Page 1

anovafurnishings.com

Right Leg

Left Leg

888.535.5005 tel

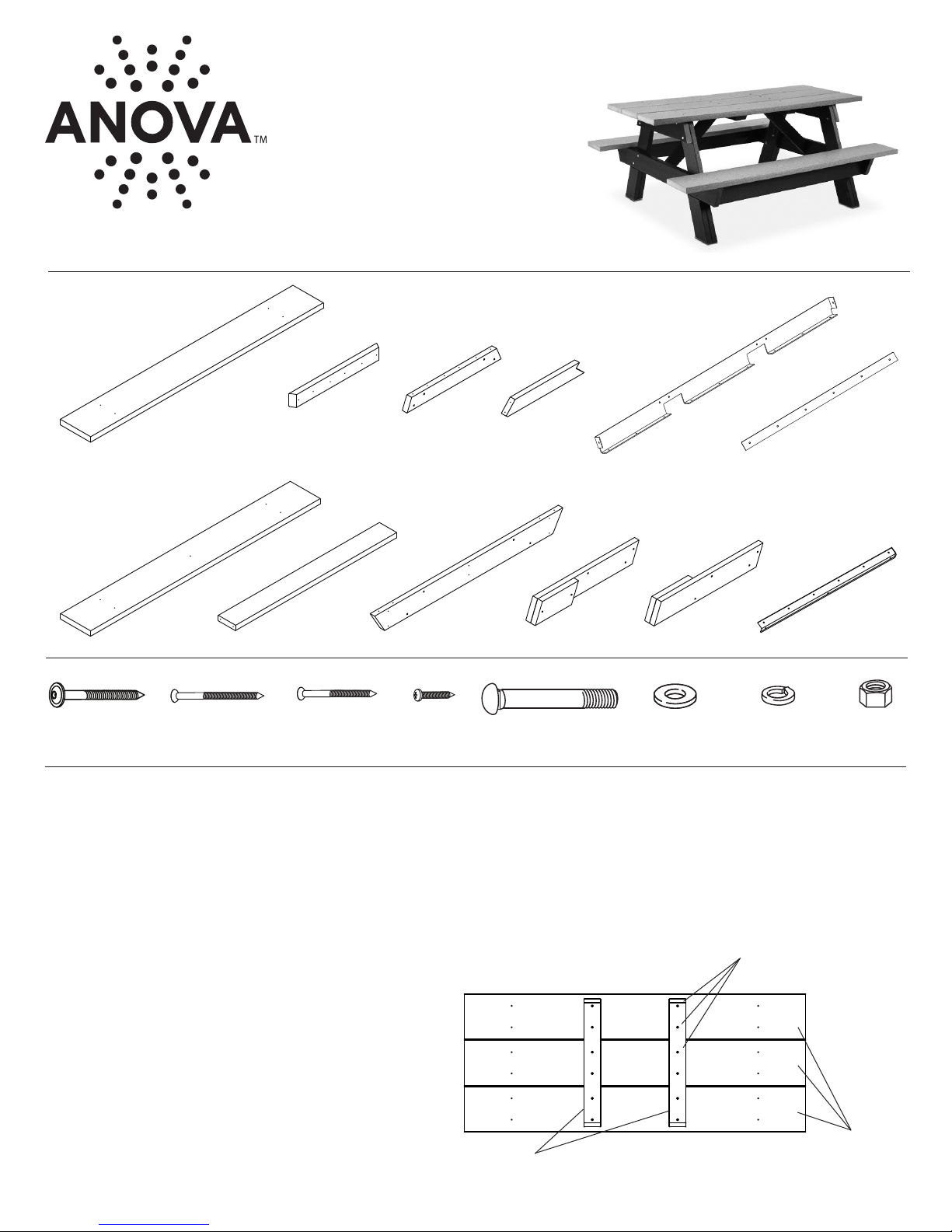

TABLE COMPONENTS:

ASSEMBLY INSTRUCTIONS

RCP6 Recycled Plastic Picnic Table

TOOLS NEEDED:

Ratchet with 9/16” Socket•

T25 Torx Driver•

T30 Torx Driver•

Phillips Head Driver•

Hammer•

3 x Table Top Plank

2 x Seat Plank

ASSEMBLY HARDWARE:

22 x

Torx T30 X 3.0”

Washer Head Screw

ASSEMBLY:

The assembly is a two-person operation.

