APL5930

3A, Ultra Low Dropout (0.23V Typical) Linear Regulator

Features

• Compatible with APL5913

• Ultra Low Dropout

- 0.23V(typical) at 3A Output Current

• Low ESR Output Capacitor (Multi-layer

Chip Capacitors (MLCC)) Applicable

• 0.8V Reference Voltage

• High Output Accuracy

- ±1.5% over Line, Load, and Temperature Range

• Fast Transient Response

• Adjustable Output Voltage

• Power-On-Reset Monitoring on Both VCNTL and

VIN Pins

• Internal Soft-Start

• Current-Limit and Short Current-Limit Protections

• Thermal Shutdown with Hysteresis

• Open-Drain VOUT Voltage Indicator (POK)

• Low Shutdown Quiescent Current (<30 µA)

• Shutdown/Enable Control Function

• Simple SOP-8P Package with Exposed Pad

• Lead Free and Green Devices Available

(RoHS Compliant)

General Description

The APL5930 is a 3A ultra low dropout linear regulator.

The IC needs two supply voltages, one is a control voltage

(V

) for the control circuitry, the other is a main supply

CNTL

voltage (VIN) for power conversion, to reduce power dissipation and provide extremely low dropout voltage.

The APL5930 integrates many functions. A Power-OnReset (POR) circuit monitors both supply voltages on

VCNTL and VIN pins to prevent erroneous operations.

The functions of thermal shutdown and current-limit protect the device against thermal and current over-loads. A

POK indicates the output voltage status with a delay time

set internally. It can control other converter for power

sequence. The APL5930 can be enabled by other power

systems. Pulling and holding the EN voltage below 0.4V

shuts off the output.

The APL5930 is available in a SOP-8P package which

features small size as SOP-8 and an Exposed Pad to

reduce the junction-to-case resistance to extend power

range of applications.

Applications

• Front Side Bus VTT (1.2V/3A)

• Note Book PC Applications

• Motherboard Applications

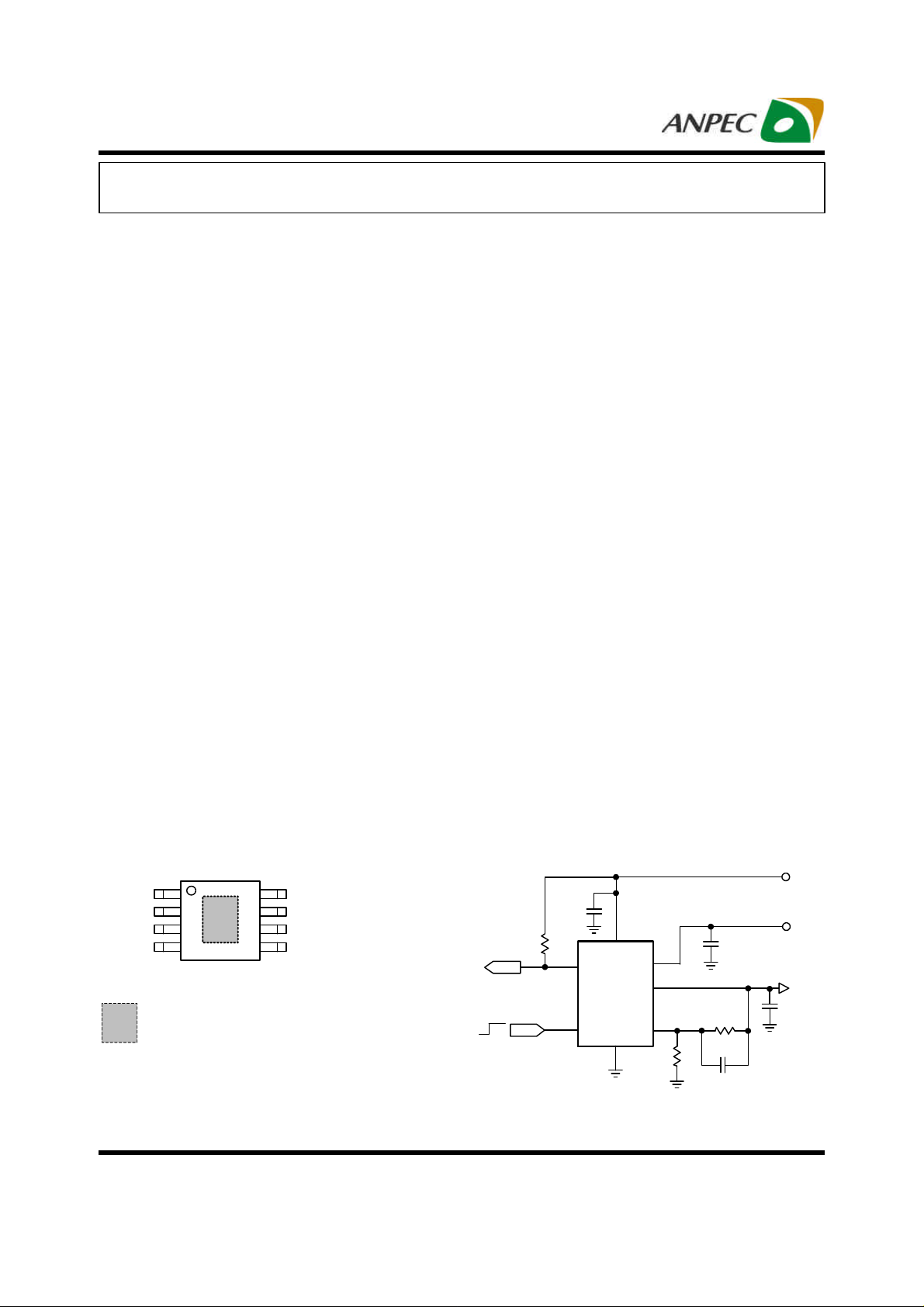

Simplified Application CircuitPin Configuration

V

1

GND

2

FB

3

VOUT

4

VOUT

SOP-8P (Top View)

= Exposed Pad

(connected to VIN plane for better heat dissipation)

ANPEC reserves the right to make changes to improve reliability or manufacturability without notice, and

advise customers to obtain the latest version of relevant information to verify before placing orders.

Copyright ANPEC Electronics Corp.

