Page 1

2052 O’Neil Rd, Macedon NY 14502

Telephone: (315) 986-8090

Fax: (315) 986-8091

www.ankom.com

Operator’s Manual

Rev F 12/08/14

Page 2

This page intentionally left blank

Page 3

Table of Contents

Introduction .................................................................................................................................................................. 5

Warranty ....................................................................................................................................................................... 5

Filter Bags ..................................................................................................................................................................... 5

Operating Environment ................................................................................................................................................ 5

Contact Information ..................................................................................................................................................... 6

Instrument Description ................................................................................................................................................. 7

Safety Precautions ........................................................................................................................................................ 8

Instrument Installation ................................................................................................................................................. 9

Fat Extraction Calculations ......................................................................................................................................... 10

Fat Extraction Support Items ...................................................................................................................................... 10

Sample Preparation .................................................................................................................................................... 11

Fat Extraction step-by-step procedure using the ANKOM

Periodic Maintenance ................................................................................................................................................. 20

Troubleshooting & Replacement Parts ....................................................................................................................... 22

Diagnostics .................................................................................................................................................................. 23

Appendix A – AOCS Official Fat Extraction Procedure ................................................................................................ 27

Appendix B – Electrical Diagram (pg. 1 of 3) ............................................................................................................... 29

XT15

.................................................................................... 16

Page 4

This page intentionally left blank

Page 5

Operator’s Manual

Please review the entire contents of this manual before you begin operating this

product.

Introduction

ANKOM Technology designs, manufactures, and markets instruments and support products used by analytical

laboratories around the world in the environmental, agricultural, biomass, and food industries. ANKOM

Technology can provide you with products for determining or monitoring dietary fiber, detergent fiber, fat,

digestibility, microbial fermentation (anaerobic or aerobic) and more.

Committed to Total Customer Satisfaction, ANKOM designs every product based on a thorough assessment of

customer needs.

Congratulations on your purchase of the ANKOM

effectively serve your needs.

The ANKOM

technician variation, increasing precision. By carefully following the operating instructions in this manual you will

understand the details of sample and filter bag handling as well as the instrument controls, helping you to achieve

the best possible results.

XT15

Extraction System was designed to automate the process of fat extraction. This reduces

XT15

Extraction System. We are confident that this product will

Warranty

ANKOM Technology warrants the ANKOM

or material for one year after the original date of purchase. This warranty does not include damage to the instrument

resulting from neglect or misuse. During the warranty period, should any failure result from defects in

workmanship or materials ANKOM Technology will, at its discretion, repair or replace the instrument free of

charge.

Extended warranties are available upon request.

XT15

Extraction System against any defects due to faulty workmanship

Filter Bags

Use only ANKOM Technology filter bags (part # XT4) in your ANKOM

filter mechanism will void the warranty. Filter bags can be purchased from ANKOM Technology or from your local

authorized ANKOM distributor.

XT15

Extraction System. Use of any other

Operating Environment

Your ANKOM

Ambient Temperature Range: 15°−35°C

Power: 100V−120V ~ 50/60Hz 10A

XT15

Extraction System is designed to operate within the following environments:

220V−240V ~ 50/60Hz 5A

Rev F 12/08/14 pg. 5

Page 6

Operator’s Manual

Contact Information

At ANKOM Technology we are committed to your total satisfaction and therefore always available to help you get

the most from your ANKOM products. We are also very interested in any comments or suggestions you may have

to help us improve.

For any questions or suggestions regarding your instrument, please contact us at:

Telephone: (315) 986-8090

Fax: (315) 986-8091

Email: service@ankom.com

www.ankom.com

pg. 6 Rev F 12/08/14

Page 7

Operator’s Manual

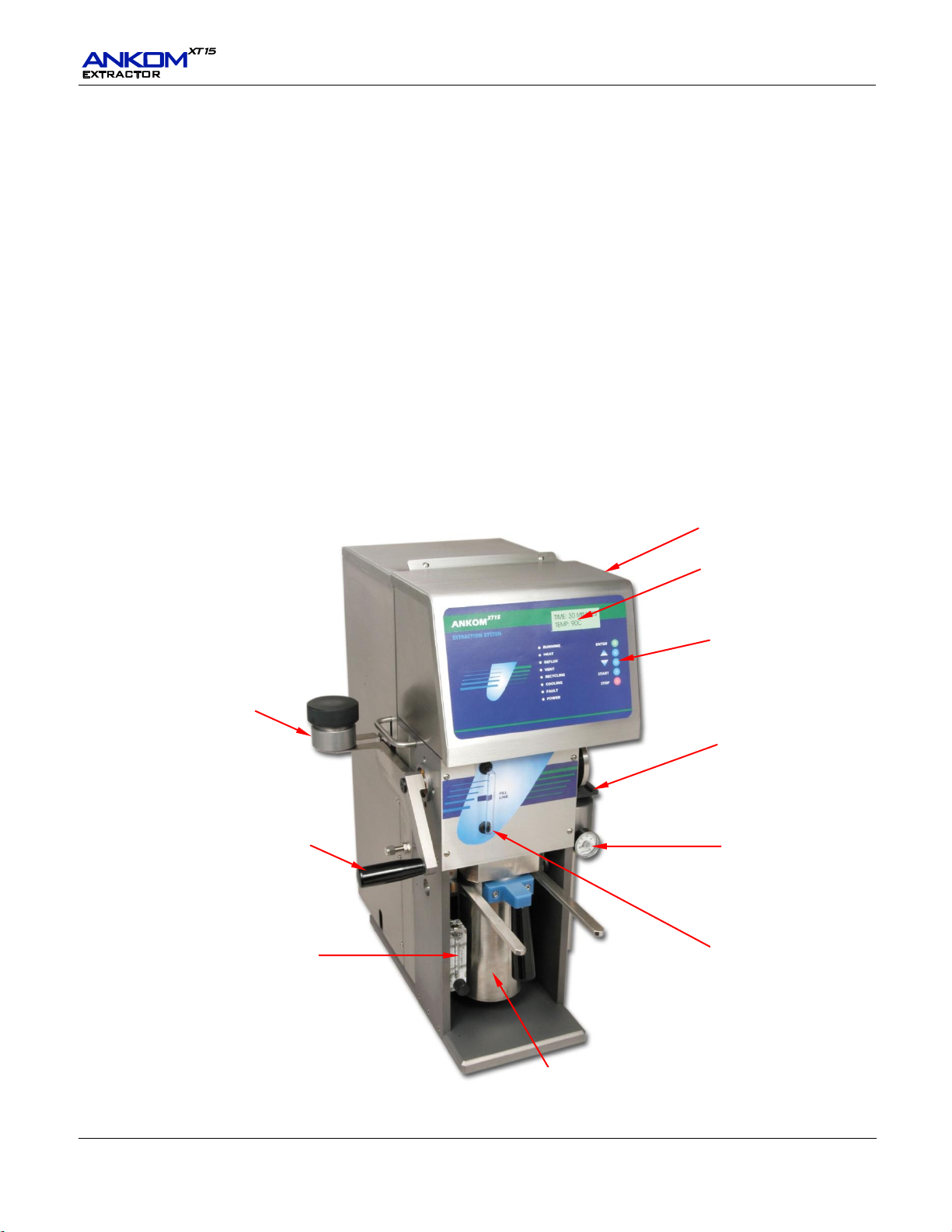

Keypad

Display

Power Switch (not visible)

