Page 1

/i

ComBi-line

user manual

Page 2

Copyright

© 2018 Animo®

No part of this document may be reproduced and/or made public in print, microfilm, electronic media or

any other form without the manufacturer’s prior consent. This also applies to the corresponding

diagrams and/or charts.

Animo retains the right to alter parts at any given time without prior or immediate announcement to the

consumer. The content of this manual can also be changed without any prior warning. This manual is

valid for the standard model of the device. Animo can therefore not be held liable for possible damage

resulting from specifications deviating from the standard model for the device supplied to you.

This manual was created with the utmost care, but the manufacturer cannot be held responsible for any

mistakes in this document or their consequences.

This manual was originally written in English. All other languages in this document are a translation of

the English source text.

EN 2 2018/07 Rev 3.0

Page 3

ComBi-line

TABLE OF CONTENTS

Copyright ................................................................................................................................... 2

1 Safety .......................................................................................................................................... 5

1.1 Important information ......................................................................................................... 5

1.2 Warning signs ..................................................................................................................... 5

1.3 Intended use ....................................................................................................................... 6

1.4 Modifications ...................................................................................................................... 6

1.5 Safety devices .................................................................................................................... 7

1.6 Safety precautions .............................................................................................................. 8

1.7 Users ................................................................................................................................ 10

1.8 Directives .......................................................................................................................... 10

1.9 Guarantee ........................................................................................................................ 11

1.10 Disposal ............................................................................................................................ 11

1.11 Further help and information ............................................................................................ 11

2 Description ............................................................................................................................... 12

2.1 Overview .......................................................................................................................... 12

2.2 Working principle .............................................................................................................. 18

2.3 Specifications ................................................................................................................... 21

2.4 Display .............................................................................................................................. 29

2.5 Operator system configuration ......................................................................................... 29

3 Transport and Installation ...................................................................................................... 35

3.1 Transport .......................................................................................................................... 35

3.2 Preparation for transport .................................................................................................. 35

3.3 Drain the coffee brew system ........................................................................................... 36

3.4 Drain the boiler system of W models ................................................................................ 36

3.5 Installation ........................................................................................................................ 37

3.6 First-time use .................................................................................................................... 44

4 Operation ................................................................................................................................. 47

4.1 Preparation ....................................................................................................................... 47

4.2 Prepare a container for coffee .......................................................................................... 47

4.3 Prepare a container for tea ............................................................................................... 47

4.4 Switch the machine on ..................................................................................................... 48

4.5 Prepare the boiler system for use .................................................................................... 48

4.6 Select the brewing amount for coffee ............................................................................... 49

4.7 Select the brewing amount for tea .................................................................................... 50

4.8 Start the brewing process ................................................................................................. 50

4.9 Complete the coffee brewing process .............................................................................. 52

4.10 Serve the beverage .......................................................................................................... 53

4.11 Use the timer function ...................................................................................................... 54

4.12 Complete the tea brewing process ................................................................................... 55

5 Maintenance ............................................................................................................................. 56

5.1 Cleaning and disinfecting detergents ............................................................................... 56

5.2 Cleaning ........................................................................................................................... 56

5.3 Descale the machine ........................................................................................................ 60

2018/07 Rev 3.0 3 EN

Page 4

ComBi-line

6 Troubleshooting ...................................................................................................................... 66

6.1 Error codes and problems ................................................................................................ 66

6.2 Temperature protection .................................................................................................... 67

2018/07 Rev 3.0 4 EN

Page 5

ComBi-line

1 Safety

1.1 Important information

This user manual is intended to help you operate this machine safely and effectively. This manual gives

information about installation, operation and maintenance of the equipment. Make sure to read and

understand the manual before use.

It is your responsibility to operate this machine in accordance with all the safety instructions and

procedures in this manual, and with all other safety procedures in your workplace. It is the user's

responsibility to make sure that the machine is correctly installed, configured, commissioned, operated,

serviced and maintained and that such actions are only carried out by people who have been fully and

properly trained for those tasks. It is also the user's responsibility to make sure that the machine is only

used in full accordance with laws - and regulations, which have the force of law - in the jurisdiction in

which the machine is installed.

WARNING

Before attempting to use the machine, read, understand and know all the safety information in

this chapter. Pay particular attention to all warnings and cautions throughout this manual. If

you do not follow all the warnings and procedures in this manual, this could lead to serious

injury to yourself or others, including death.

WARNING

If there is any safety instruction or procedure that you do not understand, do not use the

machine. Contact your supervisor and arrange proper training on the use of the machine. Use

of the machine without understanding and following all the safety instructions and procedures

in this manual could lead to serious injury to yourself or others, including death.

WARNING

Do not use the machine until you have received adequate and proper training in its safe and

effective use. If you are unsure of your ability to use the machine safely and effectively, do not

do so. Never attempt to remove, modify, over-ride or frustrate any safety device on the

machine. Interfering with safety devices could lead to fatal or other serious personal injury.

Note

The A-weighted sound pressure level of the machine is below 70 dB.

1.2 Warning signs

Safety signs are attached to the machine to give safety information. All safety signs are repeated and

usually further explained in this manual.

1.2.1 Classification of safety signs

Safety signs are of the internationally accepted types and described below.

WARNING

Warning sign that identifies a hazard.

2018/07 Rev 3.0 5 EN

Page 6

ComBi-line

1.2.2 Warning, caution and note

WARNING

‘Warning' identifies a hazard that could lead to personal injury, including death.

Caution

'Caution' identifies a hazard that could lead to damage to the machine, damage to other

equipment and/or environmental pollution.

Note

’Note' is used to highlight additional information.

1.3 Intended use

The machine makes coffee or tea. Any other or additional use will be considered to be not in conformity

with the intended use. The manufacturer cannot be held liable for any damages caused by use for any

other purposes than what is described above or by incorrect operation.

WARNING

Do not use products that do not comply with the applicable foodstuffs regulations.

Note

This machine may only be used for commercial settings. This is not a household appliance.

1.4 Modifications

WARNING

Do not attempt to make any modifications or alterations to the machine without the prior

express agreement of Animo. Unauthorised modifications or alterations to the machine could

lead to serious personal injury, including death.

WARNING

Do not attempt to change, remove or defeat the safety features.

WARNING

Do not attempt to apply changes that violate local, regional or national regulations.

WARNING

Make sure the main switch and operating button are freely accessible.

WARNING

Only connect the container(s) to the power socket(s) on the tower. Do not connect any other

appliance(s).

Animo is always willing to discuss improving the value of its machines to users by means of

modifications or alterations. Refer to 1.11.

2018/07 Rev 3.0 6 EN

Page 7

ComBi-line

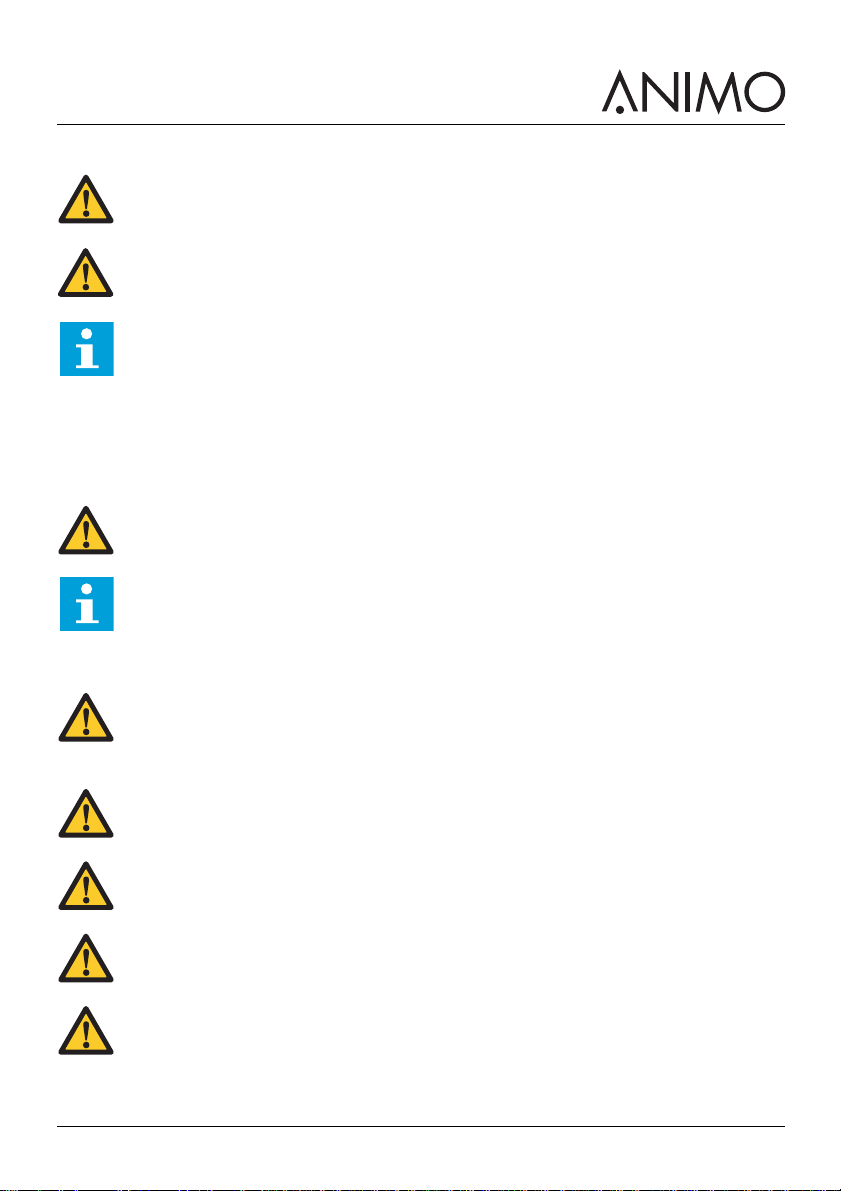

A

A

1.5 Safety devices

1.5.1 On/Off switch

The on/off switch (A) puts the machine in the on/off position. The machine can still be charged after the

machine is switched off. Unplug the machine to make sure that the machine is entirely uncharged.

WARNING

The on/off switch does not switch off all internal parts. Always disconnect the machine from

the electricity before opening it.

1.5.2 Stop button on the control panel

The stop button (A) stops the brewing process. The machine is still charged after the brewing process is

stopped. Unplug the machine to make sure that the machine is entirely uncharged.

1.5.3 Swivel arm and container detection

The brewing process only starts if the swivel arm and container are in the correct position. During

operation, the brewing process automatically stops if the swivel arm or container is moved.

2018/07 Rev 3.0 7 EN

WARNING

The stop button does not switch off all internal parts. Always disconnect the machine from the

electricity before opening it.

Page 8

ComBi-line

A

1.5.4 Swivel arm protection for wall mounted CB and CB W models

The wall mounted CB and CB W models have an adjustable stop at the bottom of the swivel arm. The

stop prevents the starting of a brewing process when the swivel arm is not in the correct pre-set

position.

1.5.5 Boiler system steam outlet for CB W models

All CB W models have a steam outlet at the top of the tower. The steam outlet lets excess steam

escape from the boiler system. Do not touch the boiler steam outlet while the machine is switched on.

The boiler steam outlet is hot.

1.5.6 Temperature safety device in the coffee brew system

A temperature safety device in the coffee brew system turns off the heating element if the temperature

of the system is too high.

1.5.7 Temperature safety device in the boiler system

A temperature safety device in the boiler system turns off each the heating element if the temperature of

the system is too high.

1.5.8 Current overload switch

A current overload switch isolates the mains power supply to the machine if there is a current overload.

1.5.9 Display

The display (A) shows technical malfunctions with error codes. The display also provides additional

user information or warnings.

1.6 Safety precautions

1.6.1 General safety precautions

• Make sure that the environment around the machine is dry, clean and lit sufficiently well.

• Only persons that have specific knowledge and practical experience with the machine, particularly

in regard to safety and hygiene, should be permitted into the service area where the beverage(s)

are prepared.

• Keep away from moving parts.

2018/07 Rev 3.0 8 EN

Page 9

ComBi-line

• Use Animo replacement parts only.

• Use Animo recommended products only.

1.6.2 During installation

• Observe local regulations and use approved materials and parts.

• Only install the machine in locations where it can be overseen by trained personnel.

• Do not place the machine in an area with temperatures below 0 °C.

• Do not place the machine in an area where a water jet could be used.

• The machine can be used outdoors if all the relevant safety conditions specified in section 1 of this

manual are met.

• Place the machine at work top height on a firm and flat surface.

• Plug the machine into a safety-grounded power outlet.

• Make sure the machine does not leak.

• Check if the details on the type plate correspond to the country.

• Always use the new hose-set that was supplied with the machine. Do not use old hose-sets or other

hose-sets.

1.6.3 During normal operation

• Inspect the machine for damage before use.

• Do not tilt the machine.

• Do not submerge or hose down the machine.

• Do not use sharp objects to operate the machine.

• Keep the operating controls free of dirt and grease.

• Do not heat the container with open fire or an external heating element or device.

• Unplug the machine before you move the container.

• Switch off the machine and unplug the water supply when the machine is not used for a longer

period of time.

1.6.4 During maintenance and repair

• Perform regular maintenance on the machine.

• Wear protective gloves and safety glasses when performing maintenance.

• Do not clean the machine using a water jet.

• Do not leave the machine during maintenance.

• Make sure that the repairs are performed by trained and authorised personnel only.

• Unplug the machine to perform maintenance regarding error messages.

• Descale the elements regularly or when alerted by the display.

