Anets MX-14-2AA Installation Manual

Anets, Inc PO Box 501, Concord, NH 03302-0501

!

!

Tel: 603-225-6684 Fax: 603-225-5231

FR YER

Models

MX-14E, MX-14-2E,

MX-7E,

MX-14AA, MX-14-2AA,

MX-7A

Installation,

User Operation,

&

Maintenance

Manual

MX-14E shown with optional casters

DANGER

Improper installation, adjustment, alteration, service, or maintenance can

cause property damage, injury or death. Read the insta llation, operating

and maintenance instructions thoroughly before installing or servicing this

equipment.

After installation of this equipment, immediately contact your local gas

supplier to obtain information about what action to take whenever any

person smells gas. Post this info rmation in a prominent location.

DO NOT store or use gasoline or other flammable vapors

or liquids in the vicinity of this or any other appliance.

!

FOR YOUR SAFETY

WARNING

Keep this Manual in a Convenient Location for Reference

The Anets GoldenLine

Quality Equipment For The Restaurant, Supermarket, and Bakery Industries

L20-341 Rev 3

CONTENTS

Sh ippi ng Co ntai ner I nspe cti on .......................................................

Fry er Gas Supp ly Sp ecif icat ions ....................................................

Fry er E lect ric al Sp ecif ica tion s .......................................................

Figure 1 - Fry er MX-1 4E W iring Diagra m ............................

Cod e Req uire ment s ......................................................................

Figure 2 - Fr yer Si te Inst allat ion Req uirem ents .......................

Installation Requirements

...............................................................

In sta lla tio n In str uct ion s ..................................................................

Le g Ins tal lat ion I nst ruc tio ns .....................................................

Figure 3 - Typica l Leg Install ation .........................................

Le g Le vel ing Ins tr uct ion s .........................................................

Cas ter I nst alla tion Inst ruc tion s .................................................

Figure 4 - T ypica l Caste r Insta llatio n .....................................

Cas ter Leve lin g In stru ctio ns ....................................................

Fryer Restraining Device Installation Instructions

Gas & Electric Connection Instructions .......................................

..................... 10

10

Fry er Op erati ng In stru ctio ns ........................................................ 11

3

4

5

5

6

6

7

7

7

8

8

8

9

9

Frye r Prep arati on For Use (“ Boil O ut” In struc tions) ..............

Figure 5

Lighting Procedure

- Draining the Kettle

................................................................

...............................................

Figure 6 - Gas C ontrol Valve & Knob Pos itions ...................

Shut down P roced ure ............................................................

Food Product Frying Time Charts

................................. ... 15, 16

12

12

13

13

14

Dai ly Cle anin g Pr oce dure ....................................................... 17

Monthly Maintenance Instructions

Fryer Troubleshooting Guide

Fryer W arranty

............................................................................ 27

.................................................

.............................. ............ 18

19 - 26

2

! DANGER

r

A

A

rWith

Hig

h Efficie

n

ainle

lHa

erW

ith A

L

i

Read these specifications, Code Requirements, Installation Requirements, Installation Instructions, and Operating Instructions very carefully. Failure to follow the

Instructions could cause the fryer to malfunction. A fryer malfunction can result in

property damage, serious bodily injury, or death.

SHIPPING CONTAINER INSPECTION

1

. Carefully examine the shippi ng container for external damage. When damage is noted, notify the

delivery carrier immediately . Save all packing materials for damage claim examination.

2

. If no external damage is noted, remove the shipping container from the fryer and examine the fryer

carefully for damage. Place the fryer in a safe location, if damage is noted, so that the freight damage

claims adjuster can examine the fryer .

3

. Save the shipping container for use during leg/ caste r installation. Refer to the Installation Instructions

for that procedure.

