Page 1

andronic XPanel

Operation Instructions

Page 2

2

andronic CNC

XPanel Operating instructions

Version

V 1.1.01

Date

23.08.2012

Author

Na/Vol/Pa

Editing/Illustrations

Pa

Trade mark

All product names or trademarks are properties of their respective owners.

Copyright

© andron GmbH 2012. All rights reserved.

are liable for the payment of damages. All rights are reserved in the event of the

Validity

There could be additional f unctions runni ng in the con trol that are not mentione d in this doc umentation. No le gal

Published by

andron GmbH, Schlätterstr. 2, 88142 Wass erburg/Bodensee, Germany

A member of the LTi group of companies

Copying this do cument, giv ing it to othe rs and the use o r communica tion of the co ntents ther eof without ex press

authority, are forbidden. Offenders

grant of a patent or the registration of a utility model or design.

right exists, however, to these functions when a new system is delivered or the system is serviced.

All rights are reserved with respect to the contents of this documentation and the availability of the product.

Telephone +49 (0) 8382/9855-0, Fax +49 (0) 8382/9855-50

e-Mail: info@andron.de

www.andron.de

Page 3

andronic CNC

XPanel Operating instructions

Table of contents

Version

Date

Additions and changes

Initials

V 0.9

07.05.2009

First edition

Vol/Na/Pa

V 1.0

14.11.2011

Revised edition

Vol/Na/Pa

V 1.1

08.12.2011

Revised edition

Vol/Na/Pa

Table of contents .................................................................. 3

Revisions .............................................................................. 3

Notice .................................................................................. 4

Safety notes ......................................................................... 4

Warning notes and symbols ............................................. 4

Use as directed ............................................................... 5

Introduction ........................................................... 5

Field of applications ................................................ 5

Not used as directed ....................................................... 5

Switch on, start-up phase, turn off ......................................... 6

Switch on ....................................................................... 6

Boot phase ..................................................................... 6

