APW7060

Dual Controllers - Step Down Synchronous PWM and Linear Controller

Features

••

Provides Two Regulated Voltages

•

••

- One Synchronous DC/DC Buck Controller

- One Linear Controller

••

0.8V Internal Reference Voltage

•

••

- Both Controllers: 0.8V ± 2% Line, Load

and Temp.

••

Output Voltage Range

•

••

- PWM Controller : 0.8V to V

- Linear Controller : 0.8V to (12VCC-V

••

• Full Duty Cycle Range for PWM Controller

••

IN

)

GSpass

- 0% to 100%

••

• Internal Loop Compensation for PWM Controller

••

••

• Internal 2ms Soft Start and Short Circuit Protec

••

tion for both Controllers

••

• Both Controllers Drive N-Channel MOSFETs

••

••

• Small Converter Size

••

- 600kHz Constant Switching Frequency

- Simple SO-14 Package

••

• Shutdown Control

••

Applications

••

• Motherboard

••

••

• Graphics Cards

••

General Description

The APW7060 integrates a synchronous buck PWM

controller and a linear controller to provide two regulated voltages in a single package. The PWM controller drives external N-channel MOSFETs and operates

at a fixed 600kHz frequency. When the input supply

drops close to the output, the upper MOSFET remains

on, achieving 100% duty cycle. Internal loop compensation is optimized for fast transient response, eliminating external compensation network. The linear controller drives an external N-channel MOSFET to form a

linear regulator. The internal 0.8V reference makes this

part suitable for a wide variety of low voltage

applications.

The APW7060 has an undervoltage lockout circuitry

to ensures that both the 5VCC and 12VCC must be

present before its internal circuitry is power up. Soft

start is internally set to 2ms and will bring both outputs into regulation in a controlled manner. When either output goes into short, soft start will be initiated.

If the short condition still remains after three cycles,

both regulators will be shut down. To restart both

regulators, recycle the voltage at 5VCC or 12VCC pin

or momentarily pull the FB2 pin above 1.28V.

The APW7060 can be shutdown by pulling the FB2

pin above 1.28V. In shutdown, all gate drive signals

will be low. This dual controller is available in SO-14

package.

Pinouts

FB2

NC

1

2

3

4

5

6

7

••

• 12V , 5V and 3.3V Inputs DC-DC Converter

••

••

• DSP Supplies

••

••

• Embedded processor and I/O supplies

••

ANPEC reserves the right to make changes to improve reliability or manufacturability without notice, and advise

customers to obtain the latest version of relevant information to verify before placing orders.

Copyright ANPEC Electronics Corp.

Rev. A.3 - Oct., 2003

LGATE

GND

GND

5VCC

DRIVE2

UGATE

14

13

12VCC

NC

12

NC

11

NC

10

FB

9

NC

8

www.anpec.com.tw1

APW7060

Ordering and Marking Information

APW 7060

APW7060 K :

