APL5912

0.8V Reference Ultra Low Dropout (0.2V@5A) Linear Regulator

Features

• Ultra Low Dropout

- 0.2V (typical) at 5A Output Current

• Low ESR Output Capacitor (Multi-layer Chip

Capacitors (MLCC)) Applicable

• 0.8V Reference Voltage

• High Output Accuracy

- ±1.5% over Line, Load and Temperature

• Fast Transient Response

• Adjustable Output Voltage by External

Resistors

• Power-On-Reset Monitoring on Both VCNTL and

VIN Pins

• Internal Soft-Start

• Current-Limit Protection

• Under-Voltage Protection

• Thermal Shutdown with Hysteresis

• Power-OK Output with a Delay Time

General Description

The APL5912 is a 5A ultra low dropout linear regulator.

This product is specifically designed to provide well supply voltage for front-side-bus termination on motherboard

and NB applications. The IC needs two supply voltages, a

control voltage for the circuitry and a main supply volatege

for power conversion, to reduc e power dissipation and

provide extremely low dropout.

The APL5912 integrates many functions. A Power-OnReset (POR) circuit monitors both supply voltages to prevent wrong operations. A thermal s hutdown and current

limit functions protect the device against thermal and current over-loads. A POK indicates the output status with

time delay which is set internally. It can control other converter for power sequence. The APL5912 is enabled by

other power system. Pulling and holding the EN pin below 0.3V shuts off the output.

The APL5912 is available in SOP-8P package which features small size as SOP-8 and an Exposed Pad to reduce

the junction-to-case resistanc e, being applicable in

2~2.5W applications.

• Shutdown for Standby or Suspend Mode

• Simple SOP-8P Package with Exposed Pad

• Lead Free and Green Devices Available

(RoHS Compliant)

Applications

• Front Side Bus VTT (1.2V/5A)

• Note Book PC Applications

• Motherboard Applications

Copyright ANPEC Electronics Corp.

Rev. A.9 - Apr., 2008

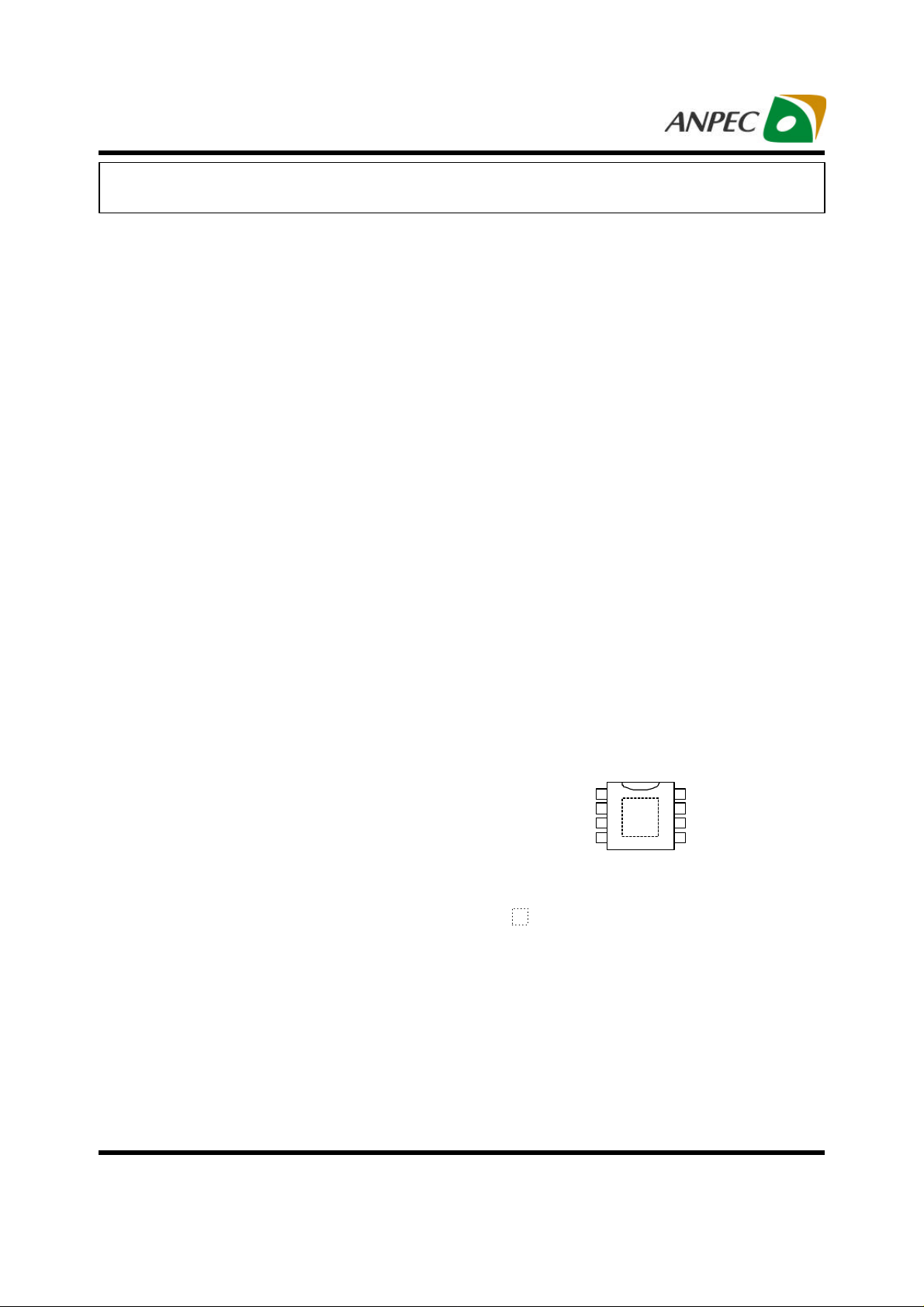

Pin Configuration

1

GND

2

FB

VOUT

VOUT

SOP-8P (Top View)

(connected to VIN plane for better heat

dissipation)

= Exposed Pad

VIN

3

4

8

7

6

5

EN

POK

VCNTL

VIN

www.anpec.com.tw1

APL5912

o

Ordering and Marking Information

APL5912

Assembly Material

Handling Code

Temperature Range

Package Code

Package Code

KA : SOP-8P

Operating Ambient Temperature Range

C : 0 to 70 C

Handing Code

TR : Tape & Reel

Assembly Material

L : Lead Free Device

G : Halogen and Lead Free Device

APL5912 KA :

APL5912

XXXXX

XXXXX - Date Code

Note: ANPEC lead-free products contain molding compounds/die attach materials and 100% matte tin plate termination finish; which

are fully compliant with RoHS. ANPEC lead-free products meet or exceed the lead-free requirements of IPC/JEDEC J-STD-020C for

MSL classification at lead-free peak reflow temperature. ANPEC defines “Green” to mean lead-free (RoHS compliant) and halogen

free (Br or Cl does not exceed 900ppm by weight in homogeneous material and total of Br and Cl does not exceed 1500ppm by

weight).