Switch off / Shut down .................................................... 7

Operating system setting, system additions, user profiles, etc. . 8

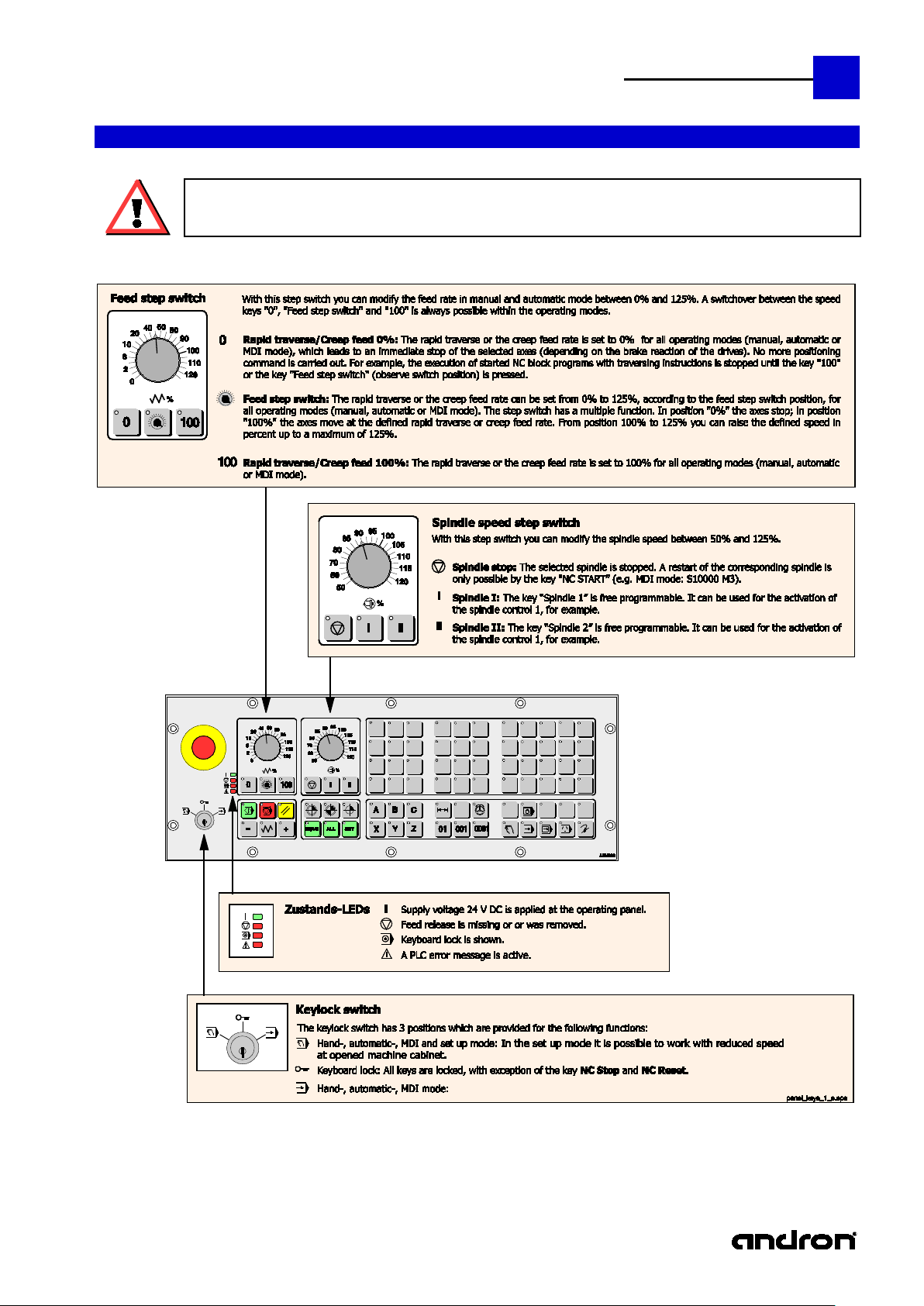

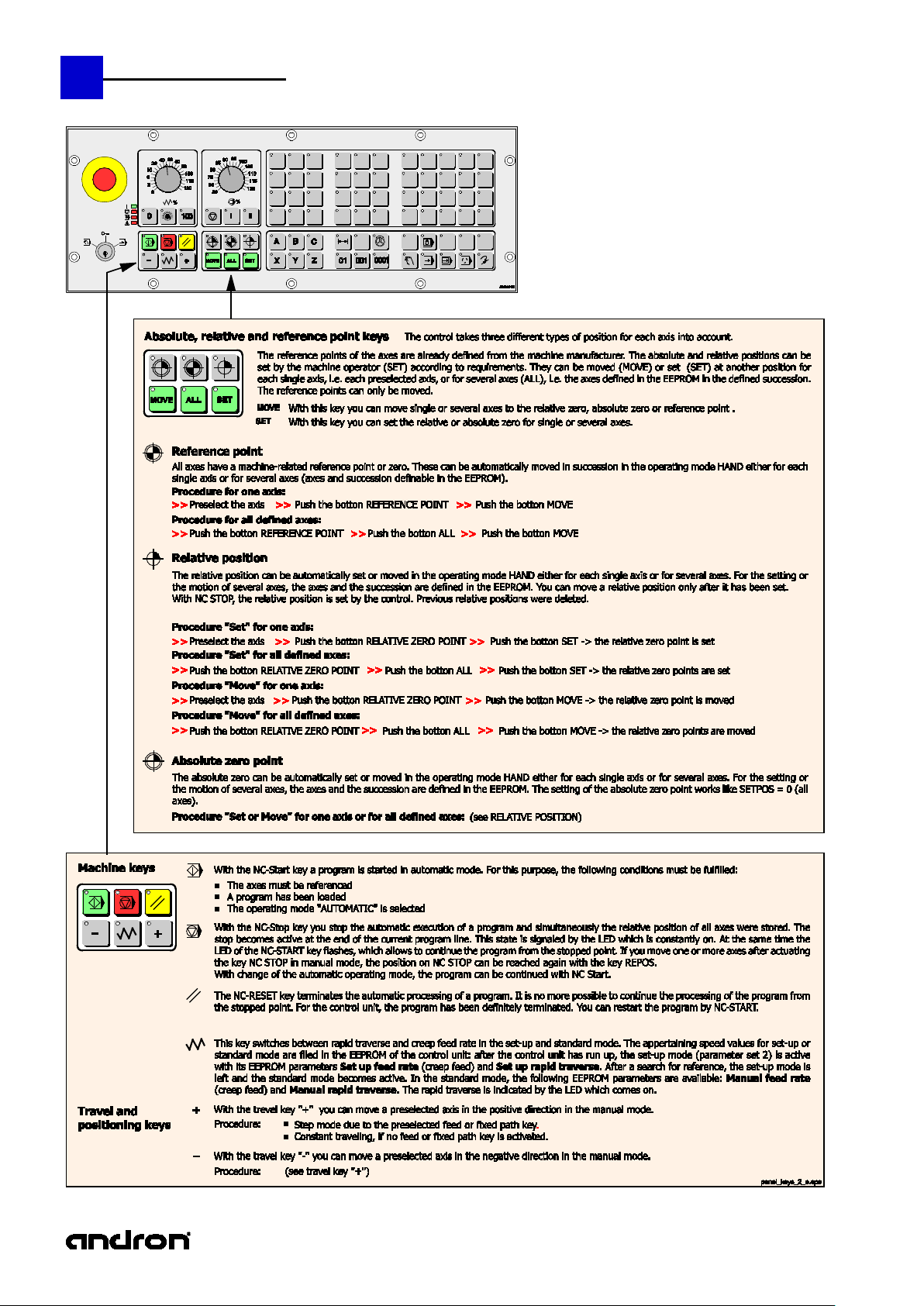

