Page 1

Anetsberger Br others, Inc.

180 North Anets Drive • Northbrook, Illinois 60062 • 847-272-0770 • Fax 847-272-1943

For ANETS Factory Warranty Service • 800-837-2638

FR YER

Model

CF14

Installation,

User Operation,

&

Maintenance

Manual

DANGER

!

Improper installation, adjustment, alteration, service, or maintenance can

cause property damage, injury or death. Read the installation, operating

and maintenance instructions thoroughly before installing or servicing this

equipment.

FOR YOUR SAFETY

!

DO NOT store or use gasoline or other flammable vapors

or liquids in the vicinity of this or any other appliance.

WARNING

!

After installation of this equipment, immediately contact your local gas

supplier to obtain information about what action to take whenever any

person smells gas. Post this information in a prominent location.

Keep this Manual in a Convenient Location for Reference

Quality Equipment For The Restaurant, Supermarket, and Bakery Industries

The Anets Golden Line

www.anetsberger.com

Form I-152 ;

Rev. 12/03

Price: $20.00 US

1

Page 2

!

DANGER

Read these specifications, Code Requirements, Installation Requirements, Installation Instructions, and Operating Instructions

Instructions could cause the fryer to malfunction. A fryer malfunction can result in

property damage, serious bodily injury, or death.

CONTENTS

Shipping Container Inspection ........................................................ 3

Fryer Gas Supply Specifications..................................................... 3

Fryer Electrical Specifications ....................................................... 4

Figure 1 - Fryer Model CF14 Wiring Diagram ....................... 4

Code Requirements ...................................................................... 4

Figure 2 - Fryer Site Installation Requirements ....................... 5

Installation Requirements............................................................... 5

Leg Leveling Instructions............................................................... 5

very carefully. Failure to follow the

Gas Connection Instructions.......................................................... 6

Fryer Operating Instructions.......................................................... 6

Fryer Preparation For Use (“Boil Out” Instructions) ................ 7

Figure 5 - Draining The Kettle ............................................... 7

Lighting Procedure.................................................................. 8

Figure 6 - Gas Safety V alve & Control Knob Positions .......... 8

Shutdown Procedure .............................................................. 9

Daily Cleaning Procedure....................................................... 10

Monthly Maintenance Instructions .......................................... 11

Fryer Troubleshooting Guide ................................................... 11-15

Fryer W arranty ............................................................................ 16

2

Page 3

SHIPPING CONTSHIPPING CONT

SHIPPING CONT

SHIPPING CONTSHIPPING CONT

AINER INSPECTIONAINER INSPECTION

AINER INSPECTION

AINER INSPECTIONAINER INSPECTION

1. Carefully examine the shipping carton for

external damage. When damage is noted, notify

the delivery carrier immediately . Save all packing

materials for damage claim examination.

2. If no external damage is noted, remove the

shipping carton from the fryer and examine the

fryer carefully for damage. Place the fryer in a

safe location, if damage is noted, so that the freight

damage claims adjuster can examine the fryer.

3. Save the shipping container for use during leg/

caster installation. Refer to the Installation Instructions for that procedure.

Model Covered By This Manual

CF14 14” Gas Counter Fryer

Standard Accessories furnished in the shipping carton for this fryer include:

2 Fryer Baskets 1 Drain Valve Extension 1 Screen

1 Basket Hanger

Note: A Parts List for each Anets fryer is among the items shipped with each fryer. If an

additional copy of this list is needed please contact the factory as directed on the back

cover.

FRYER GAS SUPPLY SPECIFICATIONS

Please make sure that your desired fr yer location has gas

supply factors that are suitable for this product:

Gas Input: CF14 70,000BTU/Hr*

Natural Gas Propane

MANIFOLD PRESSURE

SUPPLY PRESSURE ***

* -

BTU/Hr Rating is based on sea level operation. For sites above 2000 feet, reduce this

rating 4% for each 1000 feet above sea level.

** -

“W.C. = Inches, Water Column.

*** -

Measure Supply Pressure when all other gas-powered equipment is operating.

Gas Supply Inlet Pipe size must be 1/2“ NPT

(National Pipe Thread) standard gas line. The gas

supply inlet line should be as straight as possible

(fewest bends or elbows) to obtain the highest

available gas pressure at the fryer . Locate this

inlet line horizontally at the center of the desired

fryer location.

3½“ W.C. **

6“ W.C., minimum 11“ W.C., minimum

10“ W.C.

NOTE: Using a flexible inlet line permits variation

in the gas supply line location, both horizontally and

vertically .

Anets fryers are only for use with the type of gas

specified on the spec plate. if a fryer requires

modification to use a gas other than that which is

identified on the fryer spec plate, contact your

Anets representative or call (800) 837-2638.

3

Page 4

FRYER ELECTRICAL SPECIFICATIONS

ANETSANETS

The

ANETS Fryer Model CF14 requires no external electric power source.