WARNING

To entirely uncharge the machine, unplug the machine.

1.6.5 Electrical connection

• An expert, competent electrician must attach the correct plug for your location for first-time use. The

connection must have an RCD of 30mA with all phases, including the zero point. The connection

must also be able to be easily disconnected (contact distance at least 3mm).

• The machine must be connected to a properly grounded power socket in accordance with

applicable national regulations.

• If the power cable is damaged or worn after use:

2018/07 Rev 3.0 9 EN

Page 10

ComBi-line

- If the machine has a separate, detachable power cable, replace the damaged power cable with

a new supply cable. Only use an Animo replacement part. Refer to 2.3.14

- If the machine has a fixed power cable, the damaged power cable must be replaced by Animo,

an official Animo service agent, or a similarly qualified person.

WARNING

To entirely uncharge the machine, unplug the machine.

1.7 Users

1.7.1 Personnel qualifications

• The machine is designed only for personnel being 8 years or older. Consider the respective national

regulations for occupational safety and health.

• This appliance can be used by children aged from 8 years and above and persons with reduced

physical, sensory or mental capabilities or lack of experience and knowledge if they have been

given supervision or instruction concerning use of the appliance in a safe way and understand the

hazards involved.

• Children must not play with the machine.

• Cleaning and user maintenance shall not be made by children without supervision.

• Only personnel who have been given permission are allowed to work with the machine.

• All personnel must only carry out the work they have been trained to perform. This applies to both

maintenance work and the normal machine operation.

• All personnel working with the machine must have free access to the applicable manuals.

• The operators must be familiar with all situations that may occur so that they can act rapidly and

effectively in the event of emergencies.

1.7.2 Personal and food hygiene

The machine processes drinks for human consumption. So the highest standards of hygiene are to be

maintained within the process area.

Caution

As an operator, you should have received training in personal and food hygiene from your

employer(s). If you have not, do not use the machine or enter the process area. Arrange

training with your supervisor or training manager. Working in the process area without a good

understanding of hygiene can lead to contamination of drinks.

• Wash your hands thoroughly before entering the process area.

• Remove your watch and any loose jewellery before entering the process area.

• Make sure that the machine is cleaned regularly.

1.8 Directives

This machine meets the following EC directives:

EMC directive: 2014/30/EC

Low voltage directive: 2014/35/EC

Machinery directive: 2006/42/EC

2018/07 Rev 3.0 10 EN

Page 11

ComBi-line

/i

RoHS directive: 2011/65/EC

WEEE directive: 2012/19/EC

/i

Food contact directive: 1935/2004/EC

1.9 Guarantee

The guarantee provisions that apply to this machine are part of the general terms of delivery.

1.10 Disposal

The use and maintenance of the machine includes no environmental dangers. Most parts can be

disposed in the regular way.

Note

Ensure compliance with local legislation, regulations, instructions and precautions concerning

health, safety and environment.

1.11 Further help and information

Animo is committed to provide the highest level of support to users and operators of its products.

Contact the dealer for information regarding settings, maintenance and repair work, which is not

included in this document.

2018/07 Rev 3.0 11 EN

Page 12

ComBi-line

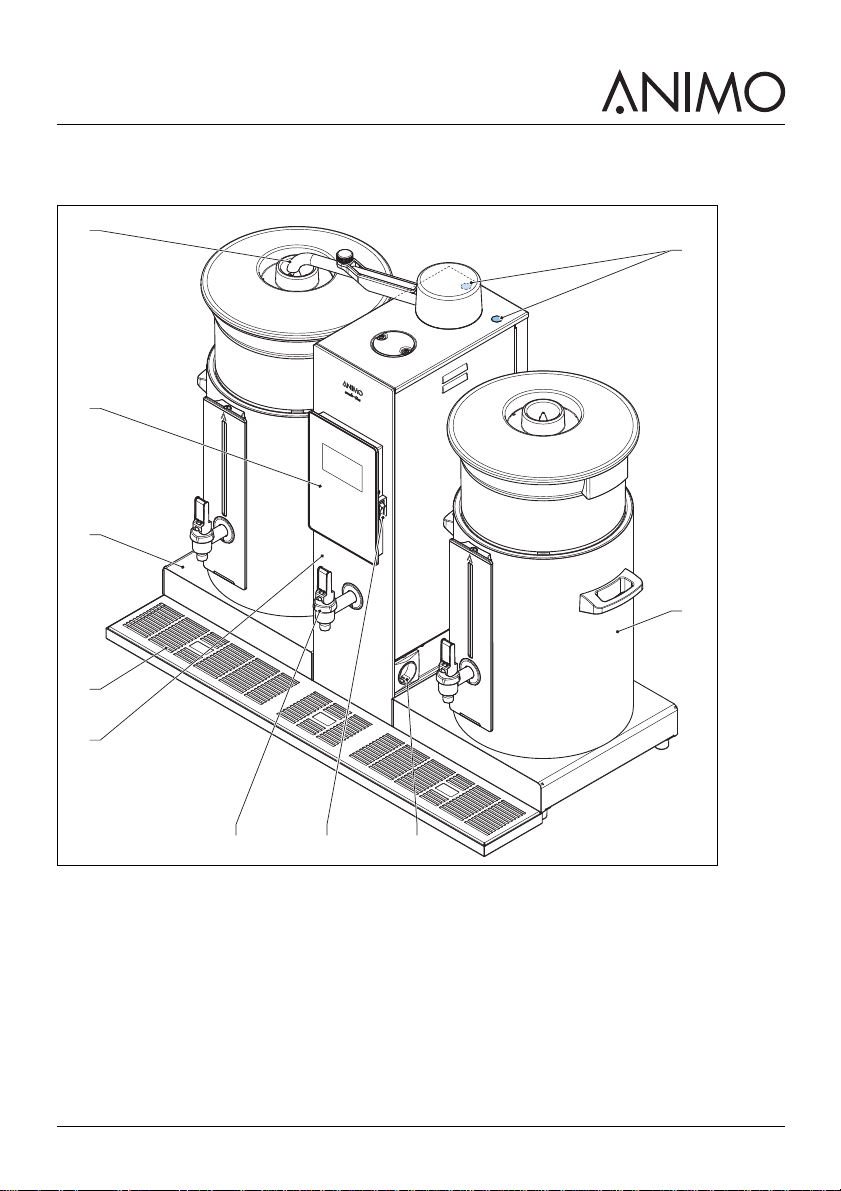

EFG H

ABC D

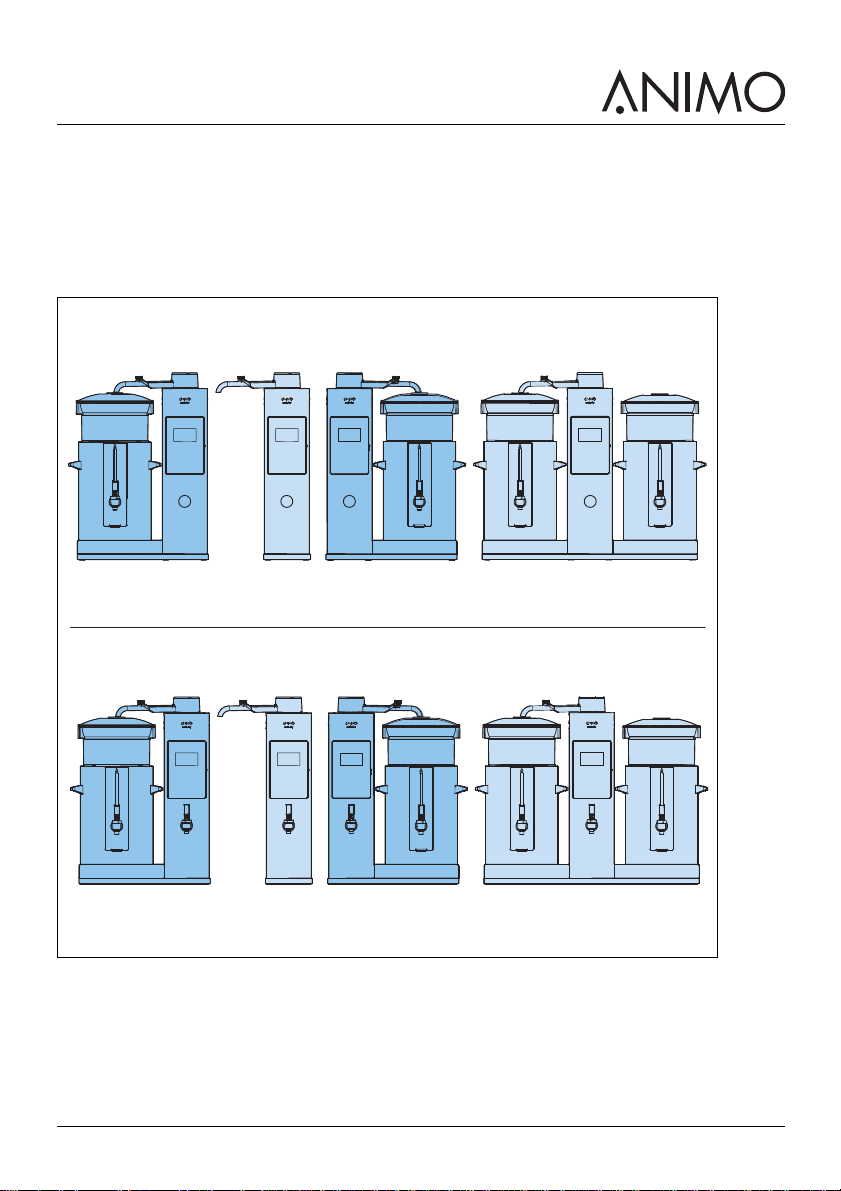

2 Description

2.1 Overview

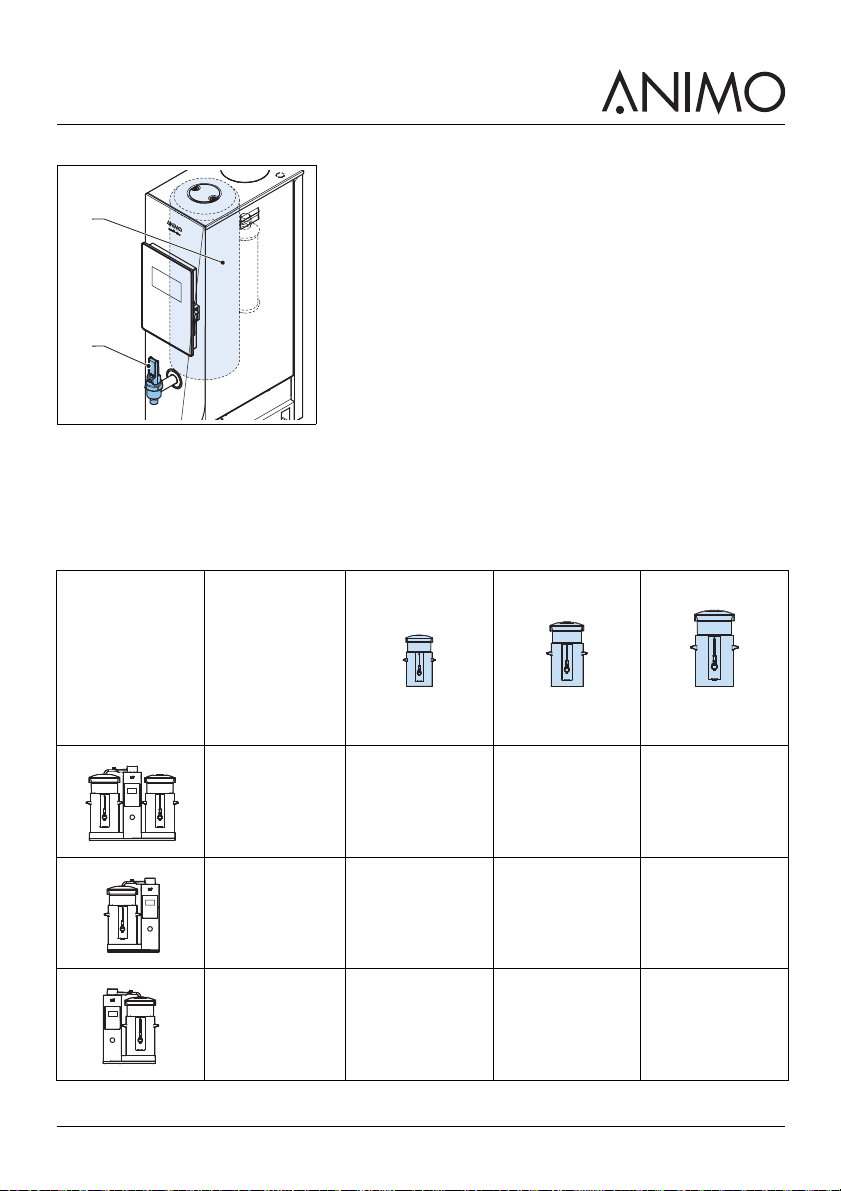

2.1.1 Models

The illustrations in this manual typically show a CB 2x W model. Disregard the illustrations, the

descriptions, and the instructions that do not relate to your model.

