Page 1

Anetsberger Br others, Inc.

180 North Anets Drive • Northbrook, Illinois 60062 • 847-272-0770 • Fax 847-272-1943

For ANETS Factory Warranty Service • 800-837-2638

Model Filt II-14W shown banked

to (2) 14” fryers

Model FM-14 Filter Mate

shown under the base system

of (2) 14” fryers

GoldenFRGoldenFR

GoldenFR

GoldenFRGoldenFR

YY

Y

YY

Models

FM-14 Filter Mate

FM-18 Filter Mate

Filt II-14/14W Filtronic

Filt II-18/18W Filtronic

Installation,

User Operation,

&

Maintenance

Manual

DANGER

!

Improper installation, adjustment, alteration, service, or maintenance can

cause property damage, injury or death. Read the installation, operating

and maintenance instructions thoroughly before installing or servicing this

equipment.

!

FOR YOUR SAFETY

DO NOT store or use gasoline or other flammable vapors

or liquids in the vicinity of this or any other appliance.

!

WARNING

After installation of this equipment, immediately contact your local gas

supplier to obtain information about what action to take whenever any

person smells gas. Post this information in a prominent location.

Keep this Manual in a Convenient Location for Reference

FM-14

FM-18

Filt II-14/14W

Filt II-18/18W

Quality Equipment For The Restaurant, Supermarket, and Bakery Industries

The Anets GoldenLine

Form I-225

Rev. 6/03

Price $20.00 US

1

Page 2

TABLE OF CONTENTS

Shipping Container Inspection ....................................................... 2

Code Requirements ...................................................................... 2

Filter Unit Preparation Instructions ................................................ 3

Filter System Diagrams .................................................................. 4

Filtering Instructions ...................................................................... 5

Oil Disposal Instructions ............................................................... 6

Replacing The Filter Paper ............................................................ 7

Filter Troubleshooting Guide .......................................................... 8

Filter W arranty .............................................................................. 9

DD

ANGERANGER

D

ANGER

DD

ANGERANGER

!

Read these specifications, Code Requirements, Installation Requirements, Installation Instructions, and Operating Instructions

tions could cause the filter system to malfunction. A filter system malfunction can result

in property damage, serious bodily injury, or death.

very carefully . Failure to follow the Instruc-

SHIPPING CONTSHIPPING CONT

SHIPPING CONT

SHIPPING CONTSHIPPING CONT

1. Carefully examine the shipping container for external damage. When damage is noted, notify the

delivery carrier immediately . Save all packing materials for damage claim examination.

2. If no external damage is noted, remove the shipping container from the filter and examine the unit

carefully for damage. Place the filter in a safe location, if damage is noted, so that the freight damage

claims adjuster can examine it.

Models CoModels Co

Models Co

Models CoModels Co

FM-14 Filter Mate, Under Fryer Filter System - 14”

FM-18 Filter Mate, Under Fryer Filter System - 18”

Filt II-14 14” Filtronic Filter System in Cabinet

Filt II-14W 14” Filtronic Filter System with Heat Lamp

Filt II-18 18” Filtronic Filter System in Cabinet

Filt II-18W 18” Filtronic Filter System with Heat Lamp

vv

v

vv

erer

er

erer

ed By ed By

ed By

ed By ed By

AINER INSPECTIONAINER INSPECTION

AINER INSPECTION

AINER INSPECTIONAINER INSPECTION

TT

his Manhis Man

T

his Man

TT

his Manhis Man

ualual

ual

ualual

Standard Accessories furnished in the shipping carton with this filter include:

(1) Filter Screen Assembly

Box of Filter Paper (100 pcs.)

Other available Optional equipment may include a separate hose assembly for shortening removal and a

cleaning brush. These would be packed with the fryers, if ordered.

NOTE: A Parts List for each Anets Filter System is among the items shipped with each unit. If an

additional copy of this list is needed, please contact the factory as directed on the back cover.

2

Page 3

INSTINST

!

INST

INSTINST

This Manual will detail the Installation and Operation of the Filter-

Mate system, with notes where the Filtronic II System differs.

