Page 1

Operator’s Manual

Rev L 11/12/14

2052 O’Neil Rd, Macedon NY 14502

Telephone: (315) 986-8090

Fax: (315) 986-8091

www.ankom.com

Page 2

This page intentionally left blank

Page 3

Table of Contents

Introduction .................................................................................................................................................................. 5

Warranty ....................................................................................................................................................................... 5

Filter Bags ..................................................................................................................................................................... 5

Operating Environment ................................................................................................................................................ 5

Contact Information ..................................................................................................................................................... 6

Instrument Description ................................................................................................................................................. 7

Safety Precautions ........................................................................................................................................................ 8

Instrument Installation and Setup ................................................................................................................................ 9

Hydrolysis Procedure .................................................................................................................................................. 13

Periodic Maintenance ................................................................................................................................................. 21

Troubleshooting .......................................................................................................................................................... 23

Appendix A – Electrical Diagram (pg. 1 of 3) .............................................................................................................. 25

Page 4

This page intentionally left blank

Page 5

Operator’s Manual

Rev L 11/12/14

pg. 5

The ANKOM

HCl

and XT Extractors are coated with acid resistant polymer to

maintain the appearance of the system. Allowing these systems to be

subjected to acid contact for long periods of time will affect their appearance

and should be avoided. Regular attention to periodic maintenance and proper

set-up will assure long life.

Please review the entire contents of this manual before you begin operating

this product.

Introduction

ANKOM Technology designs, manufactures, and markets instruments and support products used by analytical

laboratories around the world in the food, feed, bio-energy, agricultural, and environmental industries. ANKOM

Technology can provide you with products for determining or monitoring dietary fiber, detergent fiber, crude fiber,

fat, digestibility, microbial fermentation (anaerobic or aerobic) and more.

Committed to Total Customer Satisfaction, ANKOM designs every product based on a thorough assessment of

customer needs.

Congratulations on your purchase of the ANKOM

effectively serve your needs.

By carefully following the operating instructions in this manual, you will minimize errors in results. Experience

indicates that errors in results are usually associated with minor variations in carrying out the procedure. This

manual will provide you with details that will help assure accuracy of your results.

HCl

Hydrolysis System. We are confident that this product will

Warranty

ANKOM Technology warrants the ANKOM

or material for one year after the original date of purchase. This warranty does not include damage to the instrument

resulting from neglect or misuse. During the warranty period, should any failure result from defects in

workmanship or materials, ANKOM Technology will, at its discretion, repair or replace the instrument free of

charge.

Extended warranties are available upon request.

HCl

Hydrolysis System against any defects due to faulty workmanship

Filter Bags

For optimal function, only ANKOM Technology filter bags (part # XT4) should be used in your ANKOM

Hydrolysis System. Filter bags can be purchased from ANKOM Technology or from your local authorized

ANKOM distributor.

Operating Environment

Your ANKOM

Ambient Temperature Range: 15°−35°C

Power (domestic): 100V−120V ~ 50/60Hz 10A

Power (international): 220V−240V ~ 50/60Hz 5A

HCl

Hydrolysis System is designed to operate within the following environments:

HCl

Page 6

Operator’s Manual

pg. 6

Rev L 11/12/14

Contact Information

ANKOM Technology is committed to your total satisfaction and therefore always available to help you get the most

from your ANKOM products. We are also very interested in any comments or suggestions you may have to help us

improve.

For any questions or suggestions regarding your instrument, please contact us at:

Telephone: (315) 986-8090

Fax: (315) 986-8091

www.ankom.com

Page 7

Operator’s Manual

Rev L 11/12/14

pg. 7

Fat extraction can be done using the ANKOM

XT15

and ANKOM

XT10

Extractors.

