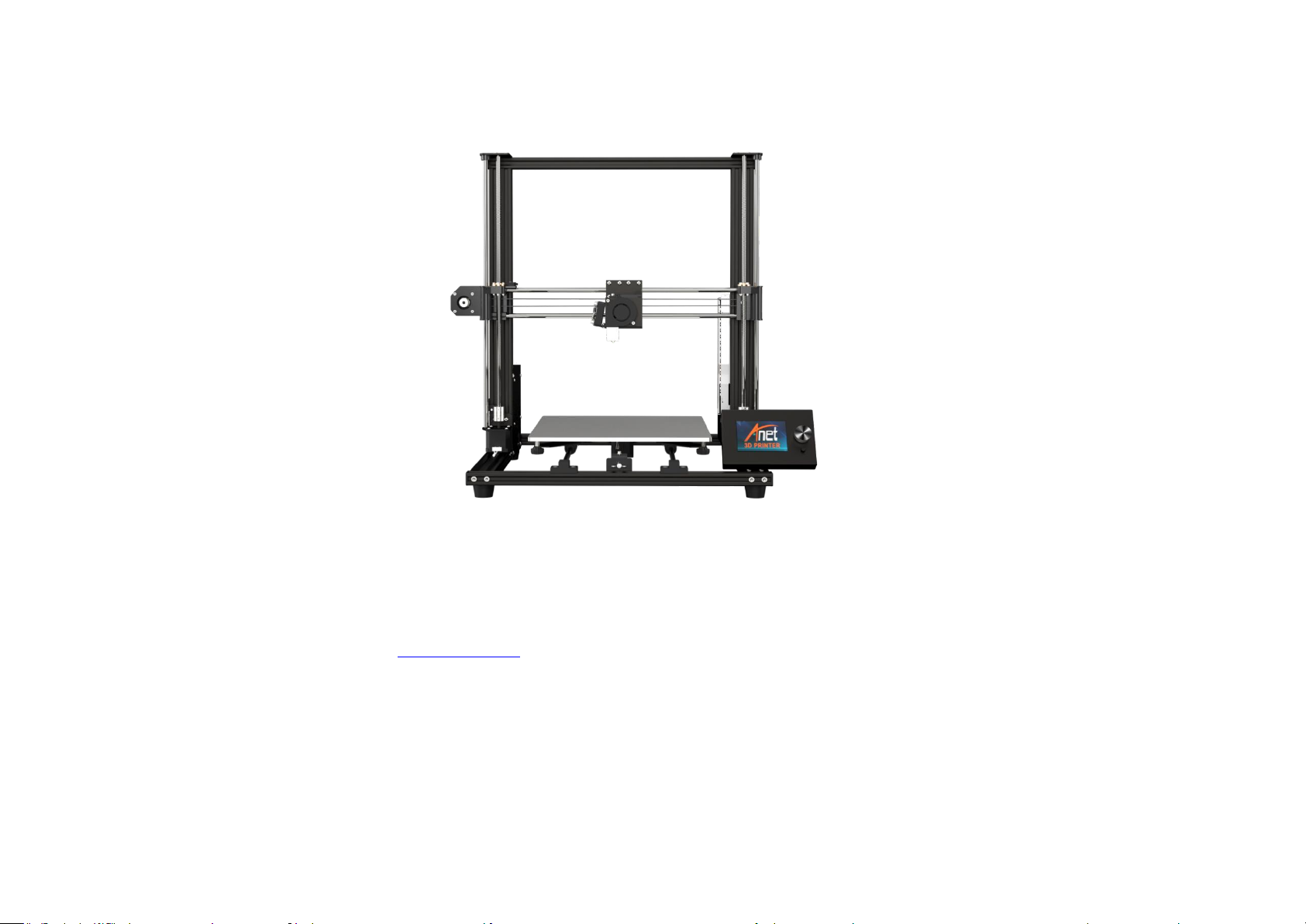

Page 1

If you have any problems with the product, you can obtain the relevant services through the

following channels :

Facebook after - sales group: www.facebook.com/groups/anet3dprintersupport

Anet official website: www.anet3d.com

After – sales service email: anet@anet3d.com

User Manual

Page 2

Preface

1. Use Instruction

2. Installation Instruction

3. Spare Parts List

4. Parameter

5. Name of Parts

6. Installation

7. Machine Function Introduction

CONTENTS

7.1 Operation Interface

7.2 First Printing

7.2.2 Machine leveling

7.2.3 Load Filament

7.2.4 Remove Model

7.2.5 Unload Filament

Page 3

Preface

Dear customer:

Thanks for choosing and using Anet 3D printer. For your convenience, please read the instructions carefully before using and

follow the instructions strictly.

Special Version:

1. All the contents in this manual have been checked carefully. If there is any misprint or misunderstanding of them, Anet reserves the

right to interpret it.

2. This user manual is for reference only and does not constitute any form of commitment.

3. It is recommended to use Anet original filament.

Page 4

1. Use Instruction

In order to prevent damage to you and others in the process of using, Please be aware of the following:

● Please do not attempt to use the machine in any way undescribed in the instructions to avoid accidental personal injury and property

damage.

● Please do not place this machine near inflammable and explosive materials or high heat sources. Please place this machine in a

ventilated, cool and dust free environment.

● Please do not place the printer on a larger vibrating or other unstable platform. The shaking of the machine will affect the printing

quality.

● Please do not replace the power line of other products during installation. Please use the original power line supplied with the

machine. The working power supply uses 115V/230V AC. The power plug must be plugged into the three holes socket with ground wire

to avoid damage to components or accidents such as fire and electric shock.

● Please do not touch the nozzle and heating bed during the printer working to prevent high temperature burns and personal injury.

● Please do not wear gloves or wrappers when operating the machine in case the movable parts cause entanglement and cutting damage

on the human body parts.

● After printing, please use the remaining temperature of the nozzle to clean up the filament on the it with the help of tools.

Do not touch the nozzle directly with your hands during cleaning to prevent scalding.

● Please often do product maintenance. In the circumstance of power off, please regularly clean the printer body with dry cloth

to wipe away dust and bonded printing materials, foreign objects on guide rails, and lubricating oil is recommended for sliding

parts, screw rods and bearing parts.

● Children under 14 years old or people above 60 years old, please use this machine under the adult people to avoid personal injury.

● Some filaments will produce slight odor but it won't make people feel uncomfortable

Page 5

● Self-disassembly or modification may cause damage or abnormal performance, and your machine will no longer enjoy warranty service.

● It is recommended to use in a well-ventilated environment. Please cut off the power supply after using.

2 Installation Instruction

●Please make sure the packing is intact before receiving the goods.

●After unpacking, please check carefully whether the parts list is consistent with the physical parts.

●If you have any problems, please contact your supplier or Anet in time.

