Page 1

Rev 9/20/18

Operator’s Manual

2052 O’Neil Rd, Macedon NY 14502

Telephone: (315) 986-8090

Fax: (315) 986-8091

www.ankom.com

Page 2

This page intentionally left blank

Page 3

Table of Contents

Introduction .................................................................................................................................................................. 5

Warranty ....................................................................................................................................................................... 5

Filter Bags ..................................................................................................................................................................... 5

Contact Information ..................................................................................................................................................... 5

Method Comparison (Manual vs. Automated) ............................................................................................................. 6

Instrument Description ................................................................................................................................................. 7

Service Access Position ............................................................................................................................................... 10

Operating Environment .............................................................................................................................................. 10

Safety Precautions ...................................................................................................................................................... 10

Instrument Installation ............................................................................................................................................... 11

Dietary Fiber Analysis Support Items .......................................................................................................................... 16

Analysis Options using the ANKOM

TDF

Dietary Fiber Analyzer ................................................................................... 16

Blanks .......................................................................................................................................................................... 16

IDF/SDF Analysis ......................................................................................................................................................... 17

TDF Analysis (AOAC 991.43) ....................................................................................................................................... 31

TDF Analysis (AOAC 985.29 / 2001.03) ....................................................................................................................... 44

Protein Determination ................................................................................................................................................ 59

Ash Determination ...................................................................................................................................................... 61

Productivity Enhancement ......................................................................................................................................... 63

Status Screen .............................................................................................................................................................. 67

Fault Handling ............................................................................................................................................................. 71

Diagnostics Mode ....................................................................................................................................................... 73

Periodic Maintenance ................................................................................................................................................. 81

Troubleshooting & Replacement Parts ....................................................................................................................... 82

QC / Calibration Checks .............................................................................................................................................. 83

Appendix A – Reagents (AOAC 991.43, 985.29, 2001.03) .......................................................................................... 89

Appendix B – Instrument Out-of-use Procedure ........................................................................................................ 91

Appendix C – De-fatting Procedure ............................................................................................................................ 93

Appendix D – Accessories (sold separately) ............................................................................................................... 95

Page 4

This page intentionally left blank

Page 5

Operator’s Manual

Rev 9/20/18 pg. 5

Introduction

ANKOM Technology designs, manufactures, and markets instruments and support products used by analytical laboratories

around the world in the food, feed, bio-energy, agricultural, and environmental industries. ANKOM Technology can provide

you with products for determining or monitoring dietary fiber, detergent fiber, crude fiber, fat, digestibility, microbial

fermentation (anaerobic or aerobic) and more.

Committed to Total Customer Satisfaction, ANKOM designs every product based on a thorough assessment of customer needs.

Congratulations on your purchase of the ANKOM

TDF

Dietary Fiber Analyzer. We are confident that this product will

effectively serve your needs.

The ANKOM

TDF

Dietary Fiber Analyzer was designed to eliminate most of the manual steps required by the method. This

reduces technician variation, increasing precision. By carefully following the operating instructions in this manual you will

understand the details of sample and filter bag handling as well as instrument control, helping you to achieve the best possible

results.

Please review the entire manual before you begin operating this product.

Warranty

ANKOM Technology warrants the ANKOM

TDF

Dietary Fiber Analyzer against any defects in workmanship or material for one

year after the original date of purchase. This warranty does not include damage to the instrument resulting from neglect or

misuse. During the warranty period, should any failure result from defects in workmanship or materials, ANKOM Technology

will, at its discretion, repair or replace the instrument free of charge.

Extended warranties are available upon request.

Filter Bags

Use ANKOM Technology filter bags (part #’s DF-I, DF-S, DF-FT) in your ANKOM

TDF

Dietary Fiber Analyzer. Filter bags can

be purchased from ANKOM Technology or from your local authorized ANKOM distributor.

Contact Information

Committed to your total satisfaction, we are always available to help you get the most from your ANKOM products and to

receive any comments or suggestions you might have to help us improve.

For any questions or suggestions regarding your instrument, please contact us at:

• Telephone: (315) 986-8090

• Fax: (315) 986-8091

• Email: service@ankom.com

• www.ankom.com

Page 6

Operator’s Manual

pg. 6 Rev 9/20/18

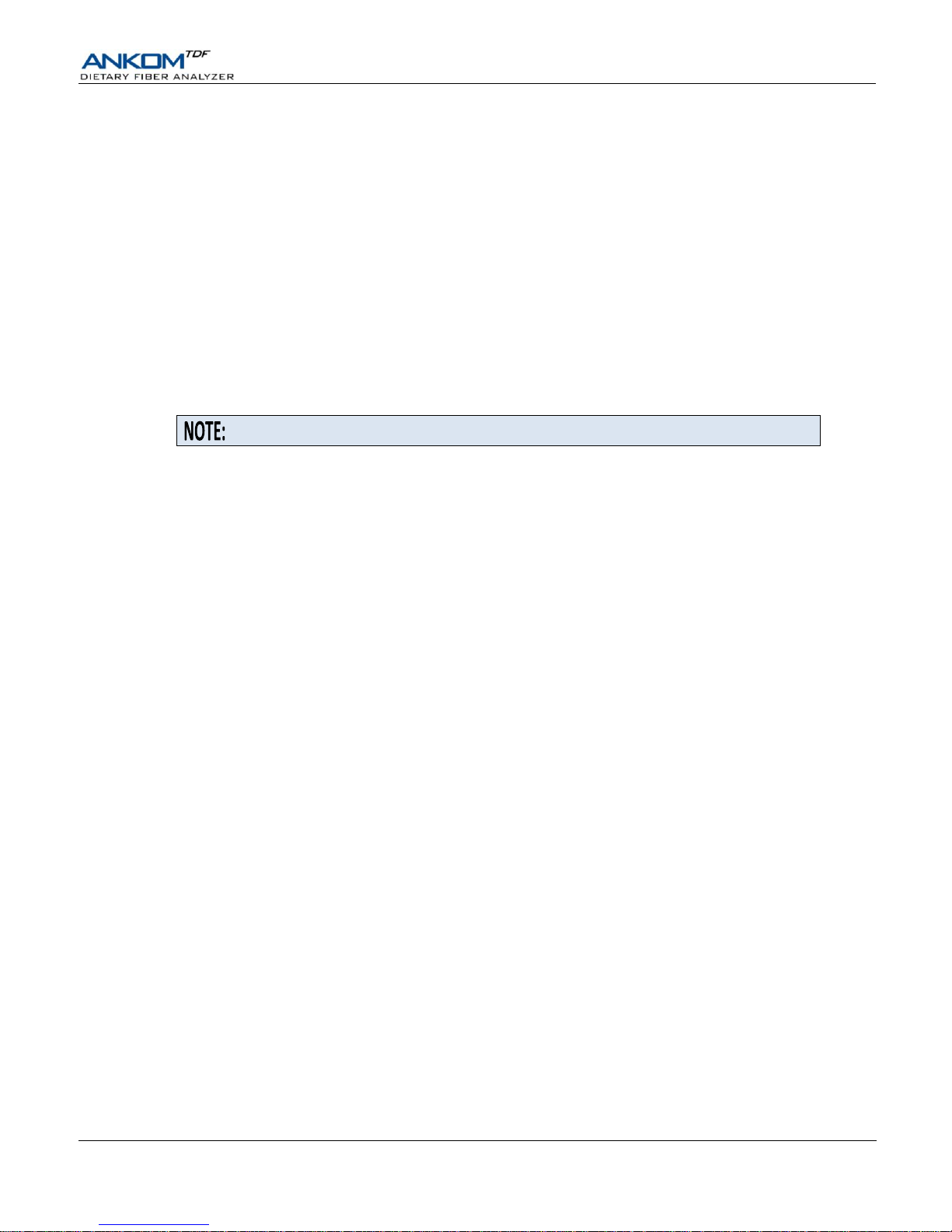

Method Comparison (Manual vs. Automated)

AOAC 991.43 Method – IDF/SDF assay without automation

Below is the AOAC 991.43 method flow done manually by a technician using glass crucibles and beakers, vacuum to assist

with filtering, and water baths to control temperature and mixing. DE refers to Diatomaceous Earth.

Prepare for Test

Digest Sample

Isolate IDF Residue

Isolate SDF Residue

1

Prepare crucibles

5 Heat to 95°C

17

Transfer to filter

26

Add 95% EtOH to fitrate

1a

Ash crucibles overnight

6 Add buffer

18

Filter with vacuum assist

27

Precipitate for 60 min

1b

Clean with vacuum

7 Add Amylase

19

Scratch filter bed as

needed

28

Transfer to filter

1c

Soak 1 hr @ room temp

8 Digest at 95°C for 35 min

29

Filter with vacuum assist

1d

Rinse with 3 solutions

9

Scrape beaker walls and

rinse with H2O to move

all residue to bottom

20

Rinse with 70°C H2O

30

Scratch filter bed as

needed

1e

Prepare DE filter bed

21

Rinse with 78% EtOH

1f

Dry @ 130°C

22

Rinse with 95% EtOH

31

Rinse with 78% EtOH

1g

Cool 1 hr and weigh

10

Cool to 60°C

23

Rinse with Acetone

32

Rinse with 95% EtOH

2

Weigh samples

11

Add Protease

24

Dry IDF residue

33

Rinse with Acetone

3

Prepare H2O bath(s)

12

Digest at 60°C for 30 min

25

Weigh IDF residue

34

Dry SDF residue

4

Place samples in beakers

13

Add HCl

35

Weigh SDF residue

14

Add AMG

15

Check/adjust pH

Calculate Results

16

Digest at 60°C for 30 min

36

Correct for Protein

37

Correct for Ash

38

Calculate results using

weights and corrections

AOAC 991.43 Method – IDF/SDF assay with ANKOM

TDF

Dietary Fiber Analyzer automation

Below is the AOAC 991.43 method flow when using the ANKOM

TDF

Dietary Fiber Analyzer. Steps highlighted in YELLOW

represent tasks done by a technician. Steps highlighted in GREEN (1a-1g, 9, 19, and 30) are no longer needed because of Filter

Bag Technology. All other steps (including mixing) are done automatically by the ANKOM

TDF

Dietary Fiber Analyzer under

computer control. DE refers to Diatomaceous Earth.

Prepare for Test

Digest Sample

Isolate IDF Residue

Isolate SDF Residue

5 Heat to 95°C

17

Transfer to filter

26

Add 95% EtOH to fitrate

6 Add buffer

18

Filter with pressure assist

27

Precipitate for 60 min

7 Add Amylase

28

Transfer to filter

8 Digest at 95°C for 35 min

29

Filter with pressure assist

20

Rinse with 70°C H2O

21

Rinse with 78% EtOH

22

Rinse with 95% EtOH

31

Rinse with 78% EtOH

1

Weigh filter bags

10

Cool to 60°C

23

Rinse with Acetone

32

Rinse with 95% EtOH

2

Weigh DE and samples

11

Add Protease

24

Dry IDF residue

33

Rinse with Acetone

3

Install filter bags

12

Digest at 60°C for 30 min

25

Weigh IDF residue

34

Dry SDF residue

4

Add DE & Sample to bags

13

Add HCl

35

Weigh SDF residue

14

Add AMG

15

Check/adjust pH

Calculate Results

16

Digest at 60°C for 30 min

36

Correct for Protein

37

Correct for Ash

38

Calculate results using

weights and corrections

This section is just an overview of how the ANKOM

TDF

Dietary Fiber Analyzer

executes the AOAC 991.43 method. Please see the “IDF/SDF Analysis” and “TDF

Analysis” sections of this manual for detailed instructions on how to perform

IDF/SDF and TDF assays with the analyzer.

Page 7

Operator’s Manual

Rev 9/20/18 pg. 7

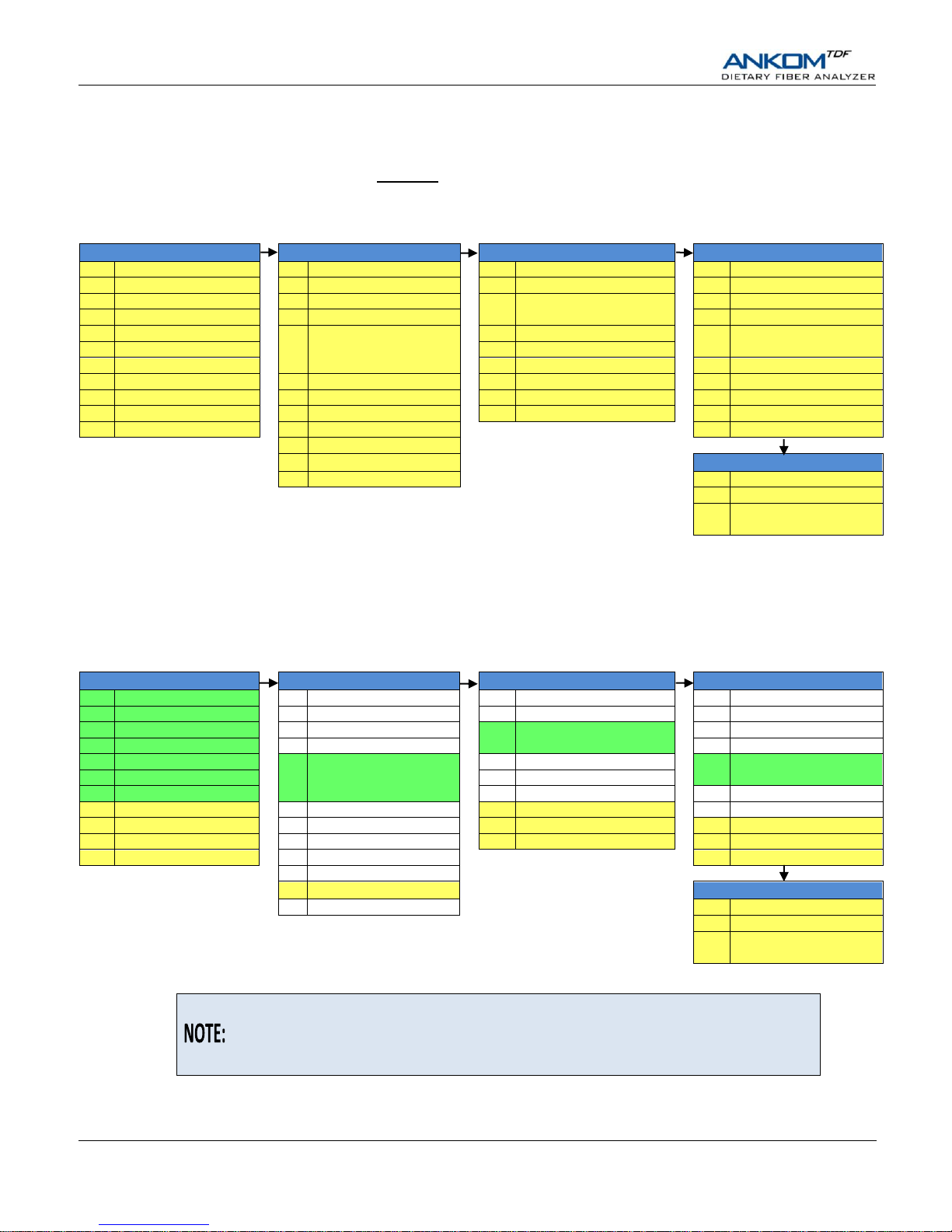

Instrument Description

The ANKOM

TDF

Dietary Fiber Analyzer is designed to efficiently, accurately, and precisely recover Insoluble Dietary Fiber

(IDF), Soluble Dietary Fiber (SDF), and Total Dietary Fiber (TDF) residue from food and/or feed samples in accordance with

the AOAC 991.43, AOAC 985.29, AOAC 2001.03, AACC 32-07.01, and NMKL 129, 2003 methods.

Contact ANKOM Technology about an upgrade to Total Integrated Dietary Fiber

(AOAC 2009.01 and 2011.25 methods). See the Diagnostics section of this

document for instructions on how to enable these methods.

Enabled by Filter Bag Technology, the instrument can run six digestion and six precipitation processes at the same time. The

filter bags are designed to capture the appropriate fiber particles while allowing all non-fiber components to pass through. The

instrument will use IDF bags and SDF bags when configured to recover IDF and SDF residue. The instrument will use IDF

Flow-Thru bags and SDF bags when configured to recover TDF residue.

The automated fiber recovery is achieved by first digesting samples within bags using enzyme treatments. Depending on the

filter bag configuration, the instrument then collects the IDF and SDF residue using two separate filters, or collects the TDF

residue using one filter. Once captured in the filters the residue is dried, weighed, and corrected for protein and ash content to

determine the IDF, SDF, and/or TDF values.

Digestion, precipitation, rinse (H2O and EtOH), and filter operations are performed by the instrument, eliminating manual

transfer and filtration steps. An on-board computer precisely controls process temperatures, agitation, and fluid delivery along

with digestion, precipitation, and filtration times.

