Instruction Manual

SPRAY GUN AZ3 HTE2, AZ3 HTE2 AV, AZ3 HTE2 HVLP

Before use, adjustment or maintenance, it is important

to read this instruction manual very carefully. This manual

GB

must be stored in a safe place for any future reference.

This AIR GUNSA spray guns kit complies to ATEX regulations 94/9/EC,

protection level:II 2 G X Suitable for using Zones 1 and 2.

X marking: Any static electricity discharge from the spray gun is to be diverted to the ground via the conductive air hose as stipulated.

ALWAYS observe WARNINGS and CAUTIONS in this

instruction manual.

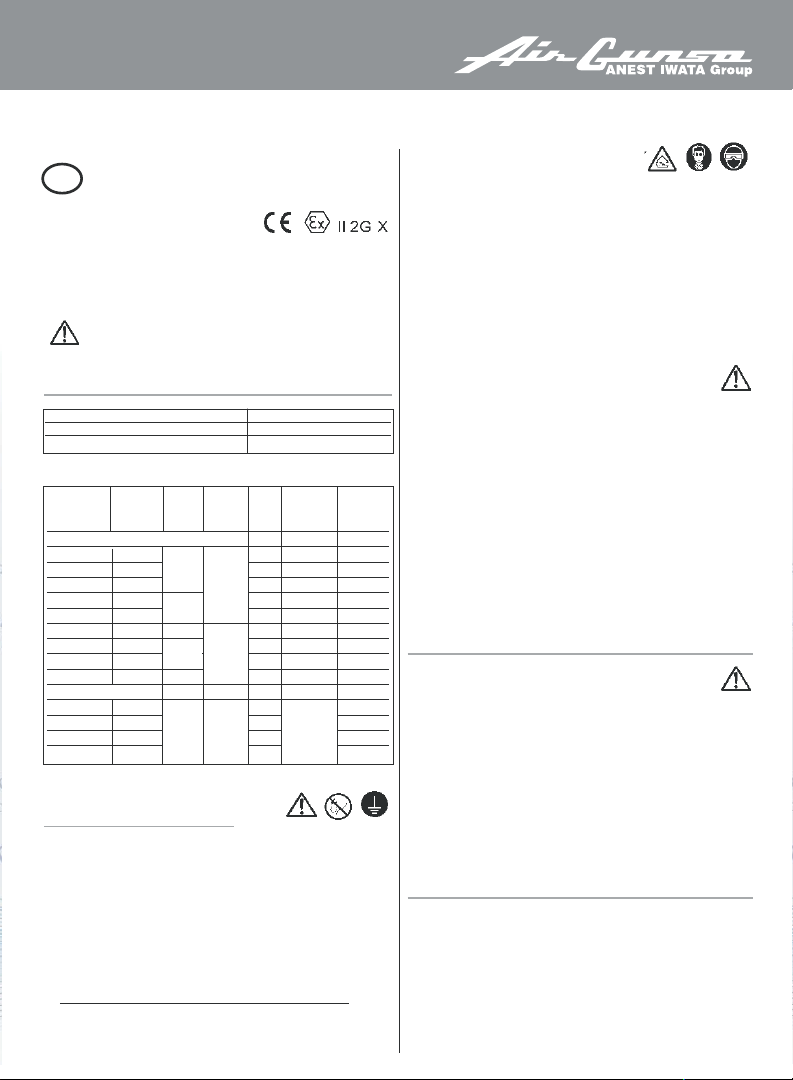

TECHNICAL SPECIFICATIONS

Max. working air pressure: 7.0 bar (100 PSI) Air connection: G 1/4”M

Noise Level (LAeqT); 77.6 dB (A) * Fluid connection: G 1/4”F

Max. Temperature range: 5 ~ 40 °C Weight g (lbs): 517 (1.14)

* Measuring point: 1m backwards from gun, 1.6m height

Model Nozzle Airc ap

AZ3 HTE2 / AZ3 HTE2 AV Gravity feed

AZ3 HTE2 1.0 1.0 (0.039) 80 200 (7.06) 180 (7.08)

AZ3 HTE2 1.3 1.3 (0.051) 140 200 (7.06) 240 (9.44)