Models Covered By This Manual

MX-14E High Efficiency Stainless Steel Fryer

MX-14-2E

MX-14-7E

MX-14

MX-14-2AA

MX-7A

High EfficiencyStainlessSteelFrye

High EfficiencyStainlessSteelSplitPot Frye

High Efficiency Stainless Steel Half Size Fryer

High Efficiency Stainless Steel Split Pot Fryer W ith Automatic Lifts

cySt

ssStee

lfSizeFry

Automatic Lifts

utomatic

fts

Standard Accessories furnished in the shipping carton with this fryer include:

Models MX-14AA, -14- 2AA, MX-14E, and MX-14-2E Models MX-7A and MX-7E

2 Fryer Baskets 1 Screen 1 Fryer Basket 1 Screen

4 Adjustable Legs 1 Basket Hanger* 4 Adjustable Legs 1 Basket Hanger*

1 Drain Valve Extension 2 Basket Lift Frames ** 1 Drain Valve Extension 1 Basket Lift Frame **

1 Cleanout Rod 1 Cleanout Rod

*- Basket Hanger for MX-14E, MX-14-2E, or MX-7E onl y.

** - Basket Lift Frame for MX- 14AA, MX-14-2AA, or MX-7A o nly.

NOTE: Other available optional equipment may include a sediment tray; a microprocessor-based cooking

computer with shortening melter, boil-out m ode, and digital timers (Fri-tronic

(Filtronic™ II or Filter Mate™); a fryer cover; a drain table; a fron t drain tray; o r four cas ters.

NOTE: A Parts List for each

tional copy of this list is needed, please contact the factory as directed on the back cover.

Anets

Fryer is among the items shipped with each fryer.

®

); a built-in filter system

If an addi-

3

FRYER GAS SUPPLY SPECIFICATIONS

Please make sure that your desired fr yer location has gas

supply factors that are suitable for this product:

Models MX-14E, MX-14-2E, MX-14AA, &MX-14-2AA

*

- BTU/Hr Rating is based on sea level operation. For sites above 2000 feet, reduce this rating 4% for

**

***

INPUT REQUIRED:

11 1,000 BTU/Hr *

MANIFOLD PRESSURE

SUPPL Y PRESSURE***

Models MX-7E & MX-7A

INPUT REQUIRED:

55,000 BTU/Hr *

MANIFOLD PRESSURE

SUPPL Y PRESSURE***

each 1000 feet

- “ W.C. = Inches, Water Column.

- Measure Supply Pressure when all other gas-powered equipment is operating.

above

sea level.

Natural Gas Propane Gas

10“ W.C.

10“ W.C.

W.C.

**

**

3½“ W.C.

6“ W.C., minimum 11“ W.C., minimum

Natural Gas Propane Gas

“

3½

6“ W.C., minimum 11“ W.C., mini-

Gas Supply Inlet Pipe must be ¾” NPT (Na tional Pipe Thread) standard gas line. The gas supply inlet

line should be as straight as possible (fewest bends or elbows) to obtain the highest available gas pressure at

the appliance. Locate this inlet line horizontally at the center of the desired fryer location, approximately

8¼” above the floor.

NOTE: Using a flexible inlet line permits variation in the gas suppl y line location, both horizontally and

vertically .

Anets fryers are only for use with the type of gas specified on the spec plate. If a fryer requires modification

to use a gas other than that which is identified on the fryer spec plate, contact your Anets representative or

1-603-225-6684.