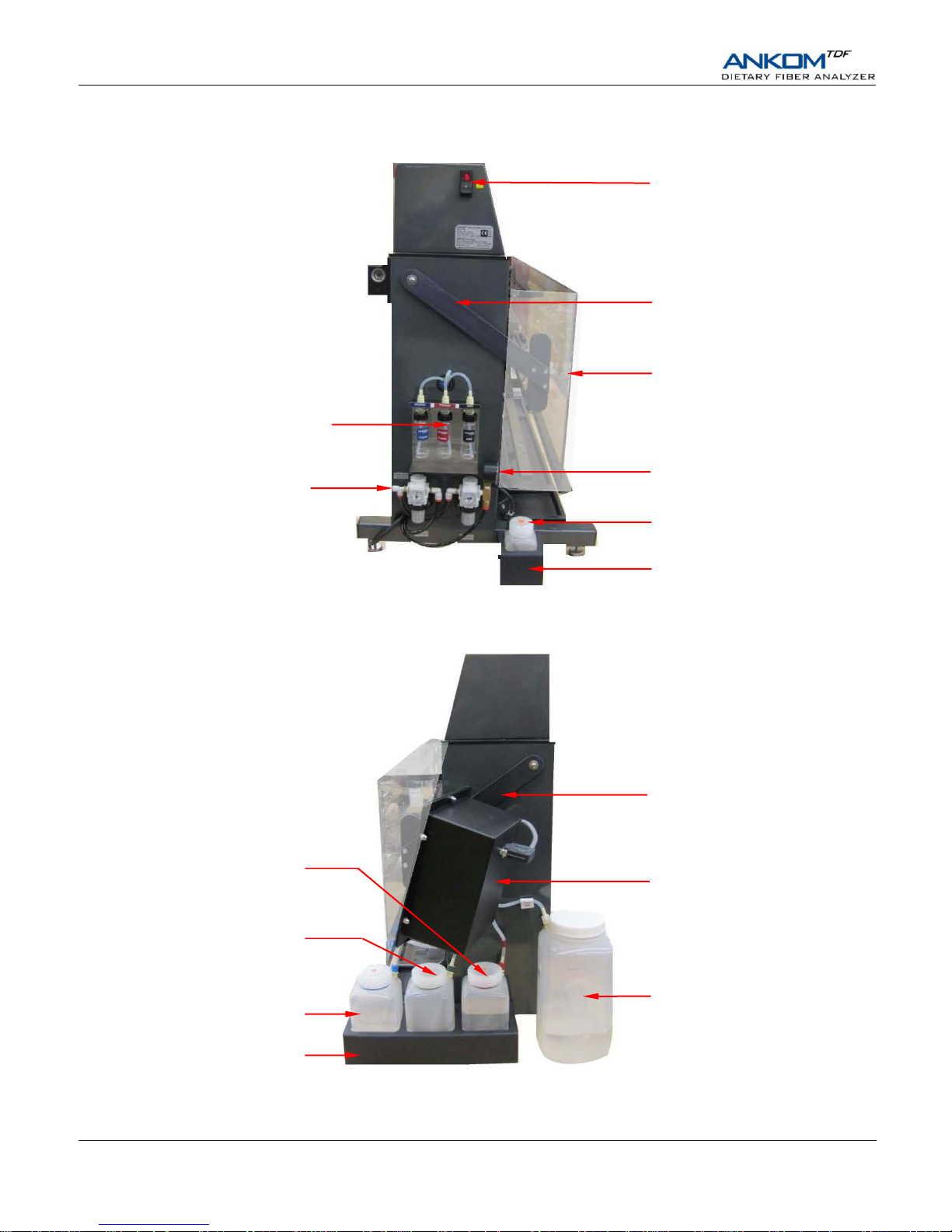

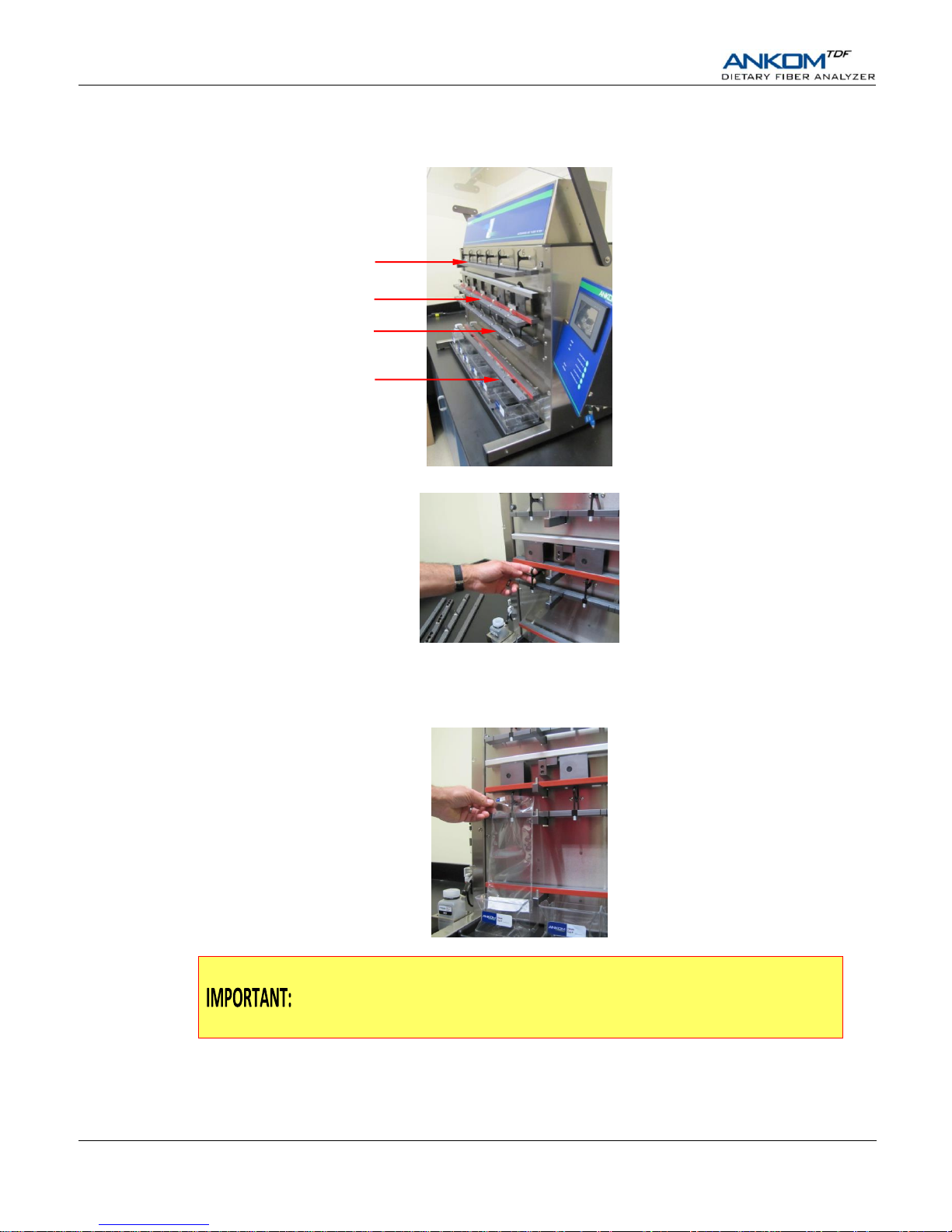

External Components – Front View

Touch

Screen

Display

Filtrate Cup

(TDF53 - #1 of 6)

Waste Tray

IDF Station (#4 of 6)

SDF Delivery

Nozzle

(#1 of 6)

Clamp Bar A

Clamp Bar B

Control

Buttons

Hook for SDF Bag

(#3 of 6)

IDF Delivery

Nozzle

(#1 of 6)

Control Panel (TDF17)

Clamp Bar D

Clamp Bar C

SDF Station (#6 of 6)

Heating Paddle (#1 of 6)

Mixing Pad

(#2 of 6)

Service Access

Screw #1

Service Access Screw #2

Front Cover

(In UP position)

Pressure Gauge

Page 8

Operator’s Manual

pg. 8 Rev 9/20/18

External Components – Left Side View

External Components – Right Side View

Control Panel (TDF17)

95% EtOH Container (TDF42)

HCl Container (TDF38)

Enzyme Containers

(TDF35, TDF36, TDF37)

Nitrogen Supply Port

80-100 psi

(5.5-6.9 bar)

Front Cover Arm

Power Switch

Front Cover (TDF56)

78% EtOH Container (TDF41)

Buffer Container (TDF39)

Distilled Water Container (TDF40)

Front Cover Arm

Three Container Holder

Single Container Holder

Pressure Gauge

Page 9

Operator’s Manual

Rev 9/20/18 pg. 9

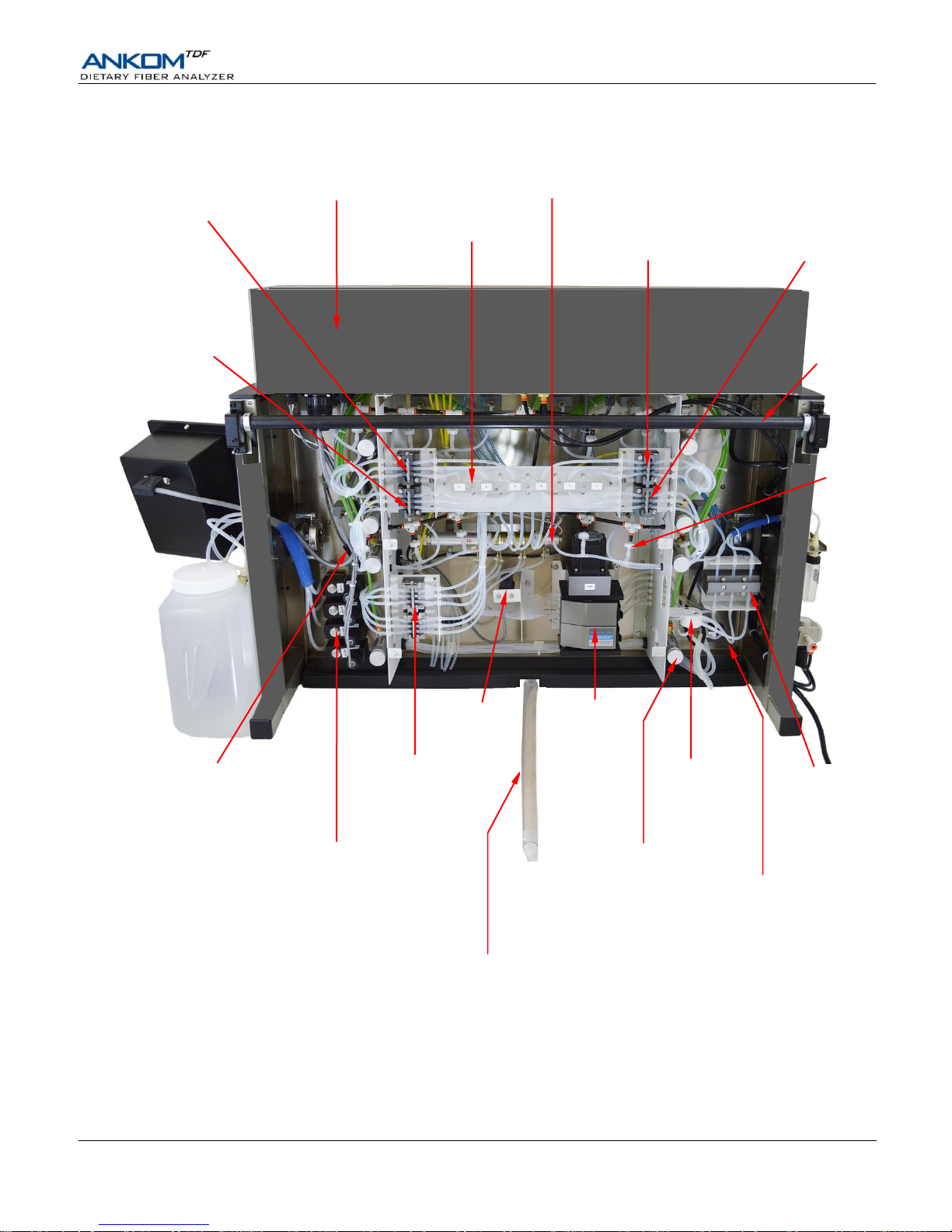

Internal Components – Rear View

N2

Check Valve

(1 of 12)

Main Electrical Cabinet

IDF Inlet Valve

Stations 4, 5 & 6

SDF Inlet Valve

Stations 4, 5 & 6

In-Line Heater

Tubing Support Panel

IDF Inlet Valve

Stations 1, 2 & 3

SDF Inlet Valve

Stations 1, 2 & 3

Waste Valves

(1 – 6)

Supply Valves

− Water

− Buffer

− 78% EtOH

− 95% EtOH

Vacuum Sensor

Supply

Manifold

Clamp Bar Cylinder

(1 of 8)

HCl

Supply Valve

Peristaltic

Pump

Pressure

Sensors

Drain Tube

Supply Valves

− Amylase

− Protease

− AMG

Torsion Bar (for

Front Cover)

Page 10

Operator’s Manual

pg. 10 Rev 9/20/18

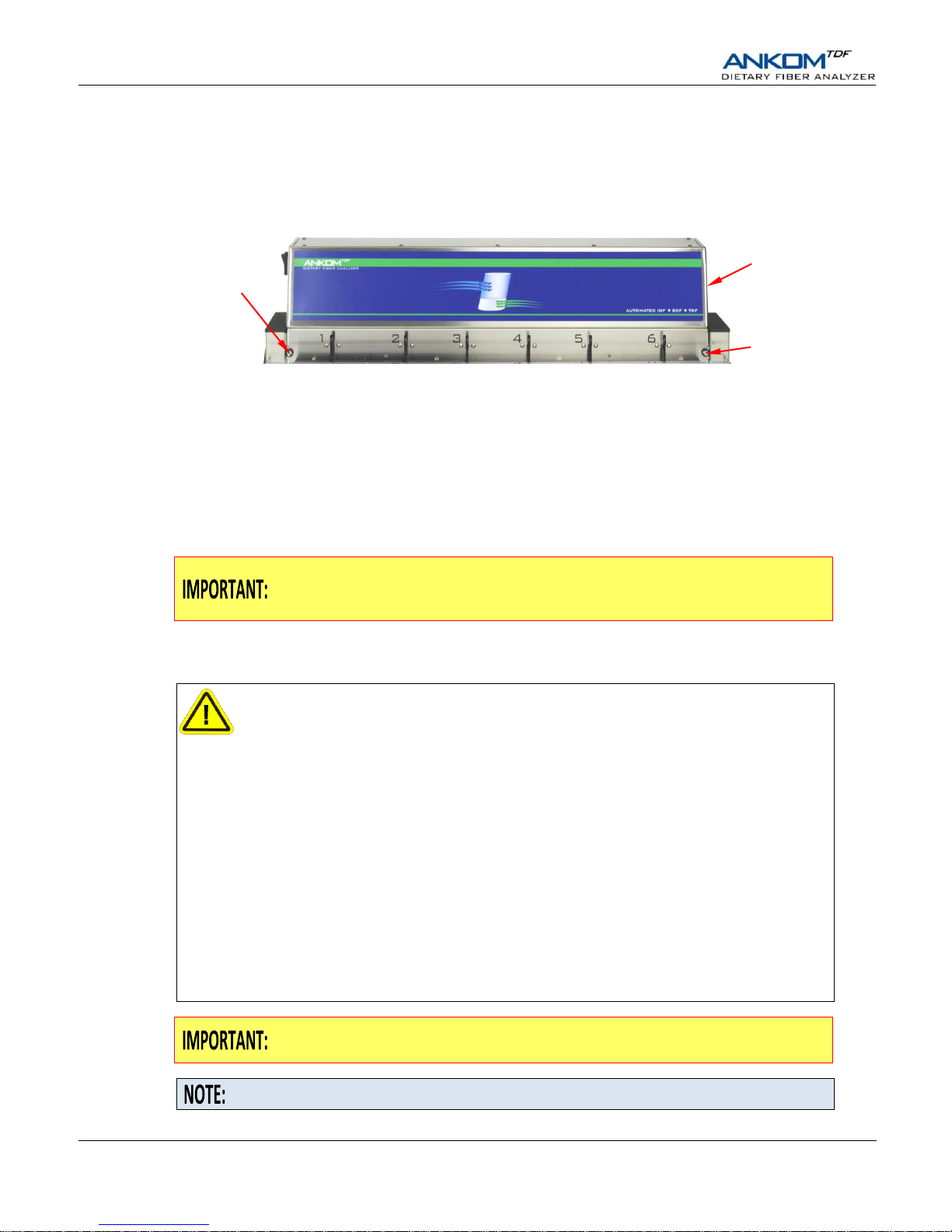

Service Access Position

If your instrument must be located in such a way as to restrict access to the back, you can tilt it forward to access the rear of the

instrument by removing the two Service Access Screws on the front of the instrument and gently pulling the top of the Main

Electrical Cabinet forward and down. The instrument will pivot at its center.

Operating Environment

Your ANKOM

TDF

Dietary Fiber Analyzer is designed to operate within the following environments:

• Ambient Temperature Range: 19°−30°C

• Humidity: 20–60% RH

• Power: 100V−120V ~ 50/60Hz 15A

220V−240V ~ 50/60Hz 8A

If after running this instrument you plan to leave it unused for 1 week or longer, you

must clear out the fluid lines to ensure proper operation. See “Appendix B –

Instrument Out-of-use Procedure” for more information.

Safety Precautions

Hot Surfaces – Do NOT touch the Heating Paddle surfaces during operation. The

surface can exceed 100°C (212°F). Failure to observe this caution may result in

burns.

Hazardous Voltages – Do NOT operate the instrument with the back of the Main

Electrical Cabinet removed. Hazardous voltages are present during operation. Failure

to observe this caution may result in electrical shock or electrocution.

Hazardous Materials – Ethanol is used within this instrument. Follow both local

and federal regulations for vent hood requirements when operating this instrument.

Do NOT heat seal or place filter bags in an oven until all acetone has evaporated.

Failure to observe this caution may be hazardous to your health.

WARNING: Attempts to override safety features or to use this instrument in a

manner not specified by ANKOM Technology voids the warranty and may result in

serious injury or even death.

This system is designed to meet and/or exceed the applicable standards of CE and

CSA.

The Power Switch must be in the OFF position before plugging the instrument Power

Cord into the power source.

Please review the entire manual before you begin operating this instrument.

Service Access

Screw #1

Service Access

Screw #2

Main Electrical

Cabinet

Page 11

Operator’s Manual

Rev 9/20/18 pg. 11

Instrument Installation

Site Requirements

To install and operate the ANKOM

TDF

Dietary Fiber Analyzer you will need the following:

• Adequate power (see “Operating Environment” section of this manual)

• Drain or waste container to capture waste fluids

• Bench space that can accommodate the instrument dimensions of 132 cm (52”) L x 92 cm (35”) H x 77 cm (30”) D

• 80-100 psi (5.5-6.9 bar) Nitrogen Supply and connection tubing

Because the instrument is powered by pneumatics, do NOT run it without an

adequate Nitrogen Supply. You can run approximately 5 to 10 full assays

(IDF/SDF or TDF) with a 304 cu ft tank of nitrogen.

Instrument Installation Procedure

To install the ANKOM

TDF

Dietary Fiber Analyzer, follow the steps below.

1. Unpack and place the instrument where it will be used.

The instrument shipping container consists of three separate cardboard pieces: a top, a bottom, and a sleeve that forms the

body of the container. Remove the top and the sleeve of the instrument shipping container. Lift the instrument off of the

shipping container bottom and place it on a surface that is firm and level in an area near a Nitrogen Supply and a drain or

chemical waste container.

