Anets 14G Installation Manual

Anets Inc.

!

!

Mailing Address: P.O. Box 501, Concord,NH 03302-0501 USA Telephone: 603-225-6684

Shipping Address: 10 Ferry Street, Concord, NH 03301 USA

www.anets.com

FRYER

Models

14G, 14GS

14GS shown on standard 6” legs

Improper installation, adjustment, alteration, service, or maintenance can

cause property damage, injury or death. Read the installation, operating

and maintenance instructions thoroughly before installing or servicing this

equipment.

DO NOT store or use gasoline or other flammable vapors

or liquids in the vicinity of this or any other appliance.

DANGER

FOR YOUR SAFETY

!

14GU, 14GSU,

MX-14EG, MX-14EGU

Installation,

User Operation,

&

Maintenance

Manual

WARNING

After installation of this equipment, immediately contact your local gas

supplier to obtain information about what action to take whenever any

person smells gas. Post this information in a prominent location.

Keep this Manual in a Convenient Location for Reference

The Anets Golden Line

Quality Equipment For The Restaurant, Supermarket, and Bakery Industries

L20-362 rev 3

1

DANGER

!

Read these specifications, Code Requirements, Installation Requirements, Installation

Instructions, and Operating Instructions very carefully. Failure to follow the

could cause the fryer to malfunction. A fryer malfunction can result in

serious bodily injury, or death.

CONTENTS

property damage,

Instructions

Shipping Container Inspection

Fryer Gas Supply Specifications

Fry er E lect ric al S peci fic atio ns .......................................................

Figure 1 - Fry er Mode l 14GS W i ring Dia gram .......................

Cod e Req uire ment s ......................................................................

Figure 2 - Fr yer Si te Inst allat ion Req uirem ents .......................

In sta lla tio n Re qu ire men ts ...............................................................

In sta lla tio n Ins tru cti ons ..................................................................

Le g Ins tal lat ion I nst ruc tio ns .....................................................

Le g Le vel ing Ins tr uct ion s .........................................................

Figure 3 - Typica l Leg In stalla tion .........................................

Cas ter Inst alla tio n Ins tru ctio ns .................................................

Figure 4 - T ypica l Caste r Insta llatio n .....................................

Cas ter Leve lin g In stru ctio ns ....................................................

Fryer Restraining Device Installation Instructions

Gas Connection Instructions

Fry er Op erati ng In stru ctio ns ........................................................ 11

........................................................ 3

..................................................... 4

....................... 9

........................................................

10

4

4

5

6

6

7

7

7

7

8

8

8

Frye r Prep arati on For Use (“ Boil O ut” In struc tions) ..............

Figure 5 - Draining The Kettle .............................................

Lighting Procedure

Figure 6 - Gas Saf ety Valve & Cont rol Knob Posi tions ........

Shut down P roced ure ............................................................

Food Product Frying Time Chart

Dai ly Cle anin g Pr oce dure ....................................................... 16

Monthly Maintenance Instructions

Fryer Troubleshooting Guide

Fryer W arranty

2

............................................................................ 23

................................................................

................................... ......... 15

.............................. ............ 17

.................................................

12

12

13

13

14

18 - 22

SHlPPlNG CONTAlNER lNSPECTlON

1

. Carefully examine the shipping carton for

external damage. When damage is noted, notify

the delivery carrier imm ediately . Save all packing

materials for damage claim examination.