Block Diagram

0.4V

UV

EN

Soft-Start

and

Control Logic

Power-

On-Reset

Thermal

Limit

VINVCNTL

VREF

0.8V

FB

POK

90%

VREF

Typical Application Circuit

1. Using an Output Capacitor with ESR≥18mΩ

C

CNTL

1µF

R3

1k

POK

EN

Enable

7

POK

APL5912

8

EN

EAMP

6

VCNTL

GND

1

Delay

POK

VIN

VOUT

VOUT

FB

Current

Limit

VOUT

GND

VCNTL

+5V

VIN

OUT

+1.5V

VOUT

+1.2V / 5A

C

IN

5

3

4

2

R2

2k

100µF

R1

1k

C1

(in the range of 12 ~ 48nF)

33nF

C

220µF

Copyright ANPEC Electronics C orp.

www.anpec.com.tw2

Rev. A.9 - Apr., 2008

APL5912

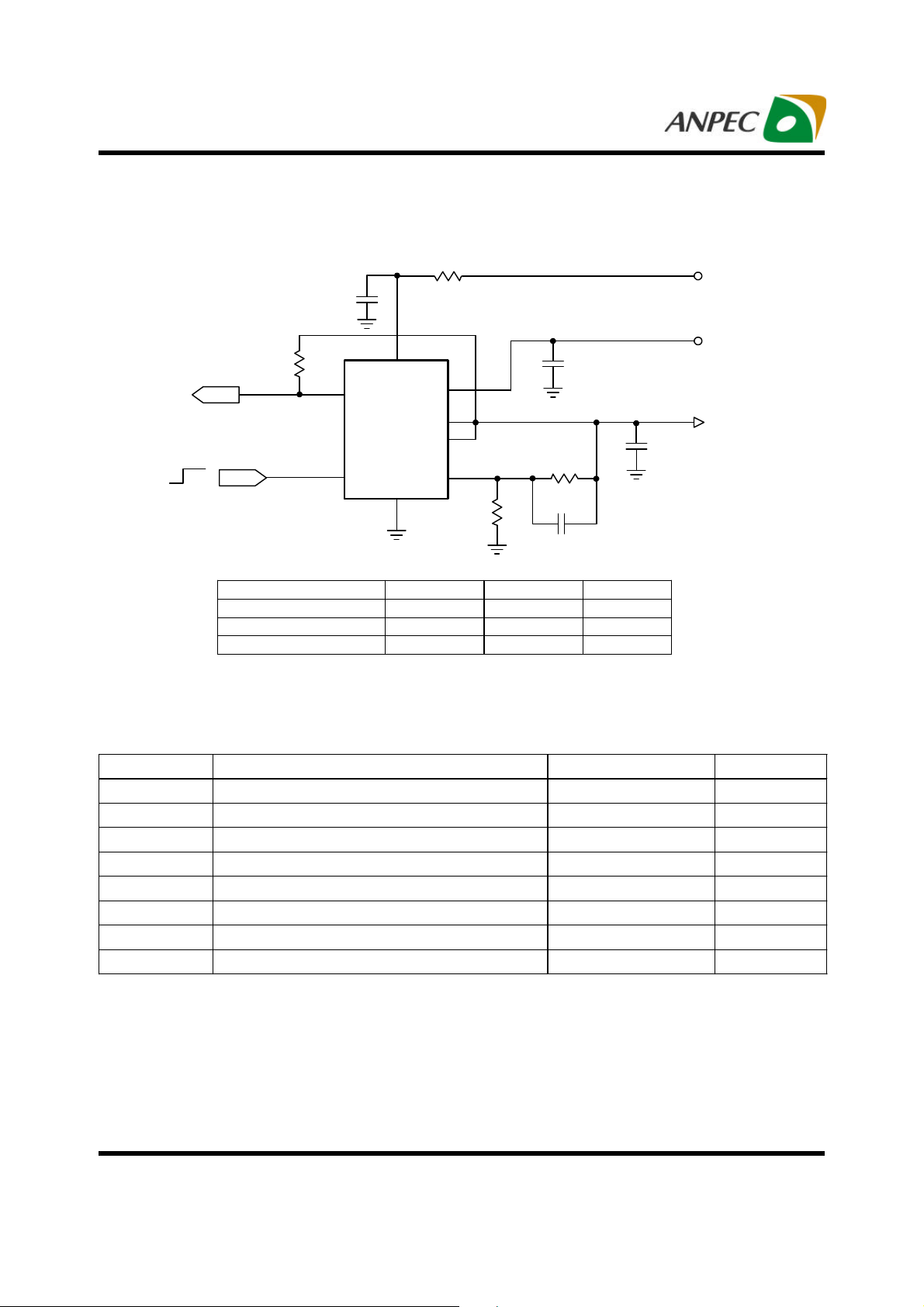

Typical Application Circuit (Cont.)

2. Using an MLCC as the Output Capacitor

R4

10 (in the range of 5.1~15Ω)

6

5

VIN

FB

3

4

2

VOUT

VOUT

1

Enable

POK

EN

R3

1k

C

1µF

CNTL

7

8

VCNTL

POK

APL5912

EN

GND

R2

78k

R1

39k

C1

30pF

C

IN

22µF

C

OUT

22µF

V

CNTL

+5V

V

IN

+1.5V

V

OUT

+1.2V / 5A

V

OUT

(V)

R1 (kΩ) R2 (kΩ)

C1 (pF)

1.05 43 137.6 27

1.5 27 30.86 36

1.8 15 12 68

Absolute Maximum Ratings

Symbol Parameter Rating Unit

V

VCNTL Supply Voltage (VCNTL to GND) -0.3 ~ 7 V

CNTL

VIN VIN Supply Voltage (VIN to GND) -0.3 ~ 3.3 V

V

EN and FB to GND -0.3 ~ V

I/O

V

POK to GND -0.3 ~ 7 V

POK

PD Power Dissipation 3 W

TJ Junction Temperature 150

T

Storage Temperature -65 ~ 150

STG

T

Maximum Lead Soldering Temperature, 10 Seconds 260

SDR

+0.3 V

CNTL

o

C

o

C

o

C

Copyright ANPEC Electronics C orp.