A: Model CB 1x L

B: Model CB

C: Model CB 1x R

D: Model CB 2x

E: Model CB 1x W L

F: Model CB W

G: Model CB 1x W R

2018/07 Rev 3.0 12 EN

Page 13

ComBi-line

C

B

A

D

E

G HF

J

I

H: Model CB 2x W

2.1.2 Front

A: Swivel arm

B: Control panel (refer to 2.1.5)

C: Base plate (only on models with a ’1x’ or ’2x’ designation in the model name)

D: Drip tray with grid

E: To w e r

F: Hot water tap (only on models with a ’W’ designation in the model name)

G: On / Off switch

H: Socket for container heating

I: Container (refer to 2.1.6)

J: Descale filling openings

2018/07 Rev 3.0 13 EN

Page 14

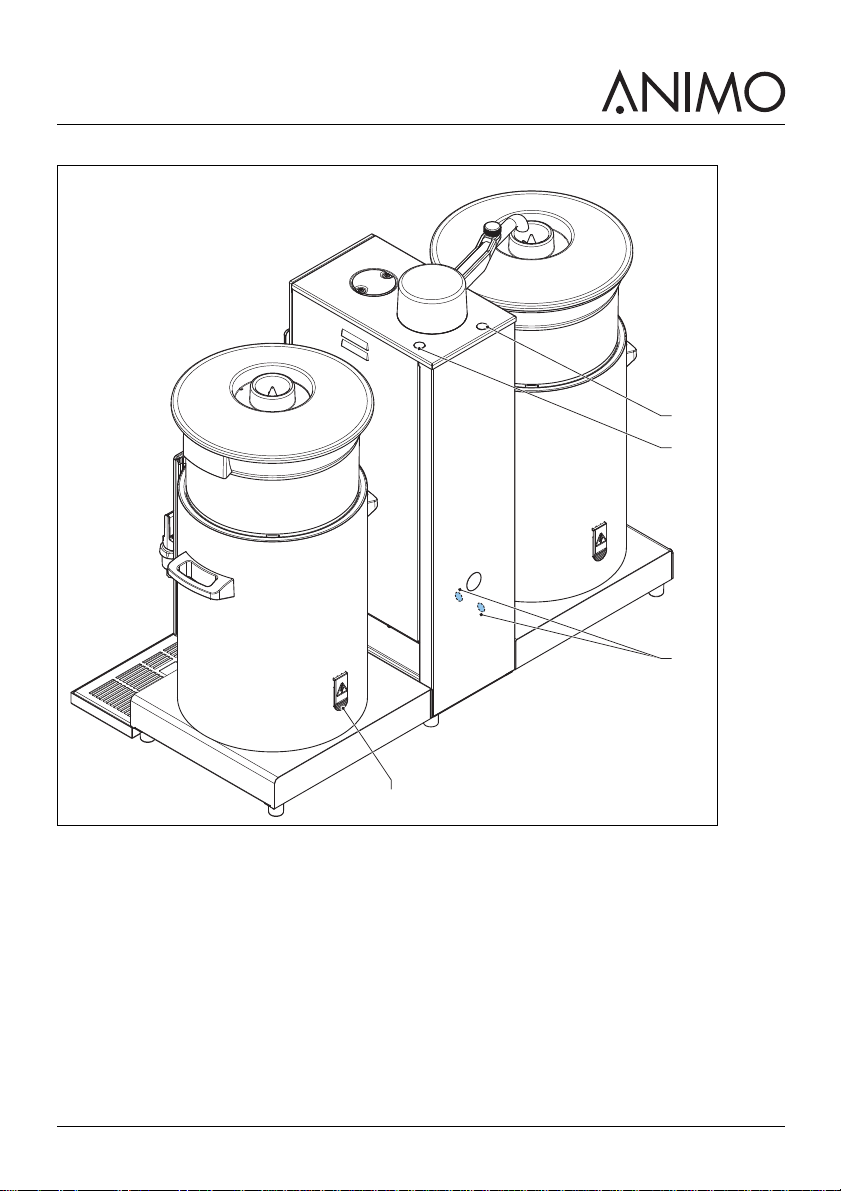

ComBi-line

A

B

C

D

2.1.3 Back

A: Descale filling opening for the coffee brew system

B: Descale filling opening for the boiler system

C: Covers of the temperature safety devices

D: Socket with splash protection (only on a container CNe model)

2018/07 Rev 3.0 14 EN

Page 15

ComBi-line

A

E

D

B

C

2.1.4 Underneath

A: Drain hose of the coffee brew system

B: Drain hose of the boiler system (W models only)

C: Protection plate

D: Power cable

E: Mains water supply

2018/07 Rev 3.0 15 EN

Page 16

ComBi-line

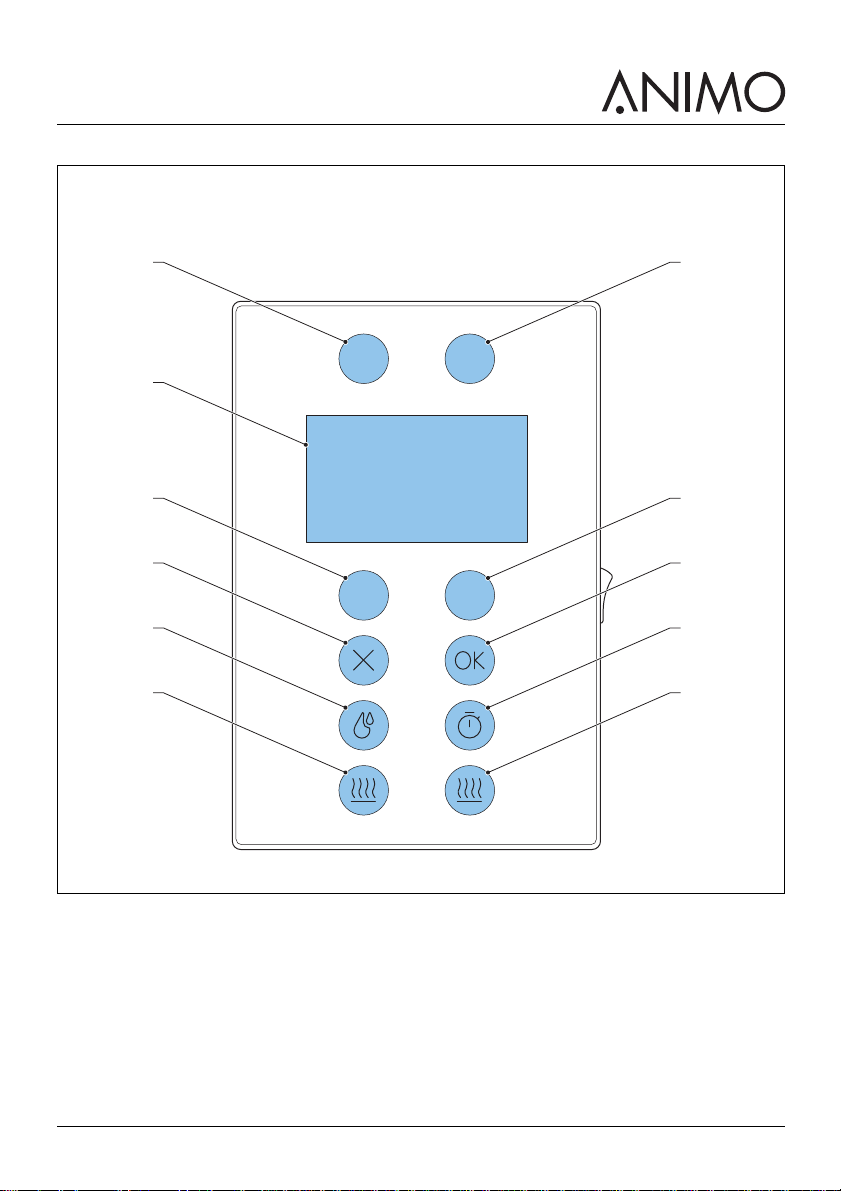

A1 A2

B

A3 A4

C F

D G

E H

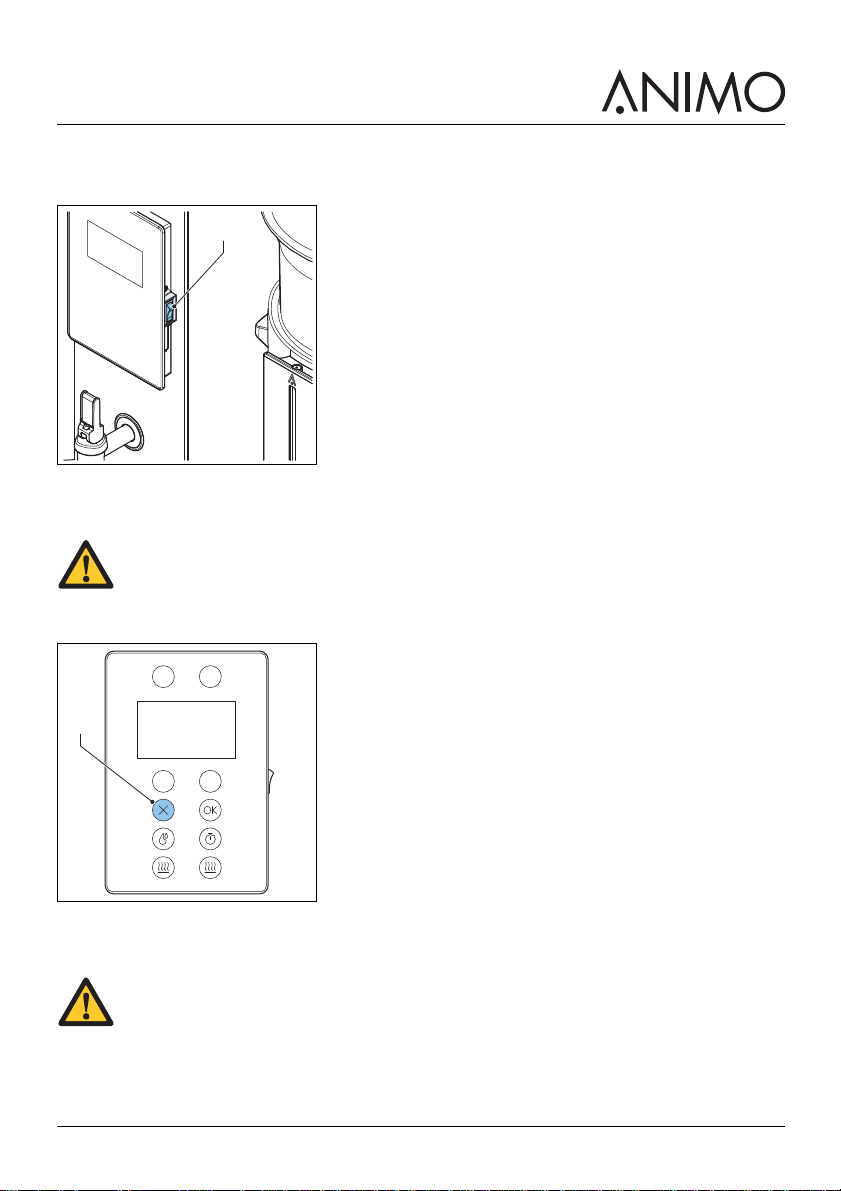

2.1.5 Control panel

A: (A1, A2, A3, A4) Selection buttons. Also use A2 to go to the operator menu. Refer to section 2.5.1

B: Display

C: Stop process or Cancel selection button

D: Switch on/off hot water boiler

E: On / Off button to switch the power socket on for the container heating LHS

F: Confirm process or Start selection button

G: Timer program button

H: On / Off button to switch the power socket on for the container heating RHS

2018/07 Rev 3.0 16 EN

Page 17

ComBi-line

A

B

C

D

E

F

G

H

I

K J

L

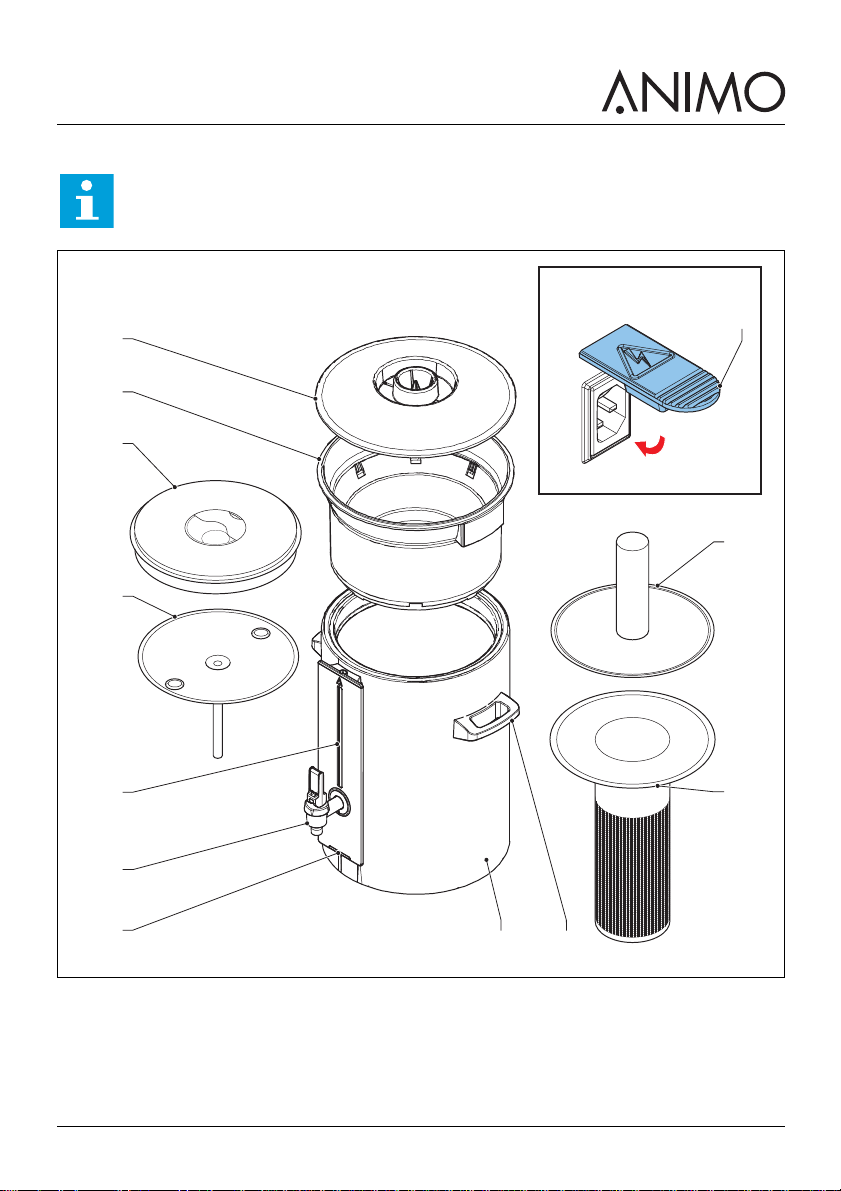

2.1.6 Container assembly

Note

The CN 40 model may differ from the illustrations and descriptions in this manual. In all other

respects, follow the instructions and data as applicable.

