Page 1

Operator’s Manual

2052 O’Neil Rd, Macedon NY 14502

Telephone: (315) 986-8090

Fax: (315) 986-8091

www.ankom.com

Rev E 1/14/15

Page 2

This page intentionally left blank

Page 3

Table of Contents

Introduction .................................................................................................................................................................. 5

Warranty ....................................................................................................................................................................... 5

Filter Bags ..................................................................................................................................................................... 5

Operating Environment ................................................................................................................................................ 5

Contact Information ..................................................................................................................................................... 6

Instrument Description ................................................................................................................................................. 7

Safety Precautions ...................................................................................................................................................... 10

Instrument Installation ............................................................................................................................................... 11

Fiber Analysis Support Items ...................................................................................................................................... 13

Analysis Options using the ANKOM

ADF Analysis ................................................................................................................................................................ 15

NDF Analysis ............................................................................................................................................................... 19

Crude Fiber Analysis ................................................................................................................................................... 25

Flush Procedure .......................................................................................................................................................... 31

Periodic Maintenance ................................................................................................................................................. 33

Troubleshooting .......................................................................................................................................................... 36

Appendix A – ADF Method ......................................................................................................................................... 37

Appendix B – NDF Method ......................................................................................................................................... 39

Appendix C – Crude Fiber Method ............................................................................................................................. 41

Appendix D – Parts & Assemblies ............................................................................................................................... 45

2000

Fiber Analyzer ............................................................................................... 13

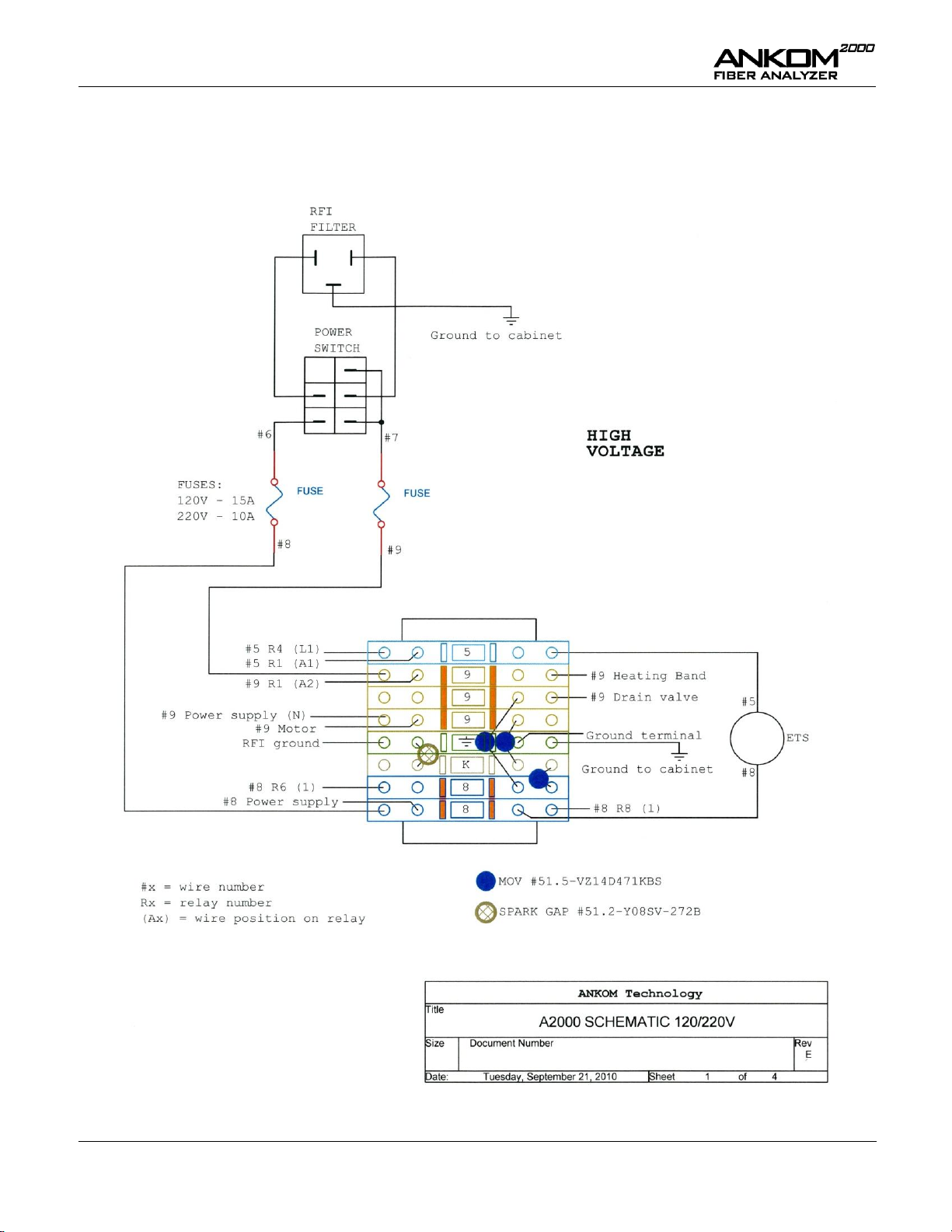

Appendix E – Wiring Diagrams (1 of 4) ....................................................................................................................... 48

Page 4

This page intentionally left blank

Page 5

Operator’s Manual

Please review the entire contents of this manual before you begin operating this

product.

Introduction

ANKOM Technology designs, manufactures, and markets instruments and support products used by analytical

laboratories around the world in the environmental, agricultural, biomass, and food industries. ANKOM

Technology can provide you with products for determining or monitoring detergent fibers, dietary fibers, fat,

digestibility, microbial fermentation (anaerobic or aerobic) and more.

Committed to Total Customer Satisfaction, ANKOM designs every product based on a thorough assessment of

customer needs.

Congratulations on your purchase of the ANKOM

effectively serve your needs.

By carefully following the operating instructions in this manual, you will minimize errors in results. Experience

indicates that errors in results are usually associated with minor variations in carrying out the procedure. This

manual will provide you with details that will help assure accuracy of your results.

2000

Fiber Analyzer. We are confident that this product will

Warranty

ANKOM Technology warrants the ANKOM

material for one year after the original date of purchase. This warranty does not include damage to the instrument

resulting from neglect or misuse. If the instrument is damaged as a result of defects in the workmanship or

materials during the warranty period, ANKOM Technology will repair or replace the instrument free of charge.

Extended warranties are available for purchase if desired.

2000

Fiber Analyzer against any defects due to faulty workmanship or

Filter Bags

ANKOM Technology filter bags (part # F57) are designed to support precision and accuracy in analysis. Use of

other types of filtration media not tested and approved by ANKOM Technology may cause damage to electrical

valves and other components and void your warranty. Filter bags can be purchased from ANKOM Technology or

from your local authorized ANKOM distributor.

Operating Environment

Your ANKOM

Ambient Temperature Range: 15°−30°C

Humidity: 20–60% RH

Power (domestic): 110V−120V ~ 50/60Hz 15A

Power (international): 220V−240V ~ 50/60Hz 10A

2000

Fiber Analyzer is designed to operate within the following environments:

Rev E 1/14/15 pg. 5

Page 6

Operator’s Manual

Contact Information

At ANKOM Technology we are committed to your total satisfaction and therefore always available to help you get

the most from your ANKOM products. We are also very interested in any comments or suggestions you may have

to help us improve.

For any questions or suggestions regarding your instrument, please contact us at:

Telephone: (315) 986-8090

Fax: (315) 986-8091

Email: service@ankom.com

www.ankom.com

pg. 6 Rev E 1/14/15

Page 7

Operator’s Manual

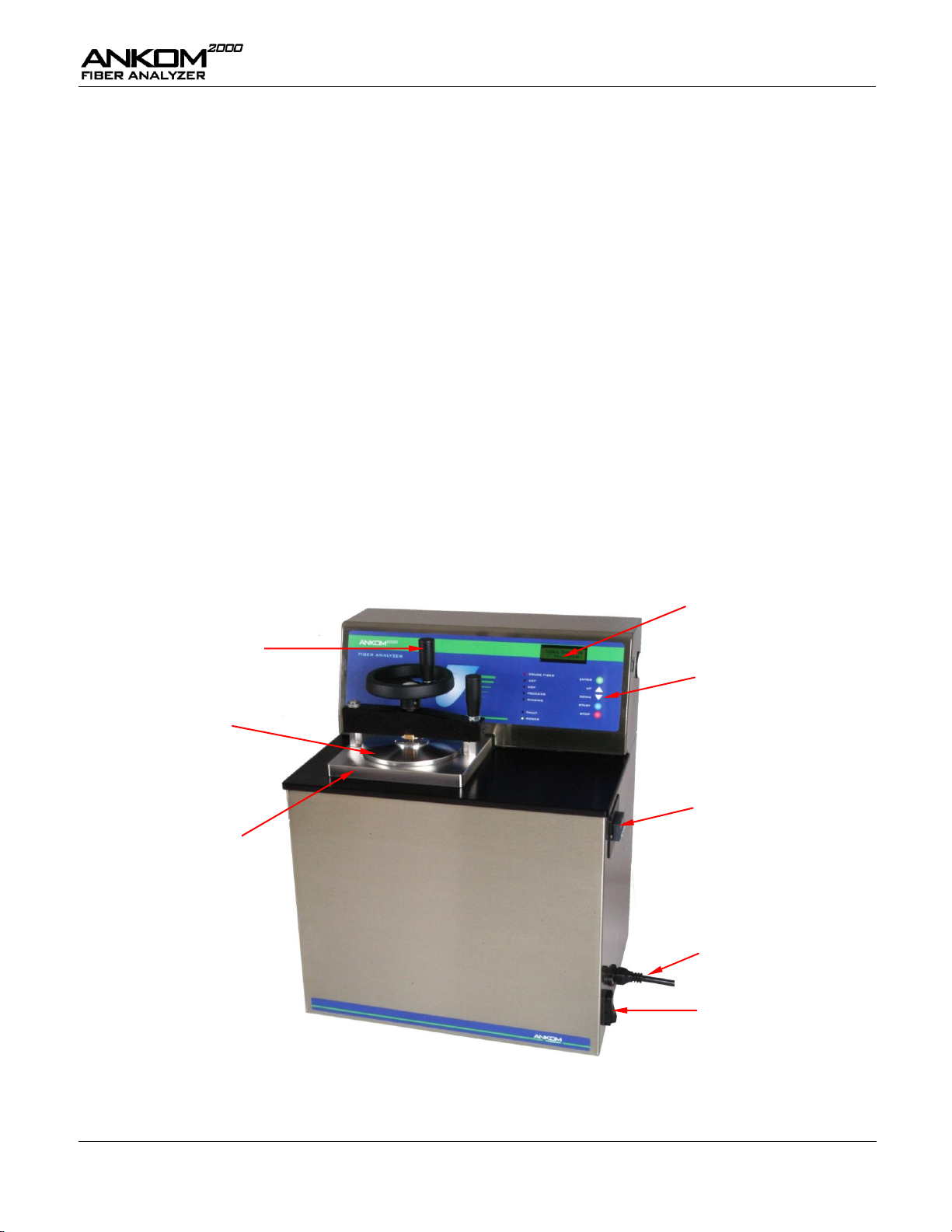

Keypad

Display

Vessel Lid

Vessel

Vessel Clamp Handle

Temperature Controller

Power Cord

Power Switch

Instrument Description

General Description

The ANKOM

Neutral Detergent Fiber (NDF), and Crude Fiber within food and/or feed samples. Enabled by Filter Bag

Technology, up to 24 samples can be processed at one time.

During analysis cell contents are removed as the encapsulated sample is subjected to the appropriate chemical (AD,

ND, or crude fiber acid and base) solutions, leaving the desired fiber fraction. Results are determined

gravimetrically. The filter bags are designed to allow proper flow of solutions while retaining non-soluble

components. The fiber residue captured in the filter bag can be used for follow-on assays such as ADIN, NDIN, and

ADL.