Rev. A.9 - Apr., 2008

www.anpec.com.tw3

APL5912

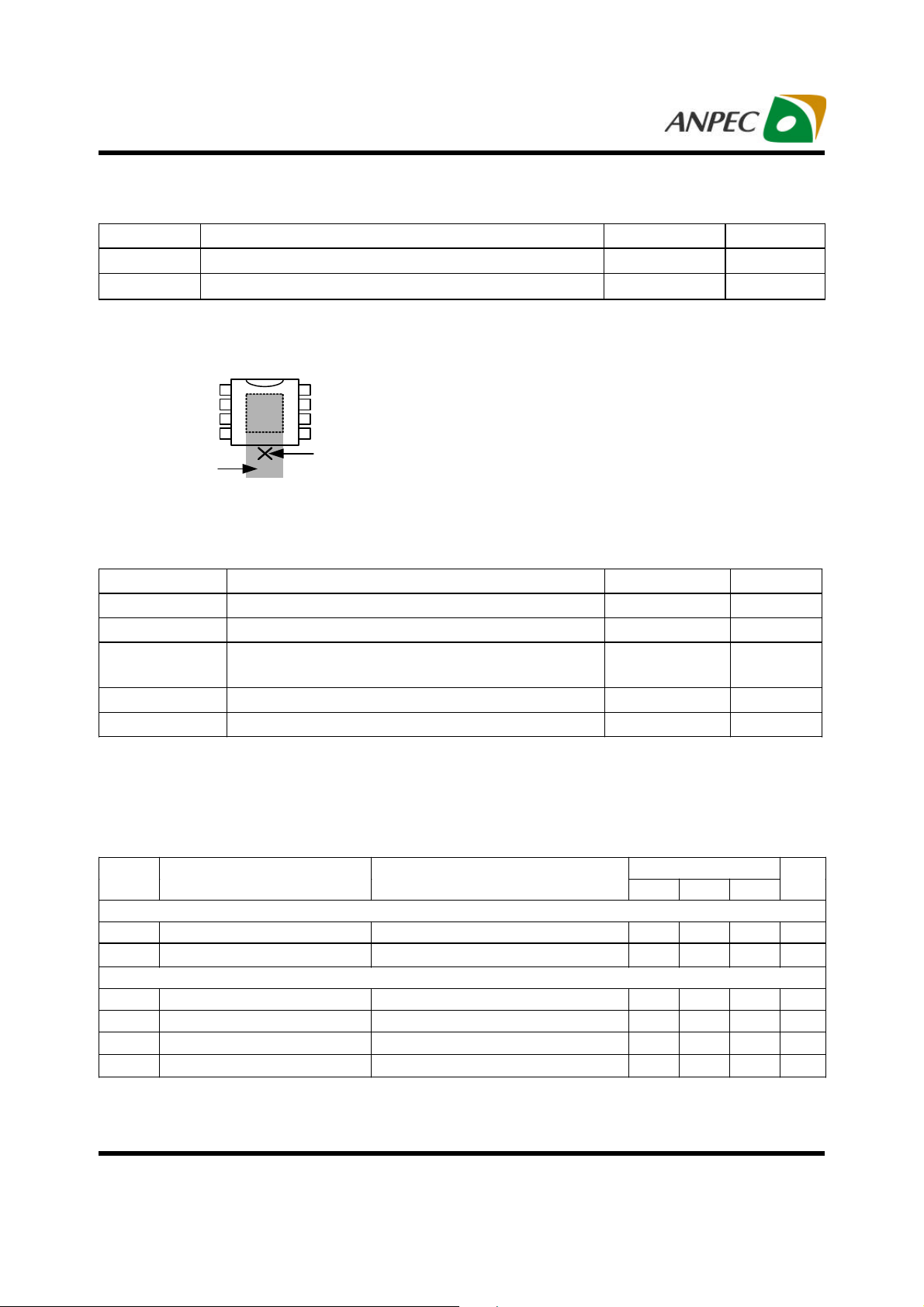

Thermal Characteristics

Symbol Parameter Value Unit

Junction-to-Ambient Thermal Resistance in Free Air

Junction-to-Case Thermal Resistance

(Note 2)

17

is measured with the component mounted on a high effective thermal conductivity test board in free air. The exposed pad

Note 1 : θ

θ

JA

θJC

JA

of SOP-8P is soldered directly on the PCB.

Note 2 : The “Thermal Pad Temperature” is measured on the PCB copper area connected to the thermal pad of package.

(Note 1)

40

o

C/W

o

C/W

1

2

VIN

3

4

8

7

6

5

Measured Point

PCB Copper

Recommended Operating Conditions

Symbol Parameter Range Unit

V

VCNTL Supply Voltage 3.1 ~ 6 V

CNTL

VIN VIN Supply Voltage 1.1 ~ 3.3 V

OUT

I

VOUT Output Current 0 ~ 6 A

OUT

V

V

CNTL

CNTL

=3.3±5%

=5.0±5%

V

Output Voltage

0.8 ~ 1.2

0.8 ~ VIN-0.2

TJ Junction Temperature -25 ~ 125

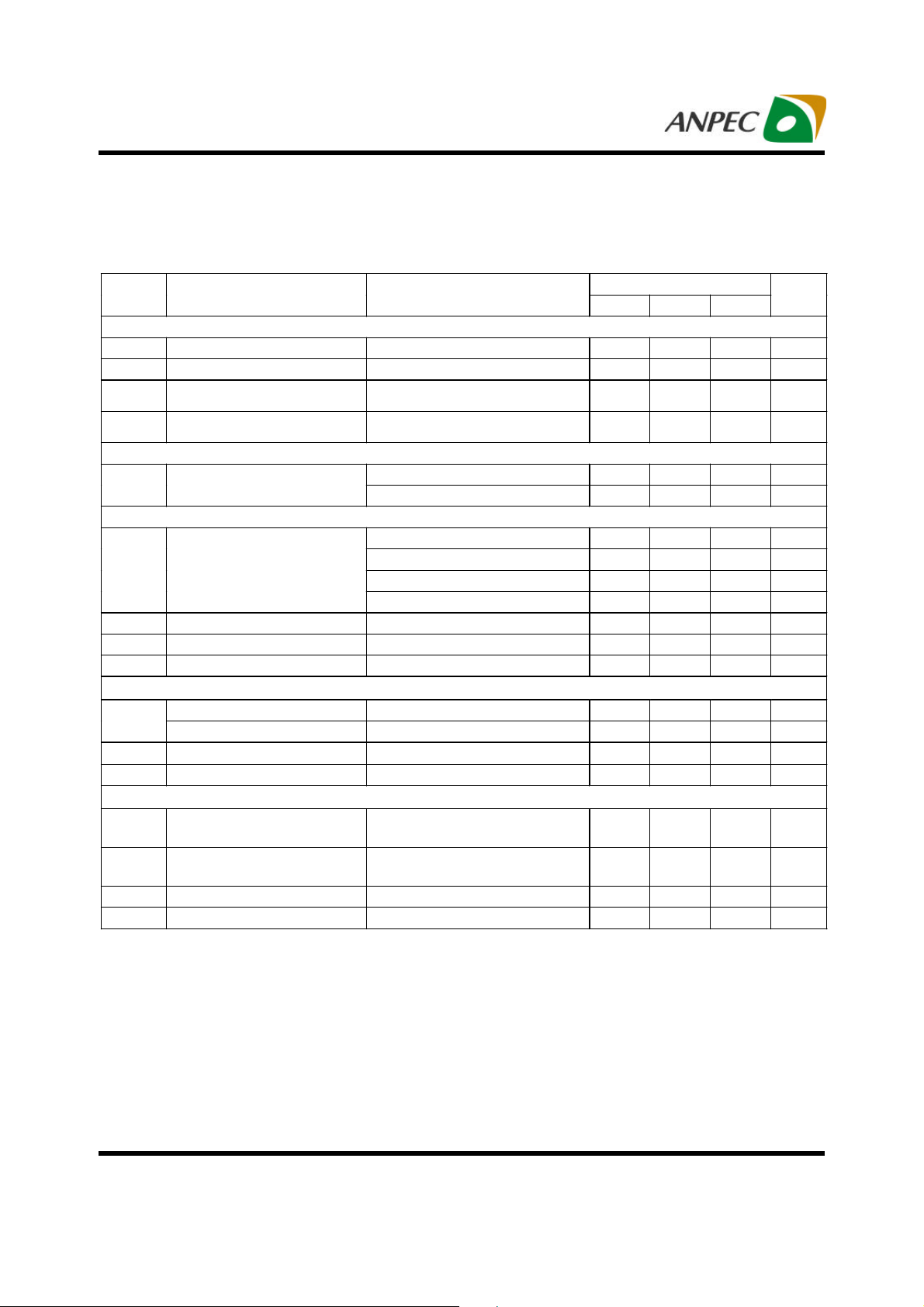

Electrical Characteristics

Refer to “Typical Applic ation Circuits”. These specifications apply over, V

70°C, unless otherwise specified. Typical values refer to TA =25°C.