APW7060

XXXXX

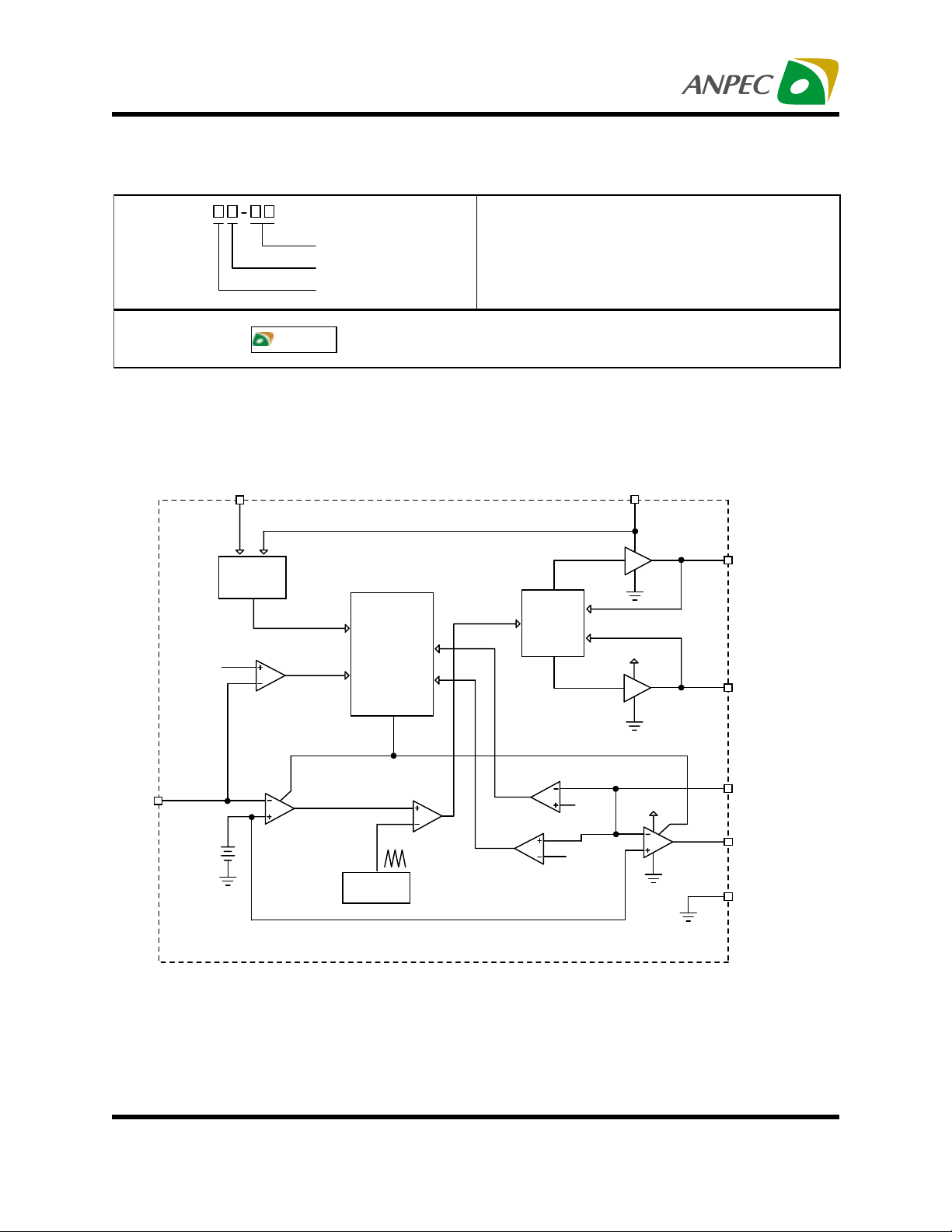

Block Diagram

5VCC

Under

Voltage

Lockout

UVLO

0.5V

Handling Code

Temp. Range

Package Code

UVP1

Soft-Start

and Fault

Logic

Packag e Cod e

K : S OP-1 4

Operating Junction Temp. Range

C : 0 to 7 0 °C

Handling Code

TU : T u be

TR : T a pe & R e e l

XXXXX - Date Code

12VCC

PWM

Gate

Control

UGATE

5VCC

LGATE

FB

VREF

0.8V

COMP

Error

Amplifier

Copyright ANPEC Electronics Corp.

Rev. A.3 - Oct., 2003

Inhibit /

Soft-Start

Os c illa t or

.ECKH/Figure 1.