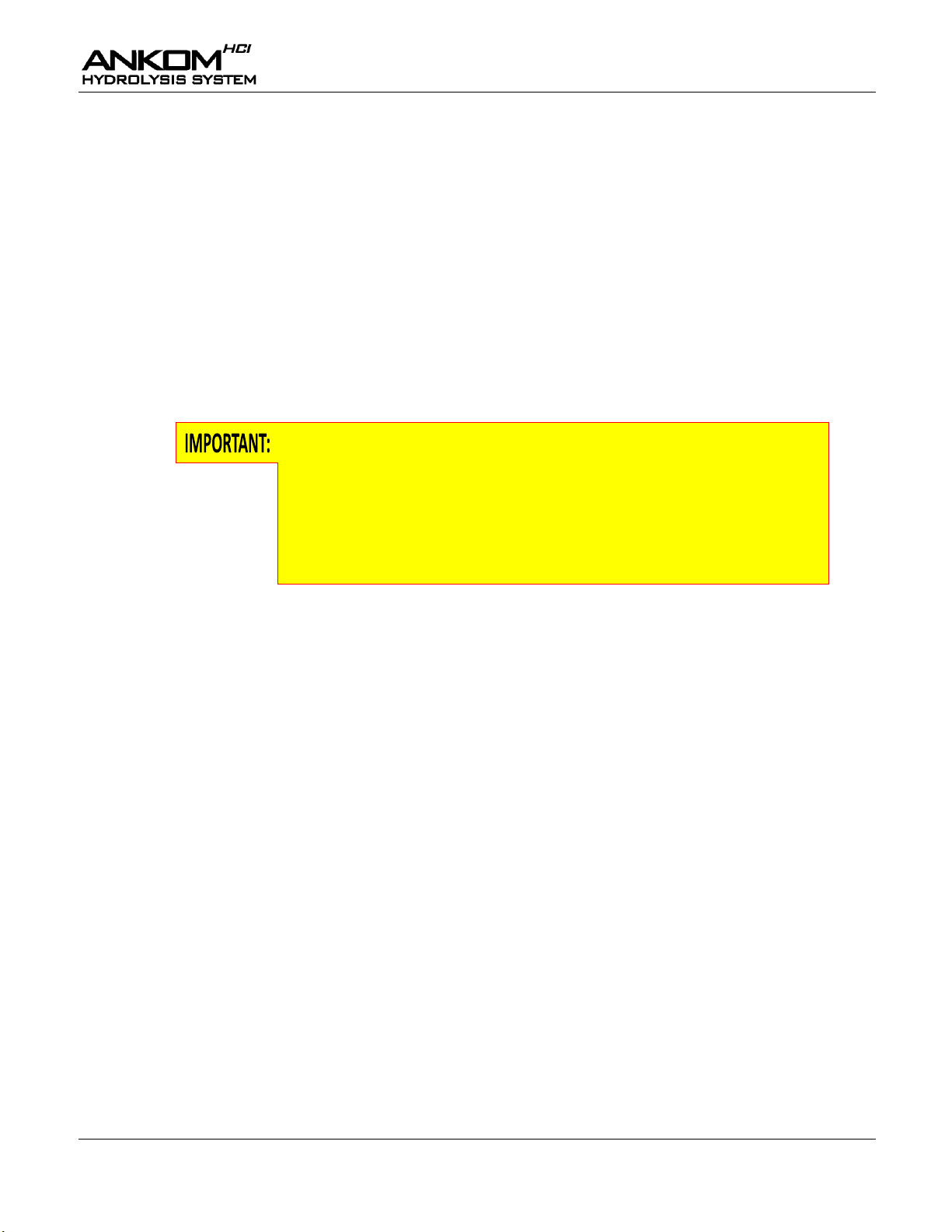

Top Cover (electrical compartment)

Display

Vessel Lid

Hydrolysis

Vessel

Vent Hose

Water Supply

Connection

Water Drain

Hose

Keypad

Lid Latch

Instrument Description

General Description

The ANKOM

the same time in an automated fashion using acid hydrolysis so that the fat from the samples can then be extracted

using fat solvents.

Below is a detailed exterior view of the ANKOM

HCl

Hydrolysis System is designed to release complexed lipids from multiple food or feed samples at

HCl

Hydrolysis System.