=5V, VIN=1.5V, V

CNTL

OUT

V

o

C

= 1.2V and TA=0 to

Symbol

Parameter Test Conditions

APL5912

Min Typ Max

Unit

SUPPLY CURRENT

I

VCNTL Supply Current EN = VCNTL, VFB is well regulated. 0.4 1 2 mA

CNTL

ISD VCNTL Shutdown Current EN = GND 180 380

µ

A

POWER-ON-RESET

VCNTL POR Threshold V

Rising 2.7 2.9 3.1 V

CNTL

VCNTL POR Hysteresis 0.4 V

VIN POR Threshold VIN Rising 0.8 0.9 1.0 V

VIN POR Hysteresis 0.5 V

Copyright ANPEC Electronics C orp.

Rev. A.9 - Apr., 2008

www.anpec.com.tw4

APL5912

Electrical Characteristics (Cont.)

Refer to “Typical Application Circuit”. These specifications apply over, V

= 5V, VIN = 1.5V, V

CNTL

= 1.2V and TA = 0 to

OUT

70°C, unless otherwise specified. Typical values refer to TA =25°C.

Symbol

Parameter Test Conditions

OUTPUT VOLTAGE

V

Reference Voltage FB =VOUT 0.8 V

REF

Output Voltage Accuracy I

Line Regulation V

Load Regulation I

=0A ~ 5A, TJ= -25 ~125oC -1.5 +1.5 %

OUT

=3.3 ~ 5.5V -0.13 0.13 %/V

CNTL

=0A ~ 5A 0.06 0.15 %

OUT

DROPOUT VOLTAGE

Dropout Voltage

I

OUT

OUT

= 5A, V

= 5A, V

=5V, TJ= 25oC 0.15 0.2 V

CNTL

=5V, TJ= -25~125oC 0.25 V

CNTL

I

PROTECTION

V

=5V, TJ= 25oC 7 8 9 A

CNTL

V

=5V, TJ= -25 ~ 125oC 6 A

I

Current Limit

LIM

CNTL

V

=3.3V, TJ= 25oC 6.8 7.8 8.8 A

CNTL

V

=3.3V, TJ= -25 ~ 125oC 6 A

CNTL

TSD Thermal Shutdown Temperature TJ Rising 150

Thermal Shutdown Hysteresis 50

Under-Voltage Threshold VFB Falling 0.4 V

ENABLE AND SOFT-START

EN Logic High Threshold Voltage VEN Rising 0.3 0.4 0.5 V

EN Hysteresis 30 mV

EN Pin Pull-Up Current EN=GND 10

TSS Soft-Start Interval 2 ms

POWER OK AND DELAY

POK Threshold Voltage for

POK

Power OK

POK Threshold Voltage for

Power Not OK

VFB Rising 90% 92% 94% V

VFB Falling 79% 81% 83% V

V

V

PNOK

POK Low Voltage POK sinks 5mA 0.25 0.4 V

T

POK Delay Time 1 3 10 ms

DELAY

APL5912

Min Typ Max

Unit

o

C

oC

µ

A

REF

REF

Copyright ANPEC Electronics C orp.

www.anpec.com.tw5

Rev. A.9 - Apr., 2008

APL5912

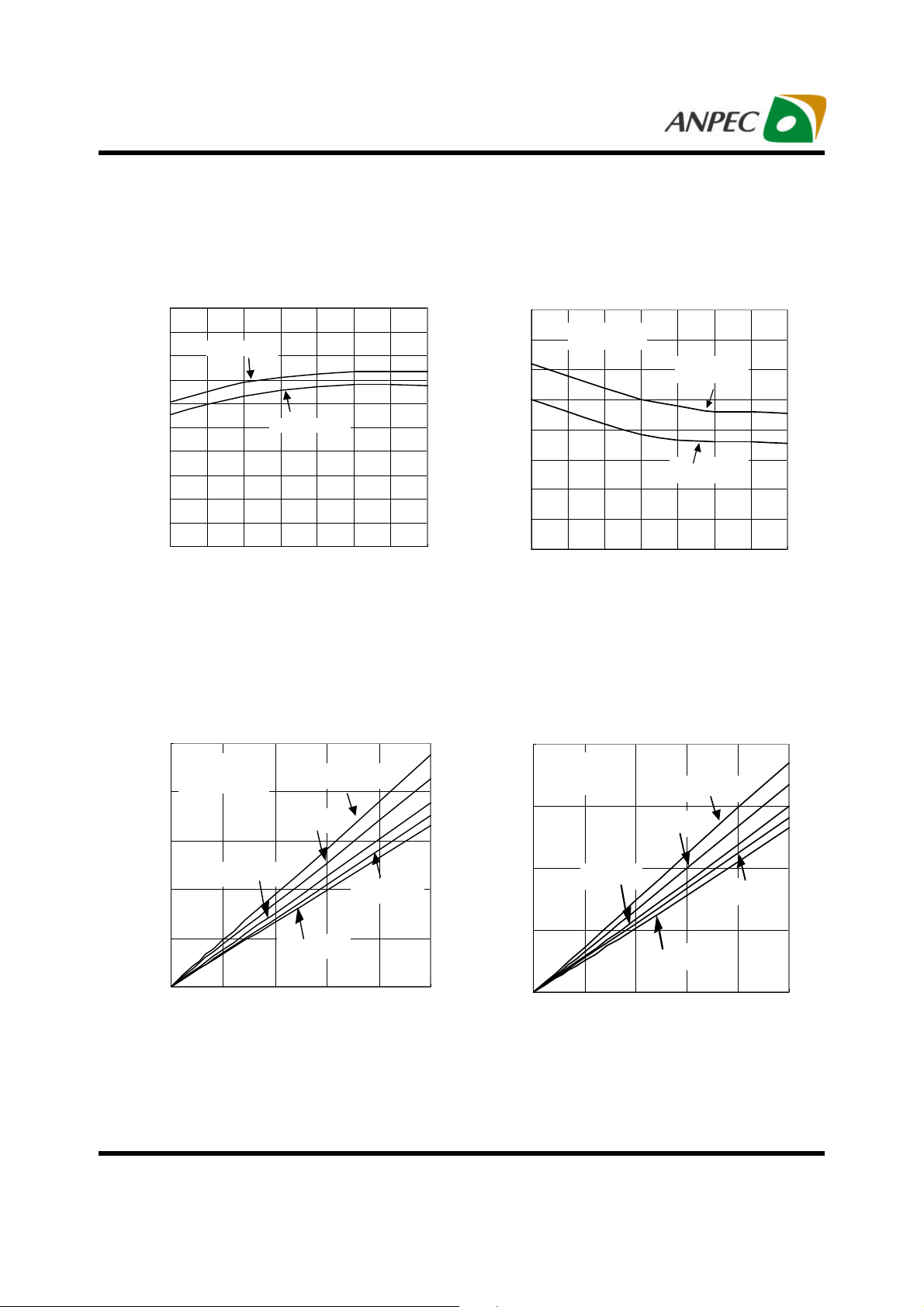

Typical Operating Characteristics

VCNTL Supply Current vs.