ANETSANETS

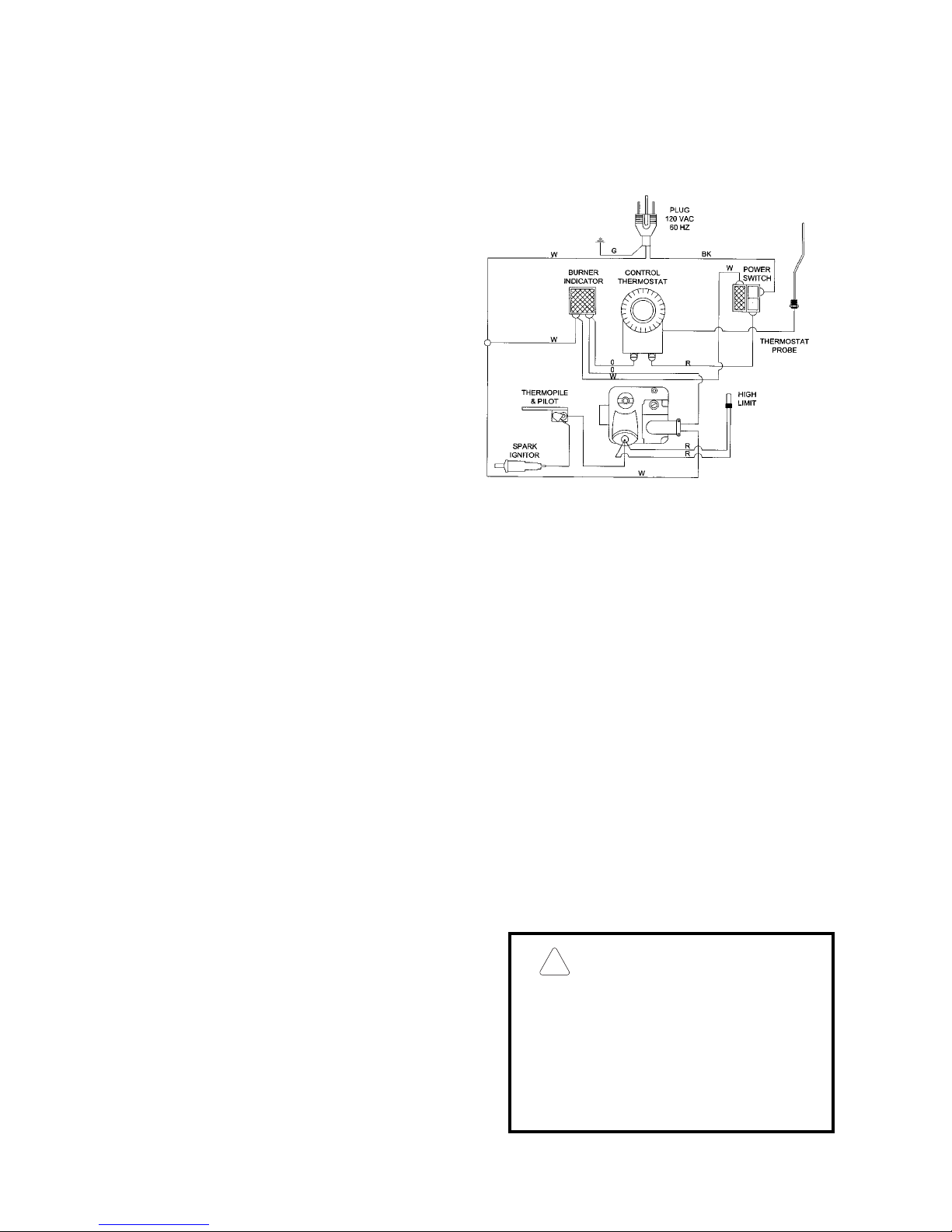

Figure 1 is a wiring diagram of an

ANETSANETS

ANETS CF14 Fryer. Some fryers

ANETSANETS

may have other options that do not

appear in this basic wiring diagram. A

model-specific wiring diagram included

with each fryer shows all the actual parts

and their associated wiring connections.

Figure 1. Fryer Model CF14 Wiring Diagram

CODE REQUIREMENTSCODE REQUIREMENTS

CODE REQUIREMENTS

CODE REQUIREMENTSCODE REQUIREMENTS

IMPORTANT: Read the Code Requir ements

and ALL installation instructions carefully ,

before starting the installation. Contact the

factory if any problems or questions arise.

The fryer installation must conform with local

codes, or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1 (latest

edition); the Natural Gas Installation Code, CAN/

CGA-B149.1 (latest edition); or the Propane Gas

Installation Code, CAN/CGA-B149.2 (latest

edition), as applicable, including:

a. Disconnect the fryer and its individual shutoff

valve from the gas supply piping system during

any pressure testing of the gas supply system at

test pressures in excess of ½ psig (3.45 kPa).

b. Isolate the fryer from the gas supply piping

system during any pressure testing of the gas

supply system at test pressures equal to or

less than ½ psig (3.45 kPa).