call (

4

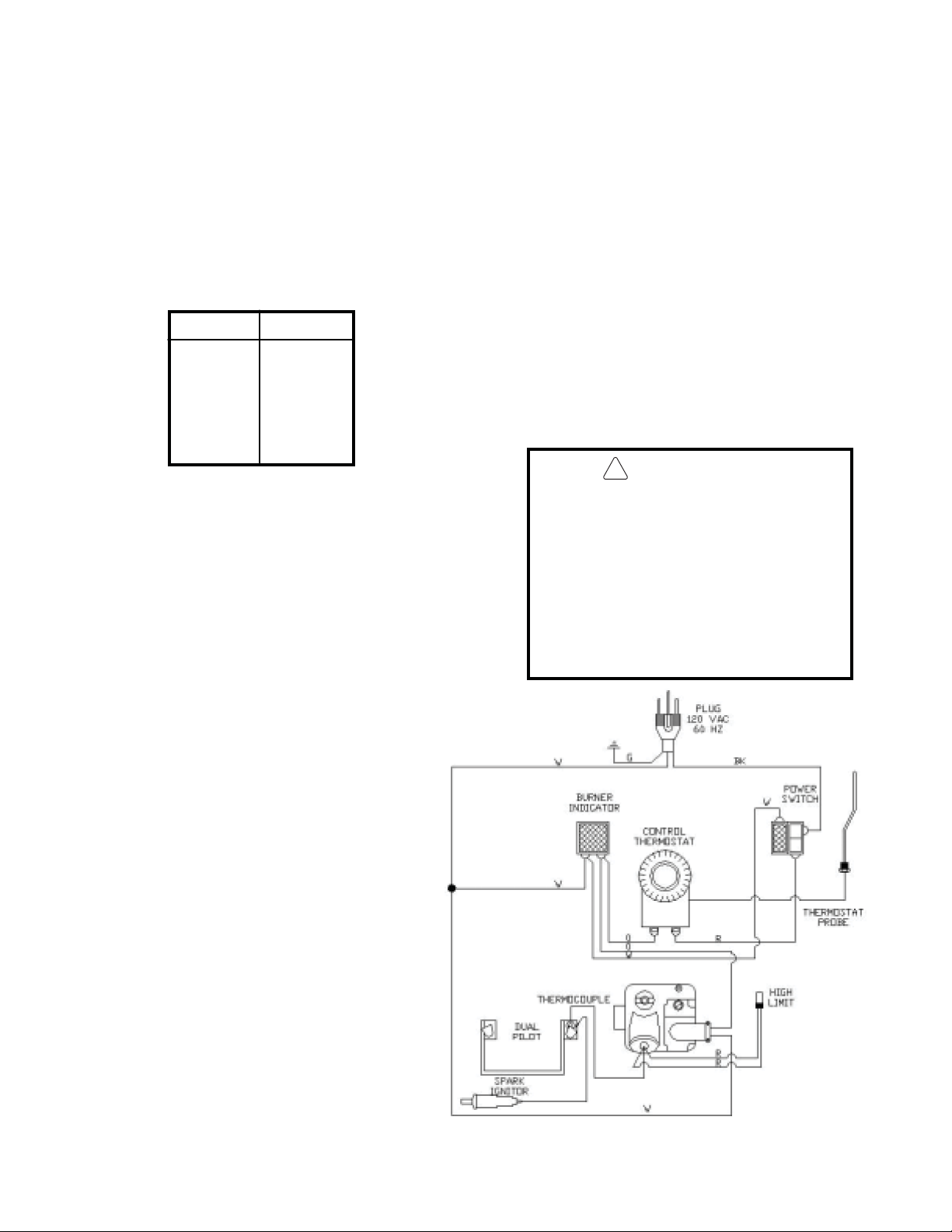

FRYER ELECTRICAL SPECIFICATIONS

WA

G

Please make sure that your desired fryer location has electrical

supply factors that are suitable for this product:

120 Volts, 60 Hz, (Refer to T able 1 for amperage requirements), 1-phase, three-wire connection, including

an electrical ground, via a dedicated circuit breaker. A model-specific electrical circuit diagram is

mounted inside the front door of each fryer .

Install a dedicated, three-prong, outlet/ receptacle

within 5 feet of the desired fryer location to allow

the fryer’s power cable to be connected. Ensure

that the green (ground) wire of the fryer’s power

cable is attached to the fryer’s structure, providing

an electrical ground in accordance with applicable

local codes, or in the absence of local codes, with

the National Electrical Code, ANSI/N FP A 70

(latest edition) or the Canadian Electrical Code,

CSA C22.1 (latest edition) and CSA C22.2 (latest

edition).

Figure 1 is the basic wiring diagram of an

MX-series fryer showing a typical circuit.

