Page 1

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual

for the life of the equipment:

Model #: __________________________

Serial #: __________________________

Date Purchased: ___________________

Service & Parts Manual

Covering

SLG Series

AUSTRALIA

UK, MT

L22-348 Rev 1, 5/13

Page 2

FOR YOUR SAFETY

DO NOT store or use gasoline or other flammable vapors or liquids in the

vicinity of this or any other appliance. Do not spray aerosols in the vicinity of

this appliance while it is in operation.

WARNING

Improper installation, alteration, service or maintenance can cause property

damage, injury or death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

TO THE PURCHASER

Post, in a prominent location, the

instructions to be followed in the event that

an operator smells gas. Obtain this

information from your local gas supplier.

WARNING

There is an open flame inside this appliance.

The unit may get hot enough to set nearby

materials on fire. Keep the area around the

appliance free from combustibles.

WARNING

DO NOT supply the appliance with a gas

that is not indicated on the data plate. If you

need to convert the appliance to another

type of fuel, contact your dealer.

WARNING

DO NOT use an open flame to check for

gas leaks!

WARNING

If gas flow to appliance is interrupted, or pilots

extinguish, wait 5 minutes before attempting to

relight the pilot to allow any residual gas in

appliance to dissipate.

WARNING

Ensure that the appliance can get enough air to

keep the flame burning correctly. If the flame is

starved for air, it can give off a dangerous carbon

monoxide gas. Carbon monoxide is a clear

odorless gas that can cause suffocation.

WARNING

Adequate means must be provided to limit the

movement of this appliance without depending on

the gas line connection. Single appliances

equipped with legs must be stabilized by installing

anchor straps. All appliances equipped with

casters must be stabilized by installing restraining

chains. If a flexible gas line is used, an additional

restraining cable must be connected at all times

when the appliance is in use.

An appliance equipped with casters and a flexible

gas line must be connected to the gas supply with

a quick disconnect device. This quick disconnect

must comply with AS4631 (Australia only). To limit

the movement of the appliance without depending

on the connector or quick disconnect, a

restraining cable must also be installed.

Installation of this appliance must be done by a

qualified professional. This appliance should be

inspected by a qualified professional on an annual

basis to insure safe and proper operation.

In Australia, this appliance must be installed in

accordance with AS 5601 (current revision) or local

codes, or National Codes as applicable.

This appliance must be installed by a competent

installer. Install only in a well-ventilated area.

Read the instructions before operating this

appliance.

If the appliance has a power supply, it must be

disconnected before servicing or cleaning this

appliance.

Do not attempt to move this appliance when the

unit is at operating temperature. Serious personal

injury could result if skin comes in contact with the

hot surfaces.

DO NOT sit or stand on this appliance. Serious

injury could result from falling or contact with hot

shortening/oil.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

L22-348 Rev 1, 5/13

Page 3

TABLE OF CONTENTS

1 Leg Installation and Leveling ........................................................................................................................... 2

1.1 Installation Clearances ............................................................................................................................ 2

1.2 Gas Connection ....................................................................................................................................... 2

1.3 Gas Connection and Sealing Compound ................................................................................................ 3

1.4 Fuel Supply Line Leak and Pressure Testing ......................................................................................... 3

2 INITIAL ADJUSTMENTS ................................................................................................................................. 3

2.1 Pilot Flame Adjustment after gas valve replacement .............................................................................. 3

2.2 Main Burner System Adjustment ............................................................................................................. 4

3 Thermostat Calibration ..................................................................................................................................... 4

3.1 Thermostat Calibration Check (Standard) ............................................................................................... 4

3.2 For Gas Operated and Electric Thermostats refer to the following procedure. ...................................... 5

4 Trouble Shooting .............................................................................................................................................. 6

4.1 Testing the Thermocouple: ...................................................................................................................... 7

4.2 Testing the Radix wire: ............................................................................................................................ 7

4.3 Testing the Hi Limit: ................................................................................................................................. 7

4.4 Testing the Gas Valve: ............................................................................................................................ 7

5 SLG40 Exploded Parts Diagram ...................................................................................................................... 8

5.1 SLG40 Exploded Parts List ..................................................................................................................... 9

6 SLG100 Exploded Parts Diagram .................................................................................................................. 10

6.1 SLG100 Exploded Parts List ................................................................................................................. 11

7 SLG40 Gas Assembly Exploded AU & CE Diagram .................................................................................... 12

7.1 SLG40 Gas Assembly Exploded AU & CE Parts .................................................................................. 13

8 SLG100 Gas Supply Exploded AU & CE Diagram ........................................................................................ 14

8.1 SLG100 Gas Supply Exploded AU & CE Parts ..................................................................................... 15

9 TSTAT Assembly Exploded AU Diagram ...................................................................................................... 16

9.1 TSTAT Assembly Exploded AU Parts ................................................................................................... 17

