Anest Iwata DDP 120 B WB.TE, DDP 90 E, DPS 120 C.TE, DPS 120 CN.TE, DPS 120 C WB.TE Instruction, Use And Maintenance Manual

...

Instruction Use and Maintenance Manual

GB

DIAPHRAGM PUMP SET

DDP 120 B Series

DDP 120 B.TE (Aluminium)

DDP 120 BN.TE (Stainless Steel)

DDP 120 B WB.TE (Anodized Aluminium)

DPS 120 C Series

DPS 120 C.TE (Aluminium)

DPS 120 CN.TE (Stainless Steel)

DPS 120 C WB.TE (Anodized Aluminium)

DDP 90 E Series

DDP 90 E.TE (Aluminium)

DDP 90 EN.TE (Stainless Steel)

DDP 90 E WB.TE (Anodized Aluminium)

DPS 90 G Series

DPS 90 G.TE (Aluminium)

DPS 90 GN.TE (Stainless Steel)

DPS 90 G WB.TE (Anodized Aluminium)

This ANEST-IWATA diaphragm paint pump complies to ATEX regulations 94/9/EC.

Protection level: II 2 GX Suitable for use in Zones 1 and 2.

X marking:

Any static electricity discharge from the pump is to be diverted to the ground through

the grounding wire which is included in this product.