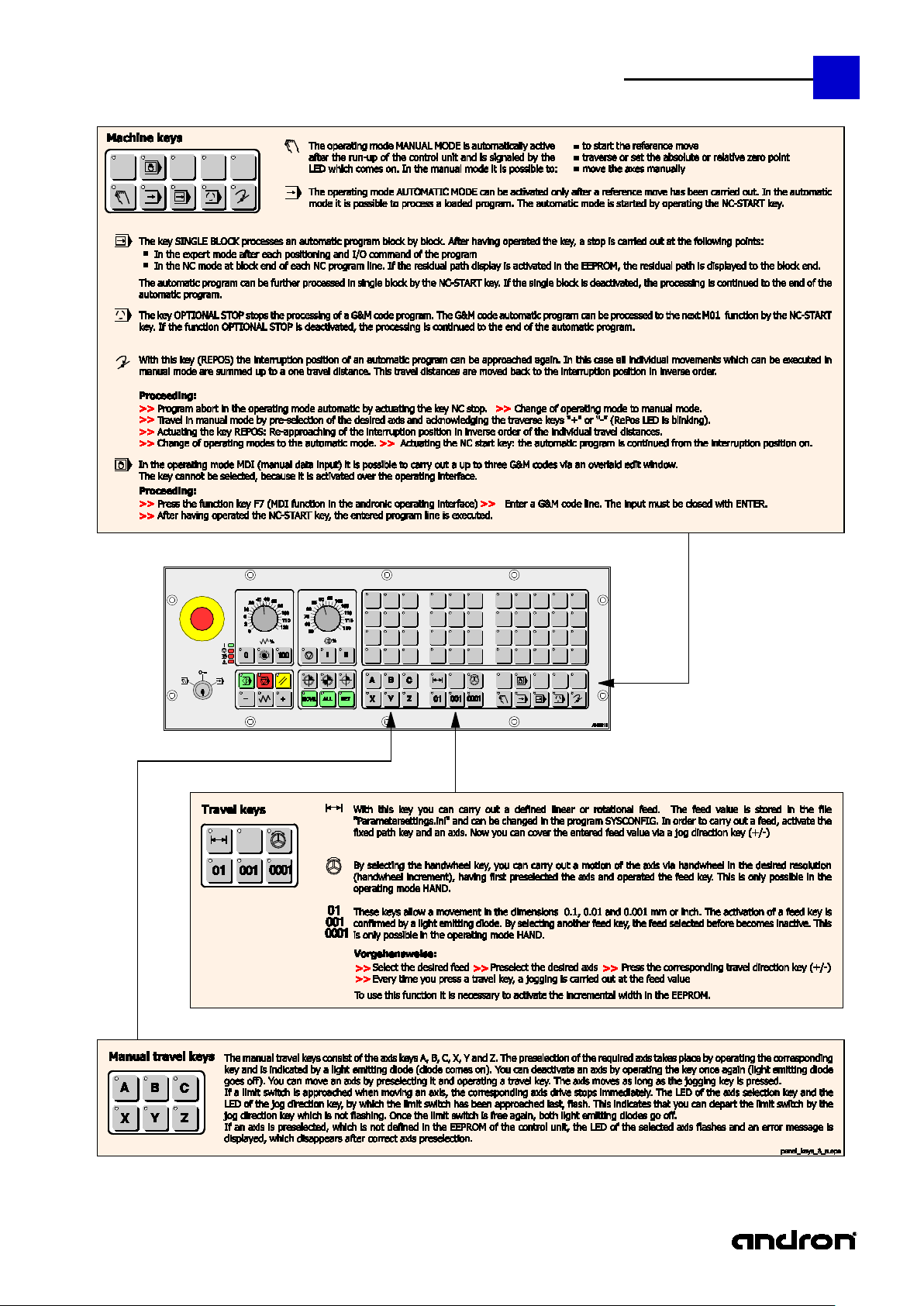

Operating panel keys ............................................................ 9

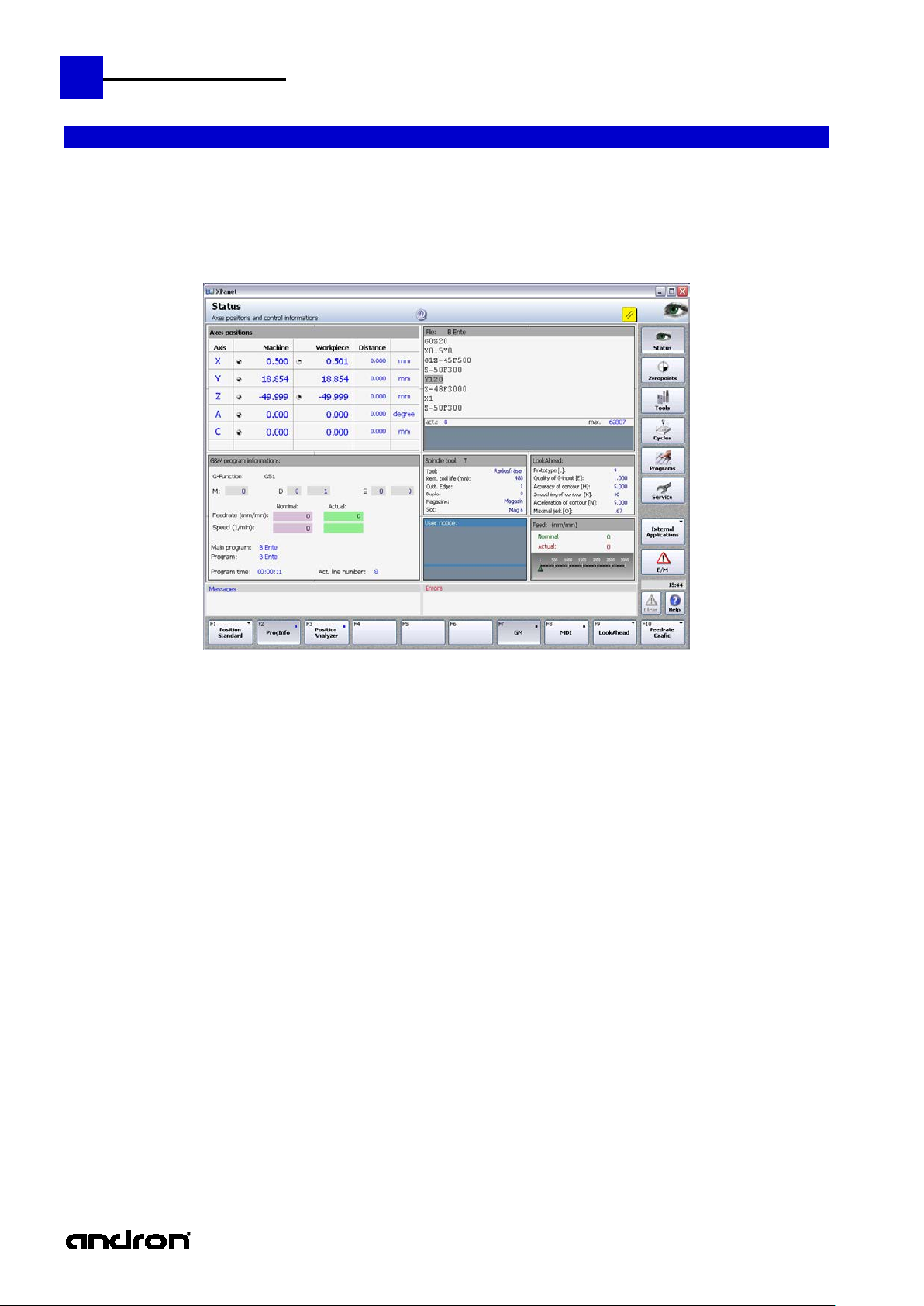

The XPanel user interface .................................................... 12