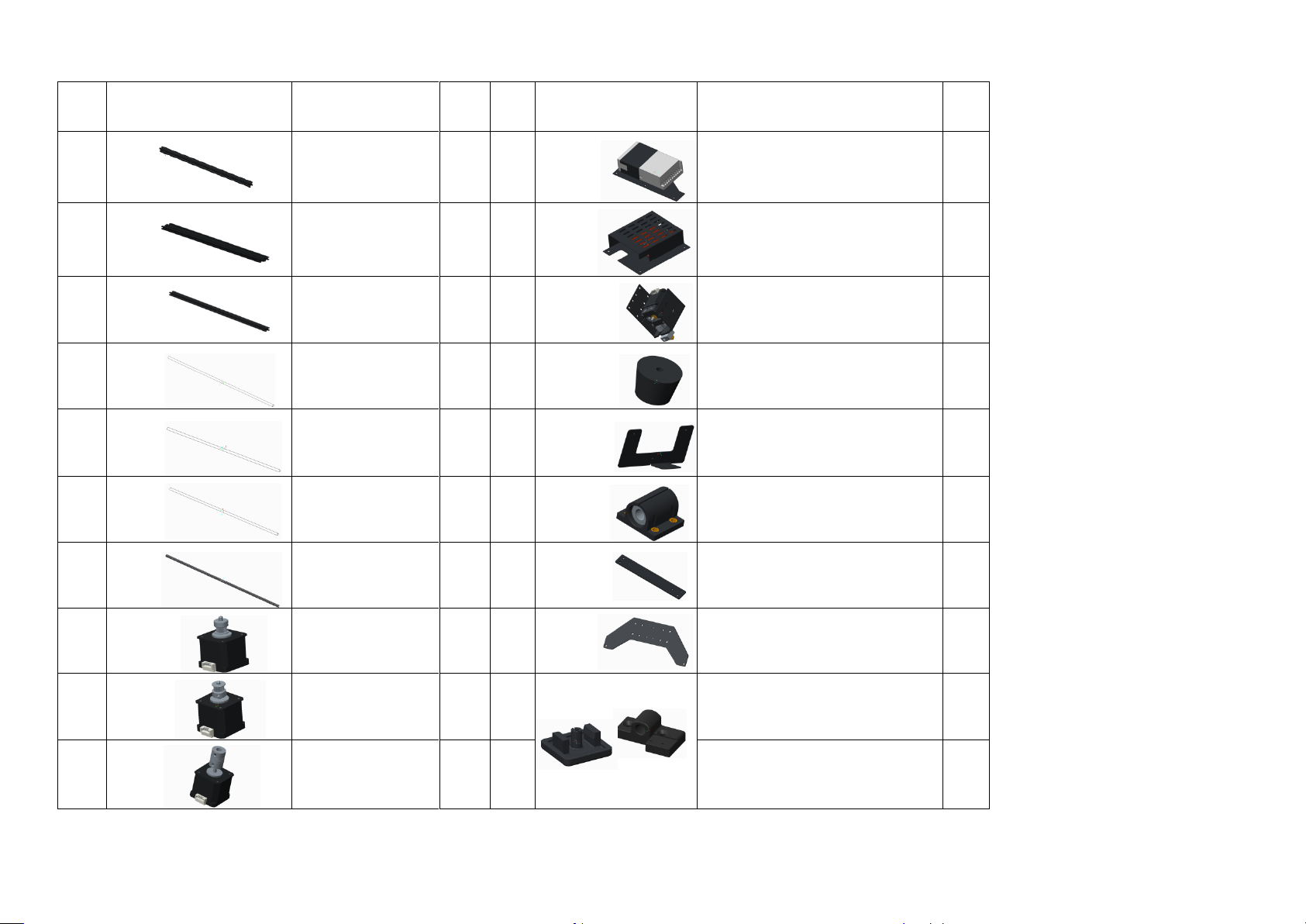

3 Spare Parts List

Page 6

A8 Plus Parts List 1

No.

Picture

Name

Qty.

No.

Picture

Name

Qty.

1

X axis aluminum

profile 472mm

3

11

Power supply kit

1

2

Y axis aluminum

profile 422mm

2

12

Mainboard kit

1

3

Z axis aluminum

profile 500mm

2

13

Extruder kit(Black)