Page 8

Operator’s Manual

pg. 8

Rev L 11/12/14

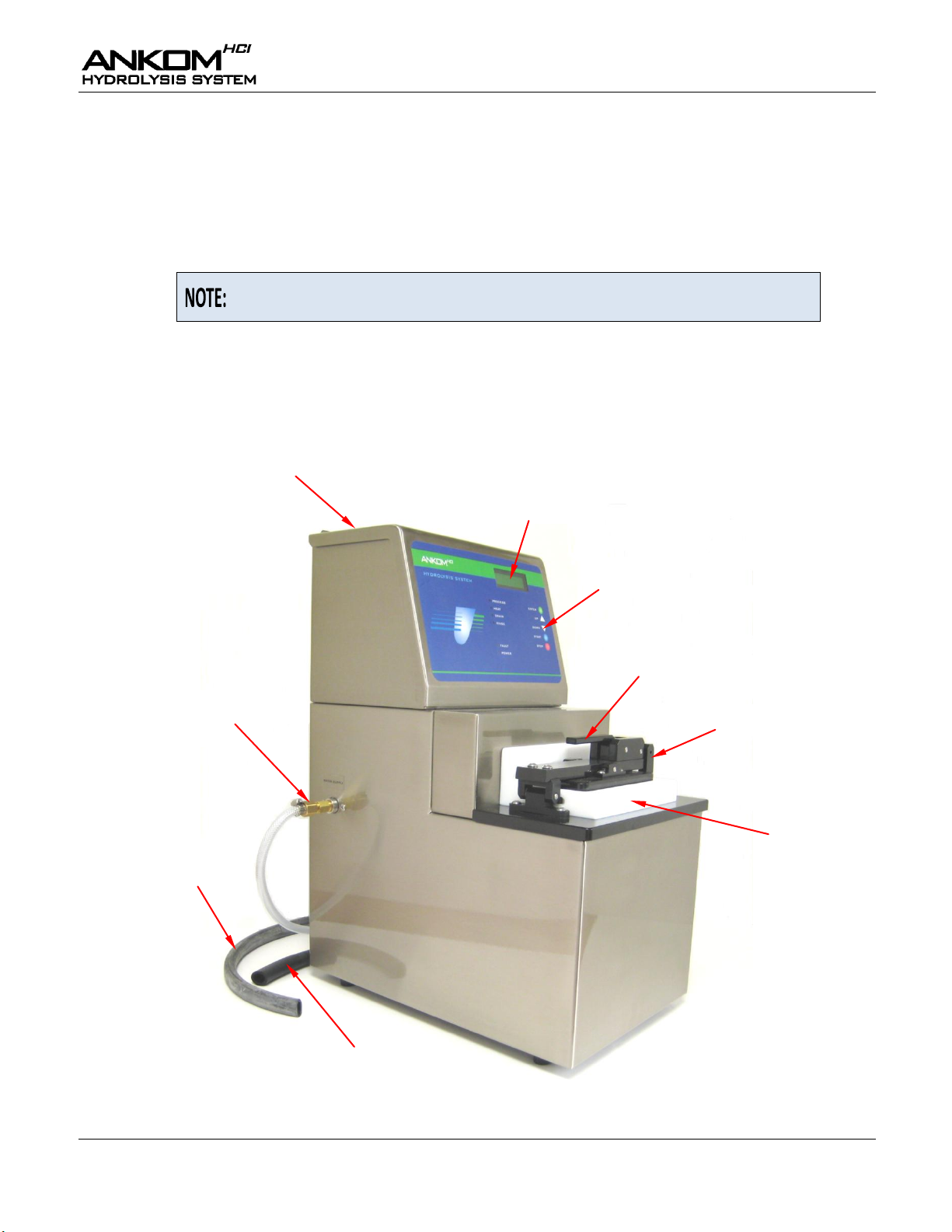

Hot Surfaces – Do not touch the Vessel Lid during operation. The surface can

exceed 70°C (158°F). Failure to observe this caution may result in injury.

Hazardous Voltages – Do not operate the instrument with the Top Cover

(electrical compartment) open. Hazardous voltages are present during

operation. Failure to observe this caution may result in electrical shock or

electrocution.

Hazardous Materials – Acid solution is corrosive. Do not allow acid solution

to contact the skin. Use caution when discarding waste. Dispose of waste in

accordance with safe practices and regulatory provisions.

WARNING: Attempts to override safety features or to use the instruments in a

manner not specified by the manufacturer voids the warranty and may result

in serious injury or even death.

This system is designed to meet and/or exceed the applicable standards of

CE and CSA.

Please review the entire contents of this manual before you begin operating

this instrument.

Safety Precautions

Page 9

Operator’s Manual

Rev L 11/12/14

pg. 9

If you use a dryer, remember to regularly check the air flow through the

filter. For details, refer to the operator’s manual for your dryer.

1.

Remove the instrument from the shipping container and set it on a smooth level surface near a drain and a

cold water supply.

WARNING: Due to the corrosive nature of hydrochloric acid, it is

recommended that the instrument be operated in an acid ventilation hood

separate from other instruments that are subject to corrosion.

2.