CONTENTS

USE OF THE MANUAL ………………………………………………………………………………………3

WARRANTY ……………………………………………………………………………………………………3

1. SAFETY WARNING …………………………………………………………………………………………4

2. TRANSPORT AND HANDLING ……………………………………………………………………………6

2.1 TRANSPORT …………………………………………………………………………………………………6

2.2 TRANSPORT WITH CARDBOARD PACKAGING ………………………………………………………6

2.3 HANDLING ……………………………………………………………………………………………………6

2.4 TEMPORARY STORAGE ……………………………………………………………………………………7

2.5 CHECK ON THE PURCHASED PRODUCT ………………………………………………………………7

3. PRODUCT IDENTIFICATION ………………………………………………………………………………8

3.1 PLATE DATA …………………………………………………………………………………………………8

4. THECNICAL SPECIFICATIONS ……………………………………………………………………………9

4.1 DPS MODELS DIMENSIONS & WEIGHTS ………………………………………………………………9

4.2 DPS_MODELS ……………………………………………………………………………………………… 10

4.3 SAFETY SYSTEMS ……………………………………………………………………………………… 12

4.4 SAFETY PICTOGRAMS ………………………………………………………………………………… 12

4.5 WORKABLE PRODUCTS ………………………………………………………………………………… 13

5. PUMP OPERATION ……………………………………………………………………………………… 14

5.1 OPERATION DESCRIPTION …………………………………………………………………………… 15

6. INSTALLATION AND STARTING ……………………………………………………………………… 15

6.1 CONDITIONS FOR INSTALLATION …………………………………………………………………… 15

6.2 INSTALLATION …………………………………………………………………………………………… 15

6.3 INSTALLATIONS OF DPS MODELS …………………………………………………………………… 16

7. USE …………………………………………………………………………………………………… 19

7.1 USE …………………………………………………………………………………………………… 19

7.2 SAFETY RULES DURING USE ………………………………………………………………………… 19

7.3 CLOTHES …………………………………………………………………………………………………… 19

7.4 PREWASH ………………………………………………………………………………………………… 19

7.5 STARTING ………………………………………………………………………………………………… 20

7.6 DAILY INTERRUPTIONS ………………………………………………………………………………… 20

7.7 WRONG AND DANGEROUS USES …………………………………………………………………… 21

7.8 PRESSURE RELEASE PROCESS ……………………………………………………………………… 22

8. MAINTENANCE AND INSPECTIONS …………………………………………………………………… 23

8.1 GENERAL NOTES ………………………………………………………………………………………… 23

8.2 SAFETY RULES DURING MAINTENANCE …………………………………………………………… 23

8.3 RECOMMENDED SCHEDULED OPERATIONS ……………………………………………………… 23

8.4 DIAPHRAGM PUMP DISASSEMBLY FROM IT BASE SUPPORT ………………………………… 23

8.5 LID, CONNECTOR &AIR OPERATING VALVE DISASSEMBLY …………………………………… 24

8.6 DIAPHRAGM SET DISASSEMBLY ……………………………………………………………………… 24

8.7 DIAPHRAGM SET REASSEMBLY ……………………………………………………………………… 24

8.8 INTAKE AND EXHAUST VALVE DISASSEMBLY …………………………………………………… 25

8.9 INTAKE AND EXHAUST VALVE REASSEMBLY …………………………………………………… 25

8.10

PAINT REGULATOR MAINTENANCE, DISASSEMBLY & ASSEMBLY

8.11

PAINT REGULATOR SPARE PARTS

8.12 PAINT FILTER MAINTENANCE ………………………………………………………………………… 27

9. TROUBLE SHOOTING …………………………………………………………………………………… 28

10. SPARE PARTS LIST ……………………………………………………………………………………… 31

10.1 DPS DIAPHRAGM PUMP SET ASSEMBLY …………………………………………………………… 31

10.2 DDP DIAPHRAGM SPARE PARTS LIST ……………………………………………………………… 32

10.3 AIR OPERATING VALVE SPARE PARTS LIST ……………………………………………………… 33

10.4 PAINT FILTER SET ……………………………………………………………………………………… 34

10.5 AIR REGULATOR SET …………………………………………………………………………………… 34

10.6 ACCESSORIES …………………………………………………………………………………………… 34

10.7 SUCTION HOSE, SUCTION PIPE & DRAIN HOSE ………………………………………………… 35

10.8 2-WAY REGULATOR SET ……………………………………………………………………………… 35

11 DISMALTING ……………………………………………………………………………………………… 36

11.1 EQUIPMENT STORAGE ………………………………………………………………………………… 36

11.2 DISMALTING ……………………………………………………………………………………………… 36

2

……………………………………………………………………… 27

…………………………………… 26

Use of the This use and maintenance manual is an integral part of the equipment and must be easily available

Manual to the staff in charge of its use and maintenance. The user and the personnel in charge of mainte-

nance must be aware of the contents of this manual.

Read the manual carefully before starting ANY ACTIVITY involving the equipment, including its

handling. For easier references the instruction manual has been divided into the following sections:

WARNING

THE ORIGINAL CONFIGURATION OF THE EQUIPMENT MUST NOT BE CHANGED.

Upon receiving the equipment make sure that:

- The supply corresponds to the order specications.

- In case of non-compliance, inform our Technical Service immediately.

WARNING

ALL RIGHTS ARE RESERVED. THE REPRODUCTION OF ANY PART OF THIS MANUAL, IN ANY

FORM, IS STRICTLY FORBIDDEN WITHOUT PRIOR WRITTEN AUTHORIZATION OF THE

MANUFACTURING COMPANY.

Warranty All the products of ANEST IWATA Srl have a one-year warranty from invoice date, unless otherwise

stated in writing. The warranty covers all manufacturing faults and material defects. Any spare part

replacement or repair operation is covered only if it is carried out by our technicians at our servicing

shops.

The warranty covers no intervention of our technicians during installation or dismantling operations.

If for practical purposes one of our technicians is sent to the premises, the time plus extra for tra

velling and expenses will be invoiced at current prices. Our warranty does not cover direct or indirect

damage to people or property caused by our equipment. It covers no repair operations carried out by

the customer or by a third party, either.

THE WARRANTY DOES NOT COVER:

- Damage or breakdown caused by improper use or assembly.

- Damage or breakdown caused by the use of spare parts different from the original or recommen ded ones.

- Damage or breakdown caused by bad preservation.

- Components subject to wear (described in the spare parts list).

WARRANTY FORFEITURE:

- In case of delayed payment or other breaches of contract.

- Whenever changes or repairs are carried out on our equipment without our prior authorisation.

- Whenever the serial number is damaged or removed.

- When the damage is caused by improper use or functioning, or if the equipment falls, is bumped or

by other causes not due to normal working conditions.

