Page 1

Operator’s Manual

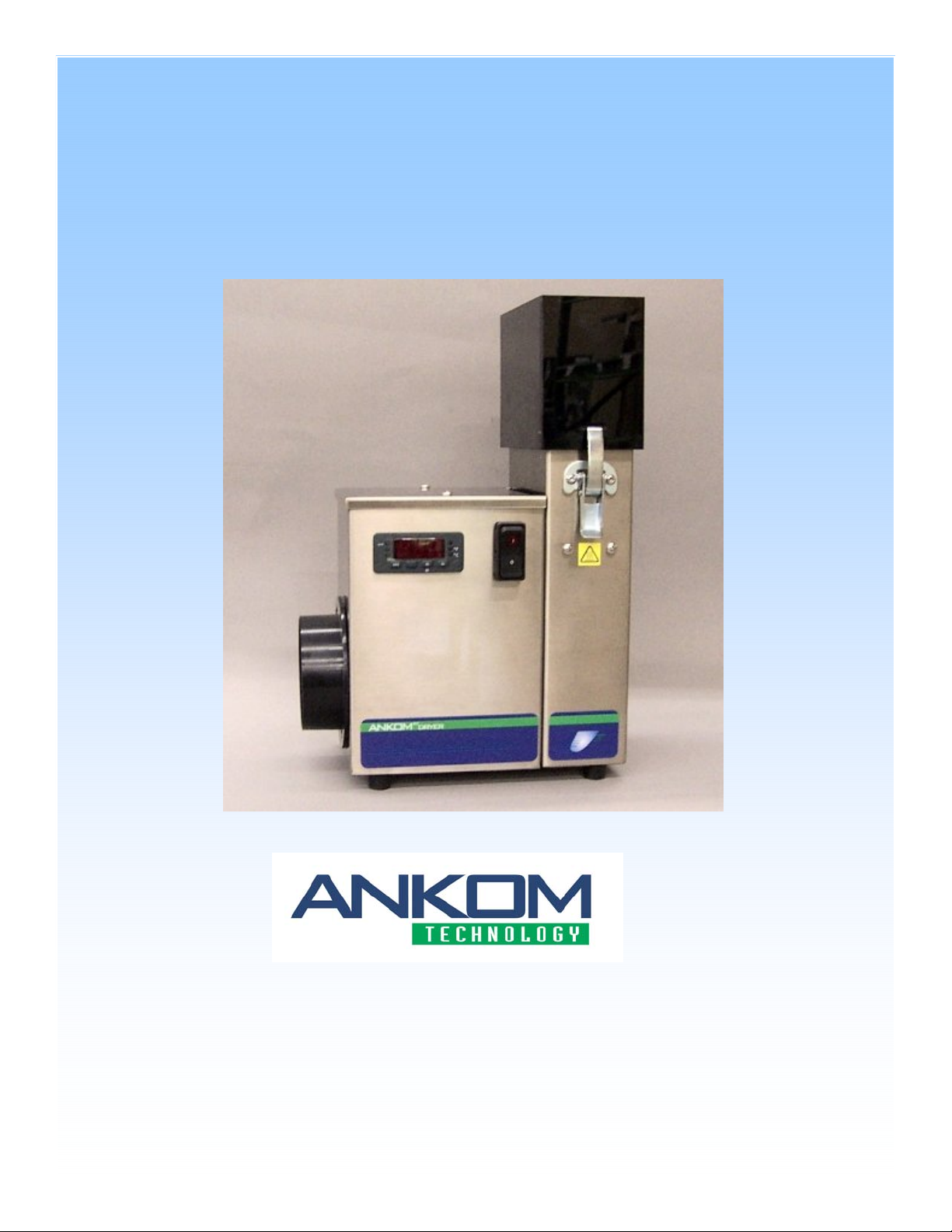

RD

ANKOM

(RD, RDI)

Dryer

Telephone: (315) 986-8090 · Fax: (315) 986-8091

2052 O’Neil Rd Macedon NY 14502

www.ankom.com

Helping to Feed the World

Page 2

Warranty

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Instrument Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Instrument Setup and Installation. . . . . . . . . . . . . . . . . . . . . .6

Operating I ns tructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Periodic Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

W i ring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

REV C(6-05-08)

TABLE OF CONTENTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2

Page 3

WARRANTY

ANKOM Technology Corporation warrants the ANKOMRD Dryer against any defects due to faulty

workmanship or material for a one-year period after the original date of consumer purchase. This

warranty does not include damage to the instrument resulting from neglect or misuse. If the instrument

is damaged as a result of defects in the workmanship or materials during the warranty, ANKOM will

repair or replace the instrument free of charge.