Safety Valve Handle

Pressure Gauge

Extraction Vessel

Solvent Fill Port

Main Handle

Solvent Sight Level

Reflux Water Flow Control

Instrument Description

General Description

The ANKOM

petroleum ether. The compounds extracted are primarily triacylglycerols together with a small quantity of related

lipids, traditionally termed “Crude Fat.” The analysis is achieved by measuring the loss of mass due to the

extraction of fat/oil from the sample encapsulated in a filter bag. The quantitative isolation of the sample is

accomplished by surrounding the sample in a sealed filter bag with a filtering capacity in the 2 to 3 micron range.

The filter bag has sufficient porosity to permit rapid solvent passage and is composed of polymeric material that is

resistant to the higher temperatures and solvents used in the instrument.

The quantitative isolation achieved by the filter bag permits the ANKOM

process samples in batches of up to 15. With the solvent reservoir filled, simply place filter bags with sample in the

Extraction Vessel, lock the vessel in place, select the extraction time and temperature, and press “Start.” The

instrument will automatically fill the Extraction Vessel with solvent, extract the fat from the sample, and recycle the

solvent.

Below is a detailed view of the ANKOM

XT15

Extraction System is designed to extract Crude (Free) Fat using conventional solvents, typically

XT15

Extraction System to automatically

XT15

Extraction System.

Rev F 12/08/14 pg. 7

Page 8

Operator’s Manual

Flammable Hazard: Static electricity is to be avoided as it is a spark hazard.

Hot Surfaces: Do not touch the extraction vessel during operation. The surface

can exceed 70°C (158°F). Failure to observe this caution may result in injury.

Hazardous Voltages: Do not operate the instrument with the electrical

compartment open. Hazardous voltages are present during operation. Failure to

observe this caution may result in electrical shock or electrocution.

Hazardous Materials: The ANKOM

XT15

Extraction System comes equipped with

a charcoal filter which traps any residual vapor in the vent system. By properly

maintaining the charcoal filter, volatiles will not escape the vent system. We

recommend replacement of the filter every 3 months or after 100 extraction runs.

Trace amounts of vapor may also be present when samples are removed. It is

recommended that the ANKOM

XT15

Extraction System be placed in a well

ventilated environment, away from any heat or ignition sources. Organic

solvents may be flammable. Follow safe laboratory practices according to both

local and federal regulations when installing this instrument and when handling

any organic solvents.

WARNING: Attempts to override safety features or to use this instrument in a

manner not specified by ANKOM Technology voids the warranty and may result

in serious injury or even death.

This system is designed to meet and/or exceed the applicable standards of CE,

CSA, NRTL and OSHA.

Please review the entire contents of this manual before you begin operating this

instrument.

Safety Precautions

pg. 8 Rev F 12/08/14

Page 9

Operator’s Manual

1.

Remove the instrument from the shipping container and place in an area that is free of dust and excessive

moisture, and is well ventilated (away from any heat or ignition sources).

Because the ANKOM

XT15

Extraction System is a closed system, there is very

limited exposure to solvents. When used in conjunction with a charcoal filter on

the vent line the instrument produces less than 1ml of volatiles. It is the user’s

responsibility to determine whether venting of this instrument requires placement

in a hood. Please follow both local and federal regulations when installing this

instrument.

2.

Connect the tube from the top fitting to the water supply and the one from the bottom fitting to the drain.

Ensure that there are no kinks or bends in any of the tubing connected to the

instrument.

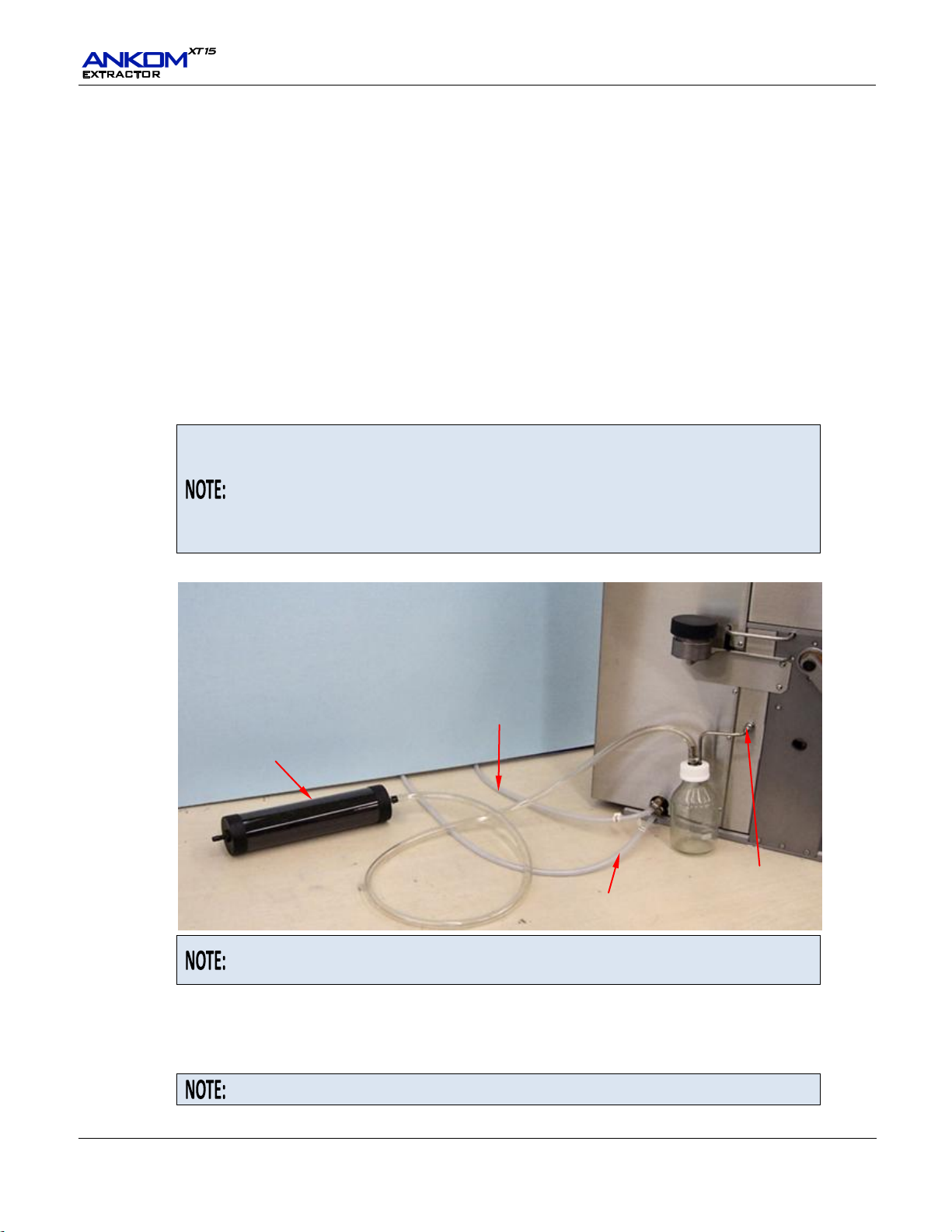

3.