- Whenever the unit is disassembled, tampered with or repaired without the authorisation of

ANEST IWATA S.r.l.

All repair interventions carried out under warranty do not interrupt its duration.

All disputes will be settled in the court of justice of Turin.

3

1. SAFETY WARNING

• Be sure to read and understand this instruction manual. The operator shall be fully conversant

with the requirements stated within this instruction manual including important warnings, cau tions and operations.

• Wrong operation (mishandling) can cause serious bodily injury, death, re or explosion.

SAFETY FACTOR

• Pay special attention to items which are shown by the below marks and symbols.

WEAR PROTECTIVE GEAR

During painting, be sure to wear protective gear such as glasses, mask or gloves

to avoid serious injury caused by paints or solvents which might enter your eyes

or you might inhale.

BE CAREFUL ABOUT VENTILATION

Use it in a well-ventilated area. Painting or cleaning in a narrow area with insufficient ventilation

can cause organic solvent intoxication or explosion due to sprayed mist of paint or solvent which

catches re.

If you feel any abnormality during operation, consult a medical doctor immediately.

CONTACT IS FORBIDDEN

If paint leaks, never try to stop it by hand. In that case please proceede as follows:

1. Follow the instructions about relaese pressure procedure, provided in section 7.8.

2. Check the leackage causes.

3. Replace or repair the faulty component.

BE CAREFUL ABOUT BODILY INJURY

Paint can enter human body directly through eyes, mouth or skin. It is very dangerous. If you feel

any abnormality or receive any injury, consult a medical doctor immediately.

LIMIT OF FLUID TO BE USED

Do not use it for food products.

KEEP AWAY FROM ORIGINS OF EXPLOSIONS OR FIRES

Never use near sparks or open re. Especially the following will cause re

• Open ames such as cigarettes, pipes.

• Electric goods such as stoves, lamps or heates.

4

CONNECT GROUNDING

Securely ground pump, spray gun, workpieces and containers containing paint or solvent.

Be sure to use ground wire set supplied with pump set.

Connect it to ground to have continuous grounding.

Insufficient grounding will cause explosion or re if exposed to a spark of electricity.

BE CAREFUL ABOUT EXPLOSION

Be sure to use paint pump at less than max. uid working pressure (section 4.).

Use at more than max. uid operating pressure can cause explosion of pump resulting in great

danger.

Never bend hose with a radius of less than 50mm. Never put heavy things on it (in order not to

damage the hose). If done, hose can explode causing great danger.

Securely connect hose to avoid leak and looseness. If hose is disconnected during operation,

hazardous hose movement and paint ejection will cause severe bodily injury.

Never use cracked, damaged, bent, crushed or distorted hose. Leakages from such a hose can

cause great danger during operation.

WARNING!

Never alter the equipment

When you replace parts, be sure to use our genuine parts. If not done, it can cause insufficient

performance or failure.

Install or keep pump free from rain or splashes. If not done, it can cause pump failure

Install pump on a horizontal surface

Install pump free of paint mist. Attached paint mist etc., can cause pump failure

Use clean air ltered through dryer and lter (ner than 50 microns).If not done, it can cause pump

failure.

* We shall not be responsible for any injury or damage caused by disregard of warnings, cau-

tions or instructions.

IMPORTANT

5

2. TRANSPORT AND HANDLING

2.1 TRANSPORT

To transport the equipment only the systems described below can be used. In any case make sure that

the transport and lifting device can bear the weight of the equipment with its packaging.

WARNING

ALWAYS KEEP THE PACKAGING IN VERTICAL POSITION.

WARNING

IT IS ADVISABLE THAT THE STAFF IN CHARGE OF HANDLING THE EQUIPMENT WEAR

PROTECTIVE GLOVES AND SAFETY SHOES.

WARNING

WHILE LIFTING OR HANDLING THE EQUIPMENT OR ANY OF ITS COMPONENTS CLEAR THE

WORKING AREA. LEAVE ALSO A SUFFICIENT SAFETY AREA AROUND THE EQUIPMENT TO

AVOID DAMAGING PEOPLE OR OBJECTS WHICH COULD BE THERE.