2000

Fiber Analyzer is designed to efficiently and accurately determine Acid Detergent Fiber (ADF),

Like the ANKOM

200

Fiber Analyzer, digestion and rinse operations are all performed within the same instrument,

allowing for the elimination of the separate filtration step. Process temperatures are precisely controlled while

providing proper agitation to ensure a uniform flow of chemical solutions and rinses across each sample.

Below are detailed views of the ANKOM

2000

Fiber Analyzer.

Rev E 1/14/15 pg. 7

Page 8

Operator’s Manual

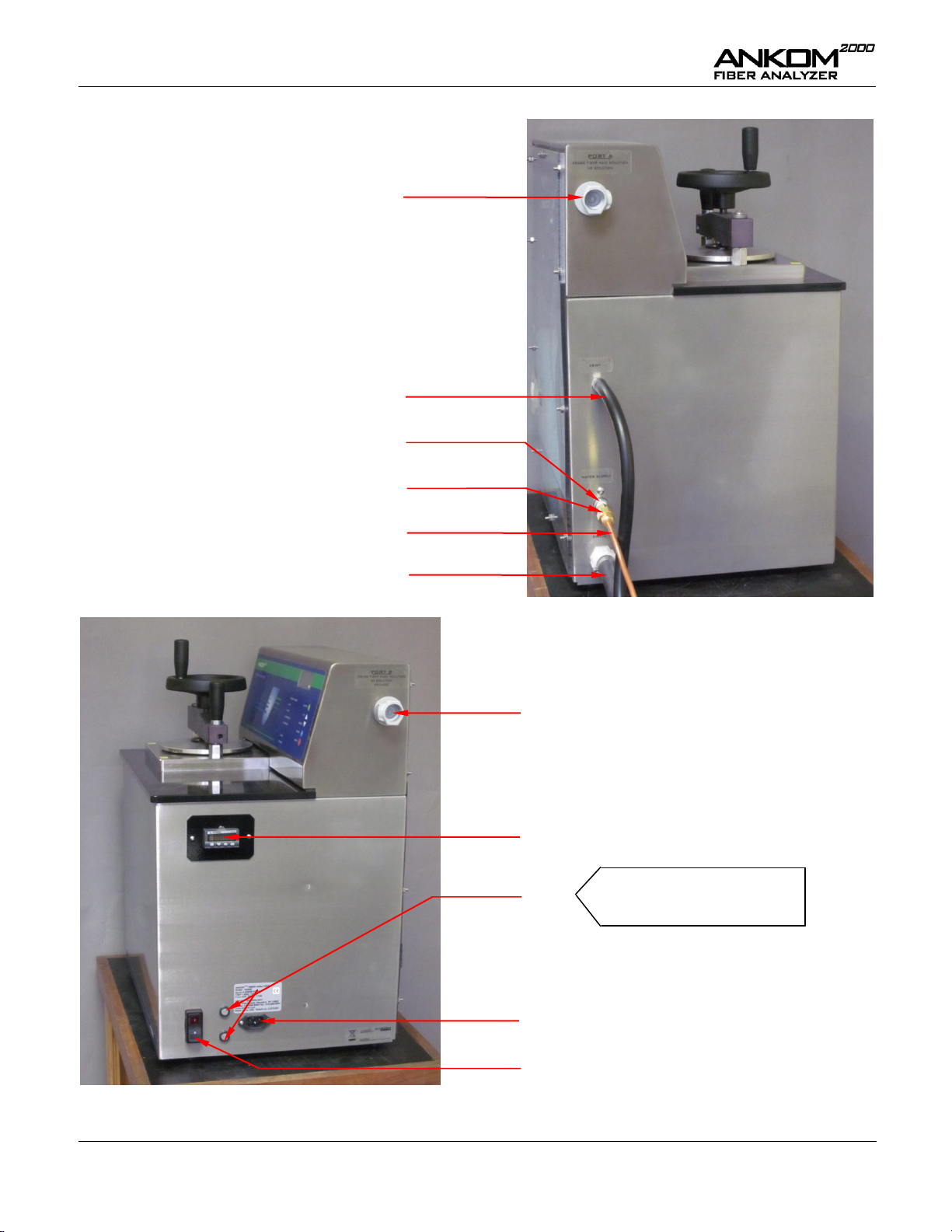

Power Switch

Port B – Used for Crude Fiber Base solution, AD

solution, and Diluted Amylase

Power Cord Inlet

Temperature Controller

Port A – Used for Crude Fiber

Acid solution and ND solution

Fuses

Vent Tube

Line to Hot Water Supply

Drain Hose

Water Filter

Left Side View

Right Side View

Water Supply Fitting

Domestic: 15A/120V

International: 10A/220V

pg. 8 Rev E 1/14/15

Page 9

Operator’s Manual

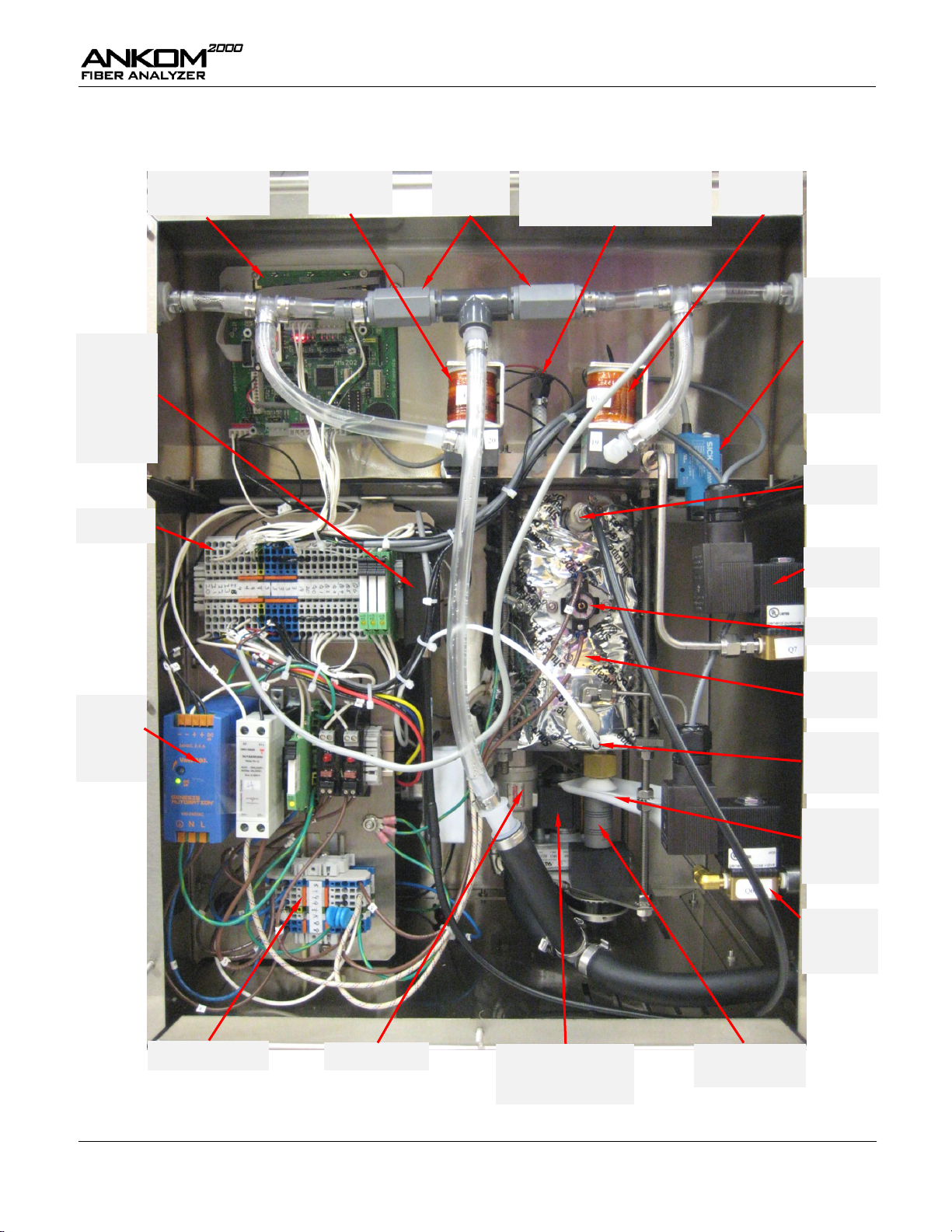

A2000 Computer

(part # A09)

Check Valve

Assembly

Pressure Transducer (part # 6121)

&

Fitting Assembly (part # A25)

Valve B

(part # A19 B)

SICK Fiber

Optic

Module - for

Instruments

delivered

before 4/09

(part # A18)

Vent Valve

(part # A22)

24 VDC

Power

Supply

(part # 963)

High Voltage DIN Rail

Drain Valve

Level Sensor

Fitting

ETS Switch

Water

Supply Valve

(part # A21)

Maintenance

Alert

Collector

(part # F27)

Motor Coupler

(part # 632)

24V DIN Rail

Motor

(part # A08 – 120/60)

(part # A10 – 220/50)

Digestion

Vessel

Temperature

Probe

(part # A17)

Analog Level

Sensor

Module - for

Instruments

delivered

after 4/09

(part # A31)

Valve A

(part # A19 A)

Internal Components

Rev E 1/14/15 pg. 9

Page 10

Operator’s Manual

Hazardous Pressure – Do NOT open the Vessel Lid during operation. The

contents of the Vessel are hot and under pressure. Failure to observe this

caution may result in scalding or burning.

Hot Surfaces – Do NOT touch the Vessel surfaces during operation. The surface

can exceed 70°C (158°F). Failure to observe this caution may result in

burning.

Hazardous Voltages – Do NOT operate the instrument with the cover removed.

Hazardous voltages are present during operation. The Power Cord must be

disconnected prior to removal of the rear panel. Failure to observe this caution

may result in electrical shock or electrocution.

Hazardous Materials – Caution should be used when handling hot effluent that

may be caustic or corrosive. If necessary, the solution can be collected in a

container and neutralized before disposal. Follow safe laboratory practices

according to your local regulations when installing and using this instrument and

associated chemicals.

WARNING: Attempts to override safety features or to use this instrument in a

manner not specified by ANKOM Technology voids the warranty and may result

in serious injury or even death.

This system is designed to meet and/or exceed the applicable standards of

CE, CSA, NRTL and OSHA.

IMPORTANT

The Power Switch must be in the OFF position before plugging the instrument Power

Cord into the power source.

In the event of an instrument malfunction, the internal heater will be automatically

turned off by one of the following safety devices:

1) Electrical Fuses

2) The Emergency Temperature Shut-off Switch (ETS)

3) The Pressure Transducer

Do NOT open the Vessel Lid during or after an operation until both pressure and

liquid are thoroughly exhausted. Connect and secure the Drain Hose along the path to

the drain so it will not move when hot pressurized fluid is exhausted. Failure to

secure the hose could result in uncontrolled chemical flow.

Please review the entire contents of this manual before you begin operating this

instrument.

Safety Precautions

pg. 10 Rev E 1/14/15

Page 11

Operator’s Manual

1.

Remove the instrument from the shipping container and place it in an area that is within six feet of a

drain and water supply on a surface that is firm and level. The instrument must not be subject to

excessive shock, vibration, dirt, moisture, oil, or other fluids.

IMPORTANT

Do NOT place this instrument near microwave ovens or mechanical devices.

Your instrument comes complete with a Power Cord, a Drain Hose, a Vent Tube, a Bag Suspender

Assembly (including Bag Suspender Trays and a Bag Suspender Weight), and an Amylase Container.

2.

With the Power Switch in the OFF position, plug the Power Cord into the Power Cord Inlet.

3.

Plug the Power Cord into the power source.

4.

Install the Water Filter assembly. Attach ¼” copper tubing to the hot water source (+50°C Crude Fiber,

+70°C ND and AD) and to the Water Supply Fitting located on the left side of the instrument.

5.

Connect and secure the Drain Hose so that it will not move when hot pressurized fluid is exhausted.

Instrument Installation

Site Requirements

To install and operate the ANKOM

Adjustable wrench

Water supply located close to the ANKOM

70°C for ADF/NDF analyses

Adequate power (see “Operating Environment” section)

Drain

Instrument Installation Procedure

To install the ANKOM

2000

Fiber Analyzer, follow the procedure detailed below.