Connect the vent flask to the Vent Flask Connector on the instrument and run the tubing to the inline

charcoal filter. Periodically check the vent line to verify that it is free from any blockage or kinks.

Generally, there should not be any significant solvent in the vent flask. Any solvent visible in the flask

may indicate a problem with the water supply to the instrument.

Change the Charcoal Filter every 3 months or after 100 extraction runs.

4.

Plug the power cord into a grounded receptacle.

Charcoal Filter

Water Supply

Drain

Vent Flask

Connector

Instrument Installation

Site Requirements

To install and operate the ANKOM

Adjustable wrench

Chilled or tap water supply not to exceed 23°C

Adequate power (see “Operating Environment” section)

Drain

Instrument Installation Procedure

To install the ANKOM

XT15

Extraction System, follow the procedure detailed below.

XT15

Extraction System you will need the following:

Rev F 12/08/14 pg. 9

Page 10

Operator’s Manual

Crude Fat contained within a food or feed sample can be calculated using the following formula:

% Crude Fat

=

100 x (W2 – W3)

W1

Where:

W1 = Original weight of sample

W2 = Weight of pre-extraction dried sample and filter bag

W3 = Weight of dried sample and filter bag after extraction

For Liquid Samples, W2 and W3 in the equation above will include the weight of Diatomaceous Earth (DE).

For Meat Samples with > 15% fat and plant samples with > 20% fat:

% Crude Fat

=

100 x ((W2 – W4) – W3)

W1

Where:

W4 = Weight of the weigh tin

If hydrolysis is done prior to fat extraction, then Total Fat contained within a food or feed sample can be calculated

using the following formula:

% Total Fat

=

100 x (W2 – (W3 + (C1 – C2)))

W1

Where:

W1 = Original weight of sample

W2 = Weight of dried sample, filter bag, and Diatomaceous Earth (DE) after hydrolysis

W3 = Weight of dry extracted sample, filter bag, and DE

C1 = Blank filter bag dry weight after hydrolysis

C2 = Blank filter bag weight after extraction

The Hydrolysis procedure can be found in the ANKOM HCl Operator's Manual.

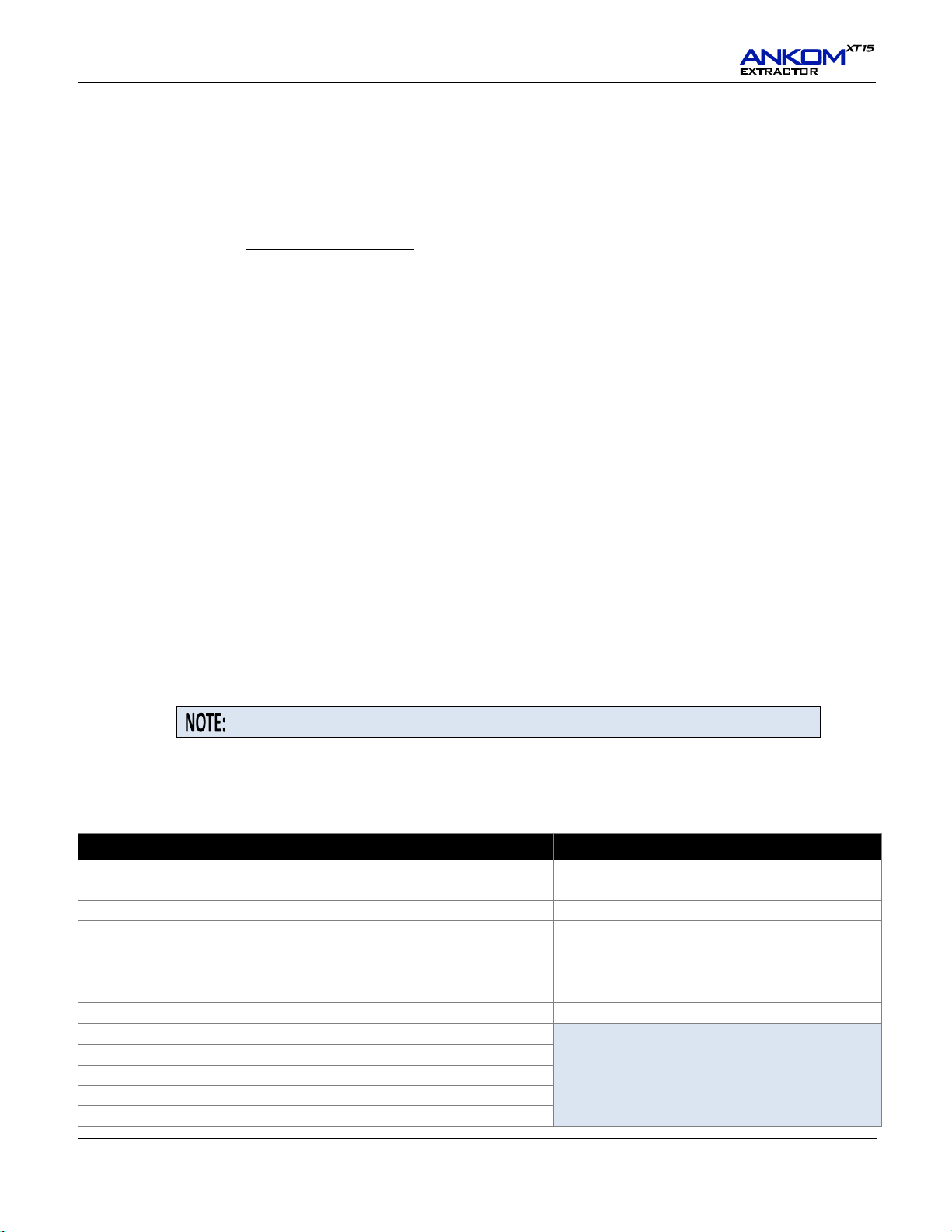

Item

Recommended Product

Electronic Balance with four-place readout

ANKOM #TB Balance Hardware

ANKOM #TBS Balance Software

Filter Bags

ANKOM #XT4

Bag Holder (used for adding sample to an empty filter bag)