A: Water distributor lid

B: Basket filter

C: Insulated lid

D: Blender - transport disk

E: Integrated gauge glass

2018/07 Rev 3.0 17 EN

Page 18

ComBi-line

A

B

A

F: Ta p

G: LED light

H: Filling pipe (brewing tea application)

I: Tea filter with disk (brewing tea application)

J: Handle

K: Container

L: Electrical socket with splash protector (CNe)

2.2 Working principle

2.2.1 Coffee brew system

The user selects a desired quantity of beverage on the control panel (A). The coffee brew system (B)

inside the tower heats the corresponding quantity of water.

2.2.2 Swivel arm

The swivel arm (A) directs hot water from the coffee brew system into the top of a distributor lid.

2018/07 Rev 3.0 18 EN

Page 19

ComBi-line

A

B

A

2.2.3 Coffee blender and basket filter

The basket filter (A), a paper filter, and a pre-loaded coffee product receive the hot water. The filtered

coffee then flows through the coffee blender (B) into the container.

2.2.4 Tea filling pipe and filter unit

The tea filling pipe and filter unit (A) receive the hot water and combine it with a pre-loaded tea product

inside the container.

2018/07 Rev 3.0 19 EN

Page 20

ComBi-line

A

C

B

B

A

2.2.5 Container

The container (A) keeps the hot beverage ready for consumption. The container has a tap (C) to serve

the beverage. The CNe model container has an electric element (B) to keep the beverage heated.

2.2.6 Base plate and electric sockets

A container must be correctly positioned on a base plate (A) for operation. The container model CNe is

connected to the electric sockets (B) with an electric cable.

2018/07 Rev 3.0 20 EN

Page 21

ComBi-line

A

B

2.2.7 Hot water tap on tower

CB models with a ’W’ designation in the model name, have a hot water tap (A) to serve hot water from

an additional boiler (B) inside the tower.

2.3 Specifications

2.3.1 Model names and model numbers

/i

CB 5 (liter) CB 10 (liter) CB 20 (liter)

Unit

Type /

description

CB 2x

2 base plates

CB 1x L

1 base plate on

Model name /

Model number

CB 2x5

1005390

CB 1x5L

1005392

Model name /

Model number

CB 2x10

1005398

CB 1x10L

1005400

Model name /

Model number

CB 2x20

1005406

CB 1x20L

1005408

the left hand side

CB 1x R

1 base plate on

CB 1x5R

1005391

CB 1x10R

1005399

CB 1x20R

1005407

the right hand side

2018/07 Rev 3.0 21 EN

Page 22

ComBi-line

CB 5 (liter) CB 10 (liter) CB 20 (liter)

Unit

Type /

description

CB

Wall mounted CB

CB 2x W

2 base plates with

a boiler and a hot

water tap

CB 1x WL

1 base plate on

the left hand side,

with a boiler and a

hot water tap

CB 1x WR

1 base plate on

the right hand

side, with a boiler

and a hot water

tap

CB W

Wall mounted. Has

a boiler and a hot

water tap

Model name /

Model number

CB 5

1005393

CB 2x5W

1005394

CB 1x5W L

1005396

CB 1x5W R

1005395

CB 5W

1005397

Model name /

Model number

CB 10

1005401

CB 2x10W

1005402

CB 1x10W L

1005404

CB 1x10W R

1005403

CB 10W

1005405

Model name /

Model number

CB 20

1005409

CB 2x20W

1005410

CB 1x20W L

1005412

CB 1x20W R

1005411

CB 20W

1005413

2.3.2 CB 40 liter model names and model numbers

/i

40 liter container 1 base plate 1 base plate on the

left hand side

1 base plate on the

right hand side

Wall mounted

2018/07 Rev 3.0 22 EN

Page 23

ComBi-line

Model name /

Model number

CB 2x40

1007173

CB1x40L

1007175

CB 1x40R

1007174

CB 40

1007176

CB 40 liter models with the ’W’ designation are not available. CB 40 liter models do not have a hot

water tap or additional boiler inside the tower. Refer to section 2.2.7.

2.3.3 Model specifications

/i

Model (Length x Breadth x

Height)

CB 5 CB 10 CB 20

CB 2x machine dimensions 815 x 470 x 700 mm 980 x 470 x 790 mm 1095 x 500 x 895 mm

CB 1x L or R machine

505 x 470 x 700 mm 590 x 470 x 790 mm 645 x 500 x 895 mm

dimensions

CB machine dimensions 235 x 380 x 725 mm 235 x 380 x 820 mm 235 x 380 x 920 mm

CB W machine dimensions 235 x 490 x 725 mm 235 x 490 x 820 mm 235 x 490 x 920 mm

CB 2x W machine

815 x 470 x 700 mm 980 x 470 x 790 mm 1095 x 500 x 895 mm

dimensions

CB 1x W L or R machine

505 x 470 x 700 mm 590 x 470 x 790 mm 645 x 500 x 895 mm

dimensions

CB 2x weight: empty / full 45 / 56kg 59 / 80 kg 79 / 118 kg

CB 1x L or R weight: empty /

40 / 46 kg 51 / 62 kg 67 / 75 kg

full

CB weight: empty / full 12 / 12 kg 15 / 16 kg 23 / 24 kg

CB 2x W weight: empty / full

49 / 65 kg 63 / 89 kg 83 / 116 kg

(approx.)

CB W 1 x L or R weight:

44 / 54 kg 55 / 71 kg 71 / 84 kg

empty/full (approx.)

CB W weight: empty / full

16 / 21 kg 19 / 25 kg 27 / 35 kg

(approx.)

2.3.4 CB 40 Model specifications

/i

Model (Length x Breadth x

Height)

CB 40

CB 2x machine dimensions 1320 x 685 x 970 mm

CB 1x L or R machine

810 x 685 x 970 mm

dimensions

CB machine dimensions 235 x 345 x 985 mm

CB W machine dimensions Not available

CB 2x W machine

Not available

dimensions

CB 1x W L or R machine

Not avaialble

dimensions

CB 2x weight: empty / full 28 / 120

CB 1x L or R weight: empty /

24 / 73

full

2018/07 Rev 3.0 23 EN

Page 24

ComBi-line

Model (Length x Breadth x

Height)

CB 40

CB weight: empty / full 20 / 23

CB 2x W weight: empty / full

Not available

(approx.)

CB W 1 x L or R weight:

Not available

empty/full (approx.)

CB W weight: empty / full

Not available

(approx.)

2.3.5 Containers

/i

Model

CB 5 CB 10 CB 20 CB 40

Containers with an electric

CN5e CN10e CN20e CN40e

element

Containers without an electric

CN5i CN10i CN20i Not available

element

Contents 5 ltr 10 ltr 20 ltr 40 ltr

Contents Maximum 5.5 ltr 11 ltr 22 ltr 44 ltr

Electrical connection (only

1N~ 220-240 V 1N~ 220-240 V 1N~ 220-240 V 1N~ 220-240 V

CNe container models)

Frequency (only CNe

50-60 Hz 50-60 Hz 50-60 Hz 50-60 Hz

container models)

Power (only CNE container

50 W 100 W 100 W 150 W

models)

2018/07 Rev 3.0 24 EN

Page 25

ComBi-line

2.3.6 Electrical system

/i

Model CB 5 CB 10 CB 20

Electrical connection 1N~ 220-240 V 3N~ 380-415 3N~ 380-415

Frequency 50-60 Hz 50-60 Hz 50-60 Hz

Power 3075 W 6075 W 9075 W

/i

Model CB 5W CB 10W CB 20W

Electrical connection 1N~ 220-240 V 3N~ 380-415 3N~ 380-415

Frequency 50-60 Hz 50-60 Hz 50-60 Hz

Power 3375 W 6075 W 9075 W

/i

Model CB 1x5 L/R CB 1x10 L/R CB 1x20 L/R

Electrical connection 1N~ 220-240 V 3N~ 380-415 3N~ 380-415

Frequency 50-60 Hz 50-60 Hz 50-60 Hz

Power 3125 W 6175 W 9175 W

/i

Model CB 1x5 WL/R CB 1x10 WL/R CB 1x20 WL/R

Electrical connection 1N~ 220-240 V 3N~ 380-415 3N~ 380-415

Frequency 50-60 Hz 50-60 Hz 50-60 Hz

Power 3425 W 6175 W 9175 W

/i

Model CB 2x5 CB 2x10 CB 2x20

Electrical connection 1N~ 220-240 V 3N~ 380-415 3N~ 380-415

Frequency 50-60 Hz 50-60 Hz 50-60 Hz

Power 3175 W 6275 W 9275 W

/i

Model CB 2x5W CB 2x10W CB 2x20W

Electrical connection 1N~ 220-240 V 3N~ 380-415 3N~ 380-415

Frequency 50-60 Hz 50-60 Hz 50-60 Hz

Power 3475 W 6275 W 9275 W

2.3.7 CB 40 Electrical system

/i

Model CB 40 CB 1x40 L/R CB 2x40

Electrical connection 3N~ 380-415 V 3N~ 380-415 3N~ 380-415

Frequency 50-60 Hz 50-60 Hz 50-60 Hz

Power 18075 W 18225 W 18375 W

/i

2018/07 Rev 3.0 25 EN

Page 26

ComBi-line

E

D

C

B

A

D

C

B

A

C

B

A

2.3.8 Mains power cable and wire types

/i

Cable type Name Wire description

3N~ 400 V (5 core cable) (A) Green / yellow - Earth (E)

(B) Blue - Neutral (N)

(C) Brown - Phase / Live (L1)

(D) Black - Phase / Live (L2)

(E) Grey - Phase / Live (L3)

3~ 400 V (4 core cable) (A) Green / yellow - Earth (E)

(B) Brown - Phase / Live (L1)

(C) Black - Phase / Live (L2)

(D) Grey - Phase / Live (L3)

1N~ 230 V (3 core cable) (A) Green / yellow - Earth (E)

(B) Brown - Phase / Live (L)

(C) Blue - Neutral (N)

2.3.9 Capacities - coffee

/i

Item

Brew time (water dosing time) approx. 10

Hour capacity (water volume) 30 ltr 60 ltr 90 ltr 180 ltr

Buffer stock 2 x .. 10 ltr 20 ltr 40 ltr 80 ltr

Buffer stock 1 x L/R 5 ltr 10 ltr 20 ltr 40 ltr

Filter paper Ø101/317 Ø152/457 Ø203/533 Ø280/635

CB 5 CB 10 CB 20 CB 40

min./5 ltr

approx. 10

min./10 ltr

Tow er

approx. 14

min./20 ltr

approx. 14

min./40ltr

2.3.10 Capacities - hot water for all models with a ’W’ designation in the model name

/i

Item

Boiler volume (approx.) 4.2 ltr 5.6 ltr 5.6 ltr

Buffer stock water (approx.) 2.6 ltr 4.1 ltr 4.1 ltr

Boiler heating time (approx. 1596 °C)

Recovery time after maximum

drain (aaprox.)

Boiler temperature (approx.) 90 °C 90 °C 90 °C

2018/07 Rev 3.0 26 EN

CB 5W CB 10W CB 20W

9 minutes 9 minutes 9 minutes

6 minutes 6 minutes 6 minutes

Specification

Page 27

ComBi-line

............

...~.......V ..........Hz .........W

................ ............MPA

Made in The Netherlands

Dr. A.F. Philipsweg 47 • NL-9403 AD Assen • www.animo.eu

P/N

XXXXXXXX

S/N Water pressure

A D

B

C

E

F

G

2.3.11 Water system

/i

Water hardness min. 5°dH (min. 9°fH, 0,9 mmol/l)

Water conductivity greater than or equal to 15 µ Siemens/cm

Water connection 3/4" outer tread

Minimum water pressure 0.2 MPa (2 bar)

Maximum water pressure 1 MPa (10 bar)

Flow pressure 5 l. / min

Overflow connection tube Ø 25 mm

2.3.12 Ambient conditions

/i

Temperature 0 °C < T < 40 °C

Relative humidity 80%

2.3.13 Type plate

A: Model number

B: Article number

C: Supply voltage [V]

D: Machine number

E: Water pressure [MPa]

F: Power [W]

G: Frequency [Hz]

2.3.14 Consumer articles and accessories

Order these items from your dealer.