2

. If no external damage is noted, remove the

shipping carton from the fryer and examine the

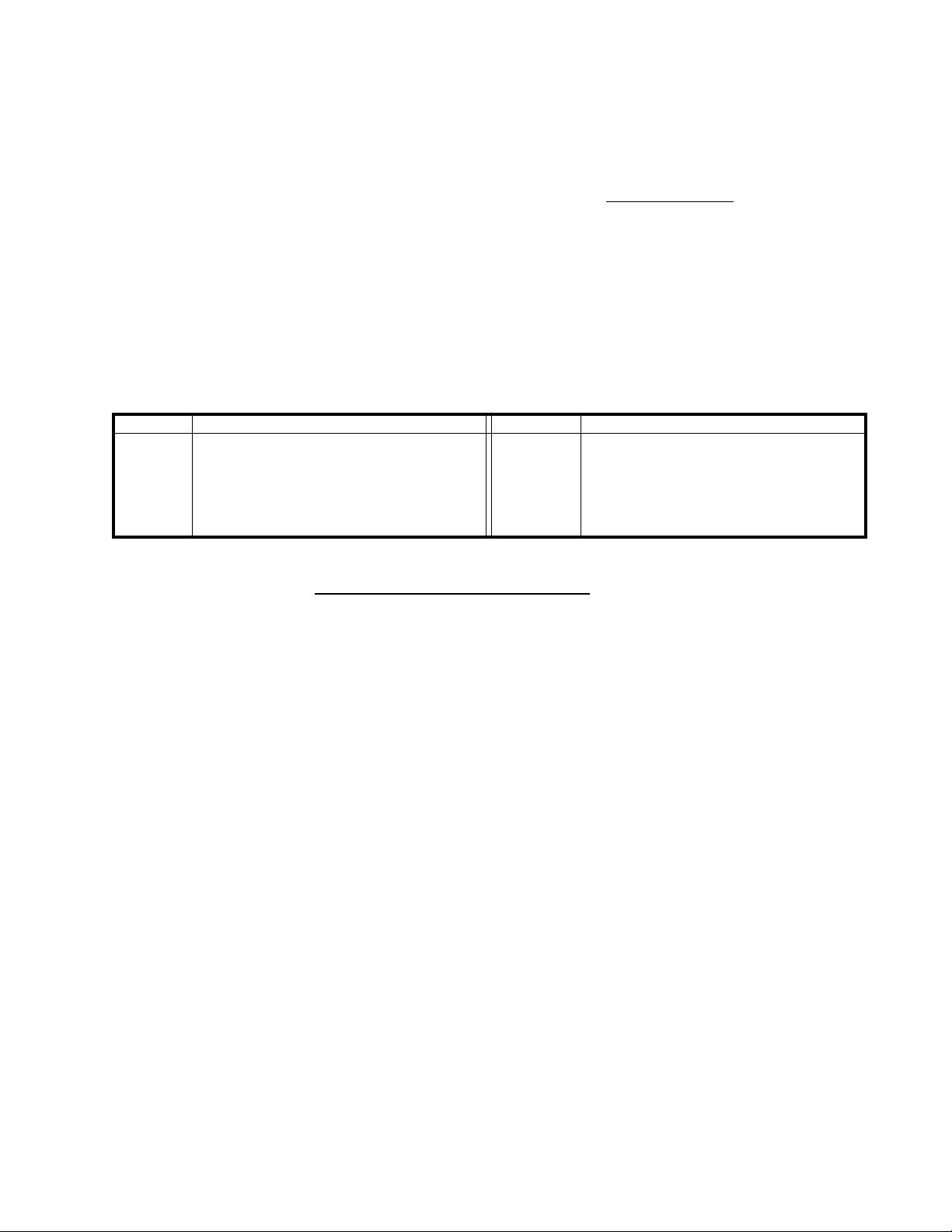

Models Covered By This Manual

Model Features Model Features

14G

14GU

14GS

14GSU

Plain Steel Fryer Kettle

Plain Steel Fryer Kettle, CE version

Stainless Steel Fryer Kettle

Stainless Steel Fryer Kettle, CE version

fryer carefully for damage. Place the fryer in a

safe location, if damage is noted, so that the freight

damage claims adjuster can examine the fryer.

3

. Save the shipping container for use during leg/

caster installation. Refer to the Installation Instructions for that procedure.

MX-14EG

MX-14EGU

High Efficiency Fryer

High Efficie ncy Fryer, CE vers ion

Standard Accessories

furnished in the shipping carton for this fryer include:

2 Fryer Baskets 1 Drain V alve Extension 1 Screen

4 Adjustable L egs 1 Cleanout Rod 1 Basket Hanger

Other optional equip ment includes a sediment tray; single or triple baskets; a built-in Filtronic™ II or Filter

Mate under-fryer filter system; a fryer cover; a drain table; a front drain tray; or four casters.