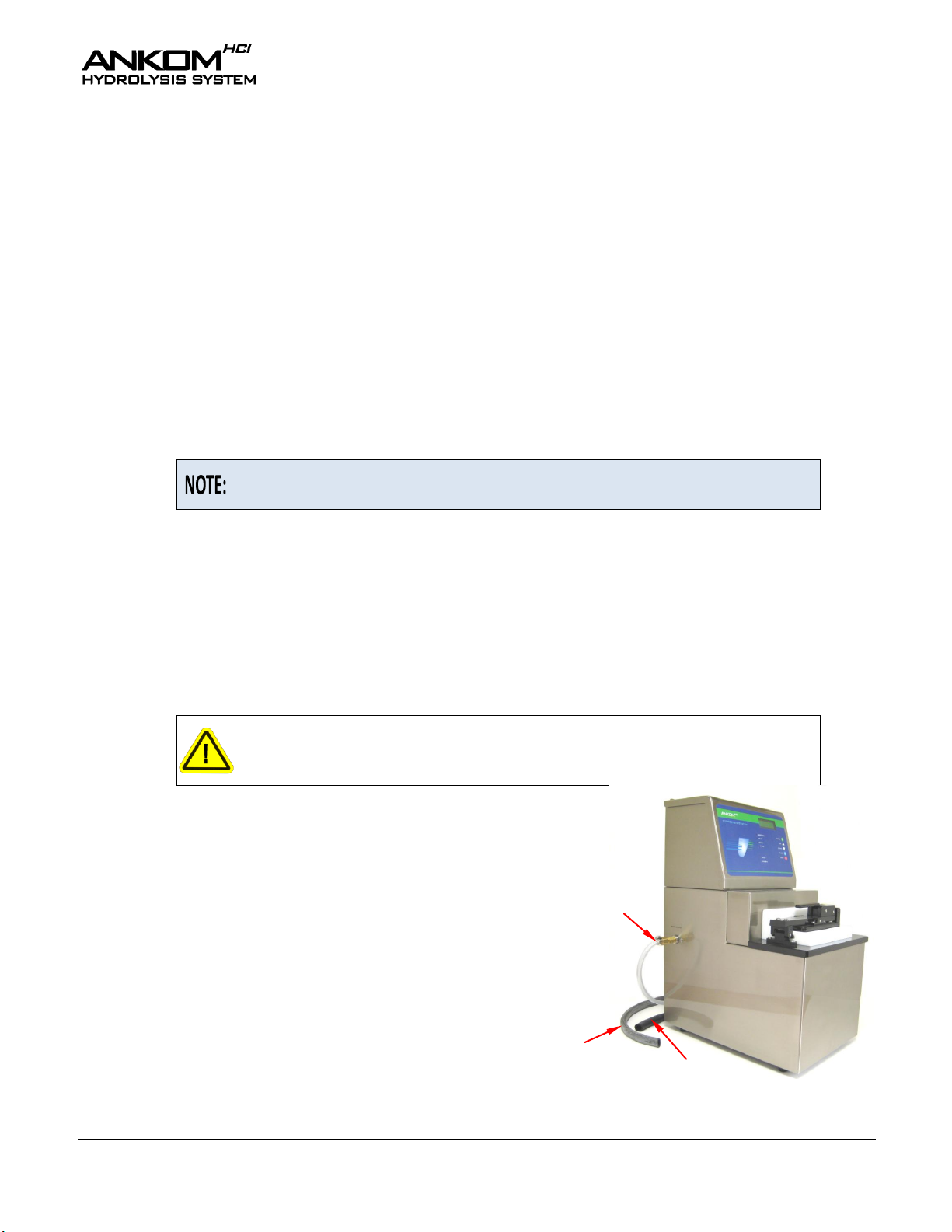

Connect the instrument to a water supply using the

“Water Supply Connection.”

3.

Install the “Water Drain Hose” and position it to run

downhill from the instrument to a drain, allowing

for proper drainage and preventing condensation

from accumulating inside.

Water Drain

Hose

Water Supply

Connection

Vent Hose

Instrument Installation and Setup

Site Requirements

To install and operate the ANKOM

Adjustable wrench

Tap water connection

Adequate power (see “Operating Environment” section)

Drying capability

It is extremely important that you completely dry your food or feed samples in an ANKOMRD Dryer or an oven

resistant to HCl fumes. If samples are not dried enough, residual water and acid left in the samples will lead to

inaccurate fat values. Overheating samples can lead to complexing of the fats resulting in lower values.

The ANKOMRD Dryer is specifically designed for hydrolysis samples and should be set at 110°C. This will result in

the appropriate temperature of 102°C inside the bag. If you are drying samples using a laboratory oven, it is

recommended that you use a mechanical convection oven set to 102°C±2°.

Instrument Installation

The ANKOM

instrument’s power cord must be plugged into a grounded receptacle. Ensure there are no kinks or bends in any of

the tubing that is connected to the instrument.

To install the ANKOM

HCl

Hydrolysis System should be installed in a clean area free of dust and excessive moisture. The

HCl

Hydrolysis System, follow the procedure detailed below.

HCl

Hydrolysis System you will need the following:

Page 10

Operator’s Manual

pg. 10

Rev L 11/12/14

4.

Attach the HCl Zinc Filter Assembly (part# H36) to the “Vent Hose” as shown below. Position the hose

and the filter to run downhill from the instrument to prevent condensation from accumulating inside.

Replace the filter every four months or when pH paper placed at the end of

the filter indicates that acid fumes are exiting the filter.

5.

Plug the power cord into a grounded receptacle.

Water Drain

Hose

Vent Hose

HCl Zinc Filter

Assembly (H36)

Page 11

Operator’s Manual

Rev L 11/12/14

pg. 11

This step is extremely important to fill the waste tank in the instrument with

water to dilute the waste acid from the first and subsequent runs.

1.

Turn the instrument power switch ON.

When the power is on, the switch light and the

power light on the Keypad are lit.

2.

Turn the water supply on.

3.

Pull up on the Lid Latch to open the Hydrolysis

Vessel.

4.

Pour enough water into the Hydrolysis Vessel to cover the ports in the

back.

5.

Using the UP/DOWN arrows on the Keypad, enter an extraction time of 20 minutes.

6.

Press ENTER on the Keypad.

7.

Using the UP/DOWN arrows on the Keypad, enter a temperature of 90°C.

8.

Press ENTER on the Keypad.

9.

Using the UP/DOWN arrows on the Keypad, enter a rinse time of 10 minutes.

10.

Press ENTER on the Keypad.

11.

Close the Vessel Lid (a message on the Display will remind you to do this).

12.

Press START on the Keypad. Within 20 minutes the water should heat to 90°C. Then the Water Drain will

open.

13.

Make sure that all of the water has drained out of the Hydrolysis Vessel. You should then observe two rinses

with each rinse taking approximately 5 minutes to complete.

Repeat the above procedure every three months to verify that the instrument

is functioning properly.

Keypad

Vessel Lid

Lid Latch

Display

Hydrolysis

Vessel

Instrument Setup

To get your ANKOM

HCl

Hydrolysis System set up and ready for use, follow the procedure detailed below.