F

OSC

600kHz

UVP2

Shutdown

0.5V

1.28V

12VCC

Linear

Controller

FB2

DRIVE2

GND

www.anpec.com.tw2

APW7060

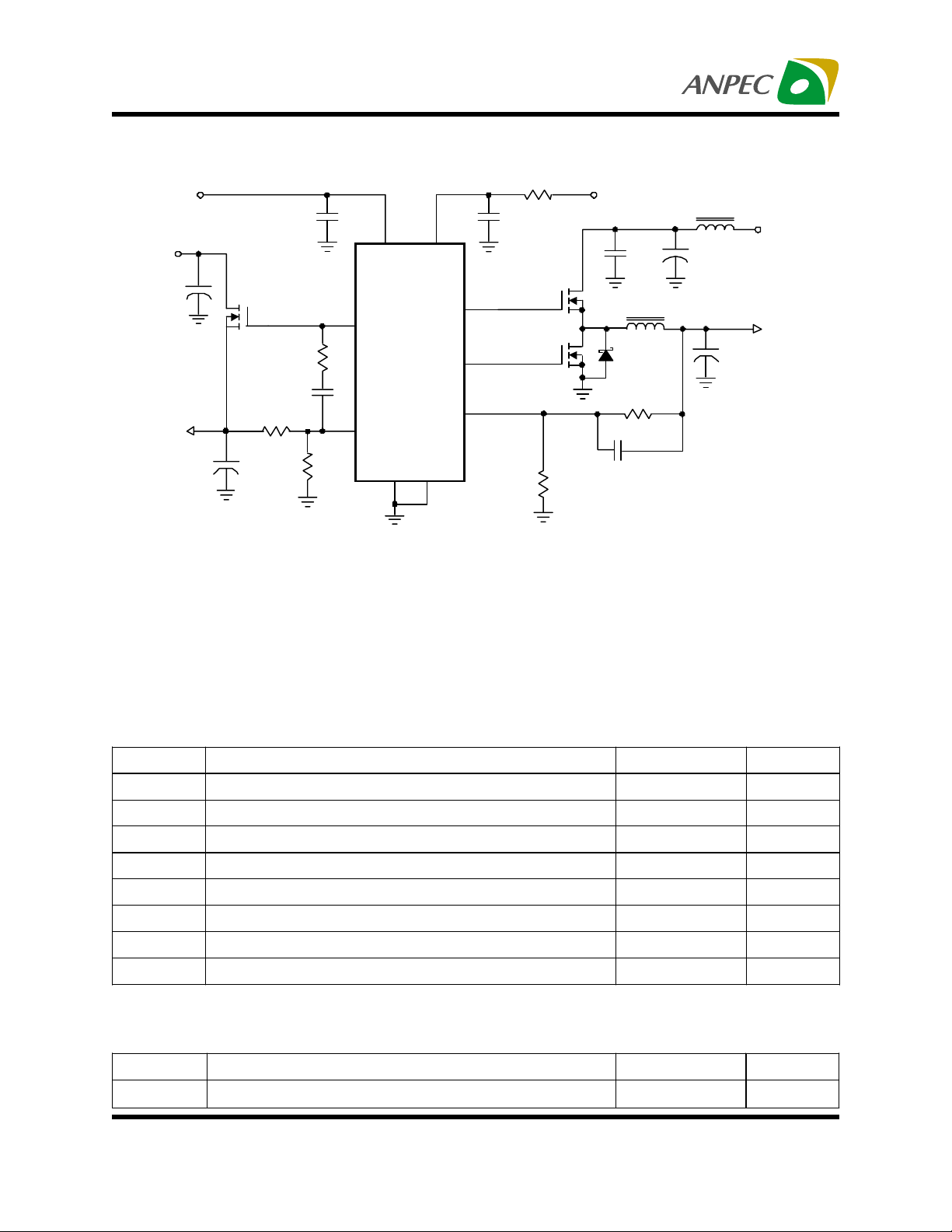

Typical Application

+12V

V

IN2

+3.3V

C10

470uF

V

OUT2

+2.5V/3A

C11

470uF

Q1 : APM2014N UC

Q2 : APM2014N UC

Q3 : APM2055N UC

D1 : 3A Schottky Diode

C2, C3, C5, C6, C10, C1 1 : 470uF/6.3V, ESR=30mΩ

Q3

R10

6.8k

C9

470pF

R7

2.37k R8

1.13k

C8

1uF

5

6

12VC C

DR IVE2

FB2

13

U1

APW 7060

GND

2

5VC C

UGATE

LGATE

GND

R4

+5V

2.2

C1

4

1uF

C4

4.7uF

Q1

14

L1

1uH

L2

1uH

C2, C3

2 x 470uF

V

IN1

+3.3V

V

OUT1

+1.263V

1

Q2

9

FB

3

R2

1.02k

D1

C7

68nF

C5, C6

2 x 470uF

R1

590

/10A

.ECKH/Figure 2.

Absolute Maximum Ratings

Symbol Parameter Rating Unit

5V

12V

5VCC Supply Voltag e ( 5 V CC to GND) -0.3 ~ 7 V

CC

12VCC Supply Voltage (12VCC to GND) -0.3 ~ 15 V

CC

UAGTE, DRIVE2 to GND -0.3 ~ 12V

LGATE, FB, FB2 to GND -0.3 ~ 5V

CC

CC

Maximum Junction Temperature 150

T

STG

T

SDR

V

ESD

Storage Temperature -65 ~ 150

Maximum Soldering Temperature, 10 Seconds 300

Minimum ESD R ating (Human b ody model)

2

±

Thermal Characteristics

Symbol Parameter Value Unit

JA

θ

Junction-to-Ambient Resistance in free air (SOP-14) 160

o

o

o

KV

o

C/W

V

V

C

C

C

Copyright ANPEC Electronics Corp.

Rev. A.3 - Oct., 2003

www.anpec.com.tw3

APW7060

Recommended Operating Conditions

(Note)