Introduction .................................................................. 12

XPanel structure ............................................................ 12

XPanel pictograms of the status area.............................. 13

Revisions

3

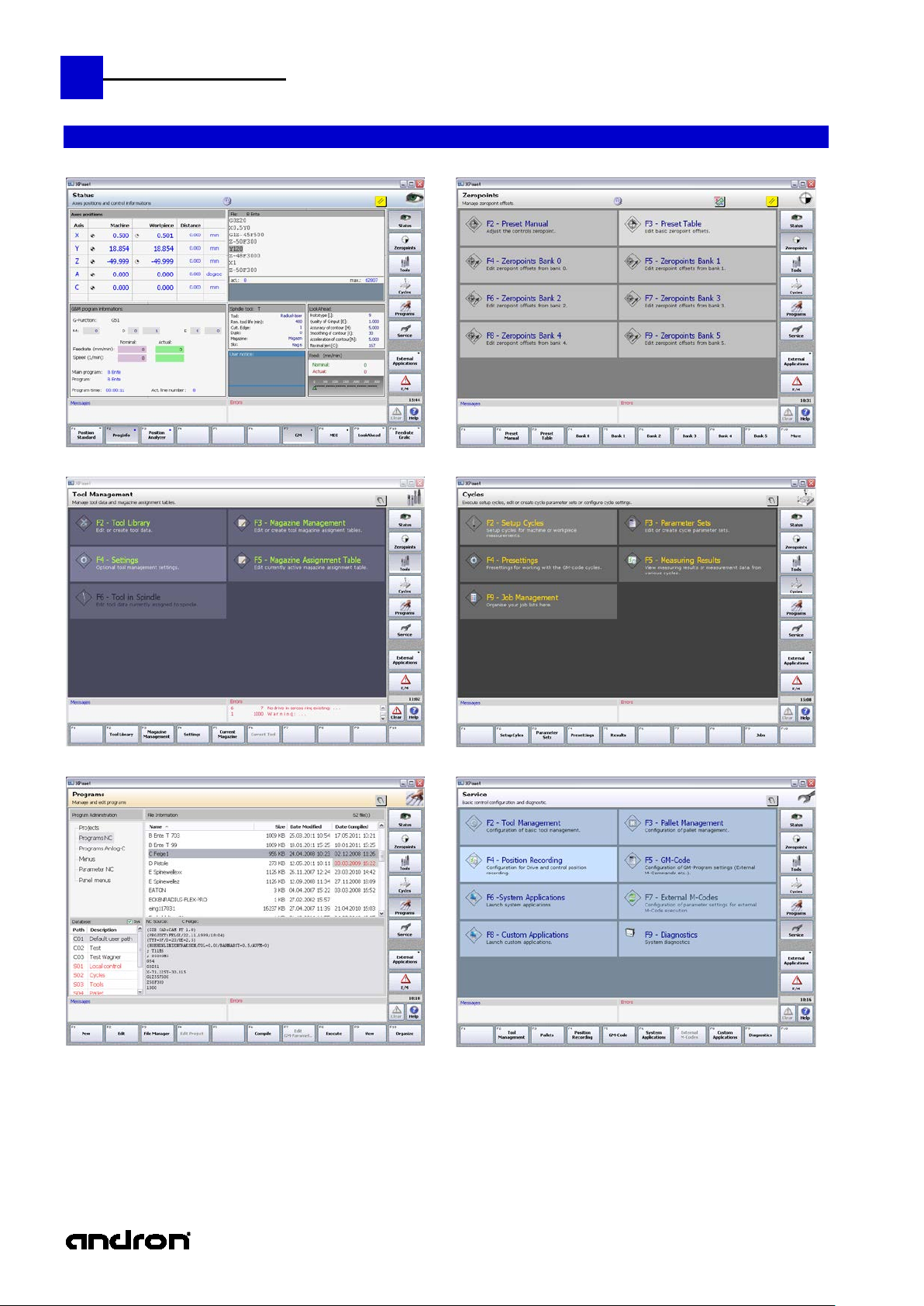

Overview of the eight main groups ....................................... 14

The status display ............................................................... 16

The main menu of the status display .............................. 16

Zero points , Manage Zeropoint offsets ................................. 21

The main menu of the zero points .................................. 21

Tool management ............................................................... 23

Overview of functions .................................................... 23

The main menu of the tool management ........................ 23

Cycles ................................................................................. 30

The main menu of the cycles .......................................... 30

Programs ............................................................................ 33

The main menu "Programs" ........................................... 33

andron NC Editor .......................................................... 35

Service ............................................................................... 39

The Service main menu ................................................. 39

Error and Messages ............................................................. 45

The main menu Error and Messages (E/M) ...................... 45

Page 4

4

andronic CNC

XPanel Operating instructions

In the creation of this manual, w e have made the greates t effort and have taken the greatest care. We reserve the right

part of or the

Before the connection and the start-up of the control, it is imperative that

the documentation is carefully read!

