Antennatek Lpda 200 User Manual

OWNER'S MANUAL

®

THIS MANUAL CONTAINS

INSTRUCTIONS FOR: LPDA 200

- INSTALLATION

- OPERATION

- TROUBLESHOOTING

- EXPLODED PARTS DRAWING

- WARRANTY

AntennaTek, Inc.

425 S. Bowen, #4

Longmont, CO 80501

SIGNAL COMMANDER

(303)772-9591 FAX (303) 774-9533

www.antennatek.com

Form: manv12

SECTION I INSTALLATION INSTRUCTIONS

This manual contains information on the following Signal Commander® LPDA models and accessories;

the model you have purchased is clearly marked on the front of this manual.

MODEL 200 Amplied Antenna with 2nd TV & Cable TV Ready

INSTALLATION KIT CONTENTS:

ALL MODELS

Qty. Description

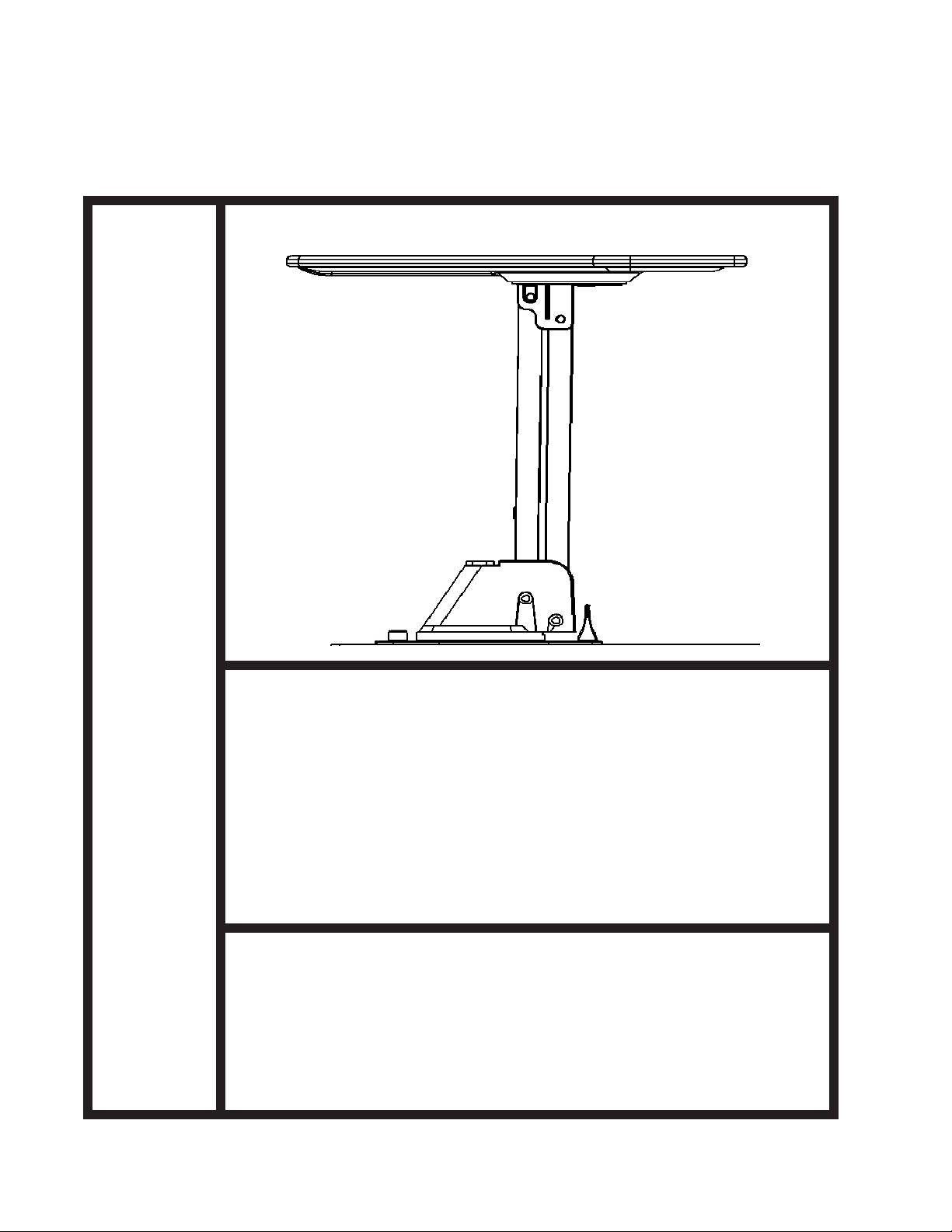

1 Amplied Head Assembly

1 Lift Mechanism Assembly

1 4.5 m (15 feet) Coaxial Cable

1 1.8 m (6 feet) Coaxial Cable

1 Coaxial Coupling

1 75 Ohm Wall Mount Power Supply

1 Ceiling Plate

1 Rotation Handle

1 Elevation Handle Assembly

10 #8x1" Pan Head Sheet Metal Screws

4 #8X3/4" Pan Head Screws

2 Groove Pins

2 E Clips

TOOLS AND SUPPLIES REQUIRED:

Mechanical Installation

- Electric Drill 13 mm (1/2") capacity

- Drill bits: 1.6 mm (1/16") and 13 mm (1/2") Dia.

- 38 mm (1-1/2") Diameter Hole Saw

- Phillips screwdriver

- Extension Cord

- Tape Measure

- Hacksaw

- Pliers or Vise Grips

Electrical Installation

- Volt Meter(DC)

- Sabre Saw

- Crimping tool

Supplies

- Non-hardening Caulking Compound or Silicon

- Electrical Tape

- Electrical Wire 14 AWG or Heavier

- Electrical Box if not Already Installed

WARNING

Driving with the antenna raised or partially raised will damage your antenna and void your

warranty

1. Installation Planning

A. Pre-wired Vehicles

Follow the instructions in this manual in conjuction with the RV Manufacture's recommendations to locate and install the

Signal Commander Antenna and power supply.

B. All other Vehicles

Location of the antenna must allow antenna head to point towards the rear of the vehicle when resting in the travel position,