1

L22-348 R1 5/13

Page 4

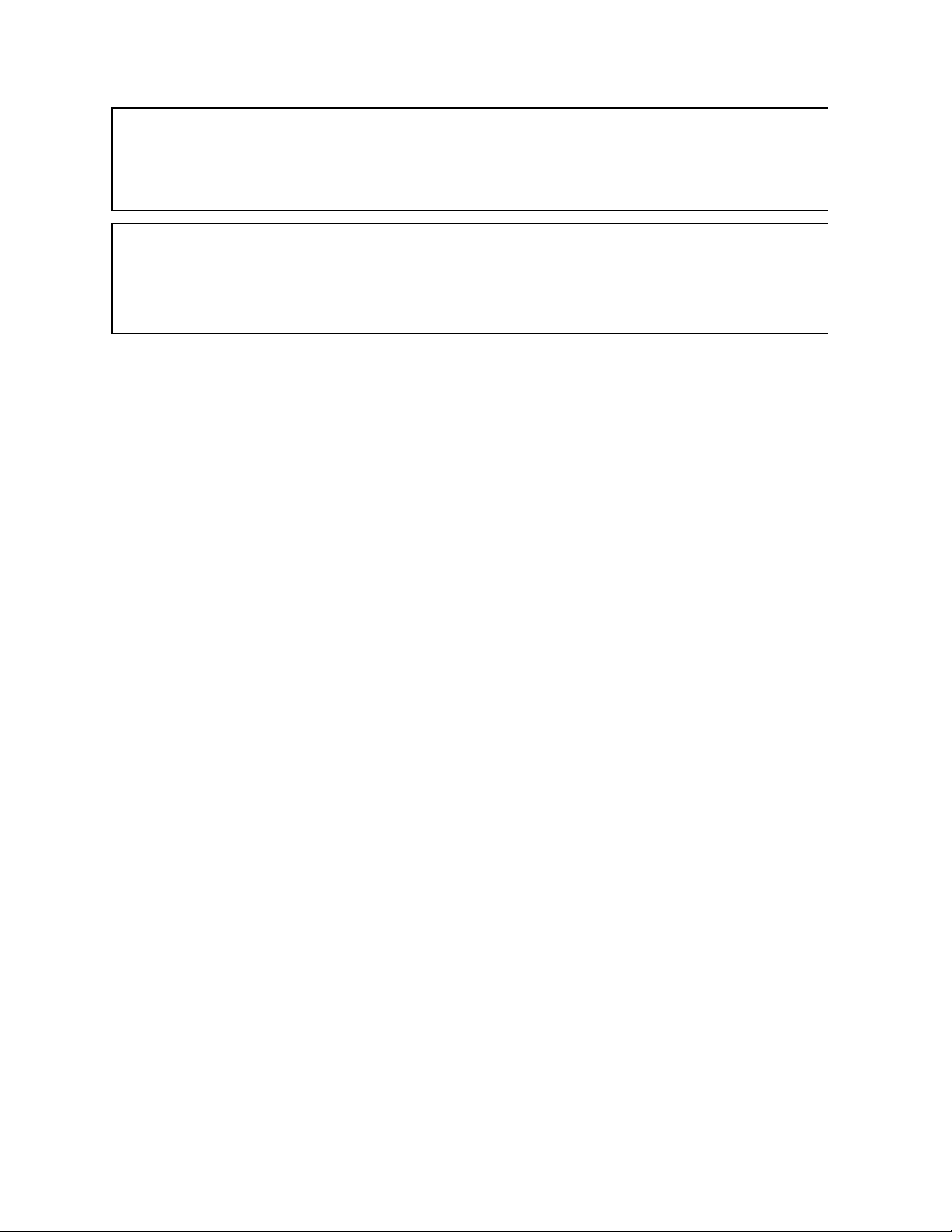

Combustible

Construction

Non-

Combustible

Construction

Back

6 in. (15 cm)

6 in. (15 cm)

Sides

6 in. (15 cm)

6 in. (15 cm)

Floor

N/A*

4 ¾ (11.5 cm)

1 Leg Installation and Leveling

This appliance must be installed with legs; it cannot be curb mounted. Curb

mounting will seriously inhibit this appliances ability to effect proper

combustion.

WARNING

This appliance must be installed with the legs provided by the

manufacturer.

WARNING

Do not install legs or perform leveling procedure when unit is in operation or full of cooking medium.

Serious injury could result.

Required tools: 7/16 “ wrench and socket and a large pair of water pump pliers. The legs must be installed

before connecting the appliance to the gas supply. The legs provide the necessary height to meet sanitation

requirements and assure adequate air supply to the combustion system. Use the following procedure.

a. Lay the appliance on its back, being careful not to damage the flue area by pulling on it. Protect

the outside of the appliance with cardboard or a drop cloth when laying it down.

b. Attach each leg with the hex head screws and nuts supplied. Each leg requires four ¼-20 x 5/8”

hex head screws and nuts. Insure that all screws are tight.

c. Mount the screws from the inside of the appliance with the nut on the outside (bottom) of the

appliance. The nuts have lock washers attached to them, therefore it is not necessary to use

lock washers

d. When all four legs are securely mounted, stand the unit up, being careful not to put too much

weight on any one leg. Adjust the height and level the appliance by adjusting the leveling

devices (B) with water pump pliers.

1.1 Installation Clearances

The clearances shown below are for combustible and non-combustible installations and will allow for safe and

proper operation of your appliance.

*For use only on Non Combustible Floors. This appliance must be installed on a fireproof base.

In addition to the above clearances there must also be at least 28 inches (71 cm) of aisle space in front of the

appliance.

1.2 Gas Connection

Your appliance will give you peak performance when the gas supply line is of sufficient size to provide the

correct gas flow. The gas inlet of the appliance is located in the back of the appliance on the lower right hand

side about 21 cm from the floor. The gas line must be installed in accordance with the requirements of AS 5601

or local codes, by a qualified professional. Gas line sizing requirements can be determined by a qualified

installation professional, your local gas company or by the Technical Regulator. The gas line needs to be large

enough to supply the necessary amount of fuel to all appliances without losing pressure to any appliance. A

properly sized and installed gas line will deliver a minimum supply pressure of 7.0 ± 2.0 inches w.c. (1.75 ± 0.5

kPa/17.5± 5 mbar)) for natural gas and 12.0 ± 2.0 inches (3.0 ± 0.5 kPa/30± 5 mbar) for propane to all

appliances connected to the supply line, operating simultaneously at full demand. Each appliance is equipped to

operate on one certain fuel type. The type of fuel with which the appliance is intended to operate is stamped on

the data plate, which is attached to the inside of the door.