Rev. A.4 - Sep., 2009

8

7

6

5

EN

POK

VCNTL

VIN

POK

Enable

EN

VCNTL

POK

VOUT

APL5930

EN

GND

VIN

FB

Optional

www.anpec.com.tw1

CNTL

V

IN

V

OUT

APL5930

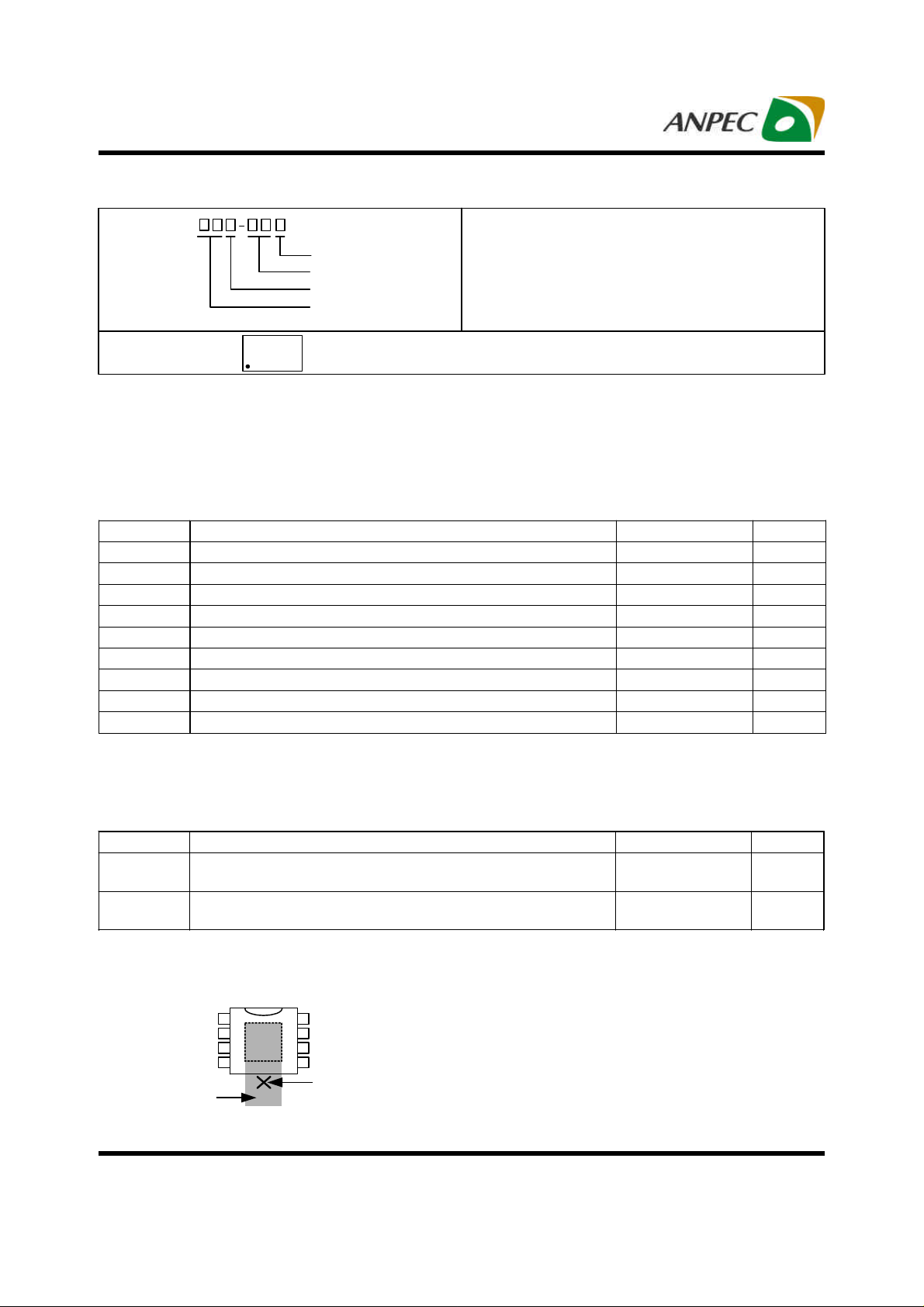

Ordering and Marking Information

APL5930

Assembly Material

Handling Code

Temperature Range

Package Code

APL5930 KA :

APL5930

XXXXX

Note: ANPEC lead-free products contain molding compounds/die attach materials and 100% matte tin plate termination finish; which

are fully compliant with RoHS. ANPEC lead-free products meet or exceed the lead-free requirements of IPC/JEDEC J-STD-020D for

MSL classification at lead-free peak reflow temperature. ANPEC defines “Green” to mean lead-free (RoHS compliant) and halogen

free (Br or Cl does not exceed 900ppm by weight in homogeneous material and total of Br and Cl does not exceed 1500ppm by

weight).

Absolute Maximum Ratings (Note 1)

Symbol Parameter Rating Unit

VIN VIN Supply Voltage (VIN to GND) -0.3 ~ 4.0 V

V

VCNTL Supply Voltage (VCNTL to GND) -0.3 ~ 7 V

CNTL

V

VOUT to GND Voltage -0.3 ~ VIN +0.3 V

OUT

POK to GND Voltage -0.3 ~ 7 V

EN, FB to GND Voltage -0.3 ~ V

PD Power Dissipation 3 W

TJ Maximum Junction Temperature 150

T

Storage Temperature -65 ~ 150

STG

T

Maximum Lead Soldering Temperature, 10 Seconds 260

SDR

Note 1: Absolute Maximum Ratings are those values beyond which the life of a device may be impaired. Exposure to absolute

maximum rating conditions for extended periods may affect device reliability.

Package Code

KA : SOP-8P

Operating Ambient Temperature Range

I : -40 to 85 oC

Handling Code

TR : Tape & Reel

Assembly Material

G : Halogen and Lead Free Device

XXXXX - Date Code

CNTL

+0.3 V

o

o

o

C

C

C

Thermal Characteristics

Symbol Parameter Typical Value Unit

θJA

θJC

Note 2: θJA is measured with the component mounted on a high effective thermal conductivity test board in free air. The exposed pad

Junction-to-Ambient Resistance in Free Air

Junction-to-Case Resistance in Free Air

of SOP-8P is soldered directly on the PCB.

Note 3: The “Thermal Pad Temperature” is measured on the PCB copper area connected to the thermal pad of package.

1

2

VIN

3

4

8

7

6

5

Measured Point

PCB Copper

Copyright ANPEC Electronics C orp.

Rev. A.4 - Sep., 2009

(Note 2)

(Note 3)