/i

Item Description Item number

Coffee fur remover per box (100) sachets of 10 gm) 49009

Scale remover per box (48 sachets of 50 gm) 49007

per can of 1 kg 00008

per can of 1 kg 00009

2018/07 Rev 3.0 27 EN

Page 28

ComBi-line

Item Description Item number

Combi filter Container CN5 1006095

Container CN10 1006096

Container CN20 1006097

Container CN40 95008

Coffee blender Container CN5 56004

Container CN10 96001

Container CN20 56010

Container CN40 96006

Basket filter paper 101/317 - container CN5 01115

152/457 - container CN10 01116

203/533 - container CN20 01117

280/635 - container CN40 01131

Tea filter with disk Container CN5 57003

Container CN10 57005

Container CN20 57011

Container CN40 57007

Filling pipe Container CN5 17018

Container CN10 17019

Container CN20 17020

Container CN40 17004

S-swivel arm With "Click" connection to use

with the drip-free ComBi-line tap

99497

Container tube 99499

Gauge glass brush 08094

Descale funnel 99740

Cable + plug 1.5 m 03072

Cable + plug 0.6 M 03071

2018/07 Rev 3.0 28 EN

Page 29

ComBi-line

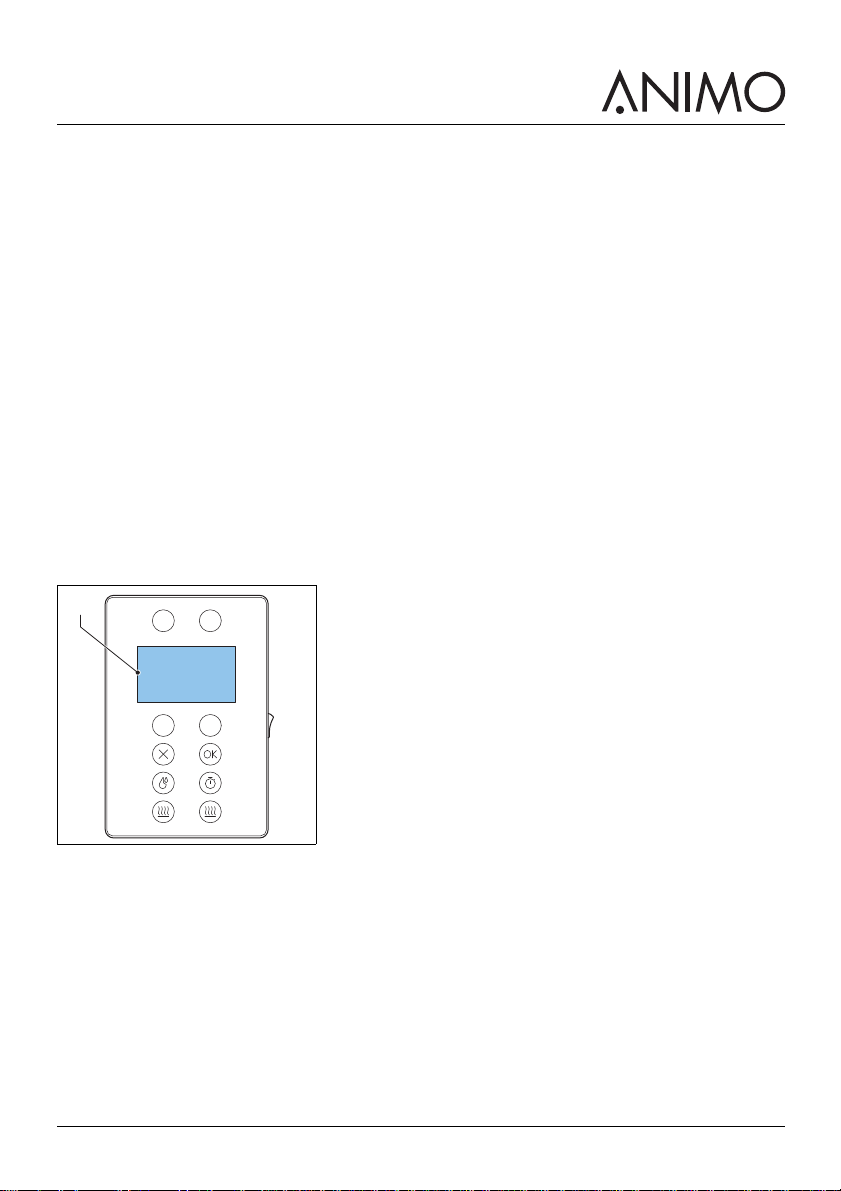

A

B

2.4 Display

2.4.1 Display layout

A: An option (A) can appear in each of the corners of the display. Each option matches 1 of the 4

selection buttons on the control panel.

B: The icons and text in the main area (B) of the display provide status information and prompts to

start, confirm, or cancel a process.

2.5 Operator system configuration

2.5.1 Operator menu navigation

Note

To access the Operator menu:

1. If the machine is switched to on, then switch the machine to off. Use the on/off switch.

Refer to the section 1.5.1

2. Switch the machine to on.

3. When you see the ’opening’ screen, tap the A2 selection button on the upper right-hand

side of the control panel. Refer to the section 2.1.5

Note

When you select Descale items 1.1.2 or 1.1.4, a QR code and website reference appears on

the display. Use the instructions on these pages to do the descale procedures.

/i

Main menu Sub menu Options

1.0 Counters

1.0.1 Day counter brew system Show the brewed coffee per day

1.0.2 Reset day counter brew system No / Yes

1.0.3 Total counter brew system Show the total amount of

brewed coffee

1.0.4 Reset total coffee No / Yes

1.0.5 Day counter hot water Show the total amount of hot

water per day

2018/07 Rev 3.0 29 EN

Page 30

ComBi-line

Main menu Sub menu Options

1.0.6 Reset day counter hot water No / Yes

1.0.7 Total counter hot water Show the total amount of hot

water

1.0.8 Reset total counter hot water No / Yes

1.1 Descale

1.1.1 Counter brew system Counter brew system = 1000L [=

1.1.2 Start descaling brew system No / Yes. If Yes, use the QR

1.1.3 Counter hot water = 1000L [= default]

1.1.4 Start descaling hot water boiler No / Yes. If Yes, use the QR

1.2 System settings

1.2.1 Language Make a choice

1.2.2 Time hh:mm - use the selection

1.2.3 Date dd:mm:yyyy - use the selection

1.2.4 Sound signal No / Yes [default: Yes]

1.2.5 Tea and / or coffee Coffee

1.2.6 Tea dosage [g/L] To set the dosage in g/L: 0-100

default]

code and follow the prompts on

the display

code and follow the prompts on

the display

buttons

left selection buttons for '+' and '' the hours

right selection buttons for '+' and

'-' the minutes

buttons.

left selection buttons for '+' and '' the days

right selection buttons for '+' and

'-' the months [default]

Coffee + tea [default]

Te a

(Step 1) [default: 6]

2018/07 Rev 3.0 30 EN

Page 31

ComBi-line

Main menu Sub menu Options

1.2.7 Own image

1.2.7.1 Low level display. To set

the backlight of the display in %:

10 - 80 (step: 10) [default: 10]

1.2.7.2 Display dim time. To set

the time when the display will

dim in seconds: 10-360 [default:

120]

1.2.7.3 Remove logo No / Yes

1.2.7.4 Choose logo

1.2.8 Energy Save Mode (ESM) 1.2.8.1 Active. If Yes, ESM is

activated. [default: no]

1.2.8.2 Set time to activate the

ESM in minutes: 15 - 240 (step 5

[default:15]

1.3 Brew settings

1.3.1 Water volume [mL] Brew amount in mL (step: 50ml)

CB 5: 4800 - 5800 [default: 5300

= required amount + 6%]

CB 10: 9800 - 11800 [default:

10800 = required volume + 8%]

CB 20: 20000 - 24000 [default:

22000 = required volume + 10%]

CB 40: 40000 - 48000 [default:

44000 = required volume + 10%]

1.3.2 Unit To set the unit: (volume)

Liter (default)

Jug

Cup

Gallon

1.3.3 Cup volume [mL] - Refer to 2.5.2 Set in mL: 100 - 500 (step: 1)

[default: 125]

1.3.4 Jug volume [mL] - Refer to 2.5.3 Set in mL: 200 - 2500 (step: 1)

[default: 250]

1.3.5 Button A1 Set the brew amount in L (step

0.1)

CB 5: 1.0 - 5.0 [default: 1.0]

CB 10: 2.0 - 10.0 [default: 2.5]

CB 20: 4.0 - 20.0 [default: 5.0]

CB 40: 8.0 - 40.0 [default: 10.0]

2018/07 Rev 3.0 31 EN

Page 32

ComBi-line

Main menu Sub menu Options

1.3.6 Button A2 Set the brew amount in L (step:

0.1)

CB 5: 1.0 - 5.0 [default: 3.0]

CB 10: 2.0 - 10.0 [default: 5.0]

CB 20: 4.0 - 20.0 [default: 10.0]

CB 40: 8.0 - 40.0 [default: 20.0]

1.3.7 Button A3 Set the brew amount in L (step:

1.3.8 Button A4 Set the brew amount in L (step:

1.3.9 Auto container heating No / Yes. [default: Yes] If yes,

1.3.10 Descale brew system [L] - Refer to

2.5.4

1.3.11 Coffee dosing [g/L] Set the in g/L: 0 - 100 (step: 1)

1.3.12 Interval [%] Set the duration of interruption

1.3.13 First charge vol. [m/L] To set the first charge volume in

0.1)

CB 5: 1.0 - 5.0 [default: 4.0]

CB 10: 2.0 - 10.0 [default: 7.5]

CB 20: 4.0 - 20.0 [default: 15.0]

CB 40: 8.0 - 40.0 [default: 30]

0.1)

CB 5: 1.0 - 5.0 [default: 5.0]

CB 10: 2.0 - 10.0 [default: 10.0]

CB 20: 4.0 - 20.0 [default: 20.0]

CB 40: 8.0 - 40.0 [default: 40.0]

the correct socket for container

heating will automatically switch

to on. You must always manually

switch the socket to off.

Set the descale indicator in L: 0 10000 (step: 100) [default: 1000]

[default: 50]

of the brew process in case of

fine coarsed coffee or very weak

water in % 50 - 100 (step: 5)

[default: 100 (no interruption)]

mL (step: 100) the basket filter

overflows during the brewing

process.

Activation of the first charge

volume only if menu 1.3.12 is

set to 95% or below.

First charge volume normally is

the half of the total brewing

processRefer to the table.

2018/07 Rev 3.0 32 EN

Page 33

ComBi-line

Main menu Sub menu Options

1.3.14 Filter dripping time(s) Set the filter dripping time in

seconds (step: 10)

CB 5: 0 - 900 [default: 240]

CB 10: 0 - 900 [default: 300]

CB 20: 0 - 900 [default: 360]

CB 40: 0 - 900 [default: 360]

1.3.15 Pre-wet (The pre-wet function

provides you with the option to brew a little

amount of water to soak the coffee before

the brew process so as to improve taste and

aroma)

Activate Pre-wet. To activate the

pre-wet function - No / Yes

To set the pre-wet quantity in mL

(step: 50) 50 - 550 [default: 250]

To set the length of the soaking

time in seconds (step: 5) 5- 600

[default: 30]. This is time period

of the pause before the brewing

process continues.

1.3.16 Gallon volume To set the volume in mL (step: 1)

3600 - 3910 [default: 3785]

1.4 Hot water settings

1.4.1 Unit of temperature Fahrenheit / Celcius [=default]

1.4.3 Temperature To set the temperature in C

(step: 1) 60.0 - 97.0+ [default:

96] 97.0+ means boil through

during 50 - 80 sec (depends on

the model)

1.4.4 Descale boiler [L] - Refer to 2.5.4 To set the descale indicator in

litre (step: 100) 0 - 10000

[default: 1000]

1.5 Load defaults Load settings No / Yes

1.6 Pincode Enter pincode -

1.7 Hard and software

info

- Information about the hardware

and the software.

2.5.2 Selection buttons unit cups

/i

Model Factory settings Settings scope: cup = 125ml Step

CB 5 8 - 24 - 32 - 40 8 - 40 cups 1 cup

CB 10 20 - 40 - 60 - 80 16 - 80 cups 1 cup

CB 20 40 - 80 - 120 - 160 32 - 160 cups 5 cups

CB 40 80 - 160 - 240 - 320 64 - 320 10 cups

2.5.3 Selection buttons unit jugs

/i

Model Factory settings Settings scope: jug = 250ml Step

CB 5 4 - 12 - 16 - 20 4 - 20 jugs 1 jug

2018/07 Rev 3.0 33 EN

Page 34

ComBi-line

Model Factory settings Settings scope: jug = 250ml Step

CB 10 10 - 20 - 30 - 40 8 - 40 jugs 1 jug

CB 20 20 - 40 - 60 - 80 16 - 80 jugs 1 jug

CB 40 40 - 80 - 120 - 160 32 - 160 5 jugs

2.5.4 Descale indicator settings calculator

/i

Water quality Hardness Descale indicator: litres

°dH °F mmol/l mgCaCo3/l

Very hard 18 - 30 32 - 55 3.2 - 5.3 321 - 536 250

Hard 12 - 18 22 - 32 2.2 - 3.2 214 - 321 500

Average 8 - 12 15 - 22 1.4 - 2.2 268 - 214 1000 (Standard setting)

Soft 4 - 8 7 - 15 0.7 - 1.4 72 - 268 1500

Very soft 0 - 4 0 - 7 0 - 0.7 0 - 72 2000

2018/07 Rev 3.0 34 EN

Page 35

ComBi-line

3 Transport and Installation

3.1 Transport

3.1.1 Inspection after transport

• Check the machine for damage.

