Anets 14ELU14 Installation Manual

14ELU14/17

ELECTRIC FRYER

INSTALLATION & USER OPERATION MANUAL

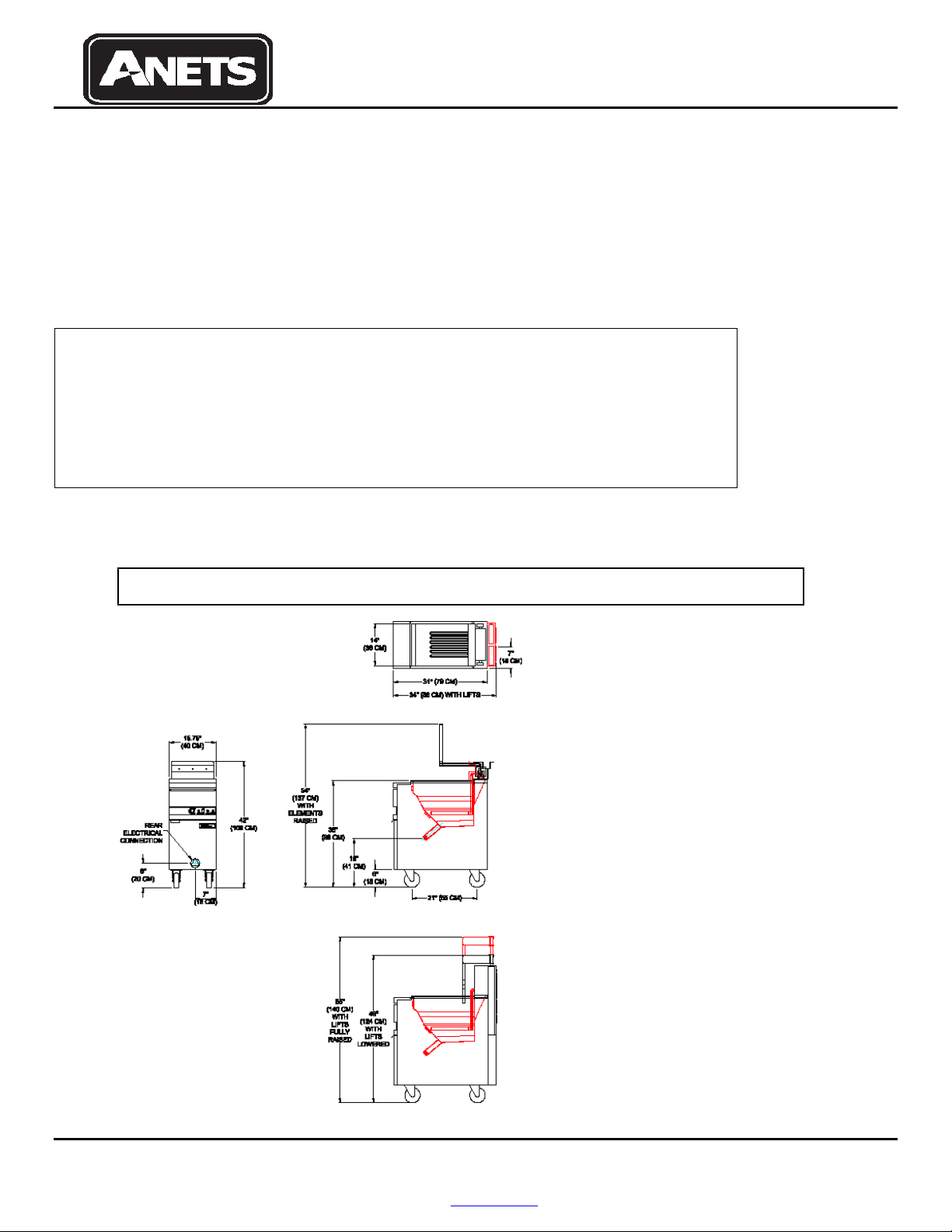

Shown with optional casters

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

KEEP THIS MANUAL IN A CONVENIENT LOCATION FOR FUTURE REFERENCE.

WARNING!

injury or death. Read the installation, operating and maintenance instructions thoroughl y

before installing or servicing this equipment

FOR YOUR SAFETY!

DO NOT store or use gasoline or other flammable vapors or liquids

in the vicinity of this or any other appliance.

Anetsberger Brothers, Inc. z 180 North Anets Drive z Northbrook, Illinois 60062

Main: 847-272-0770 z Toll Free: 800-837-2638 z Fax: 847-272-1943

www.anets.us

14ELU14/17

ELECTRIC FRYER

SHIPPING CONTAINER INSPECTION

1. Carefully examine the shipping container for external damage. If damage is noted, notify the delivery carrier immediately. Save

all packaging materials for claim examination.