2

L22-348 R1 5/13

Page 5

REGULATOR ADJUSTOR

(UNDER CAP SCREW)

PILOT ADJUSTOR

(UNDER CAP SCREW)

1.3 Gas Connection and Sealing Compound

As with any gas appliance, be sure to use a suitable gas joint sealant whenever gas connections are loosened

and retightened. Also remember to check for leaks before allowing the appliance to be put into service.

1.4 Fuel Supply Line Leak and Pressure Testing

The fuel supply system must be tested before the appliance is used. If the fuel line is going to be tested at a

pressure greater than ½ PISG (3.45 kPa/34.5 mbar), insure that that appliance is disconnected from the fuel

line. If the fuel line is to be tested at a pressure equal to or less than ½ PSIG (3.45 kPa/34.5 mbar), the

appliance can be connected during the test, but the unit’s gas valve must be shut. Test all gas line connections

for leaks with a solution of soap and water when pressure is applied.

2 INITIAL ADJUSTMENTS

After the appliance has been properly installed as described in the installation section of this manual, it will need

to be adjusted to ensure that it will perform as designed. These adjustments must be performed by a qualified

person. To perform these adjustments the following tools will be needed:

• Manometer • Digital Thermometer (Temperature Probe)

• DC Millivolt Meter • DC Milliameter

Before you begin filling and adjusting the appliance, perform the following visual checks:

a. After the appliance is in its permanent location, check the levelness. Any additional leveling that

is necessary can be performed as previously described.

b. Check the temperature probe and high limit bulb (in the tank) to ensure that the mounting

screws are tight.

c. Review the installation portion of this manual and ensure

that all steps have been followed and executed properly.

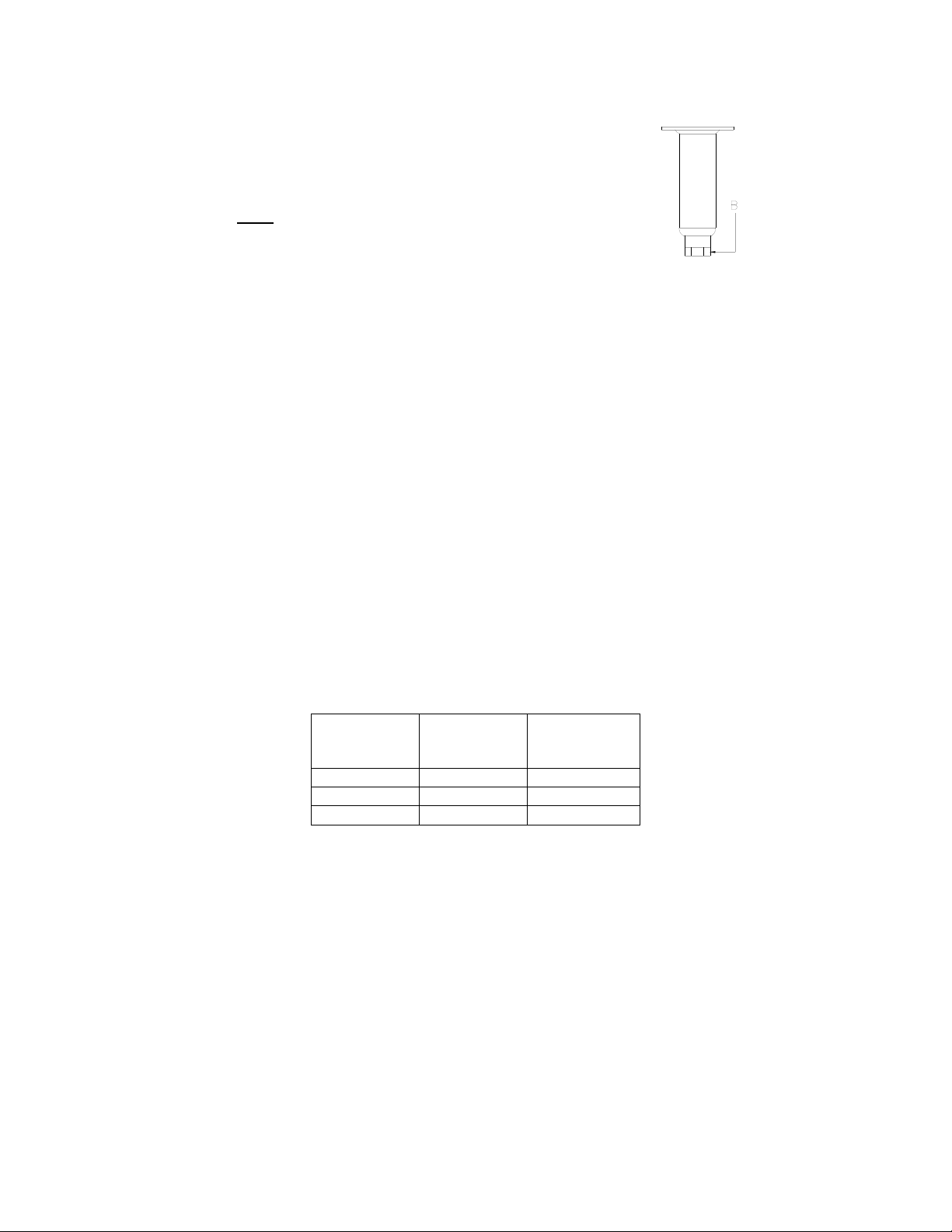

2.1 Pilot Flame Adjustment after gas valve replacement

For manual pilots, refer to the following instructions. Perform this procedure once the pilot is lit.

NOTE: This procedure requires a DC millivolt meter set to a scale of 0-1000 mV.

Using test leads with sharp probes will help in taking the required readings.

a. Locate the thermocouple wires coming from the thermostat/limit box going to the gas

valve. The wire size decreases near the gas valve connections.

b. Using the positive (+) test probe, connect the probe to the high limit wire terminal. On

UFM systems, pierce the high limit wire insulation, with the tip of the test lead probe, at

the gas valve safety magnet connection.

c. Connect the negative (-) test probe to the pilot tubing.

d. Remove the cap screw located below the pilot tubing on the gas

valve. The pilot flame adjustment screw is recessed behind this.