• Make sure that all the required consumer articles and accessories are present and in good order.

Refer to 3.5.1

3.2 Preparation for transport

Note

This procedure only prepares the machine for upright transportation to another local position.

Caution

• Switch the machine off.

• Disconnect the machine from the mains power outlet.

WARNING

Beware of burn injuries from hot fluids. Hot beverage(s) and water may come out from the

overflow hose, the drain hose(s), the container(s) and the tap on the machine.

1 Disconnect the container(s) from the socket(s) and remove the cords.

2 Drain the container(s) and hot water tap of all contents.

3 Close the mains water supply tap.

4 Disconnect the mains water hose from the tap.

5 Disconnect the overflow hose, if the hose is connected.

6 Drain the water from the coffee brew system. Refer to 3.3

7 Drain the water from the boiler system if you have a W model. Refer to 3.4

2018/07 Rev 3.0 35 EN

Page 36

ComBi-line

3.3 Drain the coffee brew system

WARNING

• Beware of burn injuries from hot water. Hot water may come out from the drain hose.

• Beware of crush injuries or damage to the machine. Be careful when you tilt the machine.

Note

This procedure is not applicable for CB 40 models.

1 Tilt the machine to access the drain hose. Refer to 2.1.4

2 Pull out the drain hose (1).

3 Pull the cap (A) out of the drain hose.

4 Drain the water into a receptacle. The receptacle must have

more than 5 litres of capacity.

5 Put back the cap on the drain hose.

6 Put back the drain hose.

3.4 Drain the boiler system of W models

WARNING

1

2

A

• Beware of burn injuries from hot water. Hot water may come out from the drain hose.

• Beware of crush injuries or damage to the machine. Be careful when you tilt the machine.

Note

This procedure is not applicable to CB 40 models.

1 Use the tap to drain as much water as possible.

2 Tilt the machine to access the drain hose. Refer to 2.1.4

3 Pull the drain hose out of the protection plate.

4 Pull the cap out of the drain hose.

5 Drain the water into a receptacle. The receptacle must have more than 5 litres of capacity.

6 Put back the cap on the drain hose.

7 Put back the drain hose into the protection plate.

2018/07 Rev 3.0 36 EN

Page 37

ComBi-line

3.5 Installation

Note

The machine can be used outdoors if all the relevant safety conditions set out by this manual

are met.

Caution

• Only install the machine in locations where it can be overseen by trained personnel.

• Use a filter system with a water softener if the tap water has been chlorinated or is too

hard. This increases the quality of the drink and will ensure that you do not have to

descale the machine too often.

• Do not place the machine in an area with temperatures below 0 °C.

• The tap that is used to connect the hose of the machine to the mains water supply must

be aerated.

• Only use the hose-set that was supplied with the machine.

3.5.1 Package contents

/i

Cartons and

accessories

Contents

Models

CB 1x L (or) R

CB 1x WL (or) R

Model carton 1 2 1

Machine (tower and base

plate)

Swivel arm

Drip tray

Centering pads 4 8 -

Basket filter carton 1 2

Synthetic filter

Water distributor lid

Basket filter papers

(approximately 25 pieces)

Container carton 1 2 -

Container CNe 1 2 -

Container CNi - - -

Insulated lid

Blender / transport disk

Gauge glass brush

Label sheet: coffee / tea /

hot water / blank

Mains power cable (1.5

meter)

Models

CB 2x

CB 2x W

Models

CB

CB W

-

2018/07 Rev 3.0 37 EN

Page 38

ComBi-line

Cartons and

accessories

Accessories

3.5.2 Unpacking

Caution

• Be gentle to avoid damage. Take care not to mishandle the equipment and accessories,

1 Unpack the components and accessories.

2 Make sure you have a complete set of undamaged components and accessories.

3 Make sure the tower and base plate are securely attached.

4 Contact your dealer if any items are damaged or missing.

5 Contact a qualified electrician to connect a plug to the power cable. Refer to 1.6.5.

6 Contact a service engineer to do the first-time installation and all the required connections.

Contents

Mains water connection

hose

Descaling funnel 1 1 1

Coffee fur remover sachet 1 1 1

Scale remover sachet 1 1 1

Quick guide 1 1 1

Electrical plug guide 1 1 1

Container power cables 1 2 0

Wall bracket 0 0 1

or cut through them with a sharp object.

Models

CB 1x L (or) R

CB 1x WL (or) R

111

Models

CB 2x

CB 2x W

Models

CB

CB W

2018/07 Rev 3.0 38 EN

Page 39

ComBi-line

3.5.3 Installation of wall mounted CB and CB W models

Note

The installation of the wall mounted CB and CB W models requires a wall bracket, a severy

trolley, or a product stand. Only use Animo accessories. Contact your Animo agent to order

these accessories. Refer to the back cover of this manual.

Note

The installation of the wall mounted CB or a CB W model must be performed by a service

engineer. The installation must include these items:

• the attachment of the machine onto a wall, with the Animo wall bracket.

• the attachment of a drip tray holder for a CB W model.

• the attachment of the parking rails for an Animo servery trolley onto the wall. Refer to

3.5.4

• the attachment of position studs onto the trolley for a container.

• or, the installation of a product stand.

• the connection of the electricity, the water supply, and the overflow pipe.

Caution

The electrical connection must have an RCD of 30mA with all phases, including the zero

point. The connection must have an easy disconnection (contact distance at least 3 mm ).

3.5.4 Position the servery trolley for wall mounted CB and CB W models

Caution

• The swivel arm should always be at a slight downward angle when in position over the

distributor lid on a container that is on the servery trolley.

1 Position the servery trolley so that a distributor lid on a

container is slightly below, and directly under, the outlet of the

swivel arm. Use the parking rails (A) on the wall get the correct

position.

2 Adjust the stop of the swivel arm for this position. Refer to

3.5.5

A

2018/07 Rev 3.0 39 EN

Page 40

ComBi-line

3.5.5 Adjust the stop of the swivel arm of wall mounted CB and CB W models

WARNING

Adjust the stop of the swivel arm especially if the servery trolley will only be used on 1 side of

the machine. The stop of the swivel arm prevents the possiblity of starting a brewing process

when the swivel arm is not positioned over the position for the servery trolley.

1 Position the container so that the distributor lid is directly under the swivel arm. Use the servery

trolley. Refer to 3.5.4

2 Lift the swivel arm vertically out of the tower.

3 Loosen the relevant stop from the bottom of the swivel arm. Use a 7mm wrench.

4 Adjust the position of the relevant stop to match the position of the magnet.

5 Tighten the relevant stop. Use the adjustable wrench.

6 Put back the swivel arm into the tower.

7 Do a test to make sure the brewing process can only be started when the swivel arm is directly over

the distributor lid of the container. Refer to 4.8

8 If the stop of the swivel arm is not in the correct position repeat the steps 2 to 6.

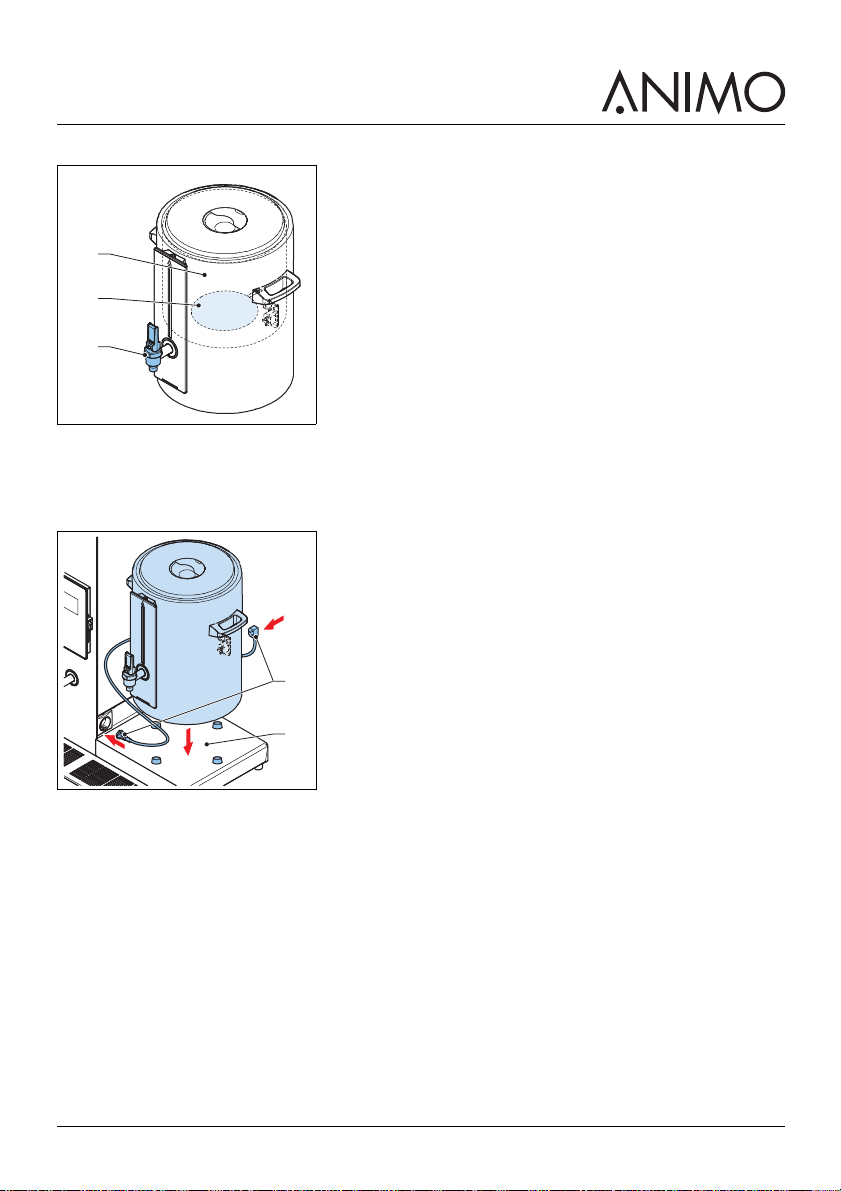

3.5.6 Position a CB model that has base plates

Note

• This procedure only relates to the temporary relocation of the machine as a portable

buffet unit. The first-time technical installation must be performed by a service engineer.

• An Animo product stand is an ideal platform for a CB model that has baseplates. Contact

your Animo agent to order this optional accessory. Refer to the back cover of this manual.

Caution

• Select a sturdy platform for the machine. Make sure the platform can support the weight

of the machine and the container(s) filled with the beverage(s). Refer to 2.3.4

• Avoid damage to other items. Make sure the machine is positioned away from anything

that might be damaged by water leakage.

• Choose a position where utilities are easily accessible. Make sure that a mains water

supply, a drain for the overflow hose, and a mains power outlet are all within 50 cm of the

position you select for the machine.

• Choose a position where the descaling functions can be easily performed. Avoid positions

where items above and in front of the machine might obstruct access to the descaler filler

openings. Refer to 5.3

1 Put the machine on a firm, level surface.

2018/07 Rev 3.0 40 EN

Page 41

ComBi-line

A

A

B

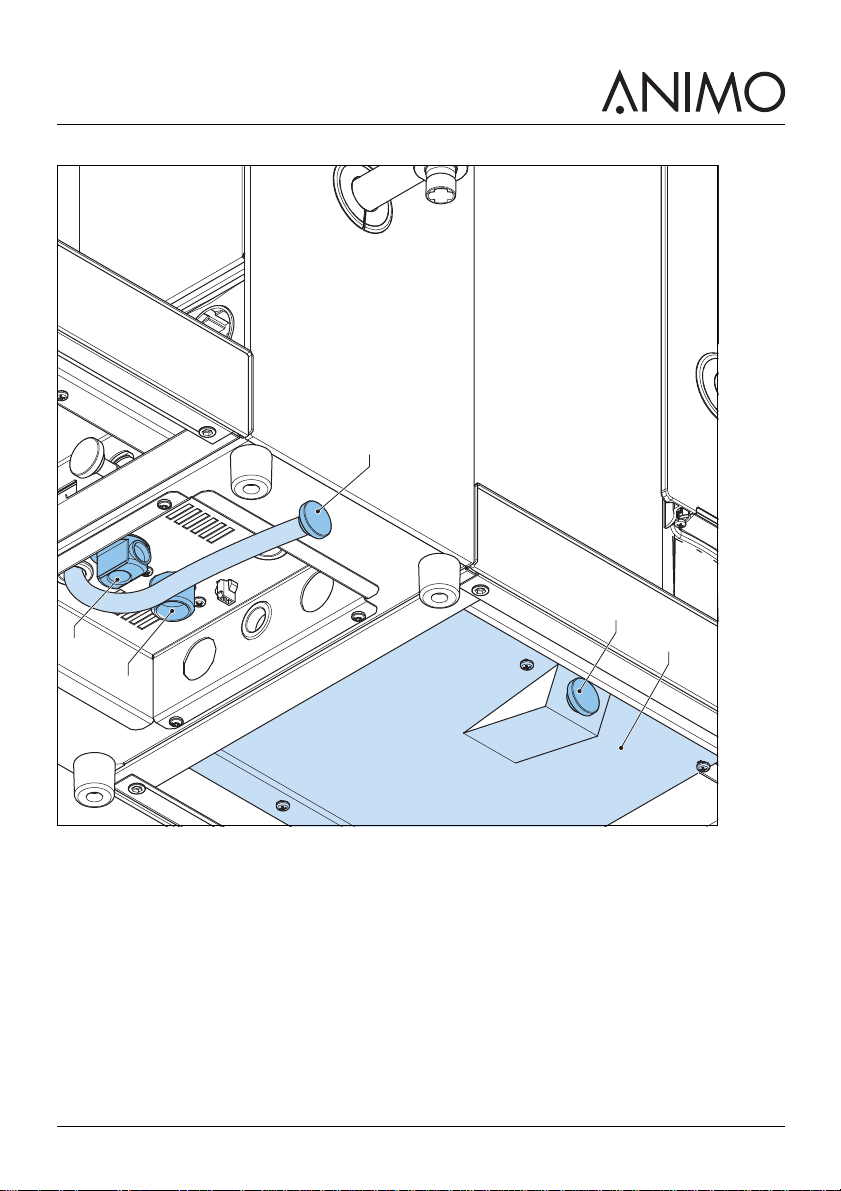

3.5.7 Attach the centering pads

1 For W models, remove the protection plate (A) from

underneath the base plate on the right-hand-side. Use a

screwdriver.