1. Inspect the shipping container contents for damage and to determine that all components and hardware are present.

2. Assemble the Table over the shipping packaging or padded work area to avoid scratching the product.

Note: Before assembling the Nuts to the Bolts, it is recommended that a light oil or petroleum jelly be applied to the screw threads

T25 X 3.0”

Torx Head Screw

2 x Seat Stiener

8 x

2 x Angle

Brace Mount

20 x

T25 X 2.5”

Torx Head Screw

2 x Leg Mount

2 x Seat Support 2 x Right Leg

60 x

#10 X 3/4”

Phillips Screw

2 x Angle

Brace

2 x Le Leg

16 x

3/8-16 X 3.5”

Carriage Bolt

2 x Angle

Support

16 x

3/8” Flat

Washer

2 x Leg Mount Brace

16 x

3/8” Split

Washer

2 x Support Bar

16 x

3/8-16

Hex Nut

3. Lay the three Table Top Planks out on the padded work area. The Table Top Planks can be distinguished from the Seat Planks

because the Table Top Planks have four predrilled through holes and four inner pilot holes while the Seat Planks have ve

predrilled through holes. Arrange the Table Top planks with the four inner pilot holes facing up.

4. Locate the two Angle Brace Mounts. Use the T25

Torx Driver to start six T25 x 2.5” Torx Screws

into the predrilled holes in one of the Angle Brace

Mounts. Drive the Screws into the Brace Mount

until the points emerge on the other side. Place

the Angle Brace Mount over one of the inner rows

of predrilled pilot holes in the Table Top Planks,

aligning the points of the Torx Screws with the

pilot holes.

Use the T25 Torx Driver to drive the Screws into

the Table Top Planks until tight.

Repeat this step for the other Angle Brace Mount.