Page 12

Operator’s Manual

pg. 12

Rev L 11/12/14

This page intentionally left blank

Page 13

Operator’s Manual

Rev L 11/12/14

pg. 13

% Total Fat

=

100 x (W2 – (W3 + (C1 – C2)))

W1

Where:

W1 = Original weight of sample

W2 = Weight of dried sample, filter bag, and Diatomaceous Earth (DE) after hydrolysis

W3 = Weight of dry extracted sample, filter bag, and DE

C1 = Blank filter bag dry weight after hydrolysis

C2 = Blank filter bag weight after extraction

Item

Recommended Product

Electronic Balance with four-place readout

ANKOM #TB Balance Hardware

ANKOM #TBS Balance Software

Filter Bags

ANKOM #XT4

Bag Holder (used for adding sample to an empty filter bag)

ANKOM #101.2

Diatomaceous Earth (DE)

ANKOM #XTC

Heat Sealer for sealing the filter bags

ANKOM #1915 (120V), #1920 (220V)

Solvent Resistant Marker

ANKOM #F08

Multi-bag Holder (used to hold bags in the Hydrolysis Chamber)

ANKOM #H33

Desiccant Pouch for drying

ANKOM #X45

Oven for drying

ANKOM #RD (120V), #RDI (220V)

Sample

Spoon

Hydrolysis Procedure

Total Fat Calculation

The hydrolysis procedure is done prior to fat extraction. When both hydrolysis and fat extraction are done, the Total

Fat contained within a food or feed sample can be calculated using the following formula:

Hydrolysis Support Items

The following support items are needed to perform the hydrolysis procedure:

Page 14

Operator’s Manual

pg. 14

Rev L 11/12/14

For best results, it is important to determine the correct ratio of Diatomaceous Earth (DE) to sample. Before using

your ANKOM

HCl

Hydrolysis System for production testing, it is recommended that you categorize your samples

into types and determine the standard amount of DE needed for each sample type. The following information is

from testing done in the ANKOM lab. This information is meant to help you categorize your own samples.

Sample Type

Fat %

DE

Weight

Sample

Weight

Notes

Yogurt

1 - 1.5 %

0.75 g

0.75 g

Whole Milk

~ 3%

1.25 g

1.25 g

After adding the DE to the filter bag, press the eraser end

of a pencil into the DE to create an indentation into which

the milk can be added using a pipette. Record the weight

(to make sure DE was not transferred to the pencil) & tare.

Whipping Cream

35%

1.25 g

0.5 g

After adding cream to the filter bag using a pipette (see

milk technique above) and not overflowing the indentation

in the DE, leave the filter bag open and dry it in an oven

for 1 hour at 100-105°C. Seal the bag.

Whey Powder

2%

0.75 g

0.75 g

Veggie Chips

20%

0.9 g

0.6 g

Tortilla Chips

25%

0.9 g

0.6 g

Swiss Cheese

30%

1.0 g

0.5 g

Soybean

20%

0.75 g

0.75 g

Sour Cream

20%

0.8 g

0.7 g

Processed Cheese

20 - 25 %

1.0 g

0.5 g

Processed Cheese

> 25 %

1.2 g

0.3 g

Pretzels

5%

0.5

1.0 g

Powdered Non-Dairy Creamer

35%

1.0 g

0.5 g

Potato Chips

30 - 40 %

1.2 g

0.3 g

Mozzarella Cheese

20%

1.0 g

0.5 g

Moist Pet Food (canned)

< 10 %

0.75 g

0.75 g

Moist Distillers Grain (syrup)

10 - 12 %

0.7 g

1.0 g

Milk Replacer

> 30%

0.9 g

0.6 g

Milk Replacer

20 - 30 %

0.75 g

0.75 g

Milk Powder

15 - 20 %

0.75 g

0.75 g

Milk Chocolate

25 - 30 %

0.8 g

0.7 g

Meat & Bone Meal

10 - 15 %

0.5 g

1.0 g

Mayonnaise

75 - 80 %

1.2 g

0.3 g

Hot Dog

30%

1.2 g

0.3 g

Ground Beef

< 20 %

1.0 g

0.5 g

Ground Beef

> 20 %

1.2 g

0.3 g

Forages

2 - 3 %

0.3 g

1.2 g

Most forages are light. Do not allow the mass in the bag to

puff out the sides of the filter bag which will make it more

difficult to completely saturate the sample.

Fish Feed

15%

0.75 g

0.75 g

Feed Mixtures

< 10%

0.3 - 0.4 g

1.1 - 1.2 g

Dried Pet Food

5 - 15 %

0.5 g

1.0 g

Dried Distillers Grain

< 15 %

0.5 g

1.0 g

Dried Algae

15 - 20 %

0.8 g

0.7 g

Cream Cheese

15 - 35 %

1.0 g

0.5 g

Cottage Cheese

< 5 %

0.6 g

0.9 g

Chocolate Liquor

> 50 %

1.1 g

0.4 g

Cheese Curls

~ 25 %

0.9 g

0.6 g

Cheddar Cheese

35%

1.2 g

0.3 g

Sample Categorization

Sample Categorization Data from ANKOM Lab (sorted in alphabetical order by Sample Type)

Page 15

Operator’s Manual

Rev L 11/12/14

pg. 15

Sample Type

Fat %

DE Weight

Sample

Weight

Notes

Whole Milk

~ 3%

1.25 g

1.25 g

After adding the DE to the filter bag, press the eraser end

of a pencil into the DE to create an indentation into which

the milk can be added using a pipette. Record the weight

(to make sure DE was not transferred to the pencil) & tare.