Turning the pilot flame adjustment screw clockwise

lowers the pilot flame and millivolt output. Turning the pilot flame

adjustment screw counter- clockwise increases the pilot flame size

and millivolt output.

e. While monitoring the DC millivolt meter, rotate the pilot flame

adjustment screw in the direction necessary to achieve a reading of

400 ± 50mV.

f. Replace the cap screw.

Note: Allow 3 to 5 minutes between flame adjustments to allow

the reading to stabilize.

3

L22-348 R1 5/13

Page 6

MAIN BURNER

MAIN BURNER ORIFICE

2.2 Main Burner System Adjustment

For the main burners to operate the gas supply valve must be open and the thermostat must be turned on. For

models with electric controls, the main power switch must be on. The main burners receive gas from the main

gas supply through the thermostatically controlled valve. When the thermostat is turned up to a setting higher

than the temperature of the oil in the tank, the gas control valve opens.

The main burner pressure must be adjusted to deliver optimum flame. Refer to the following procedure to adjust

the main burners.

CAUTION

Before proceeding any further, fill the tank with WATER. Water is used for the installation

adjustments because the temperature will never exceed 212°F (100°C), thereby allowing plenty of

adjustment time. Never let the water level go below the MIN LEVEL mark stamped on the tank.

a. Ensure that the main gas valve is shut off; remove the manifold pressure tap plug and connect

an accurate pressure gauge having a range from 0 to 16 “ w.c. in 0.1” increments (0 to 4 kPa in

.025 kPa/0-40 in 0.25 mbar increments) or manometer with similar resolution.

b. Turn on this and all appliances connected to the gas supply

line and light their main burners. The pressure reading of

the installed pressure gauge should not drop from the

required installation pressure. Any loss of pressure

indicates inadequate supply line installation, which will

cause poor performance of all appliances during peak

usage.

c. The installed pressure gauge should be the same, ±0.1”

w.c. (.025 kPa/.250 mbar), as that marked on the data plate

on the inside door of the appliance. If the pressure is

correct, go to step e, if it is not, adjust the pressure as

outlined in step d.

d. To adjust the pressure, remove the regulator adjustment

screw cap on the gas valve and, with a flat head

screwdriver, adjust the regulator screw until the proper burner pressure is reached. Turning the

screw clockwise will increase the burner pressure. Turning the screw counterclockwise will

decrease the burner pressure.

e. When the pressure is correct, replace the regulator adjustment screw cover.

f. Turn off the ALL appliances, shut the main gas valve to your appliance and remove the

pressure gauge. Apply pipe joint compound to the manifold pressure tap plug and reinstall it.

3 Thermostat Calibration

NOTICE

Thermostat calibration requires that the temperature of the appliance be raised above 212°F

(100°C). If you have water in the tank you will need to drain it, dry it and fill it with shortening/oil.

Follow the filling instructions in this manual.

3.1 Thermostat Calibration Check (Standard)

To check the calibration of your appliance, refer to the following procedure.

a. Remove the tube screen from the tank.

b. Place the tip of a digital thermometer probe in the shortening/oil approximately one inch above

the temperature sensor.

c. Light the pilot as described in this manual, set the thermostat to 325°F (163 °C) and allow the

shortening/oil to come up to temperature. Watch the thermometer closely as the temperature

rises.

d. If the shortening/oil temperature reaches 350°F (177 °C) and the burners do not turn off, turn

the thermostat down. Keep lowering the thermostat setting until the burners go out.Let the

appliance cycle 4 to 6 times before checking the temperature. Compare the thermometer

temperature against the thermostat setting. If the values are more than 5°F (3 °C) apart,

calibrate the thermostat using procedure in this manual.

4

L22-348 R1 5/13

Page 7

CAUTION

If the burners do not shut off at the LOWEST thermostat setting, the thermostat may be

defective. Contact your local service company.

3.2 For Gas Operated and Electric Thermostats refer to the following procedure.

a. Remove the tube screen from the tank and place the tip of a digital thermometer in the

shortening/oil approximately one inch above the temperature sensor.

b. Light the pilot as described in this manual, set the thermostat to 325°F (163 °C) and allow the

shortening/oil to come up to temperature; let the appliance cycle 4-6 times to insure that the

shortening/oil temperature has stabilized. Compare the thermostat setting of 325°F (163 °C) to

the digital thermometer reading.

c. Remove the thermostat dial by pulling the knob straight out. DO NOT rotate the dial.

d. Holding the outside of the shaft so that it DOES NOT MOVE, scrape away the sealing

compound in the center of the shaft with a small flat blade screwdriver.

e. Turn the adjustment screw clockwise to lower the thermostat’s temperature setting or counter-

clockwise to raise it.

NOTE

One-quarter turn of the adjustment screw changes the temperature setting

approximately 24°F (13 °C).

f. Turn the adjustment screw until the burners come on at 325°F (163 °C).

g. Replace the knob and allow the appliance to cycle 4 to 6 times. Check the temperature of the

digital thermometer against the thermostat dial setting; if there is greater than a 5°F

(3 °C) difference, repeat the calibration procedure.

5

L22-348 R1 5/13

Page 8

NO

YES

YES

Appliance does not

work.

Will the

pilot

light?

NO

Is the gas

supply

valve

open?

NO

Open the gas

valve and light

pilot

Purge air from

gas line

Does pilot

stay lit after

pilot knob is

released?

YES

YES

NO

Is all the

air purged

from the

pilot gas

YES

NO

Is high

limit

switch

open?

Will high

limit switch

reset?

YES

Reset switch

and light pilot.

Contact a

qualified service

technician

NO

NO

Does pilot go

out when the

temperature

increases?