1

4

X axis guiding rod

496mm

2

14

Environmentally friendly rubber

pillar washer

4

5

Y axis guiding rod

442mm

2

15

Display screen

base

1

6

Z axis guiding rod

486mm

2

16

Linear bearing kit

7

7

Z axis screw rod

462mm

2

17

Heating bed shelf

1

8

X axis motor

1

18

Heating bed support

2

9

Y axis motor

1

19

Leading rod –limit switch

mounting block with pulley

1

10

Z axis motor

2

20

End cap

6

A8 Plus Parts List 2

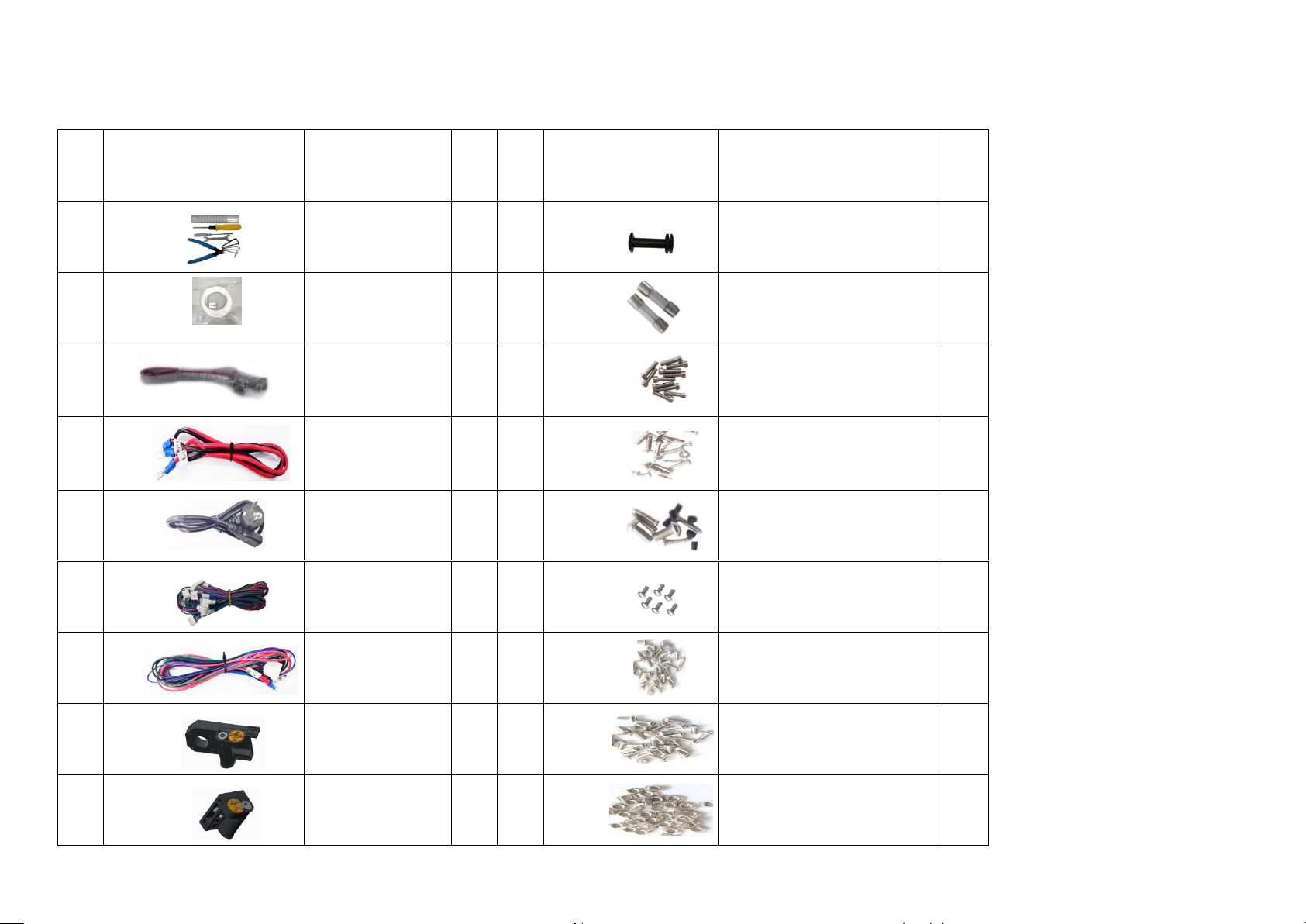

Page 7

No.

Picture

Name

Qty.

No.

Picture

Name

Qty

.

21

Guiding rod shaft

sleeve

2

31 Limit switch

3

22

Leading rod fixed

block

3

32 Z axis limit switch holder

1

23 5015 air blower bag

1

33

Limit switch line

3

24 Wind mouth

1

34 GT2 belt bag 2m

1

25 Fan bag

1

35 Z1 axis motor fixed plate

1

26

Spare parts

1

36 Z2 axis motor fixed plate

1

27

Corner bracket

2

37 Z axis guiding rod fixed plate

2

28

Y axis belt bearing fixed

kit

1

38 Y axis motor fixed plate

1

29

Black winding pipe

bag

1

39

Power outlet

1

30

Rubber finger cot

10

40

M4*25 cross recessed

countersunk screw

M4*14 cylindrical head screw

M4 hand screw

10

Page 8

A8 Plus Parts List 3

No.

Picture

Name

Qty.

No.

Picture

Name

Qty.

41

Tool bag

1

52 Filament holder kit 2

1

42 PLA filament*10m

1

53 Protective tube bag(10A/15A)

2

43

FPC grey ribbon line

bag 1000mm

1

54

Screw bag 2

(M3*20/M3*25 、M5*20/M5*30)

25

44

Red and black belt

U-shaped cross line

(Double head)

1

55

Screw bag 3

(KM3*10/KM4*14/KM2*10/KM3*6)

19

45

Power line

1

56

Screw bag 4

(M4*10/ KB2.3*12/ M3*4)

14

46

A8 plus motor line

bag

1

57

Screw bag 5

(M3*6、M3)

20

47

Heating bed line

1

58

Screw bag 6

(M4*6)

26

48

Left Z axis screw

rod nut support

1

59

Screw bag 7

(M4*8)

34

49

Right Z axis screw

rod nut support

1

60

Screw bag 8

(M4 T nut)

33

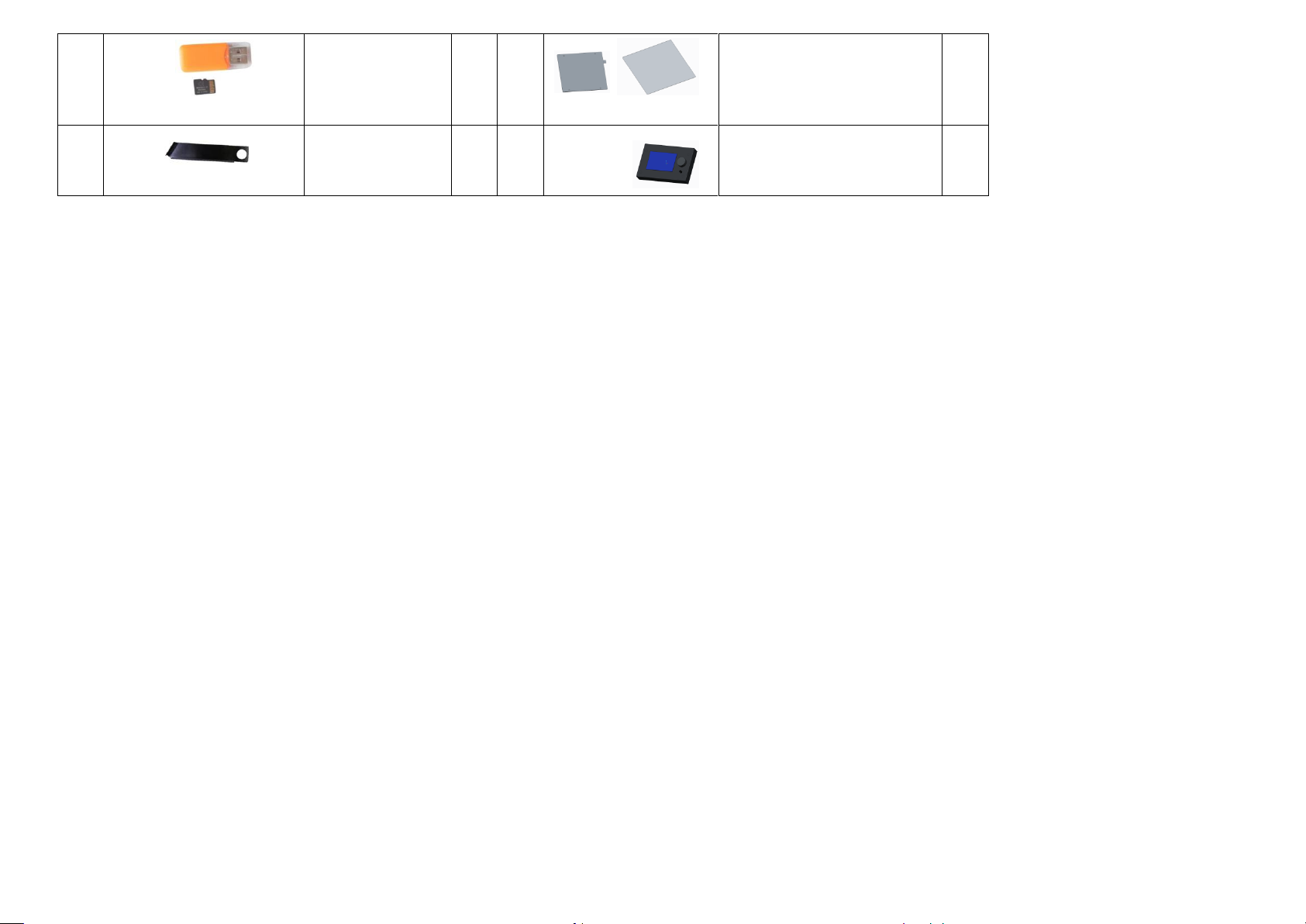

Page 9

50

A8 Plus electronic data

(TF card, reader)