SOP-8P

SOP-8P

42

18

o

C/W

o

C/W

www.anpec.com.tw2

APL5930

Recommended Operating Conditions

Symbol Parameter Range Unit

V

VCNTL Supply Voltage 3.0 ~ 5.5 V

CNTL

VIN VIN Supply Voltage 1.2 ~ 3.65 V

V

VOUT Output Voltage (when V

OUT

I

VOUT Output Current

OUT

C

VOUT Output Capacitance

OUT

ESR

ESR of VOUT Output Capacitor

COUT

CNTL-VOUT

TA Ambient Temperature -40 ~ 85

TJ Junction Temperature -40 ~ 125

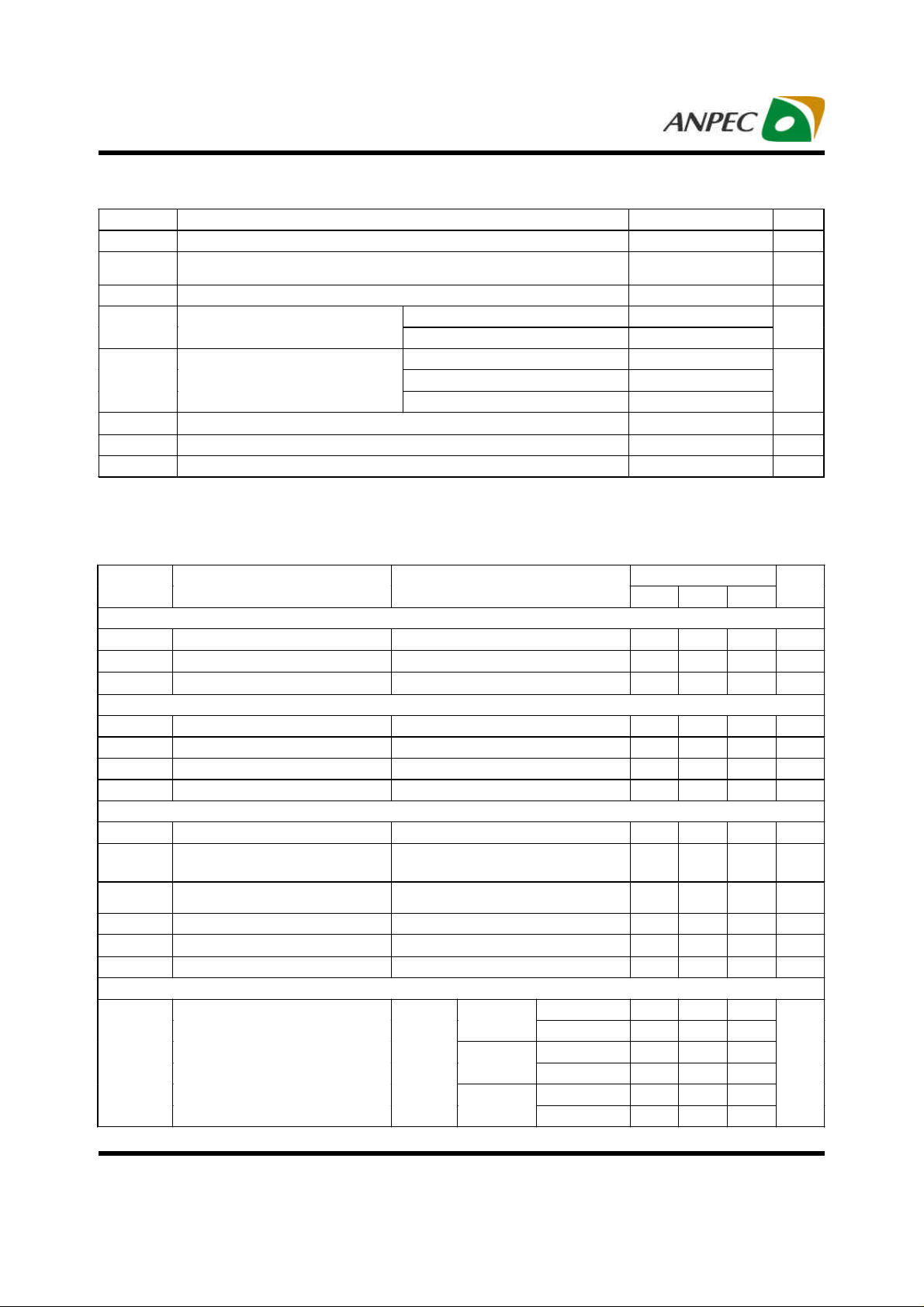

Electrical Characteristics

Unless otherwise specified, these specifications apply over V

are at TA=25oC.

>1.9V) 0.8 ~ VIN – V

Continuous Current 0 ~ 3

Peak Current 0 ~ 4

I

= 3A at 25% nominal V

OUT

I

= 2A at 25% nominal V

OUT

I

= 1A at 25% nominal V

OUT

8 ~ 1100

OUT

8 ~ 1700

OUT

8 ~ 2400

OUT

0 ~ 200

=5V, VIN=1.8V, V

CNTL

= 1.2V and TA= -40 ~ 85 oC. Typical values

OUT

V

DROP

A

µF

mΩ

o

C

o

C

Symbol Parameter Test Conditions

APL5930

Min. Typ. Max.

SUPPLY CURRENT

I

VCNTL Supply Current EN = VCNTL, I

VCNTL

=0A - 1.0 1.5 mA

OUT

ISD VCNTL Supply Current at Shutdown EN = GND - 15 30

VIN Supply Current at Shutdown EN = GND, VIN=3.65V - - 1

POWER-ON-RESET (POR)

Rising VCNTL POR Threshold 2.5 2.7 2.9 V

VCNTL POR Hysteresis - 0.4 - V

Rising VIN POR Threshold

VIN POR Hysteresis

0.8 0.9 1.0 V

- 0.5 - V

OUTPUT VOLTAGE

V

Reference Voltage FB=VOUT - 0.8 - V

REF

V

=3.0 ~ 5.5V, I

Output Voltage Accuracy

Load Regulation I

Line Regulation I

VOUT Pull-low Resistance

CNTL

TJ= -40~125oC

=0A ~3A - 0.06 0.25

OUT

=10mA, V

OUT

V

=3.3V, VEN=0V, V

CNTL

FB Input Current VFB=0.8V -100

= 0~3A,

OUT

= 3.0 ~ 5.5V - 0.15 - + 0.15 %/V

CNTL

<0.8V

OUT

-1.5

- +1.5 %

- 85 -

- 100

DROPOUT VOLTAGE

TJ=25oC - 0.26 0.31

TJ=-40~125oC - - 0.42

TJ=25oC - 0.24 0.29

TJ=-40~125oC - - 0.40

TJ=25oC - 0.23 0.28

TJ=-40~125oC - - 0.38

V

VIN-to-VOUT Dropout Voltage

DROP

V

=2.5V

OUT

V

V

OUT

OUT

=1.8V

=1.2V

V

=5.0V

CNTL

, I

=3A

OUT

Unit

µA

µA

%

Ω

nA

V

Copyright ANPEC Electronics C orp.

www.anpec.com.tw3

Rev. A.4 - Sep., 2009

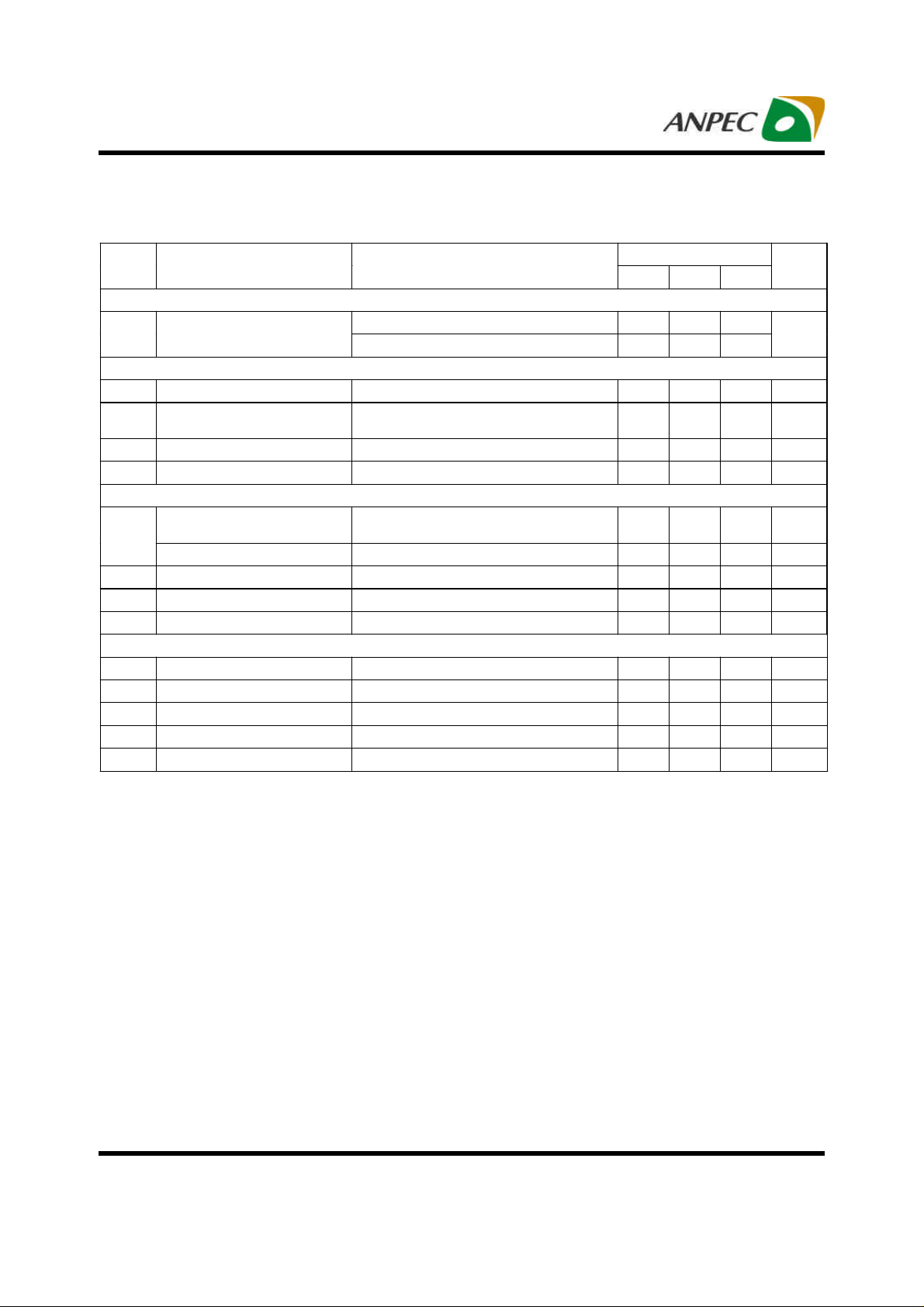

APL5930

Electrical Characteristics (Cont.)

Unless otherwise specified, these specifications apply over V

are at TA=25oC.