Waste fluids are drained from the instrument using gravity. Therefore, position the

instrument so that the drain tube can run down from the Waste Tray.

The instrument must not be subjected to excessive shock, vibration, dirt, moisture, oil, or other fluids.

Ethanol is used within this instrument. Follow both local and federal regulations for

vent hood requirements when installing this instrument.

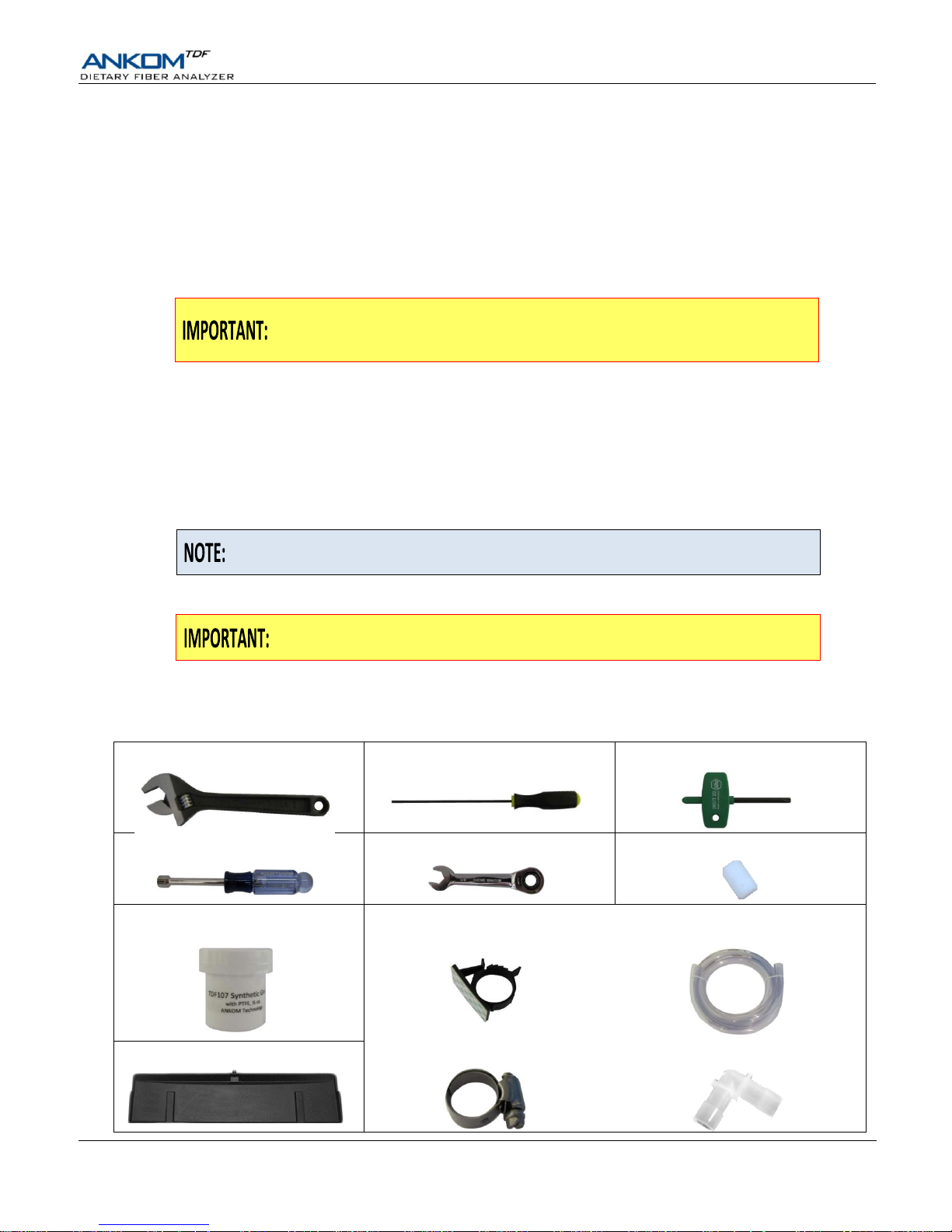

2. Unpack the attachments and accessories.

Within the shipping container is a cardboard box containing attachments and accessories. Open the box and verify that all

of the following items are there.

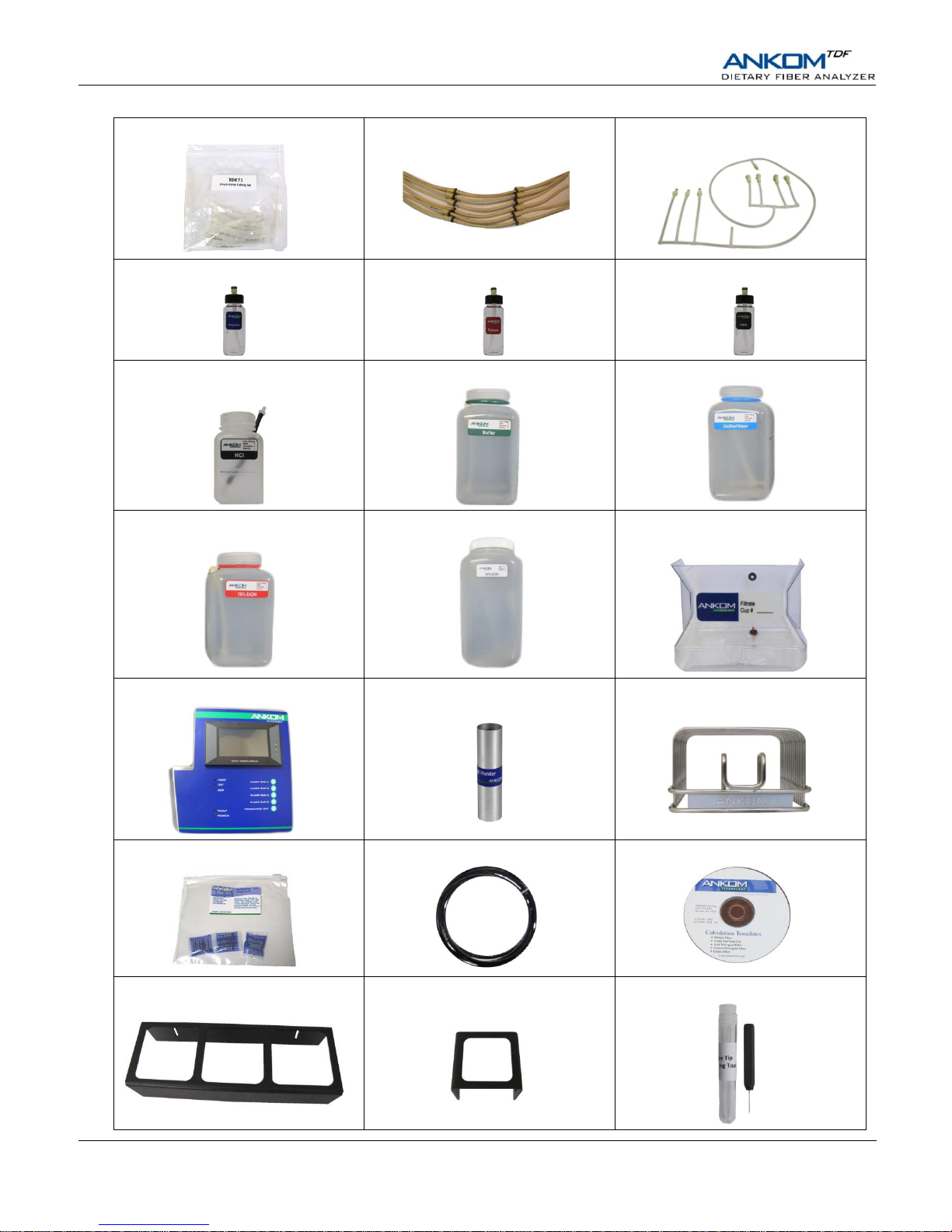

1 – Crescent Wrench (204.9)

1 – 1/8” Allen Wrench (Z303)

1 – T-Handle Torx T20 Driver (Z276)

1 – 3/8” Nut Driver (8416)

1 – 3/8” wrench (8418)

2 – Spray Tips (TDF44)

1 - TDF Synthetic Grease (TDF107)

1 – Drain Hose Assembly (TDF96) that includes these five parts

1 - Adhesive Clamp (8133) 1 – Drain Tube (8132)

1 – Drain Tray (8002)

1 – Drain Tube Clamp (6138)

2 – Drain Tube Elbow Connectors (8288)

Page 12

Operator’s Manual

pg. 12 Rev 9/20/18

1 – Pinch Valve Tubing Set (TDF71)

1 – Long Life Pump Tube Set (TDF99)

1 - Line Flush Tubing assy (TDF70)

1 – Amylase Container assy (TDF35)

1 – Protease Container assy (TDF36)

1 – AMG Container assy (TDF37)

1 – HCl Container assy (TDF38)

1 – Mes-Tris Buffer Container assy (TDF39)

1 – Distilled Water Container assy (TDF40)

1 – 78% EtOH Container assy (TDF41)

1 – 95% EtOH Container assy (TDF42)

6 – Filtrate Cups (TDF53)

1 – Control Panel assy (TDF17)

1 – Bag Weigh Holder assy (TDF52)

1 – Drying Rack assy (TDF50)

2 – Desiccant Pouches (X45)

1 – 3 meter Air Tube (8216)

1 – CD with Calculation Templates

1 – three container holder (8191)

1 – single container holder (8192)

1 – Spray Tip Cleaning Tool Kit (TDF94)

Page 13

Operator’s Manual

Rev 9/20/18 pg. 13

2 – Container Filters (8202)

1 – Buffer Filter (8203)

4 – Bolts (5626)

4 – Nuts with star washers (167)

4 – Acorn Nuts (8409)

1 – Lighted Magnifier (TDF45)

2 – Fuses (8305-15A or 8306-8A)

Accessories specific to the 2009.11 & 2011.25 method upgrades can be found in

the "Automated AOAC 2009.01/2011.25 and AACC 32-45.01 method" addendum.

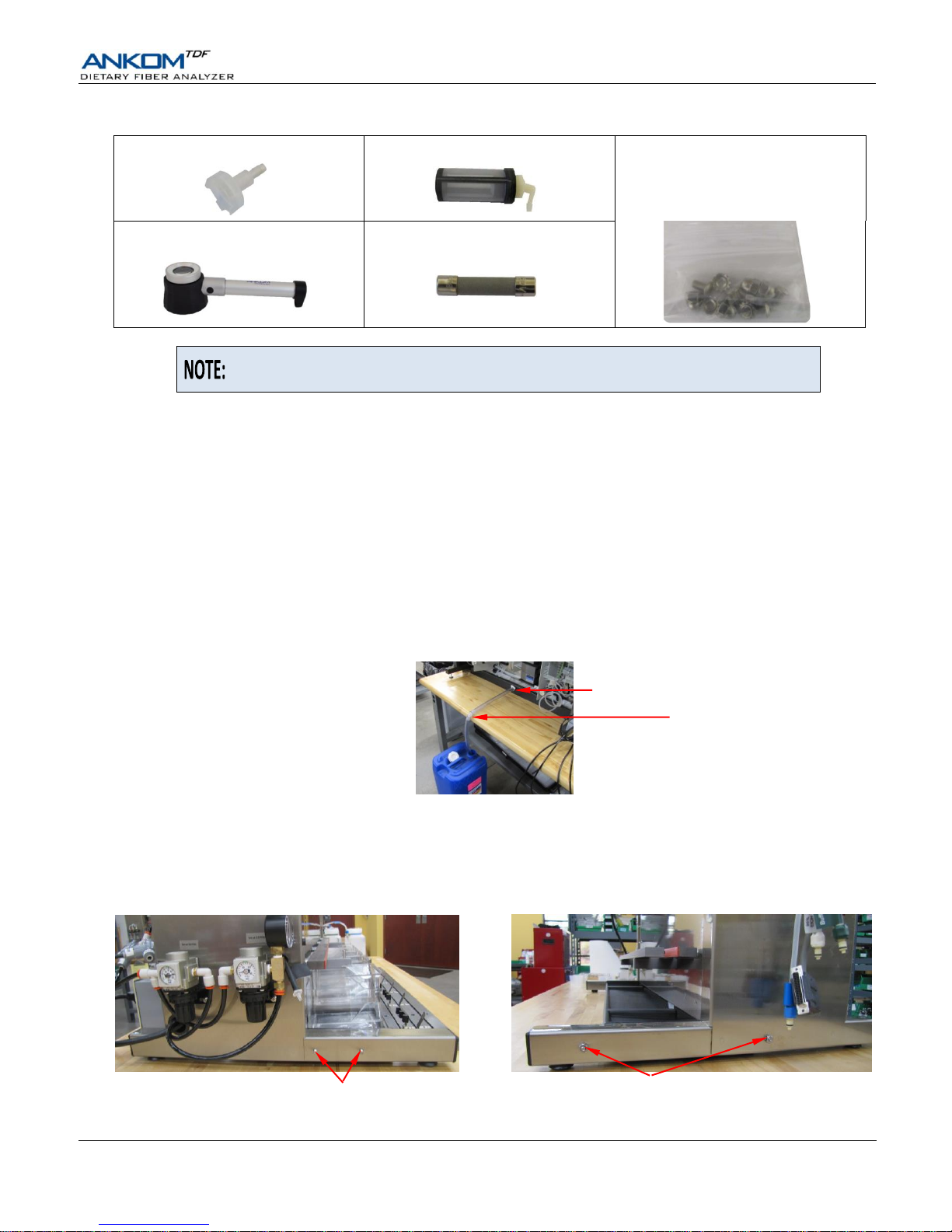

3. Place the Waste Tray under the front of the instrument.

With the Drain Tube connector pointing away from you, slide the tray under the front of the instrument until it cannot go

back any farther. (When the tray is in place, the side ridges will contact the front face of the steel frame.)

4. Place the six Filtrate Cups on the Waste Tray.

If filtrate collection is required for further analysis, leave the red plug in the lower port near the bottom of each of the

filtrate cups. If filtrate collection is not needed, keep the filtrate cups in place on the drain tray. However, the red plug can

be pulled from the lower port to drain the filtrate into the drain tray. Store the plug in the upper port.

5. Connect the Drain Tube to the Waste Tray.

Connect and secure the Drain Tube to the Waste Tray using the supplied Drain Tube Clamp. Run it to either a drain or a

waste container, avoiding twists in the tube. If necessary cut the Drain Tube and use the Elbow Connectors to meet the

needs of your location.

As needed, place the Adhesive Clamp (8133) between the Drain Tube Clamp and the Elbow Connector to create the

appropriate tube slope for good fluid flow.

6. Connect the Chemical Container Holders to the feet of the instrument.

Remove the nuts from the outside of the left and right feet of the instrument. Slide the single container holder onto the

bolts on the left foot and the three container holder onto the bolts on the right foot. Secure the holders using the nuts.

Bolts to attach the

three container holder

Bolts to attach the

single container holder

Elbow Connector

Drain Tube Clamp

Page 14

Operator’s Manual

pg. 14 Rev 9/20/18

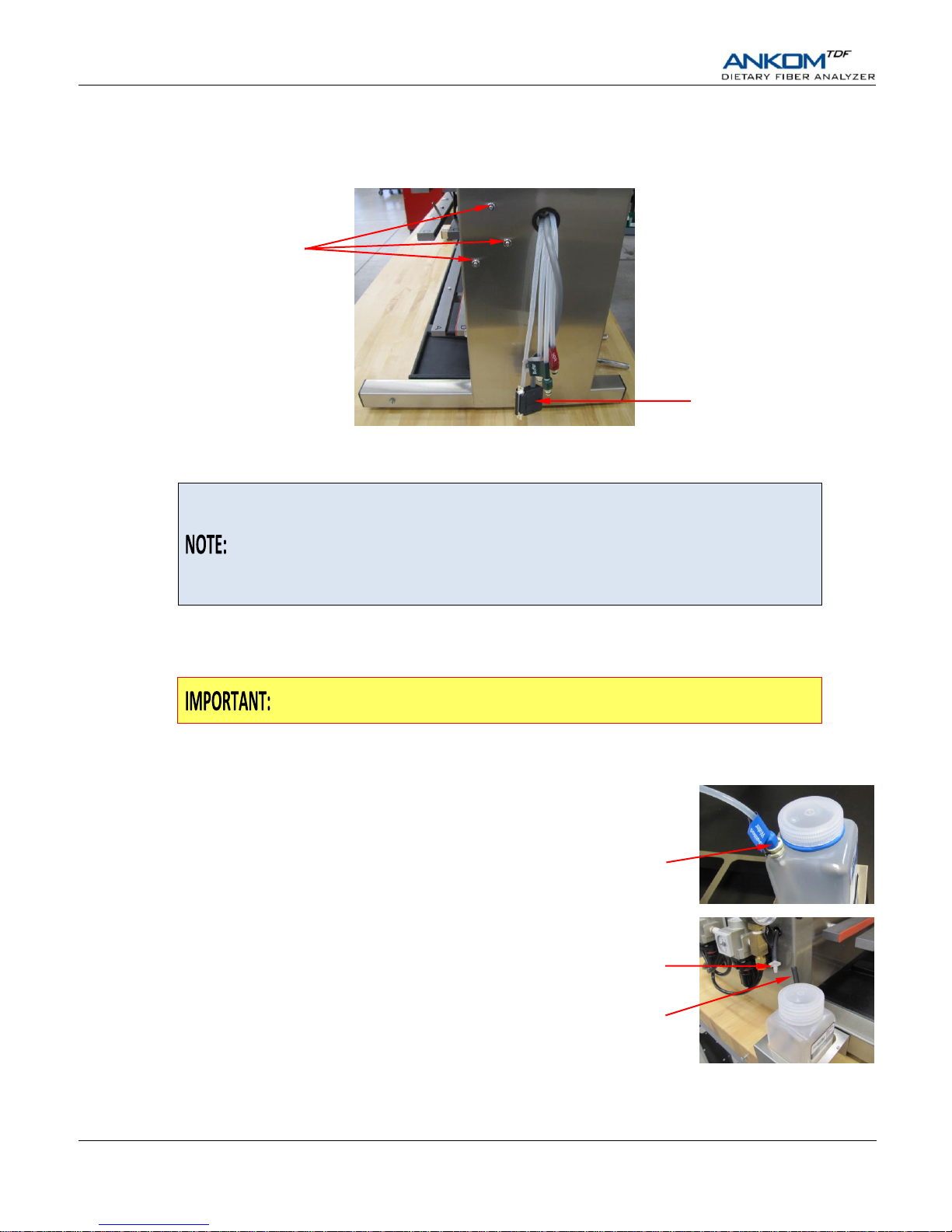

7. Connect the Control Panel to the instrument.

Remove the nuts from the right side of the instrument. Connect the 25 pin connector from the instrument to the Control

Panel. Slide the Control Panel onto the bolts and secure it in place using the nuts.