YES

Do the main

burners

light?

NO

Purge air from pilot line by

turning pilot knob to the

"PILOT" position and

holding it in for approx. 1

minute.

Is the gas

valve knob in

the "ON"

position?

Is the

thermostat

knob in the

OFF position?

NO

YES

If the main burners are

lighting, but not performing

properly refer to the

INSTALLATION section of

this manual to verify proper

installation.

Turn the gas

valve knob to

the "ON"

position.

NO

Turn the

thermostat knob

to a

temperature

4 Trouble Shooting

Refer to this section to correct common problems that may be encountered during the course of normal

operation. If applicable, a schematic is provided behind the panel containing the electrical components.

6

L22-348 R1 5/13

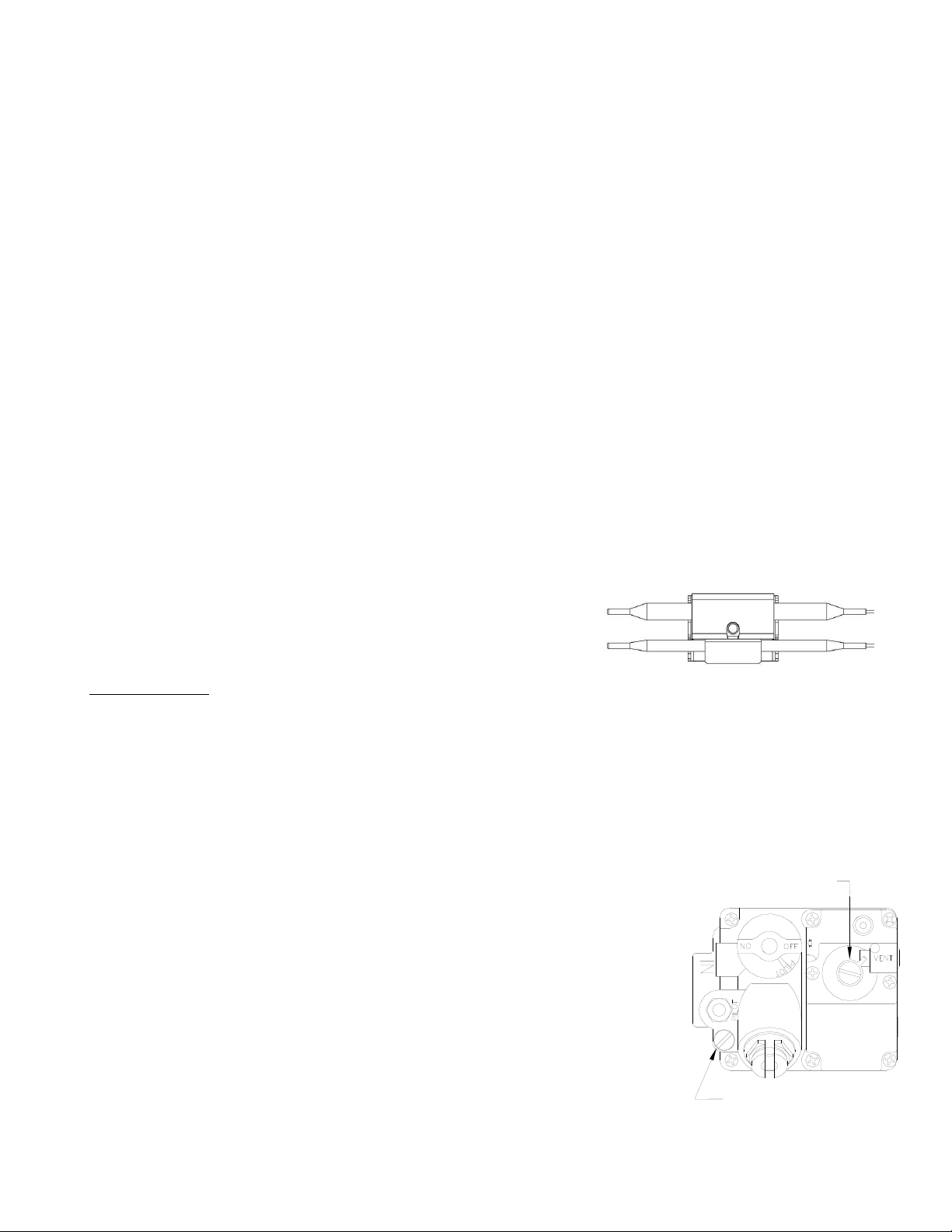

Page 9

IGNITOR

THERMOCOUPLE

& PILOT

GAS

VALVE

PILOT

W

W

IN

VENT

THERMOSTAT

IN

OUT

THERMOSTAT

PROBE

HIGH

LIMIT

IN

OUT

4.1 Testing the Thermocouple:

You will need a multimeter that can measure millivolts. Make sure that after holding a flame to the

thermocouple it produces 30 mv. You can test for this by heating the thermocouple for about a minute and then

place one lead on the copper casing of the thermocouple and the other lead on one of terminals of the hi limit

wire connection. This is the easiest way to check the thermocouple but you are also going on the faith that the

Radix wire and hi limit are good. If you do not get between 25 and 30 millivolts you need to replace this part,

part number is P5047540.

Stay away from any hard or sharp bends in the thermocouple. It tends to separate the wire inside the

copper casing. Another good tip is when screwing in the thermocouple always start by hand. You should get

several turns out of it before needing a wrench. Cross threading will damage the aluminum threads for the

magnet. After the thermocouple is finger tight give it a quarter turn with a wrench, no more. If all these parts

check out and the pilot still wont stay lit you need to recheck everything something there is missing.

4.2 Testing the Radix wire:

Make sure that your Radix (gas valve to hi limit) wire isn't damaged or broken. The easiest is to remove

the thermocouple from the valve, remove the Radix wire and inspect both sides of that butterfly connector. Make

sure the wires aren't broken and then check for continuity through it. If it is bad the part number is B6779850.