Some fryers may have other options that do

not appear in this basic wiring diagram. A

model-specific wiring d iagram included with

each fryer shows all the actual parts and

their associated wiring connections. In

addition, fryers equipped with a built-in filter

system (Filtronic II or Filter Mate) and/or

built-in computer controls (Fri-tronic) have

a supplementary manual included for each

option.

Table 1. Fryer Amperage

Model Amperage

MX-14E

MX-14-2E

MX-7E

MX-14AA

MX-14-2AA

MX-7A

Requirements

2 A.

4 A.

2 A.

7 A.

9 A.

5 A.

!

Electrical Grounding Instructions

(See inside of door for wiring diagram.)

This appliance is equipped with a threeprong (grounding) plug for your protection against shock hazard, and should

be plugged directly into a properly

grounded, three-prong receptacle

NOT

cut or remove the grounding prong

from this plug.

Figure 1. Fryer Model MX-14E Wiring Diagram

RNIN

. DO

5

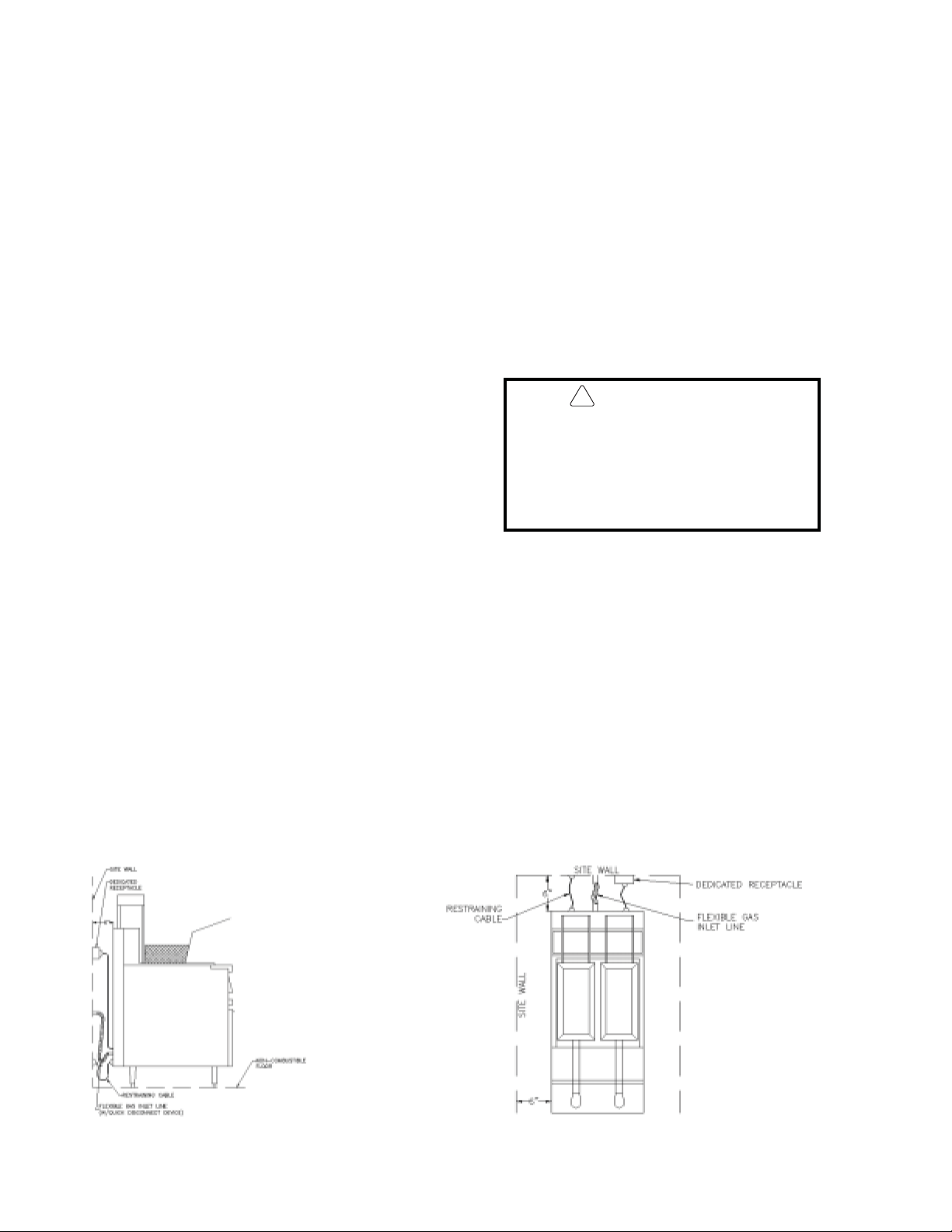

CODE REQUIREMENTS

i

b

W

G

!

IMPORTANT:

Read the Code Requirements

and the Installation Requirements and Iinstructions carefully , befor e starting the installation.

Contact the factory

1-603-225-6684

if any

problems or questions arise.

The fryer installation must conform with local

codes, or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1 (latest

edition); the Natural Gas Installation Code, CAN/

CGA-B149.1 (latest edition); or the Propane Gas

Installation Code, CAN/CGA-B149.2 (latest

edition), as applicable, including:

a

. Disconnect the fryer and its individual shutoff

valve from the gas supply piping system during

any pressure testing of the gas supply system at

test pressures in excess of ½ psig (3.45 kPa).

b.

Isolate the fryer from the gas supply piping

system during any pressure testing of the gas

supply system at test pressures equal to or less

than ½ psig (3.45 kPa).

c

. For fryers utilizing floor casters, the fryer instal-

lation shall be made with a connector that

complies with the Standard for Connectors for

Movable Gas Appliances, ANSI Z21.69

(latest edition) or CAN/CGA 6.16 (latest

edition), and a quick-disconnect device that

complies with the Standard for Quick-Disconnect Devices for Use with Gas Fuel, ANSI

Z21.41 or CAN/CGA 1-6.9 (latest edition).

d.

Restrict the movement of a caster-equipped