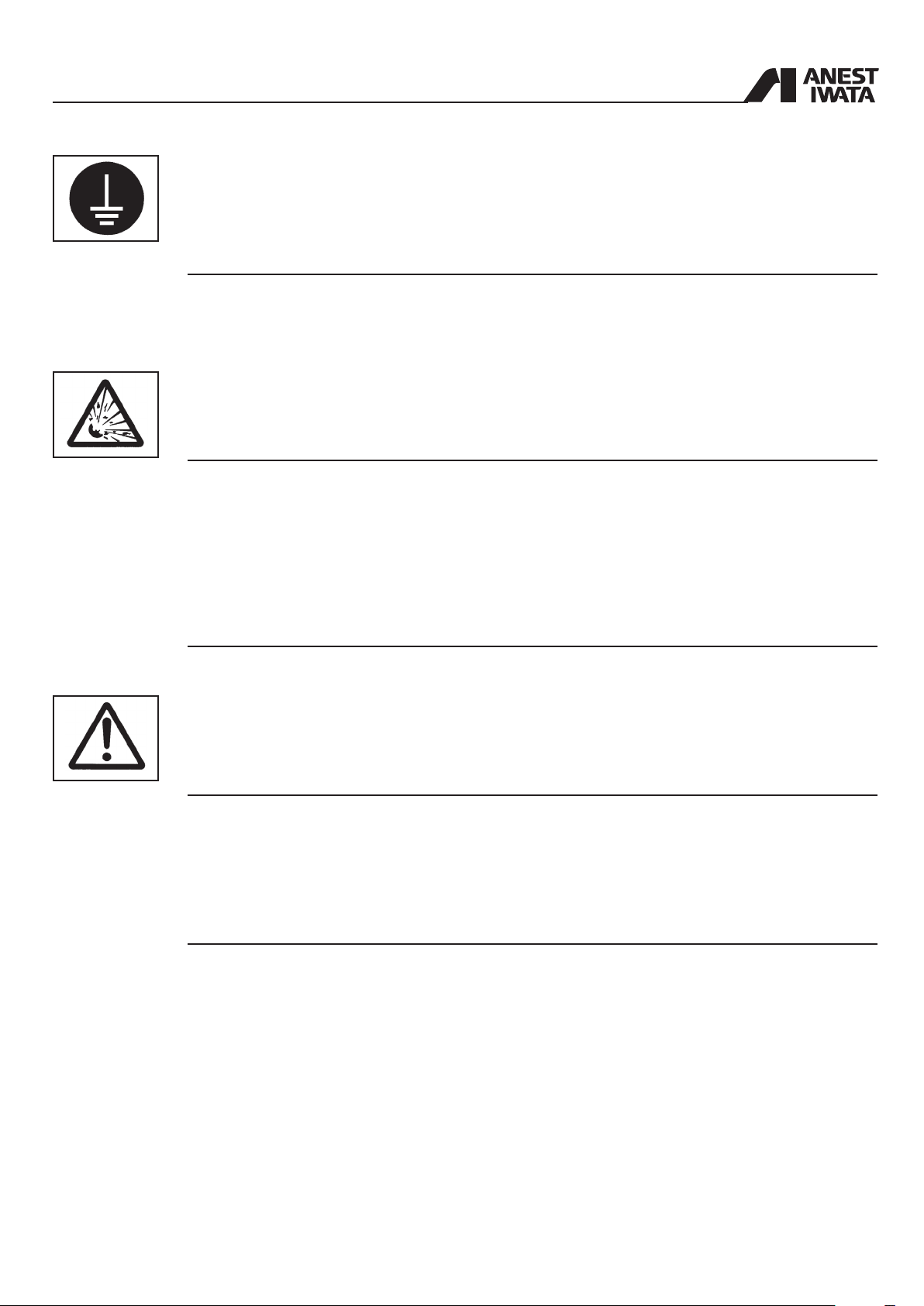

2.2 TRANSPORT WITH CARDBOARD PACKAGING

The equipment is put inside a cardboard packaging and wrapped with some shockproof material.