Angle Brace

Mounts

T25 x 2.5” Torx Screws

Table Top

Planks

Page 2

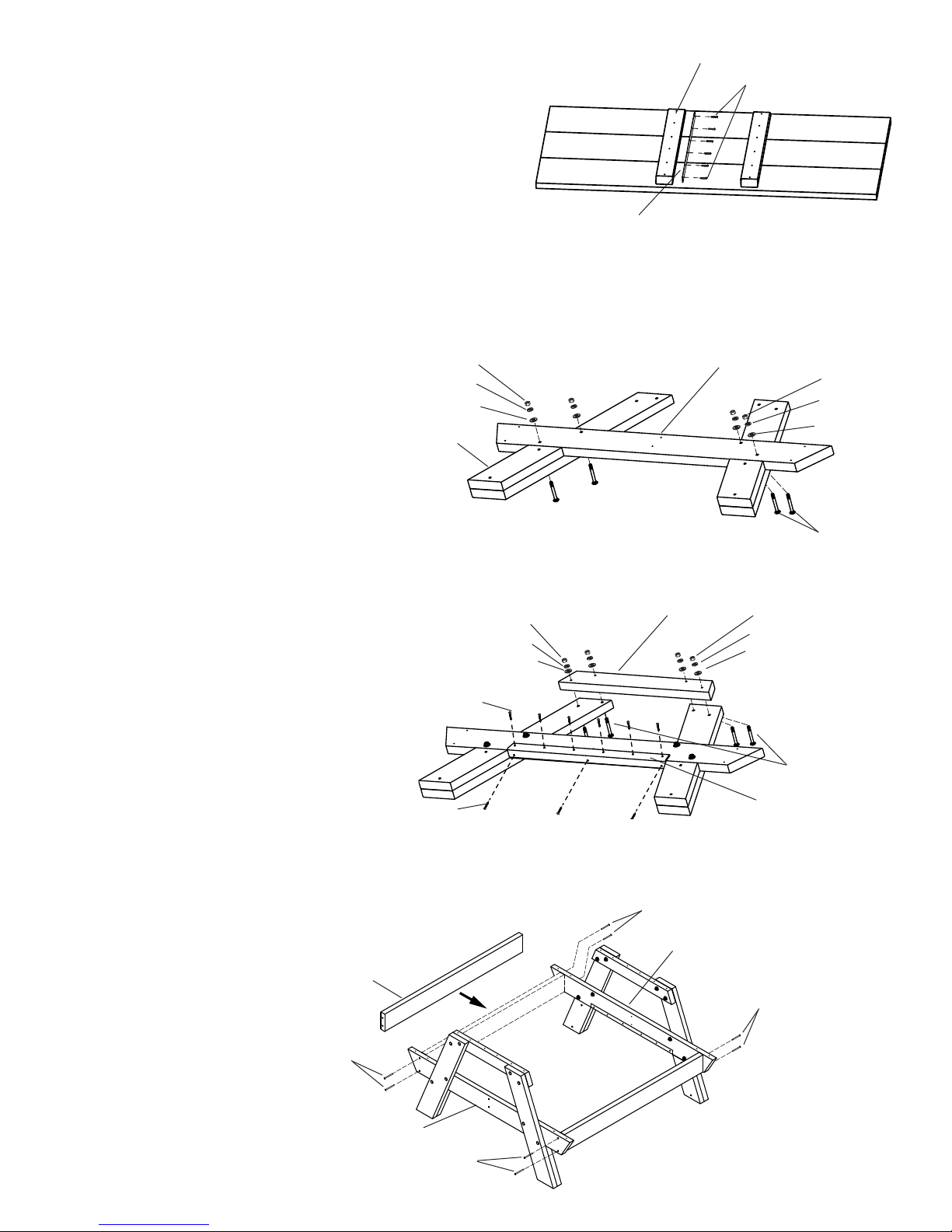

5. Install a Support Bar along the inside edge of one of the Angle Brace Mounts.

Note:

The Support Bar has small chamfers on the upper corners. Install

the Support Bar so the chamfers are away from the Table Top

Surface.

Place the Support Bar on the Table Top rst, then slide it against the

Angle Brace Mount. Make sure the Support Bar maintains contact

with the Table Top. Drive the Phillips Screws through the holes in

the Support Bar, into the Angle Brace Mount.

Install the remaining Support Bar against the other Angle Brace

Mount in the same manner.

6. Set the Table Top aside on a padded surface.

7. Locate a Le Leg and a Right Leg and insert Carriage Bolts through the two holes closest to the thick ends. Insert the Bolts from

the single-layer side toward the double-layer side. Use the Hammer to seat the Bolts. Lay the Legs out in an “A” shape with the

Thick Leg Ends facing up.

Position a Seat Support over the Legs and Bolts with the bottom of the Support contacting the thicker portion of the Leg end.

Place a Flat Washer, Split Washer and

Hex Nut on the end of each Carriage Bolt.

NOTE: Installing the Carriage Bolt in this

direction reduces the risk of being

scratched by the bolt end while using or

moving the assembled Table.

Leave the hardware nger tight so

adjustments can be made while

attaching the Seat Stieners (Step 9).

Repeat this step for the other pair of

Legs and Seat Support.

8. Locate the Leg Mounts. Place one of them at the top of each set of Legs. Insert Carriage Bolts through the Mounting Holes near

the top of each Leg and through the matching holes in the Leg Mounts. Use the Hammer to seat the Carriage Bolt and expose

the threads. Place a Flat Washer, Split Washer and Hex Nut on the end of each Carriage Bolt. Leave the hardware nger tight.

NOTE: Installing the Carriage Bolt in this

direction reduces the risk of being scratched

by the bolt end while using or moving the

assembled Table.

9. Install the Leg Mount Brace along the lower

edge of the Leg Mount. The face of the

Brace with 6 holes should be installed on

the wide face of the Leg Mount. Use nine

#10 x 3/4” Phillips Screws to fasten the

brace. Repeat this step for the other Leg

Mount Brace on the second Leg Mount

Assembly.

Thick Leg End

Phillips Screws

Hex Nut

Split Washer

Flat Washer

Hex Nut

Split Washer

Flat Washer

Phillips Screws

Support Bar

Angle Brace Mount

Seat Support

Leg Mount

Phillips Screws

Hex Nut

Split Washer

Flat Washer

Carriage Bolts

Hex Nut

Split Washer

Flat Washer

Carriage Bolts

Leg Mount Brace

10. Use the Torx T25 driver to start two T25 x 3.0” Torx Screws into the pilot holes at the end of one of the Seat Supports in the Leg

Assembly. Stop as the points of the Screws emerge from the other side of the Seat Support.

Hold the Leg Assembly upright and position one of the Seat Stieners so the pilot holes in the end of the Stiener line up with the

emerging Screw points of the Seat Support. Use the Torx T25 Driver to drive the T25 x 3.0” Torx Screws into the Seat Stiener.

Repeat this step to attach

the other Seat Stiener to

the other side of the Leg

Assembly.

Attach the other Leg

Assembly to the other end

of the Seat Stieners in the

same manner.