fryer by using a limiting device (for exam ple, a

cable attached both to the fryer and to a fixture attached to the site structure) to avoid

depending on the connector and the quickdisconnect device or its associated piping to

limit fryer movement.

e

. Inst all th is fr yer on a non-combustible floor

with its back and sides at least 6” away from

anycombust

lewall, as shown in Figure2.

ARNIN

Install this fryer under a ventilation

hood that conducts combustion products outside the building. V enting

must comply with ANSI/NFPA 96

(latest edition).

f . Install this fryer in a loca tion where adequate

combustion and ventilation air is available.

Keep the area directly in front of the fryer open

for adequate air flow to the burners. DO

NOT obstruct the flow of combustion and

ventilation air.

g. Keep the fryer area free and clear from

combustibles and debris.

h. Attach a restraining device to each fryer, to

prevent the unit from tipping, which could

cause splashing of hot liquid .

From the top of the flue on

the fryer, allow a minimum

of at least 10 inches vertical clearance beneath a

ventilating hood.

Figure 2. Fryer Site Installation Requirements

6

INSTALLATION

t

w

REQUIREMENTS

Install the fryer in accordance with the preceding

Code Requirements, as well as the following

Installation Requirements.

1.

DO NOT install this fryer in a mobile home,

trailer, or recreational vehicle.

2.

Install this fryer in a location that has the f ryer’s

electrical receptacle nearby (5 feet or less

away) to avoid straining the fryer’ s power

cord

. (See Figure 2.)

3.

Install this fryer in a location that allows it to be

moved away from other adjacent appliances

for cleaning and maintenance.

NOTE: If the fryer is installed among

a row of appliances (“banked”), with

its only convenient m ovement forward,

sufficient room must be available in

front of the fryer to permit its separation from adjacent appliances for

cleaning and maintenance.

4.

Tightly fasten the legs (or casters) to the bottom of the fryer using the supplied hardware, to

prevent the fryer from tipping, wobbling or

rocking when it is in its desired location. Refer

to the following Leg Installation Instructions

or Caster Installation Instructions for leg

or caster attachment and leveling information.