Symbol

Parameter Test Conditions

DROPOUT VOLTAGE (CONT.)

I

Current-Limit Level

LIM

TJ=25oC 4.7 5.7 6.7

TJ= -40 ~ 125oC 4.2 - -

PROTECTIONS

I

Short Current-Limit Level VFB<0.2V - 1.1 - A

SHORT

Short Current-Limit Blanking

Time

From beginning of soft-start 0.6 1.5 - ms

TSD Thermal Shutdown Temperature TJ rising - 170 -

Thermal Shutdown Hysteresis - 50 -

ENABLE AND SOFT-START

EN Logic High Threshold

Voltage

VEN rising 0.5 0.8 1.1 V

EN Hysteresis - 0.1 - V

EN Pull-High Current EN=GND - 5 -

TSS Soft-Start Interval 0.3 0.6 1.2 ms

Turn On Delay From being enabled to V

POWER-OK AND DELAY

V

Rising POK Threshold Voltage VFB rising 90 92 94 %

THPOK

POK Threshold Hysteresis - 8 - %

POK Pull-low Voltage POK sinks 5mA - 0.25 0.4 V

POK Debounce Interval VFB<falling POK voltage threshold - 10 POK Delay Time From VFB =V

=5V, VIN=1.8V, V

CNTL

rising 10% 60 120 180

OUT

to rising edge of the V

THPOK

= 1.2V and TA= -40 ~ 85 oC. Typical values

OUT

APL5930

Min. Typ. Max.

POK

1 2 4 ms

Unit

A

o

C

o

C

µA

µs

µs

Copyright ANPEC Electronics C orp.

www.anpec.com.tw4

Rev. A.4 - Sep., 2009

APL5930

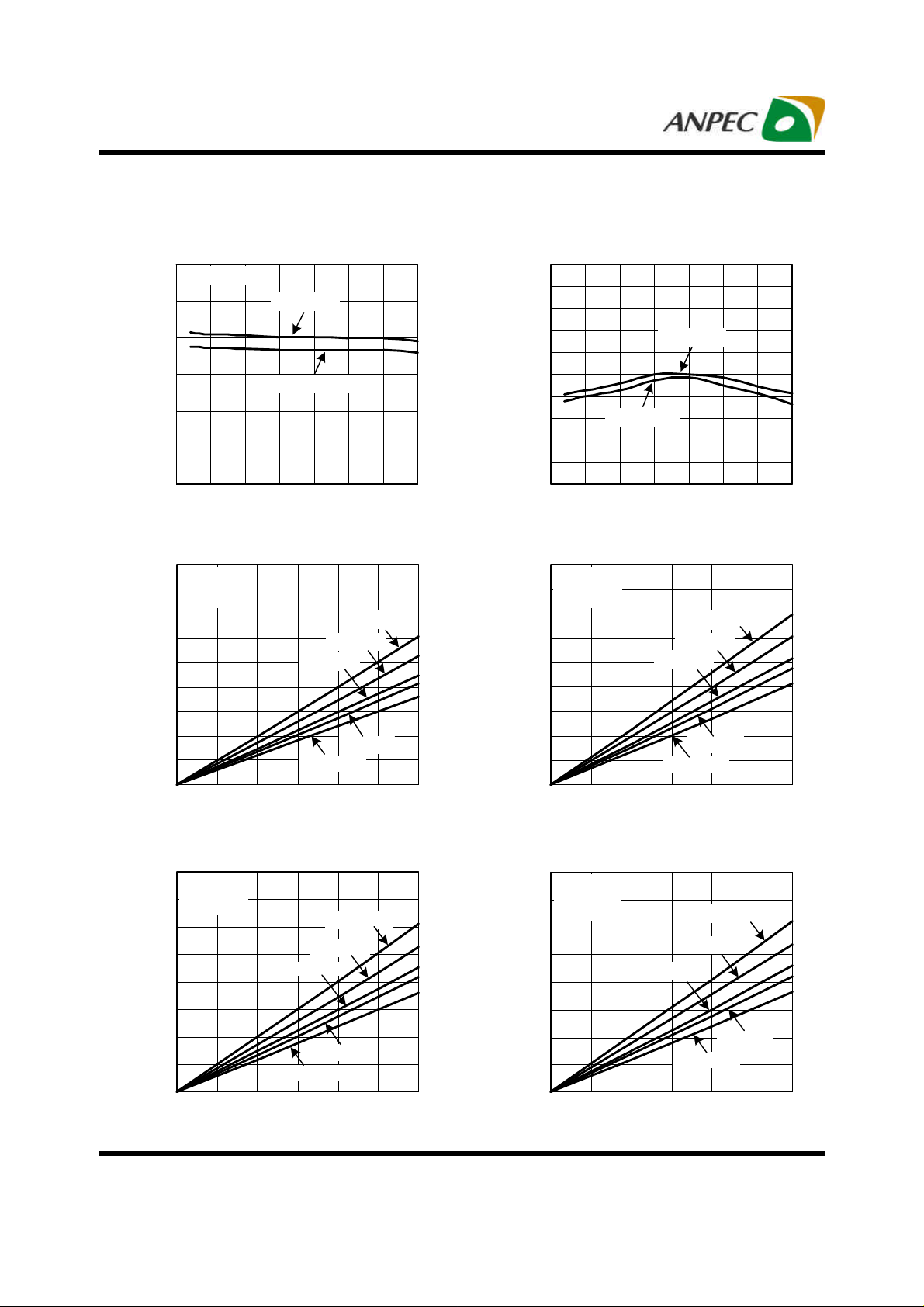

Typical Operating Characteristics

Current-Limit vs. Junction

Temperature

6.5

V

= 1.2V

OUT

6.0

(A)

5.5

LIM

5.0

4.5

V

CNTL

V

CNTL

= 5V

= 3.3V

Current-Limit, I

4.0

3.5

-50 -25 0 25 50 75 100 125

Junction Temperature (

Dropout Voltage vs. Output Current

450

V

= 5V

CNTL

400

V

= 1.2V

OUT

350

(mV)

300

DROP

250

200

150

100

Dropout Voltage, V

50

0

0 0.5 1 1.5 2 2.5 3

Output Current, I

TJ = 75°C

TJ = 25°C

TJ = - 40°C

OUT

Dropout Voltage vs. Output Current

400

V

= 5V

CNTL

350

V

= 1.5V

OUT

300

(mV)

DROP

250

200

TJ = 125°C

TJ = 75°C

TJ = 25°C

o

)

C

TJ = 125°C

TJ = 0°C

(A)

Short Current-Limit vs. Junction

Temperature

1.20

1.18

1.16

(mA)

1.14

SHORT

1.12

1.10

1.08

1.06

1.04

Short Current-Limit, I

1.02

1.00

-50 -25 0 25 50 75 100

V

CNTL

= 3.3V

V

CNTL

= 5V

Junction Temperature (

Droput Voltage vs. Output Current

450

V

= 3.3V

CNTL

400

V

= 1.2V

OUT

350

(mV)

300

DROP

250

200

150

100

Dropout Voltage, V

50

0

0 0.5 1 1.5 2 2.5 3

Output Current, I

TJ = 125°C

TJ = 75°C

TJ = 25°C

TJ = 0°C

TJ = - 40°C

OUT

Dropout Voltage vs. Output Current

400

V

= 5V

CNTL

350

V

= 1.8V

OUT

300

(mV)

DROP

250

200

TJ = 75°C

TJ = 25°C

o

)

C

(A)

TJ = 125°C

125

150

100

Dropout Voltage, V

50

0

0 0.5 1 1.5 2 2.5 3

Output Current, I

TJ = 0°C

TJ = - 40°C

OUT

Copyright ANPEC Electronics C orp.