4.3 Testing the Hi Limit:

Press the red reset button and make sure it doesn't click. If it does, push it until it doesn't. This means

the unit overheated or the hi limit tripped early. To check the trip temp of the switch the fryer will need to be ran

at a set temp of 400°F (204°C). The limit should trip at 450°F (232°C) plus or minus 25°F (14°C) degrees.

Check for continuity through the posts to ensure that the switch is making contact. If it won't reset or it reads an

open signal you have a bad hi limit, the part number is PP10084.

One factor to look for that won't show up as a bad part is a crack in the black plastic casing of the hi

limit. This would cause a problem; it happens when the radix wire thermocouple is cross threaded or over

tightened.

4.4 Testing the Gas Valve:

With the thermocouple and Radix wire removed, take one lead of a multimeter and place it into the

center of the magnet of the valve. The magnet is the aluminum insert on the valve you screw the thermocouple

into. There is a concave landing in the center of the insert. It is insulated from the rest of the valve. Place the

other lead on the threaded part of the insert. Make sure the lead on the center landing doesn't tough anything

else or you will get an incorrect reading. You're checking resistance, and you're looking for 8 to 11 ohms. If it's

more or less you have a bad magnet inside the valve and the valve needs to be replaced.

7

L22-348 R1 5/13

Page 10

5 SLG40 Exploded Parts Diagram

8

L22-348 R1 5/13

Page 11

ITEM# PART# PART DESCRIPTION

1 B3332601 TANK,WELDMENT SLG40 (BAFFLES WELDED TO TANK)

2 B1004001 BAFFLE, WELDMENT SLG40 (SERVICE)

A1540001 CABINET SIDE, LEFT HAND SLG40 BEFORE JULY 2013

A1541101 CABINET SIDE, LEFT HAND SLG40 POST JULY 2013

A1540005 CABINET SIDE, LEFT HAND SLG40 BEFORE JULY 2013

A1541103 CABINET SIDE, LEFT HAND SLG40 POST JULY 2013

A1237801 CABINET, FRONT BOTTOM BRACE SLG40 BEFORE JULY 2013

A1861001 CABINET, FRONT BOTTOM BRACE SLG40 POST JULY 2013

A1640301 CABINET BACK, BOTTOM BRACE SLG40 BEFORE JULY 2013

A1641401 CABINET BACK, BOTTOM BRACE SLG40 POST JULY 2013

A1856901 CABINET, SPACER SLG40 BEFORE JULY 2013

A1861201 CABINET, SPACER SLG40 POST JULY 2013

8 A8048001 PIPING, BRACKET MANIFOLD REAR

9 B13811-00 FLUE, DEFLECTOR SLG40

B2306101 DOOR, ASSEMBLY SLG40 BEFORE JULY 2013

B2306301 DOOR, ASSEMBLY SLG40 POST JULY 2013

A2336502 DOOR, OUTER SLG40 BEFORE JULY 2013

A2337302 DOOR, OUTER SLG40 POST JULY 2013

A2336601 DOOR, INNER SLG40 BEFORE JULY 2013

A2337401 DOOR, INNER SLG40 POST JULY 2013

PP10752 SCREW, 10-31 X 1/2 PNH ZN

PP11006 HANDLE, DOOR RECESSED PLASTIC

D6176-00 FRONT PANEL, SLG40 BEFORE JULY 2013

A3684902 FRONT PANEL, SLG40 POST JULY 2013

12 P0091500 TINNERMAN C-12003-017 #6

13 D6180-00 SPLASH BACK, SLG40

C11020-00 FLUE, ASSEMBLY SLG40

B3506401 FLUE, ASSEMBLY SLG50

B13790-00 BURNER HOLD DOWN SLG40

A8048802 BURNER HOLD DOWN SLG50

16 A1847002 CLIP, BRACKET MAGNET CATCH

18 A1408002 BULB COVER STEPPED SLG

18 A3800603 DOOR HINGE PIN

19 E4556-04 BURNER

20 P6071300 DOOR MAGNET

21 P0020600 SCREW, 1/4-20 X 5/8 HEAX HEAD ZINC PLATED

22 B3900701 LEG, SET 6" WITH HARDWARE (SET OF 4)

23 P0093300 NUT, HEX (KEP) 1/4-20 ZINC PLATED

24 60084501 DRAIN VALVE, 1 1/4 NON-LOCKING

25 P9204-75 ANETS NAME PLATE BLACK/YELLOW

26 PP10668 NUT, 1/4-20 ACORN WITH CENTERLOCK STAINLESS

27 P0080650 WASHER, FLAT 1/4 ZINC

28 A2510101 TANK, NIPPLE DRAIN OUT 1 1/4 NPT

29 A4500601 WIRING RACK, TUBE 13.50 X 13.50

30 P9800-08 BASKETS, DOUBLE 2 PER SLG40

31 PP10023 SCREW, 10-24 X 3/8 SELF TAPPER

32 C9054-01 BASKET HANGER SLG40/50

7

14

151011

3

4

5

6

5.1 SLG40 Exploded Parts List

9

L22-348 R1 5/13

Page 12

6 SLG100 Exploded Parts Diagram

10

L22-348 R1 5/13

Page 13

ITEM# PART# PART DESCRIPTION