Meaning of the symbols used in this document:

Symbol

Meaning

Symbol

Meaning

Notice

to make changes to this manual a nd to the c ontr oller or the p rogra ms , whic h are made nec ess ary by technic al progre ss,

without previous notice. In later v ers ions, additio nal p ages ma y b e i nserted. We would appreciate your informa tion as to

errors in the manual or how the manual may be improved.

We accept no responsibility for damage resulting from neglect of the instructions contained in this manual.

We are neither liable for nor respo nsible for actual or alleged loss or damage , whether dir ect or indirect, which is caused

by the operated or delivered equipment or the software progra ms, and which are claimed by a customer or another

natural person or a legal entity. This clause includes fault y service, lost busin ess tr ansactions , loss of expec ted profi t or

consequential damages which occur due to the use of the equipment sold by us or software generated by us.

We accept absolutely no responsibility for damage due to faulty installation !

This instruction manual, the program descriptions belonging to it as well as other objects sold or supplied with the

controller, are protected by copyright. All rights ar e reserved. This handbook, the programs, and all other copyrighted

objects may be neither completely or par tially copied or in any other manner duplicated, without the previous written

consent of andron GmbH. Legally created copies, made with the permission of andron GmbH, of a

complete manual, the c omputer programs or other copyrighted objects, must have the same copy right notice as the

original material.

Safety notes

Warning notes and sym bols

This notice contains general and additional

information as well as rules and prohibitions

pertaining to damage prevention.

Danger notices for personnel and machine

damage, i.e. information as well as rules

and prohibitions pertaining to personal

injury and material damage prevention.

Important information or cross-

references to further descriptions.

Danger to life !!!

Page 5

andronic CNC

XPanel Operating instructions

Introduction

andron products are developed and produced according to the latest technologies . They are not delivered unless they

andron assumes no liability for damage due to inappropriate use. andron is not liable for payment of

The following requirements must be met before using andron products to ensure proper use:

Field of

The control is used for con trol panel integration, integration into a housing or the door of the switch c abinet or for

Each control system must be parameterized and programmed by competent service personnel before operation.

The control is "not used as directed" if it is used in a field of application not specified or if it is used under operating

Use as directed

have been tested for service reliability.

The products may only be used as directed. If they are no t used as directed, material damage and pe rs onnel inj ury may

result.

The corresponding safety instructions for use as directed must be read and understood by all who operate one of

our products.

If the products include hardware, the origi nal condition must not be changed . Software products must not be de -

compiled and the source codes must not be changed.

Damaged or faulty products must not be integrated or put into operation.

It must be guaranteed that the products have been installed according to the instructions specified in this manual.

damages. The user is liable at his own risk if the products are not used as directed.

5

applications

machine tool housing integration.

It must be ensured that the required mounting, installation and environmental conditions are fulfilled.

The control can only be used with the configurations described in this manual. Furthermore, the use of an andron

software or firmware is necessary.

Not used as directed

conditions or with technical data not spec ifie d in this manual.

The control must not be used if it is exposed to operating condition s which do not fulfill the determined environmental

conditions, e.g. use with water or with extreme temperature differences or extreme maximum temperatures is not

allowed.