and must clear all roof mounted equipment when being raised, lowered or rotated. the roof should not be more than 5.0"

thick.

The inside ceiling must be clear of obstructions to ceiling plate and handle. For the cleanest installation, it is recommended

that the coaxial cable enter through the roof and be hidden inside a closet. The wall of the closet can be used to mount the

power supply.

Locating the antenna close to the television receiver and the 12 Volt DC power source will simplify the installation. Power

supplies should be ush mounted in standard electrical boxes. Assure that the 12 Volt DC source is limited by a 7.5A fuse

maximum.

Power supplies should not be connected to existing circuits with fans or motors as this may cause interference to the television, damage the antenna amplier, and void the warranty.

2

2. Installation

WARNING!

Electricity Kills!

Power lines may be overhead.

Care must be taken when installing or

raising the antenna.

Before drilling, care must be taken not

to damage any wiring that may be located between the vehicle roof and ceiling.

Step 1: Tape the drill template to the roof of the vehicle

in the position where the antenna will be installed.

Step 6: Caulk the bottom of the baseplate with a

liberal amount of non-hardening sealing compound,

then position and attach the lift mechanism to the roof

with ten #8x1" pan head sheet metal screws. Seal

the edges of the base plate and the top of the screws

with sealing compound. Keep sealing compound

away from the surface between base plate and gear

housimg.

Note: The arrow must point towards the

rear of the vehicle. 3.3 feet (1.0 m)

of rear ward clearance is required.

Step 2: Using a 38 mm (1-1/2") diameter hole saw,

cut a hole through the roof and ceiling for the center

shaft.

Step 3: Drill one 13 mm (1/2") diameter hole through

the roof only for the coaxial cable.

Step 4: Drill ten mounting screw holes 1.6 mm (1/16")

diameter, approximately 25 mm (1") deep. Remove

drill template and clean around mounting area.