Rev. A.4 - Sep., 2009

(A)

150

100

Dropout Voltage, V

50

0

0 0.5 1 1.5 2 2.5 3

Output Current, I

TJ = - 40°C

OUT

www.anpec.com.tw5

TJ = 0°C

(A)

APL5930

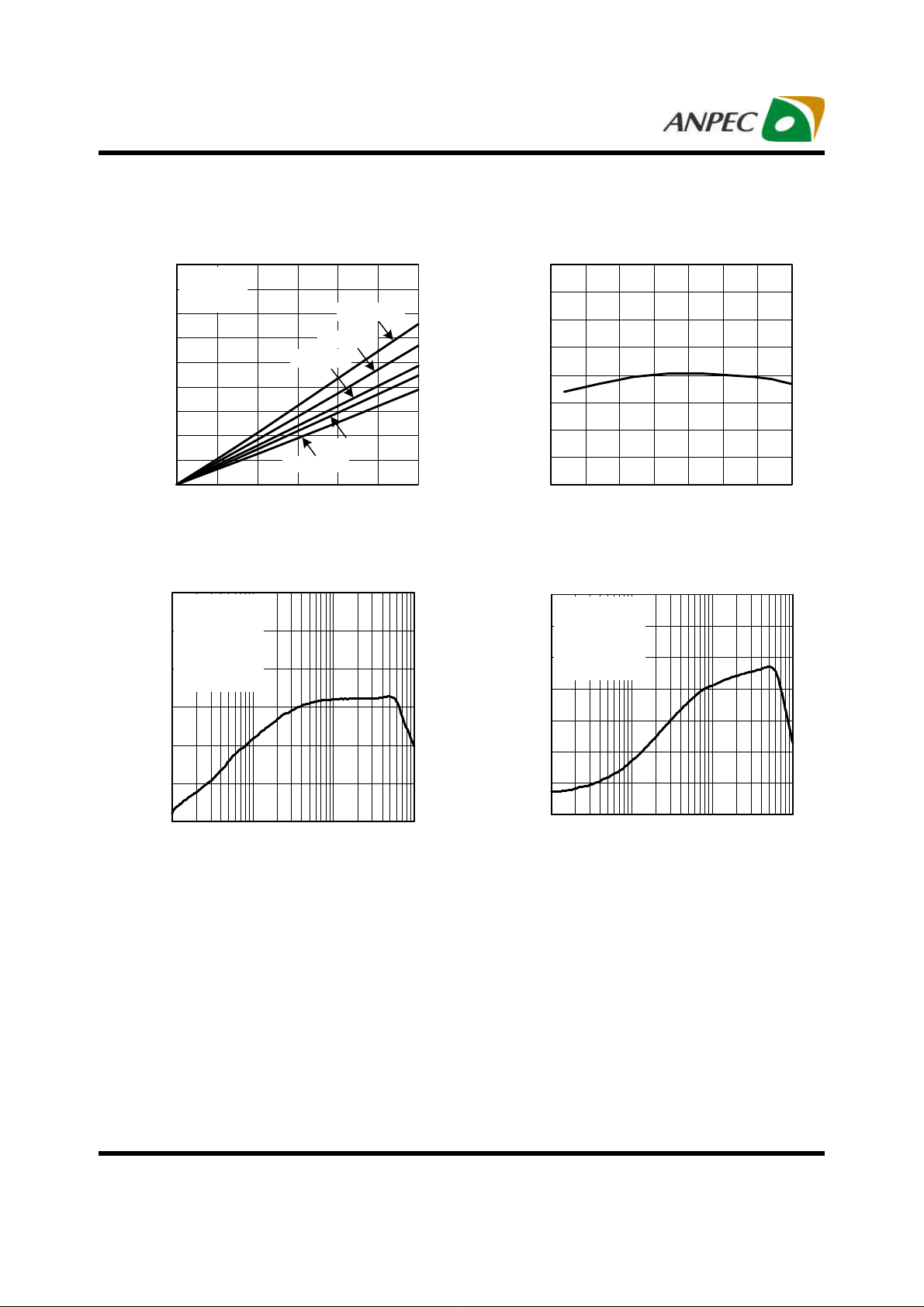

Typical Operating Characteristics (Cont.)

Dropout Voltage vs. Output Current

450

V

= 5V

CNTL

400

V

= 2.5V

OUT

350

(mV)

300

DROP

250

200

150

100

Dropout Voltage, V

50

0

0 0.5 1 1.5 2 2.5 3

TJ = 25°C

TJ = - 40°C

Output Current, I

TJ = 125°C

TJ = 75°C

TJ = 0°C

(A)

OUT

VIN Power Supply Rejection Ratio

(PSRR)

0

V

=5V

CNTL

VIN=1.8V

-10

V

=100mV

PK-PK

IN

V

=1.2V

OUT

I

=3A

OUT

-20

CIN=10µF

C

=10µF

OUT

-30

-40

-50

Power Supply Rejection Ratio (dB)

-60

1000 10000 100000 1000000

Frequency (Hz)

Reference Voltage vs. Junction

Temperature

0.808

0.806

(V)

0.804

REF

0.802

0.800

0.798

0.796

Reference Voltage, V

0.794

0.792

-50 -25 0 25 50 75 100 125

Junction Temperature (oC)

VCNTL Power Supply Rejection Ratio

(PSRR)

0

V

=4.6~5.4V

CNTL

VIN=1.8V

-10

V

=1.2V

OUT

I

=3A

OUT

-20

CIN=C

=10µF

OUT

-30

-40

-50

-60

Power Supply Rejection Ratio (dB)

-70

1000 10000 100000 1000000

Frequency (Hz)

Copyright ANPEC Electronics C orp.