Note: A Parts List for each Anets fryer is among th eitems shipped with each fryer. If an

additional copy of this list is needed please contact the factory as directed on the back

cover.

3

FRYER GAS SUPPLY SPEClFlCATlONS

-

Please make sure that Vour desired frVer location has gas

are suitable for this product:

INPUT REQUIRED:

111,000 BTU *

MANIFOLD PRESSURE

Natural Gas Propane

3½“ W.C.

**

10“ W.C.

SUPPLY PRESSURE***

6“ W.C., minimum 11“ W.C., minimum

* -

BTU/Hr Rating is based on sea level operation. For sites above 2000 feet, reduce this

rating 4% for each 1000 feet above sea level.

** -

“W.C. = Inches, Water Column.

***

Measure Supply Pressure when all other gas-powered equipment is operating.

Gas Supply Inlet Pipe size must be ¾“ NPT

(National Pipe Thread) standard gas line. The gas

supply inlet line should be as straight as possible

(fewest bends or elbows) to obtain the highest

available gas pressure at the fryer . Locate this

inlet line horizontally at the center of the desired

fryer location, 8¼“ above the floor.

NOTE: Using a flexible inlet line permits variation

in the gas supply line location, both horizontally and

vertically .

Anets fryers are only for use with the type of gas

specified on the spec plate. if a fryer requires

modification to use a gas other than th at which is

identified on the fryer spec plate, contact you Anets

representative or call 1-603-225-6684.