Symbol Parameter Range Unit

CC

5V

12V

OUT1

V

V

OUT2

V

V

T

T

IN1

IN2

A

5VCC Supply Voltage

CC

12VCC Supply Voltage

5 ± 5%

12 ± 10%

Output Voltage of the Buck converter 0.8 ~ 3.3 V

Input Voltage of the Buck converter

3.3/5 ± 5%

Output Voltage of the Linear Regulator 0.8 ~ 3.3 V

Input Voltage of the Linear Regulator

3.3/5 ± 5%

Ambient Temperature 0 ~ 70

J

Junction Temperature 0 ~ 125

V

V

V

V

o

C

o

C

Note : Refer to the typical application circuit

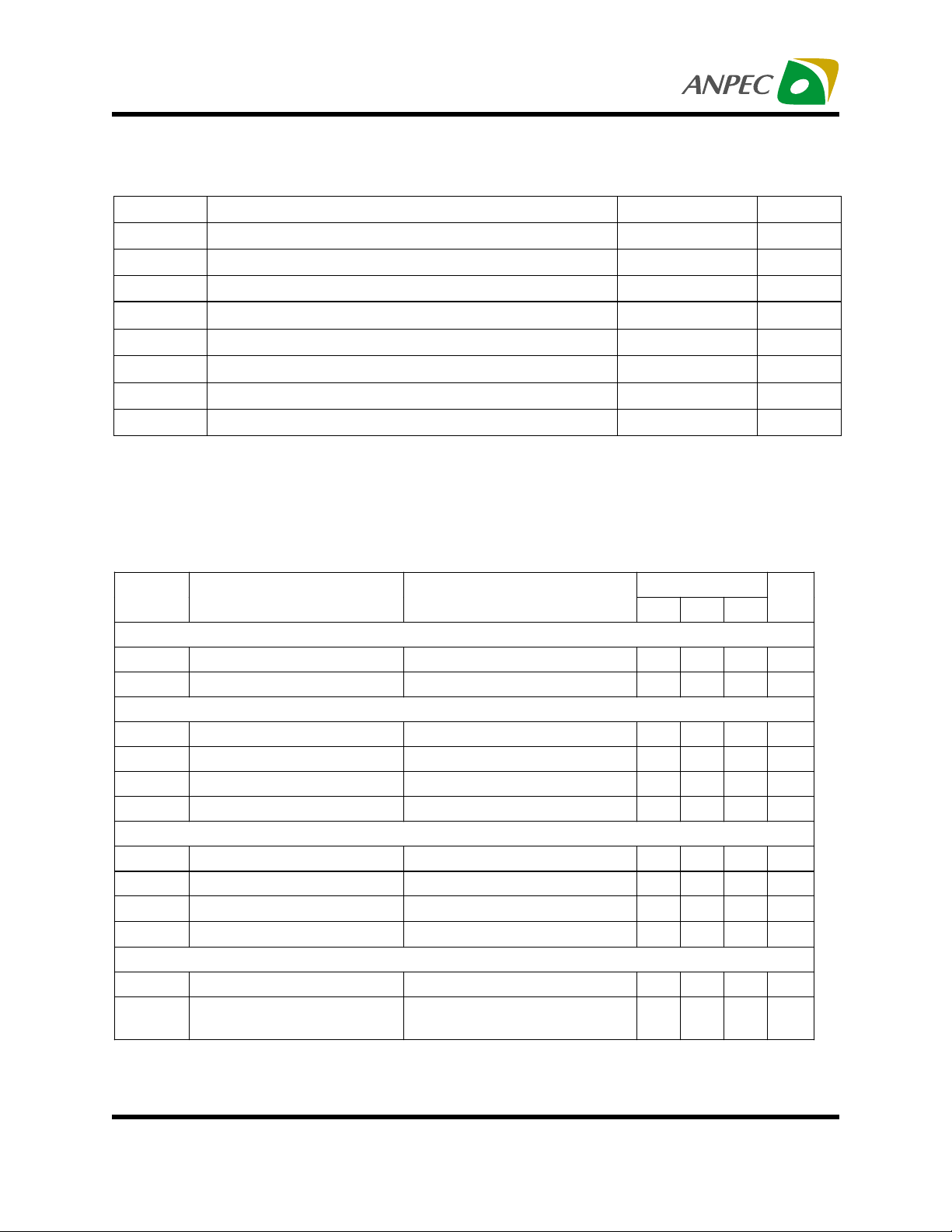

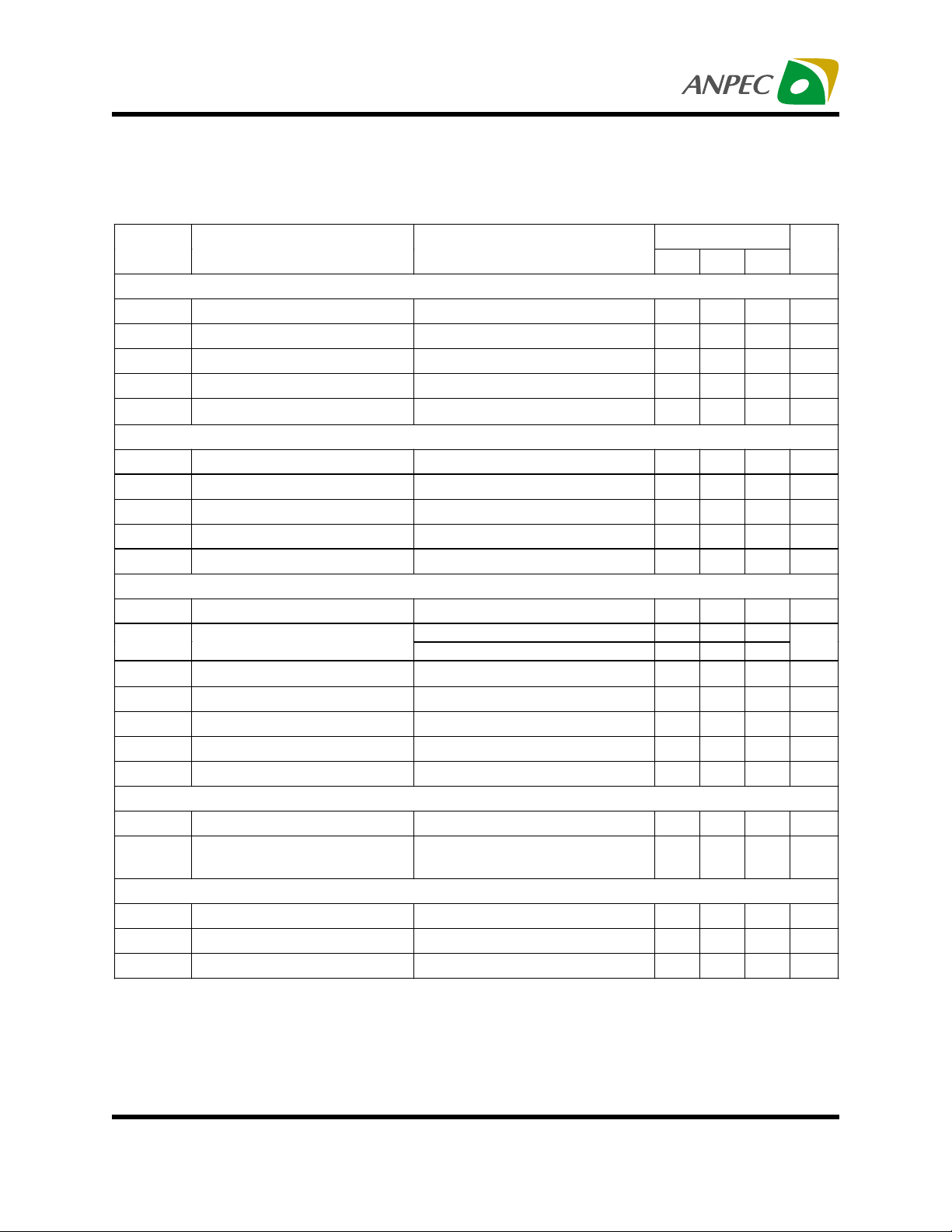

Electrical Characteristics

Unless otherwise specified, these specifications apply over 5VCC=5V, 12VCC=12V and TA= 0~70 oC. Typical

values are at TA=25oC.