2000

Fiber Analyzer you will need the following:

2000

capable of heating water to 50°C for Crude Fiber and

Rev E 1/14/15 pg. 11

Page 12

Operator’s Manual

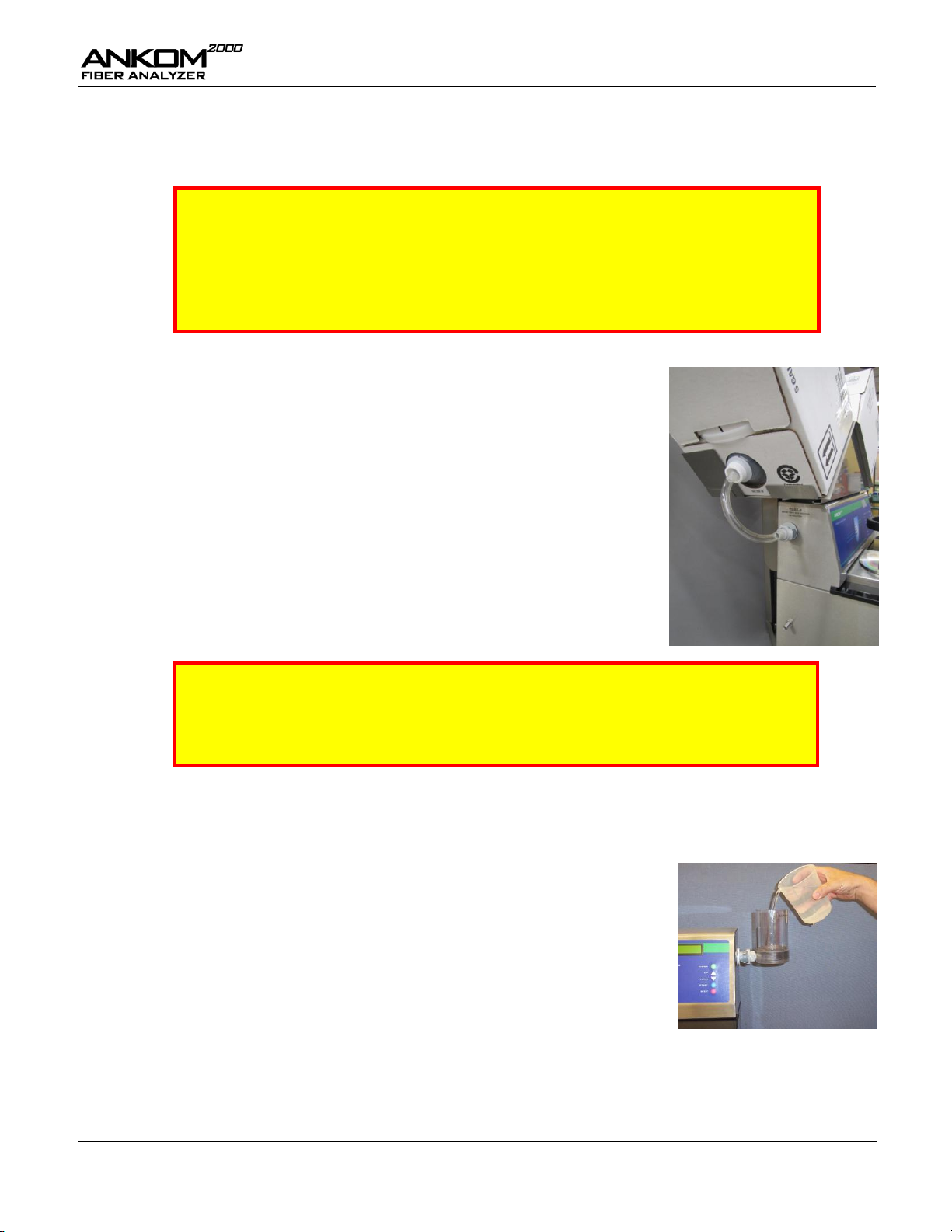

6.

If you are using Cubetainers for your chemicals, install the Cubetainer Shelf shown below (Optional).

IMPORTANT

The solutions are gravity fed into the instrument ports. The bottom of the solution level

must be at least 5” (13cm) above the port. The top of the solution level can be no more

than 20” (50cm) above either port or the solution will overflow into the drain.

pg. 12 Rev E 1/14/15

Page 13

Operator’s Manual

Item

Recommended Product

Electronic Balance with four-place readout

ANKOM #TB Balance Hardware

ANKOM #TBS Balance Software

Filter Bags

ANKOM #F57

Bag Holder (used for adding sample to an empty filter bag)

ANKOM #101.2

Heat Sealer for sealing the filter bags

ANKOM #1915 (120V), #1920 (220V)

Solvent Resistant Marker

ANKOM #F08

Desiccant Pouch

ANKOM #X45

Oven for drying (capable of maintaining 102°C ± 2°)

ANKOM #RD (120V), #RDI (220V)

Sample

-----------------

Spoon

-----------------

Fiber Analysis Support Items

The following support items are needed to perform the fiber analysis procedures:

Analysis Options using the ANKOM

The ANKOM

will run with default digestion and rinse time settings unless you select the Custom analysis option. This option

allows you to do ADF, NDF, or Crude Fiber analyses using custom digestion and rinse time settings.

For maintenance purposes, the ANKOM

The following sections provide the information you will need to use and maintain the ANKOM

2000

Fiber Analyzer can be configured to run ADF, NDF, and Crude Fiber analyses. The instrument

2000

also provides the capability to flush the solution lines.

Fiber Analyzer

2000

Fiber Analyzer.

2000

Rev E 1/14/15 pg. 13

Page 14

Operator’s Manual

This page intentionally left blank

pg. 14 Rev E 1/14/15

Page 15

Operator’s Manual

ADF contained within a food or feed sample can be calculated using the following formula:

% ADF (as-received basis)

=

100 x (W3 – (W1 x C1))

W2

Where:

W1 = Bag tare weight

W2 = Sample weight

W3 = Dried weight of filter bag with fiber after extraction process

C1 = Blank bag correction (running average of final oven-dried weight

divided by original blank bag weight)

To prepare samples for fiber analysis, follow the procedure detailed below.

IMPORTANT

When using the ANKOM

2000

Fiber Analyzer for ADF analysis, at least one blank filter bag

should be included with the sample set as an indicator of particle loss. A running average

of the blank bag weights is used in the fiber calculation as the C1 correction factor. A C1

value larger than 1.0000 indicates that sample particles were lost from filter bags and

deposited on the blank bag. Any fiber particle loss from the filter bags will generate

erroneous results. If particle loss is observed, the grinding method for the specific sample

should be evaluated.

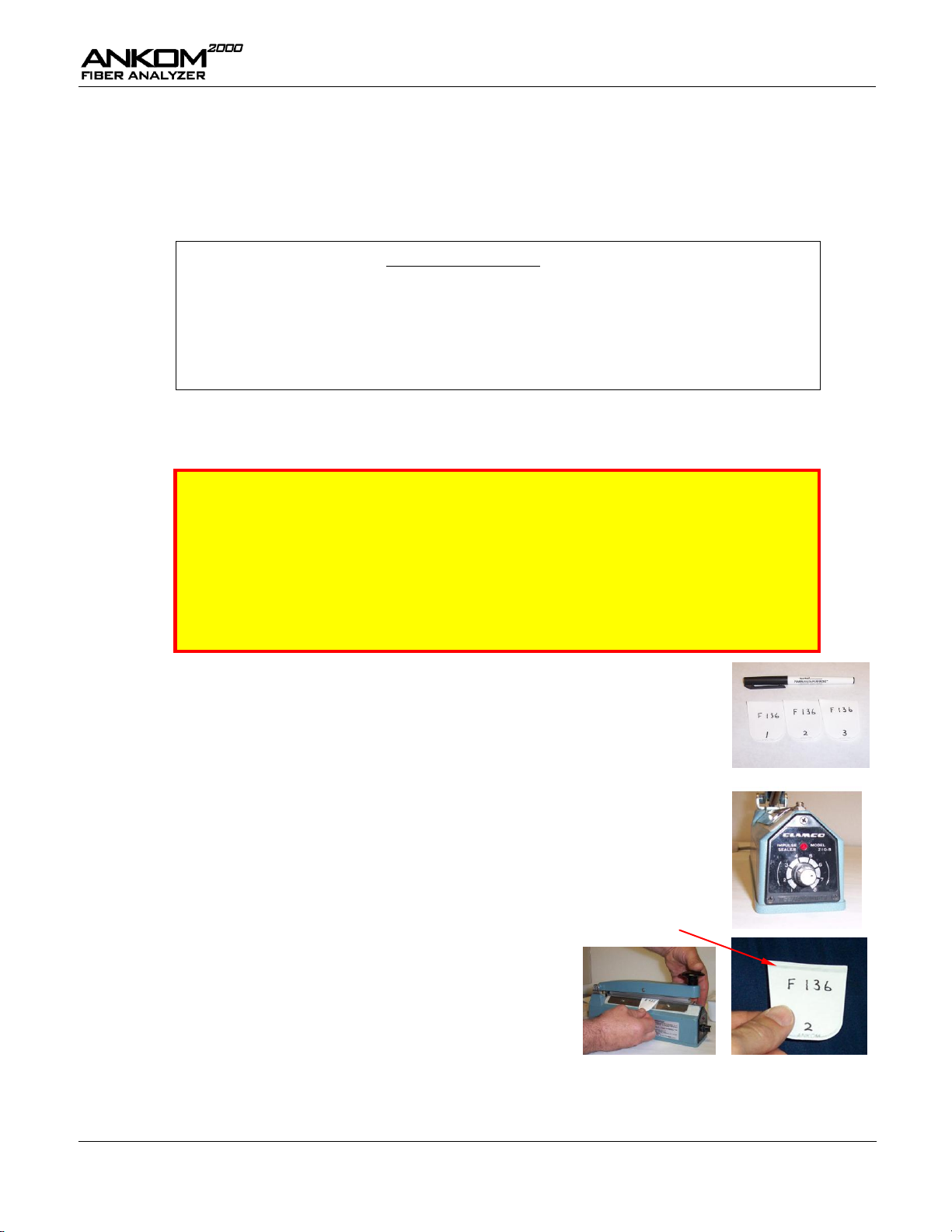

1.

Using a Solvent Resistant Marker, number all of the filter bags you will use

during the fiber analysis.

2.

Weigh and record the weight of each empty filter bag (W1).

3.

Set the Heat Sealer dial to between 4 and 5. (The setting may vary from sealer to

sealer.)

4.

Seal at least one empty filter bag (to be used as a blank)

within 4mm of its open end. Keep the sealer arm down for 2

– 3 seconds after the red sealer light turns off (to cool the

seal). The seal can be seen as a solid melted stripe along the

top edge of the filter bag (as shown to the right). If the seal

is not strong, re-seal the bag.

Seal

ADF Analysis

ADF Calculation

ADF Sample Preparation Procedure

Rev E 1/14/15 pg. 15

Page 16

Operator’s Manual

5.

Place an empty filter bag in the Bag Holder in an open position.

6.

Tare the weight of the empty filter bag and the holder together.

7.

Add 0.45 – 0.50g of sample to the filter bag. Keep all particles away from the

sealing area of the filter bag.

8.

Record the weight of the sample (W2) and tare.

9.

Seal the filter bag within 4mm of its open end. Keep the sealer arm down for 2 – 3 seconds after the red

sealer light turns off (to cool the seal). The seal can be seen as a solid melted stripe along the top edge of

the filter bag. If the seal is not strong, re-seal the bag.

10.

Spread the sample out uniformly within the filter bag by shaking and flicking the bag to eliminate

clumping.

11.

Repeat steps 5 – 10 for all filter bags that will be used in the Analyzer. (Up to 24 bags can be processed

during one procedure.)