supplV factors that

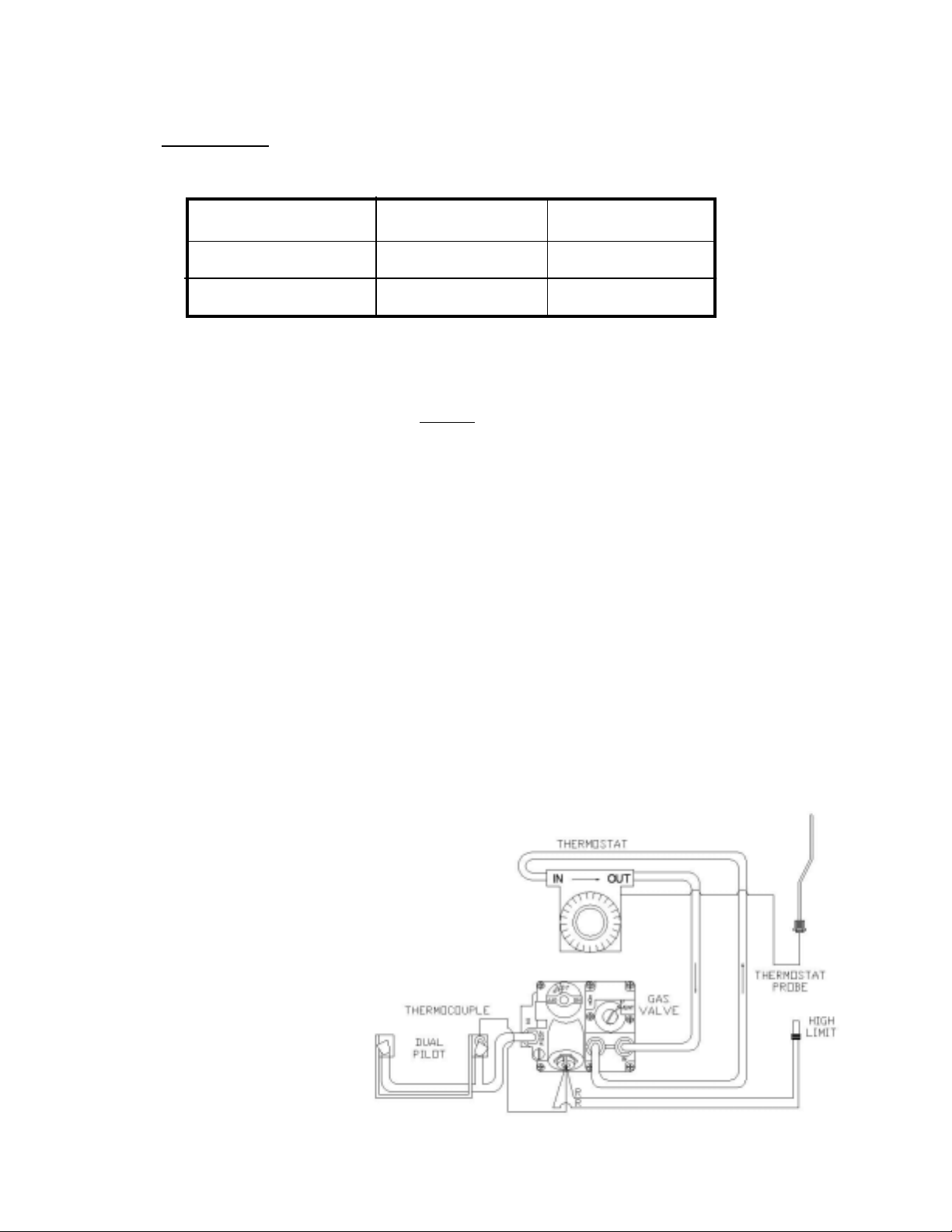

FRYER ELECTRlCAL

The

ANETS

electric power source.

Figure 1 is a wiring diagram of an

ANETS

may have other options that do not

appear in this basic wiring diagram. A

model-specific wiring diagram included

with each fryer shows all the actual parts

and their associated wiring connections.

In addition, a fryer equipped with a builtin filter sys- tem (Filtronic II or Filter

Mate) has a supplementary manual

included for that option.

Fryer Models 14GS, 14GSU, MX-14EG, and MX-14EGU require no exter-

14GS Fryer. Some fryers

SPEClFlCATlONS

nal

Figure 1. Fryer Model 14GS Wiring Diagram

4

CODE REQUlREMENTS

lMPORTANT:

and ALL installation instructions carefully ,

before starting the installation. Contact the

factory if any problems or questions arise.

The fryer installation must conform with local

codes, or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1 (latest

edition); the Natural Gas Installation Code, CAN/

CGA-B149.1 (latest edition); or the Propane Gas

Installation Code, CAN/CGA-B149.2 (latest

edition), as applicable, including:

a

. Disconnect the fryer and its individual shutoff

valve from the gas supply piping system during

any pressure testing of the gas supply system at

test pressures in excess of ½ psig (3.45 kPa).

b.

Isolate the fryer from the gas supply piping

system during any pressure testing of the gas

supply system at test pressures equal to or

less than ½ psig (3.45 kPa).

c

. For fryers utilizing floor casters, the fryer instal-

lation shall comprise a connec tor that complies

with the Standard for Connectors for Movable Gas Appliances, ANSI Z21.69 (latest

edition) or CAN/CGA 6.16 (latest edition),

and a quick-disconnect device that complies

with the Standard for Qui ck-Disconnect

Devices for Use with Gas Fuel, ANSI Z21.41

or CAN/CGA 1-6.9 (latest edition).

Read the Code Requirements

d.

Restrict the movement of a caster-equipped

fryer by using a limiting device (for example, a

cable attached both to the fryer and to a fixture

attached to the site structure) to avoid depending on the connector and the quick-disconnect

device or its associated piping to limit fryer

movement.