Rev. A.4 - Sep., 2009

www.anpec.com.tw6

APL5930

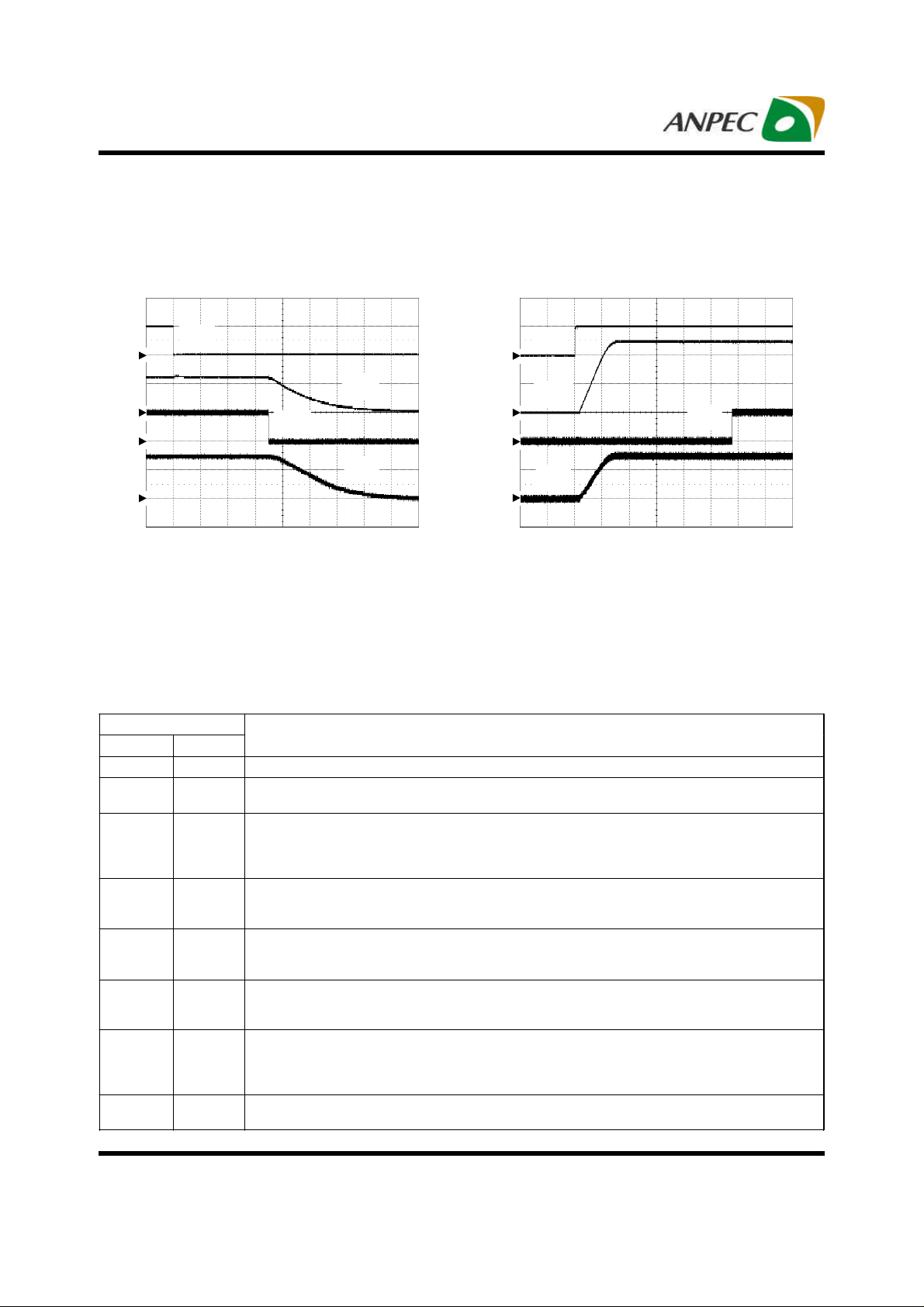

Operating Waveforms

Refer to the typical application circuit. The test condition is VIN=1.8V, V

unless otherwise specified.

CNTL

=5V, V

=1.2V, TA= 25oC

OUT

1

2

3

4

C

=10µF, CIN=10µF, RL=0.4Ω

OUT

CH1: V

CNTL

CH2: VIN, 1V/Div, DC

CH3: V

CH4: V

TIME: 2ms/Div

, 1V/Div, DC

OUT

, 5V/Div, DC

POK

Load Transient Response

Power On

, 5V/Div, DC

Power Off

V

CNTL

V

CNTL

V

IN

V

OUT

V

POK

1

2

3

4

C

=10µF, CIN=10µF, RL=0.4Ω

OUT

CH1: V

CNTL

CH2: VIN, 1V/Div, DC

CH3: V

CH4: V

TIME: 2ms/Div

, 1V/Div, DC

OUT

, 5V/Div, DC

POK

, 5V/Div, DC

V

IN

V

OUT

V

POK

Over Current Protection

V

1

2

I

=10mA to 3A to 10mA (rise / fall time = 1µs)

OUT

C

=10µF, CIN=10µF

OUT

CH1: V

OUT

CH2: I

, 1A/Div, DC

OUT

OUT

I

OUT

, 50mV/Div, AC

TIME: 50µs/Div

Copyright ANPEC Electronics C orp.

Rev. A.4 - Sep., 2009

1

4

C

=10µF, CIN=10µF, I

OUT

CH1: V

CH4: I

OUT

TIME: 0.2ms/Div

V

OUT

I

OUT

, 0.5V/Div, DC

OUT

, 2A/Div, DC

= 2A to 5.6A

OUT

www.anpec.com.tw7

APL5930

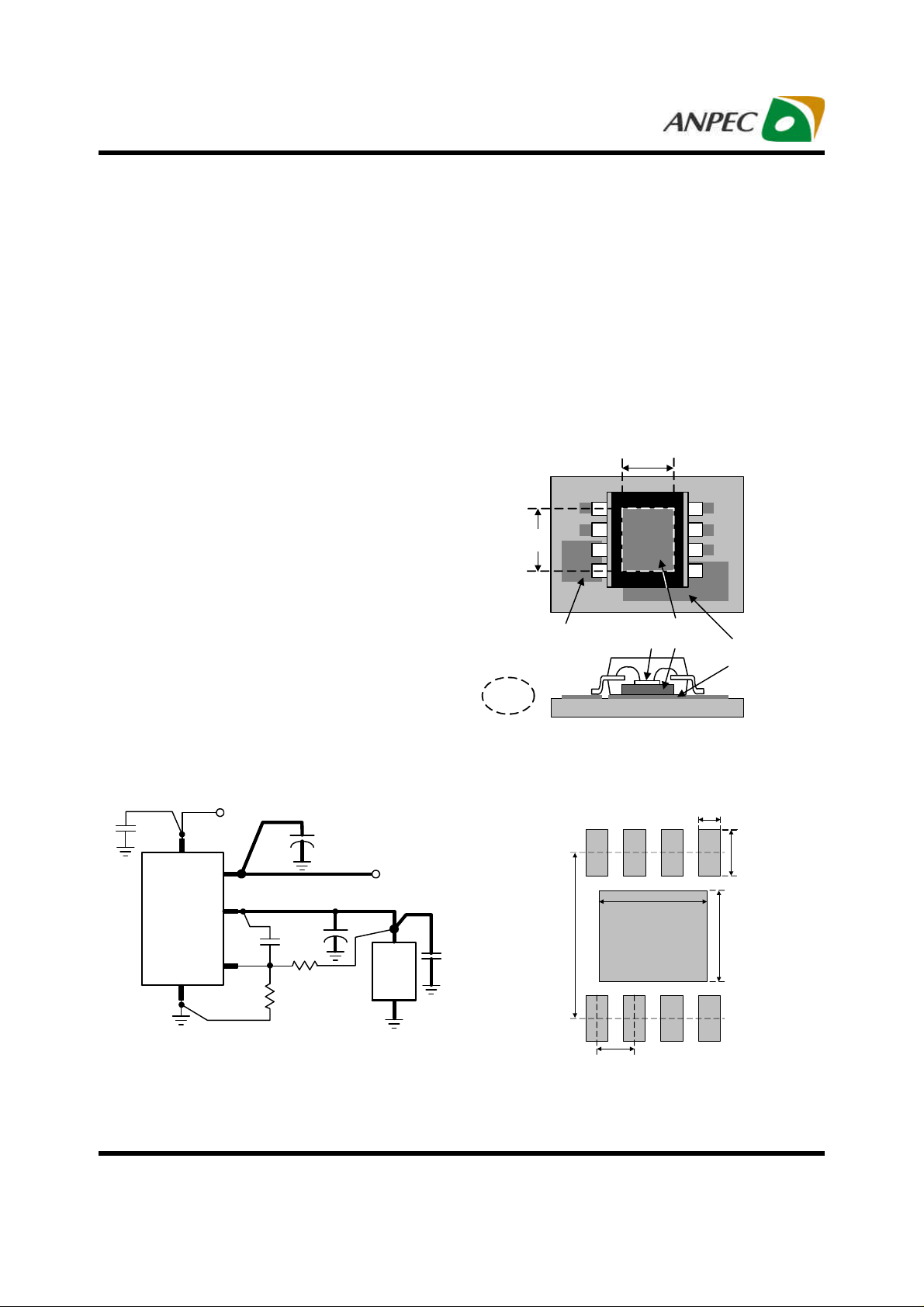

Operating Waveforms (Cont.)

Refer to the typical application circuit. The test condition is VIN=1.8V, V

unless otherwise specified.

CNTL

=5V, V

=1.2V, TA= 25oC

OUT

Shutdown

V

1

2

3

4

EN

C

=10µF, CIN=10µF, RL=0.4Ω

OUT

CH1: VEN, 5V/Div, DC

CH2: V

CH3: V

CH4: I

TIME: 2µs/Div

, 1V/Div, DC

OUT

, 5V/Div, DC

POK

, 2A/Div, DC

OUT

Pin Description

Enable

V

EN

1

V

OUT

V

POK

I

OUT

V

OUT

2

3

I

OUT

4

C

=10µF, CIN=10µF, RL=0.4Ω

OUT

CH1: VEN, 5V/Div, DC

CH2: V

CH3: V

CH4: I

TIME: 0.5ms/Div

, 0.5V/Div, DC

OUT

, 5V/Div, DC

POK

, 2A/Div, DC

OUT

V

POK

PIN

NO. NAME

FUNCTION

1 GND Ground pin of the circuitry. All voltage levels are measured with respect to this pin.

2 FB

Voltage Feedback Pin. Connecting this pin to an external resistor divider receives the feedback voltage

of the regulator.