AZ3 HTE2 1.5 1.5 (0.059) 160 200 (7.06) 260 (10.23)

AZ3 HTE2 1.8 1.8 (0.070) 250 215 (7.59) 300 (11.81)

AZ3 HTE2 2.0 2.0 (0.079) 300 215 (7.59) 340 (13.38)

AZ3 HTE2 2.5 2.5 (0.098) 25 HTE 450 280 (9.89) 360 (14.17)

AZ3 HTE2 2.8 2.8 (0.110) 540 300 (10.59) 380 (14.96)

AZ3 HTE2 3.0 3.0 (0.118) 560 300 (10.59) 400 (15.74)

AZ3 HTE2 3.5 3.5 (0.138) 35 HTE 600 300 (10.59) 420 (16.53)

AZ3 HTE2 HVLP **

AZ3 HTE2 HVLP

AZ3 HTE2 HVLP

AZ3 HTE2 HVLP

AZ3 HTE2 HVLP

** Max gun inlet pressure 2.0bar (30psi) to achieve 10psi air cap

pressure for HVLP mandated areas

Orifice

Ø mm (in) bar (PSI) ml/min Nl/min (cfm) mm (in)

1.3 (0.051) 150 280 (11.0)

1.5 (0.059) 185 290 (11.4)

1.8 (0.070) 215 340 (13.4)

2.0 (0.079) 240 360 (14.2)

set Mark

10-15

HTE

18-20

HTE

28-30

HTE

HVLP

Air pressure

Fluid Air Pattern

at gun inlet

output

2.0 (29)

3.0 (44)

2.0 (30)

Air cap press

0.7 bar (10psi)

consumption

340 (12.0)

Width

SAFETY WARNING

FIRE AND EXPLOSION

1. Never use the following HALGOGENATED HYDROCARBON SOLVENTS:

which can cause cracks or dissolution of gun body (aluminium) due to

chemical reaction. UNSUITABLE SOLVENTS: methyl chloride, dichloromethane, 1.2-dichloroethane, carbon tetrachloride, trichloroethylene,

1.1.1-trichloroethane

2. Sparks and open flames are strictly prohibited. Paints can be highly

flammable and can cause fire.Do not expose to open flames, electrical

goods, cigarettes etc.

3. Securely ground spray gun using conductive air hose. (Less than 1MÙ )

Always ensure that the spray gun is earthed correctly.

Manufactured by: AIR GUNSA s.r.l, 46 Corso Vigevano 10155 Torino - Italy

HEADQUARTERS:

3176, Shinyoshida-cho, Kohoku-ku - Yokohama, 223-8501 JAPAN

ANEST IWATA Corporation

PROTECTION OF HUMAN BODY

1. Use in a well-ventilated site, using a spray booth.

Poor ventilation can cause organic solvent poisoning and fire.

2. Always wear protective gear (safety glasses, mask, gloves) to avoid

inflammation of eyes and skin.

In case of any physical discomfort, immediately seek medical advice.

3. Wear earplugs if necessary.

Noise level can exceed 85dB(A), depending on operating conditions and

painting site.

4. Pulling the trigger many times during operation, may cause carpal

tunnel syndrome. Always rest, in case of tiredness.

IMPROPER USE

1. Never point gun towards people or animals.

2. Never exceed maximum working pressure or maximum operating

Temperature

3. Always release air and fluid pressure b efore cleaning, disassembling

or servicing.Otherwise, remaining pressure can cause bodily injury due

to improper operation or scattering of cleaning liquid.

4. Tip of fluid needle s et has a sharp point.

Do not touch the tip during maintenance to avoid accidents.

5. Never use this gun to spray foods o r chemicals.

Otherwise, foreign substance, could cause corrosion of fluid passages

which could adversely affect health.

HOW TO USE

CAUTION

- Use clean air filtered through a ir dryer and air filter.

- When using this gun for the first time after purchase, adjust fluid needle packing set, spray cleaner t o clean fluid passages and remove rust

preventive oil.