e

. Install this fryer on a non-combustible floor

with its back and sides at least 6” away from

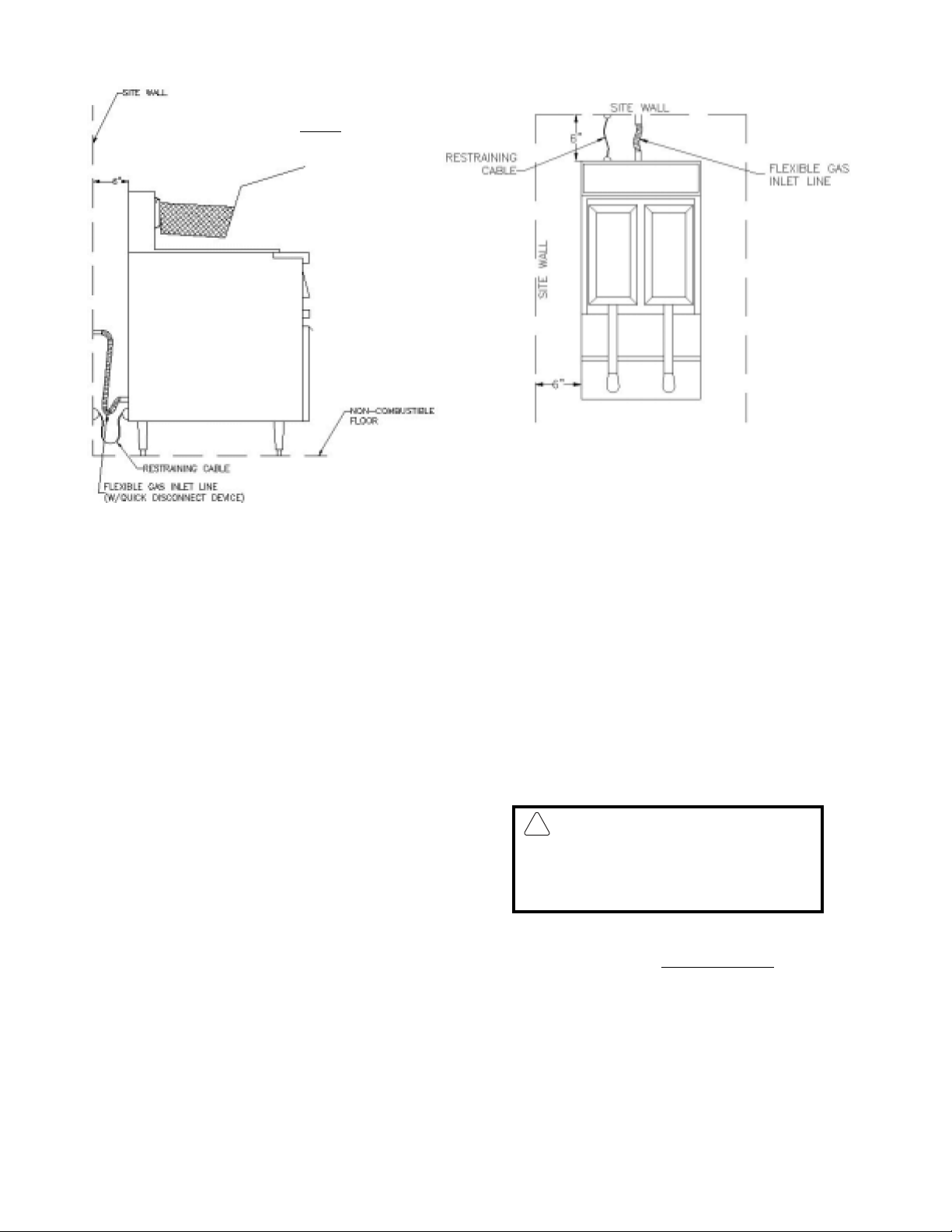

any combustible wall, as shown in Figure 2.

Install this fryer under a ventilation

hood that conducts combustion products outside the building. Venting

must comply with ANSI/NFPA 96

(latest edition).

f . Install this fryer in a location where adequate

combustion and ventilation air is available.

Keep the area directly in front of the fryer open

for adequate air flow to the burners. DO

NOT obstruct the flow of combustion and

ventilation air .

g . Keep the fryer area free and clear from

combustibles and debris.

h. Attach a restraining device to each fryer, to

prevent the unit from tipping, which could

cause splashing of hot liquid.