T25 x 3” Torx Screws

Seat Stiener

Seat Support

T25 x 3” Torx Screws

T25 x 3” Torx Screws

Seat Support

T25 x 3” Torx Screws

2 of 4

Page 3

11. Return to the Table Top Assembly. Orient the Table Top so that the top surface is facing upward. Start one T30 x 3” Washer Head

Screw into each of the corner pilot holes. Stop when the point of the screw emerges from the bottom side of the Table Top.

Carefully li the Table Top Assembly and position it over the assembled Leg Structure and line up the emerging points of the

Washer Head Screws with the appropriate pilot holes in the Leg Mount component of the assembled Leg Structure.

Use the Torx T30 Driver

to drive the Washer Head

Screws into the Leg Mount

until tight. Once these four

Screws are secured, the

remaining Washer Head

Screws can be inserted and

driven into the rest of the

Table Top pilot holes.

Aer the Table Top is

secured, tighten all of the

Carriage Bolts and Hex

Nuts in the Leg Structure.

12. Carefully turn the Table upside down onto a padded work surface.

Start two T25 x 2.5” Torx Screws into the pilot holes in the center of the both Seat Supports. Locate the two Angle Braces. Start

two T25 x 2.5” Torx Screws into the pilot holes on the notched end, just enough to hold them in place.

Position one of the Angle Braces so the

notched end ts over the edge of the Angle

Brace Mount near the center Table Top and

the other end of the Angle Brace contacts

the center of the Seat Support where the

two Torx screws are started.

While one person holds the Brace in place,

another person should drive the Torx Screws

through the Seat Support, into the end

of the Angle Brace. When those outside

Screws are secure, drive the two started

Screws through the Brace and into the

Angle Brace Mount.

Install the remaining Angle Brace in the

same manner.

13. Position one of the Angle Supports on the Table Top with the cutouts positioned over the Angle Brace Mounts. Make sure the

mounting ange is facing out toward the edge of the table. Install the nine Phillips Head Screws through the Angle Support and

into the Table Top rst.

Note: Install the Screws from the

center of the Table, alternating

outward towards the ends of the

Table.

Keep the Angle Support pressed

against the Angle Brace when

installing the screws.

Start the four corner T30

Washer Head Screws rst

T30 Washer

Head Screws

Tighten hardware

aer the Table

Top is secure

T25 x 2.5”

Torx Screws

Angle Brace Mounts

Seat Stiener removed

from illustration for clarity

T25 x 2.5”

Torx Screws

Angle Brace

Angle Brace

Leg Mount

Tighten hardware

aer the Table

Top is secure

Leg Mount

Seat Support

T25 x 2.5”

Torx Screws

Phillips Screws

Angle Brace Mounts

Angle Support with

mounting ange

outward

3 of 4

Page 4

14. Install four Phillips Head Screws through the Angle Support and into the Angle Braces, then install a Phillips Head Screw

through the ends of the Angle Support and into the Leg Mounts.

15. Install the remaining Angle Support on the other side of the Angle Braces in the same manner.

Angle Brace

Leg Mount

Phillips Head Screws

16. Carefully turn the Table right side up. Start four T30 x 3.0” Washer Head Screws into the predrilled holes near the ends of each of

the Seat Planks until the points of the screws start to emerge from the other side of the planks. Line up the points of the screws

with the predrilled holes in the Seat Supports and use the Torx T25 Driver to tighten the screws.

Place a T30 x 3.0” Washer Head Screw into the predrilled hole in the center of each Seat Plank and use the Torx T30 Driver to

tighten the screws, making sure the screws are driven into the Seat Stiener.

Install the remaining Seat

Plank in the same manner.

Move the Table to the

location where it will be

used.

Phillips Head Screws

T30 Washer

Head Screws

T30 Washer Head Screws

T30 Washer Head Screws

Furniture must not be used other than for its intended purpose and should be inspected regularly for loose, •

missing, or broken hardware, and general instability.

WARNING

CARE AND

MAINTENANCE

Furniture that is damaged or appears to be unstable must be removed from service and be repaired or replaced. •

Repairs must be made using only factory authorized parts and methods.•

Do not drag the assembled unit across any surface.•

This product requires only periodic cleaning with a sponge and a solution of mild detergent and water to •

remove surface dirt. Do not clean with a solvent or petroleum based products.

211 North Lindbergh Blvd.

St. Louis, MO 63141

tel: 888.535.5005

web: anovafurnishings.com

09/2013

Loading...

Loading...