8. Place the Chemical Containers in their holders.

If you are going to run an IDF/SDF or TDF analysis immediately after installing

the instrument, fill the Chemical Containers above the Minimum Level lines and

fill the Enzyme Containers with at least 15 ml of solution before connecting the

containers to the instrument. See Appendix A for the chemical preparations.

Do NOT fill the Chemical and Enzyme Containers if the instrument is going to sit

unused after installation.

Place the HCl Container in the holder on the left side of the instrument. In the holder on the right side of the instrument,

place the Distilled Water Container in the front section, the Buffer Container in the middle section, and the 78% EtOH

Container in the back section. The 95% EtOH Container sits on the bench behind the container holder.

To ensure proper fluid delivery, you must use the Chemical Containers provided

with the instrument and place them in their specified locations.

9. Connect the Chemical Containers to the corresponding tubes.

The Chemical Containers and associated tubes are all

labeled and color-coded for easy connection. The large

containers on the right side of the instrument also have

push-on connectors. Make sure that you hear a click

sound when you connect the tubes to the containers.

On the left side of the instrument is a black tube with an

HCl label that has a white barbed fitting on its end. Push

the white barbed fitting into the black tube connected to

the HCl container.

Push-on

Connector

Bolts for

Control Panel

25 pin connector

Barbed

Fitting

Black tube connected

to HCl container

Page 15

Operator’s Manual

Rev 9/20/18 pg. 15

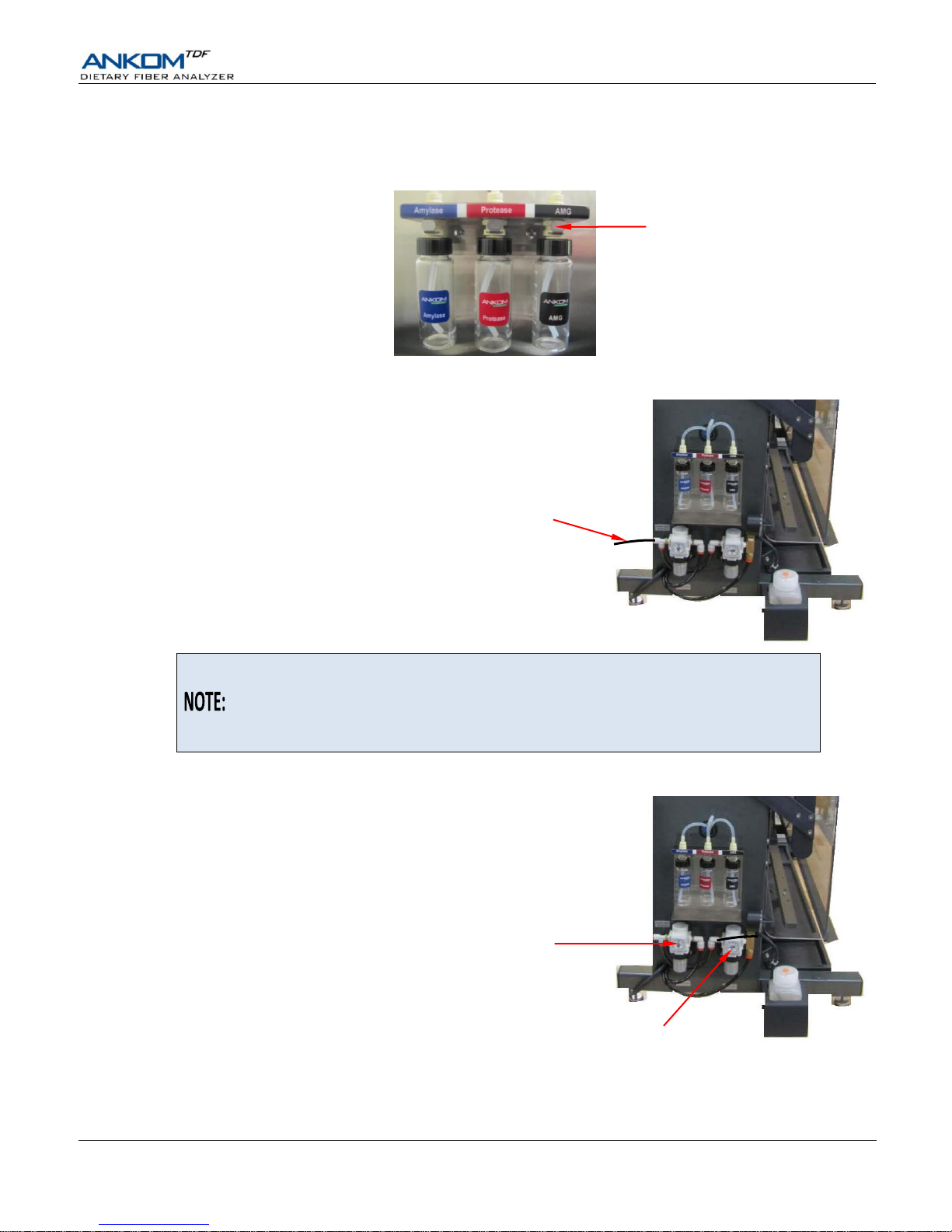

10. Connect the Enzyme Containers to the corresponding ports.

The Enzyme Containers connect into labeled, color-coded ports on the left side of the instrument using push-on

connectors. Make sure that you hear a click sound when you connect the enzyme containers to the ports.

11. Connect the Nitrogen Supply to the Nitrogen Supply Port.

Connect the 3 meter Air Tube (8216) that came with the

instrument to the Nitrogen Supply Port on the instrument

and to the Nitrogen Supply.

If you want to use a separate tube to connect your instrument to a Nitrogen Supply,

the Nitrogen Supply Port has a Push-to-Connect fitting that accepts ¼” OD tubing.

Acceptable tubing materials include Nylon, Polyurethane, Polyolefin, and

Polytetrafluoroethylene (PTFE). The tubing material must be suitable for the

specified pressure.

12. Verify that the High and Low Pressure Regulators are set properly.

Verify that the High Pressure Regulator is set to 50 psi (3.5 bar), and the

Low Pressure Regulator is set to 4-6 psi (0.3-0.4 bar).

Push-on

Connector

Nitrogen Supply Port

80-100 psi

(5.5-6.9 bar)

High Pressure Regulator

50 psi

(3.5 bar)

Low Pressure Regulator

4-6 psi

(0.3-0.4 bar)

Page 16

Operator’s Manual

pg. 16 Rev 9/20/18

Dietary Fiber Analysis Support Items

The following support items needed to perform the fiber analysis may be purchased separately:

Item

ANKOM Part #

Electronic Balance with four-place readout

TB

Electronic Balance Software

TBS

Heat Sealer for sealing the filter bags

HS (120V), HSi (220V)

IDF Filter Bags

DF-I

SDF Filter Bags (used for SDF and TDF procedures)

DF-S

IDF Flow-Thru Bags (TDF procedure only)

DF-FT

Solvent Resistant Marker

F06

Rinse Stand

TDF51

Diatomaceous Earth (DE)

DE1, DE2

Drying Oven

Ashing Oven

Protein Determination Equipment (Kjeldahl is recommended)

Analysis Options using the ANKOM

TDF

Dietary Fiber Analyzer

The ANKOM

TDF

Dietary Fiber Analyzer can be configured to recover IDF and SDF residue, or to recover TDF residue. The

following describes these analyses along with their specific filter bag configurations.

Analysis Name

Analysis Description

Upper Bag

Lower Bag

IDF/SDF

(991.43)

This analysis is used to determine IDF and SDF residue separately

using two different filter bags. TDF is calculated by adding the IDF

and SDF residue weights corrected for protein and ash content.

IDF

SDF

TDF

(991.43, 985.29 &

2001.03)

This analysis is used to determine TDF residue in one filter. In this

analysis, the TDF value consists of the weighed residue corrected

for protein and ash.

IDF Flow-Thru

(no filter)

SDF

A computer controlled Diagnostics mode is provided through the Control Panel for maintenance and troubleshooting purposes.

To maximize productivity, this instrument also allows a user to start new procedures (IDF/SDF and TDF) before the previous

ones have completed. See the “Productivity Enhancement” section of this manual for details.

Contact ANKOM about an upgrade to Total Integrated Dietary Fiber (AOAC

2009.01 and 2011.25 methods). See the Diagnostics section of this document for

instructions on how to enable these methods.

Blanks

BLANK values are used in the IDF, SDF, and TDF calculations. The following BLANK values (based on extensive research

done in the ANKOM lab) are the default values loaded in the IDF_SDF and TDF spreadsheets in the MS-Excel workbook

provided with the instrument.

IDF (AOAC 991.43 method): -0.0072 TDF (AOAC 991.43 method): -0.0047

SDF (AOAC 991.43 method): -0.0030 TDF (AOAC 985.29 method): -0.0028

You do not need to run BLANKS with every set of samples. However, if you want to determine your own BLANK values,

especially when you change chemical lots, ANKOM recommends that the BLANK value in the IDF, SDF, and TDF

calculations be the average of at least 18 BLANK values.

If you determine your own BLANK values, you can overwrite the values currently in the MS-Excel spreadsheets.

Page 17

Operator’s Manual

Rev 9/20/18 pg. 17

IDF/SDF Analysis

An IDF/SDF analysis measures the amount of IDF and SDF within a given sample. This requires the use of ANKOM DF-I and

DF-S filter bags. When starting a new run, the ANKOM

TDF

Dietary Fiber Analyzer must have bags installed at all stations (a

total of twelve bags).

To enhance the productivity of your instrument, you can begin the IDF process of a

new run while the SDF process of a previous run is finishing. See the “Productivity

Enhancement” section of this manual for more details.

To perform an IDF/SDF analysis, follow the steps below.

1. Prepare chemicals and enzymes.

When using the ANKOM

TDF

Dietary Fiber Analyzer for the AOAC 991.43, AACC 32-07.01, and NMKL 129,2003

methods use the chemicals and enzymes referred to therein. See Appendix A of this manual for the list of chemicals and

enzymes and the instructions for how to prepare them for use in this instrument.

2. De-fat your samples as needed according to the official methods. See "Appendix C – De-fatting

Procedure" in this manual for an ANKOM procedure.

3. Label the filter bags using a Solvent Resistant Marker.

4. Prepare for data collection.

You will need a place to store the data collected during this analysis. For your convenience a CD titled “Calculation

Templates” was included with the instrument. This CD has data spreadsheets that can be used for this analysis. Please

read the “Instructions” tab in the MS-Excel file for information about the spreadsheets.

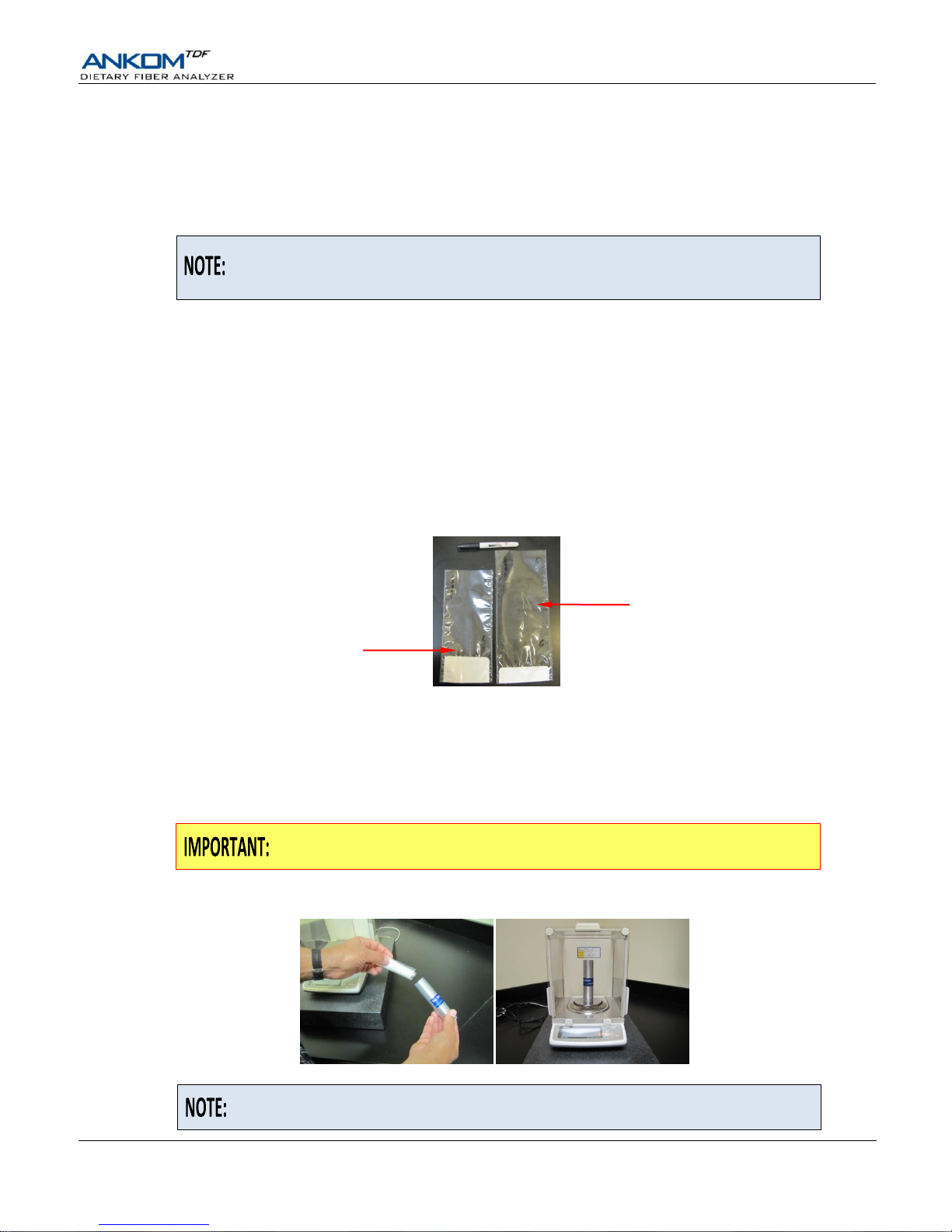

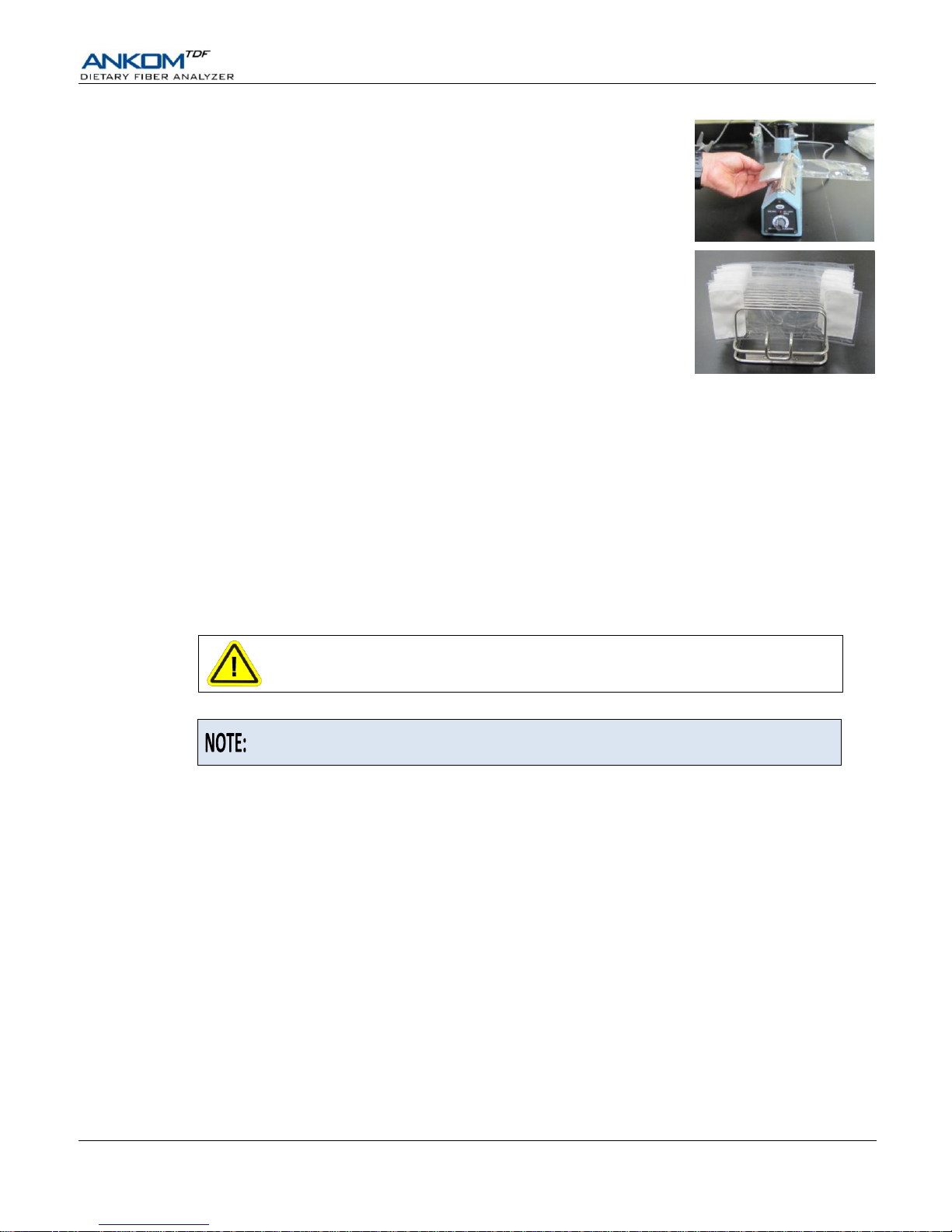

5. Weigh filter bags.

Using a Bag Weigh Holder is critical to eliminate the effects of static electricity

during the weighing process.