Junction Temperature

1.0

0.9

V

= 5V

(mA)

CNTL

0.8

0.7

CNTL

0.6

V

0.5

CNTL

= 3.3V

0.4

0.3

0.2

VCNTL Supply Current, I

0.1

0.0

-50 -25 0 25 50 75 100 125

Junction Temperature (°C)

Dropout Voltage vs. Output Current

Current-limit vs. Junction Temperature

8.6

V

=1.2V

8.4

8.2

8

(A)

LIM

7.8

7.6

7.4

Current-limit, I

7.2

7

-50 -25 0 25

OUT

V

CNTL

V

=3.3V

CNTL

75 100 125

50

Junction Temperature (°C)

Dropout Voltage vs. Output Current

=5V

250

V

=3.3V

200

V

CNTL

OUT

=1.2V

TJ=125 C

TJ=75 C

150

TJ=25 C

100

Dropout Voltage (mV)

50

TJ=-25 C

0

0 1 2 3 4 5

Output Current, l

OUT

Copyright ANPEC Electronics C orp.

Rev. A.9 - Apr., 2008

(A)

TJ=0 C

200

V

=5V

CNTL

V

=1.2V

OUT

TJ=125 C

150

TJ=75 C

100

Dropout Voltage (mV)

50

TJ=25 C

TJ=-25 C

0

0 1 2 3 4 5

Output Current, l

OUT

(A)

www.anpec.com.tw6

TJ=0 C

APL5912

Typical Operating Characteristics

Reference Voltage vs. Junction Temperature

0.808

0.806

0.804

(mV)

REF

0.802

0.800

0.798

0.796

Reference Voltage, V

0.794

0.792

-50 -25 0 25 50 75 100 125

Junction Temperature (°C)

POK Delay Time vs. Junction Temperature

4.5

4.3

4.1

3.9

3.7

3.5

3.3

3.1

POK Delay Time (ms)

2.9

2.7

2.5

-50 -25 0 25 50 75 100 125

V

=5V

CNTL

V

=3.3V

CNTL

Junction Temperature (°C)

VCNTL PSRR

0.00

V

= 4.5V~5.5V

CNTL

VIN = 1.5V

-10.00

V

= 1.2V

OUT

I

= 5A

OUT

CIN = 100µF

C

-20.00

-30.00

-40.00

-50.00

Ripple Rejection (dB)

-60.00

-70.00

Copyright ANPEC Electronics C orp.

Rev. A.9 - Apr., 2008

= 330µF(ESR=30mΩ)

OUT

100 1000 10000 100000 1000000

Frequency (Hz)

VIN PSRR

0

V

= 5V

CNTL

VIN = 1.5V(lower bound)

V

-10

-20

-30

-40

Amplitude (dB)

-50

-60

= 100mV

INPK-PK

CIN = 47µF

C

= 330µF(30m ohm)

OUT

I

= 5A

OUT

V

= 1.2V

OUT

100 1000 10000 100000 1000000

Frequency (Hz)

www.anpec.com.tw7

APL5912

Operating Waveforms

Test Circuit

R4

R8

8.2K

Shutdown

C8

470pF

Q3

7

6

5

VCC

OCSET

UGATE

PHASE

U2

APW7057

FB

LGATE

GND

3

C2

1µF

BOOT

1

2

8

4

2.2

D1

1N4148

C6

0.1µF

R7

2K

C3

1µF

Q1

APM2014N

Q2

APM2014N

R5

1.75k

C7

0.1µF

1. Load transient Response

1.1 Using an Output Capacitor with ESR≥18mΩ

- C

- I

= 220µF/6.3V (ESR = 30mΩ), CIN = 100µF/6.3V

OUT

= 10mA to 5A to 10mA, Rise time = Fall time = 1µs

OUT

R6

0

L2

3.3µH

L1

1µH

C4

470µF x2

1000µF x2

C5

Enable

C9

47µF

VIN

+1.5V

EN

CVCNTL

1µF

CIN

100µF

8

5

VCNTL

VIN

U1

APL5912

EN

GND

VCNTL

+5V

6

POK

VOUT

VOUT

1

+5V

FB

2

R2

2K

POK

R3

7

3

4

1K

VOUT

+1.2V/5A

COUT

220µF

R1

1K

C1

33nF

I

= 10mA ->5A I

OUT

11

VOUT

IOUT

22

Ch1 : V

Ch2 : I

, 50mV/Div

OUT

, 2A/Div

OUT

Time : 2µs/Div

Copyright ANPEC Electronics C orp.

Rev. A.9 - Apr., 2008

= 10mA -> 5A ->10mA I

OUT

R1=1kΩ, R2=2kΩ, C1=33nF

11

22

Ch1 : V

Ch2 : I

, 50mV/Div

OUT

, 2A/Div

OUT

Time : 20µs/Div

VOUT

IOUT

11

22

Ch1 : V

Ch2 : I

Time : 2µs/Div

= 5A ->10mA

OUT

, 50mV/Div

OUT

, 2A/Div

OUT

www.anpec.com.tw8

VOUT

IOUT

APL5912

Operating Waveforms (Cont.)

1.2 Using an MLCC as the Output Capacitor

- C

- I

11

= 22µF/6.3V (ESR = 3mΩ), CIN = 22µF/6.3V

OUT

= 10mA to 5A to 10mA, Rise time = Fall time = 1µs

OUT

I

= 10mA -> 5A I

OUT

= 10mA -> 5A ->10mA I

OUT

R1=39kΩ, R2=78kΩ,

R3=30nF

11

V

OUT

= 5A ->10mA

OUT

V

11

V

OUT

OUT

I

OUT

22

Ch1 : V

Ch2 : I

, 100mV/Div

OUT

, 2A/Div

OUT

Time : 2µs/Div

2. Power ON and Power OFF :

- V

- C

Ch1

Ch2

Ch3

= 1.5V, V

IN

= 220µF/6.3V (ESR = 30mΩ), CIN = 100µF/6.3V, RL = 1Ω

OUT

Power ON

CNTL

= 5V,V

V

V

V

V

POK

OUT

IN

OUT

CNTL

= 1.2V

22

Ch1 : V

Ch2 : I

Time : 20µs/Div

I

OUT

, 100mV/Div

OUT

, 2A/Div

OUT

Ch1

Ch1

Ch2

Ch2

Ch3

Ch3

22

Ch1 : V

Ch2 : I

Time : 2µs/Div

, 100mV/Div

OUT

, 2A/Div

OUT

Power OFF

Power OFF

V

VIN

VINVIN

IN

V

OUT

VOUT

VOUTVOUT

V

VCNTL

VCNTLVCNTL

CNTL

V

VPOK

VPOKVPOK

POK

I

OUT

Ch4

Ch1 : VIN, 1V/div

Ch2 : V

Ch3 : V

Ch4 : V

OUT

POK

CNTL

,1V/div

,1V/div

,2V/div

Time : 10ms/div

Copyright ANPEC Electronics C orp.