1

61

Heating bed 300*300*3mm

Tempered glass

2

51

Filament holder kit 1

1

62 Display screen

1

Page 10

Model:A8 PLUS

Nozzle diameter: 0.4mm

Layer precision:0.1-0.4mm

Product dimension:612*462*573mm

Printing speed: 40-120mm/s

Product weight:10±0.1kg

XY axis position precision:0.015mm

Packing dimension:580*375*175mm

Z axis position precision:0.004mm

Packing weight:12.1±0.1kg

Printing material: PLA, ABS, HIPS etc.

Build volume:300*300*350mm

Filament tendentiousness:PLA

LCD:12864 LCD

Filament diameter:1.75mm

Offline printing: Yes

Software language: English

Support file format:G-Code、Gco

Moulding support automatically: Yes

Operating systems:Windows, MAC

Slice software:Cura

Environmental requirements:

Temperature 0-40℃ Humidity 5-80%

4 Product Parameter

Page 11

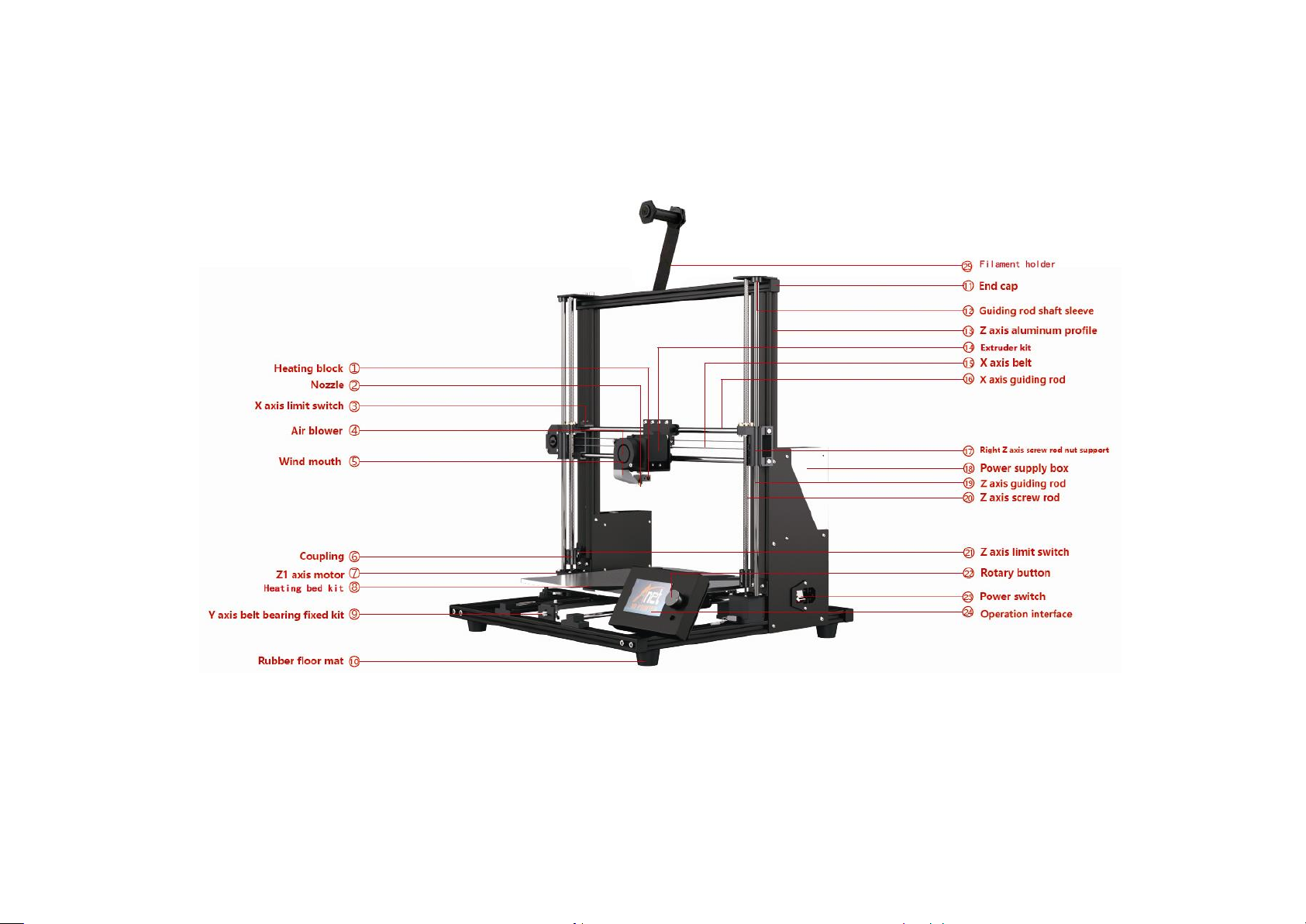

5. Name of Parts

Page 12

No.

Name

Qty.