IMPORTANT

If your samples contain soybean products or >5% fat, before doing the ADF analysis in

the ANKOM

2000

, you will need to do a pre-extraction. For samples containing non-roasted

soybean or >5% fat, follow the pre-extraction steps below:

1. Place the filter bags with sample (up to 23) into a container with a top.

2. Pour enough fresh acetone into the container to cover the bags.

3. Put the top on the container.

4. Shake the container 10 times and allow bags to soak for 10 minutes.

5. Pour out and dispose of the acetone.

6. Execute steps 1 through 5 a total of two times.

7. Place the bags on a wire screen to air-dry.

If your samples contain roasted soybean, follow the pre-extraction steps below:

1. Place the filter bags with sample (up to 23) into a container with a top.

2. Pour enough fresh acetone into the container to cover the bags.

3. Put the top on the container.

4. Shake the container 10 times.

5. Pour out and dispose of the acetone.

6. Pour fresh acetone into the container and allow the samples to soak for twelve

hours.

7. Pour out the acetone.

8. Place the bags on a wire screen to air-dry.

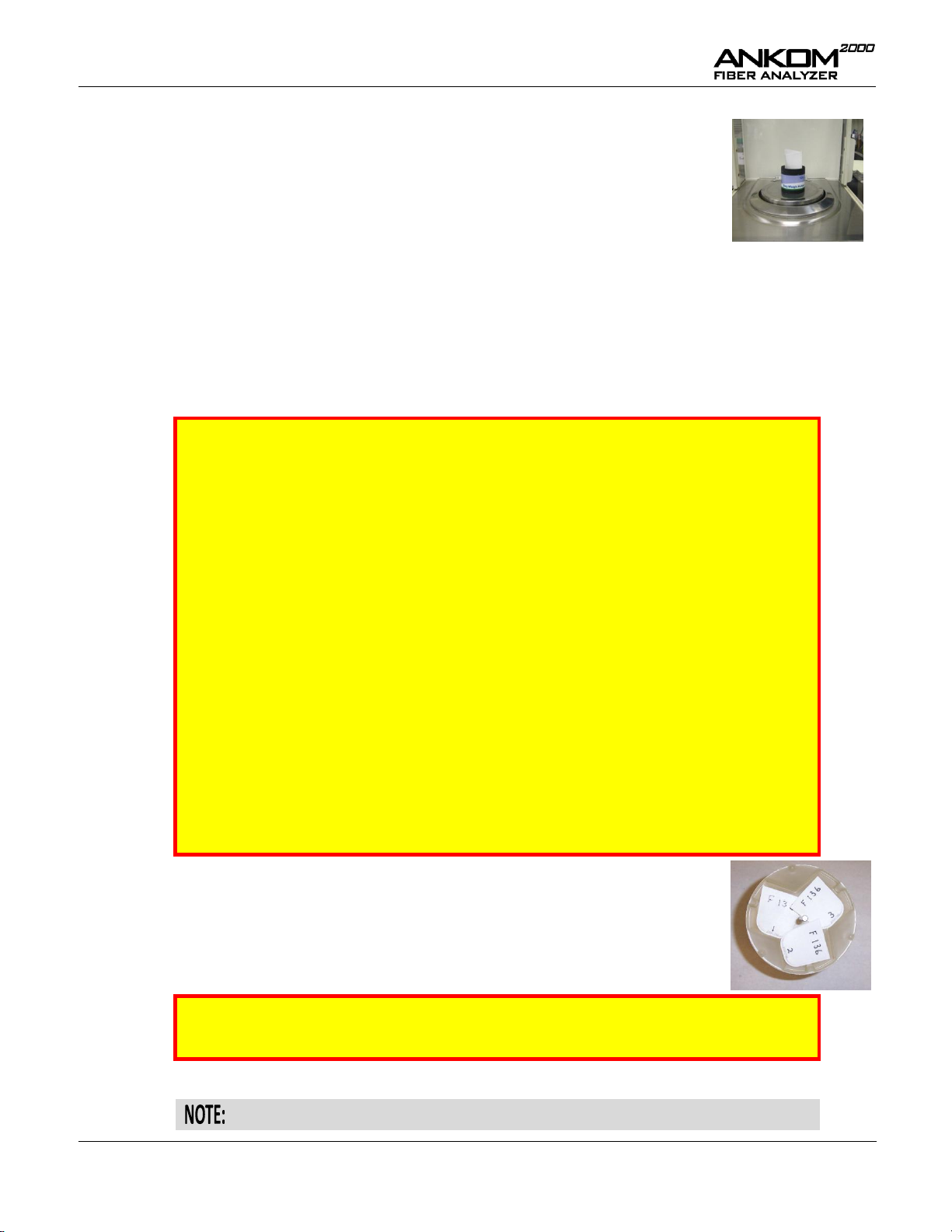

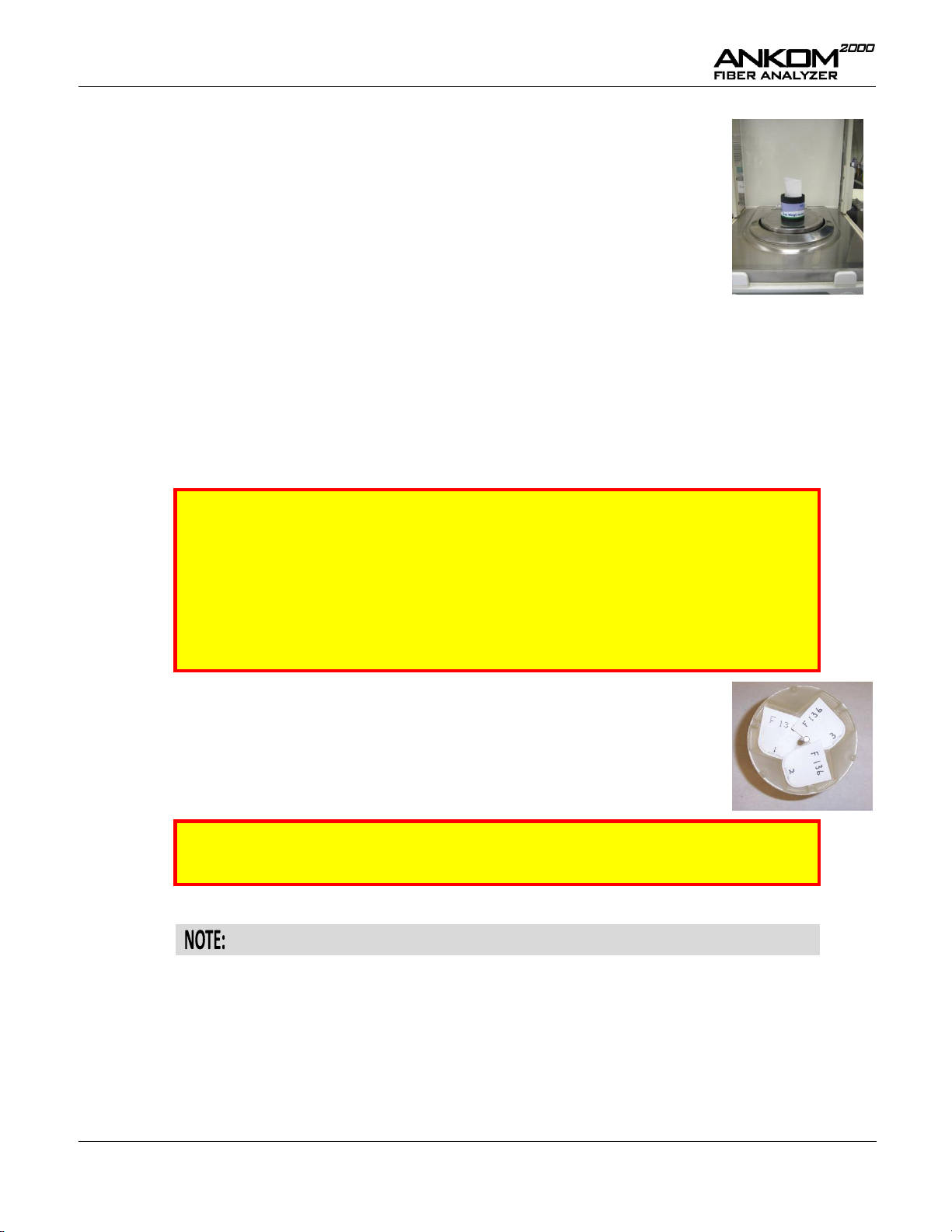

12.

Place the filter bags with sample and at least one empty bag (used as a Blank) into

the Bag Suspender trays as shown (maximum of three bags per tray).

13.

Stack each tray on the Bag Suspender rod (eight trays in total) with each tray

rotated 120 degrees from the tray below.

IMPORTANT

You must use all eight trays even if they are empty.

14.

Add the 9th tray to the top of the Bag Suspender rod. This tray contains no filter bags and acts as a cover.

The samples are now ready for the ADF analysis procedure.

pg. 16 Rev E 1/14/15

Page 17

Operator’s Manual

IMPORTANT

If you are changing from one analysis type to another, flush the system before running. See

the “Flush Procedure” section of this manual for more information.

1.

Verify that the hot water supply is on and the drain hose is securely positioned in the drain.

2.

If you are using Cubetainers for your chemicals, attach the AD solution

hose first to the Cubetainer and then to Port B on the instrument.

IMPORTANT

The solutions are gravity fed into the instrument ports. The bottom of the solution level

must be at least 5” (13cm) above the port. The top of the solution level can be no more

than 20” (50cm) above either port or the solution will overflow into the drain.

3.

Open the Vessel Lid.

4.

Place the bag suspender with the samples into the Vessel.

5.

Place the Bag Suspender Weight onto the Bag Suspender rod to hold the trays in place.

6.

Turn the instrument Power Switch to the ON position. The Display will light and allow you to select an

analysis procedure.

7.

Press the arrow keys on the Keypad until you see “Select ADF” on the

Display.

Select ADF

v <Enter>

IMPORTANT

The ADF analysis will use the following default settings:

60 minute digestion

four 5 minute rinses

If you want to run a custom ADF analysis that allows you to set the digestion time and the

number of rinses, press the arrow keys until you see “Select Custom” on the Display.

ADF Analysis Procedure using the ANKOM

2000

Fiber Analyzer

To perform ADF analysis on prepared samples, follow the procedure detailed below.

Rev E 1/14/15 pg. 17

Page 18

Operator’s Manual

8.

Press ENTER on the Keypad and follow the prompts on the Display to set up the instrument for ADF

analysis.

9.

Close the Vessel Lid and tighten it by turning the Vessel Clamp Handle.

If you do not want to use the Cubetainers to automatically add your solutions, you

can manually fill the vessel for each procedure. First make sure that the hoses to

the Cubetainers are disconnected. Then press START on the Keypad and

immediately pour 2L of solution directly into the vessel. Please note that the

solution must cover the level sensor in order for the instrument to start its

operation.

10.

Press START on the Keypad. Solution from the Cubetainer will flow into the vessel through Port B.

Once the analysis begins, digestions and rinses occur automatically, with the

analyzer Display providing information about the process time remaining, the

temperature, and the pressure. Pressing STOP on the Keypad at any time during

the analysis ends the operation and opens the drain to exhaust the solution.

11.

When the “Process Complete” message appears on the Display, the analyzer operation is complete.

Open the Vessel Lid and remove the Samples at this time.

12.

Gently press out excess water from the bags.

13.

Place bags in a 250ml beaker and add enough acetone to cover them. Let the bags soak in acetone for

3 – 5 minutes.

14.

Remove the bags from the acetone and place them on a wire screen to air-dry.

IMPORTANT

Do NOT place bags in the oven until the acetone has completely evaporated.

15.

Place air-dried bags in the oven and heat at 102°C ± 2° for 2 – 4 hours (depending on the oven).

16.

Remove the samples from the oven and place them in a Desiccant Pouch.

IMPORTANT

Do NOT use conventional countertop or cabinet desiccators for this analysis.

17.

Allow the samples to cool to room temperature. This should take about 10 – 15 minutes.

18.

Remove one filter bag from the Desiccant Pouch. Press the pouch to remove ambient air and zip it tight.

19.

Re-weigh the filter bag (W3) immediately.

20.