2. If no external damage is noted, remove the unit from the shipping container and carefully examine it for damage. If damage is

noted, place the unit in a safe location so that it can be inspected.

SPECIFICATIONS

LINE

VOLTAGE (VAC)

POWER (kW)

CURRENT PER PHASE (Amps)

OIL CAPACITY

KETTLE

THERMOSTAT

SHIPPING WEIGHT

Please check data on your fryer specification plate.

Refer to the inside door of the unit or the end of this manual for the appliance wiring diagram.

Note: This is a commercial fryer intended for other than household use.

3NAC380V50Hz: 3NAC400V50Hz: 3NAC400V50Hz:

380 400 415

14.3 17.0 15.6 17.0 14.0

21.7 25.8 22.6 25.8 19.5

20kg (19.5 liter) Liquid shortening

Stainless steel

93°C – 190°C, Analog

80 kg

Anetsberger Brothers, Inc. z 180 North Anets Drive z Northbrook, Illinois 60062

Main: 847-272-0770 z Toll Free: 800-837-2638 z Fax: 847-272-1943

www.anets.us

14ELU14/17

ELECTRIC FRYER

INSTALLATION INSTRUCTIONS

Read all Installation Instructions carefully before starting the installation.

Failure to follow instructions may result in property damage, bodily injury or death.

IMPORTANT!

When this fryer is not properly installed, a fire may result.

To reduce the risk of fire, follow all installation instructions.

IMPORTANT INFORMATION

This appliance has been CE-marked on the basis of compliance with the EMC and Low Voltage Directive for the Countries stated on

the appliance labeling.

These appliances must be installed by a competent person in compliance with the installation a nd service instructions and the National

Regulations in force at the time. Installer attention should be paid to the following:

I.E.E. Wiring Regulations for Electrical Installations

Electricity at Work Regulations

Health and Safety at Work Act

Local Electrical Code

Users should be conversant with the appropriate provisions of the Fire Precautions Act; in particular the need for regular servicing by a

competent person to ensure continued safe and efficient performance of the appliance.

Parts, which have been protected by the manufacturer, must not be adjusted or altered.

1. This equipment is for use only in non-combustible locations. Keep the appliance area free and clear from combustibles.

2. The area directly in front of the unit must be kept open so that the unit can be serviced.

3. The appliance should be installed under a vent or exhaust hood to exhaust the cooking smoke and fumes in accordance

with the Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations, NFPA 96.

4. The unit must be installed with the proper clearances to combustible materials; refer to diagram B on the previous page.

5. Restrain the unit to prevent tipping when installed in order to avoid the splashing of hot liquid. The means of restraint may

be the manner of installation, such as connection to a battery of appliances, or installed in an alcove, or by separate

means, such as adequate ties.

6. Electrical wiring and grounding must comply with local codes, or in the absence of local codes, with the National Electrical

Code ANSI/NFPA No. 70. The installer should contact local building or fire officials concerning installation requ irements or

the need for inspection of the fryer installation. In case of stationary installation, a switch providing disconnection of all

ungrounded poles should be installed.

7. After completion of proper hook-up and installation according to code, the unit may be operated.

8. Upon receipt of the Operation Manual, the installer should instruct the responsible person(s) as to the correct operation

and maintenance of the Appliance. Particular attention should be made with regard to the safe operation of the drain valve.

Anetsberger Brothers, Inc. z 180 North Anets Drive z Northbrook, Illinois 60062

DO NOT pack required air spaces with insulation or other material.

Main: 847-272-0770 z Toll Free: 800-837-2638 z Fax: 847-272-1943

DANGER!

NOTICE !