WARNlNG

!

From the top of the flue on

r

m

e

n

d l

l

ing in

!

r

t

w

ntroldama

g

the fryer, allow a minimum

of at least 10 inches vertical clearance beneath a

Figure 2. Fryer Site Installation R equirements

ventilating hood.

lNSTALLATlON

Install the fryer in accordance with the preceding

Code Requirements, as well as the following

Installation Requirements.

1.

DO NOT install this fryer in a mobile home,

trailer, or recreational vehicle.

Install this fryer in a location that allows it to be

2.

moved away from other adjacent appliances

for cleaning and maintenance.

NOTE: If the fryer is installed among

a row of appliances (“banked”) where

its only convenient movem ent is forward, sufficient room must be available in front to permit its separation

from adjacent appliances for cleaning

and maintenance.

REQUlREMENTS

tom of the fryer using the supplied hardware, to

prevent the fryer from tipping, wobbling or

rocking when it is in its d esired location. Refer

to the following Installation Instructions for leg

casterattach

o

CAUTlON:

MUST NOT flow in a manner tha

restricts or impedes the natura l flo

of combustion or ventilation air .

4. Confirm that the air from the ventilation hood

flowing near the fryer after installation is NOT

blowing on the rear of the fryer, to prevent

affecting the burner flames and possibly causing

co

nta

eve

Hood make-up ai

e.

formation.

3. Tightly fasten the legs (or casters) to the bot-

6

lNSTALLATlON

lNSTRUCTlONS

LEG INSTALLATION

INSTRUCTIONS

1.

Flatten the shipping carton (after unpacking the

fryer and its parts and accessories) for surface

protection during leg installation.