Repeat steps 18 and 19 for each filter bag in the Desiccant Pouch.

pg. 18 Rev E 1/14/15

Page 19

Operator’s Manual

NDF contained within a food or feed sample can be calculated using the following formula:

% NDF (as-received basis)

=

100 x (W3 – (W1 x C1))

W2

Where:

W1 = Bag tare weight

W2 = Sample weight

W3 = Dried weight of filter bag with fiber after extraction process

C1 = Blank bag correction (running average of final oven-dried weight

divided by original blank bag weight)

To prepare samples for fiber analysis, follow the procedure detailed below.

IMPORTANT

When using the ANKOM

2000

Fiber Analyzer for NDF analysis, at least one blank filter bag

should be included with the sample set as an indicator of particle loss. A running average

of the blank bag weights is used in the fiber calculation as the C1 correction factor. A C1

value larger than 1.0000 indicates that sample particles were lost from filter bags and

deposited on the blank bag(s). Any fiber particle loss from the filter bags will generate

erroneous results. If particle loss is observed, the grinding method should be evaluated.

1.

Using a Solvent Resistant Marker, number all of the filter bags you will use

during the fiber analysis.

2.

Weigh and record the weight of each empty filter bag (W1).

3.

Set the Heat Sealer dial to between 4 and 5. (The setting may vary from sealer to

sealer.)

4.

Seal at least one empty filter bag (to be used as a blank)

within 4mm of its open end. Keep the sealer arm down for 2

– 3 seconds after the red sealer light turns off (to cool the

seal). The seal can be seen as a solid melted stripe along the

top edge of the filter bag (as shown to the right). If the seal

is not strong, re-seal the bag.

Seal

NDF Analysis

NDF Calculation

NDF Sample Preparation Procedure

Rev E 1/14/15 pg. 19

Page 20

Operator’s Manual

5.

Place an empty filter bag in the Bag Holder in an open position.

6.

Tare the weight of the empty filter bag and the holder together.

7.

Add 0.45 – 0.50g of sample to the filter bag. Keep all particles away from the

sealing area of the filter bag.

8.

Record the weight of the sample (W2) and tare.

9.

Seal the filter bag within 4mm of its open end. Keep the sealer arm down for 2 – 3 seconds after the red

sealer light turns off (to cool the seal). The seal can be seen as a solid melted stripe along the top edge of

the filter bag. If the seal is not strong, re-seal the bag.

10.

Spread the sample out uniformly within the filter bag by shaking and flicking the bag to eliminate

clumping.

11.

Repeat steps 5 – 10 for all filter bags that will be used in the Analyzer. (Up to 24 bags can be processed

during one procedure.)

IMPORTANT

If your samples contain soybean products or >5% fat, before doing the NDF analysis in

the ANKOM

2000

, you will need to do a pre-extraction. For samples containing non-roasted

soybean or >5% fat, follow the pre-extraction steps below:

1. Place the filter bags with sample (up to 23) into a container with a top.

2. Pour enough fresh acetone into the container to cover the bags.

3. Put the top on the container.

4. Shake the container 10 times and allow bags to soak for 10 minutes.

5. Pour out and dispose of the acetone.

6. Execute steps 1 through 5 a total of two times.

7. Place the bags on a wire screen to air-dry.

If your samples contain roasted soybean, follow the pre-extraction steps below:

1. Place the filter bags with sample (up to 23) into a container with a top.

2. Pour enough fresh acetone into the container to cover the bags.

3. Put the top on the container.

4. Shake the container 10 times.

5. Pour out and dispose of the acetone.

6. Pour fresh acetone into the container and allow the samples to soak for twelve

hours.

7. Pour out the acetone.

8. Place the bags on a wire screen to air-dry.

12.

Place the filter bags with sample and at least one empty bag (used as a Blank) into

the Bag Suspender trays as shown (maximum of three bags per tray).

13.

Stack each tray on the Bag Suspender rod (eight trays in total) with each tray

rotated 120 degrees from the tray below.

IMPORTANT

You must use all eight trays even if they are empty.

14.

Add the 9th tray to the top of the Bag Suspender rod. This tray contains no filter bags and acts as a cover.

The samples are now ready for the NDF analysis procedure.

pg. 20 Rev E 1/14/15

Page 21

Operator’s Manual

IMPORTANT

If you are changing from one analytical method to another, flush the system before

running. See the “Flush Procedure” section of this manual for more information.

Amylase tends to be sticky. You should always clean the Amylase Dispenser

Assembly and flush Port B after every NDF procedure unless you are running another

NDF procedure with less than two hours between procedures.

1.

Verify that the hot water supply is on and the drain hose is securely positioned in the drain.

2.

If you are using Cubetainers for your chemicals, attach the ND solution

hose first to the Cubetainer and then to Port A on the instrument.

IMPORTANT

The solutions are gravity fed into the instrument ports. The bottom of the solution level

must be at least 5” (13cm) above the port. The top of the solution level can be no more

than 20” (50cm) above either port or the solution will overflow into the drain.

3.

Open the Vessel Lid.

4.

Place the bag suspender with the samples into the Vessel.

5.

Place the Bag Suspender Weight onto the Bag Suspender rod to hold the trays in place.

6.

Attach the Amylase Dispenser Assembly to Port B. This will be used to

automatically add amylase to the vessel during the rinses.

7.

Fill half of the dispenser with water.

8.

Add two capfuls (8ml) of amylase to the dispenser.

9.

Fill the dispenser with water.

10.

Turn the instrument Power Switch to the ON position. The Display will light and allow you to select an

analysis procedure.

NDF Analysis Procedure using the ANKOM

2000

Fiber Analyzer

To perform NDF analysis on prepared samples, follow the procedure detailed below.

Rev E 1/14/15 pg. 21

Page 22

Operator’s Manual

11.

Press the arrow keys on the Keypad until you see “Select NDF” on the

Display.

Select NDF

v <Enter>

IMPORTANT

The NDF analysis will use the following default settings:

75 minute digestion

four 5 minute rinses

If you want to run a custom NDF analysis that allows you to set the digestion time and the

number of rinses, press the arrow keys until you see “Select Custom” on the Display.

12.

Press ENTER on the Keypad and follow the prompts on the Display to set up the instrument for NDF

analysis.

If you do not want to use the Cubetainers to automatically add your solutions, you

can manually fill the vessel for each procedure. First make sure that the hoses to

the Cubetainers are disconnected. Then press START on the Keypad and

immediately pour 2L of solution directly into the vessel. Please note that the

solution must cover the level sensor in order for the instrument to start its

operation.

13.

Press START on the Keypad. Solution from the Cubetainer will flow into the vessel through Port A.

Once the analysis begins, digestions and rinses occur automatically, with the

analyzer Display providing information about the process time remaining, the

temperature, and the pressure. Pressing STOP on the Keypad at any time during

the analysis ends the operation and opens the drain to exhaust the solution.

14.

After the ND solution has been automatically inserted and agitation begins, manually add 20g of Na2SO3

and 4.0ml of alpha-amylase directly into the Vessel.

15.

Close the Vessel Lid and tighten it by turning the Vessel Clamp Handle.

16.

When the “Process Complete” message appears on the Display, the analyzer operation is complete.

Open the Vessel Lid and remove the Samples at this time.

17.

Gently press out excess water from the bags.

18.

Place bags in a 250ml beaker and add enough acetone to cover them. Let the bags soak in acetone for

3 – 5 minutes.

19.

Remove the bags from the acetone and place them on a wire screen to air-dry.

pg. 22 Rev E 1/14/15

Page 23

Operator’s Manual

IMPORTANT

Do NOT place bags in the oven until the acetone has completely evaporated.

20.

Place air-dried bags in the oven and heat at 102°C ± 2° for 2 – 4 hours (depending on the oven).

21.

Remove the samples from the oven and place them in a Desiccant Pouch.

IMPORTANT

Do NOT use conventional countertop or cabinet desiccators for this analysis.

22.

Allow the samples to cool to room temperature. This should take about 10 – 15 minutes.

23.

Remove one filter bag from the Desiccant Pouch. Press the pouch to remove ambient air and zip it tight.

24.

Re-weigh the filter bag (W3) immediately.

25.

Repeat steps 23 and 24 for each filter bag in the Desiccant Pouch.

IMPORTANT

Amylase is sticky. Unless you are running multiple NDF procedures in near succession,

you must flush the system after NDF procedures. See the “Flush Procedure” section of this

manual for details.

Rev E 1/14/15 pg. 23

Page 24

Operator’s Manual

This page intentionally left blank

pg. 24 Rev E 1/14/15

Page 25

Operator’s Manual

Crude Fiber contained within a food or feed sample can be calculated using the following formula:

% Crude Fiber

=

100 x (W3 – (W1 x C1))

W2

Where:

W1 = Bag tare weight

W2 = Sample weight

W3 = Weight of Organic Matter (loss of weight on ignition of bag and fiber)

C1 = Ash corrected blank bag factor (running average of loss of weight on

ignition of blank bag / original blank bag)

To prepare samples for fiber analysis, follow the procedure detailed below.

IMPORTANT

When using the ANKOM

2000

Fiber Analyzer for Crude Fiber analysis, at least one blank

filter bag should be included with the sample set as an indicator of particle loss. A running

average of the blank bag weights is used in the fiber calculation as the C1 correction factor.

A C1 value larger than 1.0000 indicates that sample particles were lost from filter bags and

deposited on the blank bag(s). Any fiber particle loss from the filter bags will generate

erroneous results. If particle loss is observed, the grinding method should be evaluated.

1.

Using a Solvent Resistant Marker, number all of the filter bags you will use

during the fiber analysis.

2.

Weigh and record the weight of each empty filter bag (W1).

3.

Set the Heat Sealer dial to between 4 and 5. (The setting may vary from sealer to

sealer.)

4.

Seal at least one empty filter bag (to be used as a blank)

within 4mm of its open end. Keep the sealer arm down for 2

– 3 seconds after the red sealer light turns off (to cool the

seal). The seal can be seen as a solid melted stripe along the

top edge of the filter bag (as shown to the right). If the seal

is not strong, re-seal the bag.

Seal

Crude Fiber Analysis

Crude Fiber Calculation

Crude Fiber Sample Preparation Procedure

Rev E 1/14/15 pg. 25

Page 26

Operator’s Manual

5.

Place an empty filter bag in the Bag Holder in an open position.

6.

Tare the weight of the empty filter bag and the holder together.

7.

Add 0.95 – 1.00g of sample to the filter bag. Keep all particles away from the

sealing area of the filter bag.

8.

Record the weight of the sample (W2) and tare.

9.

Seal the filter bag within 4mm of its open end. Keep the sealer arm down for 2 – 3 seconds after the red

sealer light turns off (to cool the seal). The seal can be seen as a solid melted stripe along the top edge of

the filter bag. If the seal is not strong, re-seal the bag.

10.

Spread the sample out uniformly within the filter bag by shaking and flicking the bag to eliminate

clumping.

11.

Repeat steps 5 – 10 for all filter bags that will be used in the Analyzer. (Up to 24 bags can be processed

during one procedure.)

IMPORTANT

For all samples you will need to do a pre-extraction of fat before doing a Crude Fiber

analysis in the ANKOM

2000

. Follow the pre-extraction steps below:

1. Place the filter bags with sample into a 250ml container.

2. Pour enough petroleum ether into the container to cover the bags.

3. Allow the bags to soak for 10 minutes.

4. Pour out and dispose of the petroleum ether.

5. Place the bags on a wire screen to air-dry.

12.

Place the filter bags with sample and at least one empty bag (used as a Blank) into

the Bag Suspender trays as shown (maximum of three bags per tray).

13.

Stack each tray on the Bag Suspender rod (eight trays in total) with each tray

rotated 120 degrees from the tray below.

IMPORTANT

You must use all eight trays even if they are empty.

14.

Add the 9th tray to the top of the Bag Suspender rod. This tray contains no filter bags and acts as a cover.

The samples are now ready for the Crude Fiber analysis procedure.

pg. 26 Rev E 1/14/15

Page 27

Operator’s Manual

1.

Verify that the hot water supply is on and the drain hose is securely positioned in the drain.

2.

Attach each Cubetainer hose first to the Cubetainer and then

to its specific chemical port. Port A is used for Crude Fiber

Acid solution. Port B is used for Crude Fiber Base solution.