www.anets.us

14ELU14/17

ELECTRIC FRYER

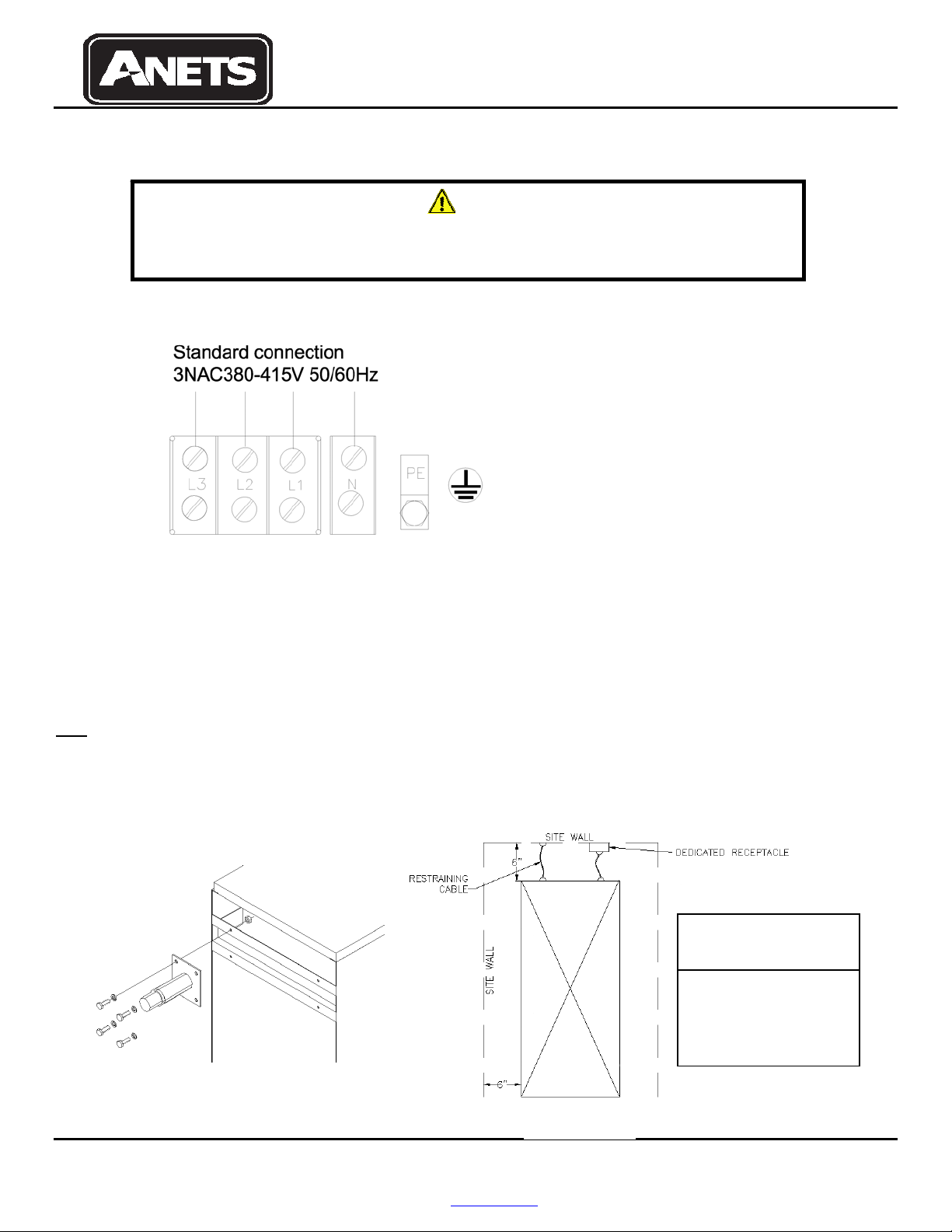

ELECTRICAL CONNECTION

The SLE-40 fryer is completely factory pre-wired. All that is required is to connect a power supply.

A terminal strip and grounding provision is located inside the controls enclosure.

Electrical connection and service should be performed by certified electrician in accordance with all

national and local electrical codes or in the absence of such codes, with the USA National Electrical

Code ANSI/NFPA No. 70. Minimum ungrounded wires size 10mm2 Cu.

NOTICE!

LEG / CASTER INSTALLATION

1. Carefully lay fryer on its back and install legs or casters as shown in diagram A below.

2. After placing unit in installation area, adjust individual leg inserts to level fryer (so unit does not rock) by turning only the

individual inserts.

3. Front casters are equipped with a brake that must be locked when operating the unit.

Note:

Permanently connected electric fryers with casters must be installed with flexible conduit and secured with a restraining

device to limit movement when installed in the United States; refer to diagram B below. Holes are available in the fryer frame

for securing the cable restraint to the fryer. The cable restraint does not prevent the fryer from tipp ing.

A minimum 6-inch clearance

is required between the unit

and the site wall(s.)

The restraining device must

be installed in a manner that

prevents strain on the

electrical connection at the

restraint’s maximum

extension.

Diagram A

Anetsberger Brothers, Inc. z 180 North Anets Drive z Northbrook, Illinois 60062

Main: 847-272-0770 z Toll Free: 800-837-2638 z Fax: 847-272-1943

www.anets.us

Diagram B

Loading...

Loading...