Page 6

6

andronic CNC

XPanel Operating instructions

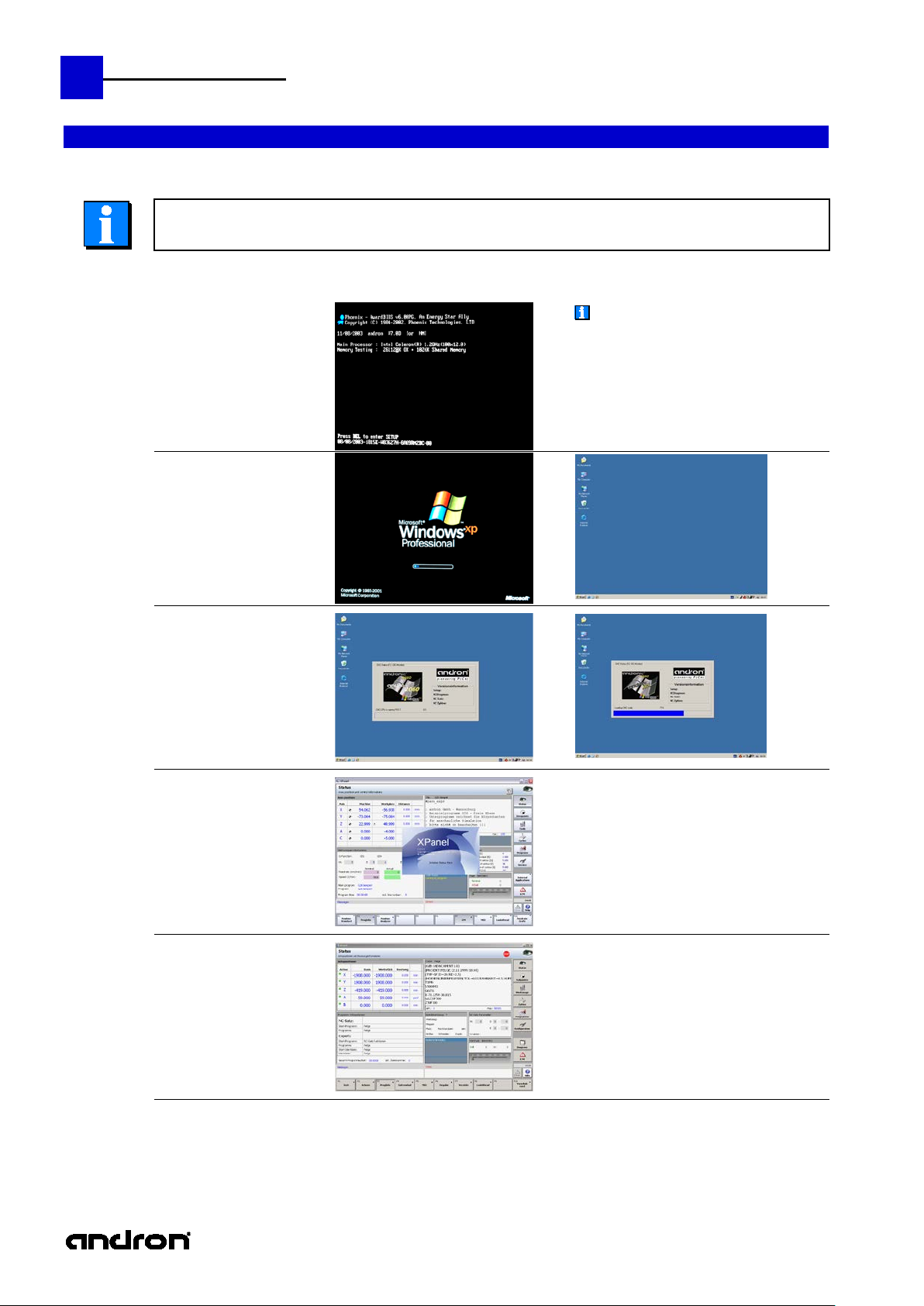

If the control was started without

Switch on, start-up phase, turn off

Switch on

Boot phase

1.

The switching on of the control as well as the entire system can be realized in different ways,

Switch on the control

Boot phase of the HMI CPU

therefore observe the information of the machine manufacturer!

connecting or switching on a display, it ma y

happen that the display remains dark after

switch-on.

In this case, press the key combination

CRTL + ALT + F1 (for VGA)

CRTL + ALT + F3 (for DVI)

in order to switch to the correct output of the

graphics card.

2.

3.

4.

Loading of the HMI

operating system

Boot phase of the NC CPU

Loading of the NC operating

Initialization of the

operating system

Start-up of the

sercos phases

from 0 to 4

system

5. Control is ready for operation

Page 7

andronic CNC

XPanel Operating instructions

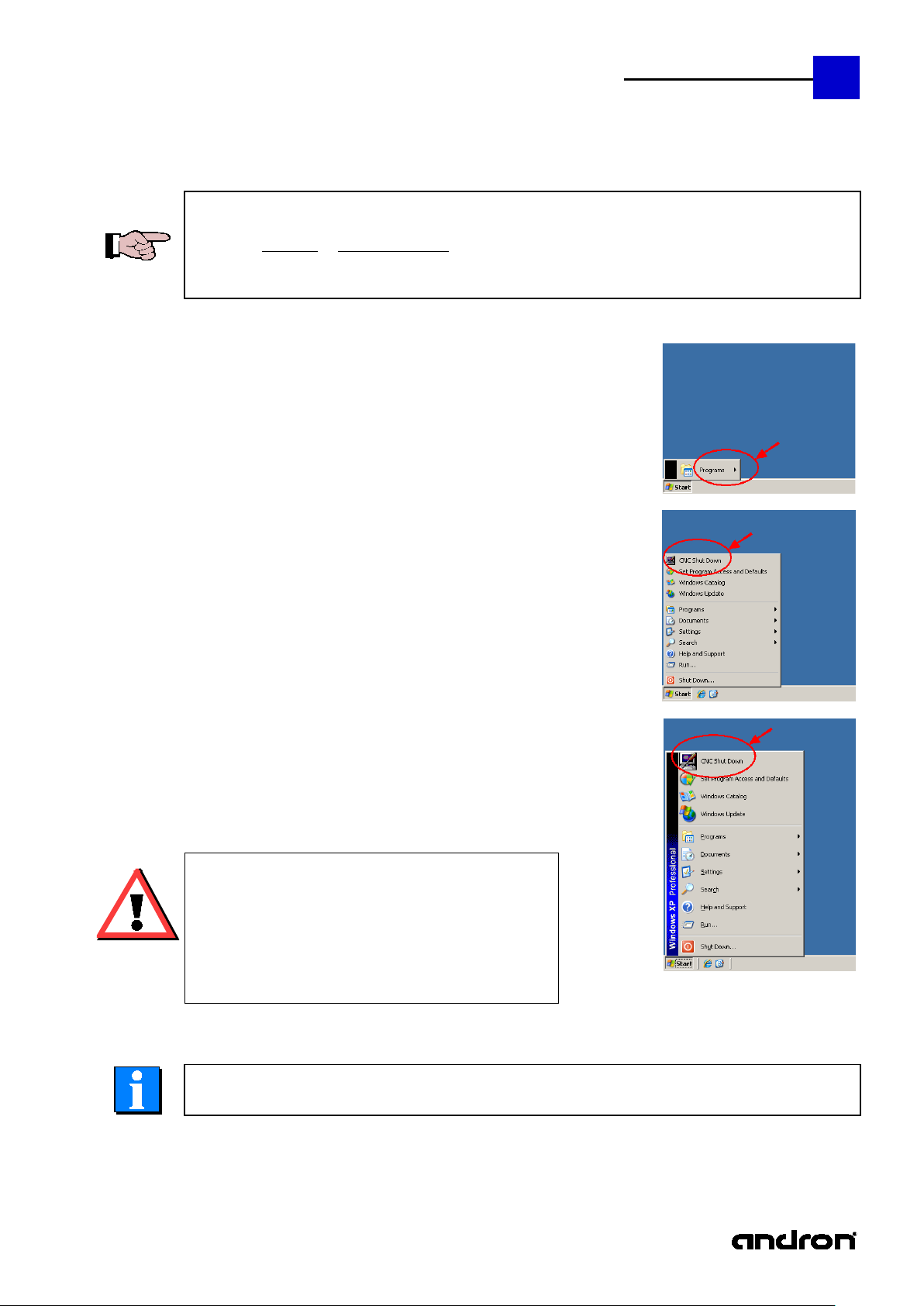

There are different possibilities to shut down the operating

Attention:

system is not monitored as to whether the machine is still

Switch off / Shut down

7

For switching off the control as well as the whole machine pay attention to the following notes:

To avoid data loss or hard disk damage the control must be shut down always in the correct way. That

means the operating system must be completely finished before switching off the control or the whole

system, depending on how you have logged in to the control:

Click in the Windows start menu on

CNC Shut Down

These actions will shut down the operating system, so that you

can surely switch off the power supply of the control..

machine.

cnc user

cnc admin

If you have logged in as User "administrator" or "cnc admin", you

can click on Shut Down in the Windows start menu. However,

your are strongly advised not to do so, because the

in the machining phase or other important functions are

still active!

Observe also the information of the machine manufacturer!

administrator

Page 8

8

andronic CNC

XPanel Operating instructions

Microsoft Windows XP Professional (SP3) is the installed operating system on the HMI computer of the

additions and other optical gadgets are deactivated. Changes in these settings can slow down the system

User-Profiles

Virus scanner

Firewall

Microsoft Security Patches

security patch or other update without permission of

Internet access

Only with full access and

Operating system setting, system additions, user profiles, etc.

andronic 3060.

In order to guarantee the highes t poss ible sys tem performa nce , all unneces sary animat ion, s uperfluo us s oftware

considerably.

Three users with corresponding user profile were arranged on the control:

administrator (Full access with administrative rights)

cnc-admin (Reduced administrative rights)

cnc-user (Considerably reduced user rights for the machine user on operating system level)

Please use only one of the three predefined users.

We recommend the use of an actual virus scanner.

A complete virus scan is executed before the control is leaving our factory. T he installat ion of a dd itional s oftware

or the use of USB memory stic ks can cause a virus infection of the system. A final virus check mu st be done

before the entire machine is delivered to the end user.

In the default setting the Windows

The installed image contains most of the availa ble Microsoft

security patch in the current version, because after every installation extensive software-tests must occur in

order to guarantee the perfect function of the entire system

It is forbidden to install any Microsoft

ANDRON. It is also not allowed to activate the automatic update function in the Windows security

center.

When using the control with not verified software, the guarantee of the control will be lost.

In the standard configuration the machine user has no internet access.

administrative rights can you connect the control to the Internet

The andronic software offers the poss ibility o f remo te diagnos is via internet with the prog ram N etVie wer. To use

this function it is necessary to make a r estricti on on administrator level s o that the mach ine user has no general

internet access.

XP firewall is activated. The use of other firewalls is dissuaded urgently.

security patc hes. It is not possible to ins tall every

Page 9

andronic CNC

XPanel Operating instructions

below. It is possible that the machine manufacturer delivers his own PLC program with different functions

Operating panel keys

andron supports the control with a basic PLC program for the operating and control functions described

and extensions. If there is no further information the following description is valid.

9

Page 10

10

andronic CNC

XPanel Operating instructions

Page 11

andronic CNC

XPanel Operating instructions

11

Page 12

12

andronic CNC

XPanel Operating instructions

Introduction

The pleasantly designed and cle arly structured operating interface can be operated i ntuitively. The Micros oft

XPanel

Despite the extensive configuration options , the different areas of the interface are clearly defin ed. The outer

Status area

At the top, extending from left to right over the en tire screen, is the s tatus area in which on the

Main group

The right-hand side of the screen features eight MG keys.

They can be activated by pointer devices (mouse, touch, etc.) or the key combinations

Underneath are two

Function

At the bottom of the screen are the function keys F1 – F10. They are assigned according to main

To delete the

The attempt was made to place the same functions in all bars on the same function key. Context-dependent,

function keys become enabled or disabled.

The XPanel user interface

.NET based panel has various configuration possibilities and can be ad justed problem-free to the needs of the

end user.

Our andronic CNC controls has a w ide range of applications, ranging from classical machi ne applications like

milling, honing, grinding and eroding to highly dynamic processing. For this reason we put a lot of value during

the design of the new panel in individual adjustment options and optimal usability.

Illustration: Structure and functional areas of the XPanel interface

structure

frame of the XPanel always has the same appearance, allowing the user to become quickly familiar with it. The

basic information always appears at defined locations:

left the name of the active main group and underneath a description of the current action

appear. This is followed by pictograms r eproduc ing the status of th e re mote mode, key-operated

switch, active transformations and of the current CNC operating mode.

On the very right in the status area, the pic togram of the acti ve main g roup (MG) is shown. The

background color of the status area depends on the main group.

area

keys area

Ctrl+Shift+Alt+F1 – Ctrl+Shift+Alt+F8.

Main group 7 cam be configured. This is indicated by t he small inverted black triangle in the right

upper corner. I t is configured by clic king this triangle or by a right mouse click on this button.

From the popup menu that appears, a function can be assigned.

Note: If the function is active, no other function can be assigned.

Remedy: End the active function.

Below MG 8, the local time and the current date are shown as tooltip.

smaller buttons.

"Clear" deletes the accumulated errors within the applic ation. The key is only active if any errors

are active. The next time XPanel is started again, these errors will reappear.

"Help" (Ctrl+Shift+F1) provides context-dependent help.

groups and can be several levels deep.

Above them on the left is the area for disp laying messages (blue) and on the right the area for

error messages. Error messages can be deleted by pressing the "Clear" key.

messages, the message bits must be removed by the PLC or CNC.