2. Position the side of the fryer flat on the carton,

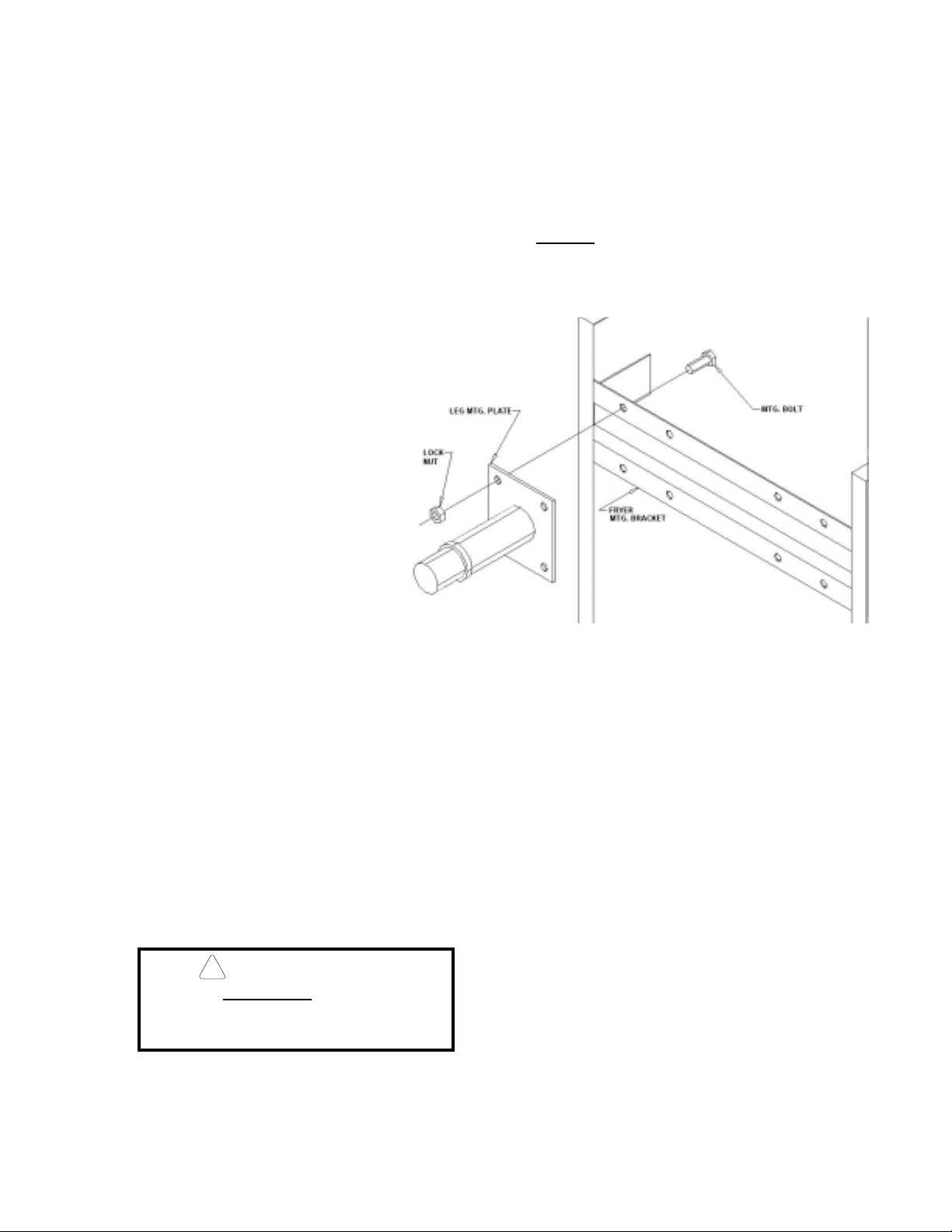

exposing the fryer bottom mounting brackets

for leg installation, as shown in Figure 3.

3.

Place the leg mounting plate flush against the

mounting bracket on the fryer bottom.

4.

Insert one mounting bol t through a flat

washer and then through the proper

hole in the fryer m ounting bracket

and through the leg mounting plate.

5.

Screw a locking nut several tur ns

onto the mounting bolt.

6. Repeat steps 4 and 5 until all four

mounting bolts for a leg are in place

with locking nuts.

LEG LEVELING INSTRUCTIONS

1.

Move the fryer to its desired location.

WARNlNG

!

The fryer MUST NOT tip, rock or wobble, to avoid splashing or spilling its HOT

frying fat contents during operation.

LEG INSTALLATION

INSTRUCTIONS

7. Tighten the four locking nuts evenly and

securely to hold the leg mounting plate against

the fryer mounting bracket.

Figure 3. Typical Leg Installation

2.

Turn the screw-type leg adjustment ends as

necessary to level the fryer , until no tipping,

rocking, or wobbling is evident.

3.

Perform the “Fryer Restraining Device

Installation Instructions.”

(Continued)

7

lNSTALLATlON lNSTRUCTlONS

p

!

CASTER INSTALLATION

INSTRUCTIONS

1. Flatten the shipping carton

(after unpacking the fryer and

its parts and accessories) for

surface protection during leg

installation.

2.