2.3 HANDLING

WARNING

FOLLOW THE INSTRUCTIONS ON THE PACKAGING BEFORE HANDLING AND OPENING IT.

HANDLING BY MEANS OF HANDLE HANDLING BY MEANS OF TROLLEY

6

To handle the cardboard packaging use a trolley.

2.4 TEMPORARY STORAGE

In case of storage, make sure the equipment is not put in places with an excessive humidity.

During transport and storage make sure the temperatures between 0 and 40° C are not exceeded.

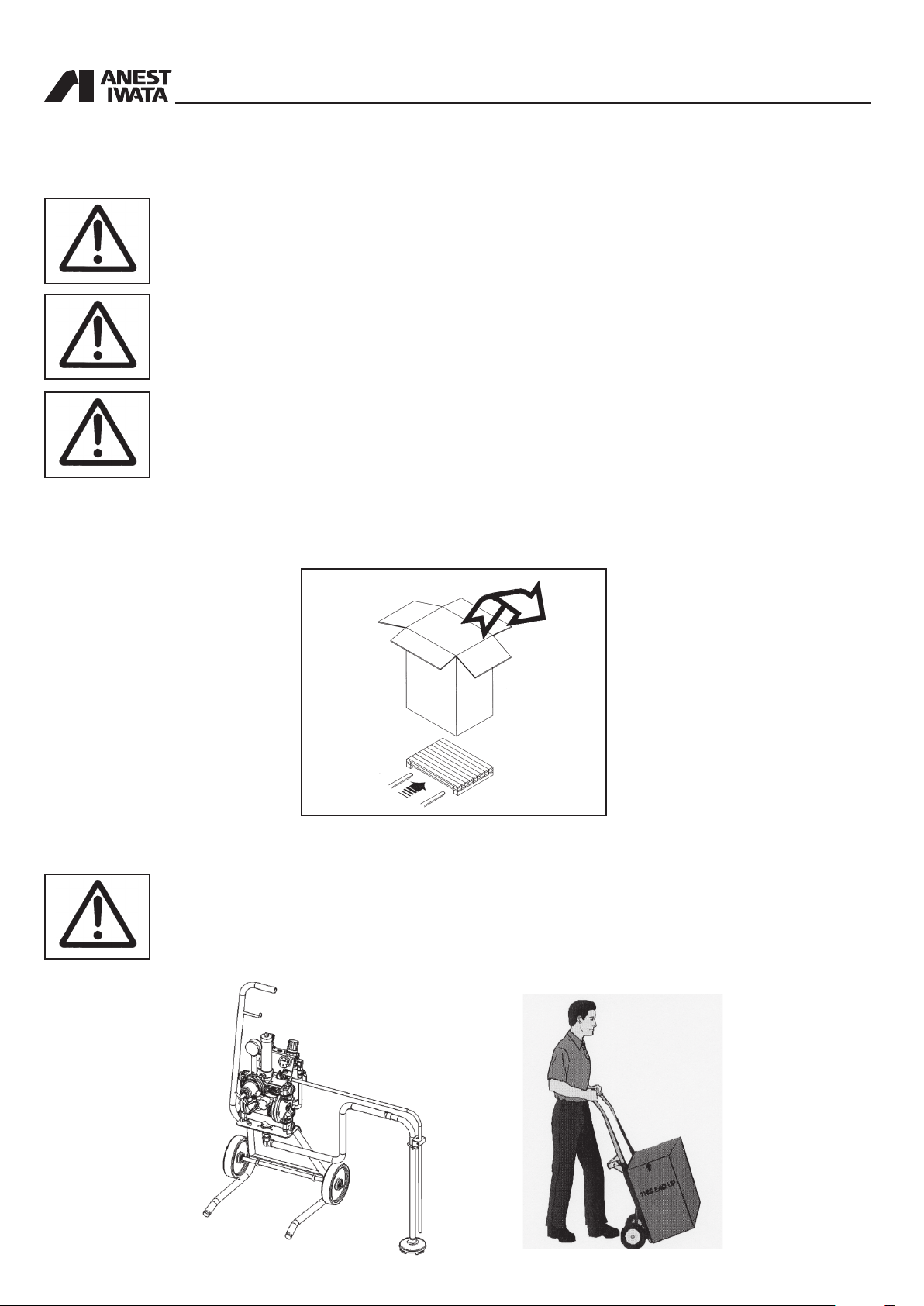

2.5 CHECK ON THE PURCHASED PRODUCT

or storage. Also check that all standard components are inside the packaging.