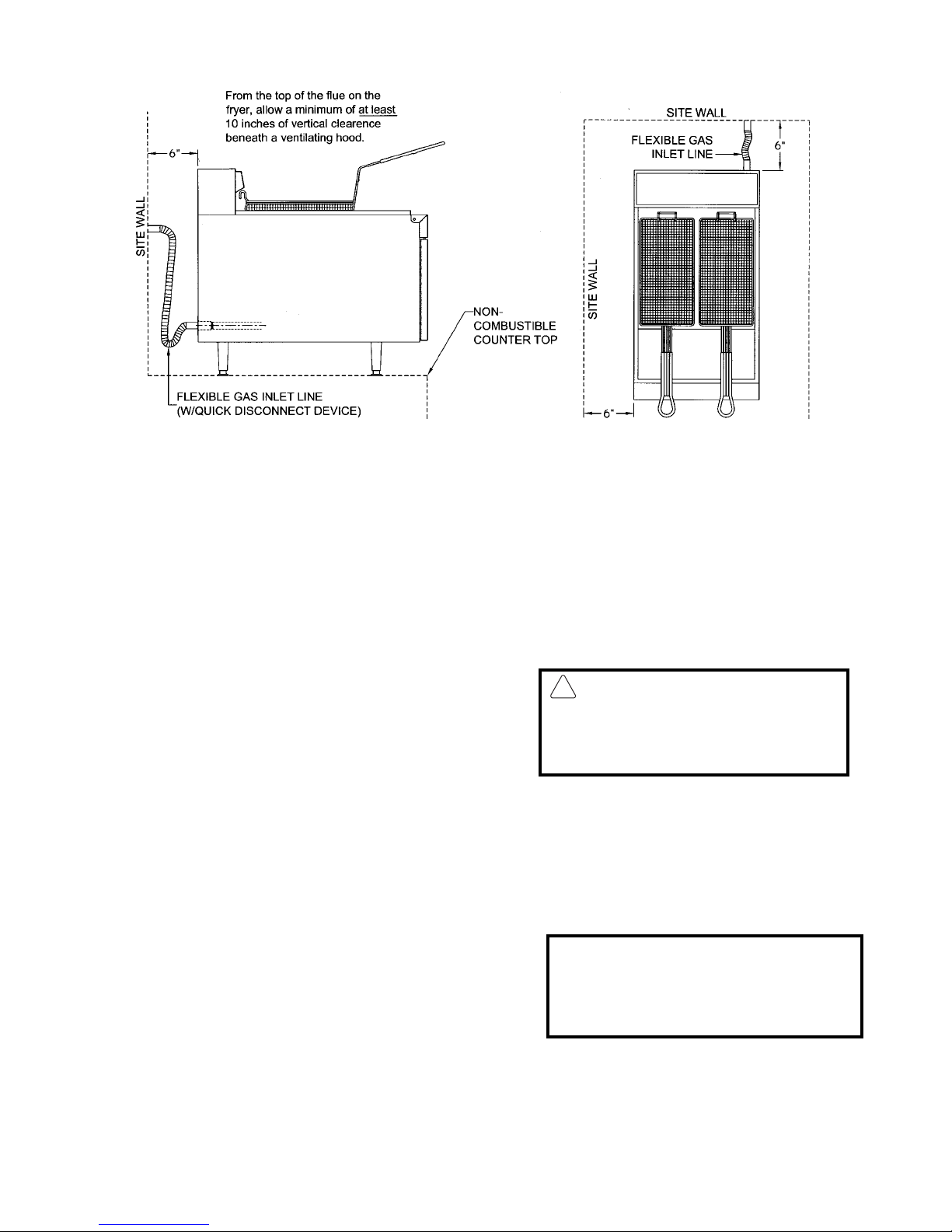

c. Install this fryer on a non-combustible surface

with its back and sides at least 6” away from

any combustible wall, as shown in Figure 2.

d. Install this fryer in a location where adequate

combustion and ventilation air is available.

Keep the area directly in front of the fryer

open for adequate air flow to the burners. DO

NOT obstruct the flow of combustion and

ventilation air.

h. Keep the fryer area free and clear from

combustibles and debris.

!

Install this fryer under a ventilation

hood that conducts combustion pro-

ducts outside the building. Venting

must comply with ANSI/NFPA 96

WARNING

(latest edition).

4

Page 5

Figure 2. Fryer Site Installation Requirements

INSTINST

INST

INSTINST

Install the fryer in accordance with the preceding

Code Requirements, as well as the following

Installation Requirements.

1. DO NOT install this fryer in a mobile home,

trailer, or recreational vehicle.

2. Install this fryer in a location that allows it to be

moved away from other adjacent appliances

for cleaning and maintenance.

NOTE: If the fryer is installed among

a row of appliances where

its only convenient movement is forward, sufficient room must be available in front to permit its separation

from adjacent appliances for cleaning

and maintenance.