IMPORTANT

The solutions are gravity fed into the instrument ports. The bottom of the solution level

must be at least 5” (13cm) above the port. The top of the solution level can be no more

than 20” (50cm) above either port or the solution will overflow into the drain.

3.

Open the Vessel Lid.

4.

Place the bag suspender with the samples into the Vessel.

5.

Place the Bag Suspender Weight onto the Bag Suspender rod to hold the trays in place.

6.

Turn the instrument’s Power Switch to the ON position. The Display will light and allow you to select an

analysis procedure.

IMPORTANT

If you are changing from one analytical method to another, flush the system before

running. See the “Flush Procedure” section of this manual for more information.

7.

Press the arrow keys on the Keypad until you see “Select Crude Fib”

on the Display.

Select Crude Fib

v <Enter>

Crude Fiber Analysis Procedure using the ANKOM

2000

Fiber Analyzer

To perform Crude Fiber analysis on prepared samples, follow the procedure detailed below.

Rev E 1/14/15 pg. 27

Page 28

Operator’s Manual

IMPORTANT

The Crude Fiber analysis will use the following settings:

40 minute Acid Digestion

40 minute Base digestion

two 5 minute Acid rinses

three 5 minute Base rinses

If you want to run a custom Crude Fiber analysis that allows you to set the digestion times

and the number of rinse cycles, press the arrow keys until you see “Select Custom” on the

Display.

8.

Press ENTER on the Keypad and follow the prompts on the Display to set up the instrument for Crude

Fiber analysis.

9.

Close the Vessel Lid tightening it by turning the Vessel Clamp Handle.

10.

Press START on the Keypad. Solution will flow first into the vessel through Port A.

Once the analysis begins, digestions and rinses occur automatically, with the

analyzer Display providing information about the process time remaining, the

temperature, and the pressure. Pressing STOP on the Keypad at any time during

the analysis ends the operation and opens the drain to exhaust the solution.

11.

When the “Process Complete” message appears on the Display, the analyzer operation is complete.

Open the Vessel Lid and remove the Samples at this time.

12.

Gently press out excess water from the bags.

13.

Place bags in a 250ml beaker and add enough acetone to cover them. Let the bags soak in acetone for

3 – 5 minutes.

14.

Remove the bags from the acetone and place them on a wire screen to air-dry.

IMPORTANT

Do NOT place bags in the oven until the acetone has completely evaporated.

15.

Place air-dried bags in the oven and heat at 102°C ± 2° for 2 – 4 hours (depending on the oven).

pg. 28 Rev E 1/14/15

Page 29

Operator’s Manual

16.

Remove the samples from the oven and place them in a Desiccant Pouch.

IMPORTANT

Do NOT use conventional countertop or cabinet desiccators for this part of the analysis.

17.

Allow the samples to cool to room temperature. This should take about 10 – 15 minutes.

18.

Re-weigh each filter bag immediately after removing from the Desiccant Pouch.

19.

Ash all filter bags in pre-weighed crucibles for 2 hours at 600°C ± 15°.

20.

Cool the ashed crucibles in a conventional desiccator.

21.

Weigh the ashed crucibles to calculate the loss of weight of organic matter (W3).

Rev E 1/14/15 pg. 29

Page 30

Operator’s Manual

This page intentionally left blank

pg. 30 Rev E 1/14/15

Page 31

Operator’s Manual

IMPORTANT

Amylase tends to be sticky. You should always clean the Amylase Dispenser Assembly

and flush Port B after every NDF procedure unless the next procedure you are running is

another NDF, and you run it within two hours of the previous procedure.

1.

Turn the instrument’s Power Switch to the ON position. The Display will light.

2.

Verify that the water supply is on and the drain hose is securely in the drain.

3.

Press the arrow keys on the Keypad until you see “Select Flush” on

the Display.

Select Flush

v <Enter>

4.

Press ENTER on the Keypad and follow the prompts on the Display

to set up the instrument for the Flush procedure.

5.

Attach the Amylase Dispenser Assembly to port B.

6.

Fill the dispenser with hot water.

7.

Attach the Amylase Dispenser Assembly to port A.

8.

Fill the dispenser with hot water.

If you press and hold the START key on the Keypad during the Flush operation,

water will flow into the Vessel. This will rinse the bottom of the Vessel, but it will

not rinse all the way to the top. If you need to rinse anything from the top part of

the inside of the Vessel, pour hot water into the Vessel as needed during the Flush

operation.

Flush Procedure

The Flush procedure allows you to clean the system with water. This procedure should be used when changing

from one procedure to another (e.g., when preparing to do an ADF analysis after completing an NDF analysis) or

when doing an NDF procedure after a previous NDF procedure with more than two hours between procedures, or

before storing the instrument.

To perform a Flush of your analyzer, follow the instructions below.

Rev E 1/14/15 pg. 31

Page 32

Operator’s Manual

This page intentionally left blank

pg. 32 Rev E 1/14/15

Page 33

Operator’s Manual

1.

Remove the back panel of the instrument.

2.

Inspect the Maintenance Alert Collector.

Rear View of instrument with cabinet back removed

3.

Clean any residue from the collector.

4.

Unscrew the filter body (the fixture on the

outside of the instrument that attaches to the

water supply).

5.

Unscrew and clean the metal filter screen.

6.

Reassemble the filter and compression fitting.

Make sure the valve body is tight and the

Teflon washer has not come out of the filter

body.

IMPORTANT

Do NOT insert the Bag Suspender into the instrument for this procedure.

7.

Press the arrow keys on the Keypad until you see “Select Flush” on the

Display. Press “ENTER” on the Keypad to turn the agitator on.

Select Flush

v <Enter>

8.

When the motor is activated, turn the Packing

Nut to the RIGHT until you hear a change in

the sound of the motor. (The motor will start to

labor as the packing nut gets harder to turn.)

9.

Loosen the Packing Nut slightly until the

motor stops laboring.

10.

Turn off the instrument and re-install the back

panel.

Packing Nut

Maintenance Alert Collector

Periodic Maintenance

Initial Maintenance (after 10 hours of operation)

After the first 10 hours of operation, follow the procedure below:

Rev E 1/14/15 pg. 33

Page 34

Operator’s Manual

1.

Turn off the instrument power and unplug the

Power Cord from the outlet.

2.

Using a flat blade screwdriver, twist the slot on

the fuse holders counterclockwise ¼ turn to

open.

3.

Check both fuses.

4.

Pull the fuse from the grey fuse cap and

replace as needed.

(120V – 15 amp / 220V – 10 amp)

Using a cotton swab with alcohol, wipe the tip of the

level sensor at least once per month if you use the

instrument daily.

Level Sensor

Fuses (2)

If you see a leak

If you see a leak, follow steps 6 – 9 in the Initial Maintenance procedure above.

Replacing the Fuses

To replace the fuses in the ANKOM

2000

Fiber Analyzer, follow the procedure detailed below.

Cleaning the Fiber Optic Level Sensor

pg. 34 Rev E 1/14/15

Page 35

Operator’s Manual

The agitation system and bag suspender should be checked every three to six months or if fiber values are higher

than normal or inconsistent.

IMPORTANT

Poor agitation will cause higher analysis values and poor repeatability.

To check the stroke of the agitation system, follow the procedure detailed below.

1. Place a full bag suspender in the Vessel (without

the bag suspender weight), but add NO water.

2. Remove the top from a dark felt tip marker.

3. Lay the marker horizontally on the top of the bag

suspender so that the tip touches the inside wall of

the Vessel.

4. With constant downward pressure on the marker,

hold the pen in place so that it rides the top tray up

and down as you execute the Flush Procedure.

(See the Flush Procedure section of this manual

for details.)

5. Allow the bag suspender (& pen) to move up and

down three or four times as the pen marks the

Vessel wall.

6. Stop the agitation.

7. Remove the pen and the bag suspender.

8. Measure the mark on the Vessel wall. It should be

½ inch long. If the motion is less than ½ inch, you

will need to replace either the Bag Suspender Tip

(see next page) or the agitator (because the old

disc has flattened).

To test the agitator vertical positioning, follow the procedure detailed below.

1. Place the bag suspender weight on the bag

suspender within the Vessel.

2. Place a straight edge across the top of the Vessel

as shown in the picture.

3. Run the Flush Procedure. (See the Flush

Procedure section of this manual for details.)

4. The weight should not hit the straight edge at the

top of the stroke. If the weight is hitting the lid or

traveling above the top of the Vessel, the agitator

has moved up in the Vessel and must be

completely re-seated at the bottom of the Vessel.

Contact ANKOM for assistance.

Check Agitation System and Bag Suspender

Rev E 1/14/15 pg. 35

Page 36

Operator’s Manual

Check Bag Suspender

The bag suspender should be checked every three to six months or if fiber values are higher than normal or

inconsistent.

Check the trays for melting.

The pictures shown are examples of extreme cases.

However, for proper operation you must replace trays

that show signs of melting or wear.

Check that the bottom tray is flat.

If the bottom tray is concave (see picture) the bag

suspender will catch in the vessel and melt.

Check the tip for excessive wear (see pictures).

Replace worn tips.

Melted trays

Concave

Tray

Good

Tip

Worn

Tip

Troubleshooting

The ANKOM technology web site has the most current troubleshooting information. Therefore, if you have any

questions about the operation of your ANKOM

pg. 36 Rev E 1/14/15

2000

Fiber Analyzer, please visit our web site at www.ankom.com.

Page 37

Operator’s Manual

Acid Detergent Fiber in Feeds - Filter Bag Technique (for A2000 and A2000I)

Definition

This method determines Acid Detergent Fiber, which is the residue remaining after digesting with H2SO4 and CTAB. The fiber residues are

predominantly cellulose and lignin.

Scope

This method is applicable to grains, feeds, forages, and all fiber-bearing material.

Apparatus

1. Analytical Balance—capable of weighing 0.1 mg.

2. Oven—capable of maintaining a temperature of 102 ± 2°C

(ANKOMRD Dryer, ANKOM Technology).

3. Digestion instrument—capable of performing the digestion at

100 ± 0.5°C and maintaining a pressure of 10-25psi. The

instrument must be capable of creating a similar flow around

each sample to ensure uniformity of extraction (ANKOM

2000

with 65rpm agitation, ANKOM Technology).

4. Filter Bags—constructed from chemically inert and heat resistant

filter media, capable of being heat sealed closed and able to

retain 25 micron particles while permitting solution penetration

(F57, ANKOM Technology).

5. Heat sealer—sufficient for sealing the filter bags closed to ensure

complete closure (1915, ANKOM Technology).

6. Desiccant Pouch—collapsible sealable pouch with desiccant

inside that enables the removal of air from around the filter bags

(MoistureStop weigh pouch, ANKOM Technology).

7. Marking pen—solvent and acid resistant (F08, ANKOM

Technology).

Reagents

1. Acid Detergent Solution—Add 20g cetyl trimethylammonium

bromide (CTAB) to 1L 1.00N H2SO4 previously standardized

(premixed chemical solution available from ANKOM). Agitate

and heat to aid solution.

CAUTION1: Sulfuric acid is a strong acid and will cause severe

burns. Protective clothing should be worn when working with

this acid. Always add acid to water and not the reverse.

CAUTION2: CTAB will irritate mucous membranes. A dust

mask and gloves should be worn when handling this chemical.

Sample Preparation

Grind samples in a centrifugal mill with a 2mm screen or cutter type

(Wiley) mill with a 1mm screen. Samples ground finer may have

particle loss from the filter bags and result in low values.

ADF Procedure (see the ADF Analysis section of the Operator’s

Manual for more detail)

1. Use a solvent resistant marker to label the filter bags to be

used in the analysis.

2. Weigh and record the weight of each empty filter bag (W1)

and zero the balance. NOTE: Do not pre-dry filter bags. Any

moisture will be accounted for by the blank bag correction.

3. Place 0.45 – 0.50g of prepared sample in up to 23 of the

bags and record the weight (W2) of each. Avoid placing the

sample in the upper 4mm of the bag.

4. Include at least one empty bag in the run to determine the

blank bag correction (C1). See Numbered Notes 1.