Whipping Cream

35%

1.25 g

0.5 g

After adding cream to the filter bag using a pipette (see

milk technique above) and not overflowing the indentation

in the DE, leave the filter bag open and dry it in an oven

for 1 hour at 100-105°C. Seal the bag.

Processed Cheese

> 25 %

1.2 g

0.3 g

Potato Chips

30 - 40 %

Mayonnaise

75 - 80 %

Hot Dog

30%

Ground Beef

> 20 %

Cheddar Cheese

35%

Chocolate Liquor

> 50 %

1.1 g

0.4 g

Swiss Cheese

30%

1.0 g

0.5 g

Processed Cheese

20 - 25 %

Powdered Non-Dairy Creamer

35%

Mozzarella Cheese

20%

Ground Beef

< 20 %

Cream Cheese

15 - 35 %

Veggie Chips

20%

0.9 g

0.6 g

Tortilla Chips

25%

Milk Replacer

> 30%

Cheese Curls

~ 25 %

Sour Cream

20%

0.8 g

0.7 g

Milk Chocolate

25 - 30 %

Dried Algae

15 - 20 %

Yogurt

1 - 1.5 %

0.75 g

0.75 g

Whey Powder

2%

Soybean

20%

Moist Pet Food (canned)

< 10 %

Milk Replacer

20 - 30 %

Milk Powder

15 - 20 %

Fish Feed

15%

Moist Distillers Grain (syrup)

10 - 12 %

0.7 g

1.0 g

Cottage Cheese

< 5 %

0.6 g

0.9 g

Meat & Bone Meal

10 - 15 %

0.5 g

1.0 g

Dried Pet Food

5 - 15 %

Dried Distillers Grain

< 15 %

Pretzels

5%

Forages

2 - 3 %

0.3 g

1.2 g

Most forages are light. Do not allow the mass in the bag to

puff out the sides of the filter bag which will make it more

difficult to completely saturate the sample.

Feed Mixtures

< 10%

0.3 - 0.4 g

1.1 - 1.2 g

Sample Categorization Data from ANKOM Lab (sorted by DE Weight)

Page 16

Operator’s Manual

pg. 16

Rev L 11/12/14

To avoid fat migration from one filter bag to another during the hydrolysis procedure, it is very important to

prepare your samples properly.

Before running production samples, it is recommended that you do the

following:

Categorize your samples to determine the standard amount of DE needed

for each of your specific sample types. See the “Sample Categorization”

section for details.

Mix dry/granular samples with the correct amount of DE.

Cover moist samples with the correct amount of DE.

To prepare samples for hydrolysis, follow the procedure detailed below.

1.

Using a Solvent Resistant Marker, number all of the empty filter bags you will

use during the hydrolysis procedure.

2.

Record the weights of all the filter bags prior to filling them.

3.

Place an empty filter bag in the Bag Holder in an open position.

4.

Tare the weight of the empty filter bag and the holder together.

5.

Add the necessary DE and sample to the filter bag for Dry/Granular, Moist, and Liquid samples. (See the

“Sample Categorization” section for help in determining how much DE to add to the filter bag.)

For Dry/Granular or Moist samples:

The total weight of DE and sample dry matter must NOT exceed 1.5g. Too

much volume inside the bags will make it difficult for the acid to completely

saturate the sample during hydrolysis. This may reduce the number of bags

that can be processed in the Hydrolysis Vessel at one time.

For Liquid samples:

The total weight of DE and sample MAY exceed 1.5g.

Dry/Granular Samples

a. Add the full recommended amount of DE to the filter bag.

b. Record the weight of the DE and tare.

c. Add an appropriate amount of sample to the filter bag. Keep all

particles away from the sealing area of the filter bag.

d. Record the weight of the sample (W1).

Sample Preparation Procedure

Page 17

Operator’s Manual

Rev L 11/12/14

pg. 17

Moist Samples

a. Add 1/2 of the recommended amount of DE to the filter bag.

b. Using a spatula, make a valley or a space in the DE for the sample.

c. Record the weight and tare.

d. Place an appropriate amount of sample into the DE valley in the filter

bag, being careful that the sample does not touch the inside walls of

the filter bag so the sample can be fully covered with DE.

e. Record the weight of the sample (W1) and tare.

f. Add the rest of the DE to the filter bag to completely cover the sample.

g. Record the weight of the DE.

Liquid Samples

a. Add the full recommended amount of DE to the filter bag.

b. Using a pencil eraser (or similar sized utensil), make an indentation or

a space in the DE into which the liquid sample can be added using a

pipette.

c. Record the weight and tare.

d. Pipette the appropriate amount of liquid sample into the DE

indentation in the filter bag.

e. Record the weight of the sample (W1).