ALLAALLA

ALLA

ALLAALLA

TION REQTION REQ

TION REQ

TION REQTION REQ

UIREMENTSUIREMENTS

UIREMENTS

UIREMENTSUIREMENTS

3. Confirm that the air from the ventilation hood

flowing near the fryer after installation is NOT

blowing on the rear of the fryer, to prevent

affecting the burner flames and possibly causing

control damage.

CACA

UTION:UTION:

CA

UTION: Hood make-up air

CACA

!

UTION:UTION:

MUST NOT flow in a manner that

restricts or impedes the natural flow

of combustion or ventilation air.

LEG LEVELING INSTRUCTIONS

1. Move the fryer to its desired location.

WARNING

The fryer MUST NOT tip, rock or wobble, to avoid splashing or spilling its HOT

frying fat contents during operation.

2. Turn the screw-type leg adjustment ends as

necessary to level the fryer, until no tipping,

rocking, or wobbling is evident.

5

Page 6

GAS CONNECTION INSTRUCTIONSGAS CONNECTION INSTRUCTIONS

!

GAS CONNECTION INSTRUCTIONS

GAS CONNECTION INSTRUCTIONSGAS CONNECTION INSTRUCTIONS

Installing your ANETS Fryer requires the following procedure, after it is in its desired location.

1. Ensure that the gas control valve knob

in the fryer has its OFF position next to the

valve mark.

2. Ensure that the gas supply inlet line valve is

closed (cross-wise to the pipe line direction).

3. Ensure that all fryer controls are set to OFF .

4. Connect the1/2” gas supply line to the gas line

FRFR

YER OPERAYER OPERA

FR

YER OPERA

FRFR

YER OPERAYER OPERA

!

CAUTION

DO NOT attempt to operate this fryer

during a interruption of gas service. Turn

all fryer controls to OFF , including the gas

control valve knob, then close the gas

supply line valve. When notified that the

gas interruption has ended, perform the

Lighting Procedure (later in this manual).

TING INSTRTING INSTR

TING INSTR

TING INSTRTING INSTR

adapter on the lower rear of the fryer.

5. Turn the gas supply line valve ON; then, confirm that all gas supply line joints and couplings

are free of leaks, using soap suds or a leakcheck solution, after the fryer is in its desired

location.

WARNINGWARNING

WARNING

WARNINGWARNING

DO NOT use a flame to check for leaks.

6. Refer to Fryer Operating Instructions to

begin using your ANETS Fryer.

UCTIONSUCTIONS

UCTIONS

UCTIONSUCTIONS

!

CAUTION: DO NOT melt solid

shortening in this fryer because

the melting can damage the kettle,

which will void the fryer warranty.

A. This ANETS CF14 Fryer is designed for

operation with a kettle filled with

approximately 30 pounds of liquid shortening.

Solid shortening must be melted into the liquid state

before it can be used in an ANETS Fryer .

!

DANGER

A void moving the fryer while it contains

HOT shortening. Drain the shortening

from the fryer before moving it for service, clean- ing or maintenance to avoid

spilling or splashing. Burns from hot

shortening can cause serious injury or

!

DANGER

NEVER operate this fryer when its

flue is blocked or when the ventilation hood is not on because the combustion products can cause injury to

personnel.

6

B. Schedule regular cleaning of the fryer to

ensure long-term satisfactory operation.

Refer to the Daily Cleaning Procedure,

later in this manual.

C. Before servicing and maintenance, allow

the fryer to cool. AL W AYS shut off the

gas to the fryer while working on it, to

prevent burns.

D. Contact the factory (800-837-2638) for

warranty service authorization. [Always

notify the factory the next business day

about ‘after-hours’ warranty service.]

Contact your Anets Authorized Service

Agency for other service, repairs, or maintenance activities, as necessary .

Page 7

FRFR

YER OPERAYER OPERA

FR

YER OPERA

FRFR

YER OPERAYER OPERA

TING INSTRTING INSTR

TING INSTR

TING INSTRTING INSTR

UCTIONS UCTIONS

UCTIONS

UCTIONS UCTIONS

(Continued)

FRYER PREPARATION FOR USE

“BOIL OUT” INSTRUCTIONS

ANETS Fryers are leak-tested and cleaned

New

at the factory before shipping. Before using a

newly installed fryer for food preparation, clean the

kettle again, as follows:

1. Thoroughly wipe the interior of the kettle

with clean cloths. Open the front door on

the lower portion of the fryer to access the

drain ball valve. Open the drain ball valve

(by aligning the valve handle with the drain

ball valve) and wipe the entire drain line clean.

2. Close the drain ball valve (turn the valve handle cross-wise to the drain ball valve). Fill

the kettle with water to about 3“ from the

top. Add 1 to 2 cups of soap powder,

washing soda (trisodium phosphate), or

deep fat fryer kettle cleaner.

3. Perform the Lighting Procedure for the

fryer. (Refer to the Lighting Procedure

later in this manual.)