Rev. A.9 - Apr., 2008

Ch4

Ch4

Ch1 : VIN, 1V/div

Ch2 : V

Ch3 : V

Ch4 : V

OUT

POK

CNTL

, 1V/div

, 1V/div

, 2V/div

Time : 10ms/div

www.anpec.com.tw9

APL5912

Operating Waveforms (Cont.)

3. Shutdown and Enable :

- V

- C

Ch1

Ch1

= 1.5V, V

IN

= 220µF/6.3V (ESR = 30mΩ), CIN = 100µF/6.3V, RL = 1Ω

OUT

CNTL

= 5V, V

OUT

= 1.2V

Shutdown

Shutdown

V

VEN

VENVEN

EN

Ch1

Ch1

Enable

Enable

V

VEN

VENVEN

EN

Ch2

Ch2

Ch3

Ch3

Ch4

Ch4

Ch1 : VEN, 5V/div

Ch2 : V

Ch3 : I

Ch4 : V

OUT

OUT

POK

, 1V/div

, 1A/div

, 1V/div

Time : 1ms/div

4. POK Delay :

- V

- C

Ch1

Ch1

= 1.5V, V

IN

= 220µF/6.3V (ESR = 30mΩ), CIN = 100µF/6.3V, RL = 1Ω

OUT

V

IN

VIN

VINVIN

CNTL

= 5V, V

= 1.2V

OUT

POK Delay

POK Delay

V

VOUT

VOUTVOUT

OUT

I

IOUT

IOUTIOUT

OUT

V

VPOK

VPOKVPOK

POK

Ch2

Ch2

Ch3

Ch3

Ch4

Ch4

Ch1 : VEN, 5V/div

Ch2 : V

Ch3 : I

Ch4 : V

Time : 1ms/div

V

VOUT

VOUTVOUT

OUT

I

IOUT

IOUTIOUT

OUT

V

VPOK

VPOKVPOK

OUT

, 1A/div

OUT

POK

POK

, 1V/div

, 1V/div

V

VOUT

VOUTVOUT

OUT

Ch2

Ch2

V

VPOK

VPOKVPOK

Ch3

Ch3

POK

Ch1 : VIN, 5V/div

Ch2 : V

Ch3 : V

, 1V/div

OUT

, 1V/div

POK

Time : 1ms/div

Copyright ANPEC Electronics C orp.

Rev. A.9 - Apr., 2008

www.anpec.com.tw10

APL5912

Functional Pin Description

GND (Pin 1)

Ground pin of the circuitry. All voltage levels are measured

with respect to this pin.

FB (Pin 2)

Connecting this pin to an external resistor divider receives the feedback voltage of the regulator. The output

voltage set by the resistor divider is determined by :

where R1 is c onnected from VOUT to FB with Kelvin

sensing and R2 is connected from FB to GND. A bypass capacitor may be c onnected with R1 in parallel to

improve load transient response.

VOUT (Pin 3, 4)

Output of the regulator. Please c onnect Pin 3 and 4 together using wide tracks . It is necessary to connect a

output capacitor with this pin for closed-loop compensation and improve transient res ponses.

VIN (Pin 5) and Exposed Pad

R1

+⋅=

10.8 VOUT

R2

(V)

VCNTL (Pin 6)

Power input pin of the control circuitry. Connecting this

pin to a +5V (recommended) supply voltage provides the

bias for the control circuitry. The voltage at this pin is

monitored for Power-On-Reset purpose.

POK (Pin 7)

Power-OK signal output pin. This pin is an open-drain

output used to indicate status of output voltage by sensing FB voltage. This pin is pulled low when the rising FB

voltage is not above the V

voltage is below the V

is not OK.

EN (Pin 8)

Enable c ontrol pin. Pulling and holding this pin below

0.3V shuts down the output. When re-enabled, the IC

undergoes a new soft-start cyc le. When leave this pin

open, an internal current source 10µA pulls this pin up to

VCNTL voltage, enabling the regulator.

PNOK

threshold or the falling FB

POK

threshold, indicating the output

Main supply input pins for power convers ions. The Exposed Pad provides a very low impedance input path for

the main supply voltage. Please tie the Exposed Pad and

VIN Pin (Pin 8) together to reduce the dropout voltage. The

voltage at this pins is monitored for Power-On-Reset

purpose.

Function Description

Power-On-Reset

A Power-On-Reset (POR) circuit monitors both input voltages at VCNTL and VIN pins to prevent wrong logic

controls. The POR function initiates a soft-start proc ess

after the two supply voltages exceed their rising POR

thres hold voltages during powering on. The POR function also pulls low the POK pin regardless the output

voltage when the VCNTL voltage falls below its falling

POR threshold.

Internal Soft-Start

An internal s oft-start function controls rising rate of the

output voltage to limit the current surge at start-up. The

typical soft-start interval is about 2ms.

Output Voltage Regulation

An error amplifier works with a tem perature-compensated 0.

8V reference and an output NMOS regulates output to the

preset voltage. The error amplifier is designed with high

bandwidth and DC gain provides very fast transient re-

Copyright ANPEC Electronics C orp.

Rev. A.9 - Apr., 2008

www.anpec.com.tw11

APL5912

Function Description (Cont.)

Output Voltage Regulation (Cont.) For normal operation, devic e power dissipation should

sponse and less load regulation. It c ompares the refer-

ence with the feedback voltage and amplifies the difference to drive the output NMOS which provides load current from VIN to VOUT.

Current-Limit

The APL5912 monitors the current via the output NMOS

and limits the maximum current to prevent load and

APL5912 from damages during overload or short-circ uit

conditions.

Under-Voltage Protection (UVP)

The APL5912 monitors the voltage on FB pin after softstart proc ess is finished. Therefore, the UVP is disable

during soft-start. When the voltage on FB pin falls below

the under-voltage threshold, the UVP circuit shuts off the

output immediately. After a while, the APL5912 starts a

new soft-start to regulate output.

Thermal Shutdown

A thermal shutdown circuit limits the junction temperature of

APL5912. When the junction temperature exceeds

+150°C, a thermal sensor turns off the output NMOS,

allowing the device to cool down. The regulator regulates

the output again through initiation of a new soft-start

cycle after the junction temperature cools by 50oC, resulting in a pulsed output during continuous thermal overload conditions. The thermal shutdown is designed with

a 50oC hysteresis to lower the average junction temperature during continuous thermal overload conditions, extending lifetime of the device.

be externally limited s o that junction temperatures will

not exceed +125°C.

Enable Control

The APL5912 has a dedicated enable pin (EN). A logic

low signal (VEN< 0.3V) applied to this pin shuts down the

output. Following a s hutdown, a logic high signal re-enables the output through initiation of a new softstart cycle.