Roll or fold each bag and place it in a tared Bag Weigh Holder. Place the Bag Weigh Holder in the center of a balance

and record the weight.

Because different balances have different sensitivities, the Bag Weigh Holder

should be placed in the center of the balance for best results.

IDF Bag (shorter bag)

SDF Bag (longer bag)

Page 18

Operator’s Manual

pg. 18 Rev 9/20/18

6. Weigh Diatomaceous Earth (DE).

DE is used during fiber analysis to enhance the flocculation and filtration of the SDF fraction. Place ca 1 g of DE in each

of six tared and numbered tins and record the weights.

7. Weigh Samples.

Place 0.50.05 g of sample in each of six tared and numbered tins and record the weights.

A larger sample (1.0 g) can be used if a larger aliquot is needed to improve

precision.

8. Turn the instrument power on.

When you turn the power on, the instrument will run through an initialization process and the Control Panel will turn on.

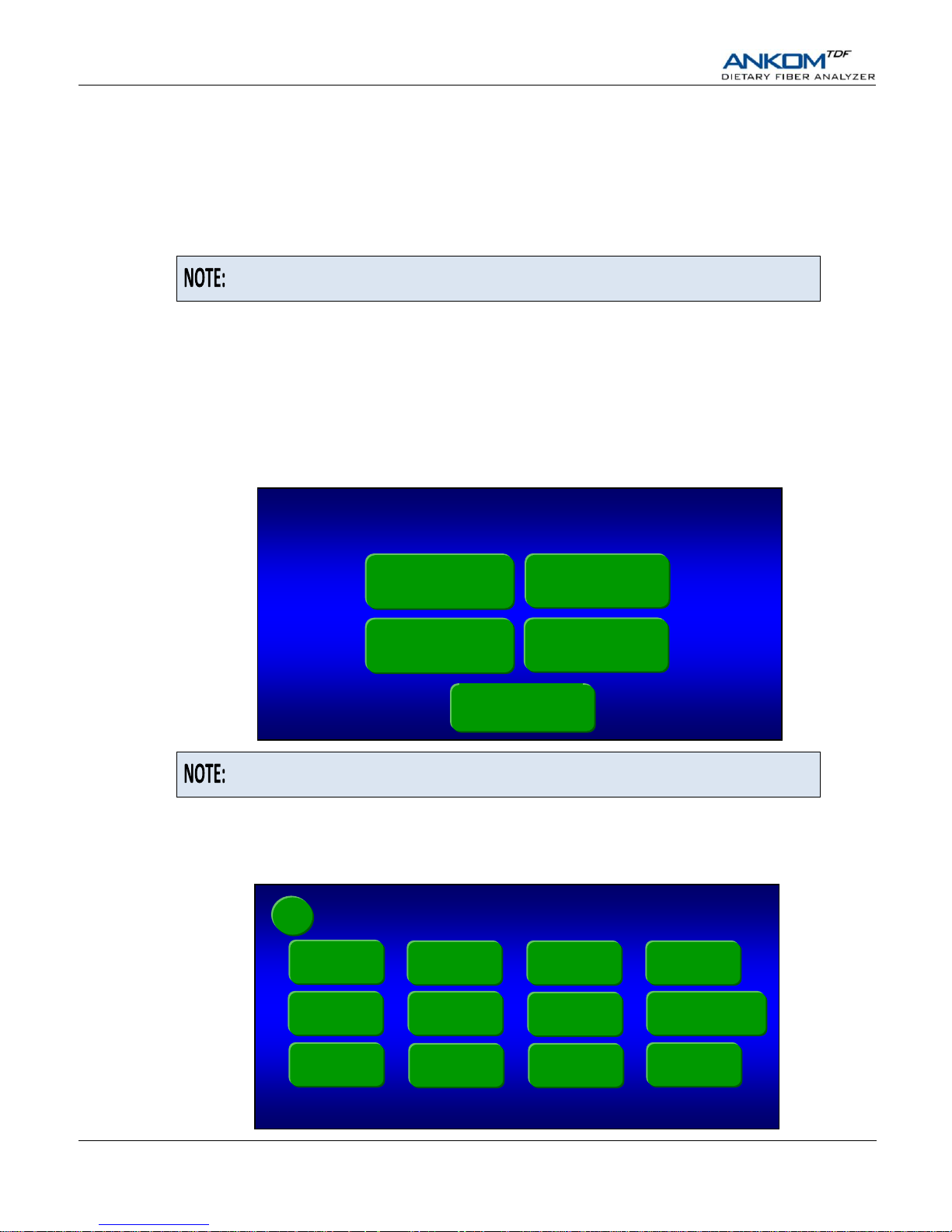

9. On the Touch Screen Display, select the instrument function you would like to perform.

The Control Panel on the ANKOM

TDF

Dietary Fiber Analyzer uses Touch Screen technology. To operate the instrument

you will press identified buttons on the Touch Screen Display and buttons below the screen.

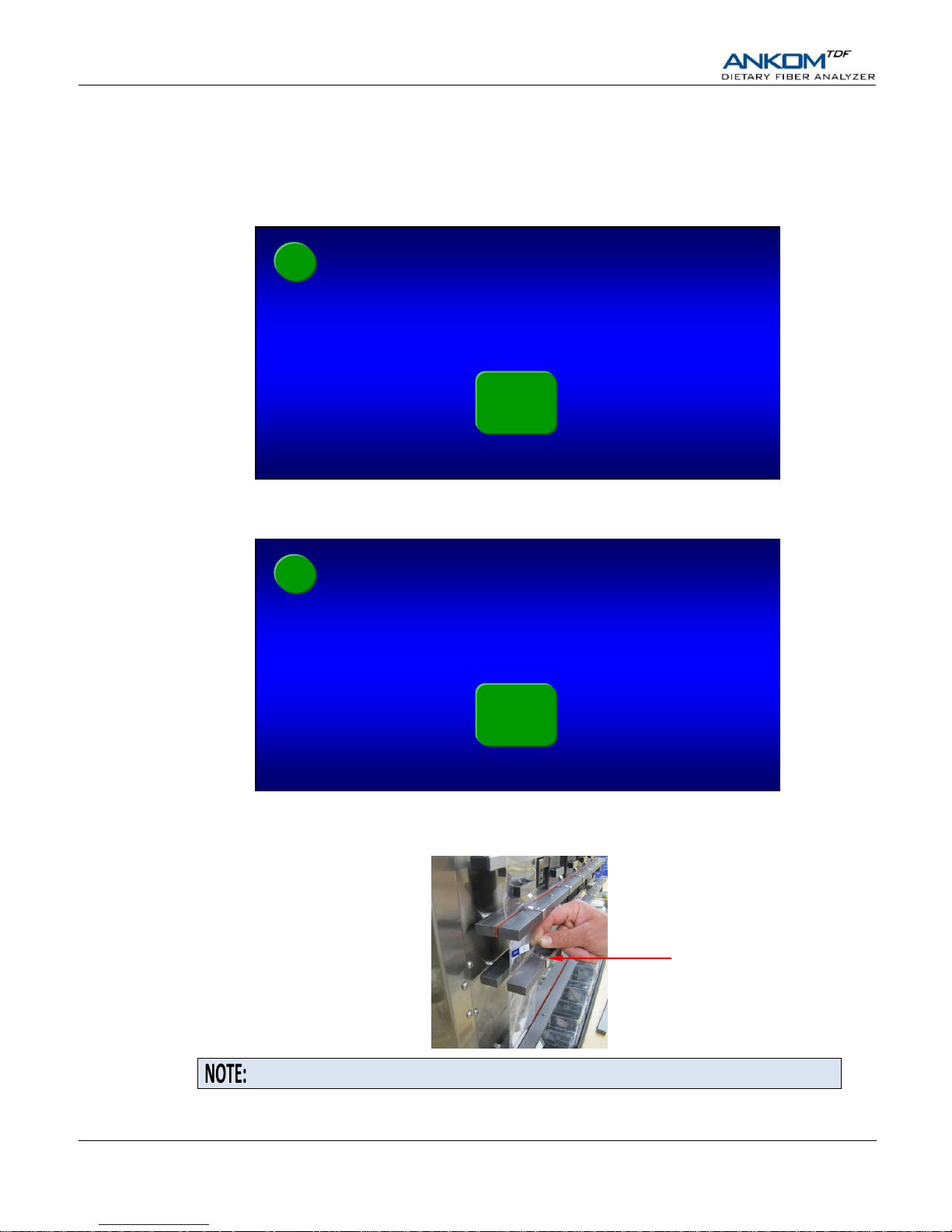

When your instrument is initialized and ready to operate, the following screen will be displayed.

Although the instrument works in accordance with AACC and NMKL methods, the

Touch Screen Display only refers to the AOAC methods.

9.1 If this is the first time the instrument is being operated after being installed, or after sitting unused for a period of

time (see Appendix B), or after tubing was replaced, the lines must be charged to avoid a Vacuum Sensor Fault.

To charge the lines follow the steps below.

9.1.1 Press the Diagnostics button on the “Select a Function” screen. The following screen will be displayed.

Diagnostics

Touch Screen Display version: A.AA

SPLat controller software version: vX.XX dd-mm-yy

Pump Tube

Test

Expert Mode

Faults

Service

Mode

Clear IDF /

SDF lines

Digestion

Times

Heater Test

Temperatures

Pressures

Line Charge

Motor Test

Valve Test

Select a Function

AOAC 991.43

IDF/SDF

AOAC 985.29

TDF

Diagnostics

AOAC 991.43

TDF

AOAC 2001.03

TDF

←

Page 19

Operator’s Manual

Rev 9/20/18 pg. 19

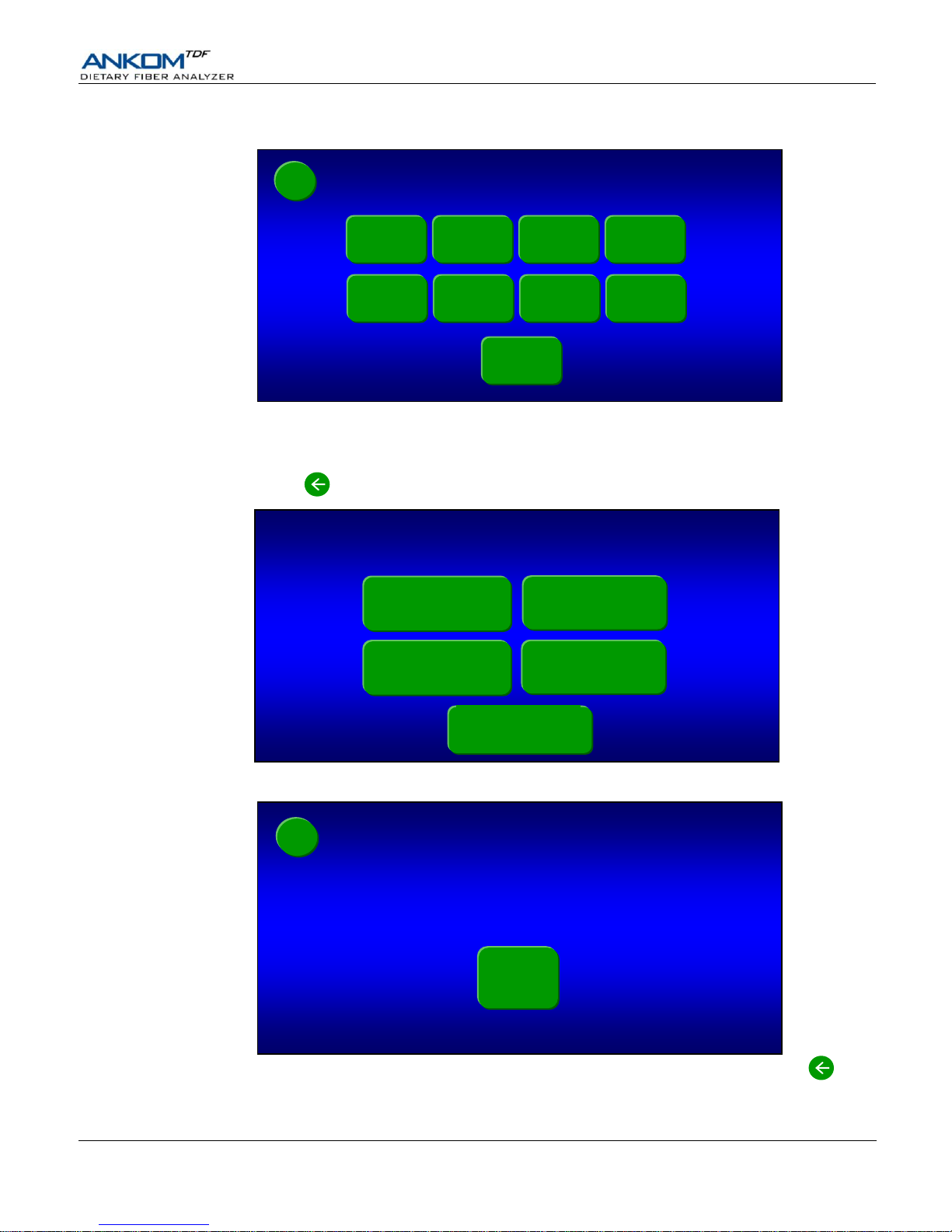

9.1.2 Press the Line Charge button. The following screen will be displayed.

9.1.3 Press the ALL button to charge all of the lines. Each button will change color as the associated line is being

charged. All lines are charged when all of the buttons return to their original green color.

9.1.4 Press the back button twice. The following “Select a Function” screen will be displayed again.

9.2 Press the AOAC 991.43 IDF/SDF button. The following screen will be displayed.

Notice that the function you selected is now displayed in the top right corner of the screen and a back button

is displayed in the top left corner of the screen.

SDF Bags (and clamp bar D) installed?

←

AOAC

991.43

IDF/SDF

Select a Function

AOAC 991.43

IDF/SDF

AOAC 985.29

TDF

Diagnostics

AOAC 991.43

TDF

AOAC 2001.03

TDF

Line Charge

Amylase

Protease

AMG

HCl

EtOH78

EtOH95

Water

Buffer

ALL

Vacuum xx.x

cur: - x.x

max: - x.x

←

Page 20

Operator’s Manual

pg. 20 Rev 9/20/18

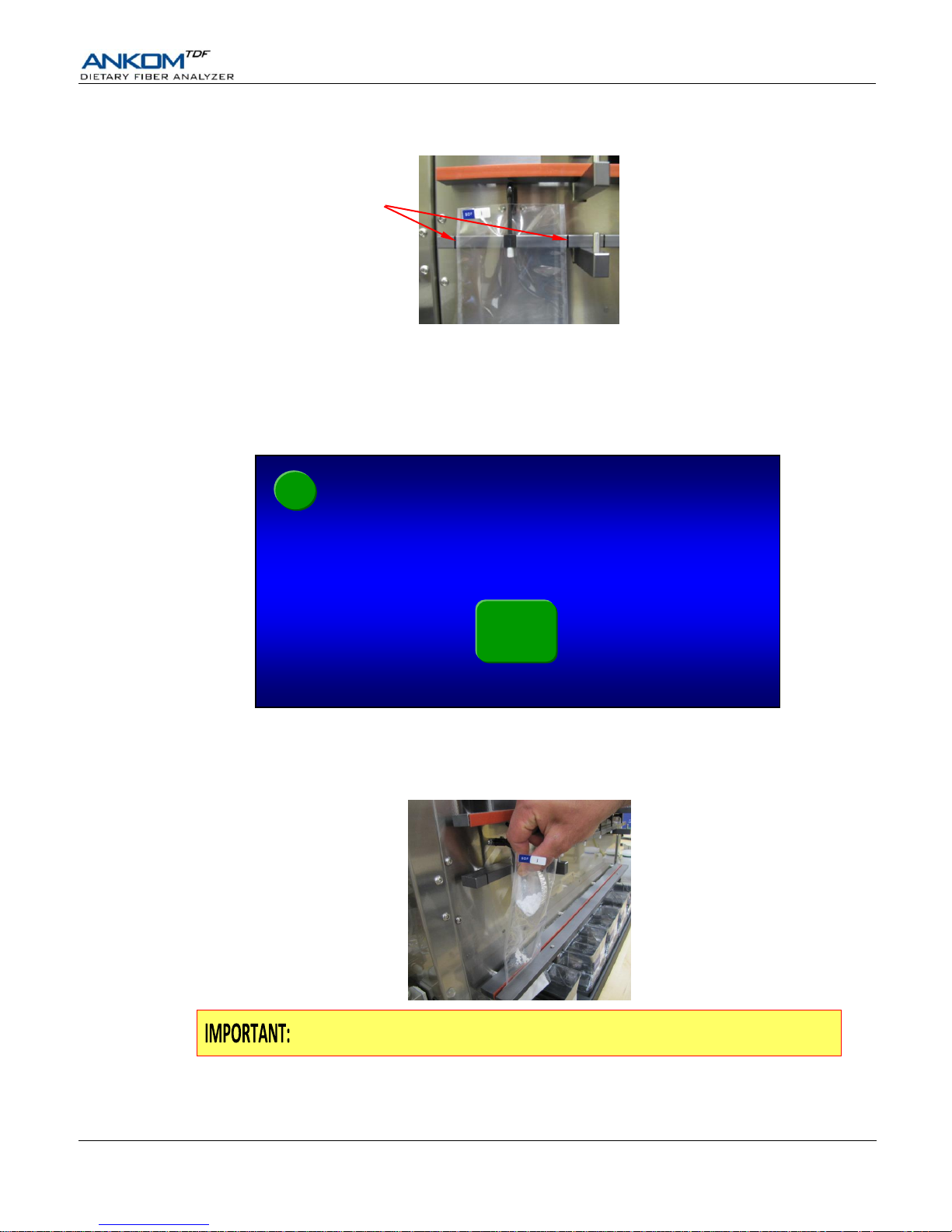

10. Install SDF filter bags on the ANKOM

TDF

Dietary Fiber Analyzer.

10.1 Remove Clamp Bars A, B, C, and D by lifting them off of the locator rods.

10.2 Gently pull the black SDF Delivery Nozzle out toward you.

10.3 Place a labeled and weighed SDF bag up underneath the SDF Delivery Nozzle so that the Delivery Nozzle is

inside the top part of the bag. Pull the bag up so that the top of the bag is about 35 mm (1.375 inches) above the

top of Clamp Bar C and return the Delivery Nozzle to its original position. This will hold the back of the bag in

place.