1

X axis aluminum profile 472mm

2

2

Y axis aluminum profile 422mm

2

3

End cap

4

4

Environmentally friendly rubber pillar washer

4

5

M5*20 socket hexagon screw

12

M5*20

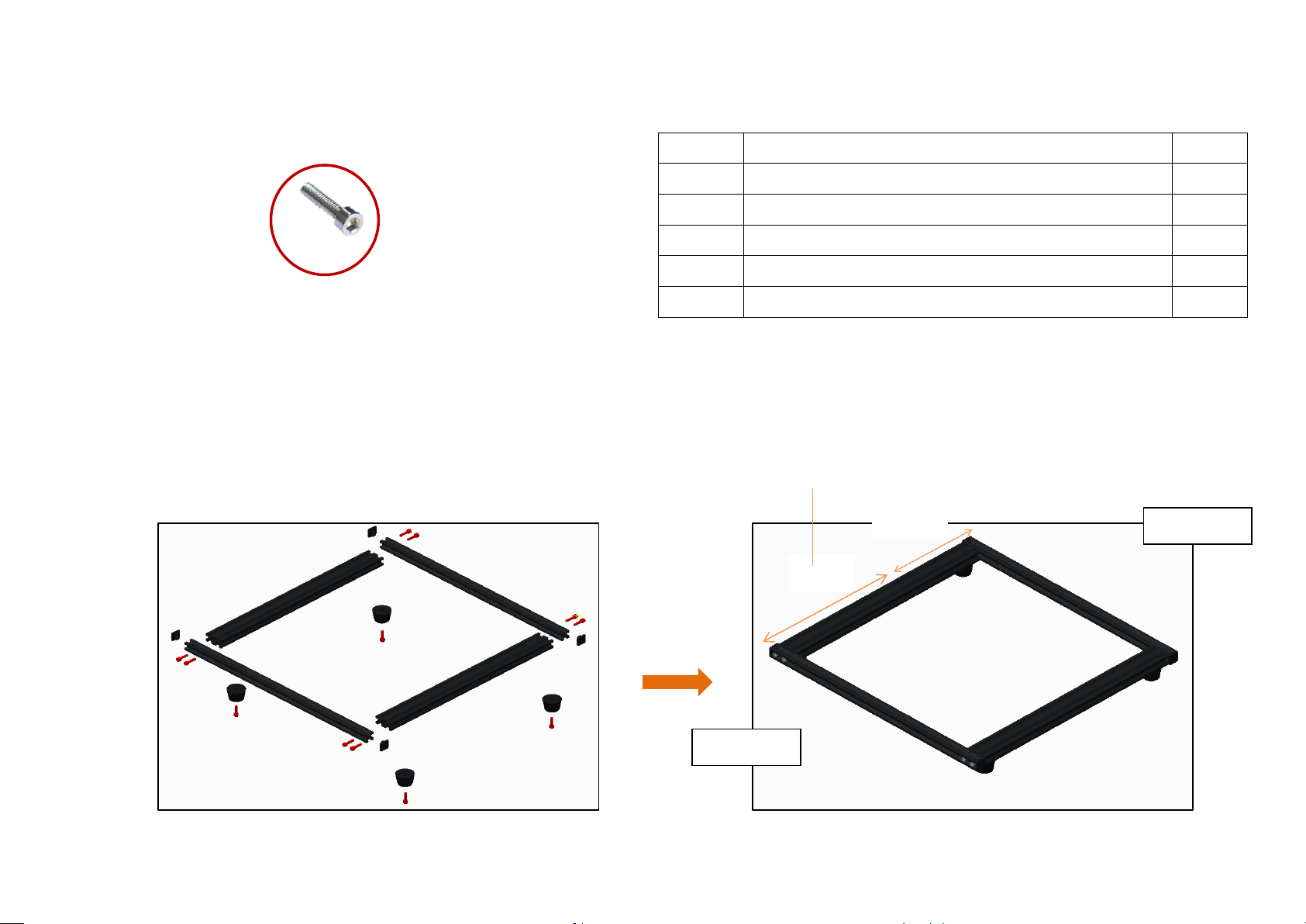

Before assembly

After assembly

Front X axis

Rear X axis

The Y axis is separated from the hole position, the

front section is long, and the rear section is short.

Long

Short

Step 1

Page 13

No.

Name

Qty.

1

Y axis guiding rod 442mm

2

2

Linear bearing kit

4

3

Leading rod fixed block

3

4

Leading rod –limit switch mounting block with pulley

1

5

Limit switch without pulley

1

6

2

Before assembly

After assembly

Step 2

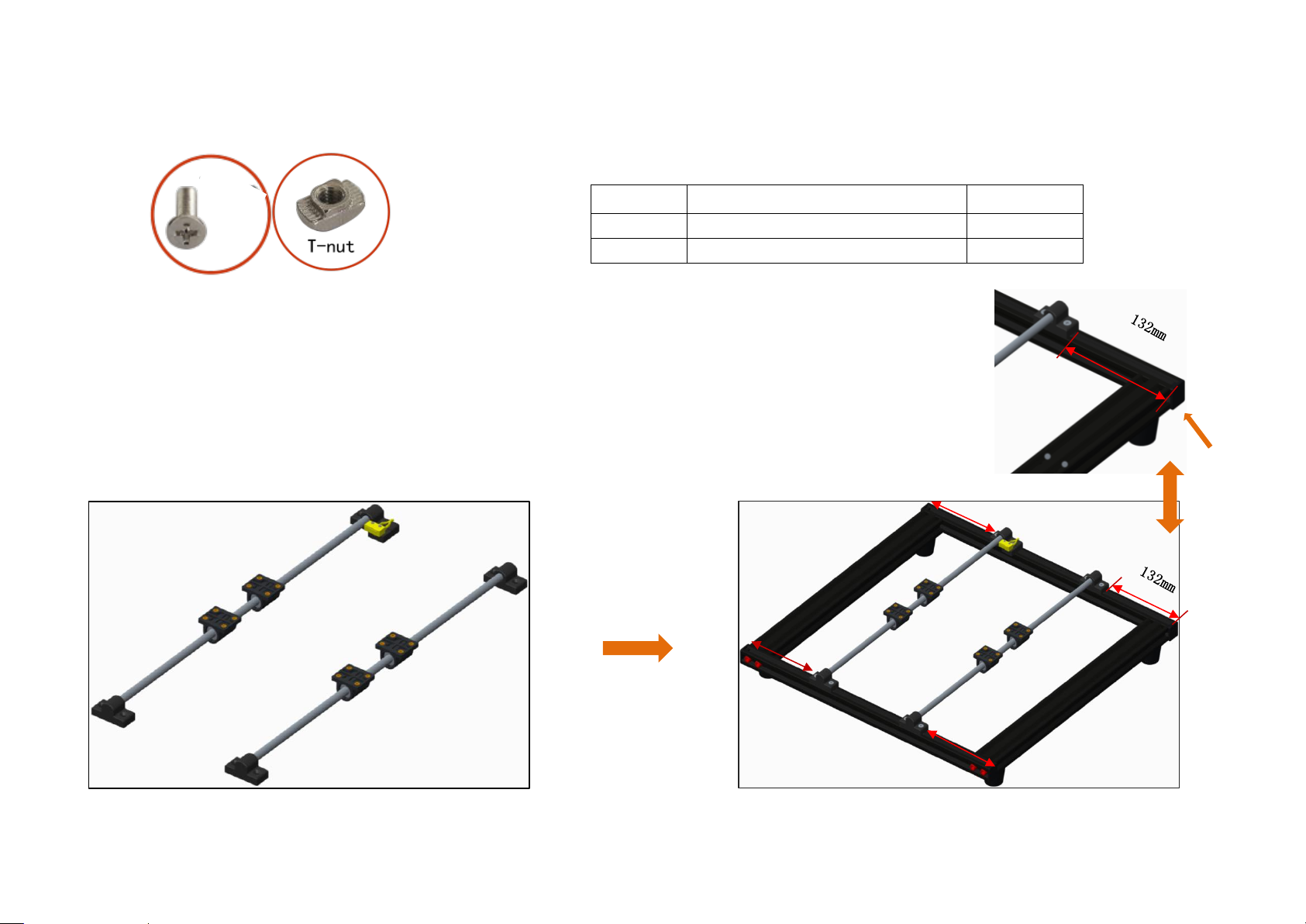

Page 14

No.