Left open, this pin is pulled up by an internal current source

(10µA typical) to enable operation. It’s not necessary to use

an external transistor to save cos t.

Power-OK and Delay

The APL5912 indicates the status of the output voltage by

monitoring the feedback voltage (VFB) on FB pin. As the

VFB rises and reaches the rising Power-OK threshold

(V

), an internal delay function starts to perform a delay

POK

time. At the end of the delay time, the IC turns off the

internal NMOS of the POK to indicate the output is OK. As

the VFB falls and reaches the falling Power-OK threshold

(V

), the IC immediately turns on the NMOS of the POK to

PNO K

indicate the output is not OK without a delay time.

Application Information

Power Sequencing

The power s equencing of VIN and VCNTL is not necessary to be concerned. However, do not apply a voltage to

VOUT for a long time when the main voltage applied at

VIN is not present. The reason is the internal parasitic

diode from VOUT to VIN conducts and dissipates power

without protections due to the forward-voltage.

Copyright ANPEC Electronics C orp.

Rev. A.9 - Apr., 2008

Output Capacitor

The APL5912 requires a proper output capacitor to maintain stability and improv e transient response over temperature and current. The output capacitor selection is to

select proper ESR (equivalent s eries resistance) and

capacitance of the output capacitor for good stability and

load transient response.

www.anpec.com.tw12

APL5912

Application Information (Cont.)

Output Capacitor (Cont.)

The APL5912 is designed with a programmable feedback

compensation adjusted by an external feedback network for

the use of wide ranges of ESR and capacitance in all

applications. Ultra-low-ESR capacitors (such as ceramic

chip capacitors) and low-ESR bulk capacitors (such as

solid tantalum, POSCap, and Aluminum electrolytic

capacitors) can all be used as an output capacitor. The

value of the output capacitors c an be increased without

limit.

During load transients, the output capacitors, depending on

the stepping amplitude and slew rate of load current, are

used to reduce the s lew rate of the current seen by the

APL5912 and help the device to minimize the variations

of output voltage for good transient response. For the applications with large stepping load current, the low-ESR

bulk capacitors are normally recommended.

Decoupling ceramic capacitors must be placed at the load

and ground pins as close as possible and the impedance of the layout must be minimized.

Input Capacitor

The APL5912 requires proper input capacitors to supply

current surge during stepping load transients to prevent

the input rail from dropping . Because the parasitic inductor from the voltage sources or other bulk capacitors to the

VIN pin limit the s lew rate of the surge currents, more

parasitic inductance needs more input capacitance.

Ultra-low-ESR capacitors (such as ceramic chip

capacitors) and low-ESR bulk capacitors (such as solid

tantalum, POSCap, and Aluminum electrolytic capacitors)

can all be used as an input capacitor of VIN. For most of

applications, the recommended input capacitance of VIN

is 10µF at least. If the drop of the input voltage is not

cared, the input capacitance can be less than 10µF. More

capacitance reduces the variations of the input voltage of

VIN pin.

Feedback Network

Figure 1 shows the feedback network among VOUT, GND,

and FB pins. It works with the internal error amplifier to

provide proper frequency response for the linear regulator.

The ESR is the equivalent series resistance of the output

capacitor. The C

capacitor. The V

is ideal capacitance in the output

OUT

is the setting of the output voltage.

OUT

VOUT

VOUT

APL5912

ESR

COUT

VERR

EAMP

VREF

FB

VFB

Figure 1

R1

R2

C1

The feedback network selection, depending on the values of the ESR and C

, has been classified into three

OUT

conditions :

• Condition 1 : Large ESR ( ≥18mΩ )

- Select the R1 in the range of 400Ω ~ 2.4kΩ

- Calculate the R2 as the following:

0.8(V)

)R1(k)R2(k

⋅Ω=Ω

OUT

0.8(V)-(V)V

(1) ..........

- Calculate the C1 as the following:

10

(V)V

⋅

)R1(k

Ω

40C1(nF)

(V)V

OUTOUT

⋅≤≤

Ω

(2) ......

)R1(k

• Condition 2 : Middle ESR

- Calculate the R1 as the following:

1500

)R1(k OUT +⋅−

=Ω

)ESR(m

Ω

(3) ......... 30(V)V37.5

Select a proper R1(selected) to be a little larger than

the calculated R1.

- Calculate the C1 as the following:

F)(C

OUT

[ ]

Where R1=R1

Select a proper C1

(selected)

50)ESR(mC1(pF)

(selected)

µ

⋅+Ω=

)R1(k

Ω

(4) ...................

to be a little smaller than the

calculated C1.

- The C1 calculated from equation (4) must meet

the following equation :

50

)ESR(m

Ω

⋅

1

+⋅

15.1C1(pF)

+⋅≥

OUT

Ω

(V)V37.5

(5) ..

)R1(k

Copyright ANPEC Electronics C orp.

Rev. A.9 - Apr., 2008

www.anpec.com.tw13

APL5912

Application Information (Cont.)

Feedback Network (Cont.)

Where R1=R1(calculated) from equation (3)

If the C1(calculated) can not meet the equation

(5), please use the Condition 3.

- Use equation (2) to calc ulate the R2.

• Condition 3: Low ESR (eg. Ceramic Capacitors)

- Calculate the R1 as the following:

Select a proper R1(selected) to be a little larger than

the calculated R1. The minimum selected R1 is

equal to 1kΩ when the calculated R1 is smaller

than 1k or negative.

- Calculate the C1 as the following :

(V)V37.5

OUT

⋅

)R1(k

Ω

Where R1=R1

(selected)

OUT

1F)(C8.5))ESR(m(0.17C1(pF)

+⋅µ⋅+Ω⋅=

Select a proper C1(selected) to be a little smaller

than the calculated C1.

- The C1 calculated from equation (7) must meet

the following equation :

0.033C1(pF) OUT

⋅

+≥

OUT

Ω

(V)V1.25

)R1(k

µ⋅Ω⋅

Where R1=R1(calculated) from equation (6)

PCB Layout Consideration (See Figure 2)

1. Please solder the Exposed Pad and VIN together on

the PCB. The main current flow is through the exposed

pad.

2. Please place the input capacitors for VIN and VCNTL

pins near pins as clos e as possible.

3. Ceramic decoupling capacitors for load must be placed

near the load as close as possible.

4. To place APL5912 and output capacitors near the load

is good for performance.

(6) .. (V)V37.5F)(C294))ESR(m(5.9)R1(k OUTOUT ⋅−µ⋅+Ω⋅=Ω

5. The negative pins of the input and output capacitors

and the GND pin of the APL5912 are connected to the

ground plane of the load.

6. Please connect PIN 3 and 4 together by a wide track or

plane on the Top layer.

7. Large current paths must have wide tracks.

8. See the Typical Application

- Connect the one pin of the R2 to the GND of APL5912.

(7) ..

V

CNTL

C

CNTL

VCNTL

APL5912

(8) .. F)(C)ESR(m

VIN

VOUT

VOUT

C1

FB

GND

R2

R1

C

IN

C

OUT

V

IN

V

OUT

Load

If the C1(calculated) can not meet the equation

(8), please use the Condition 2.

- Use equation (2) to calculate the R2.