APW7060

Symbol Parameter Test Conditions

Min Typ Max

SUPPLY CURRENT

ICC 5VCC Supply Current

12VCC Supply Current

LGATE Open, FB2=DRIVE2

UGATE Open

2.5 mA

2.5 mA

UNDER VOLTAGE LOCKOUT

Rising 5VCC Threshold 12VCC=12V 4.0 4.2 4.4 V

Falling 5VCC Threshold 12VCC=12V 3.5 3.7 3.9 V

Rising 12VCC Threshold 5VCC=5V 9.6 10.3 10.8 V

Falling 12VCC Threshold 5VCC=5V 9.3 9.7 10.2 V

OSCILLATOR

OSC

F

Free Running Frequency 550 600 650 kHz

Ramp Upper Threshold 2.85 V

Ramp Lower Threshold 0.95 V

Ramp Amplitude 1.9 V

OSC

∆V

REFERENCE VOL TAGE

REF

V

Reference Voltage 0.8 V

System Accura cy

Over Line, Load and

Temperature

-2 +2 %

Unit

P-P

Copyright ANPEC Electronics Corp.

Rev. A.3 - Oct., 2003

www.anpec.com.tw4

APW7060

Electrical Characteristics (Cont.)

Unless otherwise specified, these specifications apply over 5VCC=5V, 12VCC=12V and TA= 0~70 oC. Typical

values are at TA=25oC.

Symbol Parameter Test Conditions

BUILT-IN PWM FEEDBACK COMPENSATION

DC Gain 75 dB

P

F

F

First Pole Frequency 10 Hz

Z

First Zero Frequency 1

UGATE Duty Range 0 100 %

FB Input Current

PWM CONTROLLER GATE DRIVERS

UGATE Source V

UGATE Sink

LGATE Source V

LGATE Sink V

D

T

Dead Time 50

UAGTE

=1V 0.6 A

UGATE

V

=1V 7.3

LGATE

=1V 0.6 A

LGATE

=1V 1.8

LINEAR CONTROLLER

DC Gain 78 dB

Gain Bandwidth Product

CL=0.5nF 1.6

L

C

=1nF 1

FB Input Current 0.1

DRIVE2 S ourc e C ur re nt V

DRIVE2 Sink Current V

FB2=VREF

FB2=VREF

-20mV, V

+20mV, V

DRIVE2

DRIVE2

DRIVE2 Output High Vo ltage DRIVE2 Open 11.7 V

DRIVE2 Output Low Voltage DRIVE2 Ope n 0.01 V

UNDER-VOLTAGE PROTECTION

FB

UV

FB/FB2 Under-Voltage Level FB or FB2 Falling 0.5 V

FB/FB2 Under-Voltage

Hysteresis

15 mV

SOFT-START AND SHUTDOWN

SS

T

Soft-Start Interval 2 mS

FB2 Shutdown Threshold FB2 Rising 1.28 V

FB2 Shutdown Hysteresis 30 mV

APW706 0

Unit

Min Typ Max

kHz

0.1

µA

Ω

Ω

nS

MHz

µA

=7V 9.8 mA

=3V 2.6

mA

Copyright ANPEC Electronics Corp.

Rev. A.3 - Oct., 2003

www.anpec.com.tw5

APW7060

Functional Pin Description

LGA TE (Pin 1)

This pin provides the gate drive signal for the low side

MOSFET .

GND (Pin 2, 3)

Signal and power ground for the IC. All voltage levels

are measured with respect to this pin. Tie this pin to

the ground plane through the lowest impedance connection available.

5VCC (Pin 4)

This is the main bias supply for the DC/DC controller

and its low side MOSFET driver. Must be closely

decoupled to GND (Pin 2,3). The voltage at this pin is

monitored for undervoltage lockout (UVLO) purposes.

DO NOT apply a voltage greater than 5.5V to this pin.

DRIVE2 (Pin 5)

This pin provides the gate drive voltage for the linear

regulator N-channel MOSFET pass transistor. It also

provides a means of compensating the linear controller for applications where the user needs to optimize

the regulator transient response.

NC (Pin 7, 8, 10, 11, 12)

No internal connection.

FB (Pin 9)

This pin is the inverting input of the internal error amplifier of the buck controller. Connect this pin to the

output (VOUT1) of the DC/DC converter via a proper sized

resistor divider to form a complete feedback loop. The

VOUT1 is determined using the following formula :

VOUT1=0.8V x (1+ )

where R1 is the resistor connected from VOUT1 to FB,

and R2 is the resistor connected from FB to GND.

This pin is also monitored for under-voltage events.

12VCC (Pin 13)

This pin provides the supply voltage to the high side

MOSFET driver and the linear controller. A voltage no

greater than 13V can be connected to this pin. The

voltage at this pin is monitored for undervoltage lockout (UVLO) purposes.

UGATE (Pin 14)

R1

R2

FB2 (Pin 6)

Connect this pin to the output (VOUT2) of the linear

regulator via a proper sized resistor divider. The voltage at this pin is regulated to 0.8V and the VOUT2 is

determined using the following formula :

VOUT2=0.8V x (1+ )

where R7 is the resistor connected from VOUT2 to FB2,

and R8 is the resistor connected from FB2 to GND.

This pin is also monitored for under-voltage events.

Pulling and holding FB2 above 1.28V shuts down both

regulators. Releasing FB2 initiates soft-start on both

regulators.

Copyright ANPEC Electronics Corp.