When you receive and before using the pump, make sure it has not been damaged during transport

Stand Cart

All Models

Tank Wall

PR-5BL 1

Drain hose set 1

*Cart set - 1 - -

Supply lid - - 1 -

Hose band 3 3 - 3

Suction hose set with lter 1 1 - 1

Dip tube with lter - - 1 -

**Gravity hopper set - 1 - -

* Cart set 1 Handle

4 Washer

4 Snap pin

2 + 4 “U” Bolt _ Hex. nut

1 Bolt with Hex. hole (M6)

1 Bolt with Hex. hole (M8)

1 Axle

2 Solid tire

1 Hex. nut (M6)

1 Hex. nut (M8)

** Hopper set 1 Gravity hopper

1 Suction hose

7

3. PRODUCT IDENTIFICATION

3.1 PLATE DATA

The manufacturer’s identication plate is applied on the diaphragm pump (see picture below).

It must not be removed at all, even if the equipment is resold. For any communication with the manu facturer always mention the serial number written on the plate itself.

Model

Max air working pressure

Construction year

The case of DPS 120-1C.TE

Serial number

• Equipment group : II

• Category: Gas 2G (Suitable for use in zones 1 and 2)

• Max. surface temperature: temperature class T6

• X marking : Any static electricity discharge from the pump is to be diverted to the ground through

the grounding wire which is included in this product.

8

4. TECHNICAL SPECIFICATIONS

Pump Version DPS-120C.TE DPS-90G.TE

PUMP Type DDP-120B DDP-120BN DDP-120B-WB DDP-90E DDP-90EN DDP-90E-WB

Paint Passages Aluminum

Air Working

Pressure Range

Stainless

Steel

Anodized

Aluminum

22~100 psi

Aluminum

1.5~7 bar

Stainless

Steel

Anodized

Aluminum

Max. Fluid

Working Pressure

Air Inlet G 1/4”

Fluid Outlet G 3/8”

Fluid Inlet G 1/2”

Paint Delivery

at 30 cyc/min

Paint Delivery

at 200 cyc/min

4.5 lt./min 1.5 lt./min

30lt./min 10lt./min

Paint viscosity

Working

Temperature

Compressor

(required power)

Noise Level 70 dB(A) 68 dB(A)

0.4~1.5 kW 0.4~0.75 kW

7 bar (100 psi)

85sec/Ford#4

5~40°C

4.1 DPS MODELS DIMENSIONS and WEIGHT

STAND TYPE TANK MOUNT TYPE

Dimensions (L_W_H) [mm]

DPS-120-1C.TE

DPS-120-1CN.TE

DPS-120-1C-WB.TE

DPS-90-1G.TE

DPS-90-1GN.TE

DPS-90-1G-WB.TE

409x358x806

409x358x764

Weight [kg]

10.5

13.9

10.5

9.6

11.7

9.6

DPS-120-2C.TE

DPS-120-2CN.TE 12.1

DPS-120-2C-WB.TE 9.6

DPS-90-2G.TE

DPS-90-2GN.TE 10.8

DPS-90-2G-WB.TE 8.7

Dimensions (L_W_H) [mm]

357x312x798

357x312x756

Weight [kg]

9.6

8.7

CART TYPE WALL MOUNT TYPE

Dimensions (L_W_H) [mm]

DPS-120-3C.TE

DPS-120-3CN.TE

DPS-120-3C-WB.TE

DPS-90-3G.TE

DPS-90-3GN.TE

DPS-90-3G-WB.TE 12.1 DPS-90-4G-WB.TE 8.6

437x452x868

437x452x868

Weight [kg]