The reason to have three conditions desc ribed above is

to optimize the load transient respons es for all kinds of

the output capacitor. For stability only, the Condition 2, regardless of equation (5), is enough for all kinds of output

capacitor.

Copyright ANPEC Electronics C orp.

Rev. A.9 - Apr., 2008

Figure 2

- Connect the one pin of R1 to the Pin 3 of APL5912

- Connect the one pin of C1 to the Pin 3 of APL5912

www.anpec.com.tw14

APL5912

Application Information (Cont.)

Thermal Consideration

See Figure 3. The SOP-8P is a cost-effective package featuring a small size like a standard SOP-8 and a bottom

exposed pad to minimize the thermal resis tance of the

package, being applicable to high current applications.

The exposed pad must be soldered to the top VIN plane.

The copper of the VIN plane on the Top layer conducts heat

into the PCB and air. Please enlarge the area to reduce the

case-to-ambient resistance (θCA).

102 mil

1

2

3

4

SOP-8P

Exposed

Die

Ambient

Air

118 mil

Top

VOUT

plane

Figure 3

Recommended Minimum Footprint

8 7 6 5

0.138

0.212

Pad

0.024

8

7

6

5

PCB

Top

VIN

plane

0.072

0.118

1 2 3 4

0.050

Unit : Inch

Copyright ANPEC Electronics C orp.

Rev. A.9 - Apr., 2008

www.anpec.com.tw15

APL5912

Pack age Information

SOP-8P

D

D1

SEE VIEW

A

THERMAL

PAD

e

S

Y

M

B

O

L

A

A1

A2

b

c

D

D1

E

E1

E2

e

h

0

E

E1

E2

h X 45

cb

A

A1 A2

SOP-8P

MILLIMETERS

MIN.

0.00

1.25

0.31

0.17

4.80 5.00

2.25

5.80 6.20

3.80 4.00

2.00

1.27 BSC

0.25

0.40L

o

0

Note : 1. Follow JEDEC MS-012 BA.

2. Dimension "D" does not include mold flash, protrusions

or gate burrs. Mold flash, protrusion or gate burrs shall not

exceed 6 mil per side .

3. Dimension "E" does not include inter-lead flash or protrusions.

Inter-lead flash and protrusions shall not exceed 10 mil per side.

MAX.

1.60

0.15

0.51

0.25

3.50

3.00

0.50

1.27

o

8

VIEW A

MIN.

0.000

0.049

0.012

0.007

0.098

0.079

0.010

0.016

0

L

INCHES

0.050 BSC

o

0.25

GAUGE PLANE

SEATING PLANE

0

MAX.

0.063

0.006

0.020

0.010

0.1970.189

0.138

0.2440.228

0.1570.150

0.118

0.020

0.050

o

8

Copyright ANPEC Electronics C orp.

Rev. A.9 - Apr., 2008

www.anpec.com.tw16

APL5912

Carrier Tape & R eel Dimensions

OD0

B0

P0

P2

P1

A

E1

F

W

Application

SOP-8(P)

K0

SECTION A-A

B

HT1A

A0

SECTION B-B

OD1

B

T

A

d

A H T1 C d D W E1 F

330.0±

2.00

50 MIN.

12.4+2.00

-0.00

13.0+0.50

-0.20

1.5 MIN. 20.2 MIN.

12.0±0.30 1.75±0.10 5.5±0.05

P0 P1 P2 D0 D1 T A0 B0 K0

4.0±0.10 8.0±0.10 2.0±0.05

1.5+0.10

-0.00

1.5 MIN.

0.6+0.00

-0.40

6.40±0.20 5.20±0.20 2.10±0.20

(mm)

Devices Per Unit

Package Type Unit Quantity

SOP- 8P

Copyright ANPEC Electronics C orp.

Rev. A.9 - Apr., 2008

Tape & Reel 2500

www.anpec.com.tw17

APL5912

Reflow Condition (IR/Convection or VPR Reflow)

T

P

Ramp-up

T

L

Tsmax

Tsmin

Temperature

ts

Preheat

25

°

t 25 C to Peak

tp

t

Ramp-down

Critical Zone

TL to T

P

L

Time

Reliability Test Program

Test item Method Description

SOLDERABILITY MIL-STD-883D-2003

HOLT MIL-STD-883D-1005.7

PCT JESD-22-B, A102

TST MIL-STD-883D-1011.9

ESD MIL-STD-883D-3015.7 VHBM > 2KV, VMM > 200V

Latch-Up JESD 78 10ms, 1tr > 100mA

Classification Reflow Profiles

245°C, 5 sec

1000 Hrs Bias @125°C

168 Hrs, 100%RH, 121°C

-65°C~150°C, 200 Cycles

Profile Feature Sn-Pb Eutectic Assembly Pb-Free Assembly

Average ramp-up rate

(TL to TP)

Preheat

- Temperature Min (Tsmin)

- Temperature Max (Tsmax)

- Time (min to max) (ts)

Time maintained above:

- Temperature (TL)

- Time (tL)

Peak/Classification Temperature (Tp)

Time within 5°C of actual

Peak Temperature (tp)

Ramp-down Rate

Time 25°C to Peak Temperature

Note: All temperatures refer to topside of the package. Measured on the body surface.

Copyright ANPEC Electronics C orp.

Rev. A.9 - Apr., 2008

3°C/second max. 3°C/second max.

100°C

150°C

60-120 seconds

183°C

60-150 seconds

See table 1 See table 2

10-30 seconds 20-40 seconds

6°C/second max. 6°C/second max.

6 minutes max. 8 minutes max.

60-180 seconds

60-150 seconds

150°C

200°C

217°C

www.anpec.com.tw18

APL5912

Classification Reflow Profiles (Cont.)

Table 1. SnPb Eutectic Process – Package Peak Reflow Temperatures

Package Thickness Volume mm

<350

<2.5 mm

≥2.5 mm 225 +0/-5°C 225 +0/-5°C

240 +0/-5°C 225 +0/-5°C

3

Volume mm

≥

350

3

Table 2. Pb-free Process – Package Classification Reflow Temperatures

Package Thickness Volume mm3

<350

<1.6 mm

1.6 mm – 2.5 mm

≥2.5 mm 250 +0°C* 245 +0°C* 245 +0°C*

*Tolerance: The device manufacturer/supplier shall assure process compatibility up to and including the

stated classification temperature (this means Peak reflow temperature +0°C. For example 260°C+0°C)

at the rated MSL level.

260 +0°C* 260 +0°C* 260 +0°C*

260 +0°C* 250 +0°C* 245 +0°C*

Volume mm3

350-2000

Volume mm3

>2000

Customer Service

Anpec Electronics Corp.

Head Office :

No.6, Dusing 1st Road, SBIP,

Hsin-Chu, Taiwan

Tel : 886-3-5642000

Fax : 886-3-5642050

Taipei Branch :

2F, No. 11, Lane 218, Sec 2 Jhongsing Rd.,

Sindian City, Taipei County 23146, Taiwan

Tel : 886-2-2910-3838

Fax : 886-2-2917-3838

Copyright ANPEC Electronics C orp.

Rev. A.9 - Apr., 2008

www.anpec.com.tw19

Loading...

Loading...