Name

Qty.

1

M4*14

8

2

T – nut

8

Attention: The size of the double arrow in the drawing is

132 mm ( the distance from the center of the leading rod fixed

block to the edge of the profile ), which is controlled

during assembly.

M4*14

Before assembly

After assembly

End cap

Step 3

Page 15

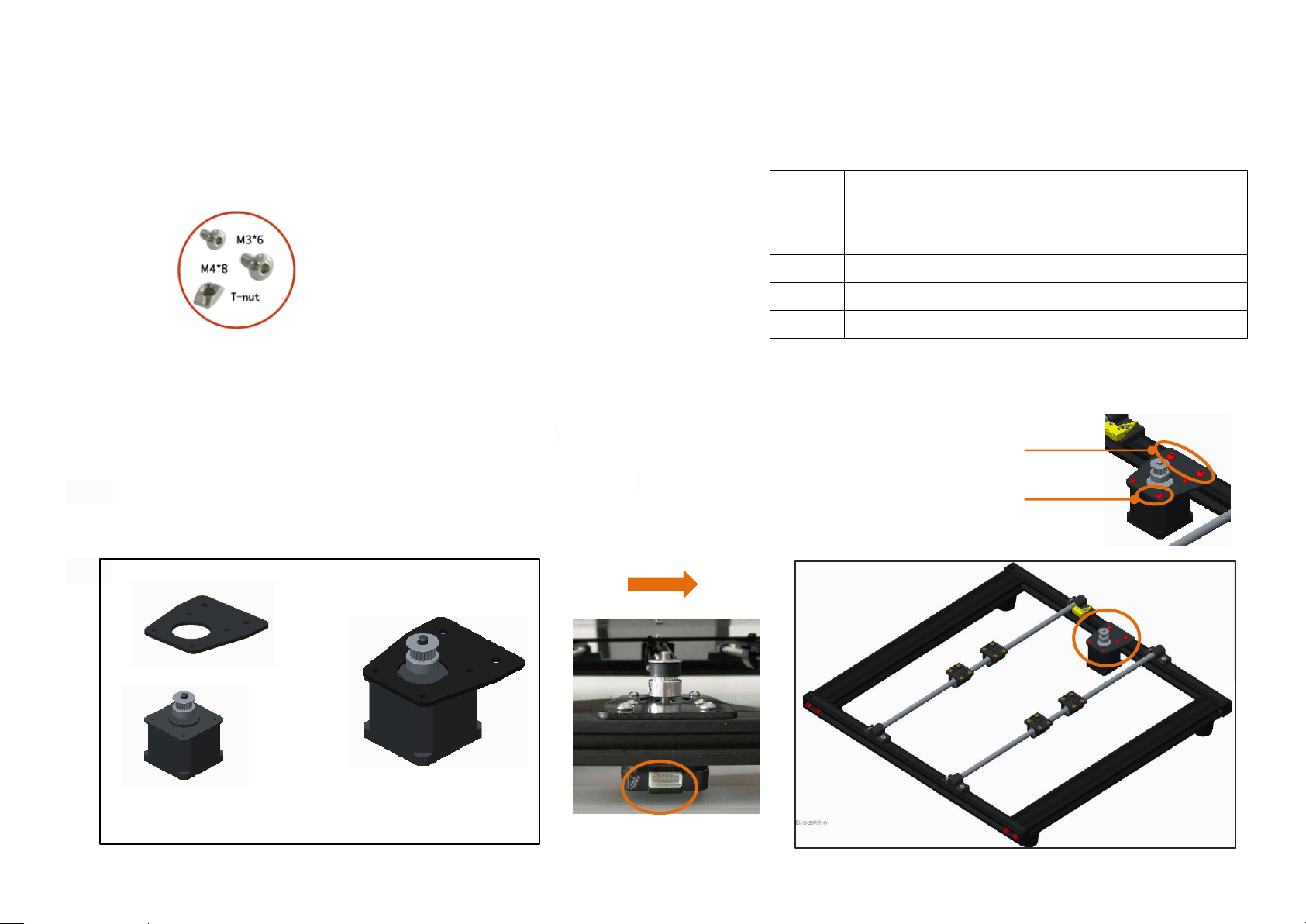

No.

Name

Qty. 1 Y axis motor fixed plate

1

2

Y axis motor kit

1 3 socket hexagon screw M3*6

4

4

socket hexagon screw M4*8

2

5

M4 T – nut M4

2

M3*6

M4*8

Note: 1. Please fix it in the center of rear X axis aluminum

profile

2. M4 * 8 screws pass through the Y axis motor fixed plate,

screw on the T - nut ( entering 2 - 3 thread teeth ), put

it into the X - axis profile slot, tighten the screw ( the

nut will rotate 90 degrees during this process ), and corner

bracket will be fixed.

Note: Fix the Y axis motor fixed plate to the Y axis motor

kit with 4 M3*6 screw

Before assembly

After assembly

Step 4

Page 16

No.

Name

Qty. 1 Y axis belt bearing fixed kit

1

2

M4*8 Socket hexagon screw

2

3

T-nut M4

2

1.ease fix it in the center of front X axis aluminum profile.

( entering 2 - 3 thread teeth ), put it into the X - axis profile slot, tighten

the screw ( the nut will rotate 90 degrees during this process ), and corner bracket

will be fixed.

Before assembly

After assembly

Step 5

Page 17

No.

Name

Qty.

1

Hotbed support

2

2

Hotbed shelf

1

3

M4*8 Socket hexagon screw

22

4

Cylindrical head screw M4*14 Black

2

Fix M4*14 screw in the left hole

Before assembly

After assembly

Step 6

Page 18

No.

Name

Qty. 1 Belt

1 2 Belting

2

Note: The belt is cut to a proper length and fixed on the two M4 * 14 crews in step 6,

Please tighten the belt and press it to see if it is loose.

Before assembly

After assembly

Step 7

Page 19

No.

Name

Qty.

1

M4*25

4

2

Spring

4

3

Plastic hand screw

4

4

Heating bed300*300*3mm

1

5

Toughened glass

1

6

Clips

4

M4*25

Attention: Fix the hot bed on the heating bed support in sequence as shown in the picture.

M4*25

Heating bed

Spring

Hotbed support

Plastic hand screw

Before assembly

After assembly

Step 8

Page 20

No.

Name

Qty. 1 Right Z axis screw rod nut support

1

2

X axis motor kit

1

3

Limit switch with pulley

1 4 Socket hexagon cylindrical head screw M3*20

4

5

Cross recessed countersunk screw

KB2.3*12

2

The motor connection port is facing

down, as shown in the figure

Before assembly

After assembly

Step 9

Page 21

No.

Name

Qty.

1

Linear bearing

3

2

496mm X axis guiding rod

2 3 Right Z axis screw rod nut support

1

Before assembly

After assembly

Step 10

Attention: Please install in the direction shown in the picture.