FRYER PREPARATION FOR USE

(Continued)

7. Open the front door and mount the drain

extension to the drain ball valve. Position a

container (bucket) capable of holding VERY

HOT cleaning solution beneath the end of the

drain extension to hold the cleaning solution

being drained, as shown in Figure 5.

4. Set the thermostat to 190°F. Heat, but

NOT boil the water. Stir the water to dissolve the cleaning material.

WARNING

!

Hot cleaning solution can cause severe

burns. T ake care when handling hot cleaning solution to avoid spilling or splashing the

solution.

5. Clean the fryer kettle for at least 20 minutes.

Use a small hand mop (an optional brush can

be ordered for this purpose) to clean the

upper portion of the kettle (above the 3“

waterline) and the top rim of the kettle.

6. Shut down the fryer using the Shutdown

Procedure for the fryer. (Refer to the Shut-

down Procedure later in this manual.) Allow

the water to cool slightly.

DO

Figure 5. Draining The Kettle

8. Open the drain ball valve SLOWLY, to

avoid splashes while draining the cleaning

solution from the kettle.

9. Close the drain ball valve (valve handle

crosswise) and remove the drain extension.

Close the front door.

10. Safely dispose of the cleaning solution.

1 1 . Fill the kettle with water to about 3“ from

the top. Add 2 cups of vinegar to neutralize

the cleaning solution.

12. Repeat steps 3 through 10 of this procedure.

13. Thoroughly wipe the interior of the kettle

and the drain ball valve with clean, dry ,

wiping cloths to remove ALL water.

14. Dry the kettle

maining water can cause sputtering of hot

shortening when the kettle is later filled and

heated.

thoroughly because any re-

7

Page 8

FRFR

YER OPERAYER OPERA

FR

YER OPERA

FRFR

YER OPERAYER OPERA

TING INSTRTING INSTR

TING INSTR

TING INSTRTING INSTR

UCTIONS UCTIONS

UCTIONS

UCTIONS UCTIONS

(Continued)

Normal operation of an

ANETSANETS

ANETS Fryer requires that the kettle is filled with liquid shortening above the

ANETSANETS

lower indent level, marked on the rear of the kettle, before lighting the fryer’s pilot and turning on the main

burner.

CAUTION: Shortening MUST be in liquid form to avoid scorching or discoloration and possible

!

damage to the kettle. Damage caused by melting solid shortening will NOT be covered by the warranty .

LIGHTING PROCEDURE

NOTE: The gas line of a new fryer installation

may contain a considerable amount of air that will

hinder immediate lighting. Y ou may have to press

in the gas safety valve control knob as long as

several minutes before the pilot flame burns

steadily .

1. Ensure that the fryer’s thermostat knob is set

to OFF.

2. Open the gas supply line inlet valve to the

fryer by aligning the gas valve handle with the

gas line piping.

3. Open the front door and move the right pilot

viewing/lighting port cover aside.

4. Turn the gas control valve knob to align the

PILOT setting with the valve mark. Figure 6

shows the possible gas control valve knob

positions.

Load the fryer basket with the food product while

the basket is not in the hot liquid shortening. DO

NOT overload the fryer basket. Load only a

premeasured quantity of food product (1lb,

typically; less, if smaller portions are desired).

Place the loaded fryer basket into the hot liquid

shortening carefully to avoid splashing.

When the basket of food product has reached the

desired point of “doneness”, lift the basket from

the hot shortening and hang the basket on the

basket hanger to let it drain for approximately 15

- 30 seconds before serving.

NEVER increase the thermostat setting above the

recommended setting to reduce the cooking time;

this will produce a lower quality product and will

cause more rapid shortening breakdown.

5. Press, and hold down, the valve control

knob to allow pilot gas to flow . Manually light

pilot. Continue holding down the control

knob for at least 30 seconds until the pilot

flame burns steadily without going out.

6. Release the control valve knob and observe

that the pilot flame remains lighted. Close the

right pilot viewing/lighting port.

7. Turn the gas control valve knob to align the

ON setting with the valve mark.

8. Turn the thermostat knob to the desired

temperature. Observe that the fryer’s main

burners light to heat the kettle.

8

Valve Mark

Pilot Valve Adjustment Cover

Main Burner Regulator Adjustment Cover

Valve Mark

T

O

L

I

P

OFF

ON

OFF PILOT ON

Figure 6. Gas Control Valve & Knob P ositions

T

ON

O

L

OFF

I

P

Valve Control Knob

ON

OFF

P

I

L

O

T

European Valv e

Markings

OFF

PILOT

ON

Page 9

FRFR

YER OPERAYER OPERA

FR

YER OPERA

FRFR

YER OPERAYER OPERA

SHUTDOWN PROCEDURE

TING INSTRTING INSTR

TING INSTR

TING INSTRTING INSTR

UCTIONS UCTIONS

UCTIONS

UCTIONS UCTIONS

(Continued)

NOTE: Shutdown is recommended at the end of

a workday or whenever no frying is required for a

period of several hours. The fryer should be

shutdown during any power outage or interruption

of gas service. The fryer MUST also be shutdown

before draining the kettle, or whenever there is no

shortening in the kettle to prevent damage.