As part of normal operation, solution from the IDF bag will flow into the SDF bag.

Therefore, when installing the SDF filter bags it is very important to position them

high enough vertically so that at least 20 mm (0.75 inches) of the filter part of the

IDF bag can fit inside the top of the SDF bag.

Clamp Bar C

Clamp Bar D

Clamp Bar B

Clamp Bar A

Page 21

Operator’s Manual

Rev 9/20/18 pg. 21

10.4 With the bag being held by the Delivery Nozzle, center it horizontally between the lines on the back part of

Clamp Bar C.

10.5 Repeat steps 10.2 – 10.4 for all six stations.

10.6 Re-install Clamp Bar D by setting it on the locator rods. Make sure the letter is on the top of the bar and the

rubber material is facing in toward the instrument.

10.7 Flatten the bags to remove any wrinkles.

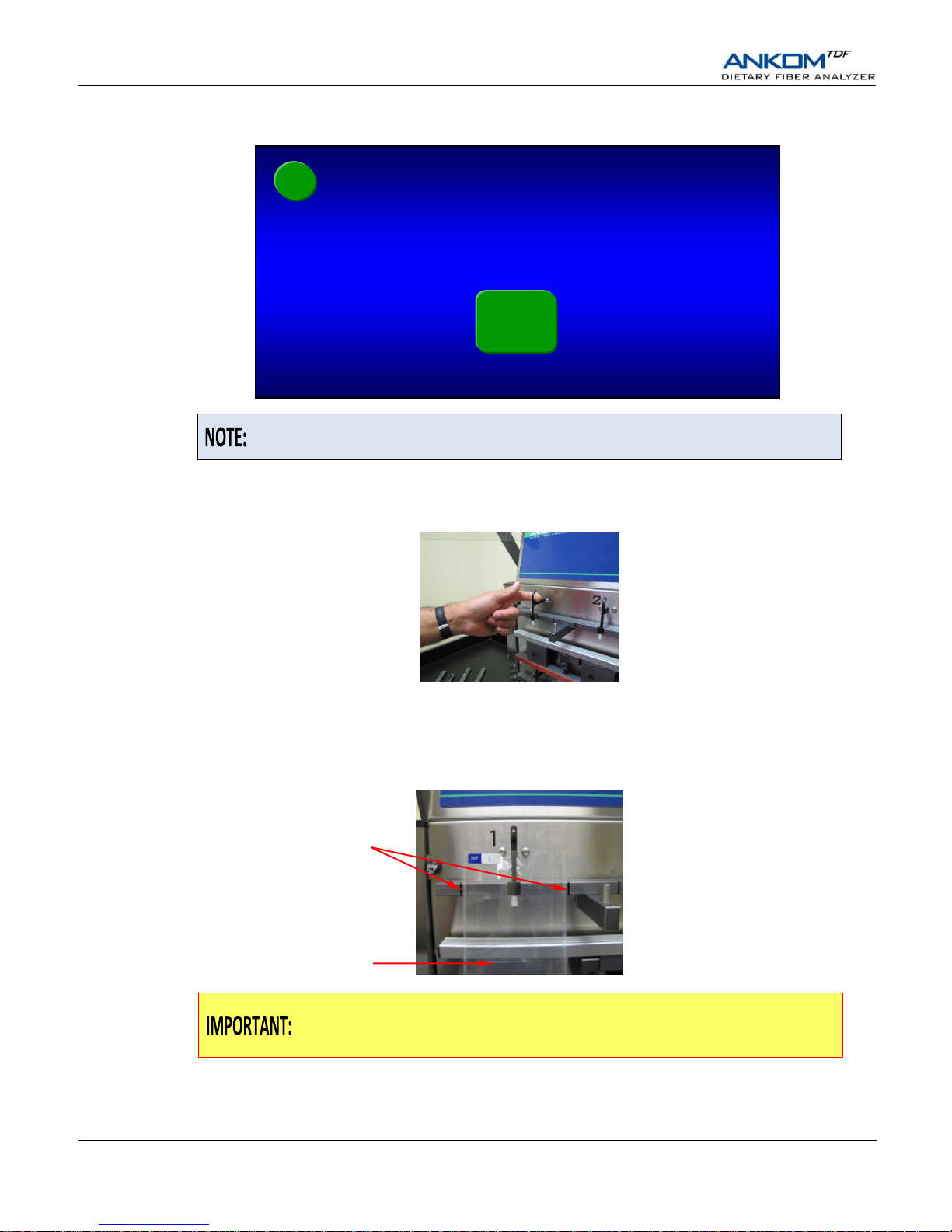

10.8 With fingers away from the clamp bars, press the check mark () button on the Touch Screen Display to pinch

the bags just above the filter. The following screen will be displayed.

11. Add DE to the SDF filter bags on the ANKOM

TDF

Dietary Fiber Analyzer.

11.1 Open the top of the SDF bag and add a weigh tin of DE to the bag by folding the tin and then dipping it down into

the bag below the tip of the Delivery Nozzle.

When adding DE to the filter bags it is very important to keep it below the tip of

the Delivery Nozzle so that the DE material can be properly rinsed.

11.2 Rinse the tin with no more than 3 ml of 78% EtOH to ensure complete transfer.

11.3 Repeat steps 11.1 – 11.2 for all six stations.

Diatomaceous Earth

added in SDF Bags?

AOAC

991.43

IDF/SDF

←

Centering Lines

Page 22

Operator’s Manual

pg. 22 Rev 9/20/18

11.4 Press the check mark () button on the Touch Screen Display. The following screen will be displayed.

After you confirm that the DE is added, the Clamp Bar D button on the Control

Panel is disabled until the SDF process completes.

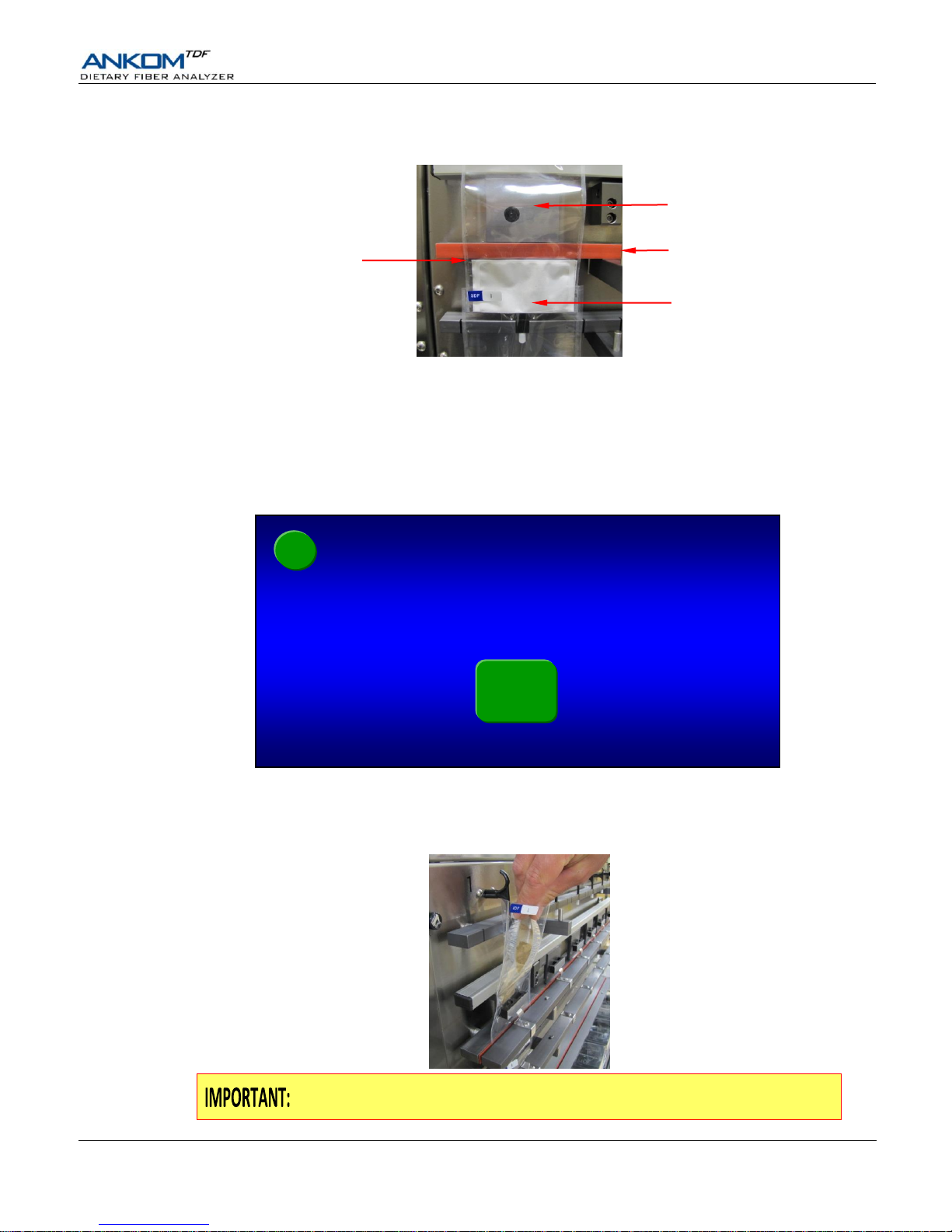

12. Install IDF filter bags on the ANKOM

TDF

Dietary Fiber Analyzer.

12.1 Gently pull the black IDF Delivery Nozzle out toward you.

12.2 Place a labeled and weighed IDF bag up underneath the Delivery Nozzle so that the Delivery Nozzle is inside the

top part of the bag. Pull the bag up so that the top of the filter part of the IDF bag is just below the bottom of

Clamp Bar B and return the Delivery Nozzle to its original position. This will hold the back of the bag in place.

12.3 With the bag held by the Delivery Nozzle, center it horizontally between the Centering Lines on the back part of

Clamp Bar A.

For proper mixing during the IDF process the IDF bags must be horizontally

centered over the Heating Paddles and between the Centering Lines on the back

part of Clamp Bar A.

IDF Bags (and clamp bar B) installed?

←

AOAC

991.43

IDF/SDF

Centering Lines

Heating Paddle

Page 23

Operator’s Manual

Rev 9/20/18 pg. 23

12.4 Place at least 20 mm (0.75 inches) of the filter section of the IDF bag inside the top of the SDF bag to allow for

the flow of liquid into the SDF bag after the IDF process is complete.

12.5 Repeat steps 12.1 – 12.4 for all six stations.

12.6 Re-install Clamp Bar B by setting it on the locator rods. Make sure the letter is on the top of the bar and the

rubber material is facing in toward the instrument.

12.7 Flatten the IDF bags to remove any wrinkles.

12.8 With fingers away from the clamp bars, press the check mark () button on the Touch Screen Display to pinch

the IDF bags just above the filter. The mixing pads will make contact with the bags when Clamp Bar B pinches

the IDF bags. The following screen will be displayed.

13. Add samples to the IDF bags.

13.1 Open the top of the IDF bag and transfer the sample from a weigh tin into the IDF bag by folding the tin and then

dipping it down into the bag below the tip of the Delivery Nozzle.

When adding sample to the filter bags it is very important to keep it below the tip

of the Delivery Nozzle so that it can be properly rinsed.

Samples in IDF Bags?

←

AOAC

991.43

IDF/SDF

Clamp Bar B

Top part of the filter is

positioned just below the

bottom of Clamp Bar B

20 mm (0.75 inches) of

the IDF filter inside the

top of the SDF bag

Heating Paddle

Page 24

Operator’s Manual

pg. 24 Rev 9/20/18

13.2 Rinse the tin with no more than 3 ml of Distilled Water to ensure complete transfer.

13.3 Repeat steps 13.1 – 13.2 for all IDF stations.

13.4 Re-install Clamp Bar A by setting it on the locator rods. Make sure the letter is on the top of the bar and the

rubber material is facing in toward the instrument.

13.5 Press the check mark () button on the Touch Screen Display. The following screen will be displayed.

13.6 Make sure that all clamp bars are installed with the letter on the top of the bar and the rubber material facing in

toward the instrument. Press the check mark () button on the Touch Screen Display. The following screen will

be displayed.

14. Hook the front of each SDF bag in place.

14.1 Secure the SDF filter bags in place with the hooks located on the front part of Clamp Bar C.

Hooking the bags in place will put a physical hole in the front of each SDF bag.

14.2 Press the check mark () button on the Touch Screen Display. If you ran a method other than 991.43 prior to this

run, the following screen will be displayed.

Front of SDF Bags hooked to clamp bar C?

←

AOAC

991.43

IDF/SDF

All remaining clamp bars installed?

←

AOAC

991.43

IDF/SDF

Hook on front part of

Clamp Bar C

Page 25

Operator’s Manual

Rev 9/20/18 pg. 25

15. Verify that the fluid containers have the correct fluids for this procedure.

Verify that the fluid supply containers are configured according to the screen above and press the check mark () button.

The following screen will be displayed.

16. Fill fluid containers.

To ensure that you have enough fluids to run a complete IDF/SDF procedure, you must begin with fluid levels above the

Minimum Level lines on the chemical containers and at least 15 ml of each enzyme. Add fluids and enzymes as

necessary.

Do NOT leave the enzyme ports on the instrument open to the air or the enzymes

in the valves may dry up and plug the ports.

With all fluid containers filled to the proper levels, press the check mark () button on the Touch Screen Display. The

following screen will be displayed.

Nitrogen supply ON?

←

AOAC

991.43

IDF/SDF

Fluid levels correct?

←

AOAC

991.43

IDF/SDF

Amylase -> Amylase

AMG -> AMG

HCL -> HCL

Buffer -> Mes Tris Buffer

←

Check supply containers

AOAC

991.43

IDF/SDF

Page 26

Operator’s Manual

pg. 26 Rev 9/20/18

17. Connect the Nitrogen Supply to the instrument and turn on.

Make sure the Nitrogen supply in your lab is connected to the instrument and turned on. The pressure gauges on the

instrument should show 50-55 psi on the left and about 4 psi on the right.

Press the check mark () button on the Touch Screen Display. The following screen will be displayed.

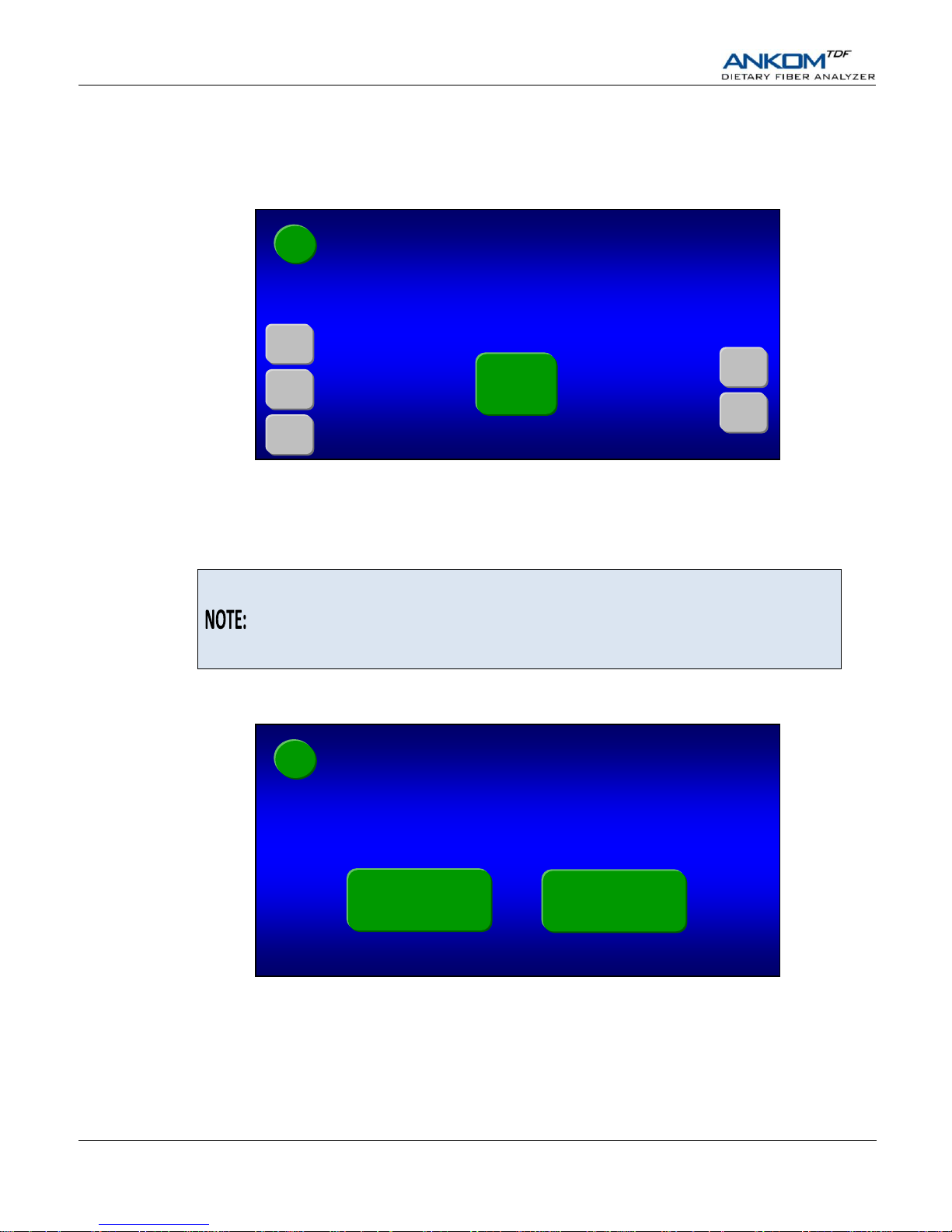

18. Set filter times (in minutes).

Because different samples take different amounts of time to filter, the above screen allows you to set your filter times. To

change any of the times shown on the screen, press the specific gray button. A number pad will be displayed that will

allow you to enter the time that you want. The times you enter will remain until you change them again.

The initial filter times shown when you first run the instrument are based on factory

experience. During filtration the computer allows you to bypass the filter time if

you notice the filtering is complete. The computer also allows you to add time

during filtering if needed (see the “Status Screen” section of this manual for more

detail).