6.

Set the Heat Sealer dial to 6. (The setting may vary from sealer to sealer.)

7.

Seal the filter bag within 4mm of its open end. Keep the

sealer arm down for 2 – 3 seconds after the red sealer light

turns off (to cool the seal). The seal can be seen as a solid

melted stripe along the top edge of the filter bag (as shown

to the right). If the seal is not strong, re-seal the bag.

8.

For Dry/Granular or Moist samples, squeeze the edges of the filter bag then

shake it to mix or cover the sample with the DE. Flatten the bag after shaking.

9.

If the sample is liquid or clumpy (for example ground beef) and makes the filter bag bulge, gently

squeeze the bag at the bulge location to flatten it.

10.

Repeat steps 3 – 9 for all filter bags that will be used in the ANKOM

HCl

Hydrolysis System. (Up to 15

bags can be processed during one procedure.)

Seal

Page 18

Operator’s Manual

pg. 18

Rev L 11/12/14

11.

Include two blank bags (C1 and C2) filled with approximately 0.5g – 0.75g of DE.

Blank bags serve as correction factors for slight losses of weight that may

occur during extraction. Blank bags with DE also act as indicators of fat loss

during hydrolysis. When placed next to a sample that loses fat, a blank bag

will absorb some of the fat lost by the other bag. The result is a blank loss

during extraction that exceeds the normal expected blank loss of 0.0025g by

0.0005g or more. This indicates that fat migrated from a bag with sample to

a blank bag during hydrolysis, and then that same fat was lost during

extraction. If fat migrates from the bags, a pre-extraction with solvent may

be necessary.

12.

Insert filter bags into the Multi-bag Holder and snap the handle in place. Samples

are now ready for the hydrolysis procedure.

Page 19

Operator’s Manual

Rev L 11/12/14

pg. 19

1.

Turn the instrument power switch ON.

2.

Turn the cold water supply on.

3.

Pull the Lid Latch up to open the Vessel Lid.

4.

Place the Multi-bag Holder into the Hydrolysis

Vessel.

5.

Pour 500ml of 3N HCl into the Hydrolysis

Vessel to cover the ports in the back.

6.

Roll up a piece of paper towel and place it on

the Vessel Lid just above the Hinge as shown

to the right. This will help prevent drips of

liquid from getting on the Hinge after a run.

7.

Push the Lid Latch down to close the Vessel Lid.

8.

Press ENTER on the Keypad.

9.

Use the UP/DOWN arrows on the Keypad to enter the hydrolysis time (suggested time is 60 minutes).

10.

Press ENTER on the Keypad.

11.

Use the UP/DOWN arrows on the Keypad to enter the hydrolysis temperature (suggested temperature is

90°C).

12.

Press ENTER on the Keypad.

13.

Use the UP/DOWN arrows on the Keypad to enter the rinse time (suggested time is 20 minutes).

14.

Press ENTER on the Keypad.

15.

Make sure the Vessel Lid is closed (a message on the Display will remind you to do this).

Display

Keypad

Lid Latch

Vessel Lid

Hinge on

Vessel Lid

Hydrolysis

Vessel

Rolled-up

Paper Towel

Ports in back

of Vessel

Hydrolysis step-by-step procedure using the ANKOM

HCl

Hydrolysis System

To perform hydrolysis on prepared samples, follow the procedure detailed below.

Page 20

Operator’s Manual

pg. 20

Rev L 11/12/14

16.

Press START on the Keypad. The ANKOM

HCl

Hydrolysis System will automatically heat and maintain

the set temperature. After hydrolysis is complete, the samples are automatically rinsed with cold water.

When the instrument has completed the automated process, the Display will show “Process Complete”.

17.

When the automated process is complete, open the Lid Latch and immediately wipe the Teflon pad on the

underside of the lid with paper towel.

This step is extremely important to prevent acid from corroding the hinge

on the Vessel Lid.

18.

Remove the Multi-bag Holder from the Hydrolysis Vessel.

19.

Remove the individual filter bags from the Multi-bag Holder and place

them on four layers of paper towel.

20.

Place two layers of paper towel on top of the wet filter bags. Using the

ANKOM Blotter, apply uniform pressure to the top of the paper towels

for two minutes to gently press the water out of the filter bags. Blotting

helps to reduce the drying time and the amount of acid residue in the

bags.

21.

Repeat the blotting process for two more minutes before drying.

22.

Completely dry the samples in an ANKOMRD Dryer or in an oven resistant to HCl fumes. (ANKOM

recommends drying for around three hours at around 100°C.)

Residual acid left in the samples due to incomplete drying will cause

corrosion in the extractor and artificially high fat values.

23.

Remove samples from the dryer/oven and place them directly into a Desiccant Pouch containing pH

paper.

24.

Allow samples to cool to room temperature and check the pH paper. If the presence of acid shows on the

paper, continue drying. If the pH paper is neutral, record weight (W2) of samples.