ANKOM #101.2

Heat Sealer for sealing the filter bags

ANKOM #1915 (120V), #1920 (220V)

Solvent Resistant Marker

ANKOM #F08

Desiccant Pouch or Weigh Tin Desiccator for drying

ANKOM #X45, #X49

Dryer (capable of temperatures from 60-120°C) - optional

ANKOM #RD (120V), #RDI (220V)

Oven for drying (capable of maintaining 102°C±2°)

Ventilated oven trays to allow for sufficient oven air flow

Weigh Tins (used with samples of > 20% fat)

Sample

Spoon

Fat Extraction Calculations

Crude Fat Calculation

Total Fat Calculation

Fat Extraction Support Items

The following support items are needed to perform the fat extraction procedure:

pg. 10 Rev F 12/08/14

Page 11

Operator’s Manual

To prepare meat samples with ≤ 15% fat by weight or plant samples with ≤ 20% fat by weight for fat extraction,

follow the procedure detailed below.

1.

Using a Solvent Resistant Marker, number all of the empty filter bags you will

use during the fat extraction procedure. Although it is not necessary in the

determination of fat, it is recommended that you weigh and record the weights of

all the filter bags prior to filling them in order to calculate the moisture value for

the samples.

% Moisture = 100 x ((Filter Bag Weight + Sample Weight) - Weight after drying)

Sample Weight

2.

Place an empty filter bag in the Bag Holder in an open position.

3.

Tare the weight of the empty filter bag and the holder together.

4.

Add 1.5 – 2g of sample to the filter bag. Keep all particles away from the sealing

area of the filter bag.

5.

Record the weight of the sample (W1) and tare.

6.

Set the Heat Sealer dial to 6. (The setting may vary from sealer to sealer.)

7.

Seal the filter bag within 4mm of its open end. Keep the

sealer arm down for 2 – 3 seconds after the red sealer light

turns off (to cool the seal). The seal can be seen as a solid

melted stripe along the top edge of the filter bag (as shown

to the right). If the seal is not strong, re-seal the bag.

8.

Repeat steps 1 – 7 for all filter bags that will be used in the ANKOM

XT15

Extraction System. (Up to 15

bags can be processed during one procedure.)

9.

Dry all samples at 102°C±2° for 3 hours to remove moisture prior to the

extraction.

10.

Remove the samples from the oven and place them in a Desiccant Pouch.

11.

Allow the samples to cool to room temperature. This should take about 10 – 15

minutes.

12.

Re-weigh each bag (W2) immediately after removing from the Desiccant Pouch.

The samples are now ready for the fat extraction procedure.

Seal

Sample Preparation

Sample Preparation Procedure for Crude Fat – ffoorr LLOOWW ffaatt ssaammpplleess

Rev F 12/08/14 pg. 11

Page 12

Operator’s Manual

To prepare meat samples with > 15% fat by weight or plant samples with > 20% fat by weight for fat extraction,

follow the procedure detailed below.

1.

Using a Solvent Resistant Marker, number all of the weigh tins and empty

filter bags you will use during the fat extraction procedure. Use one weigh tin

per filter bag. Although it is not necessary in the determination of fat, it is

recommended that you weigh and record the weights of all the filter bags

prior to filling them in order to calculate the moisture value for the samples.

% Moisture = 100 x ((Filter Bag Weight + Sample Weight) - (Weight after drying - Tin Weight))

Sample Weight

2.

Dry all weigh tins in an oven at 102°C±2° for 15 minutes.

3.

Remove weigh tins from the oven and place them in a

Weigh Tin Desiccator or in a Desiccant Pouch.

4.

Allow weigh tins to cool to room temperature.

5.

Weigh and record tin weights (W4).

6.

Place an empty filter bag in the Bag Holder in an open position.

7.

Tare the weight of the empty filter bag and the holder together.

8.

Add 1.5 – 2g of sample to the filter bag. Keep all particles away from the

sealing area of the filter bag.

9.

Record the weight of the sample (W1) and tare.

10.

Set the Heat Sealer dial to 6. (The setting may vary from sealer to sealer.)

Sample Preparation Procedure for Crude Fat – ffoorr HHIIGGHH ffaatt ssaammpplleess

pg. 12 Rev F 12/08/14

Page 13

Operator’s Manual

11.

Seal the filter bag within 4mm of its open end. Keep the

sealer arm down for 2 – 3 seconds after the red sealer light

turns off (to cool the seal). The seal can be seen as a solid

melted stripe along the top edge of the filter bag (as shown

to the right). If the seal is not strong, re-seal the bag.

12.

Repeat steps 1 – 11 for all filter bags that will be used in the ANKOM

XT15

Extraction System. (Up to 15

bags can be processed during one procedure.)

13.

Place the sealed filter bags in their corresponding weigh tins for pre-drying.

14.

Dry all samples at 102°C±2° for 3 hours to remove moisture prior to the extraction.

15.

Remove the weigh tins and filter bags from the oven and place them together

in a Weigh Tin Desiccator.

A Weigh Tin Desiccator is recommended because it will hold between 10 and 14

weigh tins with filter bags, depending on the size of the weigh tins. A Desiccant

Pouch will hold about 4.

16.

Allow the samples to cool to room temperature. This should take about 10 – 15 minutes.

17.

Re-weigh and record the weights of each weigh tin (W4) and filter bag (W2) immediately after removing

from the Weigh Tin Desiccator.

The samples are now ready for the fat extraction procedure.

Seal

Rev F 12/08/14 pg. 13

Page 14

Operator’s Manual

To prepare liquid samples for fat extraction, follow the procedure detailed below.

1.

Using a Solvent Resistant Marker, number all of the empty filter bags you will

use during the fat extraction procedure. Although it is not necessary in the

determination of fat, it is recommended that you weigh and record the weights of

all the filter bags prior to filling them in order to calculate the moisture value for

the samples.

% Moisture = 100 x ((Filter Bag Weight + Sample Weight) - Weight after drying)

Sample Weight

2.

Place an empty filter bag in the Bag Holder in an open position.

3.

Tare the weight of the empty filter bag and the holder together.

4.

Add Diatomaceous Earth (DE).

4.1 Add 1.0 – 1.25 g of DE to the filter bag.

4.2 Using a pencil eraser (or similar sized utensil) make an indentation or a

space in the DE into which the liquid sample can be added using a pipette.

4.3 Record the weight and tare.

5.

Pipette 1.5 – 2 g of liquid sample into the DE indentation in the filter bag.

(Do NOT use more liquid sample than can be absorbed by the DE.)

6.

Record the weight of the sample (W1).