1 B3336301 TANK,WELDMENT SLG100 (BAFFLES WELDED TO TANK)

2 B1004002 BAFFLE, WELDMENT SLG100 (SERVICE)

A1540003 CABINET SIDE, RIGHT SIDE SLG100 BEFORE JULY 2013

A1541105 CABINET SIDE, RIGHT SIDE SLG100 POST JULY 2013

A1540007 CABINET SIDE, RIGHT SIDE SLG100 BEFORE JULY 2013

A1541107 CABINET SIDE, RIGHT SIDE SLG100 POST JULY 2013

A1237803 CABINET, FRONT BOTTOM BRACE SLG100 BEFORE JULY 2013

A1861003 CABINET, FRONT BOTTOM BRACE SLG100 POST JULY 2013

A1640303 CABINET BACK, BOTTOM BRACE SLG100 BEFORE JULY 2013

A1641403 CABINET BACK, BOTTOM BRACE SLG100 POST JULY 2013

A1857001 CABINET, SPACER SLG100 BEFORE JULY 2013

A1861203 CABINET, SPACER SLG100 POST JULY 2013

8 A8048001 PIPING, BRACKET MANIFOLD REAR

9 B14090-00 FLUE, DEFLECTOR SLG100

B2306102 DOOR, ASSEMBLY SLG100 BEFORE JULY 2013

B2306302 DOOR, ASSEMBLY SLG100 POST JULY 2013

A3636504 DOOR, OUTER SLG100 BEFORE JULY 2013

A2337304 DOOR, OUTER SLG100 POST JULY 2013

A2336603 DOOR, INNER SLG100 BEFORE JULY 2013

A2337403 DOOR, INNER SLG100 POST JULY 2013

PP10752 SCREW, 10-31 X 1/2 PNH ZN

PP11006 HANDLE, DOOR RECESSED PLASTIC

A3681802 FRONT PANEL, SLG100 BEFORE JULY 2013

A3684904 FRONT PANEL, SLG100 POST JULY 2013

12 P0091500 TINNERMAN C-12003-017 #6

13 E5192-00 SPLASH BACK, SLG100

C10880-00 FLUE, ASSEMBLY SLG100

E5190-00 FLUE BACK

D6265-00 FLUE FRONT

C10860-00 FLUE SUPPORT

15 B14052-00 BURNER HOLD DOWN SLG100

16 A1847002 CLIP, BRACKET MAGNET CATCH

18 A1408002 BULB COVER STEPPED SLG

18 A3800603 DOOR HINGE PIN

19 E4556-04 BURNER

20 P6071300 DOOR MAGNET

21 P0020600 SCREW, 1/4-20 X 5/8 HEAX HEAD ZINC PLATED

22 B3900701 LEG, SET 6" WITH HARDWARE (SET OF 4)

23 P0093300 NUT, HEX (KEP) 1/4-20 ZINC PLATED

24 60084501 DRAIN VALVE, 1 1/4 NON-LOCKING

25 P9204-75 ANETS NAME PLATE BLACK/YELLOW

26 PP10668 NUT, 1/4-20 ACORN WITH CENTERLOCK STAINLESS

27 P0080650 WASHER, FLAT 1/4 ZINC

28 A2510101 TANK, NIPPLE DRAIN OUT 1 1/4 NPT

29 P6073186 TUBE RACK

P9800-48 BASKET

P9800-56 TRIPLE BASKET

31 PP10023 SCREW, 10-24 X 3/8 SELF TAPPER

32 C9183-00 BASKET HANGER SLG100

30

1134

5

6

10

14

6.1 SLG100 Exploded Parts List

11

L22-348 R1 5/13

Page 14

7 SLG40 Gas Assembly Exploded AU & CE Diagram

12

L22-348 R1 5/13

Page 15

ITEM# PART# PART DESCRIPTION

1 A8049901 PIPING, MANIFOLD BRACKET FRONT SLG40

PP11001 GAS VALVE G20 U7000 SLG40

PP11002 GAS VALVE G31 U7000 SLG40

PP11110 GAS VALVE G20 BGOL/S UNREGULATED

3 60179801 INTERRUPTOR,MV 11/32 THREAD

4 P7037090

NIPPLE, BLACK 1/2 NPT X CLOSE

5 P7037750

ELBOW, STREET 1/2 NPT 90 DEGREE

6 P8820-91

NIPPLE, BLACK 1/2 NPT X 17"

7 P7036902

UNION BLACK 1/2 NPT

B8058801

PIPING, WELDMENT GAS MANIFOLD AU

P8841-38

PIPING, WELDMENT GAS MANIFOLD CE

9 60132801

PRESSURE TEST FITTING 1/8 NPT

10 PP10023

SCREW, 10-24 X 3/8 SELF TAPPER

P8905-04

ORIFICE, BURNER #31 NAT/G20 SLG40

A8047103

ORIFICE, BURNER 1.9mm PROPANE SLG40

P8905-16

ORIFICE, BLANK

ELEVATION CHANGE

P8905-83

ORIFICE, BURNER #34 NATURAL

A8047101

ORIFICE, BURNER 3.4mm NATURAL G25

A8047104

ORIFICE, BURNER #35 NATURAL

A8047105

ORIFICE, BURNER #36 NATURAL

A8047106

ORIFICE, BURNER #37 NATURAL

A8047107

ORIFICE, BURNER #38 NATURAL

A8047108

ORIFICE, BURNER #39 NATURAL

A8047110

ORIFICE, BURNER #33 NATURAL

P8905-84

ORIFICE, BURNER #50 PROPANE

A8047102

ORIFICE, BURNER #51 PROPANE

A8047103

ORIFICE, BURNER 1.9mm PROPANE G31

A8047109

ORIFICE, BURNER #52 PROPANE

12 60094101

BRASS STREET ELBOW 1/8 NPT

13 PP10067

METRIC GAS SUPPLY ADAPTER FITTING

60128801 PILOT REVERSE STANDING NAT

60128802 PILOT REVERSE STANDING LP

15

P0075200 SELF DRILLING SCREW 8-18 X 1/2

16 P9131-55 GAS VALVE VENT TUBE (DOMESTIC ONLY)

17 60088014

NIPPLE, BLACK 1/2 NPT X 2"

18 60119001

ELBOW, STREET 1/2 NPT 90 DEGREE

19 60125501

NIPPLE, BLACK 1/2 NPT X 17"