When all of the times shown on the screen are what you want, press the check mark () button on the Touch Screen

Display. The following screen will be displayed.

19. Set the Manual pH Check.

If you plan to check the pH after the required HCl is added (during the IDF process), press the Yes button on the screen

above. Otherwise, press the No button. The following screen will be displayed.

Check pH manually?

←

Yes

No

AOAC

991.43

IDF/SDF

Filter minutes OK?

←

After release

After water rinses

After EtOH rinses

After release

After EtOH rinses

5.0

1.0

1.0

10.0

3.0

IDF

SDF

(Press button with number to change)

AOAC

991.43

IDF/SDF

Page 27

Operator’s Manual

Rev 9/20/18 pg. 27

20. Start the instrument.

The instrument is now completely set up and ready to automatically run the IDF/SDF procedure. Press the START button

to begin. At the beginning of each new run, the instrument automatically runs a tube integrity test.

For the first run after a power-up cycle, or for the first run after the instrument has been idle for twelve hours, the

following screen will be displayed.

If the fluid lines are already charged properly, or when the line charge is complete, the following screen will be displayed.

When the tube integrity check is complete, the instrument will automatically execute the IDF/SDF procedure stopping

only for faults, aborts, and manual pH measurement (if enabled). The Status screen will show actions and faults as they

occur during the automatic operation.

Testing pump tubing.

Please wait..........

Initializing lines…

Amylase

EtOH78

Protease

EtOH95

AMG

Water

HCL

Buffer

Vacuum xx.x

cur: - x.x

max: - x.x

Press START to begin

←

START

AOAC

991.43

IDF/SDF

Page 28

Operator’s Manual

pg. 28 Rev 9/20/18

21. Manually measure pH.

One of the questions you are asked before starting the automated procedure is: “Check pH manually?” If you answered

“Yes” to this question, the instrument will stop after adding the required HCl, open Clamp Bar A, display the screen

below, and make a sound to remind you to manually measure pH and adjust to 4.0 - 4.7 if necessary.

When measuring pH, use a probe that can be easily rinsed (with Distilled Water) to

avoid loss of sample. If you add 0.5N HCl or base to adjust the pH, you must mix

the solution in order to get an accurate pH reading. To manually mix the solution,

press the outside of the bag with your fingers just above Clamp Bar B multiple

times.

When you have completed the pH measurement process, press the Continue button on the Status screen. You will see

“COMPLETE” next to “pH required?” in the upper left corner of the screen.

22. Rinse the IDF filter bags with acetone.

After the instrument has completed an IDF process the IDF residue that has been collected in the IDF bag must be

manually rinsed twice with acetone. It is recommended that you use an ANKOM TDF51 Rinse Stand (sold separately) for

rinsing filter bags with acetone.

To rinse the IDF filter bags with acetone using the ANKOM TDF51 Rinse Stand, follow the steps below.

22.1 Remove the IDF bags from the instrument.

22.2 Place the bags on the Rinse Stand by sliding the back part of each bag under the

pinch mechanism. Keep the top of the bag open.

22.3 Using a wash bottle, squirt acetone completely around the inside polypropylene

surfaces of each bag, making sure that all residue on the surfaces is rinsed down

into the filter.

22.4 Repeat step 22.3 so that each bag gets rinsed a total of two times.

22.5 Allow acetone to evaporate from the bags.

Hazardous Materials – Do NOT heat seal or place bags in an oven until all

acetone has evaporated.

Status

Overall Progress

Action in progress

IDF

Time remaining:

Amylase/AMG Phase

XX:XX:XX

Time remaining: XX:XX:XX

SDF

Time remaining:

XX:XX:XX

pH required?

Display

Temps/Pressures

YES

IDF

ABORT

PAUSE

SDF

ABORT

AOAC

991.43

IDF/SDF

Vacuum xx.x

cur: - x.x

max: - x.x

Check pH

then press continue

xx:xx:xx

Continue

Page 29

Operator’s Manual

Rev 9/20/18 pg. 29

22.6 With your Heat Sealer set between 3 and 4 (settings may vary depending on the

heat sealer and the power source), press the Heat Sealer arm down. Hold the

arm down for 3 to 4 seconds after the light goes out to seal each bag just

above the filter. This keeps all residue contained to the filter area while handling

the bags.

22.7 Place each bag in the Drying Rack.

23. Rinse the SDF filter bags with acetone.

After the instrument has completed an SDF process the SDF residue that has been collected in the SDF bag must be

manually rinsed with acetone. It is recommended that you use an ANKOM TDF51 Rinse Stand for rinsing filter bags with

acetone.

To rinse the SDF filter bags with acetone using the ANKOM TDF51 Rinse Stand, follow the steps below.

23.1 Remove the SDF bags from the instrument.

23.2 Place the bags on the Rinse Stand by sliding the back part of each bag under the pinch mechanism. Keep the top

of the bag open.

23.3 Using a wash bottle, squirt acetone completely around the inside polypropylene surfaces of each bag, making sure

that all residue on the surfaces is rinsed down into the filter.

23.4 Repeat step 23.3 so that each bag gets rinsed a total of two times.

23.5 Allow acetone to evaporate from the bags.

Hazardous Materials – Do NOT heat seal or place bags in an oven until all

acetone has evaporated.

23.6 Seal each bag just above the filter to keep all residue contained to the filter area while handling the bags.

Sealing each bag as close to the filter as possible allows you to trim the maximum

amount of polypropylene from the bag before determining the protein content.

23.7 Place each bag in the Drying Rack.

24. Dry the IDF and SDF filter bags.

24.1 Make sure your oven is 105°C at the location where the bags will be placed.

24.2 Place the Drying Rack with the filter bags in the oven and dry to constant weight (about 90 minutes).

24.3 When dry, remove all IDF and SDF filter bags from the oven and place them in separate desiccant pouches.

25. Weigh the IDF residue.

25.1 Remove only one IDF filter bag from the desiccant pouch at a time.

25.2 Roll or fold the bag, place it in a tared Bag Weigh Holder (BWH), and place the BWH in the center of a balance.

25.3 Record the weight of the filter bag.

25.4 Repeat steps 25.1 – 25.3 for each IDF filter bag used in the fiber analysis.

26. Weigh the SDF residue.

26.1 Remove only one SDF filter bag from the desiccant pouch at a time.

26.2 Roll or fold the bag, place it in a tared Bag Weigh Holder (BWH), and place the BWH in the center of a balance.

26.3 Record the weight of the filter bag.

26.4 Repeat steps 26.1 – 26.3 for each SDF filter bag used in the fiber analysis.

Page 30

Operator’s Manual

pg. 30 Rev 9/20/18

27. Determine the Protein content within the IDF and SDF residue.

See the “Protein Determination” section of this manual for recommended procedures.

28. Determine the Ash content within the IDF and SDF residue.

See the “Ash Determination” section of this manual for recommended procedures.

29. Calculate the % IDF value.

% IDF = [(R1 + R2)/2] - P - A - B

(M1 + M2)/2

=

[(( fF1 - fS1) + ( fF2 - fS2))/2] - P - A - B

(M1 + M2)/2

Where:

M1, M2

=

Original wt of duplicate samples adjusted for pre-treatment fat and sugar losses (g)

R1, R2

=

Residue for duplicate samples (g)

fF

=

Final Filter Bag with residue (g)

fS

=

Initial Filter Bag (g)

P =

Protein of residue and bag (g)

A

=

Ash of residue and bag (g)

B

=

Blank (g)

= [(BR1 + BR2)/2] - PB - AB

= [((f

BF1

- f

BS1

) + (f

BF2

- f

BS2

))/2] - PB - AB

BR1, BR2

=

Residue for duplicate blanks (g)

fBF

=

Final Blank Filter Bag (g)

fBS

=

Initial Blank Filter Bag (g)

PB

=

Protein of Blank Filter Bag (g)

AB

=

Ash of Blank Filter Bag (g)

30. Calculate the % SDF value.

% SDF

=

[(R1 + R2)/2] - P - A - B

(M1 + M2)/2

=

[(( fF1 - fS1 - D1) + ( fF2 - fS2 - D2))/2] - P1 - (A2 - D2) - B

(M1 + M2)/2

Where:

M1, M2

=

Original wt of duplicate samples adjusted for pre-treatment fat and sugar losses (g)

R1, R2

=

Residue for duplicate samples (g)

fF

=

Final Filter Bag with residue (g)

fS

=

Initial Filter Bag (g)

D =

Original wt of Diatomaceous Earth (g)

P =

Protein of residue and bag (g)

A

=

Ash of residue and bag (g)

B

=

Blank (g)

= [(BR1 + BR2)/2] - PB - (AB - DB)

= [((f

BF1

- f

BS1

- DB1) + (f

BF2

- f

BS2

- DB2))/2] - PB1 - (AB2 - DB2)

BR1, BR2

=

Residue for duplicate blanks (g)

fBF

=

Final Blank Filter Bag (g)

fBS

=

Initial Blank Filter Bag (g)

PB

=

Protein of Blank Filter Bag (g)

AB

=

Ash of Blank Filter Bag (g)

DB

=

Original wt of Diatomaceous Earth in Blank Filter Bag (g)

31. Calculate the % TDF value by adding the % IDF and % SDF values.

X 100

X 100

X 100

X 100

Page 31

Operator’s Manual

Rev 9/20/18 pg. 31

TDF Analysis (AOAC 991.43)

A TDF analysis directly measures the amount of TDF within a given sample without separately measuring the IDF and SDF

fractions. TDF can be determined using multiple methods. This section describes the procedure for using the ANKOM

TDF

Dietary Fiber Analyzer to determine TDF based on the AOAC 991.43 method.

This analysis requires an SDF filter bag (ANKOM DF-S) for the precipitation process and a non-filter IDF Flow-Thru bag

(ANKOM DF-FT) for the digestion process. When starting a new run, the ANKOM

TDF

Dietary Fiber Analyzer must have bags

installed at all stations (a total of twelve bags).

To enhance the productivity of your instrument, you can begin the IDF process of a

new run while the SDF process of a previous run is finishing. See the “Productivity

Enhancement” section of this manual for more details.

To perform a TDF analysis, follow the steps below.

1. Prepare chemicals and enzymes.

When using the ANKOM

TDF

Dietary Fiber Analyzer for the AOAC 991.43, AACC 32-07.01, and NMKL 129,2003

methods use the chemicals and enzymes referred to therein. See Appendix A of this manual for the list of chemicals and

enzymes and the instructions for how to prepare them for use in this instrument.

2. De-fat your samples as needed according to the official methods. See "Appendix C – De-fatting

Procedure" in this manual for an ANKOM procedure.

3. Label the bags using a Solvent Resistant Marker.

4. Prepare for data collection.

You will need a place to store the data collected during this analysis. For your convenience a CD titled “Calculation

Templates” was included with the instrument. This CD has data spreadsheets that can be used for this analysis. Please

read the “Instructions” tab in the MS-Excel file for information about the spreadsheets.

5. Weigh filter bags.

Using a Bag Weigh Holder is critical to eliminate the effects of static electricity

during the weighing process.

Roll or fold each bag and place it in a tared Bag Weigh Holder. Place the Bag Weigh Holder in the center of a balance

and record the weight.

Because different balances have different sensitivities, the Bag Weigh Holder

should be placed in the center of the balance for best results.

SDF Bag (longer bag with filter)

IDF Flow-thru Bag (shorter bag / no filter)

Page 32

Operator’s Manual

pg. 32 Rev 9/20/18

6. Weigh Diatomaceous Earth (DE).

DE is used during fiber analysis to enhance the flocculation and filtration of the SDF fraction. Place ca 1 g of DE in each

of six tared and numbered tins and record the weights.

7. Weigh Samples.

Place 0.50.05 g of sample in each of six tared and numbered tins and record the weights.

A larger sample (1.0 g) can be used if a larger aliquot is needed to improve

precision.

8. Turn the instrument power on.

When you turn the power on, the instrument will run through an initialization process and the Control Panel will turn on.

9. On the Touch Screen Display, select the instrument function you would like to perform.

The Control Panel on the ANKOM

TDF

Dietary Fiber Analyzer uses Touch Screen technology. To operate the instrument

you will press identified buttons on the Touch Screen Display and buttons below the screen.

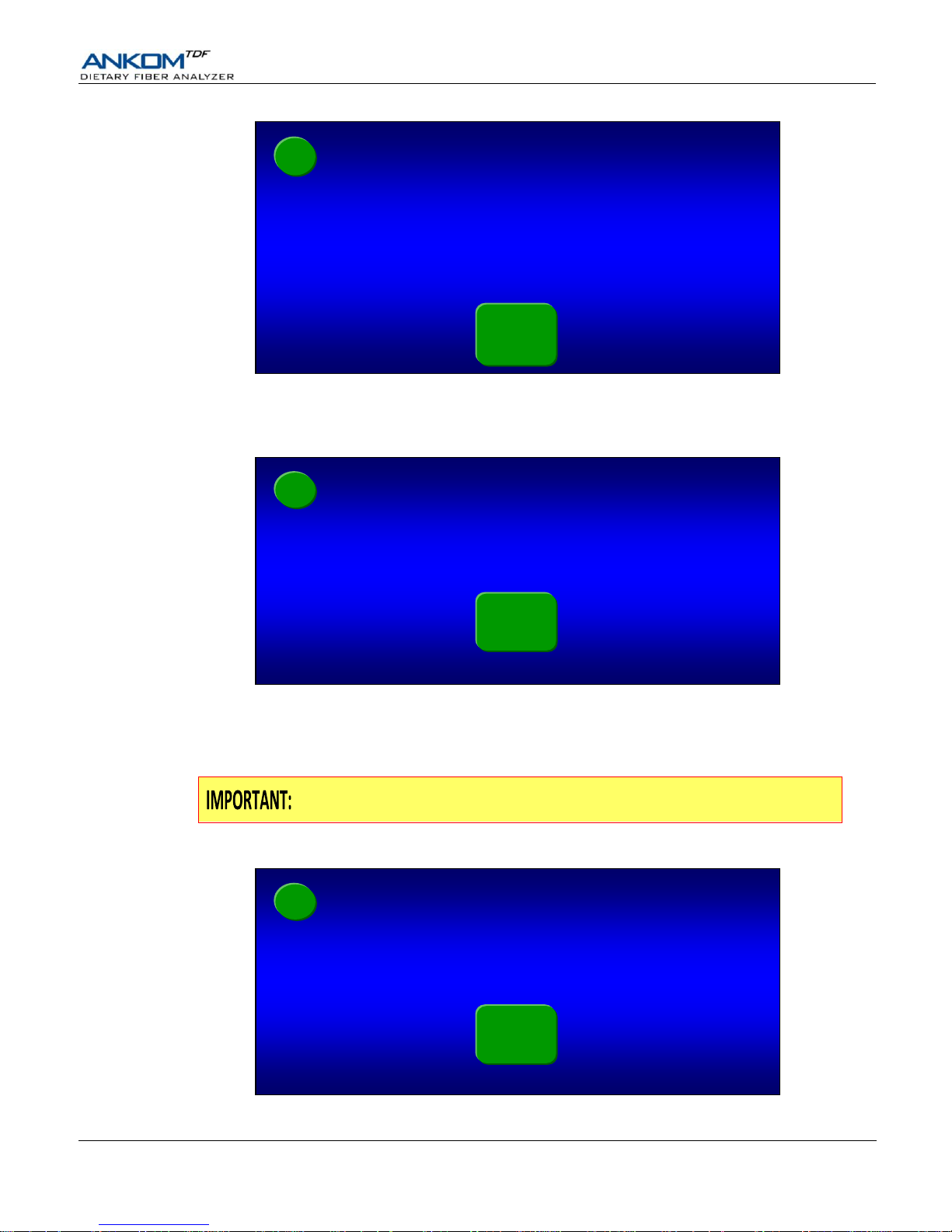

When your instrument is initialized and ready to operate, the following screen will be displayed.

Although the instrument works in accordance with AACC and NMKL methods, the

Touch Screen Display only refers to the AOAC methods.

9.1 If this is the first time the instrument is being operated after being installed, or after sitting unused for a period of

time (see Appendix B), or after tubing was replaced, the lines must be charged to avoid a Vacuum Sensor Fault.

To charge the lines follow the steps below.

9.1.1 Press the Diagnostics button on the “Select a Function” screen. The following screen will be displayed.

Diagnostics

Touch Screen Display version: A.AA

SPLat controller software version: vX.XX dd-mm-yy

Pump Tube

Test

Expert Mode

Faults

Service

Mode

Clear IDF /

SDF lines

Digestion

Times

Heater Test

Temperatures

Pressures

Line Charge

Motor Test

Valve Test

Select a Function

AOAC 991.43

IDF/SDF

AOAC 985.29

TDF

Diagnostics

AOAC 991.43

TDF

AOAC 2001.03

TDF

←

Page 33

Operator’s Manual

Rev 9/20/18 pg. 33

9.1.2 Press the Line Charge button. The following screen will be displayed.

9.1.3 Press the ALL button to charge all of the lines. Each button will change color as the associated line is being

charged. All lines are charged when all of the buttons return to their original green color.

9.1.4 Press the back button twice. The following “Select a Function” screen will be displayed again.

9.2 Press the AOAC 991.43 TDF button. The following screen will be displayed.

Notice that the function you selected is now displayed in the top right corner of the screen and a back button

is displayed in the top left corner of the screen.

SDF Bags (and clamp bar D) installed?

←

AOAC

991.43

TDF

Select a Function

AOAC 991.43

IDF/SDF

AOAC 985.29

TDF

Diagnostics

AOAC 991.43

TDF

AOAC 2001.03

TDF

Line Charge

Amylase

Protease

AMG

HCl

EtOH78

EtOH95

Water

Buffer

ALL

Vacuum xx.x

cur: - x.x

max: - x.x

←

Page 34

Operator’s Manual

pg. 34 Rev 9/20/18

10. Install SDF filter bags on the ANKOM

TDF

Dietary Fiber Analyzer.

10.1 Remove Clamp Bars A, B, C, and D by lifting them off of the locator rods.

10.2 Gently pull the black SDF Delivery Nozzle out toward you.

10.3 Place a labeled and weighed SDF bag up underneath the SDF Delivery Nozzle so that the Delivery Nozzle is

inside the top part of the bag. Pull the bag up so that the top of the bag is about 35 mm (1.375 inches) above the

top of Clamp Bar C and return the Delivery Nozzle to its original position. This will hold the back of the bag in

place.