1. T urn the thermostat knob to OFF .

2. Turn the gas control valve knob to align the

PILOT setting with the valve mark.

3. Press down and turn the gas control valve

knob to align the OFF setting with the valve

mark. Observe that the pilot flame goes out.

NOTE: For extended periods of non-use

or when servicing the fryer, close the gas

supply line inlet valve to the fryer by turning

the gas valve handle cross-wise with the gas

line piping.

9

Page 10

FRFR

!

YER OPERAYER OPERA

FR

YER OPERA

FRFR

YER OPERAYER OPERA

TING INSTRTING INSTR

TING INSTR

TING INSTRTING INSTR

UCTIONS UCTIONS

UCTIONS

UCTIONS UCTIONS

(Continued)

DAILY CLEANING PROCEDURE

NOTE: Cleaning is recommended at the end of a

workday , to prepare the fryer for proper operation

the next time it is to be used.

DANGER

!

DO NOT move the fryer while it contains

HOT shortening. Allow it to cool and

drain the shortening from the fryer before moving it for service, cleaning, or

maintenance to avoid spilling or splashing. [Refer to steps 1 through 7.] Burns

from HOT shortening can cause serious injury or death.

When cleaning, if relocation of your fryer is

necessary , disconnect the gas supply line to the

fryer. Move the fryer as necessary to allow the

following cleaning procedure to occur:

1. Open the front door of the fryer. Attach the

drain extension to the drain ball valve.

2. Perform the Shutdown Procedure. Ensure

that the gas supply line inlet valve is closed

(handle cross-wise to pipe line) and the pilot

flame is extinguished.

3. Position a steel drum [NEVER use plastic!]

with a filter cone, directly beneath the drain

extension end.

4. Remove the fryer baskets from the kettle.

Thoroughly clean, and rinse, these items in

the sink. MAKE SURE that these items are

completely dry before their next use.

5. Allow the shortening to cool before draining.

Slowly open the drain ball valve to drain the

shortening. T ake care to avoid spilling or

splashing the shortening.

™

DAILY CLEANING PROCEDURE

(Continued)

7. Close the drain ball valve, after the kettle is

completely empty of shortening and sediment. Detach the drain extension. Clean,

rinse, and dry it before storing.

WARNING

Wait until the kettle has cooled

before performing step 8, to avoid

injury from burns.

8. Thoroughly wipe the kettle interior using

clean cloths.

9. Periodically perform the “BOIL OUT”

Instructions to ensure thorough cleaning of

the kettle. ( Refer to the earlier FRYER

PREP ARA TION FOR USE section.)

10. Return the fryer to its normal operating location and reconnect both the gas supply line

and the movement-limiting cable. (For

caster-equipped fryers, lock the locking casters to prevent movement.)

11. Refill the kettle with filtered (or fresh) liquid

shortening to the desired indent mark on the

rear wall of the kettle, only if fryer operation

is to continue during a subsequent shift.

Otherwise, melt shortening into its liquid state

and refill the kettle before fryer operation is

scheduled during the next working shift.

12. Return the screen to its proper position in the

kettle. Place the fryer baskets on the basket

hanger,ready for use.

13. Perform the Lighting Procedure to return

the fryer to operation, when desired.

6. Flush out all sediment in the bottom of the

kettle by pouring filtered, liquid shortening

into the kettle until the shortening being

drained runs clear.

10

Page 11

FRFR

YER OPERAYER OPERA

FR

YER OPERA

FRFR

YER OPERAYER OPERA

MONTHLY MAINTENANCE INSTRUCTIONS

TING INSTRTING INSTR

TING INSTR

TING INSTRTING INSTR

UCTIONS UCTIONS

UCTIONS

UCTIONS UCTIONS

(Continued)

NOTE: Regular maintenance is recommended to

keep the fryer operating properly .

Once each month, before beginning fryer operation, check the flue (behind the backsplash panel)

to ensure that it is clear, enabling exhaust combustion gases to flow freely toward the ventilation

hood area. DO NOT allow the flue to become

excessively dirty . NEVER allow the flue to be

blocked.

FRFR

YER YER

FR

YER

FRFR

YER YER

All service (repairs or part replacement) must be performed by a qualified Service Agency.

PROBLEM CAUSE REMEDY

TRTR

OUBLESHOOOUBLESHOO

TR

OUBLESHOO

TRTR

OUBLESHOOOUBLESHOO

Monthly , observe the condition of the ventilation

hood. If it shows evidence of a great deal of

greasy residue, remove (clean) the residue to allow

free flow of ventilation air.

TING GUIDETING GUIDE

TING GUIDE

TING GUIDETING GUIDE

Pilot flame does not

stay lighted.

1. Dirty/sooty pilot burner .

2. Low gas supply pressure [less than 6”

W.C. for natural gas; (11” W.C. for propane) when

ment is operating].