2

11A

11B

14

8

7.1 SLG40 Gas Assembly Exploded AU & CE Parts

13

L22-348 R1 5/13

Page 16

8 SLG100 Gas Supply Exploded AU & CE Diagram

14

L22-348 R1 5/13

Page 17

PLOT PART# PART DESCRIPTION

1 P9315-61 PIPING, WELDMENT GAS MANIFOLD SLG100

PP10955 GAS VALVE G20/G25 U7000

PP10956 GAS VALVE G31 U7000

PP11110 GAS VALVE G20 BGOL/S UNREGULATED

3 PP10067 GAS SUPPLY METRIC ADAPTER

4 P7037093

NIPPLE, BLACK 1/2 NPT X 2"

5 P7037750

ELBOW, STREET 1/2 NPT 90 DEGREE

6 P8820-91

NIPPLE, BLACK 1/2 NPT X 17"

7 P7036902

UNION BLACK 1/2 NPT

8

A8048001

GAS SUPPLY WELDMENT SUPPORT BRACKET SLG100

9 60132801

GAS MANIFOLD TEST FITTING 1/8 NPT

10 PP10023

SCREW, 10-24 X 3/8 SELF TAPPER

P8905-04

ORIFICE, BURNER #31 NATURAL SLG100

P8905-05

ORIFICE, BURNER #49 PROPANE SLG100

11A P8905-16

ORIFICE, BLANK

ELEVATION CHANGE OR CE ORIFICE TIPS

P8905-83

ORIFICE, BURNER #34 NATURAL

A8047101

ORIFICE, BURNER 3.4mm NATURAL

A8047104

ORIFICE, BURNER #35 NATURAL

A8047105

ORIFICE, BURNER #36 NATURAL

A8047106

ORIFICE, BURNER #37 NATURAL

A8047107

ORIFICE, BURNER #38 NATURAL

A8047108

ORIFICE, BURNER #39 NATURAL

A8047110

ORIFICE, BURNER #33 NATURAL

P8905-84

ORIFICE, BURNER #50 PROPANE

A8047102

ORIFICE, BURNER #51 PROPANE

A8047103

ORIFICE, BURNER 1.9mm PROPANE

A8047109

ORIFICE, BURNER #52 PROPANE

12

60125501

THERMOPILE MILLIVOLT

13

B12326-00

THERMOPILE SUPPORT WELDMENT

14

P9131-62

SPARK IGNITOR

15

P0075300

SELF DRILLER 10/16 X 5/8

C9163-00

PILOT RUNNER TUBE WELDMENT NAT SLG100

C9163-01

PILOT RUNNER TUBE WELDMENT LP SLG100

17

B12821-00

PILOT STANDOFF SPACER

P8904-98

RUNNER TUBE ORIFICE NAT #55 SLGOO

P9804-99

RUNNER TUBE ORIFICE LP #72 SLGOO

19

P8805-11

COUPLING 1/8 NPT

20

P7037797

ELBOW 1/4 COMPRESSION X 1/8 NPT

21

P8840-92

COMPRESSION TEE 1/4 TUBE

22

P7037092

NIPPLE, BLACK 1/2 NPT X 1 1/2

23

P7037096

NIPPLE, BLACK 1/2 NPT X 3 1/2

24

PP11260

FLEXIBLE TUBE 1/4 X 10

25

P9315-61

FLEXIBLE TUBE 1/4 X 12

26

60119001

FLEXIBLE TUBE 1/4 X 18

27

60094101

BRASS STREET ELBOW 1/8 NPT

28

PP10067

METRIC GAS SUPPLY ADAPTER FITTING

161811

11B

2

8.1 SLG100 Gas Supply Exploded AU & CE Parts

15

L22-348 R1 5/13

Page 18

9 TSTAT Assembly Exploded AU Diagram

16

L22-348 R1 5/13

Page 19

ITEM# PART# PART DESCRIPTION

1 PP10084 SWITCH, HI-LIMIT

2 P5047590 THERMOSTAT, GS 190C

3 B14503-00 PIPING, BRACKET THERMOSTAT WITH IGNITOR

4 PP10687 SCREW, 6-32 X 5/16 TH PHILLIPS

5

PP10539 KNOB, THERMOSTAT

6

P0007300 SCREW, 8-32 X 1/4 HEX HEAD ZINC

7

B6744402 WIRING, MILLIVOLT HI-LIMIT/THERMOSTAT

8

P9132-34 CONTROL, SPARK IGNITOR

9 60172101 BATTERY, TRIPLE A 1.5V

10 60167801 CONTROL, WIRE SPARK IGNITOR 24"

11

P9132-37 CONTROL, SPARK IGNITOR GROUND WIRE

12

P9204-18 LABEL, IGNITOR

60119001

FLEX TUBING 18" CE

A8049701 PIPING, THERMOSTAT IN-GAS VALVE-OUT SLG40 AU

A8049703 PIPING, THERMOSTAT IN-GAS VALVE-OUT SLG100 AU

A8049702 PIPING, THERMOSTAT OUT-GAS VALVE-IN SLG40 AU

A8049704 PIPING, THERMOSTAT OUT-GAS VALVE-IN SLG100 AU

13

14

9.1 TSTAT Assembly Exploded AU Parts

17

L22-348 R1 5/13

Page 20

MAILING ADDRESS – P.O. BOX 501, CONCORD, NH 03302-0501

SHIPPING ADDRESS – 10 FERRY ST., CONCORD, NH 03301

In the event of problems with or questions about

your order, please contact the Anetsberger

Factory at:

+001 (603) 225-6684 (World Wide)

In the event of problems with or questions about

your equipment, please contact the Anetsberger

Authorized Service and Parts representative

(ASAP) covering your area, or contact

Anetsberger at the number listed to the left.

18

L22-348 R1 5/13

Loading...

Loading...