Output pin of the regulator. Connecting this pin to load and output capacitors (10µF at least) is required

3,4

VOUT

for stability and improving transient response. The output voltage is programmed by the resistor-divider

connected to FB pin. The VOUT can provide 3A (max.) load current to loads. During shutdown, the

output voltage is quickly discharged by an internal pull-low MOSFET.

Main supply input pin for voltage conversions. A decoupling capacitor (≥10µF recommended) is usually

5 VIN

connected near this pin to filter the voltage noise and improve transient response. The voltage on this

pin is monitored for Power-On-Reset purpose.

Bias voltage input pin for internal control circuitry. Connect this pin to a voltage source (+5V

6 VCNTL

recommended). A decoupling capacitor (1µF typical) is usually connected near this pin to filter the

voltage noise. The voltage at this pin is monitored for Power-On-Reset purpose.

Power-OK signal output pin. This pin is an open-drain output used to indicate the status of output

7 POK

voltage by sensing FB voltage. This pin is pulled low when output voltage is not within the Power-OK

voltage window.

Active-high enable control pin. Applying and holding the voltage on this pin below the enable voltage

8 EN

threshold shuts down the output. When re-enabled, the IC undergoes a new soft-start process. When

leave this pin open, an internal pull-up current (5µA typical) pulls the EN voltage and enables the

regulator.

Exposed

Pad

-

Connect this pad to system VIN plane for good thermal conductivity.

Copyright ANPEC Electronics C orp.

Rev. A.4 - Sep., 2009

www.anpec.com.tw8

APL5930

Block Diagram

VCNTL

VCNTL

5µA

EN

0.8V

POK

PWOK

Delay

Typical Application Circuit

C

CNTL

1µF

R3

5.1kΩ

POK

EN

Enable

7

POK

APL5930

8

EN

Thermal

Shutdown

Enable

POR

90%

V

6

VCNTL

VOUT

GND

1

V

0.8V

REF

VIN

REF

FB

Control Logic

and

Soft-Start

Soft-Start

Error Amplifier

FB

5

3,4

2

R2

24kΩ

POR

Enable

Current-Limit

and

Short Current-

Limit

R1

12kΩ

Power-

On-Reset

(POR)

ISEN

C

IN

10µF

VIN

VOUT

GND

V

CNTL

(+5V is preferred)

V

IN

+1.8V

V

OUT

+1.2V / 3A

C

OUT

10µF

(X5R/X7R Recommended)

Copyright ANPEC Electronics C orp.

Rev. A.4 - Sep., 2009

Optional

(X5R/X7R Recommended)

10µF: GRM31MR60J106KE19 Murata

C1

www.anpec.com.tw9

APL5930

Function Description

Power-On-Reset

A Power-On-Reset (POR) circuit monitors both of supply

voltages on VCNTL and VIN pins to prevent wrong logic

controls. The POR function initiates a soft-start process

after both of the supply voltages exceed their rising POR

voltage thresholds during powering on. The POR function also pulls low the POK voltage regardless the output

status when one of the supply voltages falls below its

falling POR voltage threshold.

Internal Soft-Start

An internal soft-start function controls rise rate of the output voltage to limit the current surge during start-up. The

typical soft-start interval is about 0.6 ms.

Output Voltage Regulation

An error amplifier works with a temperature-compensated 0.8V reference and an output NMOS regulates

output to the preset voltage. The error amplifier is designed with high bandwidth and DC gain provides very

fast transient response and less load regulation. It compares the reference with the feedback voltage and amplifies the difference to drive the output NMOS which provides load current from VIN to VOUT.

Thermal Shutdown

A thermal shutdown circuit limits the junction temperature of APL5930. When the junction temperature exceeds

+170oC, a thermal sensor turns off the output NMOS, allowing the device to cool down. The regulator regulates

the output again through initiation of a new soft-start process after the junction temperature cools by 50oC, resulting in a pulsed output during continuous thermal overload conditions. The thermal shutdown is designed with

a 50oC hysteresis to lower the average junction temperature during continuous thermal overload conditions, extending lifetime of the device.

For normal operation, the device power dissipation should

be externally limited so that junction temperatures will

not exceed +125oC.

Enable Control

The APL5930 has a dedicated enable pin (EN). A logic

low signal applied to this pin shuts down the output. Following a shutdown, a logic high signal re-enables the

output through initiation of a new soft-start cycle. When

left open, this pin is pulled up by an internal current source

(5µA typical) to enable normal operation. It’s not necessary to use an external transistor to save cost.

Current-Limit Protection

The APL5930 monitors the current flowing through the

output NMOS and limits the maximum current to prevent

load and APL5930 from damages during current overload conditions.

Short Current-Limit Protection

The short current-limit function reduces the current-limit

level down to 1.1A (typical) when the voltage on FB pin

falls below 0.2V (typical) during current overload or shortcircuit conditions.

The short current-limit function is disabled for successful start-up during soft-start interval.

Copyright ANPEC Electronics C orp.

Rev. A.4 - Sep., 2009

Power-OK and Delay

The APL5930 indicates the status of the output voltage by

monitoring the feedback voltage (VFB) on FB pin. As the

VFB rises and reaches the rising Power-OK voltage threshold (V

the end of the delay time, the IC turns off the internal

NMOS of the POK to indicate that the output is ok. As the

VFB falls and reaches the falling Power-OK voltage

threshold, the IC turns on the NMOS of the POK (after a

debounce time of 10µs typical).

), an internal delay function starts to work. At

THPOK

www.anpec.com.tw10

APL5930

Application Information

Power Sequencing

The power sequencing of VIN and VCNTL is not necessary to be concerned. However, do not apply a voltage to

VOUT for a long time when the main voltage applied at

VIN is not present. The reason is the internal parasitic

diode from VOUT to VIN conducts and dissipates power

without protections due to the forward-voltage.

Output Capacitor

The APL5930 requires a proper output capacitor to maintain stability and improve transient response. The output

capacitor selection is dependent upon ESR (equivalent

series resistance) and capacitance of the output capacitor over the operating temperature.

Ultra-low-ESR capacitors (such as ceramic chip

capacitors) and low-ESR bulk capacitors (such as solid

tantalum, POSCap, and Aluminum electrolytic capacitors)

can all be used as output capacitors.

During load transients, the output capacitors, depending

on the stepping amplitude and slew rate of load current,

are used to reduce the slew rate of the current seen by

the APL5930 and help the device to minimize the variations of output voltage for good transient response. For

the applications with large stepping load current, the lowESR bulk capacitors are normally recommended.

Decoupling ceramic capacitors must be placed at the

load and ground pins as close as possible and the impedance of the layout must be minimized.

Ultra-low-ESR capacitors (such as ceramic chip capacitors) and low-ESR bulk capacitors (such as solid

tantalum, POSCap, and Aluminum electrolytic capacitors)

can all be used as an input capacitor of VIN. For most

applications, the recommended input capacitance of VIN

is 10µF at least. However, if the drop of the input voltage

is not cared, the input capacitance can be less than 10µF.

More capacitance reduces the variations of the supply

voltage on VIN pin.

Setting Output Voltage

The output voltage is programmed by the resistor divider

connected to FB pin. The preset output voltage is calculated by the following equation :

R1

+⋅=

10.8 VOUT

R2

........... (V)

Where R1 is the resistor connected from VOUT to FB with

Kelvin sensing connection and R2 is the resistor connected from FB to GND. A bypass capacitor(C1) may be

connected with R1 in parallel to improve load transient

response and stability.

Input Capacitor

The APL5930 requires proper input capacitors to supply

current surge during stepping load transients to prevent

the input voltage rail from dropping. Because the parasitic inductor from the voltage sources or other bulk capacitors to the VIN pin limit the slew rate of the surge

currents, more parasitic inductance needs more input

capacitance.