2 Attach the centering pads (A) to the base plates. Use the

fasteners (B).

3 For W models, put back the protection plate.

3.5.8 Water connection

1 Connect the mains water hose (A) to an aerated mains water

tap (B).

2 Open the tap and make sure there is no leakage.

3 If there is a leakage, contact a service engineer.

B

A

2018/07 Rev 3.0 41 EN

Page 42

ComBi-line

4 If necessary, connect the mains supply hose (A) to

a filter system (B).

5 Connect the filter system to a mains supply tap with a hose

(C).

3.5.9 Water drainage

1 Put the drainage hose into a sink or a drain.

2 Make sure that excess water will correctly drain down the hose.

3.5.10 Install the drip tray

Note

For the wall mounted CB model or the CB W model use the side strips supplied with the

model to attach the drip tray to the wall bracket.

1 Put the drip tray (A) in front of the machine (B).

C

B

A

A

3.5.11 Electrical connection

WARNING

Avoid death, or serious injury, or damage to the machine. Do not use the mains power cable if

it is damaged. If the mains power cable is damaged, refer to 1.6.5.

1 Connect the power cable to the mains power outlet.

2018/07 Rev 3.0 42 EN

Page 43

ComBi-line

B

A

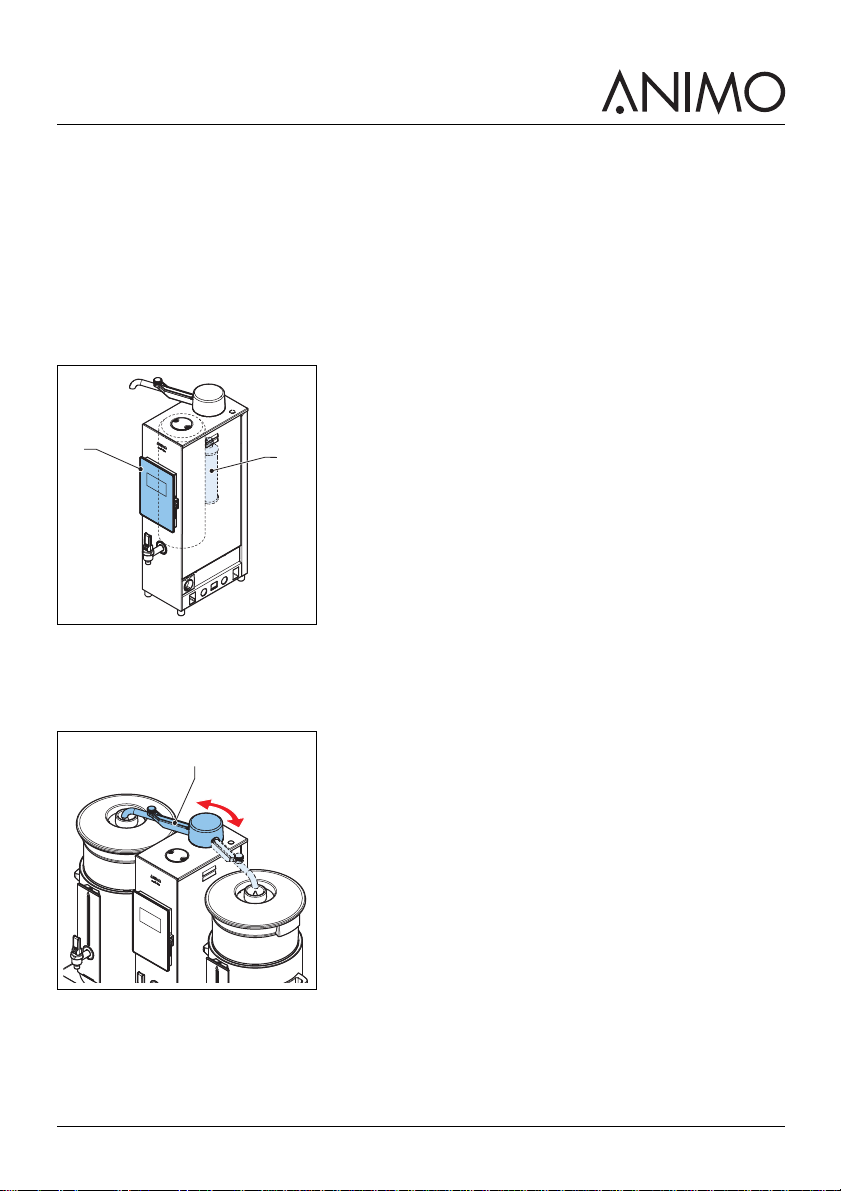

3.5.12 Install a container

Note

If you have a model with 2 base plates, do this procedure twice.

1 Check that the inside of the container is clean and dry.

2 Put the container (B) onto the centering pads on the base

plate (A).

3 Put the coffee blender (A) into the container (B).

4 Put the basket filter (C) into the container.

5 Put the put the water distributor (D) onto the basket filter.

D

C

A

B

AC B

2018/07 Rev 3.0 43 EN

Page 44

ComBi-line

6 If you have a container with an electric element, connect the power socket on the container (A) to

the power socket on the tower (C). Use the container power cable (B).

WARNING

Avoid serious injury, or damage to the machine. Do not use the container power cable if it is

damaged. If the container power cable is damaged follow the safety precautions for damaged

mains power cables. Refer to 1.6.5.

3.6 First-time use

Note

• When you start the machine for the very first time, follow the automatic prompts on the

display to insert your system preferences, then flush the container(s), the coffee brew

system, and the boiler system. After this set-up process, the machine will automatically

switch to the normal operation state.

• If the machine has not been used for a period longer than a week, do the procedure to

start the machine, then flush the coffee brew system, and flush the boiler system. Refer to

sections 3.6.1, 3.6.2, and 3.6.3.

• Do not put a beverage product in the machine for any of these procedures.

• While the swivel arm fills the container the text BREWING appears on the display. When

the process is complete the machine makes a single beep sound. The text DRIPPING

appears on the display. The text remains on the screen while the water is filtered through

the filter unit. The end of the process is signalled by 3 short beep sounds.

Caution

Stop the process if at any time a fault or error becomes evident. Use the stop button on the

control panel. Contact a service engineer before you attempt to use the machine again.

3.6.1 Start the machine for the first time

Note

The default language of the system is English.

1 Make sure that all the installation procedures have been done correctly. Refer to 3.5

2 Switch the machine ON. Refer to 4.4

3 If this is the first-time use of the machine, follow the prompts on the display for Step 1, then follow

the prompts for Step 2.

2018/07 Rev 3.0 44 EN

Page 45

ComBi-line

A

B

A

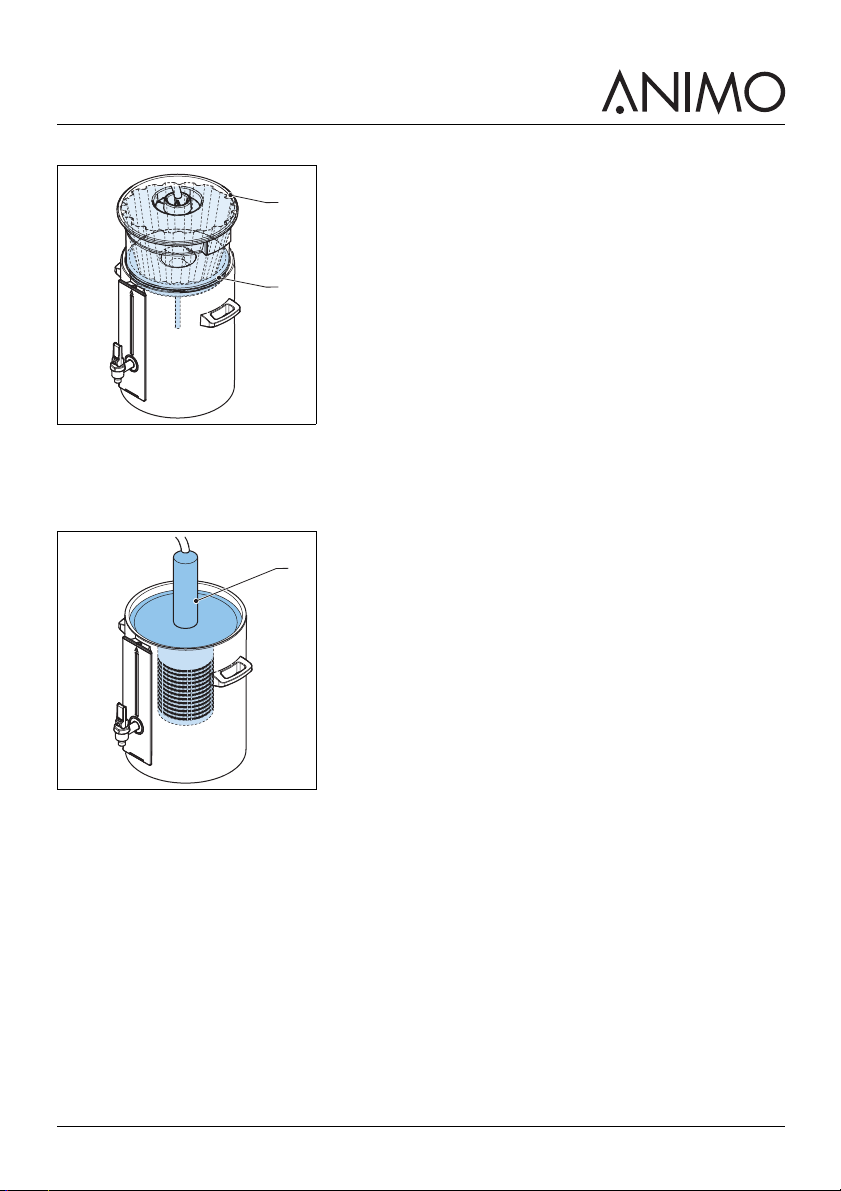

3.6.2 Flush the coffee brew system

WARNING

Beware of burn injuries. Be careful to avoid splashes. Make sure the receptacle you use to

empty the hot water into has proper handles to protect your hands from the heat of the hot

water.

1 Make sure the machine is switched on (A).

2 Make sure a filter basket and distributor lid is in the correct

position on a base plate.

3 Make sure the swivel arm is in the correct position over the

distributor lid.

4 Tap the selection button (B) for the smallest amount of

coffee.

5 Tap the OK button (C).

6 Wait for the brewing and dripping processes to finish. This

will be signalled by 3 short beep sounds. (Refer to the note.)

7 Empty the container (A). Use the tap (B).

B

A

C

8 If you have a model that has 2 containers, put the swivel arm

(A) over the distributor lid of the other container and flush the

coffee brew system again.

2018/07 Rev 3.0 45 EN

Page 46

ComBi-line

3.6.3 Flush the boiler system

Note

• Only do this procedure on W models.

• The boiler system automatically refills itself with water.

• The on/off button of the hot water system blinks until the water is ready to serve.

WARNING

Beware of burn injuries. The hot water temperature in the boiler is set at 96°C. Make sure the

receptacle you use to empty the hot water into has proper handles to protect your hands from

the heat of the hot water.

1 Turn the boiler system on. Tap the on/off button for the hot water system on the control panel. Refer

to 2.1.5

2 Wait for the on/off button to stop blinking.

3 Empty at least 2 liters of water from the boiler system into a jug. Use the tap on the front of the

tower.

Note

The tap of the tower has 2 modes of supply. The modes are short burst, and locked on. Refer

to 4.9

2018/07 Rev 3.0 46 EN

Page 47

ComBi-line

E

B

A

A

C

D

4Operation

4.1 Preparation

1 If this is the first-time use of the machine, do the procedures for first-time use. Refer to 3.6

2 If the machine has not been used for a period longer than a week, do the procedures for first-time

use. Refer to 3.6

3 Make sure the machine and the accessories are in good condition. If the machine or accessories

are in poor condition, contact a service engineer.

4 Make sure that the inner pot of the container is clean. Refer to 5.2.6

4.2 Prepare a container for coffee

1 Put the coffee blender (C) into the container (B).

2 Put the basket filter (D) into the container.

3 Put the filter paper (E) into the basket filter.

4 Put a coffee label into the label holder (A) on the tap of the

container. Snap the holder open with your fingernail.

4.3 Prepare a container for tea

1 Put the tea filter (B) into the container.

2 Put the filling pipe (C) onto the tea filter.

3 Put a tea label into the label holder (A) on the tap of the

container. Snap the holder open with your fingernail.