3. Pilot flame too small to heat the thermopile.

4. Pilot flame ‘wavering’ (being blown about

by a draft).

5. Improper thermopile output voltage

(must be at least 150 millivolts, measured

at the thermopile junction block).

all other gas-powered equip-

1. Clean the pilot burner. Perform

the Lighting Procedure.

2. Measure the gas supply pressure.

Contact your local gas supplier

to obtain adequate gas supply

pressure.

3. Adjust the pilot valve (part of

the gas control valve) to increase the flame size: Unscrew and retain the slotted

threaded cover; turn the pilot

valve adjustment screw two

turns counterclockwise;

reinstall the threaded cover.

4. Block or redirect the draft, to

keep the flame burning steadily .

5. Replace the thermopile

.

11

Page 12

FRFR

YER YER

FR

YER

FRFR

YER YER

PROBLEM CAUSE REMEDY

TRTR

OUBLESHOOOUBLESHOO

TR

OUBLESHOO

TRTR

OUBLESHOOOUBLESHOO

TING GUIDE TING GUIDE

TING GUIDE

TING GUIDE TING GUIDE

(Continued)

Pilot flame does not

stay lighted. (Continued)

Pilot flame goes out

repeatedly.

6. High-limit thermostat problem has shut off

the gas. (Continued)

CAUTION: DO NOT return

!

the fryer to normal operation

with its high-limit thermostat

bypassed/disconnected.

7. Gas control valve has failed.

1. Low gas supply pressure [less than 6”

W.C. for natural gas; (11” W.C. for propane) when

equipment is operating].

all other gas-powered kitchen

6. Check for, and repair, any damaged high-limit thermostat wiring. T est the high-limit thermo

stat by disconnecting the

thermopile at the gas control

valve. Then, disconnect the red

wires to the high-limit thermo

stat from the gas control valve.

Reconnect the thermopile;

next, perform the Lighting Procedure, to check whether the

pilot flame lights. If the pilot

flame stays lit, the high-limit

thermostat has failed and must

be replaced.

7. Replace the gas control valve.

1. Measure the gas supply pressure.

Contact your local gas supplier

to obtain adequate gas supply

pressure.

2. Loosen thermopile or high-limit thermostat connection(s) on gas control valve.

3. Pilot flame does not continuously touch

the thermocouple because of excessive

air flow around the pilot burner assembly .

4. High-limit thermostat problem has shut off

the gas.

!

CAUTION: DO NOT return

the fryer to normal operation

with its high-limit thermostat

bypassed/disconnected.

2. Check and tighten the connections.

3. Block the excessive air flow to

make the pilot flame contact

the thermocouple.

4. Check for, and repair, any damaged high-limit thermostat wiring.

T est the high-limit thermo-

stat by disconnecting the thermocouple at the gas control

valve. Then, disconnect the red

wires to the high-limit thermostat from the gas control valve.

Reconnect the thermopile;

next, perform the Lighting Procedure, to check whether the

pilot flame lights. If the pilot

flame stays lit, the high-limit

thermostat has failed and must

be replaced.

12

Page 13

FRFR

YER YER

FR

YER

FRFR

YER YER

PROBLEM CAUSE REMEDY

TRTR

OUBLESHOOOUBLESHOO

TR

OUBLESHOO

TRTR

OUBLESHOOOUBLESHOO

TING GUIDE TING GUIDE

TING GUIDE

TING GUIDE TING GUIDE

(Continued)

Main burners do not

ignite.

1. Gas control valve knob set to OFF or

PILOT.

2. Low gas supply pressure [less than 6”

W.C. for natural gas; (11” W.C. for propane) when

equipment is operating].

3. Pilot burner problem.

4. Thermostat control set below the temperature of the liquid shortening in the

kettle.

all other gas-powered kitchen

1. Perform the normal Lighting

Procedure. Turn the gas

control valveknob to ON to

light the main burners.

If the burners do not light, the

gas control valve has failed and

must be replaced.

2. Measure the gas supply pressure.

Contact your local gas supplier

to obtain adequate gas supply

pressure.

3. Refer to the preceding Pilot

Burner problems and use the

correct remedy.

4. Increase the thermostat setting

until the burners light. If this

setting is greater than the desired temperature, reset the

thermostat to the desired setting and allow the shortening to

cool to the desired temperature.

Main burners do not

stop burning.

5. Gas control valve has failed.

1. Thermostat has failed.

2. Gas control valve has failed.

5. Replace the gas control valve.

1. Turn the thermostat control

knob to OFF. If the burners

do not quit burning, the thermostat has failed and must

be replaced.

2. Turn the gas control valve knob

to OFF. If the burners do not

quit burning, the gas control

valve has failed and must be

replaced.