Position the side of the fryer flat

on the carton, exposing the

fryer bottom mounting brackets

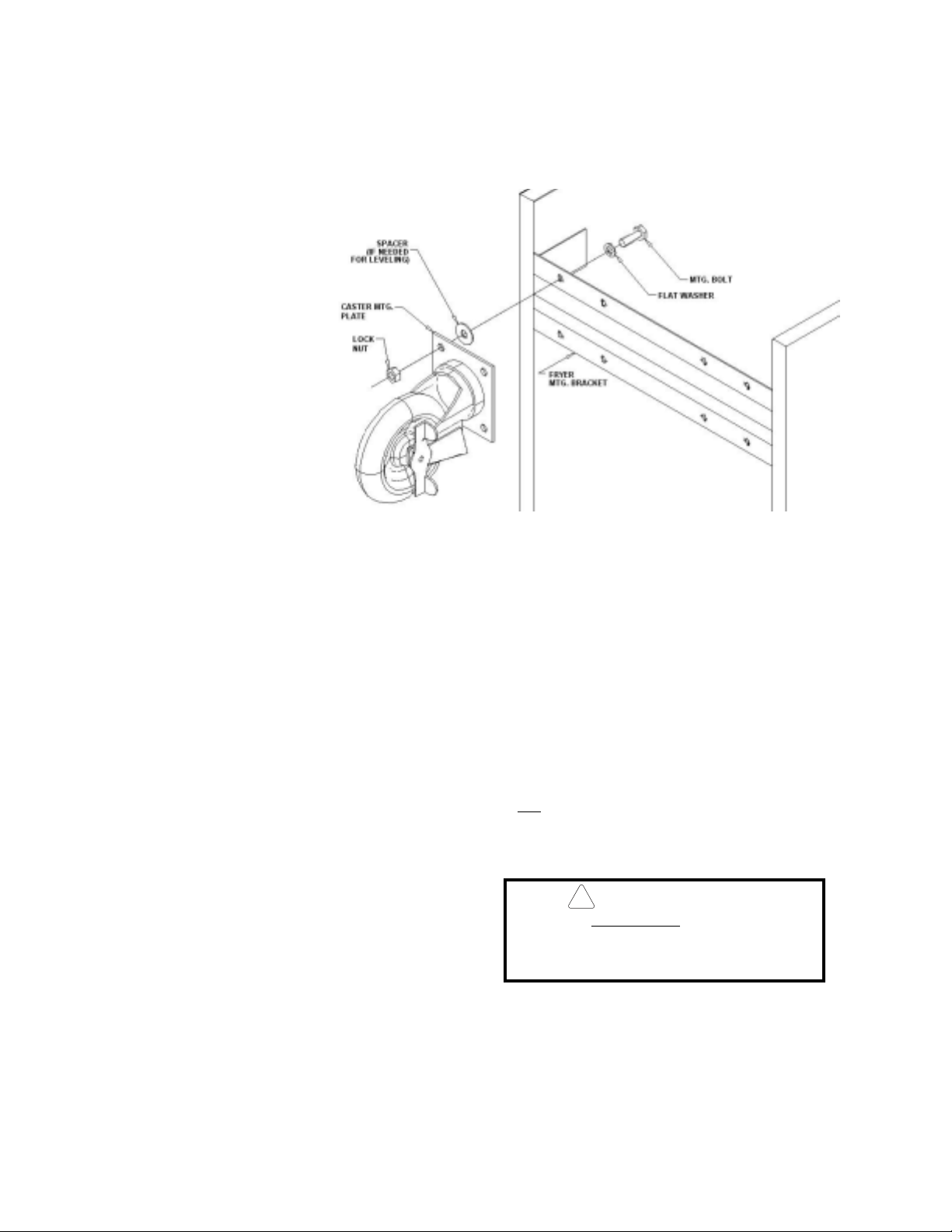

for caster installation, as shown

in Figure 4.

3. Place the caster mounting plate

flush against the mounting bracket on the fryer bottom.

4. Insert one mounting bolt

through a flatwasher (supplied) and the caster mounting

plate, then through the proper

hole in the fryer bottom mounting bracket.

5.

Screw a locking nut several turns onto the

mounting bolt.

(Continued)

Figure 4. Typical Caster Installation

CASTER LEVELING INSTRUCTIONS

6.

Repeat steps 4 and 5 until all four mounting

bolts for a caster are in place with locking nuts.

7. Tighten the four bolts evenly and securely to

hold the caster mounting p late against the fryer

mounting bracket.

8

1

. Move the fryer to its desired location.

2

. Determine whether the fryer t ends to wobble

or rock when in its desired location. If it does

not, perform step 10, then proceed to the

Fryer Operating Instructio ns. If it does,

erformsteps3through 9.

WARNlNG

The fryer MUST NOT tip, rock or wobble, to avoid splashing or spilling its HOT

shortening contents during operation.

3

. Determine which cas ter requires adjustment

and the approximate amount of change

required to level the fryer.

4

. Position the rear side of the fryer on the ship-

ping carton, exposing the bottom of the fryer

with the caster mounting plates (Figure 4).

Loading...

Loading...