1. Firmly connect an air hose to air nipple 1/4”.

2. Firmly connect a suitable cup to fluid nipple.

3. Flush fluid passages with a compatible solvent.

4. Pour paint into container, test spray, adjust fluid output and pattern width.

HOW TO OPERATE

Suggested atomizing air pressure is 2.0 to 3.0 bar (29 to 44 PSI) at gun

inlet.

Recommended paint viscosity differs according to paint property and

painting conditions. 12 to 23 sec. / Ford cup#4 is recommended.

Set the spray distance from the gun to the work piece, as near as possible within the range of 100-200 mm (3.9-7.9 in).

MAINTENANCE & INSPECTION

TROUBLESHOOTING

CAUTION

- Make sure you do not damage tip of fluid nozzle or seat section.

- Never use spare parts that are not Air Gunsa originals.

1. Pour remaining paint into another container. Clean fluid passages and

air cap set. Place a small amount of cleaner into the cup and flush out the

fluid passages. NOTE: DISCONNECT ATOMIZING AIR

DO NOT ATOMIZE CLEANING SOLUTION.

- INCOMPLETE CLEANING CAN CAUSE PATTERN SHAPE DEFECTS.

ESPECIALLY CLEAN FULLY AND PROMPTLY AFTER USE WITH TWOCOMPONENT PAINT.

2. Clean each section with brush s oaked with cleaner and wipe out with

waste cloth.

- NEVER IMMERSE THE S PRAY GUN COMPLETELY IN SOLVENT, AS IT

CAN DAMAGE PARTS.

3. Before disassembly, clean fluid passages.

a. Disassemble fluid nozzle, while keeping fluid needle pulled (trigger-

ing) in order to protect its seat section.

b. Disassemble fluid needle set.

c. Remove the fluid adj. knob and needle spring, extracting the spring

and fluid needle set, from the back of fluid adj. guide set still assem-

bled on the gun body.

(only when strictly necessary)

GUN DOES NOT SPRAY

- Fluid adj. knob closed. Check and adjust.

- Tip hole of nozzle obstructed. Check and clean.

- Paint filter obstructed. Check and clean.

- Non drip obstructed. Check and clean.

INTERMITTENT SPRAY PATTERN

- Air escapes from fluid nozzle. Check , clean & replace if

- Air escapes from fluid needle Tighten.

packing.

- Air escapes from cup joint or Tighten.

fluid hose joint .

- Dirt inside air cap. Clean.

DEFECTIVE SPRAY PATTERN

- Dirty nozzle or air cap. Clean carefully.

Nozzle or air cap has been Replace If damaged.

damaged.

- Fluid nozzle is loose Tighten.

- Paint viscosity too high or Dilute paint or increase

too low. viscosity

- Fluid output too high or Adjust fluid adj. knob to

too low. reduce or increase.

LEAKING

- Fluid nozzle seat or needle set Clean or replace if n ecesdirty, damaged or worn. sary.

- Loose fluid needle adj. knob. Adjust.

- Fluid needle spring is worn. Replace.

- Loose fluid nozzle. Tighten.

- Needle packing set loose, too Adjust, clean or replace.

tight, dirty or worn.

AIR ESCAPES FROM AIR CAP

- Air valve, air valve seat or air Clean or re place if necesvalve spring dirty or damaged. sary.

necessary.

Leakage from fluid nozzle set and fluid needle set seat sections.

Replace fluid nozzle set and fluid needle set, if leakage does not stop

after cleaning them.

them carefully and make sure there is no further leakage.

If you replace fluid nozzle or fluid needle only, match

2

DECLARATION OF CONFORMITY

We AIR GUNSA s.r.l. - Corso Vigevano, 46 - 10155 Torino - I taly declare, under our

sole responsibility, that the product:

to which this declaration relates, is in conformity with European ATEX Directive

94/9/CE for use in zone 1 a nd zone 2 and Machinery Directive 98/37/CE.

According with the following international requirements: EN 1127-1, EN 292-2 and

EN 1953.

Name and position of issuer: Mr. Marco G. VICENTINI, Managing Director

Firma: data: 04/04/2008

AZ3 HTE2 SPRAY GUN series

This is an original CE declaration of conformity is sued by AIR GUNSA s.r.l.

Other copies are considered not valid

Loading...

Loading...