As part of normal operation, solution from the IDF Flow-thru bag will flow into the

SDF bag. Therefore, when installing the SDF filter bags it is very important to

position them high enough vertically so that at least 20 mm (0.75 inches) of the

bottom of the IDF Flow-thru bag can fit inside the top of the SDF bag.

Clamp Bar C

Clamp Bar D

Clamp Bar B

Clamp Bar A

Page 35

Operator’s Manual

Rev 9/20/18 pg. 35

10.4 With the bag being held by the Delivery Nozzle, center it horizontally between the lines on the back part of

Clamp Bar C.

10.5 Repeat steps 10.2 – 10.4 for all six stations.

10.6 Re-install Clamp Bar D by setting it on the locator rods. Make sure the letter is on the top of the bar and the

rubber material is facing in toward the instrument.

10.7 Flatten the bags to remove any wrinkles.

10.8 With fingers away from the clamp bars, press the check mark () button on the Touch Screen Display to pinch

the bags. The following screen will be displayed.

11. Add DE to the SDF filter bags on the ANKOM

TDF

Dietary Fiber Analyzer.

11.1 Open the top of the SDF bag and add a weigh tin of DE to the bag by folding the tin and then dipping it down into

the bag below the tip of the Delivery Nozzle.

When adding DE to the filter bags it is very important to keep it below the tip of

the Delivery Nozzle so that the DE material can be properly rinsed.

11.2 Rinse the tin with no more than 3 ml of 78% EtOH to ensure complete transfer.

11.3 Repeat steps 11.1 – 11.2 for all six stations.

Diatomaceous Earth

added in SDF Bags?

←

AOAC

991.43

TDF

Centering Lines

Page 36

Operator’s Manual

pg. 36 Rev 9/20/18

11.4 Press the check mark () button on the Touch Screen Display. The following screen will be displayed.

After you confirm that the DE is added, the Clamp Bar D button on the Control

Panel is disabled until the SDF process completes.

12. Install IDF Flow-thru bags on the ANKOM

TDF

Dietary Fiber Analyzer.

12.1 Gently pull the black IDF Delivery Nozzle out toward you.

12.2 Place a labeled IDF Flow-Thru bag up underneath the Delivery Nozzle so that the Delivery Nozzle is inside the

top part of the bag. Pull the bag up so that the top of the bag is about 35 mm (1.375 inches) above the top of

Clamp Bar A and return the Delivery Nozzle to its original position. This will hold the back of the bag in place.

12.3 With the bag held by the Delivery Nozzle, center it horizontally between the Centering Lines on the back part of

Clamp Bar A.

For proper mixing during the IDF process the IDF Flow-thru bags must be

horizontally centered over the Heating Paddles and between the Centering Lines on

the back part of Clamp Bar A.

IDF Flow-Thru Bags (and clamp bar B) installed?

←

AOAC

991.43

TDF

Centering Lines

Heating Paddle

Page 37

Operator’s Manual

Rev 9/20/18 pg. 37

12.4 Place at least 20 mm (0.75 inches) of the bottom of the IDF Flow-Thru bag inside the top of the SDF bag to allow

for the flow of solution into the SDF bag after the digestion process is complete.

12.5 Repeat steps 12.1 – 12.4 for all six stations.

12.6 Re-install Clamp Bar B by setting it on the locator rods. Make sure the letter is on the top of the bar and the

rubber material is facing in toward the instrument.

12.7 Flatten the IDF Flow-Thru bags to remove any wrinkles.

12.8 With fingers away from the clamp bars, press the check mark () button on the Touch Screen Display to pinch

the IDF Flow-Thru bags. The mixing pads will make contact with the bags when Clamp Bar B pinches the IDF

Flow-Thru bags. The following screen will be displayed.

13. Add samples to the IDF Flow-thru bags.

13.1 Open the top of the IDF Flow-thru bag and transfer the sample from a weigh tin into the bag by folding the tin

and then dipping it down into the bag below the tip of the Delivery Nozzle.

When adding sample to the IDF Flow-thru bags it is very important to keep it

below the tip of the Delivery Nozzle so that it can be properly rinsed.

13.2 Rinse the tin with no more than 3 ml of Distilled Water to ensure complete transfer.

Samples in IDF Flow-Thru Bags?

←

AOAC

991.43

TDF

20 mm (0.75 inches) of the

IDF Flow-Thru bag inside the

top of the SDF bag

Heating Paddle

Page 38

Operator’s Manual

pg. 38 Rev 9/20/18

13.3 Repeat steps 13.1 – 13.2 for all IDF stations.

13.4 Re-install Clamp Bar A by setting it on the locator rods. Make sure the letter is on the top of the bar and the

rubber material is facing in toward the instrument.

13.5 Press the check mark () button on the Touch Screen Display. The following screen will be displayed.

13.6 Make sure that all clamp bars are installed with the letter on the top of the bar and the rubber material facing in

toward the instrument. Press the check mark () button on the Touch Screen Display. The following screen will

be displayed.

14. Hook the front of each SDF bag in place.

14.1 Secure the SDF filter bags in place with the hooks located on the front part of Clamp Bar C.

Hooking the bags in place will put a physical hole in the front of each SDF bag.

14.2 Press the check mark () button on the Touch Screen Display. If you ran a method other than 991.43 prior to this

run, the following screen will be displayed.

Front of SDF Bags hooked to clamp bar C?

←

AOAC

991.43

TDF

All remaining clamp bars installed?

←

AOAC

991.43

TDF

Hook on front part of

Clamp Bar C

Page 39

Operator’s Manual

Rev 9/20/18 pg. 39

15. Verify that the fluid containers have the correct fluids for this procedure.

Verify that the fluid supply containers are configured according to the screen above and press the check mark () button.

The following screen will be displayed.

16. Fill fluid containers.

To ensure that you have enough fluids to run a complete TDF procedure, you must begin with fluid levels above the

Minimum Level lines on the chemical containers and at least 15 ml of each enzyme. Add fluids and enzymes as

necessary.

Do NOT leave the enzyme ports on the instrument open to the air or the enzymes

in the valves may dry up and plug the ports.

With all fluid containers filled to the proper levels, press the check mark () button on the Touch Screen Display. The

following screen will be displayed.

Nitrogen supply ON?

←

AOAC

991.43

TDF

Fluid levels correct?

←

AOAC

991.43

TDF

Amylase -> Amylase

AMG -> AMG

HCL -> HCL

Buffer -> Mes Tris Buffer

←

Check supply containers

AOAC

991.43

TDF

Page 40

Operator’s Manual

pg. 40 Rev 9/20/18

17. Connect the Nitrogen Supply to the instrument and turn on.

Make sure the Nitrogen supply in your lab is connected to the instrument and turned on. The pressure gauges on the

instrument should show 50-55 psi on the left and about 4 psi on the right.

Press the check mark () button on the Touch Screen Display. The following screen will be displayed.

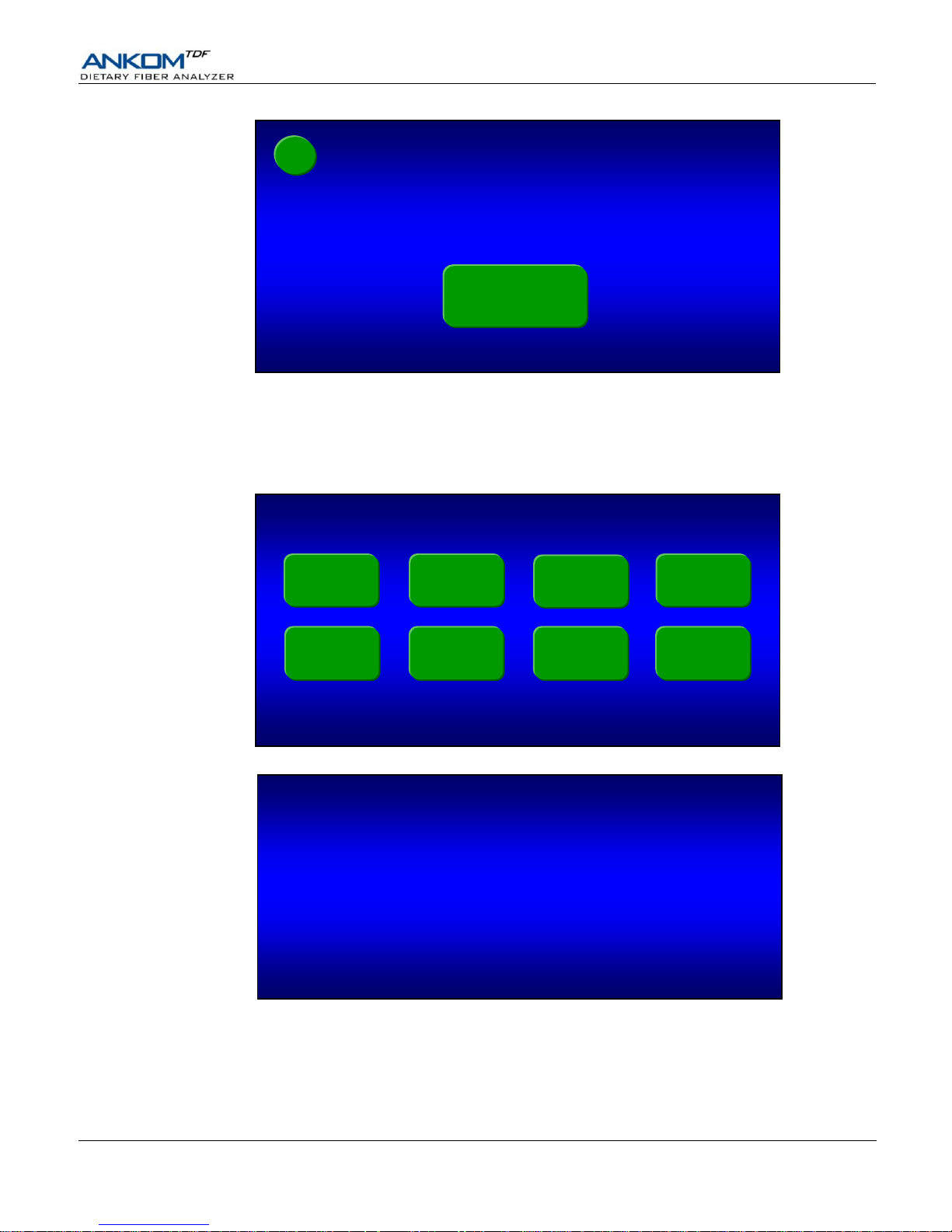

18. Set filter times (in minutes).

Because different samples take different amounts of time to filter, the above screen allows you to set your filter times. To

change any of the times shown on the screen, press the specific gray button. A number pad will be displayed that will

allow you to enter the time that you want. The times you enter will remain until you change them again.

The initial filter times shown when you first run the instrument are based on factory

experience. During filtration the computer allows you to bypass the filter time if

you notice the filtering is complete. The computer also allows you to add time

during filtering if needed (see the “Status Screen” section of this manual for more

detail).

When all of the times shown on the screen are what you want, press the check mark () button on the Touch Screen

Display. The following screen will be displayed.

19. Set the Manual pH Check.

If you plan to check the pH after the required HCl is added (during the IDF process), press the Yes button on the screen

above. Otherwise, press the No button. The following screen will be displayed.

Check pH manually?

←

Yes

No

AOAC

991.43

TDF

←

After release

After EtOH rinses

10.0

3.0

SDF Filter minutes OK?

(Press button with number to change)

AOAC

991.43

TDF

Page 41

Operator’s Manual

Rev 9/20/18 pg. 41

20. Start the instrument.

The instrument is now completely set up and ready to automatically run the TDF procedure. Press the START button to

begin. At the beginning of each new run, the instrument automatically runs a tube integrity test.

For the first run after a power-up cycle, or for the first run after the instrument has been idle for twelve hours, the

following screen will be displayed.

If the fluid lines are already charged properly, or when the line charge is complete, the following screen will be displayed.

When the tube integrity check is complete, the instrument will automatically execute the TDF procedure stopping only for

faults, aborts, and manual pH measurement (if enabled). The Status screen will show actions and faults as they occur

during the automatic operation.

Testing pump tubing.

Please wait..........

Initializing lines…

Amylase

EtOH78

Protease

EtOH95

AMG

Water

HCL

Buffer

Vacuum xx.x

cur: - x.x

max: - x.x

Press START to begin

←

START

AOAC

991.43

TDF

Page 42

Operator’s Manual

pg. 42 Rev 9/20/18

21. Manually measure pH.

One of the questions you are asked before starting the automated procedure is: “Check pH manually?” If you answered

“Yes” to this question, the instrument will stop after adding the required HCl, open Clamp Bar A, display the screen

below, and make a sound to remind you to manually measure pH and adjust to 4.0 - 4.7 if necessary.

When measuring pH use a probe that can be easily rinsed (with Distilled Water) to

avoid loss of sample. If you add 0.5N HCl or base to adjust the pH, you must mix

the solution in order to get an accurate pH reading. To manually mix the solution,

press the outside of the bag with your fingers just above Clamp Bar B multiple

times.

When you have completed the pH measurement process, press the Continue button on the Status screen. You will see

“COMPLETE” next to “pH required?” in the upper left corner of the screen.

22. Make sure that each sample is completely rinsed down into the SDF filter bags (as needed).

Since the IDF Flow-thru bags are not weighed before and after the process, it is important to make sure that each sample

gets rinsed down into the SDF filter bag when the digestion process is complete.

If you notice sample sticking to an IDF Flow-thru bag, use 78% EtOH in a wash bottle to rinse as needed.

23. Rinse the SDF filter bags with acetone.

After the instrument has completed a TDF process the TDF residue that has been collected in the SDF bag must be

manually rinsed with acetone. It is recommended that you use an ANKOM TDF51 Rinse Stand (sold separately) for

rinsing filter bags with acetone.

To rinse the SDF filter bags with acetone using the ANKOM TDF51 Rinse Stand, follow the

steps below.

23.1 Remove the SDF bags from the instrument.

23.2 Place the bags on the Rinse Stand by sliding the back part of the bag under the pinch

mechanism. Keep the top of the bag open.

23.3 Using a wash bottle, squirt acetone completely around the inside polypropylene

surfaces of each bag, making sure that all residue on the surfaces is rinsed down into

the filter.

23.4 Repeat step 23.3 so that each bag gets rinsed a total of two times.

23.5 Allow acetone to evaporate from the bags.

Hazardous Materials – Do NOT heat seal or place bags in an oven until all

acetone has evaporated.

Status

Overall Progress

Action in progress

IDF

Time remaining:

Amylase/AMG Phase

XX:XX:XX

Time remaining: XX:XX:XX

SDF

Time remaining:

XX:XX:XX

pH required?

Display

Temps/Pressures

YES

IDF

ABORT

PAUSE

SDF

ABORT

AOAC

991.43

TDF

Vacuum xx.x

cur: - x.x

max: - x.x

Check pH

then press continue

xx:xx:xx

Continue

Page 43

Operator’s Manual

Rev 9/20/18 pg. 43

23.6 With your Heat Sealer set between 3 and 4 (settings may vary depending on the heat

sealer and the power source), press the Heat Sealer arm down. Hold the arm down for

3 to 4 seconds after the light goes out to seal each bag just above the filter. This keeps

all residue contained to the filter area while handling the bags.

23.7 Place each bag in the Drying Rack.

24. Dry the SDF filter bags.

24.1 Make sure your oven is 105°C at the location where the bags will be placed.

24.2 Place the Drying Rack with the filter bags in the oven and dry to constant weight (about 90 minutes).

24.3 When dry, remove all SDF filter bags from the oven and place them in a desiccant pouch to cool.

25. Weigh the TDF residue.

25.1 Remove one SDF filter bag from the desiccant pouch.

25.2 Roll or fold the bag, place it in a tared Bag Weigh Holder (BWH), and place the BWH in the center of a balance.

25.3 Record the weight of the filter bag.

25.4 Repeat steps 25.1 – 25.3 for each SDF filter bag used in the fiber analysis.

26. Determine the Protein content within the TDF residue.

See the “Protein Determination” section of this manual for recommended procedures.

27. Determine the Ash content within the TDF residue.

See the “Ash Determination” section of this manual for recommended procedures.

28. Calculate the % TDF value.

% TDF

=

[(R1 + R2)/2] - P - A - B

(M1 + M2)/2

=

[(( fF1 - fS1 - D1) + ( fF2 - fS2 - D2))/2] - P1 - (A2 - D2) - B

(M1 + M2)/2

Where:

M1, M2

=

Original wt of duplicate samples adjusted for pre-treatment fat and sugar losses (g)

R1, R2

=

Residue for duplicate samples (g)

fF

=

Final Filter Bag with residue (g)

fS

=

Initial Filter Bag (g)

D =

Original wt of Diatomaceous Earth (g)

P =

Protein of residue and bag (g)

A

=

Ash of residue and bag (g)

B

=

Blank (g)

= [(BR1 + BR2)/2] - PB - (AB - DB)

= [((f

BF1

- f

BS1

- DB1) + (f

BF2

- f

BS2

- DB2))/2] - PB1 - (AB2 - DB2)

BR1, BR2

=

Residue for duplicate blanks (g)

fBF

=

Final Blank Filter Bag (g)

fBS

=

Initial Blank Filter Bag (g)

PB

=

Protein of Blank Filter Bag (g)

AB

=

Ash of Blank Filter Bag (g)

DB

=

Original wt of Diatomaceous Earth in Blank Filter Bag (g)

X 100

X 100

Page 44

Operator’s Manual

pg. 44 Rev 9/20/18

This page intentionally left blank

Page 45

Operator’s Manual

Rev 9/20/18 pg. 45

TDF Analysis (AOAC 985.29 / 2001.03)

A TDF analysis directly measures the amount of TDF within a given sample without separately measuring the IDF and SDF

fractions. TDF can be determined using multiple methods. This section describes the procedure for using the ANKOM

TDF

Dietary Fiber Analyzer to determine TDF based on the AOAC 985.29 and 2001.03 methods.

This analysis requires an SDF filter bag (ANKOM DF-S) for the precipitation process and a non-filter IDF Flow-Thru bag

(ANKOM DF-FT) for the digestion process. When starting a new run, the ANKOM

TDF

Dietary Fiber Analyzer must have bags

installed at all stations (a total of twelve bags).