CAUTION:

!

MUST NOT flow in a manner tha

restricts or impedes the natural flo

of combustion or ventilation air .

5.

Confirm that the air fr om the ventilation hood

flowing near the fryer after installation is NOT

blowing on the rear of the unit, to prevent

affecting the burner flames and possibly causing

damage to plastic parts.

Hood make-up air

INSTALLATION

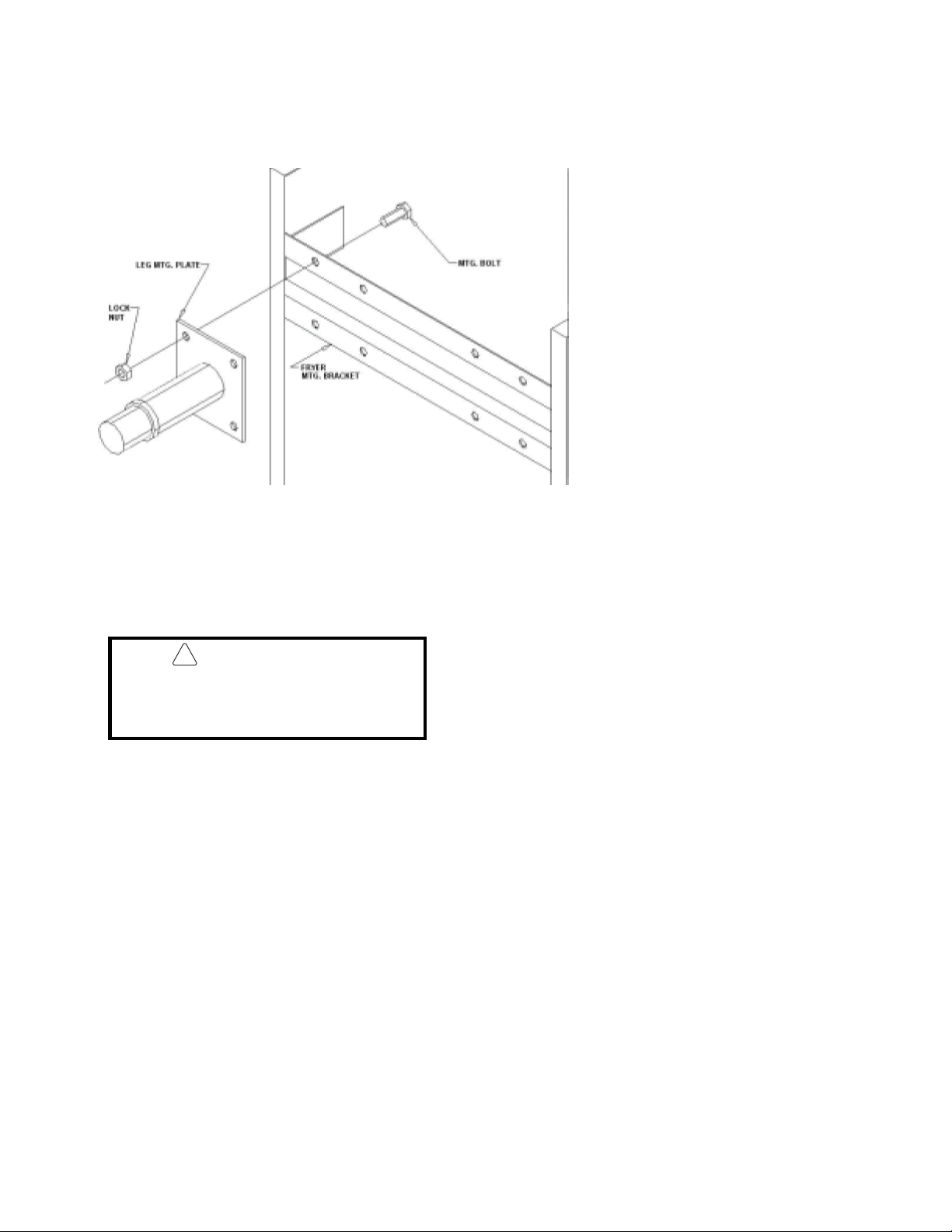

LEG INSTALLATION

INSTRUCTIONS

1. Flatten the shipping carton (after unpacking the

fryer and its parts and accessories) for fryer

surface protection during leg installation.