7.

Set the Heat Sealer dial to 6. (The setting may vary from sealer to sealer.)

8.

Seal the filter bag within 4mm of its open end. Keep the

sealer arm down for 2 – 3 seconds after the red sealer light

turns off (to cool the seal). The seal can be seen as a solid

melted stripe along the top edge of the filter bag (as shown

to the right). If the seal is not strong, re-seal the bag.

9.

Repeat steps 1 – 8 for all filter bags that will be used in the ANKOM

XT15

Extraction System. (Up to 15

bags can be processed during one procedure.)

Seal

Sample Preparation Procedure for Crude Fat – ffoorr LLiiqquuiidd ssaammpplleess

pg. 14 Rev F 12/08/14

Page 15

Operator’s Manual

10.

Dry all samples at 102°C±2° for 3 hours to remove moisture prior to the extraction.

11.

Remove the samples from the oven and place them in a Desiccant Pouch.

12.

Allow the samples to cool to room temperature. This should take about 10 – 15

minutes.

13.

Re-weigh each bag (W2) immediately after removing from the Desiccant Pouch.

The samples are now ready for the fat extraction procedure.

Rev F 12/08/14 pg. 15

Page 16

Operator’s Manual

1.

Turn the instrument power ON.

The Display will briefly show the software version number followed

by the screen to the right.

The factory default solvent shown on the Display is "Pet Ether." However, the

instrument computer will store in memory the last solvent selection made and use

it as the default solvent shown on the Display screen every time the instrument is

ready for a new run.

2.

Select the solvent you want to use.

2.1 Press the Down Arrow (v) key on the Keypad until the desired solvent is shown on the Display.

2.2 Fill the solvent reservoir as needed.

2.21 Unscrew the Fill Cap.

2.22 Pour solvent into the Fill Port up to the dark blue level mark

on the Solvent Sight Level. (About 500 ml of solvent is

needed to reach the dark blue level mark.) Do not add solvent

up to the top of the Solvent Sight Level tube or it will start

flowing into the Vent Flask.

If using Diethyl Ether or a solvent mixture that includes Diethyl Ether (such as the

Mojonnier Mixture), you will need the O-ring Kit for High Penetration Solvents

(part # X95) to replace the standard O-rings on the top of the Extraction Vessel

and the Valve Kit for High Penetration Solvents (part # X55).

Warning: Do NOT use Acetone in this instrument because it will cause damage

to the valves.

2.3 Press ENTER on the Keypad to complete the solvent selection.

The Display should now show the screen to the right.

Remove/Insert

Samples <ENTER>

PET Ether

v <ENTER>

Fat Extraction step-by-step procedure using the ANKOM

To perform fat extraction on prepared samples, follow the procedure detailed below.

XT15

pg. 16 Rev F 12/08/14

Page 17

Operator’s Manual

3.

Insert Filter Bags into the instrument.

3.1 Press down the Safety Valve Handle to release the Safety Valve

Pin and rotate the Main Handle upward until it stops.

3.2 Use the Extraction Vessel Handle to pull the Extraction Vessel

out.

3.3 Slide the Extraction Vessel toward you far enough to remove the

white Teflon Insert or to put the Bag Holder directly into the

Teflon Insert while it remains in the Extraction Vessel.

It is not necessary to remove the white Teflon Insert from the Extraction Vessel

in order to put the Bag Holder in place.

3.4 Put the Bag Holder (with up to 15 bags) into the Teflon Insert.

3.5 If you removed the Teflon Insert, put it back

into the Extraction Vessel, aligning the Teflon

Insert slot with the Extraction Vessel pin.

The Teflon Insert O-ring and the Extraction Vessel O-ring must be in

place before running the instrument.

The Teflon Insert slot must be aligned with the Extraction Vessel pin

before running the instrument.

Teflon Insert O-ring

Extraction Vessel O-ring

Teflon Insert

slot and

Extraction

Vessel pin

Teflon Insert

Bag Holder

Rev F 12/08/14 pg. 17

Page 18

Operator’s Manual

3.6 Slide the Extraction Vessel into the instrument ensuring the

Extraction Vessel O-ring stays in place.

3.7 Pull the Main Handle downward, closing and locking the Extraction

Vessel in place. You will hear a click noise when the Safety Valve

Pin locks in place.

Before running the instrument, verify that the Extraction Vessel is locked in

place by attempting to rotate the Main Handle upward. If it is not locked,

repeat step #8 above.

3.8 Press ENTER on the Keypad.

The Display should now show the screen to the right. (The

time shown will be the last time entered.)

4.

Set the Extraction Time.

4.1 Using the arrow keys on the Keypad, select the desired Extraction time. (The recommended time is

60 minutes.)

4.2 Press ENTER on the Keypad to set the Time.

The Display should now show the screen to the right. (The

temperature shown will be the last temperature entered.)

5.

Set the Extraction Temperature.

5.1 Using the arrow keys on the Keypad, select the desired Extraction Temperature. (The

recommended maximum temperature is 90°C.)

5.2 Press ENTER on the Keypad to set the Temperature.

The Display should now show the screen to the right.

6.

Verify that the water supply is on.

7.

Run the instrument.

Press START on the Keypad.

The instrument will run through its automatic operation, showing

its status on the Display. When the instrument has completed its

automatic operation, the Display will show the screen to the right.

At this time, the only light shining on the Display should be the green

power light.

PET Ether

v <ENTER>

Close Vessel

Water On <START>

Select temp 90

(^v)... <ENTER>

Select time 60

(^v)... <ENTER>

pg. 18 Rev F 12/08/14

Page 19

Operator’s Manual

8.

Determine the amount of fat that was extracted.

8.1 When the Pressure Gauge reads zero, remove the Extraction Vessel by pushing down on the Safety

Valve Handle to release the locking pin and then rotating the Main Handle to the open position.

8.2 Use the Extraction Vessel Handle to remove the Extraction Vessel.

Warning: The Extraction Vessel interior and top will be HOT when the

extraction process is complete.

8.3 Remove the Teflon Insert from the Extraction Vessel.

8.4 Remove the Bag Holder from the Teflon Insert.

8.5 Remove the filter bags from the Bag Holder.

8.6 Dry the samples for 15 – 30 minutes in the oven at 102 ± 2°C or in the

ANKOMRD Dryer set at the factory setting of 110°C.

8.7 Remove the samples from the oven or dryer and place them in a Desiccant

Pouch.

8.8 Allow the samples to cool to room temperature. This should take about 10 –

15 minutes.

8.9 Re-weigh each filter bag (W3) immediately after removing from the Desiccant Pouch.

9.

Clean the fat from the bottom of the vessel using paper towel.

If too much fat accumulates in the bottom of the Extraction Vessel, an

overtemp fault will occur.