Rev. A.3 - Oct., 2003

R7

R8

This pin provides gate drive for the high-side MOSFET.

www.anpec.com.tw6

APW7060

Typical Characteristics

Reference Voltage

vs. Junction Temperature

0.816

0.812

0.808

0.804

0.800

0.796

0.792

0.788

Reference Voltage, VREF (V)

0.784

-50 -25 0 25 50 75 100 125 150

Junction Temperature (oC)

Switching Frequency

vs. Junction Temperature

650

640

630

620

610

600

590

580

570

560

Switching Frequency, FOSC (kHz)

550

-50 -25 0 25 50 75 100 125 150

Junction Temperature (°C)

Copyright ANPEC Electronics Corp.

Rev. A.3 - Oct., 2003

www.anpec.com.tw7

APW7060

Operating Waveforms (Refer to the typical application circuit)

1.V

OUT1 Load Transient Response : IOUT = 0A -> 10A -> 0A

- IOUT1 slew rate = ±10A/µS

IOUT = 0A -> 10A

IOUT = 0A -> 10A -> 0A

I

OUT = 10A -> 0A

V

OUT1

V

UGATE

10A

I

OUT1

0A

Ch1 : VOUT1, 100mV/Div, DC,

Offset = 1.25V

Ch2 : VUGATE, 10V/Div , DC

Ax1 : IOUT1, 5A/Div

Time : 5µS/Div

Ch1 : VOUT1, 100mV/Div, DC,

Offset = 1.25V

Ax1 : IOUT1, 5A/Div

Time : 100µS/Div

BW = 20MHz

BW = 20MHz

2.VOUT2 Load Transient Response : IOUT = 0.2A -> 3A -> 0.2A

- IOUT2 slew rate = ±3A/µS

IOUT = 0.2A -> 3A

IOUT = 0.2A -> 3A -> 0.2A

V

I

OUT1

OUT1

Ch1 : VOUT1, 100mV/Div, DC,

Offset = 1.25V

Ch2 : VUGATE, 10V/Div , DC

Ax1 : IOUT1, 5A/Div

Time : 5µS/Div

BW = 20MHz

IOUT = 3A -> 0.2A

V

V

I

OUT1

UGATE

OUT1

V

OUT2

I

OUT2

Ch1 : VOUT2, 50mV/Div, DC,

Offset = 2.50V

Ax1 : IOUT2, 1A/Div

Time : 1µS/Div

BW = 20MHz

Copyright ANPEC Electronics Corp.

Rev. A.3 - Oct., 2003

V

OUT2

0.2A

Ch1 : VOUT2, 50mV/Div, DC,

Offset = 2.50V

Ax1 : IOUT2, 1A/Div

Time : 50µS/Div

BW = 20MHz

3A

I

OUT2

Ch1 : VOUT2, 50mV/Div, DC,

Offset = 2.50V

Ax1 : IOUT2, 1A/Div

Time : 1µS/Div

BW = 20MHz

www.anpec.com.tw8

V

I

OUT2

OUT2

APW7060

Operating Waveforms (Cont.)

3. Powering ON / OFF

Soft-start at Powering ON

Ch1 : +5V, 1V/Div, DC

Ch2 : +12V, 2V/Div, DC

Ch3 : VOUT1, 1V/Div, DC

Ch4 : VOUT2, 1V/Div, DC

Time : 1mS/Div

BW = 20MHz

4. UGA TE and LGATE

+12V

+5V

VOUT2

VOUT1

Powering OFF

+12V

+5V

VOUT2

VOUT1

Ch1 : +5V, 1V/Div, DC

Ch2 : +12V, 2V/Div, DC

Ch3 : VOUT1, 1V/Div, DC

Ch4 : VOUT2, 1V/Div, DC

Time : 5mS/Div

BW = 20MHz

UGA TE Rising

IOUT=10A

VLGA TE

Ch1 : VUGATE, 2V/Div , DC

Ch2 : VLGATE, 2V/Div , DC

Time : 50nS/Div

BW = 500MHz

Copyright ANPEC Electronics Corp.

Rev. A.3 - Oct., 2003

VUGA TE

UGA TE Falling

IOUT=10A

VUGA TE

VLGA TE

Ch1 : VUGATE, 2V/Div, DC

Ch2 : VLGATE, 2V/Div , DC

Time : 50nS/Div

BW = 500MHz

www.anpec.com.tw9

APW7060

Application Information

Soft Start

Soft start can be initiated in several ways. One way is

when the input bias supply to the 5VCC and 12VCC

is above 4.2V and 10.2V respectively. The other way

is when the part comes out of shutdown. In both ways,

the soft start cycle will last for 2ms. During this period,

the reference to the error amplifier of the PWM controller and linear controller will gradually slew up to its

final value of 0.8V. This effectively will force both output voltages to track this reference ramp rate. Hence

both outputs will reach regulation at the same time.

Figure 3 illustrates this graphically.

Soft-start at Powering ON

+12V

+5V

VOUT2

VOUT1

Ch1 : +5V, 1V/Div, DC

Ch2 : +12V, 2V/Div, DC

Ch3 : VOUT1, 1V/Div, DC

Ch4 : VOUT2, 1V/Div, DC

Time : 1mS/Div

BW = 20MHz

.ECKH/Figure 3.

Linear Regulator Transient Response Optimization

The linear regulator is stable over all load current.

However, the transient response can be further enhanced by connecting a RC network between the FB2

and DRIVE2 pin. Depending on the output capacitance

and load current of the application, the value of this

RC network is then varied. A good starting point for

the resistor value is 6.8kΩ and 470pF for the capacitor.