13.0

15.5

13.0

12.1

14.2

DPS-120-4C.TE

DPS-120-4CN.TE 12.0

DPS-120-4C-WB.TE 9.5

DPS-90-4G.TE

DPS-90-4GN.TE 10.7

Dimensions (L_W_H) [mm]

363x214x534

363x214x492

Weight [kg]

9.5

8.6

CART TYPE (with Hopper)

Dimensions (L_W_H) [mm]

DPS-120-36C.TE

DPS-120-36CN.TE 15.5

DPS-120-36C-WB.TE 13.0

DPS-90-36G.TE

DPS-90-36GN.TE 14.2

DPS-90-36G-WB.TE 12.1

526x528x868

526x528x868

Weight [kg]

13.0

12.1

9

4.2 DPS_MODELS

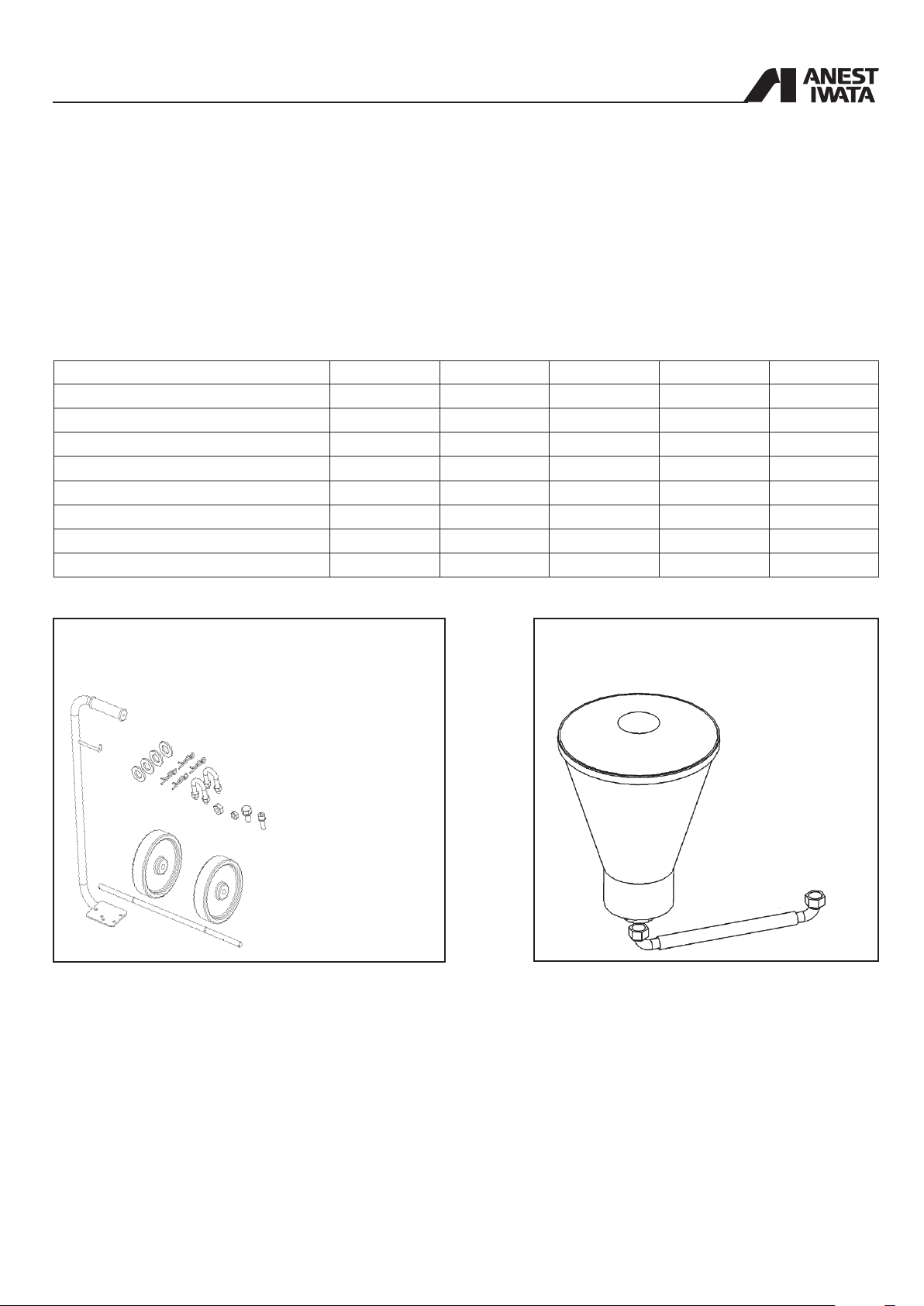

STAND TYPE

DPS 120-1C.TE/CN.TE/C-WB.TE

DPS 90-1G.TE/GN.TE/G-WB.TE

valve with exhaust hole.

• PR-5BL paint regulator for DPS 120-1C.TE and DPS 90-1G.TE

• PR-5BLN paint regulator for DPS 120-1CN.TE and DPS 90-1GN.TE

• PR-5BL WB paint regulator for DPS 120-1C-WB.TE and DPS 90-1G-WB.TE

DDP version mounted on stand, with paint regulator, 2 air regulators (for pump and

gun), paint lter unit, dip tube with lter, uid recirculation, 1 overpressure valve, ball

TANK TYPE

DPS 120-2C.TE/CN.TE/C-WB.TE

DPS 90-2G.TE/GN.TE/G-WB.TE

recirculation, overpressure valve, ball valve with exhaust hole.

DDP version mounted on Tank mount lid (without tank) with paint regulator, 2 air

regulators (for pump and gun), paint lter unit, dip pipe with lter (for 20L tank), uid

• PR-5BL paint regulator for DPS 120-2C.TE and DPS 90-2G.TE

• PR-5BLN paint regulator for DPS 120-2CN.TE and DPS 90-2GN.TE

• PR-5BL WB paint regulator for DPS 120-2C-WB.TE and DPS 90-2G-WB.TE

CART TYPE

DPS 120-3C.TE/CN.TE/C-WB.TE

