support

Bracket X

(12” high surface shown shaded)

Top

(non-coped)

end

Anthro Corporation Technology Furniture® 10450 SW Manhasset Drive Tualatin, Oregon 97062 1-800-325-3841

anthro.com

Loading...

Loading...