13

Page 14

FRFR

YER YER

FR

YER

FRFR

YER YER

PROBLEM CAUSE REMEDY

TRTR

OUBLESHOOOUBLESHOO

TR

OUBLESHOO

TRTR

OUBLESHOOOUBLESHOO

TING GUIDE TING GUIDE

TING GUIDE

TING GUIDE TING GUIDE

(Continued)

Liquid shortening does

not reach the desired

temperature for frying.

1. Low gas supply pressure [less than 6”

W.C. for natural gas; (11” W.C. for propane) when

ment is operating], causing reduced heat

from main burners.

2. Low gas manifold pressure [less than 3½”

W.C. for natural gas; (10” W.C. for propane).

3. Loosen knob on thermostat;

requires calibration (temperature setting

differs by about 10°F from measured

shortening temperature).

all other gas-powered equip-

or thermostat

1. Measure the gas supply pressure.

Contact your local gas supplier

to obtain adequate gas supply

pressure.

2. Measure the gas pressure at

the fryer’s manifold pressure

tap. Adjust the manifold pressure (see Figure 6), as necessary: [a] Unscrew (and retain) the threaded Main Burner

Regulator Adjustment Cover. [b]

Use a flat-blade screwdriver to

turn the regulator adjustment

screw (clockwise to increase;

counterclockwise to decrease)

to reset the pressure adjustment. [c] Reinstall, and tighten,

the Regulator Adjustment

Cover, when finished.

3. Stir the shortening to mix the

hot shortening with some from

the lower ‘cool zone’ and allow

it to sit for 5 minutes. Turn the

thermostat knob until it ‘clicks’

on (causing the main burners to

flame); note the setting where

this occurs. Turn the thermostat knob until it ‘clicks’ off

(causing the main burners to go

out); note the setting where this

occurs. Repeat this temperature ‘click points’ step at least

three times to ensure that

the shortening temperature has

stabilized.

Measure the temperature of

the shortening by inserting an

accurate thermometer about

4 inches into the shortening to

measure its temperature. If the

temperature difference between

the measured temperature and

the thermostat setting is 10°F

or less, the thermostat can be

recalibrated.

14

Page 15

FRFR

YER YER

FR

YER

FRFR

YER YER

PROBLEM CAUSE REMEDY

TRTR

OUBLESHOOOUBLESHOO

TR

OUBLESHOO

TRTR

OUBLESHOOOUBLESHOO

TING GUIDE TING GUIDE

TING GUIDE

TING GUIDE TING GUIDE

(Continued)

Liquid shortening does

not reach the desired

temperature for frying.

(Continued)

4. Thermostat setting is more than 20°F different than measured shortening temperature.

Recalibrate the thermostat by:

(a) removing the cap on the

thermostat control knob; (b)

loosening the center brass hex

nut portion of the knob; (c) turn

the pointer portion of the knob to

the measured temperature value

of the thermostat setting.

Tighten the brass hex nut to lock

the adjustment. Replace the

cap on the knob.

4. Check the thermostat setting

against an accurate measure of

the shortening temperature. If

the temperature difference is

greater than 20°F, the thermostat can

brated.

Recalibrate the thermostat by:

(a) removing the cap on the

thermostat control knob; (b)

loosening the center brass hex

nut portion of the knob; (c) turn

the pointer portion of the knob

to the measured temperature.

Tighten the brass hex nut to lock

the adjustment. Replace the

cap on the knob.

If this calibration is unsuccessful, the thermostat has failed and

must be replaced.

possibly be recali-

15

Page 16

LIMITED WARRANTY

ANETSBERGER BROTHERS, INC., Northbrook, Illinois, USA, certifies

that all equipment of its manufacture is, to the best of its knowledge, free

from defective material and workmanship.

ANETSBERGER BROTHERS, INC., agrees to replace any integral part

of its equipment that proves defective within 15 months of date of original

shipment from the factory , or 12 months from the date of installation, whichever is sooner . Buyer must return the defective part to the factory , freight

prepaid, for inspection. Anetsberger Brothers, Inc., further agrees to assume the cost of installing said replacement part within the same period.

All frypots are covered by the warranty above for the first year of operation.

V arious models have an extended warranty that covers the replacement of

the frypot only . See the indivdual specification sheets for details.

Overtime charges, calibration, adjustments and abnormal installation charges

shall not be at the expense of Anetsberger Brothers, Inc.

The conditions and warranty expressed above are valid only if equipment

has been properly installed and operated. No other warranty , expressed or

implied, shall govern equipment manufactured by Anetsberger Brothers, Inc.

Under no circumstances shall Anetsberger Brothers, Inc., be liable for loss

of profits or any direct or indirect cost, expenses, loss or damages arising out

of defects in or failure of the equipment or any part thereof.

180 North Anets Drive • Northbrook, Illinois 60062 • 847-272-0770 • Fax 847-272-1943

T oll-free Customer & W arranty Service: 800/ 837-2638

Keep this Manual in a Convenient Location for Reference

16

Anetsberger Br others, Inc.

www .anetsber ger.com

Form I-152; Rev. 12/03 Price $20.00 US

Loading...

Loading...