2.

Position the side of the fryer flat on the carton,

exposing the fryer bottom mounting brackets

for leg installation, as shown in Figure 3.

3. Place the leg mounting plate flush against the

mounting bracket on the fryer bottom, while

aligning the mounting holes.

4. Insert one mounting bolt through a f lat washer

and then through the proper hole in the fryer

mounting bracket and through the leg mounting

plate.

INSTRUCTIONS

5.

Screw a locking nut several turns onto the

mounting bolt.

6.

Repeat steps 4 and 5 until all four mounting

bolts for a leg are in place with locking nuts.

7.

Tighten th e four locking nuts evenly and securely to hold the leg mounting plate against the

fryer bottom mounting bracket.

7

INSTALLATION INSTRUCTIONS

Figure 3. Typical Leg Installation

LEG LEVELING INSTRUCTIONS

(Continued)

1.

Move the fryer to its desired location.

WARNING

!

The fryer MUST NOT tip, rock or wobble, to avoid splashing or spilling its HOT

shortening contents during operation.

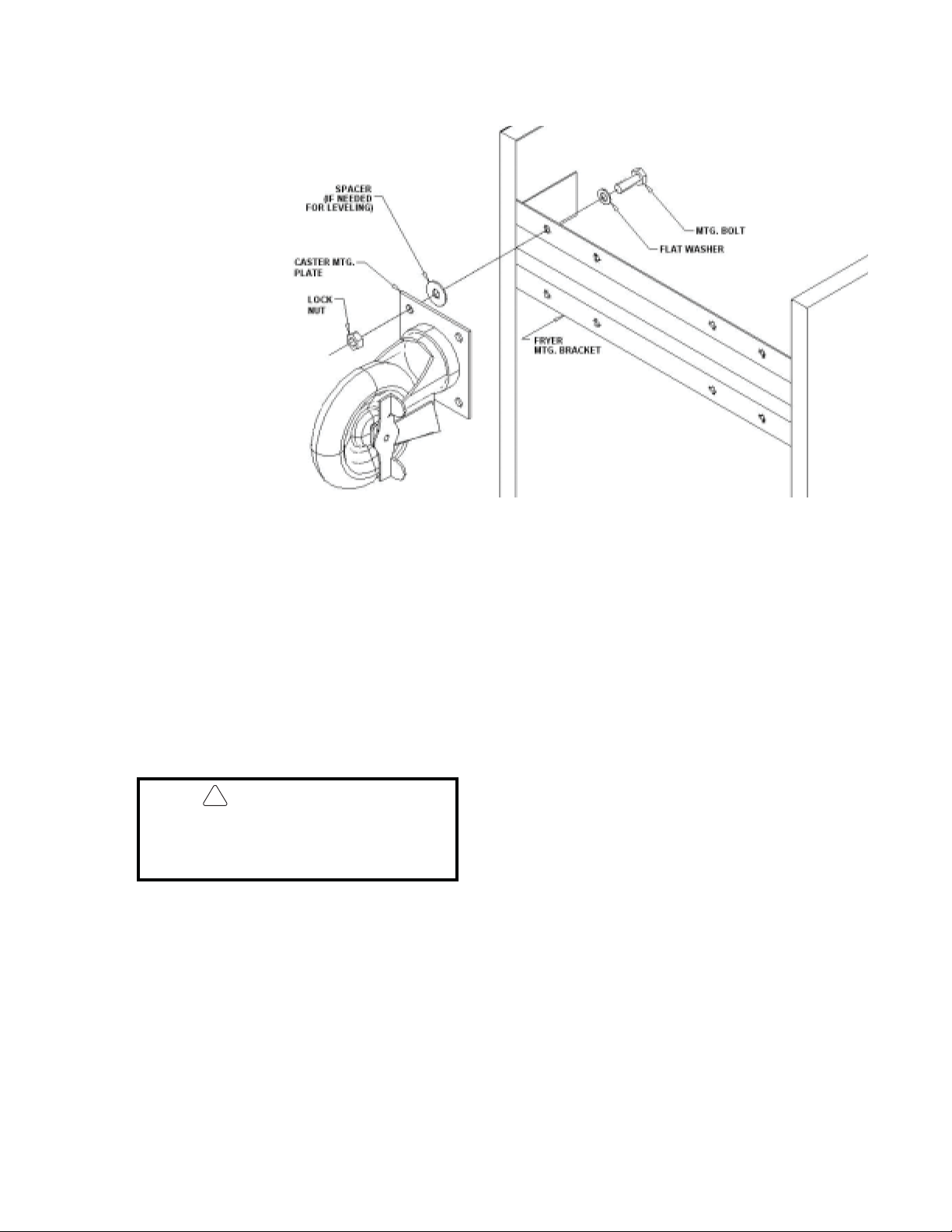

CASTER INSTALLATION

INSTRUCTIONS

1. Flatten the shipping carton (after unpacking the

fryer and its parts and accessories) for surface

protection during caster installation.

2.

Position the side of the fryer flat on the carton,

exposing the fryer bottom mounting brackets

for caster installation, as shown in Figure 4.

3.

Mount locking casters on the f ront of the fryer

and fixed casters on the rear, by placing each

caster mounting plate flush against the mounting

bracket on the fryer bottom.

2.

Turn the screw-type leg adjustment ends as

necessary to level the fryer, until NO tipping,

rocking, or wobbling is evident.

3.

Perform the Fryer Restraining Device

Installation Instructions, referring to

Figure 2.

(supplied) and the mounting bracket, then

through the caster mounting plate.

5.

Screw a locking nut several turns onto the

mounting bolt.

6.

Repeat steps 4 and 5 until all four mounting