Maximum Output Voltage of Linear Controller

The maximum drive voltage at DRIVE2 is determined

by the applied voltage at 12VCC pin. Since this pin

drives an external N-channel pass MOSFET, therefore the maximum output voltage of the linear regulator is dependent upon the required gate-to-source voltage to sustain the load current.

V

OUT2MAX

= 12VCC - V

GSpass

Component Selection Guidelines

PWM Regulator Output Capacitor

The selection of C

is determined by the required

OUT

effective series resistance (ESR) and voltage rating

rather than the actual capacitance requirement. Therefore select high performance low ESR capacitors that

are intended for switching regulator applications. In

some applications, multiple capacitors have to be

paralled to achieve the desired ESR value. If tantalum

capacitors are used, make sure they are surge tested

by the manufactures. If in doubt, consult the capacitors manufacturer.

Input Capacitor Selection

The input capacitor is chosen based on the voltage

rating and the RMS current rating. For reliable

operation, select the capacitor voltage rating to be at

least 1.3 times higher than the maximum input voltage.

The maximum RMS current rating requirement is approximately I

/2 , where I

OUT

is the load current.

OUT

During power up, the input capacitors have to handle

large amount of surge current. If tantalum capacitors

are used, make sure they are surge tested by the

manufactures. If in doubt, consult the capacitors

manufacturer.

For high frequency decoupling, a ceramic capacitor

between 0.1uF to 1uF can be connected between

5VCC and ground pin.

Copyright ANPEC Electronics Corp.

Rev. A.3 - Oct., 2003

www.anpec.com.tw10

APW7060

Application Information

Inductor Selection

The inductance of the inductor is determined by the

output voltage requirement. The larger the inductance,

the lower the inductor’s current ripple. This will translate into lower output ripple voltage. The ripple current

and ripple voltage can be approximated by:

OUT

V

OUT-IN

VV

RIPPLE

×

V

L Fs

×

x ESR

IN

I

RIPPLE

∆V

OUT

=

= I

where Fs is the switching frequency of the regulator.

There is a tradeoff exists between the inductor’s ripple

current and the regulator load transient response time

A smaller inductor will give the regulator a faster load

transient response at the expense of higher ripple current and vice versa. The maximum ripple current occurs at the maximum input voltage. A good starting

point is to choose the ripple current to be approximately 30% of the maximum output current.

Once the inductance value has been chosen, select

an inductor that is capable of carrying the required

peak current without going into saturation. In some

type of inductors, especially core that is make of

ferrite, the ripple current will increase abruptly when it

saturates. This will result in a larger output ripple

voltage.

P

UPPER

P

LOWER

where I

2

= I

(1+ TC)(R

out

2

= I

(1+ TC)(R

out

is the load current

OUT

DS(ON)

DS(ON)

)D + (0.5)(I

)(1-D)

)(VIN)(tsw)F

out

TC is the temperature dependency of R

S

DS(ON)

FS is the switching frequency

t

is the switching interval

sw

D is the duty cycle

Note that both MOSFET s have conduction losses while

the upper MOSFET include an additional transition

loss.The switching internal, t

reverse transfer capacitance C

, is a function of the

sw

. Figure 4 illustrates

RSS

the switching waveform of the MOSFET.

The (1+TC) term is to factor in the temperature dependency of the R

“R

vs T emperature” curve of the power MOSFET.

DS(ON)

and can be extracted from the

DS(ON)

Linear Regulator Input/Output Capacitor Selection

The input capacitor is chosen based on its voltage

rating. Under load transient condition, the input capacitor will momentarily supply the required transient

current. A 1uF ceramic capacitor will be sufficient in

most applications.

The output capacitor for the linear regulator is chosen

to minimize any droop during load transient condition.

In addition, the capacitor is chosen based on its voltage rating.

PWM Regulator MOSFET Selection

The selection of the N-channel power MOSFETs are

determined by the R

(C

) and maximum output current requirement.The

RSS

, reverse transfer capacitance

DS(ON)

losses in the MOSFETs have two components: conduction loss and transition loss. For the upper and

lower MOSFET, the losses are approximately given

by the following :

Copyright ANPEC Electronics Corp.

Rev. A.3 - Oct., 2003

Linear Regulator MOSFET Selection

In addition to choosing the pass MOSFET for its ability to sustain the load current requirement (see Maximum Output Voltage of Linear Controller), another criteria is its efficiency of heat removal. The power dissipated by the MOSFET is given by:

Pdiss = Iout * (VIN - V

OUT2

)

www.anpec.com.tw11

APW7060

Application Information

where Iout is the maximum load current

V

is the nominal output voltage

out2

In some applications, heatsink maybe required to help

maintain the junction temperature of the MOSFET below its maximum rating.

V

DS

Voltage a cro ss

drain and source of MOSFET

t

sw

Figure 4. Switching waveform across MOSFET

Layout Considerations

In high power switching regulator, a correct layout is

important to ensure proper operation of the regulator.

In general, interconnecting impedances should be minimized by using short, wide printed circuit traces. Signal and power grounds are to be kept separate and

finally combined using ground plane construction or

single point grounding. Figure 5 illustrates the layout,

with bold lines indicating high current paths. Components along the bold lines should be placed close

together. Below is a checklist for your layout:

• •

• Keep the switching nodes (UGATE, LGATE and

• •

the PHASE) away from sensitive small signal nodes

since these nodes are fast moving signals. There

fore keep traces to these nodes as short as

possible.