Both the Filter Mate and Filtronic II Systems enable the user to safely and efficiently filter the cooking oil or

shortening from a fryer in a banked row while the other fryers in that row are still being used. Even though

these two Filtration Systems are slightly different in physical dimensions and design, the Installation and

Operation is basically the same.

FILFIL

TER ELECTRICAL SPECIFICATER ELECTRICAL SPECIFICA

FIL

TER ELECTRICAL SPECIFICA

FILFIL

TER ELECTRICAL SPECIFICATER ELECTRICAL SPECIFICA

Please make sure that your desired filter location has electrical supply factors that are suitable for this

product. Requirements are 120 V olts, 60 Hz, 8 Amps, 1-phase, three-wire connection, including an

electrical ground.

!

Electrical Grounding Instructions

ALLAALLA

ALLA

ALLAALLA

WARNING

TIONTION

TION

TIONTION

TIONSTIONS

TIONS

TIONSTIONS

This appliance is equipped with a three-prong (grounding) plug for

your protection against shock hazard, and should be plugged

directly into a properly grounded, three-prong receptacle. DO NOT

cut or remove the grounding prong from this plug.

FILFIL

TER UNIT PREPTER UNIT PREP

FIL

TER UNIT PREP

FILFIL

TER UNIT PREPTER UNIT PREP

1. Assemble filter envelope to filter screen by sliding the envelope over the filter screen, folding

back the open end over the filter screen. Make sure the hole in the filter envelope fits over

the fitting on the filter screen.

2. Assemble filter envelope clip over folded back end of envelope and over fitting on filter

screen.

3. Attach knurled retaining nut onto fitting on screen, securing the assembly .

4. Attach quick-connect coupling on drain tube to knurled retaining nut.

5. Place filter unit into the filter tank using the lift-out handle.

6. Connect the filter assembly to the pump using the quick-connect assembly .

7. Put the filter tank cover on the tank.

8. Slide the filter tank unit into its location under the fryers or in the filter cabinet.

9. Make the connection from the fryer return line to the filter pump with the quick-connect

fitting.

10. Plug the cord on the side of the filter unit into the receptacle on the fryer frame. Make sure

that the power switch located on the side or top of filter unit is ON.

ARAARA

ARA

ARAARA

TION TION

TION (Refer to Photos On Page 4)