Rev F 12/08/14 pg. 19

Page 20

Operator’s Manual

Do not use soap and/or water to clean the vessel. When cleaning the vessel,

do not damage the level sensor tip. The tip may be cleaned with window

cleaner or alcohol.

Do not use Acetone to clean the instrument.

1.

Remove the rear cabinet of the instrument.

Rear View of instrument with cabinet back removed

2.

Unscrew the compression fitting.

3.

Unscrew the filter body.

4.

Unscrew and clean the metal filter screen.

5.

Reassemble the filter and compression

fitting. Make sure the valve body is tight and

the Teflon washer has not come out of the

filter body.

Compression Fitting

Filter

body

Periodic Maintenance

Cleaning the Extraction Vessel

Some compounds extracted during the fat extraction procedure can create a black residue in the bottom of the

Extraction Vessel. The vessel can most easily be cleaned by using a drill with a long shafted stiff wire brush

(ANKOM part # X107). This treatment will remove a lot of the black coating that accumulates on the bottom of

the vessel. When the vessel bottom is clean, put some solvent on a cloth or paper towel and wipe down the inside

of the vessel in an effort to remove any oil residue and particles that have been loosened from the vessel bottom.

Cleaning the exterior of the instrument

Wipe the outside of the instrument with window cleaner or a damp sponge as necessary.

Cleaning the solvent filter

If filter bags are not sealed properly and sample is lost from the bag, it will be recovered in the solvent filter in the

exhaust line.

To clean the solvent filter, follow the procedure detailed below.

pg. 20 Rev F 12/08/14

Page 21

Operator’s Manual

1.

Unscrew the filter from the instrument.

2.

Unscrew the filter clamp from the water supply line.

3.

Use compressed air to blow backwards through the

filter (blow opposite the arrow on the filter). If the

filter is clogged, replace it with ANKOM part # X97.

4.

Reconnect the filter and fittings.

5.

Turn on the water and check for leaks.

1.

Turn off the instrument power and unplug the Power Cord from the outlet.

2.

Remove the two screws on the Top Cover.

3.

Swing the Top Cover down exposing the electrical compartment.

4.

Locate the Fuse Holders on the terminal strip. There

are two fuses within the instrument; one for each pole

(100 – 120V 10A or 220 – 240V 5A).

5.

Press the tabs to lift the Fuse Holders up.

6.

Replace the fuses and close the Fuse Holders completely.

7.

Close the Top Cover and secure it with the two screws that you previously removed.

Fuse

Holders

Tab to open

Fuse Holder

Fuse

Filter

Cleaning the water filter

To clean the water filter (located on the water supply line), follow the procedure detailed below.

Replacing the Fuses

To replace the fuses in the ANKOM

XT15

Extraction System, follow the procedure detailed below.

Replacing the Charcoal Filter

The Charcoal Filter should be replaced every 3 months, or after 100 extraction operations using the instrument. To

replace the filter, remove the old one from the vent line and install the new one.

Rev F 12/08/14 pg. 21

Page 22

Operator’s Manual

Troubleshooting & Replacement Parts

The ANKOM technology web site has the most current troubleshooting and replacement parts information.

Therefore, if you have any questions about the operation of your ANKOM

XT15

Extraction System, or if you need

replacement parts, please visit our web site at www.ankom.com.

pg. 22 Rev F 12/08/14

Page 23

Operator’s Manual

When the instrument is powered up or when the instrument finishes a run, the

screen to the right is displayed.

The factory default solvent shown on the Display is "Pet Ether." However, the

instrument computer will store in memory the last solvent selection made and use

it as the default solvent shown on the Display screen every time the instrument is

ready for a new run.

To access the Diagnostics Screen, press the Down Arrow button (v) on the

Keypad four times. The screen to the right will be displayed. From the

Diagnostics Screen you can access all of the available diagnostics.

1. With the Diagnostics screen displayed, press the ENTER button on

the Keypad. The screen to the right will be displayed.

If you press the STOP button on the Keypad while this screen is displayed, you

will go back to the Diagnostics screen. If you press the Down Arrow button (v) on

the Keypad while this screen is displayed you will go to the next group of

diagnostics (Analog).

2. With the Outputs screen displayed, press the ENTER button on the

Keypad. The screen to the right will be displayed.

3. Press the Down Arrow button (v) on the Keypad to select the

heater relay (Q0) or valve (Q1 - Q7) you want to toggle. With

your selection made (in this example we selected the heater relay

Q0), press the ENTER button on the Keypad. The screen to the

right will be displayed.

Heater (Q0) OFF

ENTER to toggle

Heater (Q0)

v <ENTER>

Outputs <ENTER>

Exit <STOP> v

Diagnostics

^ <ENTER>

PET Ether

v <ENTER>

Diagnostics

To help solve problems that may occur while running the ANKOM

Diagnostics are available and accessible through the Display and Keypad.

1. Toggle Outputs (Q0 Heater Relay and Q1 - Q7 valves)

2. Check Temperature and Level Sensors

3. Check the state of the ETS (Emergency Temperature Shut-off switch) relay

XT15

Extractor, the following computer controlled

Access Diagnostics Screen

Toggle Outputs

To toggle outputs, follow the procedure below.

Rev F 12/08/14 pg. 23

Page 24

Operator’s Manual

4. Press the ENTER button on the Keypad to turn ON the heater relay

(Q0). The screen to the right will be displayed.

5. Press the ENTER button on the Keypad to turn OFF the heater

relay (Q0). The screen to the right will be displayed.

Warning: If the heater relay (Q0) is left ON, the Extraction Vessel interior will

become very HOT and within five minutes the instrument ETS switch will trip

resulting in the Fault screen shown here.

From this screen press ENTER to get back to the main Diagnostics screen.

6. Press the STOP button on the Keypad to go back to the main

Outputs screen (shown to the right).

7. Press the STOP button on the Keypad to go back to the main

Diagnostics screen (shown to the right).

8. Press the Up Arrow button (^) on the Keypad to exit Diagnostics.

Press the Up Arrow button (^) on the Keypad up to three more

times to return to your solvent screen (example shown to the

right).

When you exit Diagnostics, heater relay Q0 turns OFF and valves Q1 - Q7 return

to the closed position.

PET Ether

v <ENTER>

Diagnostics

^ <ENTER>

Outputs <ENTER>

Exit <STOP> v

Diagnostics ETS

Fault <ENTER>

Heater (Q0) OFF

ENTER to toggle

Heater (Q0) ON

ENTER to toggle

pg. 24 Rev F 12/08/14

Page 25

Operator’s Manual

1. Access the Diagnostics screen (see the "Access Diagnostics

Screen" section for details).

2. With the Diagnostics screen displayed, press the ENTER button on

the Keypad. The screen to the right will be displayed.

3. Press the Down Arrow button (v) on the Keypad. The screen to

the right will be displayed.