bolts for a caster are in place with locking nuts.

7. Tighten the four bolts evenly a nd securely to

hold the caster mounting plate against the fryer

mounting bracket.

4.

Insert one mounting bolt through a flatwasher

8

INSTALLATION

pin

W

CASTER LEVELING INSTRUCTIONS

INSTRUCTIONS

Figure 4. Typical Caster Installation

CASTER LEVELING

INSTRUCTIONS

(Continued)

(Continued)

1.

Move the fryer to its desired location.

Determine whether the fryer tends to wobble

2.

or rock when in its desired location. If it

does, perform steps 3 through 9.

not, skip to step 10, then proceed to the

Installation Instructions.

The fryer MUST NOT tip, rock or wobble, to avoid splashing or spilling its HOT

shortening contents during operation.

3.

Determine which c aster requires adjustmen t

and the approximate amount of change

required to leve l the fryer .

Position the side of the fryer on the ship-

4.

with the caster mounting plates (Figure 4).

Completely unscrew the bolts holding the

5.

caster mounting plate that requires the leveling

adjustment. Retain the locking nuts for later

reassembly.

!

ARNING

g carton, exposing the bottom of the fryer

Ifit does

Reinsert each bolt through its flatwasher and

6.

the fryer mounting bracket; next, place a

spacer of the required size on the bolt before

inserting the bolt through its mounting hole on

the caster mounting plate and screwing a

locking nut onto the bolt.

7.

Repeat step 6 for all remaining bolts.

8.

Tighten all fou r locking nuts evenly and securely against the caster mounting plate and

the fryer bottom mounting bracket.

Return the fryer to its desired location. Lock

9.

the front casters to prevent fryer movement

and check again for wobbling or rocking.

Repeat steps 3 through 9 until no wobbling or rocking occurs. When the fryer no

longer wobbles or rocks, perform step 10.

10.

Perform the Fryer Restraining Device

Installation Instructions, referring to

Figure 2.

9

Loading...

Loading...