If your hydrolysis results are low, it is possible that the acid was not able to

completely saturate and hydrolyze the sample. In this case, it may be

necessary to use no more than 1.0g of the combination of sample and DE in

your filter bags. Depending on the sample content, a possible combination

could be 0.5g of sample and 0.5g of DE.

Your samples are now ready for fat extraction in an ANKOM

XT15/XT10

Extractor. See the specific extractor Operator’s Manual for instructions.

Page 21

Operator’s Manual

Rev L 11/12/14

pg. 21

Do NOT use Acetone to clean the instrument.

Periodic Maintenance

Cleaning the exterior of the instrument

At the end of each day use an ammonia-based cleaner (a mild base solution) and cloth to wipe the outside of the

instrument, making sure to clean the hinge on the Vessel Lid.

Cleaning the interior of the Vessel

To restore the white color to the Vessel, periodically run a bleach solution through the instrument using the

procedure detailed below.

1. Turn the water supply on.

2. Pull the Lid Latch up to open the Vessel Lid.

3. Pour 600 ml or enough of a bleach solution into the Hydrolysis Vessel to cover the two ports in the back

wall of the vessel.

4. Push the Lid Latch down to close the Vessel Lid.

5. Press ENTER on the Keypad.

6. Use the UP/DOWN arrows on the Keypad to enter a hydrolysis time of 60 minutes.

7. Press ENTER on the Keypad.

8. Use the UP/DOWN arrows on the Keypad to enter a hydrolysis temperature of 90°C.

9. Press ENTER on the Keypad.

10. Use the UP/DOWN arrows on the Keypad to enter a rinse time of 20 minutes.

11. Press ENTER on the Keypad.

12. Make sure the Vessel Lid is closed (a message on the Display will remind you to do this).

13. Press START on the Keypad. The bleach solution will automatically run through the instrument. When the

process has completed, the Display will show “Process Complete.”

Replacing the HCl Fuses

To replace the fuses in the ANKOM

1. Turn off the instrument power and unplug the Power Cord from the outlet.

2. Remove the two screws on the Top Cover and set them aside.

3. Swing the Top Cover down exposing the electrical compartment.

4. Locate the Fuse Holders on the terminal strip (see the image on the following page). There are two fuses

within the instrument; one for each pole (100 – 120V 10A or 220 – 240V 5A).

HCl

Hydrolysis System, follow the procedure detailed below.

Page 22

Operator’s Manual

pg. 22

Rev L 11/12/14

Tab to open

Fuse Holders

Fuse

Note the arrow

orientation

Fuse

Holders

5. Press the tab and lift the Fuse Holder up.

6. Replace the fuses and close the Fuse Holder completely.

7. Close the Top Cover and secure it with the two screws that you previously removed.

Cleaning/Checking the Water Filter

To clean/check the Water Filter in the ANKOM

1. Unscrew the Water Supply Connection and barb fitting from the HCl instrument.

2. Use compressed air to clean the filter.

3. Reassemble using Teflon tape on the threads.

HCl

Hydrolysis System, follow the procedure detailed below.

Page 23

Operator’s Manual

Rev L 11/12/14

pg. 23

Troubleshooting & Replacement Parts

The ANKOM Technology web site has the most current troubleshooting and replacement parts information. If you

have any questions about the operation of your ANKOM

please visit www.ankom.com.

HCl

Hydrolysis System, or if you need replacement parts,

Page 24

Operator’s Manual

pg. 24

Rev L 11/12/14

This page intentionally left blank

Page 25

Operator’s Manual

Rev L 11/12/14

pg. 25

Appendix A – Electrical Diagram (pg. 1 of 3)

Page 26

Operator’s Manual

pg. 26

Rev L 11/12/14

Appendix A – Electrical Diagram (pg. 2 of 3)

Page 27

Operator’s Manual

Rev L 11/12/14

pg. 27

Appendix A – Electrical Diagram (pg. 3 of 3)

Page 28

Automation saves time and money!

ANKOM Technology is an international company with products that include…

TDF Dietary Fiber Analyzer

Automates AOAC 991.43 and AACC 32-07.01

Automates AOAC 2009.01/2011.25 and AACC 32-45.01

IDF/SDF and TDF values

Faster, Technician-free Filtering

Computer controlled operation

Reduced per assay costs

A2000 Fiber Analyzer

Crude Fiber (AOCS Ba 6a-05), ADF, NDF

Automatically adds solutions and rinses

Batch process - up to 24 samples at one time

XT15 Fat Extractor

Official Method AOCS Am 5-04

Fully automatic

Solvent recovery at 97% or greater

Batch process - up to 15 samples at one time

RF Gas Production System

High sensitivity pressure measurement

Anaerobic activity analyses (rumen, yeast, beer/wine fermentation, etc.)

Biodegradability analyses

Aerobic activity analyses (BOD, soil respiration, etc.)

Wireless Computer control and data storage

Chemicals

A wide variety of chemicals used for many different lab operations

Pre-mixed solutions available

Please visit our web site at www.ankom.com for more information.

2052 O’Neil Rd, Macedon NY 14502

Telephone: (315) 986-8090

Fax: (315) 986-8091

www.ankom.com

Loading...

Loading...