5. Using a heat sealer, completely seal each filter bag closed

within 4mm of the top to encapsulate the sample. NOTE:

Use sufficient heat to completely seal the filter bags and

allow enough cool time (2 sec) before removing each bag

from the heat sealer.

6. Pre-extract only samples containing soybean products or

>5% fat: Extract samples by placing 24 bags with samples

into a container with a top. Pour enough acetone into the

container to cover the bags and secure the top.

CAUTION3: Acetone is extremely flammable. Avoid static

electricity and use a fume hood when handling.

Shake the container 10 times and allow bags to soak for 10

minutes. Repeat with fresh acetone. Pour out acetone and

place bags on a wire screen to air-dry.

Exception – Roasted soybean: Due to the processing of

roasted soy a modification to the extraction is required.

Place roasted soy samples into a container with a top. Pour

enough acetone into the container to cover the bags and

secure the top. Shake the container 10 times and pour off the

acetone. Add fresh acetone and allow samples to soak for

twelve hours. After the soak time, pour out the acetone and

place the bags on a wire screen to air-dry.

7. Spread the sample uniformly inside the filter bags by

shaking and flicking the bags to eliminate clumping.

8. Place up to 3 bags on each of eight Bag Suspender Trays

(maximum of 24 bags). Stack the trays on the center post of

the Bag Suspender with each level rotated 120 degrees in

relation to the tray below it. Place the empty 9th tray on top.

NOTE: All nine trays must be used regardless of the number

of bags being processed.

9. Verify that the hot water supply is on and the drain hose is

securely positioned in the drain.

(Procedure continued on next page.)

Appendix A – ADF Method

Rev E 1/14/15 pg. 37

Page 38

Operator’s Manual

Calculations

% ADF (as-received basis)

=

100 x (W3 – (W1 x C1))

W2

Where:

W1 = Bag tare weight

W2 = Sample weight

W3 = Dried weight of bag with fiber after

extraction process

C1 = Blank bag correction (running

average of final oven-dried weight

divided by original blank bag

weight)

Numbered Notes

1. A running average blank bag correction factor (C1) should be

used in the calculation of fiber. The inclusion of at least one

blank bag in each run is mainly used as an indicator of particle

loss. A C1 larger than 1.0000 indicates that sample particles were

lost from filter bags and deposited on the blank bag during the

extraction. Any fiber particle loss from the filter bags will

generate erroneous results. If particle loss is observed then the

grinding method needs to be evaluated.

ADF Procedure (continued)

10. Read the Temperature Controller on the right side of the

instrument. If the temperature is higher than 20°C, cool the

Vessel as follows:

a. Fill the Vessel with cold water.

b. When the Temperature Controller reads 20°C, run

the Flush Procedure to drain the water.

11. If you are using Cubetainers for your chemicals, attach the

AD solution hose to the Cubetainer and then to Port B on the

instrument.

12. Open the Vessel Lid and insert the Bag Suspender with bags

into the Vessel and place the Bag Suspender Weight on top

of the empty 9th tray to keep the Bag Suspender submerged.

13. Follow the instructions on the ANKOM

2000

display:

a. Select ADF.

b. Close the Vessel Lid.

c. Confirm hot water is on (>70°C).

d. Press START.

14. When the ADF extraction and rinsing procedures are

complete, open the Vessel Lid and remove the filter bags.

Gently press out excess water from the bags. Place bags in a

250ml beaker and add enough acetone to cover bags and

soak for 3-5 minutes.

15. Remove the filter bags from the acetone and place them on a

wire screen to air-dry. Completely dry in an oven at 102 ±

2°C. (In most ovens the filter bags will be completely dry

within 2-4 hours.) NOTE: Do not place bags in the oven

until the acetone has completely evaporated.

16. Remove the filter bags from the oven and immediately place

them directly into a collapsible desiccant pouch and flatten

to remove any air. Cool to ambient temperature and weigh

the filter bags (W3). NOTE: Do not use a conventional

desiccator container.

pg. 38 Rev E 1/14/15

Page 39

Operator’s Manual

Neutral Detergent Fiber in Feeds - Filter Bag Technique (for A2000 and A2000I)

Definition

This method determines Neutral Detergent Fiber, which is the residue remaining after digesting in a detergent solution. The fiber residues are

predominantly hemicellulose, cellulose, and lignin.

Scope

This method is applicable to grains, feeds, forages, and all fiber-bearing material.

Apparatus

1. Analytical Balance—capable of weighing 0.1 mg.

2. Oven—capable of maintaining a temperature of 102 ± 2°C

(ANKOMRD Dryer, ANKOM Technology).

3. Digestion instrument—capable of performing the digestion at

100 ± 0.5°C and maintaining a pressure of 10-25psi. The

instrument must be capable of creating a similar flow around

each sample to ensure uniformity of extraction (ANKOM

2000

with 65rpm agitation, ANKOM Technology).

4. Filter Bags—constructed from chemically inert and heat resistant

filter media, capable of being heat sealed closed and able to

retain 25 micron particles while permitting solution penetration

(F57, ANKOM Technology).

5. Heat sealer—sufficient for sealing the filter bags closed to ensure

complete closure (1915, ANKOM Technology).

6. Desiccant Pouch—collapsible sealable pouch with desiccant

inside that enables the removal of air from around the filter bags

(MoistureStop weigh pouch, ANKOM Technology).

7. Marking pen—solvent and acid resistant (F08, ANKOM

Technology).

Reagents

1. Neutral Detergent Solution—Add 30g Sodium dodecyl sulfate

(USP), 18.61g Ethylenediaminetetraacetic disodium salt

(dehydrate), 6.81g Sodium borate, 4.56g Sodium phosphate

dibasic (anhydrous), and 10.0ml Triethylene glycol to 1L

distilled H2O (premixed chemical solution available from

ANKOM Technology). Check that pH is from 6.9 to 7.1. Agitate

and heat to aid solution.

CAUTION1: Powdered chemicals will irritate mucous

membranes. A dust mask and gloves should be worn when

handling these chemicals.

2. Alpha-amylase—Heat-stable bacterial alpha-amylase: activity =

17,400 Liquefon Units / ml (FAA, ANKOM Technology).

3. Sodium sulfite—Na2SO3, anhydrous (FSS, ANKOM

Technology)

Sample Preparation

Grind samples in a centrifugal mill with a 2mm screen or cutter type

(Wiley) mill with a 1mm screen. Samples ground finer may have

particle loss from the filter bags and result in low values.

NDF Procedure (see the NDF Analysis section of the Operator’s

Manual for more detail)

1. Use a solvent resistant marker to label the filter bags to be

used in the analysis.

2. Weigh and record the weight of each empty filter bag (W1)

and zero the balance. NOTE: Do not pre-dry filter bags. Any

moisture will be accounted for by the blank bag correction.

3. Place 0.45 – 0.50g of prepared sample in up to 23 of the

bags and record the weight (W2) of each. Avoid placing the

sample in the upper 4mm of the bag.

4. Include at least one empty bag in the run to determine the

blank bag correction (C1). See Numbered Notes 1.

5. Using a heat sealer, completely seal each filter bag closed

within 4mm of the top to encapsulate the sample. NOTE:

Use sufficient heat to completely seal the filter bags and

allow enough cool time (2 sec) before removing each bag

from the heat sealer.

6. Pre-extract only samples containing soybean products or

>5% fat: Extract samples by placing 24 bags with samples

into a container with a top. Pour enough acetone into the

container to cover the bags and secure the top.

CAUTION2: Acetone is extremely flammable. Avoid static

electricity and use a fume hood when handling.

Shake the container 10 times and allow bags to soak for 10

minutes. Repeat with fresh acetone. Pour out acetone and

place bags on a wire screen to air-dry.

Exception – Roasted soybean: Due to the processing of

roasted soy a modification to the extraction is required.

Place roasted soy samples into a container with a top. Pour

enough acetone into the container to cover the bags and

secure the top. Shake the container 10 times and pour off the

acetone. Add fresh acetone and allow samples to soak for

twelve hours. After the soak time, pour out the acetone and

place the bags on a wire screen to dry.

7. Spread the sample uniformly inside the filter bags by

shaking and flicking the bags to eliminate clumping.

8. Place up to 3 bags on each of eight Bag Suspender Trays

(maximum of 24 bags). Stack the trays on the center post of

the Bag Suspender with each level rotated 120 degrees in

relation to the tray below it. Place the empty 9th tray on top.

NOTE: All nine trays must be used regardless of the number

of bags being processed.

9. Verify that the hot water supply is on and the drain hose is

securely positioned in the drain.

(Procedure continued on next page.)

Appendix B – NDF Method

Rev E 1/14/15 pg. 39

Page 40

Operator’s Manual

Calculations

% NDF (as-received basis)

=

100 x (W3 – (W1 x C1))

W2

Where:

W1 = Bag tare weight

W2 = Sample weight

W3 = Dried weight of bag with fiber

after extraction process

C1 = Blank bag correction (running

average of final oven-dried

weight divided by original blank

bag weight)

Numbered Notes

1. A running average blank bag correction factor (C1) should be

used in the calculation of fiber. The inclusion of at least one

blank bag in each run is mainly used as an indicator of particle

loss. A C1 larger than 1.0000 indicates that sample particles were

lost from filter bags and deposited on the blank bag during the

extraction. Any fiber particle loss from the filter bags will

generate erroneous results. If particle loss is observed then the

grinding method needs to be evaluated.

NDF Procedure (continued)

10. If you are using Cubetainers for your chemicals, attach the

ND solution hose to the Cubetainer and then to Port A on the

instrument.

11. Open the Vessel Lid and insert the Bag Suspender with bags

into the Vessel and place the Bag Suspender weight on top

of the empty 9th tray to keep the Bag Suspender submerged.

12. Follow the instructions on the ANKOM

2000

display:

a. Select NDF. (Wait to close the Vessel Lid.)

b. Confirm hot water is on (>70°C).

c. Press START.

d. After the ND solution has been automatically

inserted and agitation begins, manually add 20g of

Na2SO3 and 4.0ml of alpha-amylase.

e. Close the Vessel Lid.

13. Attach the Amylase Dispenser Assembly to Port B on the

instrument. Add 8.0ml of alpha-amylase and enough water

to fill the dispenser. The ANKOM

2000

will automatically add

the amylase solution to the first and second rinse.

14. When the NDF extraction and rinsing procedures are

complete, open the Vessel Lid and remove the filter bags.

Gently press out excess water from the bags. Place bags in a

250ml beaker and add enough acetone to cover bags and

soak for 3-5 minutes.

15. Remove the filter bags from the acetone and place them on a

wire screen to air-dry. Completely dry in an oven at 102 ±

2°C. (In most ovens the filter bags will be completely dry

within 2-4 hours.) NOTE: Do not place bags in the oven

until the acetone has completely evaporated.

16. Remove the filter bags from the oven and immediately place

them directly into a collapsible desiccant pouch and flatten

to remove any air. Cool to ambient temperature and weigh

the filter bags (W3). NOTE: Do not use a conventional

countertop or cabinet desiccator.

pg. 40 Rev E 1/14/15

Page 41

Operator’s Manual

Crude Fiber Analysis in Feeds - Filter Bag Technique (for A2000 and A2000I)

AOCS Approved Procedure Ba 6a-05

Definition

This method determines Crude Fiber which is the organic residue remaining after digesting with 0.255N H2SO4 and 0.313N NaOH. The

compounds removed are predominantly protein, sugar, starch, lipids and portions of both the structural carbohydrates and lignin.

Scope

This method is applicable for all feed materials such as grains, meals, pet foods, mixed feeds, forages, and the following oilseeds: corn and

soybeans.

Apparatus

1. Analytical Balance—capable of weighing 0.1 mg.

2. Oven—capable of maintaining a temperature of 102 ± 2°C

(ANKOMRD Dryer, ANKOM Technology).

3. Electric muffle furnace—with rheostat control and pyrometer

that will maintain a temperature of 600 ± 15°C.

4. Digestion instrument—capable of performing the digestion at

100 ± 0.5°C and maintaining a pressure of 10-25psi. The

instrument must be capable of creating a similar flow around

each sample to ensure uniformity of extraction (ANKOM

2000

with 65rpm agitation, ANKOM Technology).