DPS 90-3G.TE/GN.TE/G-WB.TE

ball valve with exhaust hole.

• PR-5BL paint regulator for DPS 120-3C.TE and DPS 90-3G.TE

• PR-5BLN paint regulator for DPS 120-3CN.TE and DPS 90-3GN.TE

• PR-5BL WB paint regulator for DPS 120-3C-WB.TE and DPS 90-3G-WB.TE

DDP version mounted on wheel cart with paint regulator, 2 air regulators (for pump

and gun), paint lter unit, dip tube with lter, uid recirculation, 1 overpressure valve,

10

WALL MOUNT TYPE

DPS 120-4C.TE/CN.TE/C-WB.TE

DPS 90-4G.TE/GN.TE/G-WB.TE

sure valve, ball valve with exhaust hole.

• PR-5BL paint regulator for DPS 120-4C.TE and DPS 90-4G.TE

• PR-5BLN paint regulator for DPS 120-4CN.TE and DPS 90-4GN.TE

DDP version mounted on wall mounting bracket with paint regulator, 2 air regulators

(for pump and gun), paint lter unit, dip tube with lter, uid recirculation, 1 overpres-

• PR-5BL WB paint regulator for DPS 120-4C-WB.TE and DPS 90-4G-WB.TE

CART TYPE (with Hopper)

DPS 120-36C.TE/CN.TE/C-WB.TE

DPS 90-36G.TE/GN.TE/G-WB.TE

1 overpressure valve, ball valve with exhaust hole.

• PR-5BL paint regulator for DPS 120-36C.TE and DPS 90-36G.TE

• PR-5BLN paint regulator for DPS 120-36CN.TE and DPS 90-36GN.TE

• PR-5BL WB paint regulator for DPS 120-36C-WB.TE and DPS 90-36G-WB.TE

DDP version mounted on wheel cart with paint regulators, 2 air regulators (for pump

and gun), paint lter unit, plastic hopper (6 lt. with 50 mesh lter), uid recirculation,

11

Loading...

Loading...