Page 22

No.

Name

Qty. 1 Extruder kit

1

Loosen the nut and exit

the extruder

1. Loosen the nut and separate the extruder from the L-shaped black aluminum .

2..Remove the 2 M3*6 screw and use them later.

Before disassembly

After disassembly

L-shaped black aluminum

Extruder

M3*6

Step 11

Page 23

Step 12

No.

Name

Qty.

1

L-shaped aluminum holder

1

2

Socket hexagon screw M4*6

12

Fix the L-shaped aluminum holder in the linear bearing

Before assembly

After assembly

Page 24

Step 13

No.

Name

Qty.

1

Extruder

1

安装后

Put the extruder into the L-shaped

aluminum holder and tighten the nut

Before assembly

After assembly

Page 25

Step 14

No.

Name

Qty.

1

Fan fixed plate

1

2

Fan

1

3

Air blower

1

4

Wind mouth

1

5

M3*15 Socket hexagon screw M3*15

4

6

Ø3 Gasket

4 7 Socket hexagon screw M3*6

2 8 Socket hexagon screw M3*18

2

M3*6

M3*15+ φ3

M3*18

Fix the fan fixed plate in the L-shaped aluminum holder with 2 M3*6 screw

Before assembly

After assembly

Page 26

Step 15

No.

Name

Qty.

1

Belt

1 2 Belt adjusting fixing block

1 3 Belt adjusting sliding block

1 4 M3*25 Socket hexagon screw

1

5

M3 nut

1

6

M3*10 Countersunk screw

2

Flanged Bearing

Gear

Connect the gear and flanged bearing with a belt ,and sleeve the

belt adjusting fixing block and sliding block, after fixing ,press

the belt to see if it is loose.

M3 nut

M3*25

The fixing block is fixed with M3*10 countersunk

screw

Before assembly

After assembly

Page 27

Step 16

No.

Name

Qty. 1 Z1 axis motor fixed plate

1 2 Z2 axis motor fixed plate

1

3

Z axis motor kit

2

4

Socket hexagon flat round head screw M3*6

8

5

Socket hexagon flat round head screw M4*8

4

6

M4 T-nut

4

M3*6

Please install as shown in the figure, pay attention to the

direction relationship between the circular hole and the motor.

Before assembly

After assembly

Page 28

Step 17

No.

Name

Qty.

1

Z axis aluminum profile 500mm

2

The T-nut is inside the profile clamping groove

Z1 in the left ,Z2 in the right.

Z1

Z2

Before assembly

After assembly

Page 29

Step 18

No.

Name

Qty.

1

486mm

Z axis guiding rod 486mm

2

2

462mm

Z axis screw rod 462mm

2

.

Note: Rotate the screw rod clockwise down to the bottom, and

then lock the self-contained top tightening screw

462mm*2

486mm*2

Lock the self-contained top tightening screw

Before assembly

After assembly

Page 30

Step 19

No.

Name

Qty.

1

Guiding rod shaft sleeve

2

2

M3*4 Black jackscrew M3*4

4

3

Z axis guiding rod fixed plate

2

4

M5*30 Socket hexagon cylindrical head

screw

4

5

End cap

2 6 X axis aluminum profile 472mm

1

M5*30

Guidi

ng rod

shaft

sleev

e

Z axis

guiding

rod

fixed

plate

End

cap

Note: Fix the guiding rod shaft sleeve with M3*4 black jackscrew

M3*4

Before assembly

After assembly

Page 31

Step 20

No.

Name

Qty. 1 M4*8 socket hexagon screw

4

2

M4 T-nut

4

3

M5*20

Socket hexagon cylindrical head screw

4

Vertical Frame

Chassis

Attention: Put the vertical frame on the chassis, align it with the

holes on the aluminum profile of the chassis

, and fix to on the chassis with 4 M5 * 20 screws.

Corner bracket installation: Make the screws

through the corner bracket, screw on the T - nut

( 2 - 3 thread tooth ), put it into the profile

slot ( inside ), tighten the screws with a wrench,

and the T - nut will rotate 90 degrees and the

corner bracket will be fixed.

Corner bracket installation diagram

Before assembly

After assembly

Page 32

Step 21

No.

Name

Qty. 1 Power supply kit

1 2 Mainboard kit

1

Remove the M3 * 6 socket hexagon screw

for fixing the power supply, split the

power supply and power supply fixing

frame, and retain the 3 inner hexangular

set screws.

Split the motherboard kit, retain the 4 m3 * 6 socket hexagon screws, and then install the M4 *

8 socket hexagon screws and T- nuts in the 3 holes on the mainboard.

The circle is an enlarged view

( side ) of the T - nut

installation

Before assembly

After assembly

Page 33

Step 22

No.

Name

Qty. 1 Power outlet

1

2

Red and black with U-shaped line

(Double head)

1

3

M4*6 socket hexagon screw

4

3

T-nut M4

4 4 M3*6 socket hexagon screw

5

Note: The wiring diagram of the switch power supply, 1.2.3, are respectively the

input wire L ( brown ), the zero line N ( blue ) and the ground wire ( yellow green ),

which are connected to the AC socket wire. 4.5.6 are the output negative COM ( black

- ), 7.8.9 are the output positive V + ( red + ), please make sure the wiring correct

to prevent danger!

1

2

3

4 5 6

7

8

9

M3*6

The circle is an

enlarged view

( side ) of the T -

nut installation

Before assembly

After assembly

Page 34

Step 23

No.

Name

Qty.

1

KM2*10

2

2

M4*8 cross recessed countersunk screw

2

3

T-nut M4

2 4 Limit switch (without pulley)/Limit switch support

1

5

A8 plus motor line bag

1

6

Heating tube6*20mm( with line 1.5m)

1

7

Hotbed line

1

8

FPC grey ribbon line bag

2

Limit switch support

M4*6

Limit switch

Z1 axis

Z2 axis

Installation diagram of

limit switch support

70mm

The installation position of the Z - axis limit

switch is 80 mm away from the Y - axis profile

Page 35

Step 24

No.

Name

Qty.

1

Motor line bag

5 2 FPC grey ribbon line bag

1

3

Limit switch line bag

3

Fix mainboard on the groove

Please pass the lines(with -A word) of extruder, X

axis limit switch and X axis motor through the

square hole on the mainboard.

Pass all other wires through the holes

under the mainboard (The cable with the

word "-A" is connected to one end of the

mainboard.)

The cable with the word "-A" is connected to one end of the

mainboard.