TION TION

3

Page 4

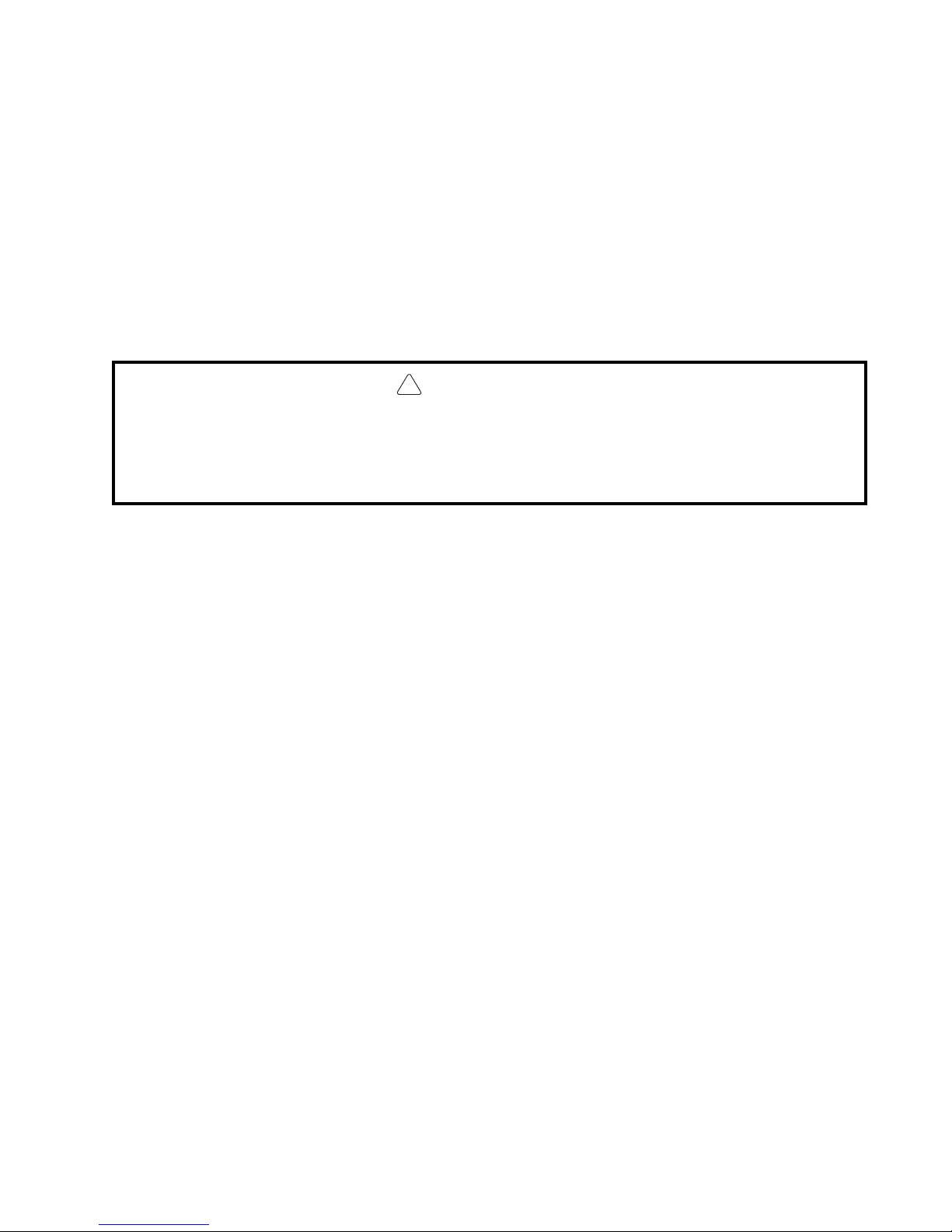

Lift out handle

Pump quick-connect coupling

Return line and optional hose

connection

FILFIL

FIL

FILFIL

TER MATER MA

TER MA

TER MATER MA

Filter envelope clip

TE TE

TE

TE TE

Filter envelope

TT

ANKANK

T

ANK

TT

ANKANK

Quick connect coupling

Knurled retaining nut

FILFIL

FIL

FILFIL

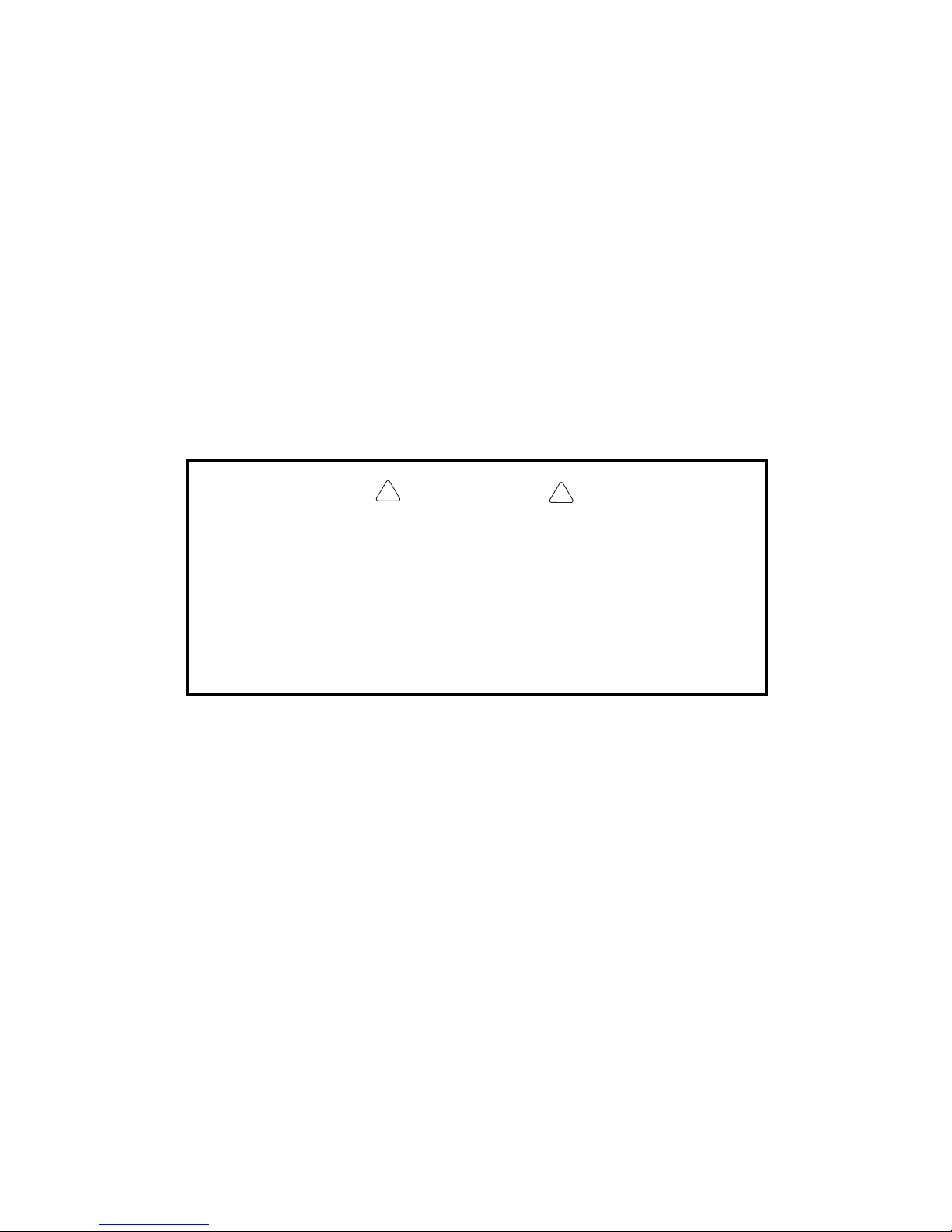

Pump quick-connect coupling

Filter envelope

Filter envelope clip

TRTR

ONIC II ONIC II

TR

ONIC II

TRTR

ONIC II ONIC II

TT

ANKANK

T

ANK

TT

ANKANK

Lift out handle

Quick connect coupling

Knurled retaining nut

4

Page 5

FILFIL

!

FIL

FILFIL

TERING INSTRTERING INSTR

TERING INSTR

TERING INSTRTERING INSTR

UCTIONSUCTIONS

UCTIONS

UCTIONSUCTIONS

CAUTION

Never operate the filter unit unless the cooking oil or shortening in the

fryers has been brought up to cooking temperature.

WARNING

Always wear protective heat-resistant gloves when performing the filtering operation.

FILFIL

TERINGTERING

FIL

TERING

FILFIL

TERINGTERING

1. Before filtering the shortening in a fryer, turn the thermostat knob to “OFF” or the Gas Valve to “PILOT” to prevent the fryer from re-lighting during filtering. On some models the system automatically

prevents the burners from lighting when the door of the fryer is open.

2. Open the drain valve (black handle) on the fryer to be filtered, letting all the shortening drain into the

filter tank. Leave this valve open.

!

DANGER

Never drain more than one fryer at a time – the filter pan may overflow .

3. Open the return line valve (yellow handle) for the fryer being filtered. This activates the power to the

pump. If the pump does not start immediately check that the switch on the side or top of the pump

frame is “ON”. While the filter system is cycling, use a long-handled cleaning brush to wipe the bottom

of the fryer and push excess crumbs through the drain and into the filter machine.

WARNING

When cleaning the inside of the frypot, do not damage the temperature and

hi-limit probes that protrude into the frypot.

4. When the shortening returning into the fryer is clear, close the drain valve (black handle) and allow the

fryer to refill.