4. Press the ENTER button on the Keypad. The screen to the right

will be displayed showing the current Temperature and Level

Sensor readings.

When the instrument has not been run for more than two hours, the temperature should read the ambient

temperature of the room. If the temperature reading does not show ambient temperature when the

instrument is cool, contact ANKOM Technology.

When the Level Sensor in the instrument Vessel is not covered by liquid, the Level Sensor should read

10.00v. If the reading is less than 10.00v and the Level Sensor is not covered by liquid, clean the Level

Sensor Tip inside the Vessel with a cotton swab and alcohol. If the Level Sensor reading is between

5.00 - 10.00v after cleaning the tip, the instrument will run, but you should consider replacing the tip.

Contact ANKOM Technology for more information.

When the instrument Vessel is filled with liquid that covers the Level Sensor, the Level Sensor should

read less than 3.00v. If the Level Sensor reading is more than 3.00v when the sensor is covered by liquid,

contact ANKOM Technology.

If you fill the Vessel with water during Diagnostics, wipe the Vessel dry before

running the instrument.

5. Press the STOP button on the Keypad to go back to the Analog

screen (shown to the right).

6. Press the STOP button on the Keypad to go back to the main

Diagnostics screen (shown to the right).

Diagnostics

^ <ENTER>

Analog <ENTER>

Exit <STOP> ^ v

Temp Lvl Sense

20°C 10.00v

Analog <ENTER>

Exit <STOP> ^ v

Outputs <ENTER>

Exit <STOP> v

Diagnostics

^ <ENTER>

Check Temperature and Level Sensors

To check the Temperature and Level Sensors, follow the procedure below.

Rev F 12/08/14 pg. 25

Page 26

Operator’s Manual

7. Press the Up Arrow button (^) on the Keypad to exit Diagnostics.

Press the Up Arrow button (^) on the Keypad up to three more

times to return to your solvent screen (example shown to the

right).

1. Access the Diagnostics screen (see the "Access Diagnostics

Screen" section for details).

2. With the Diagnostics screen displayed, press the ENTER button on

the Keypad. The screen to the right will be displayed.

3. Press the Down Arrow button (v) on the Keypad. The screen to the

right will be displayed.

4. Press the Down Arrow button (v) on the Keypad. The screen to

the right will be displayed.

5. Press the ENTER button on the Keypad. The screen to the right

will be displayed showing the state of the ETS relay. If the ETS

relay is "OFF", contact ANKOM Technology.

6. Press the STOP button on the Keypad to go back to the Inputs

screen (shown to the right).

7. Press the STOP button on the Keypad to go back to the main

Diagnostics screen (shown to the right).

8. Press the Up Arrow button (^) on the Keypad to exit Diagnostics.

Press the Up Arrow button (^) on the Keypad up to three more

times to return to your solvent screen (example shown to the

right).

PET Ether

v <ENTER>

Diagnostics

^ <ENTER>

Inputs <ENTER>

Exit <STOP> ^

ETS relay - ON

Inputs <ENTER>

Exit <STOP> ^

Analog <ENTER>

Exit <STOP> ^ v

Outputs <ENTER>

Exit <STOP> v

Diagnostics

^ <ENTER>

PET Ether

v <ENTER>

Check the state of the ETS (Emergency Temperature Shut-off switch) relay

To check the state of the ETS relay, follow the procedure below.

pg. 26 Rev F 12/08/14

Page 27

Operator’s Manual

ANKOM Technology Method

AOCS Official Procedure Am 5-04

Rapid Determination of Oil/Fat Utilizing High Temperature Solvent Extraction

Definition

This method determines crude fat by extracting with petroleum ether. The compounds extracted are predominantly triacylglycerides. Small

amounts of other lipids along with minor compounds having some solubility in petroleum ether are also extracted.

Scope

This method is applicable to solid processed foods with 0-100% fat content.

Apparatus

1. Analytical Balance—capable of weighing 0.1 mg.

2. Oven—capable of maintaining a temperature of 102 ± 2°C.

3. Extraction instrument—capable of extracting at 90 ± 2°C.

(XT10, XT15, XT20, ANKOM Technology).

4. Filter Bags—constructed from chemically inert and heat

resistant filter media, capable of being heat sealed closed and

able to retain 1 micron particles while permitting solution

penetration (XT4, ANKOM Technology).

5. Heat sealer—sufficient for sealing the filter bags closed to

ensure complete closure (1915, ANKOM Technology).

6. Desiccant Pouch—collapsible sealable pouch with desiccant

inside that enables the removal of air from around the filter bags

(MoistureStop weigh pouch, ANKOM Technology).

7. Marking pen—Solvent and acid resistant (F08, ANKOM

Technology).

8. Dryer (optional)—forced air dryer capable of maintaining a

temperature between 60-120°C (ANKOMRD Dryer, ANKOM

Technology).

Reagents

1. Petroleum Ether (B.P. 35-65º C). Depending on the method

used, other solvents such as hexanes and ethyl ether may be

used. CAUTION: Most fat solvents are extremely flammable.

Avoid static electricity and follow safe laboratory practices

according to your local regulations when handling solvents.

Precision

Results from the collaborative study (see Table 1) indicate the

precision (Sr, RSDr, r) that the analyst should use as a benchmark for

evaluation replication in the same laboratory.

Procedure (see the Fat Extraction Process section of the Operator’s

Manual for more detail)

1. Place a labeled filter bag on the balance and zero the balance.

2. Weigh 1.5 – 2g of sample into the bag and record the weight

(W1).

3. Heat seal the filter bag closed within 4mm of the top to

encapsulate the sample.

4. It is good practice to include a blank bag periodically,

especially when changing solvents, in order to measure any

effect on the filter bag.

5. If a meat sample has an expected fat value of > 15% or a plant

sample has an expected fat value of > 20%, then place the

filter bag with sample in a tared weigh tin (W4) during the

oven drying procedure in order to capture fat that may migrate

out of the bag during heating.

6. Place samples in the drying oven at 102 ± 2°C for 3 hrs (see

Numbered Note 1).

7. Cool the dried samples in the Desiccant Pouch, weigh and

record the weight (W2).

8. Place filter bags with sample into the bag holder and place in

the extractor.

9. Follow the extraction instrument instructions.

10. When the extraction process is complete dry the samples for

15 – 30 minutes in the oven at 102 ± 2°C or in the ANKOMRD

Dryer set at the factory setting of 110°C. (See Numbered Note

2.)

11. Cool in the Desiccant Pouch and weigh (W3).

Calculations

Meat samples ≤ 15% fat and plant samples ≤ 20% fat

Meat samples > 15% fat and plant samples > 20% fat

% Crude Fat

=

100 x (W2 – W3)

% Crude Fat

=

100 x ((W2 – W4) - W3)

W1

W1

Where:

W1 = Original weight of sample

Where:

W4

=

Weight of the weigh tin

W2 = Weight of pre-extracted dried sample with filter

bag

W3 = Weight of dry sample with filter bag after

extraction

NOTE: For Liquid Samples, W2 and W3 in the above equations will include the weight of Diatomaceous Earth (DE).