For any questions regarding the warranty or instrument, please call ANKOM at:

Telephone: (315) 986-8090 FAX: (315) 986-8091

3

Specifications - ANKOM Dryer

100V-120V ~ 50/60Hz 10A 220V-240V ~ 50/60Hz 5A

Page 4

4

Safety Precautions

ANKOM DryerRD

Caution: Hot Surfaces - Do not touch the cabinet during operation. The surface can exceed

70o C (158o F). Failure to observe this caution may result in injury.

Caution: Hazardous Voltages- Do not operate the instrument with the electrical compartment

open. Hazardous voltages are present during operation. Electrical shock or electrocution may

result if ignored.

WARNING: Using the instruments in a manner not specified by the manufacturer may impair the

protection provided and voids the warranty.

This system is designed to meet and/or exceed the applicable standards of CE, CSA, NRTL and OSHA.

Page 5

Power

Switch

Temperature

Controller

5

Instrument Description

Filter

Filter

Latch

Fuse Holder

(2)

Power

Receptacle

Air

Inlet

The ANKOMRD Dr yer is designed to remove moisture from ANKOM XT4 or F57 filter bags. Simply

place filter bags in the bag holder with clip-on handle in place and set the holder in the drying chamber.

Attach a filter to the top of the drying chamber and press the power switch which turns on the heat and

fans to dry the samples.

Two types of filters are used with the Dryer

-HCl Dryer Filter #RD2- This filter is used when drying samples after hydrolysis. The filter

neutralizes HCl fumes given off during drying. The filter should be changed when the maroon

bottom filter media of the filter degrades or sags below the filter frame. The effectiveness of the

filter can be checked by placing a small beaker of Ammonium Hydroxide (NH4OH) on top of the

filter while samples are drying. If white vapor is present when drying, the filter is no longer

working. PH paper can also be placed on top of the filter when drying. If the paper turns red (not

orange), replace the filter.

-Dryer Filter #RD1- This filter is used when drying fat or fiber samples. It does not need to be

replaced. It is used to optimize the drying rate of the instrument.

Page 6

Instrument Set Up and Installation

Requirements:

Tools: Flat blade screwdriver

Power: 100-120V 50-60 Hz (domestic) 220V-240 50-60 Hz (int’l)

The ANKOMRD Dryer should be installed in a vent hood free of dust and excessive moisture.

The ANKOMRD power cord must use a grounded receptacle. Hydrolysis leaves small amounts

of HCl in the filter bags even after rinsing. Drying the hydrolyzed samples in the ANKOMRD

Dryer removes moisture and the remaining HCl (For drying after fiber or crude fat

determinations, a vent hood is not necessary).

1. Plug the power cord into a grounded receptacle.

2. Tighten the Inlet hose clamp with a screwdriver and route to a clean source of air.

6

Page 7

7

Operating Instructions

Sample Drying

Follow the sample drying protocol in each specific procedure. Blotting reduces drying time for

hydrolysis samples. After completion of hydrolysis, the filter bags are blotted on paper towels. Place

the wet samples on four sheets of paper towel. Place two sheets on top of the bags. Uniform pressure

(ANKOM Blotter or similar) is used on top of the paper towels to gently press the water out of the

bags. ANKOM Blotter (part #H35) is foam cushioned and weighs ~10 lbs. After one minute repeat

the blotting process for two minutes prior to placing them into the ANKOMRD Dryer.

1. Remove the filter by lifting up both filter latches and set the filter to the side.

Drying

Chamber

2. Place processed or blotted filter bags into the bag holder. Hydrolyzed samples may use the HCl bag

holder in the ANKOMRD Dryer.

3. Place the bag holder into the ANKOMRD Dryer and attach the filter.

RD

4. Turn on the ANKOM

Dryer. The fans, then the heater, will automatically turn on.

5. Press <set> on the temperature controller and use the Up and DOWN arrows to set the drying

temperature. Push <set> to enter the temperature. Use the temperature listed in the assay method.

(usually 110

o

C)

6. Dry the samples for the required time and turn the instrument off.

7. Remove the filter. Remove the samples and immediately place into a desiccant pouch. Cool to room

temperature and weigh.

Page 8

Periodic Maintenance

Wipe the outside of the instrument with window cleaner or a damp sponge as necessary. Do

not use Acetone.

Fuse Replacement- Turn off the power and unplug the instrument.

1. Use a screwdriver to twist (counterclockwise) the gray fuse holder. Remove the holder and

replace the fuse.

2. Push in and twist (clockwise) to install the new fuse.

8

Filter Replacement-

The RD2 HCl filter should be replaced when the maroon bottom filter media of the filter

degrades or sags below the filter frame.

The effectiveness of the filter can be checked by placing a small beaker of Ammonium

Hydroxide (NH

OH) on top of the filter while samples are drying. If white vapor is present

4

when drying, the filter is no longer working. A strip of pH paper can also be placed on top of

the filter when drying. If the paper turns red (not orange), replace the filter.

Generally, the filter should be replaced every 3-6 months depending on usage.

Page 9

9

Loading...

Loading...