C

B

A

2018/07 Rev 3.0 47 EN

A

Page 48

ComBi-line

AB

4.4 Switch the machine on

1 Use the On / off switch (A) to switch the machine on.

2 Make sure the display on the control panel (B) is on.

4.5 Prepare the boiler system for use

1 Turn the boiler system on. Tap the button for the hot water

system (A) on the control panel. Refer to 2.1.5

A

Note

• If the the boiler system is idle for a specified time period, and the Energy safe mode is

activated, the boiler system switches to the Energy save mode. In the Energy save mode

the boiler system cools down and the On/off hot water button makes flashes. Tap the

On/off hot water button to re-start the boiler system. To activate, or deactivate the Energy

save mode, refer to 2.5.1

• The coffee and tea brewing processes take priority over the boiler system. The boiler

system automatically pauses if a brewing is in progress.

• For CB W models, a hot water label is supplied for the holder on the tap of the tower.

Snap the holder open with your fingernail to insert the label.

2018/07 Rev 3.0 48 EN

Page 49

ComBi-line

4.6 Select the brewing amount for coffee

Note

The display shows 4 preset brewing amounts. Each preset brewing amount shows a

recommended coffee dosage. This recommendation automatically changes if you modify the

preset brewing amount.

1 Select the coffee option on the display. Use the correct selection button on the control panel (A).

2 Select a brewing amount. Use 1 of the selection buttons on the control panel.

3 Take note of the recommended coffee dosage (A) for the

brewing amount you selected.

4 If desired, modify the brewing amount. Use the selection

buttons (B) on the control panel that correspond to the + (C)

or - (D) text on the display.

5 If you modify the brewing amount, take note of the new

coffee dosage recommendation.

6 Put the recommended coffee dosage (A) into the filter paper

inside the container. Spread the coffee evenly in the filter

paper.

7 Put the filter lid with water distributor (B) onto the basket

filter.

+

-

B

A

B

C

A

D

B

2018/07 Rev 3.0 49 EN

Page 50

ComBi-line

4.7 Select the brewing amount for tea

1 Select the tea option on the display. Use the correct selection

button on the control panel.

2 Follow the same steps as those to select a brewing amount

for coffee (refer to 4.6).

3 Take note of the recommended tea dosage.

4 Put the recommended tea dosage (A) into the tea filter in the

container.

5 Put the filling pipe (B) onto the tea filter.

4.8 Start the brewing process

Note

This procedure applies for both brewing coffee or tea.

Caution

If the swivel arm or the container is moved out of the correct position during the brewing

process, the brewing process will automatically stop. An icon and text will appear on the

display of the control panel. The machine also makes 2 short beep sounds. To restart the

brewing process, put the swivel arm and / or the container back into the correct position(s),

and tap the OK button on the control panel. You must do this within 10 minutes, or the

brewing process you selected will be cancelled.

B

A

WARNING

Beware of burn injuries. Hot water will come out of the swivel arm when the brewing process

is started.

1 If you have a model with a base plate, make sure the

container (A) is in the correct position on the base plate (B).

2 If you have a CB or CB W model, make sure the servery

trolley and the container are in the correct position. Refer to

3.5.4

3 Put the swivel arm (C) in the correct position over the

distributor lid.

4 On the control panel, tap the OK button (D).

C

D

A

B

2018/07 Rev 3.0 50 EN

Page 51

ComBi-line

5 Confirm that the container is empty. Tap the OK button.

Note

When you confirm that the container is empty the

brewing process will start.

• The power socket of the container will

automatically switch to On if the Auto Container

Heating option in the Operator menu is activated.

Refer to the section 2.5.1

• You must manually switch the power socket to On

if the option is not activated. Refer to the section

2.1.5

6 Look at the progress bar (A) on the display to see the

progress of the brew.

A

2018/07 Rev 3.0 51 EN

Page 52

ComBi-line

4.9 Complete the coffee brewing process

Note

• If you have a CB model with a second container, you can start a new brewing process

while the first container completes the brewing process. When the water supply stops

coming out of the swivel arm over the first container, put the swivel arm over the second

container and start the brewing process again.

• The container heating begins when the brewing process starts.

WARNING

• Beware of scalding injuries when you move the swivel arm.

• Beware of burn injuries from the contents of the filter basket. The contents of the filter

basket will be hot when you remove it from the container after the brewing process is

complete. Make sure you have a safe, watertight receptacle to dispose of the contents of

the filter basket.

• Beware of scalding injuries. Hot beverage is inside the container after the completion of

the brewing process. Hot beverage will come out of the tap if it is opened.

1 Wait for the machine to make 1 short beep sound.

2 Do a check that the progress bar (A) on the display shows

that the brew is Dripping.

3 After approximately 5 minutes, wait for the machine to make

3 short beep sounds.

A

4 Move the swivel arm (A) away from the container (B).

5 Take the water distributor (C) off the basket filter (D).

6 Take the basket filter off the container.

7 Put the insulated lid (E) onto the container.

8 Dispose of the filter and the contents of the filter, and clean

the filter basket. Refer to 5.2.7

A

C

E

D

B

2018/07 Rev 3.0 52 EN

Page 53

ComBi-line

4.10 Serve the beverage

Note

• In a container, the beverage is kept at an average temperature between 80 to 85°C.

• Coffee can be stored in the container for between 1 to 1.5 hours before the flavor of the

coffee deteriorates. Empty the coffee from the container after this period of time and

prepare to brew more coffee. Refer to 4.1

• The tap of the container can provide 2 modes of supply. Use the short burst supply to put

beverage into cups and mugs. Use the lock position to fill jugs and large containers.

Caution

Stop the container heater if the container is empty. To stop the heater, disconnect the power

cable from the sockets on tower, or use the control panel of the machine.

WARNING

Beware of scalding injuries. Hot beverage is inside the container after the completion of the

brewing process. Hot beverage will come out of the tap if it is opened.

1 Serve the beverage as required. Use the tap (A).

A

2 Press the tap lightly to serve the beverage in a short burst.

2018/07 Rev 3.0 53 EN

Page 54

ComBi-line

3 Press the tap fully down to lock the tap in the open position.

4 When the container becomes empty of beverage, disconnect

the power cable from the sockets on the container and the

tower.

5 Rinse the inner pot of the container before you start another

brewing process. Refer to 5.2.6

4.11 Use the timer function

Note

You can use this function to brew coffee or tea and activate the hot water system.

The timer can be programmed a maximum of 6 days in advance.

The heating element in the container switches on automatically 5 minutes before the

programmed brewing time.

You cannot start a brewing processes while the timer program is set.

If you have a model with 2 base plates, you can set a timer program on 1 container, and still

use the heating element in the other container.

The timer program is active when there is a stopwatch icon at the top of the display.

1 Prepare a container to brew either coffee or tea. Refer to 4.2

and 4.3.

2 Tap the Timer button (A) on the control panel.

3 Select Container and/or Boiler, then tap OK.

4 Select the day, then tap OK.

5 Select the time, then tap OK.

6 Select the brewing amounts for either coffee or tea. Refer to

section 4.6 or 4.7.

7 Do the preparation to start the brewing process. Refer to

section 4.8.

A

Caution

Make sure the container and swivel arm remain in the correct position while the timer program

is active. If the container or swivel arm are moved, the timer program will stop and a warning

appears on the display. Correct the position of the container and swivel arm to restart the

timer program. Refer to section 4.8

2018/07 Rev 3.0 54 EN

Page 55

ComBi-line

4.12 Complete the tea brewing process

Caution

Do not leave the tea filter in the container for longer than 15 minutes after the completion of

the brewing process. If the tea filter is left in the container for too long, the flavor of the tea

deteriorates.

1 Follow the same steps as those to complete the coffee

brewing process. Refer to 4.9.

2 Take the filling pipe (A) and tea filter (B) out of the container

(C) at least 4 minutes after the Dripping process has

stopped.

3 Serve the beverage. Refer to 4.9

A

B

C

2018/07 Rev 3.0 55 EN

Page 56

ComBi-line

5 Maintenance

5.1 Cleaning and disinfecting detergents

Caution

• Only use Animo cleaning products where specified.

• Do not immerse the container type CNe in water.

WARNING

Avoid chemical burns and eye injuries. Use safety gloves and protective glasses when using

cleaning products.

/i

Use these products where specified Remarks

Animo coffee fur remover Refer to 2.3.14

Animo scale remover Refer to 2.3.14

5.2 Cleaning

5.2.1 Daily cleaning

/i

Machine part Dishwasher proof See

Inner pot No 5.2.6

Clean the basket filter Yes 5.2.7

Clean the filter lid with water

distributor

Clean the blender No 5.2.9

Clean the drip tray No 5.2.10

Clean the exterior No 5.2.11

Yes 5.2.8

5.2.2 Weekly cleaning

/i

Machine part Dishwasher proof See

Remove coffee deposits from

No 5.2.12

the inner pot

Remove coffee deposits from

No 5.2.13

other parts

5.2.3 Descaling

Caution

Descale the machine as soon as possible after the descale indicator icon appears on the

display of the machine.

/i

Machine part Schedule See

Coffee brew system When alerted by the machine 5.3.2

Boiler system When alerted by the machine 5.3.6

2018/07 Rev 3.0 56 EN

Page 57

ComBi-line

A

5.2.4 General cleaning instructions for the machine

Caution

Never submerge or spray the machine.

1 Clean the exterior of the machine with a soft cloth or sponge that is dampened with warm water and

detergent.

2 Dry the machine with a soft dry cloth.

5.2.5 General cleaning instructions for the containers

Note

• The container type CNi can be submersed in water.

• As appropriate, increase the quantities and the sizes of the cleaning materials to clean a

CN 40 model.

Caution

Do not put the container type CNe in a dishwasher or sink.

Do not leave the lid on a container after cleaning. Position the lid ajar so that there is an air

flow into the container. The air flow avoids staleness in the container.

Leave approximately 2 cups of clean water in the container after cleaning. The water keeps

the rubber seals inside the container in good condition.

WARNING

Avoid hot water burns. Wear gloves and use a safe receptacle to clean, rinse and drain the

hot water into.

1 Disconnect the power cable from the container(s) when

cleaning the CNe container(s).

2 Close the splash protector (A).

5.2.6 Rinse the inner pot

1 Empty the contents of the container. Use the tap.

2 Remove all the accessories from the inside of the container.

3 Rinse the inner pot with hot water.

4 If required, remove beverage deposits from the inner pot. Refer to 5.2.12

2018/07 Rev 3.0 57 EN

Page 58

ComBi-line

5.2.7 Clean the basket filter

Note

You can clean the basket filter in a dishwasher.

1 Wash the basket filter in warm water with detergent.

2 Rinse the basket filter in clean water.

3 Dry the basket filter with a soft cloth.

5.2.8 Clean the filter lid with water distributor

Note

You can clean the filter lid with water distributor in a dishwasher.

1 Wash the lid in warm water with detergent.

2 Rinse the lid in clean water and dry it.

5.2.9 Clean the blender

1 Wash the blender in warm water with detergent.

2 Rinse the blender in clean water and dry it.

5.2.10 Clean the drip tray

1 Wash the drip tray in warm water with detergent.

2 Rinse the drip tray in clean water and dry it.

5.2.11 Clean the exterior

Caution

Do not use abrasive cleaning products on the exterior of the machine or the container(s).

1 Clean the exterior of the machine and the container(s) with a soft damp cloth.

2 Wipe the exterior of the machine and the container(s) dry.

5.2.12 Remove beverage deposits from the inner pot

Note

This procedure also applies to the removal of tea stains.

A sachet of coffee fur remover is required for this procedure. Refer to 2.3.14

Caution

Do not immerse the container during this procedure.

1 Empty the container. Use the tap.

2 Remove the brewing accessories from the container.

3 Fill half the container with warm water.

4 Put a sachet of coffee fur remover into the water.

5 Stir the water with a spoon to disolve the remover.

6 Wait for approxiamately 15 to 30 minutes, then empty the container. Use the tap.

2018/07 Rev 3.0 58 EN

Page 59

ComBi-line

7 Rinse the inside of the container with clean hot water several times. Use the tap to empty the

container each time you rinse the container.

8 Wipe the inside of the container dry.

5.2.13 Remove beverage deposits from other parts

Note

This procedure also applies to the removal of tea stains.

Note

This procedure requires a bucket with at least a 5 liter capacity.

A sachet of coffee fur remover is required for this procedure. Refer to 2.3.14

1 In the bucket, mix 5 liters of warm water with 1 sachet of the coffee fur remover.

2 Put the parts that need to be cleaned into the water.

3 Wait for approximately 15 to 30 minutes, then remove the parts from the receptacle.

4 Carefully discard the water.

5 Rinse the parts with clean hot water. Do this several times.

6 Repeat steps 1 to 5 if coffee deposits are still on the parts.

7 Wipe the parts dry.

5.2.14 Clean the tap on a container

1 Make sure that the container is empty and that the power

cable is disconnected.

2 Unscrew the top of the tap (A). Turn the top of the tap anti-

clockwise.

3 Take the silicon sealer (B) from the top of the tap.

4 Do the procedure to remove beverage deposits from other

parts, to clean the top of the tap and the seal. Refer to 5.2.13

5 Put back the silicon sealer and the top of the tap onto the

container. Reverse the steps 3 and 2.

B

A

2018/07 Rev 3.0 59 EN

Page 60

ComBi-line

5.2.15 Clean the gauge glass

Note