5. Allow the pump to run until no more oil is returning into the vat. Then close the return line valve

(yellow handle), which de-activates the power to the pump.

WARNING

If solid shortening is being used it is very important that all oil is allowed to flow back into

the vat and none is left in the hoses. Failure to do so could cause the pump to fail if the

oil solidifies in the line.

Note On Using Filter Powder

If filter powder is being used, add 1 cup of powder (for 14” fryers) or 2 cups (for 18” fryers) to

either the fry tank or the filter tank. If added to fry tank, make sure powder is completely flushed

during fry tank cleaning (Step 3) before closing drain valve (Step 4). If added to filter tank, the

powder will be removed when the filter envelope is changed and the filter tank is cleaned.

5

Page 6

6. On gas-operated thermostat models (14G, 14GS, MXEG, 18EG, 20EG) the thermostat knob can now

be turned back to the desired temperature. CAUTION: On these models the thermostat must be set to

“OFF” or the Gas V alve to “PILOT” before filtering or the burners MA Y come back on if the doors are

closed during filtering.

7. On electric-operated thermostat models (MX-14E, MX-14AA, 18E, 18AA, 20E, and 14EL-17) the

power switch on the control panel must be reset for the fryer to operate again.

8. The other fryers in the bank can be filtered using the same procedure.

IMPORTANT NOTE:

The pump on this filter unit is equipped with a safety that will turn off the motor if it overheats or an

electrical fault occurs. If this occurs, let the pump motor cool for 15 minutes, then press the manual

reset button on the bottom of the motor and restart the motor .

DANGER

Never run water through the filter system. This will cause rust and corrosion in the

motor and pump and will void the Warrranty.

OIL DISPOSALOIL DISPOSAL

OIL DISPOSAL

OIL DISPOSALOIL DISPOSAL

WARNING

Always wear protective heat-resistant gloves when performing the oil disposal operation.

If the cooking oil or shortening from a fryer is to be disposed, follow steps 1 and 2 from Filtering Instructions in previous section. Disconnect the line from the pump to the fryer return line, and connect the

optional hose assembly to the pump. Turn on the pump using the manual switch on the side or top of the

filter and direct the oil into an appropriate device such as an oil shuttle to move the used oil to its disposal

tank.

6

Page 7

REPLAREPLA

REPLA

REPLAREPLA

If the filter paper becomes torn, or if the time to filter the oil from one unit becomes excessive, it is time to

replace the Filter Envelope.

CING CING

CING

CING CING

THE FILTHE FIL

THE FIL

THE FILTHE FIL

TER PTER P

TER P

TER PTER P

APERAPER

APER

APERAPER

DANGER

!

Make sure the filter pan has cooled completely to room temperature before

attempting to change the paper.

1. Disconnect the oil return line from the pump.

2. Unplug the cord from the receptacle on the side of the cabinet.

3. Pull the filter unit from the cabinet.

4. Disconnect the line from the pump to the filter screen.

5. On the Filtronic II models, pivot the motor assembly up out of the way .

6. Remove the filter cover. Use lift out handle to remove screen assembly . Place on a clean surface for

disassembly .

7. Detach quick-connect coupling on drain tube from knurled retaining nut.

8. Detach knurled retaining nut from fitting in screen.

9. Remove filter envelope clip from end of filter screen and folded back end of envelope .

10. Remove filter envelope from filter screen.

WARNING

The oil soaked filter envelope may still be very hot and could cause burns.

11. Clean the filter pan, filter screen and all components thoroughly using a solution of hot water and

detergent. Make sure that all food and breading particles are removed from the pan and from the filter

screen.

12. Dry the pan, the screen and all components completely before starting to reassemble.

13. Follow instructions under FIL TER UNIT PREP ARATION to install new filter envelope.

!

7

Page 8

FILFIL

FIL

FILFIL

TER SYTER SY

TER SY

TER SYTER SY

STEM STEM

STEM

STEM STEM

TRTR

OUBLESHOOOUBLESHOO

TR

OUBLESHOO

TRTR

OUBLESHOOOUBLESHOO

TING GUIDETING GUIDE

TING GUIDE

TING GUIDETING GUIDE

PROBLEM

Pump does not

start when the

return line valve

(yellow handle) on

the fryer is opened.