Appendix A – AOCS Official Fat Extraction Procedure

Rev F 12/08/14 pg. 27

Page 28

Operator’s Manual

Numbered Notes

1. Pre-extraction drying time of the samples in the filter bags can be greatly reduced by using a microwave oven. However,

microwave ovens vary in energy output and samples vary in water and fat composition. You will need to experiment with your

microwave oven to determine the proper conditions for use. Contact ANKOM Technology for further information.

2. Some samples with large amounts of carbohydrates (starches and cellulose) may bind small quantities of solvent and require

additional post drying. To remove bound solvent, dry at 100°C for 1 – 3 hrs or at 125°C for 30 minutes.

Sample ID

oat meal

brownie mix

soybean A

canola

soybean meal

corn A

poultry starter

cattle feed

pig starter

alfalfa

cat food

cookies

bkft cereal

tortilla chips

Number of laboratories 12 12 11 9 12 12 11 10 11 11 12 11 12 12

Number of replicates 24 24 22 18 24 24 22 20 22 22 24 22 24 24

Filter Bag Average, % Crude Fat 5.8 8.7 20.9 39.0 1.6 3.3 3.3 3.2 5.6 2.4 6.3 22.7 2.3 19.9

Certified Labs Average

a

5.7 8.7 21.1 39.7 1.6 3.6 3.5 3.0 5.5 2.2 6.2 23.1 2.3 20.0

AOCS Am 2-93 Avg. for Oilseeds 21.9 44.8 3.6

S

r

0.36 0.20 0.35 0.23 0.14 0.31 0.24 0.18 0.20 0.39 0.27 0.20 0.26 0.39

S

R

0.54 0.31 0.63 0.68 0.27 0.42 0.42 0.20 0.28 0.50 0.30 0.20 0.36 0.48

RSDr, %

6.2 2.3 1.7 0.6 8.5 9.5 7.3 5.6 3.6 16.1 4.2 0.9 11.4 2.0

RSDR, %

9.4 3.5 3.0 1.7 16.3 12.7 12.6 6.1 5.0 20.7 4.7 0.9 15.7 2.4

r 0.99 0.56 0.98 0.65 0.39 0.88 0.68 0.51 0.56 1.08 0.75 0.56 0.72 1.09

R 1.52 0.86 1.76 1.90 0.75 1.18 1.16 0.55 0.78 1.39 0.83 0.56 1.00 1.35

HORRAT 3.05 1.21 1.19 0.76 4.38 3.87 3.77 1.83 1.61 5.92 1.56 0.35 4.45 0.95

Sample ID

dog food

crackers

turkey

ham

beef ground

chicken breast

soybean B

safflower

potato chips

hot dog

sausage

corn B

cheese curls

corn silage

Number of laboratories 12 10 12 9 11 11 11 9 11 12 11 12 12 12

Number of replicates 24 20 24 18 22 22 22 18 22 24 22 24 24 24

Filter Bag Average, % Crude Fat 6.8 23.8 3.2 11.6 23.8 2.8 19.4 22.5 32.0 39.5 25.7 3.4 30.6 2.3

Certified Labs Average

a

6.9 24.0 3.2 11.3 23.5 2.7 19.7 23.2 32.0 39.0 25.0 3.7 30.5 2.3

AOCS Am 2-93 Avg. for Oilseeds 20.8 24.7

S

r

0.35 0.23 0.21 0.30 0.24 0.33 0.38 0.53 0.48 0.35 0.34 0.39 0.48 0.23

S

R

0.35 0.23 0.34 0.30 0.36 0.33 0.62 0.83 0.52 0.59 0.51 0.41 0.69 0.51

RSDr, %

5.23 0.96 6.57 2.59 1.01 11.89 1.97 2.36 1.49 0.89 1.33 11.48 1.59 9.87

RSDR, %

5.23 0.96 10.84 2.59 1.49 11.89 3.19 3.69 1.61 1.49 1.98 11.93 2.27 22.45

r 0.99 0.64 0.58 0.84 0.67 0.94 1.07 1.49 1.34 0.98 0.96 1.10 1.36 0.63

R 0.99 0.64 0.96 0.84 0.99 0.94 1.73 2.33 1.45 1.65 1.43 1.14 1.94 1.44

HORRAT 1.74 0.39 3.22 0.94 0.6 3.47 1.25 1.48 0.68 0.65 0.81 3.59 0.95 6.36

aAOCS Official Methods Ba 3-38, AOAC 920.39 or equivalent

Table 1. A summary of the statistical analysis of the international collaborative study of the Filter Bag Technique for the proposed Official AOCS Method, “Rapid Determination of

Oil/Fat Utilizing High Temperature Solvent Extraction” is presented in this table. Included in the summary is a comparison of the Filter Bag Technique with the results of analysis by

AOCS certified laboratories using official AOCS or AOAC methods

pg. 28 Rev F 12/08/14

Page 29

Operator’s Manual

Appendix B – Electrical Diagram (pg. 1 of 3)

Rev F 12/08/14 pg. 29

Page 30

Operator’s Manual

Appendix B – Electrical Diagram (pg. 2 of 3)

pg. 30 Rev F 12/08/14

Page 31

Operator’s Manual

Appendix B – Electrical Diagram (pg. 3 of 3)

Rev F 12/08/14 pg. 31

Page 32

Automation saves time and money!

ANKOM Technology is an international company with products that include…

TDF Dietary Fiber Analyzer

Automates AOAC 991.43/AACC 32.07.01

IDF/SDF and TDF values

Faster, Technician-free Filtering

Computer controlled operation

Reduced per assay costs

A2000 Fiber Analyzer

Crude Fiber (AOCS Ba 6a-05), ADF, NDF

Automatically adds solutions and rinses

Batch process - up to 24 samples at one time

XT15 Fat Extractor

Official Method AOCS Am 5-04

Fully automatic

Solvent recovery at 97% or greater

Batch process - up to 15 samples at one time

RF Gas Production System

High sensitivity pressure measurement

Applications include: Ruminant Nutrition, Human Digestion, Yeast Activity,

Beer/Wine Fermentation, Biomass-to-Energy analysis (e.g., Ethanol),

Biodegradability, Soil respiration, BOD, etc.

Wireless Computer control and data storage

Chemicals

A wide variety of chemicals used for many different lab operations

Pre-mixed solutions available

Please visit our web site at www.ankom.com for more information.

2052 O’Neil Rd, Macedon NY 14502

Telephone: (315) 986-8090

Fax: (315) 986-8091

www.ankom.com

Loading...

Loading...