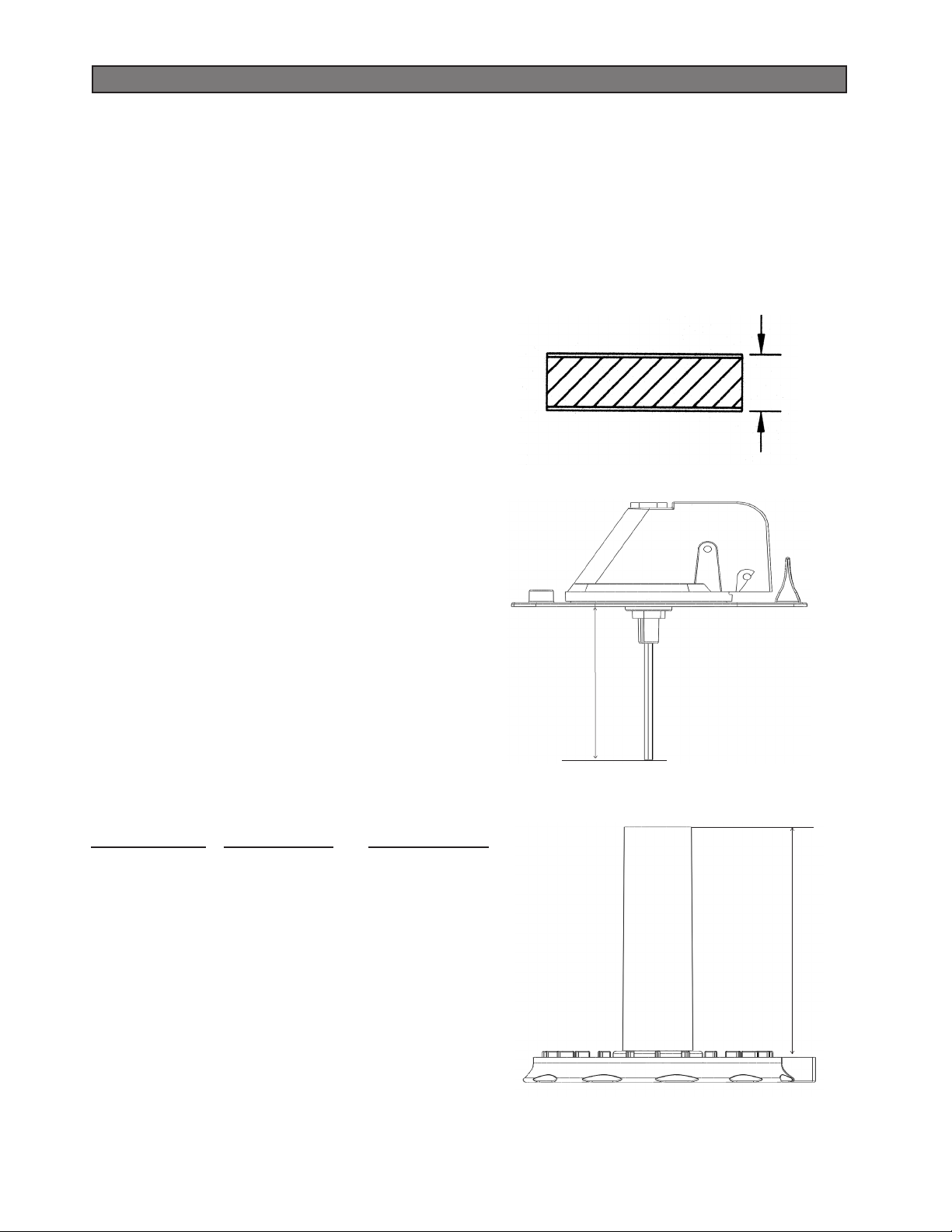

Step 5: Measure the thickness of the roof. Using the

table and illustrations below, cut the elevation shaft

and rotation handle to the correct length for the vehicle’s roof.

A B C

Roof Elev. Shaft Rot. Handle

Thickness Length Length

25 mm(1") Min. 57 mm(2.25") 13 mm(0.5")

33 mm(1.5") 70 mm(2.75") 25 mm(1.0")

51 mm(2") 82 mm(3.25") 38 mm(1.5")

63 mm(2.5") 95 mm(3.75") 51 mm(2.0")

76 mm(3") 108 mm(4.25") 63 mm(2.5")

89 mm(3.5") 120 mm(4.75") 76 mm(3.0")

101 mm(4") 133 mm(5.25") 89 mm(3.5"")

114 mm(4.5") 146 mm(5.75") 101 mm(4.0")

127 mm (5") 159 mm(6.25") NO CHANGE

A

B

C

3

Loading...

Loading...