Page 36

Step 25

Name

Cable label

Mainboard

port

Name

Cable label

Mainboard port

X axis motor

X-Motor-A

X

X axis limit switch

X axis limit switch line-A

S-X

Y axis motor

Y-Motor-A

Y

Y axis limit switch

Y axis limit switch line-A

S-Y

Z1 axis motor

Z1-Motor-A

Z1

Z axis limit switch

Z axis limit switch line-A

S-Z

Z2 axis motor

Z2-Motor-A

Z2

Heating bed

Heating bed-A

BED

E axis motor

E-Motor-A

E

Thermistor-A

B-T

Extruder

Extruder thermistor-A

E-T

TF card

TF card port

Extruder

Extruder heating tube-A

END

power supply

Power supply line-A

+ -

Display screen

LCD grey ribbon cable

-A

LCD

Fan

Fan with line-A

FAN2

Display screen

J3 grey ribbon cable-A

J3

Air blower

Air blower with line-A

FAN1

According to the schematic diagram of the line port and the label of the wiring, find the corresponding wiring and

plug in all the wiring, the cable with the word "-A" is connected to one end of the mainboard.

Wiring sheet:

1. Except that the electronic wire shown in step 6 passes through the jack at the upper end of the mainboard, the remaining

electronic wires are all pulled out from the holes under the mainboard, and the machine is connected from below the machine

to avoid affecting the operation of the machine.

Page 37

2. When all wiring is plugged in, please remove the zip ties on the black belt, plug in the power line, turn on the machine for

There is no need to separate

positive and negative electrodes

(+ red line , - black line )

Heating bed thermistor

Heating bed

TF card port

trial operation(please refer 7.2 First Printing ), and then install the mainboard shell after everything is normal.

Page 38

Step 26

No.

Name

Qty.

1

Display screen

base

1

2

Display screen

1

3

T-nut M4

4

4

M4*6

4

5

Magnet

3

magnet

Display bas

M4*6

LCD

J3

Note: 1. The LCD / J3 wiring of the display screen corresponds to the socket screen printing ( LCD / J3 ) on the control panel.

Please do not connect the wrong wiring.

2. Put the display screen directly on the magnet after installation to complete the installation of the display screen and

components.

Before assembly

After assembly

Page 39

Step 27

No.

Name

Qty. 1 Filament holder

1

2

M4*8

2

3

T-nut

2

Before assembly

After assembly

Page 40

Step 28

Front

Back

Final Schematic diagram

Page 41

7 Machine Function Introduction

Printing

Printing time

Status bar

Rotary button

(left and right for selection,

press for confirmation)

Reset button

Speed adjustment ratio

Target temperature

Actual temperature

Actual temperature of heating bed

Target temperature

XYZ axis coordinates

7.1 Operation Interface

Page 42

7.2 First Printing

TF card

TF card installation completed

7.2.1 Install TF Card

Insert TF as shown in picture 2

7.2.2 Machine leveling

1. Auto home operation: Adjust the spring around the heating bed to the tightest ( counterclockwise ), press the rotary button

to enter the main menu, select“Prepare”→“Auto home”, the machine begins to move toward the position of the limit switch until

it stops moving after touching the limit switch.

2.Disable steppers operation: Press the rotary button to enter the main menu, select“Prepare”→“Disable steppers”.

3.Manual leveling:Move the nozzle to the heating bed, and observe the distance between the nozzle and the heating bed from the

front of the machine. If the distance between the nozzle and the four corners of the heating bed is 0.1mm (the thickness of a piece

of A4 paper, A4 paper can pass through the gap and feel slight resistance), leveling is not required. If the distance between the

Page 43

nozzle and the four corners of the heating bed is greater than or less than 0.1mm, adjust according to step 4.

The distance between the nozzle

and heating bed

Attention: turning the nut counterclockwise is tight

and turning the nut clockwise is loose.

spring

Nut

A4 paper can pass through the distance between the

four corners of the heating bed and nozzle, and feel

slight resistance.

4. Adjust the distance: Fine - tuning the "distance" to make its size about 0.1mm meet the printing requirement. Move the nozzle

to the other three corners of the heating bed, and sequentially adjusting the spring compression of the four corners of the heating

bed in one direction (clockwise or counterclockwise), so that an A4 paper (about 0.1mm) can pass through this distance and feel a

slight resistance, and there is no scratch on the platform when moving the extruder.

Page 44

The heating bed and extruder reach

7.2.3 Load Filament

1. Perheat Machine

Before loading filament, the machine needs to be preheated. The following pictures illustrates PLA filament as an example, and

the operation is as follows.

Operating method: Press the knob→“ Prepare”→“ Preheat PLA”→“Preheat PLA”, the machine starts to perheat ( the main interface

shows that the machine is perheat ).

。

Note: If you want to print with ABS filament, you must select " Preheat ABS" for preheating.

Page 45

2 Load Filament

Load filament automatically:

1. A roll of PLA filament: Filament specifications: Diameter :1.75mm; Material: PLA ;Printing temperature: 200-230℃;

2.Please press rotary button →“ Prepare”→“ Change filament”, the main interface will display “Heating nozzle Please wait……”,the

interface will display “Wait for start of the filament change” after the nozzle temperature rises to the target temperature →

“Wait for filament unload ” →“Insert filament and press button to continue…” → then please press rotary button;

3. Straighten up the filament (or cut the filament into bevels with plier),then pass the filament through the extruder;

4.Meanwhile the main interface will display “Wait for filament load” →“Wait for filament extrude”,please click “Resume print”

to start printing;

5. If the nozzle has filament outflow, the installation of filament is successful. If the installation of filament is not successful,

please select“Extrude more”to re-load.

Attention: The function of automatic material advance and retreat is carried out according to the steps of material return first and material feed later, when the

first printing has not started installing filament yet, please wait for 1 - 3 minutes. After the interface displays “Insert filament and press button to continue”,

insert filament into the extruder for automatic feeding.

Page 46

Heating nozzle

Please wait…

Wait for start of the filament change

Wait for filament unload

Insert filament and press button to continue…

Wait for filament load

Wait for filament extrude

Resume print

Extrude more

Page 47

3 Printing

1. After leveling is completed and the filament is installed successfully, press the rotary button to enter the main menu, press

" Print from SD" → " Main" and select the file under " Main" to start first printing.

2. In the process of printing, if you want to pause printing, press the rotary button to enter the main menu, press " Prepare"

→ " Pause print" to pause printing, and press " Resume print" to resume printing.

3. If you want to stop printing during printing, press the rotary button to enter the main menu, press " Prepare" → " Stop print"

to stop printing, press the reset button to resume normal operation of the machine and select to reprint the model.

Page 48

7.2.4 Remove Model

Wait for start of the filament change

Wait for filament unload

Heating Nozzle

Please wait…

Please remove the model by hand after printing .

7.2.5 Unload Filament

Automatic unload filament (taking PLA as an example)

Please press rotary button →“ Prepare”→“ Change filament”, the main interface will display “Heating nozzle Please wait……”,wait

for 1-2 mins ,the interface will display“Wait for start of the filament change”after the nozzle temperature rises to the target

temperature →“Wait for filament unload ” ,the machine automatically unload filament ,then pulls out the filament in the vertical

direction and unload the filament.

Page 49

Loading...

Loading...