••

• Decoupling capacitor C

••

tance and needs to be placed close to the drain of

Q1.

Copyright ANPEC Electronics Corp.

Rev. A.3 - Oct., 2003

provides the bulk capaci

IN

Time

• •

• The ground return of C

• •

C

(-) terminal.

OUT

• •

• Capacitor C

• •

is to improve noise performance and

HF

must return to the combine

IN

a small 1uF ceramic capacitor will be sufficient. Place

this capacitor close of the drain of Q1.

• •

• Inductor L1 should be connected closely to the

• •

PHASE node.

• •

• Bypass capacitors, C

• •

, should be placed as close

BP

to the 5VCC and 12VCC pins.

V

IN

C

HF

5VCC

GND

5VCC

BP

C

+

GND

12VCC

UGATE

LGATE

APW7060

C

12VCC

PHASE

Figure 5. Recommended Layout Diagram

C

Q1

IN

C

Q2

L1

www.anpec.com.tw12

OUT

+

V

OUT

BP

APW7060

Package Information

SOP – 14 (150mil)

D

H

E

0.015x45

A

Dim

A

Ee

A1

B

Millimeters Inches

Min. Max. Min. Max.

0.010

L

A 1.477 1.732 0.058 0.068

A1 0.102 0.255 0.004 0.010

B 0.331 0.509 0.013 0.020

C 0.191 0.2496 0.0075 0.0098

D 8.558 8. 762 0.336 0.344

E 3.82 3.999 0.150 0.157

e 1.274 0.050

H 5.808 6. 215 0.228 0.244

L 0.382 1.274 0.015 0.050

°0°8

θ

°

0

°

8

°

Copyright ANPEC Electronics Corp.

Rev. A.3 - Oct., 2003

www.anpec.com.tw13

APW7060

Physical Specifications

Terminal Mate rial Solder-Plated Copper (Solder Material : 90/10 or 63/37 SnPb

Lead Solderability Meets EIA Specification RSI86-91, ANSI/J-STD-002 Category 3.

Packaging 2500 devices per reel

Reflow Condition (IR/Convection or VPR Reflow)

Reference JEDEC Standard J-STD-020A APRIL 1999

Peak temperature

temperature

Pre-heat temperature

°

183 C

Time

Classification Reflow Profiles

Convection or IR/

Convection

Average ramp-up rate(183°C to Peak) 3°C/second max. 10°C /second max.

Preheat temperature 125± 25°C)

°

Temperature maintained above 183

Time within 5°C of actual peak temperature

Peak temperature range

Ramp-down rate

Time 25°C to peak temperature

C

120 seconds max.

60 ~ 150 seconds

10 ~ 20 seconds

°

220 +5/-0

°

C /second max. 10°C /second max.

6

6 minutes max.

C or 235 +5/-0°C 215~ 219°C or 235 +5/-0°C

60 seconds

VPR

Package Reflow Conditions

pkg. thickness

and all bags

Convection 220 +5/-0°C

VPR 215-219°C

IR/Convection 220 +5/-0

Copyright ANPEC Electronics Corp.

Rev. A.3 - Oct., 2003

2.5mm

≥≥≥≥

°

C IR/Convection 235 +5/-0

pkg. thickness < 2.5mm and

pkg. volume

≥≥≥≥

350 mm

pkg. thickness < 2.5mm and pkg.

volume <

°

Convection 235 +5/-0

VPR 235 +5/-0

°

C

C

°

C

www.anpec.com.tw14

APW7060

Re lia bility tes t program

Test item Method Description

SOLDERABILITY MIL-STD-883D-2003

HOLT MIL-STD-883D-1005.7

PCT JESD-22-B, A102

TST MIL-STD-883D-1011.9

ESD MIL-STD-883D-3015.7 VHBM > 2KV, VMM > 200V

Latch-Up JE SD 78 10ms , Itr > 100mA

Carrier Tape & Reel Dimension

245°C , 5 SEC

1000 Hrs Bias @ 125 °C

168 Hrs, 100 % RH , 121°C

-65°C ~ 150°C, 200 Cycles

t

E

F

W

Po

P

P1

Ao

D

KoD1

T2

J

C

A

B

T1

Application

SOP-14

(150mil)

A B C J T1 T2 W P E

330REF 100REF

F D D1 Po P1 Ao Ko t

0.50 +

7.5

φ

0.1

13.0 + 0.5

- 0.2

1.50

φ

(MIN)

2 ± 0.5 16 .5RE F 2.5 ± 025

4.0 2.0 6.5 2.10

16.0 ± 0.3

81.75

0.3±0.05

(mm)

Copyright ANPEC Electronics Corp.

Rev. A.3 - Oct., 2003

www.anpec.com.tw15

APW7060

Cover Tape Dimensions

Application Carrier Width Cover Tape Width Devices Per Reel

SOP- 14

Customer Service

Anpec Electronics Corp.

Head Office :

5F, No. 2 Li-Hsin Road, SBIP,

Hsin-Chu, Taiwan, R.O.C.

Tel : 886-3-5642000

Fax : 886-3-5642050

Taipei Branch :

7F, No. 137, Lane 235, Pac Chiao Rd.,

Hsin Tien City, Taipei Hsien, Taiwan, R. O. C.

Tel : 886-2-89191368

Fax : 886-2-89191369

24 21.3 2500

Copyright ANPEC Electronics Corp.

Rev. A.3 - Oct., 2003

www.anpec.com.tw16

Loading...

Loading...