5. Filter Bags—constructed from chemically inert and heat resistant

filter media, capable of being heat sealed closed and able to

retain 25 micron particles while permitting solution penetration

(F57 or F58, ANKOM Technology). See Numbered Notes 1.

6. Heat sealer—sufficient for sealing the filter bags closed to ensure

complete closure (1915, ANKOM Technology).

7. Desiccant Pouch—collapsible sealable pouch with desiccant

inside that enables the removal of air from around the filter bags

(MoistureStop weigh pouch, ANKOM Technology).

8. Marking pen—solvent and acid resistant (F08, ANKOM

Technology).

Reagents

1. Sulfuric acid solution—0.255 ± 0.005N. 1.25g H2SO4/100ml.

Concentration must be checked by titration.

CAUTION1: Sulfuric acid is a strong acid and will cause severe

burns. Protective clothing should be worn when working with

this acid. Always add acid to water and not the reverse.

2. Sodium hydroxide solution—0.3130 ± 005N. 1.25g

NaOH/100ml. Concentration must be checked by titration.

CAUTION2: Sodium hydroxide can severely burn the skin,

eyes, and respiratory tract. Protective clothing should be worn

when working with this acid. Always add caustic material to

water and not the reverse.

Sample Preparation

Grind samples in a centrifugal mill with a 2mm screen or cutter type

(Wiley) mill with a 1mm screen. Samples ground finer may have

particle loss from the filter bags and result in low values.

Crude Fiber Procedure (see the Crude Fiber Analysis section of the

Operator’s Manual for more detail)

1. Use a solvent resistant marker to label the filter bags to be

used in the analysis.

2. Weigh and record the weight of each empty filter bag (W1)

and zero the balance. NOTE: Do not pre-dry filter bags. Any

moisture will be accounted for by the blank bag correction.

3. Place 0.95 – 1.00g of prepared sample in up to 23 of the

bags and record the weight (W2) of each. Avoid placing the

sample in the upper 4mm of the bag.

4. Include at least one empty bag in the run to determine the

blank bag correction (C1). See Numbered Notes 2.

5. Using a heat sealer, completely seal each filter bag closed

within 4mm of the top to encapsulate the sample. NOTE:

Use sufficient heat to completely seal the filter bags and

allow enough cool time (2 sec) before removing each bag

from the heat sealer.

6. Extract fat from samples by placing all bags into a 250ml

container. Add enough petroleum ether to cover bags and

soak for 10 minutes.

CAUTION3: Petroleum ether is extremely flammable.

Avoid static electricity. A fume hood should be used at all

times when using petroleum ether.

Pour off the solvent and allow the bags to air-dry. Spread the

sample uniformly inside the filter bags by shaking and

flicking the bags to eliminate clumping.

7. Place up to 3 bags on each of eight Bag Suspender Trays

(maximum of 24 bags). Stack the trays on the center post of

the Bag Suspender with each level rotated 120 degrees in

relation to the tray below it. Place the empty 9th tray on top.

NOTE: All nine trays must be used regardless of the number

of bags being processed.

8. Verify that the hot water supply is on and the drain hose is

securely positioned in the drain.

9. Read the Temperature Controller on the right side of the

instrument. If the temperature is higher than 20°C, cool the

Vessel as follows:

a. Fill the Vessel with cold water.

b. When the Temperature Controller reads 20°C, run

the Flush Procedure to drain the water.

(Procedure continued on next page.)

Appendix C – Crude Fiber Method

Rev E 1/14/15 pg. 41

Page 42

Operator’s Manual

Precision

Results of the collaborative study (see Tables 1&2) indicate the

precision (Sr, RSDr, r) that the analyst should use as a benchmark for

evaluating replication in the same laboratory.

Calculations

% Crude Fiber

=

100 x (W3 – (W1 x C1))

W2

Where:

W1 = Bag tare weight

W2 = Sample weight

W3 = Weight of Organic Matter (loss of

weight on ignition of bag and

fiber)

C1 = Ash corrected blank bag factor

(running average of loss of weight

on ignition of blank bag/original

blank bag)

Numbered Notes

1. F57 filter bags may produce up to 0.5% units lower values on

finely ground samples. Finely ground samples have fiber

particles less than 25 microns.

2. A running average blank bag correction factor (C1) should be

used in the calculation of fiber. The inclusion of at least one

blank bag in each run is mainly used as an indicator of particle

loss. A C1 larger than 1.0000 indicates that sample particles were

lost from filter bags and deposited on the blank bag. Any fiber

particle loss from the filter bags will generate erroneous results.

If particle loss is observed then the grinding method needs to be

evaluated.

Crude Fiber Procedure (continued)

10. Attach each Cubetainer hose to the Cubetainer and to its

specific port. Port A is used for Crude Fiber Acid solution.

Port B is used for Crude Fiber Base solution.

11. Open the Vessel Lid and insert the Bag Suspender with bags

into the Vessel and place the Bag Suspender Weight on top

of the empty 9th tray to keep the Bag Suspender submerged.

12. Follow the instructions on the ANKOM

2000

display:

a. Select Crude Fiber.

b. Close Vessel Lid.

c. Confirm hot water is on (>50°C).

d. Press START.

13. When the Crude Fiber extraction and rinsing processes are

complete, open the Vessel Lid and remove the samples.

Gently press out excess water from the bags. Place the bags

in a 250ml beaker and add enough acetone to cover the bags

and soak for 3-5 minutes.

CAUTION4: Acetone is extremely flammable. Avoid static

electricity. A fume hood should be used at all times when

using acetone.

14. Remove the filter bags from the acetone and place them on a

wire screen to air-dry. Completely dry in an oven at 102 ±

2°C. (In most ovens the filter bags will be completely dry

within 2-4 hours.) NOTE: Do not place bags in the oven

until the acetone has completely evaporated.

15. Remove the filter bags from the oven and immediately place

them directly into a collapsible desiccant pouch and flatten

to remove any air. Cool to ambient temperature and weigh

the filter bags. NOTE: Do not use a conventional desiccator

container for this step.

16. Ash the entire filter bag/sample in a pre-weighed crucible

for 2 hours at 600 ± 15°C, cool in a conventional desiccator

and weigh to calculate loss of weight of organic matter (W3).

pg. 42 Rev E 1/14/15

Page 43

Operator’s Manual

Collaborative

Laboratory No.

Rep

Whole

Corn

Cattle

Feed

Alfalfa

Whole

Soy

Poultry

Starter

Calf

Starter

Swine

Feed

Horse

Feed

Soy

Meal

Pig

Starter

Dog

Food

% Crude Fiber

1 1 2.1 14.5 22.6 9.8 4.7 11.0 17.5 6.4 3.7 2.8 1.3

2 1.8 14.2 22.4 9.9 4.9 10.7 17.2 6.5 4.0 2.9 1.3

2 1 1.7 14.8 C 22.5 7.2 C 4.4 10.4 17.4 5.8 3.4 2.6 7.1 C

2 2.0 20.2 C 23.0 10.1 C 4.7 11.1 17.4 6.0 3.5 2.8 1.0 C

3 1 1.6 14.1 22.5 10.1 4.6 10.8 17.6 6.6 3.9 3.1 2.0

2 1.9 14.6 22.5 10.3 4.7 10.9 17.6 6.8 4.0 3.2 1.6

4 1 1.6 14.2 22.2 9.5 4.4 10.6 17.1 6.2 3.4 3.0 1.3

2 1.7 14.7 22.2 9.9 4.7 10.5 16.9 6.4 3.7 2.9 1.3

5 1 1.5 13.9 22.7 9.5 4.8 10.5 17.3 5.9 3.6 2.8 1.3

2 1.8 14.5 22.4 10.1 4.7 10.5 17.6 6.0 3.5 2.7 1.4

6 1 1.8 14.1 22.6 9.3 4.7 10.9 17.2 6.3 3.7 2.8 1.2

2 2.0 14.3 21.9 9.4 4.5 10.4 17.2 6.1 3.8 3.0 1.3

7 1 1.7 14.5 24.0 10.0 4.8 10.7 17.4 6.1 3.7 3.0 1.2

2 1.5 14.8 23.6 10.0 4.3 10.4 17.4 6.2 4.0 2.9 1.1

8 1 1.6 15.0 22.3 9.3 4.6 10.7 17.4 C 6.0 C 3.7 2.5 0.5

2 1.6 14.4 22.9 10.0 4.3 10.8 2.4 C 5.2 C 3.4 2.6 1.1

9 1 1.4 14.4 21.9 8.9 4.6 10.4 17.0 5.9 3.4 2.7 1.3

2 1.8 14.3 22.6 9.6 4.2 10.4 16.6 5.9 3.7 2.7 1.2

10 1 1.7 14.1 21.4 9.3 4.5 10.8 17.0 6.3 3.8 2.9 1.4

2 1.7 14.2 22.1 9.8 4.8 10.9 17.3 6.3 3.6 2.8 1.4

11 1 1.4 14.3 23.3 8.5 4.7 10.9 17.7 C 6.1 3.6 2.8 1.3

2 1.5 15.9 24.1 8.9 5.5 11.9 19.1 C 6.2 4.2 2.9 0.6

Mean 1.69 14.44 22.62 9.60 4.65 10.73 17.27 6.21 3.70 2.83 1.25

Official Method Laboratories

a

% Crude Fiber

Central Analytical 1.8 14.5 23.0 10.2 4.4 9.3 G 14.7 G 6.8 2.9 1.9 G 3.4 G

Hahn Laboratories, Inc. 2.0 14.0 21.2 8.4 4.2 10.6 17.4 5.7 4.2 2.9 1.6

SDSU Olson Bio. Lab 2.4 14.2 23.8 10.1 4.6 10.8 17.4 6.8 4.1 2.8 1.3

Mean 2.05 14.23 22.67 9.57 4.40 10.70 17.40 6.43 3.73 2.85 1.45

Outliers: C-Chochran, G-Grubbs, DG-Double Grubbs

a

AOCS Official Method Ba 6-84, AOAC 962.09

Table 1. Results of the international collaborative study of the Filter Bag Technique for crude fiber compared

with three laboratories using an Official Crude Fiber Method.

Sample type

Whole

Corn

Cattle

Feed

Alfalfa

Whole

Soy

Poultry

Starter

Calf

Starter

Swine

Feed

Horse

Feed

Soy

Meal

Pig

Starter

Dog

Food

Number of laboratories 11 10 11 10 11 11 9 10 11 11 10

Number of replicates 22 20 22 20 22 22 18 20 22 22 20

Overall FBT mean 1.69 14.44 22.62 9.60 4.65 10.73 17.27 6.21 3.70 2.83 1.25

Official Method mean

a

2.05 14.23 22.67 9.57 4.40 10.70 17.40 6.43 3.73 2.85 1.45

S

r

0.16 0.44 0.36 0.32 0.26 0.28 0.18 0.10 0.20 0.09 0.23

S

R

0.19 0.44 0.67 0.48 0.27 0.33 0.28 0.27 0.22 0.17 0.31

RSDr, %

9.6 3.1 1.6 3.3 5.5 2.6 1.1 1.6 5.3 3.3 18.1

RSDR,%

11.4 3.1 2.9 5.0 5.8 3.1 1.6 4.3 6.0 6.0 24.5

r 0.46 1.23 1.00 0.88 0.72 0.80 0.51 0.27 0.55 0.26 0.64

R 0.54 1.23 1.86 1.34 0.75 0.94 0.78 0.75 0.62 0.48 0.86

HORRAT VALUE 3.07 1.14 1.18 1.75 1.82 1.11 0.62 1.42 1.83 1.75 6.34

a

Official Method AOCS Ba 6-84/AOAC 962.09

Table 2. Summary of the statistical analysis of the Filter Bag Technique crude fiber collaborative study, including

comparison with the Official Method.

Rev E 1/14/15 pg. 43

Page 44

Operator’s Manual

This page intentionally left blank

pg. 44 Rev E 1/14/15

Page 45

Operator’s Manual

101.2 Bag Holder

X45 Desiccant Pouch

693 Bag Suspender Tray