SOLSOL

UTIONUTION

SOL

UTION

SOLSOL

UTIONUTION

1. Make sure the power cord is plugged into the receptacle in the cabinet and the

main power cord from the system is plugged into the appropriate power supply.

2. Turn the switch on the side of the filter to “ON”.

3. Close the return line valve (yellow handle) and try opening the return line valve

on another fryer. If the pump starts, the problem is with the microswitch that

contacts the return line valve on the first fryer.

4. If pump still hasn’t started, depress the thermal overload button on the bottom

of the motor. If the motor is hot to the touch, wait at least 45 minutes before trying

this.

5. If the pump starts and stops again in a short time, or if it hums but does not

pump, there is a restriction somewhere in the filter screen or in the pump itself. Go

to Step 6. If there is no reaction from the pump, go to step 7.

6. Allow the oil/shortening in the filter pan to cool, then empty the pan and verify

that the filter paper and screen assembly is assembled correctly. Disassemble the

filter screen and look for blockages of sediment or solid shortening within.

7. Problem is with the motor/pump or the wiring. Remove the motor from the

filter and bench test by connecting a 120V line to the motor leads. If it runs, the

problem is with the wiring between the motor and the power supply . If it does not

run, the motor needs to be replaced.

Filtering procedure is

very slow . Shortening/oil returning to the

fryer very slow .

Fryers do not re-fire

after filtering.

1. After all the shortening/oil has been pumped back into the fryer, inspect the

filter paper envelope. Make sure that any excess sediment is removed from the

top of the filter paper envelope.

2. If the filter paper envelope is dirty or torn, disassemble the filter screen

assembly . Inspect for blockages in the lines. Replace with a clean filter paper

envelope.

WARNING

Only use filter paper envelopes from Anetsberger Brothers that have been

specifically designed for this filter system. Using the wrong type of filter paper

can cause damage to the pump system, and will void the warranty .

3. If the oil still returns to the fryer slowly , the problem may be a blockage within

the pump itself. The pump section of the motor can be easily disassembled to

look for blockages of sediment or solid shortening within.

1. Make sure the door on the fryer is completely closed.

2. Reset the ON/OFF switch on the fryer by flipping to OFF position and

then back to ON. (Note: Each time the fryer door is opened the ON/OFF

switch needs to be reset.

8

Page 9

LIMITED WARRANTY

ANETSBERGER BROTHERS, INC., Northbrook, Illinois, USA, certifies

that all equipment of its manufacture is, to the best of its knowledge, free from

defective material and workmanship.

ANETSBERGER BROTHERS, INC., agrees to replace any integral part of

its equipment that proves defective within 15 months of date of original shipment from the factory , or 12 months from the date of installation, whichever is

sooner . Buyer must return the defective part to the factory , freight prepaid,

for inspection. Anetsberger Brothers, Inc., further agrees to assume the cost

of installing said replacement part within the same period.

All frypots are covered by the warranty above for the first year of operation.

V arious models have an extended warranty that cover the replacement of the

frypot only . See the individual specification sheets for details.

Overtime charges, calibration, adjustments and abnormal installation charges

shall not be at the expense of Anetsberger Brothers, Inc.

The conditions and warranty expressed above are valid only if equipment has

been properly installed and operated. No other warranty , expressed or implied, shall govern equipment manufactured by Anetsberger Brothers, Inc.

Under no circumstances shall Anetsberger Brothers, Inc., be liable for loss of

profits or any direct or indirect cost, expenses, loss or damages arising out of

defects in or failure of the equipment or any part thereof.

Anetsberger Br others, Inc.

180 North Anets Drive • Northbrook, Illinois 60062 • 847-272-0770 • Fax 847-272-1943

T oll-free Customer & W arranty Service: 800/ 837-2638

W eb Site: www .anetsberger .com

email: sales@anetsberger .com

Keep this Manual in a Convenient Location for Reference

9

Loading...

Loading...