Copyright ANPEC Electronics C orp.

Rev. A.4 - Sep., 2009

www.anpec.com.tw11

APL5930

Layout Consideration

the top-layer of PCBs. The VIN pad must have wide

size to conduct heat into the ambient air through the

VIN plane and PCB as a heat sink.

2. Please place the input capacitors for VIN and VCNTL

pins near the pins as close as possible for

decoupling high-frequency ripples.

3. Ceramic decoupling capacitors for load must be

placed near the load as close as possible for

decoupling high-frequency ripples.

4. To place APL5930 and output capacitors near the

load reduces parasitic resistance and inductance

for excellent load transient response.

5. The negative pins of the input and output capacitors

and the GND pin must be connected to the ground

plane of the load.

6. Large current paths, shown by bold lines on the figure 1, must have wide tracks.

7. Place the R1, R2, and C1 near the APL5930 as close

as possible to avoid noise coupling.

8. Connect the ground of the R2 to the GND pin by using a dedicated track.

9. Connect the one pin of the R1 to the load for Kelvin

sensing.

10. Connect one pin of the C1 to the VOUT pin for reliable feedback compensation.

Thermal Consideration1. Please solder the Exposed Pad on the VIN pad on

Refer to the figure 2, the SOP-8P is a cost-effective pack-

age featuring a small size like a standard SOP-8 and a

bottom exposed pad to minimize the thermal resistance

of the package, being applicable to high current applications. The exposed pad must be soldered to the top-layer

VIN plane. The copper of the VIN plane on the Top layer

conducts heat into the PCB and ambient air. Please enlarge the area of the top-layer pad and the VIN plane to

reduce the case-to-ambient resistance (θCA).

102 mil

Ambient

Air

118 mil

Top

VOUT

plane

1

2

3

4

SOP-8P

Die

8

7

6

5

Exposed

Pad

PCB

Top

VIN

plane

Figure 2

V

CNTL

C

CNTL

VCNTL

APL5930

GND

VIN

VOUT

C1

FB

R2

C

IN

C

OUT

R1

Figure 1

Copyright ANPEC Electronics C orp.

Rev. A.4 - Sep., 2009

V

V

OUT

Load

Recommended Minimum Footprint

0.024

8 7 6 5

IN

0.138

0.212

1 2 3 4

0.050

Unit : Inch

0.072

0.118

www.anpec.com.tw12

APL5930

Pack age Information

SOP-8P

D

D1

SEE VIEW A

L

b

c

D

E

e

h

A

A1

A2

D1

E1

0

THERMAL

PAD

e

S

Y

M

B

O

L

MIN.

0.00

1.25

0.31

0.17

4.80 5.00

2.50

5.80 6.20

3.80 4.00

2.00

0.25

0.40

E2

b

MILLIMETERS

1.27 BSC

0oC

E

E1

o

h X 45

c

A

A2

0.25

A1

L

VIEW A

SOP-8P

MAX.

1.60

0.15

0.51

0.25

3.50

3.00

0.50

1.27

8oC 0oC 8oC

MIN.

0.000

0.049

0.012

0.007

0.189 0.197

0.098

0.228 0.244

0.150 0.157

0.079E2

0.010

0.016

θ

INCHES

0.050 BSC

GAUGE PLANE

SEATING PLANE

MAX.

0.063

0.006

0.020

0.010

0.138

0.118

0.020

0.050

Note : 1. Followed from JEDEC MS-012 BA.

2. Dimension "D" does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion or gate burrs shall not exceed 6 mil per side .

3. Dimension "E" does not include inter-lead flash or protrusions.

Inter-lead flash and protrusions shall not exceed 10 mil per side.

Copyright ANPEC Electronics C orp.

Rev. A.4 - Sep., 2009

www.anpec.com.tw13

APL5930

Carrier Tape & R eel Dimensions

OD0

B0

P0

P2

P1

A

E1

F

W

Application

SOP-8P

K0

SECTION A-A

B

A

H

A0

SECTION B-B

OD1

B

T

A

d

T1

A H T1 C d D W E1 F

330.0±2.00 50 MIN.

12.4+2.00

-0.00

13.0+0.50

-0.20

1.5 MIN. 20.2 MIN. 12.0±0.30 1.75±0.10 5.5±0.05

P0 P1 P2 D0 D1 T A0 B0 K0

4.0±0.10 8.0±0.10 2.0±0.05

1.5+0.10

-0.00

1.5 MIN.

0.6+0.00

-0.40

6.40±0.20 5.20±0.20 2.10±0.20

Devices Per Unit

Package Type

SOP- 8P

Copyright ANPEC Electronics C orp.

Rev. A.4 - Sep., 2009

(mm)

Unit Quantity

Tape & Reel 2500

www.anpec.com.tw14

APL5930

Taping Direction Information

SOP-8P

USER DIRECTION OF FEED

Classification Profile

Copyright ANPEC Electronics C orp.

Rev. A.4 - Sep., 2009

www.anpec.com.tw15

APL5930

Classification Reflow Profiles

Profile Feature Sn-Pb Eutectic Assembly Pb-Free Assembly

Preheat & Soak

Temperature min (T

Temperature max (T

Time (T

smin

to T

smax

smin

smax

) (ts)

)

)

Average ramp-up rate

(T

to TP)

smax

Liquidous temperature (TL)

Time at liquidous (tL)

Peak package body Temperature

(Tp)*

Time (tP)** within 5°C of the specified

classification temperature (Tc)

Average ramp-down rate (Tp to T

smax

Time 25°C to peak temperature

See Classification Temp in table 1 See Classification Temp in table 2

)

100 °C

150 °C

60-120 seconds

150 °C

200 °C

60-120 seconds

3 °C/second max. 3°C/second max.

183 °C

60-150 seconds

217 °C

60-150 seconds

20** seconds 30** seconds

6 °C/second max. 6 °C/second max.

6 minutes max. 8 minutes max.

* Tolerance for peak profile Temperature (Tp) is defined as a supplier minimum and a user maximum.

** Tolerance for time at peak profile temperature (tp) is defined as a supplier minimum and a user maximum.

Table 1. SnPb Eutectic Process – Classification Temperatures (Tc)

Package

Thickness

<2.5 mm

Volume mm

3

Volume mm

<350

235 °C 220 °C

≥350

3

≥2.5 mm 220 °C 220 °C

Table 2. Pb-free Process – Classification Temperatures (Tc)

Package

Thickness

<1.6 mm

1.6 mm – 2.5 mm

Volume mm3

<350

Volume mm3

350-2000

Volume mm3

260 °C 260 °C 260 °C

260 °C 250 °C 245 °C

>2000

≥2.5 mm 250 °C 245 °C 245 °C

Reliability Test Program

Test item Method Description

SOLDERABILITY JESD-22, B102

HOLT JESD-22, A108

PCT JESD-22, A102

TCT JESD-22, A104

HBM MIL-STD-883-3015.7

MM JESD-22, A115

Latch-Up JESD 78

Copyright ANPEC Electronics C orp.

Rev. A.4 - Sep., 2009

5 Sec, 245°C

1000 Hrs, Bias @ 125°C

168 Hrs, 100%RH, 2atm, 121°C

500 Cycles, -65°C~150°C

VHBM≧2KV

VMM≧200V

10ms, 1tr≧100mA

www.anpec.com.tw16

APL5930

Customer Service

Anpec Electronics Corp.

Head Office :

No.6, Dusing 1st Road, SBIP,

Hsin-Chu, Taiwan, R.O.C.

Tel : 886-3-5642000

Fax : 886-3-5642050

Taipei Branch :

2F, No. 11, Lane 218, Sec 2 Jhongsing Rd.,

Sindian City, Taipei County 23146, Taiwan

Tel : 886-2-2910-3838

Fax : 886-2-2917-3838

Copyright ANPEC Electronics C orp.

Rev. A.4 - Sep., 2009

www.anpec.com.tw17

Loading...

Loading...