Page 13

andronic CNC

XPanel Operating instructions

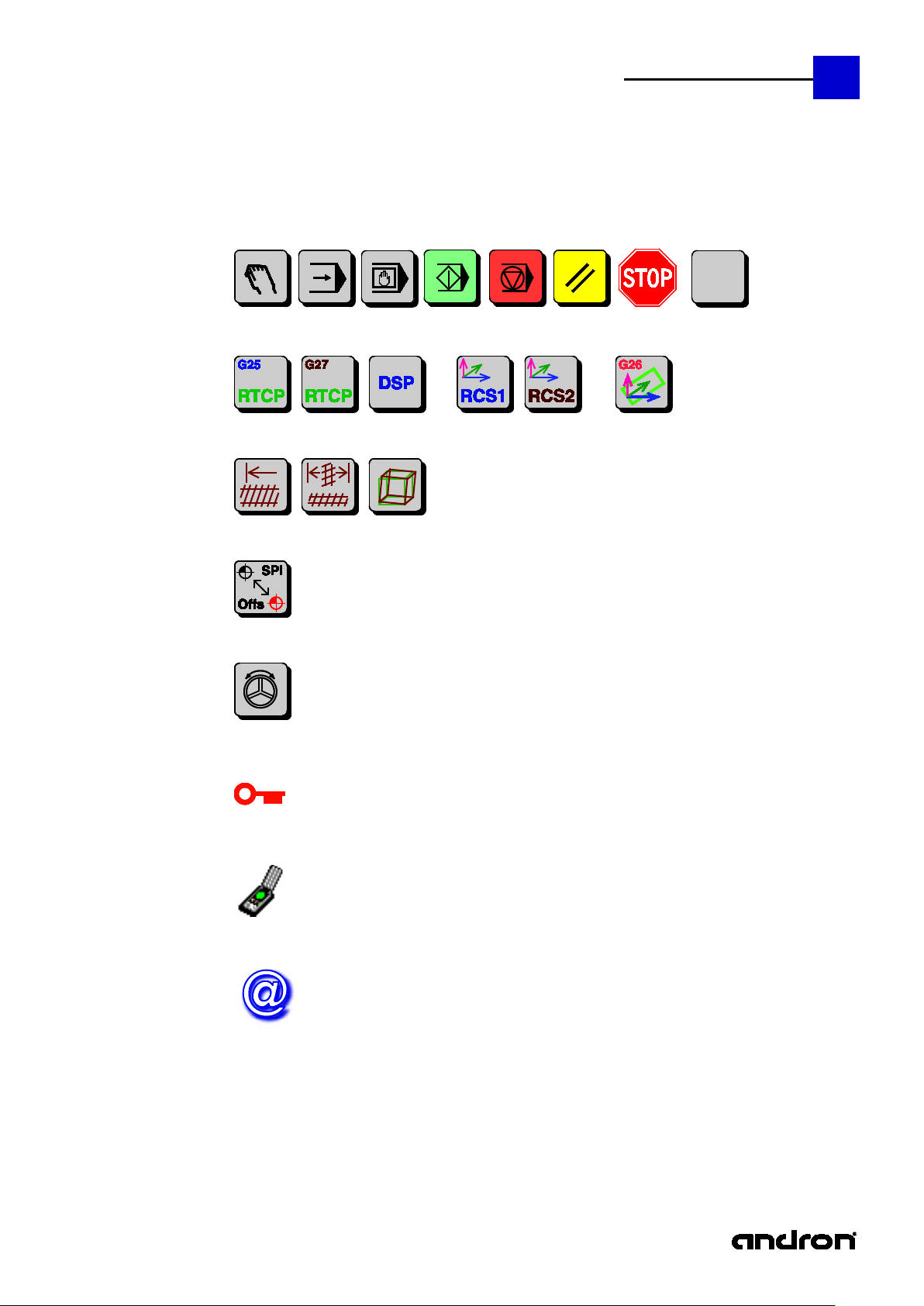

XPanel pictograms of the status area

Operating modes:

n in the event of an Emergency Stop, the empty pictogram is shown when the CNC could not

Transformations:

Compensations: (spindle, cross, grid)

Spindle Offset:

Handwheel Offset:

Control panel key-operated switch:

Remote mode:

Remote access:

13

Stop is show

initialized correctly. For the meaning of the remaining pictograms, see description of the control panel .

controls data input and remote mode

In NC block mode, the control is rem ote-controlled. Remote mode and remote access are mutually exclusive.

The control (programming station) access the data of a remote control. The toolti p provides the computer name.

Page 14

14

andronic CNC

XPanel Operating instructions

Overview of the eight main groups

Status

Tool Management

Zero points

Cycles

Programs

Service

Page 15

andronic CNC

XPanel Operating instructions

15

Configurable main menu

E/M (Error and Messages)

Page 16

16

andronic CNC

XPanel Operating instructions

The main

The status display is divided into 16 fields of equal size. These fields can be configured for each language via the

Group affiliation of

To let the user know which function keys have toggle functional ity or which keys belong to the same group,

The status display

menu of the

XML file ...\andron\Panel\Plugins\State.Config.

status display

Illustration: Division of the status display into 4x4 fields of equal size

For these fields, controls (display and input windows) of different size (multiple of the basic field size) are

available. The user can change their arrangement, but not the controls themselves.

For the configuration of the fields, a separate description is available: StateConfig

the function keys

graphic elements are shown on the function keys.

A black triangle with the tip pointing downward is a toggle key. At least two controls are

incorporated in them. You can toggle between these controls by pressing the key repeatedly.

A square means that the key belongs to a group.

The same color means the same group. The controls of a group are always shown in the same area of

the status display.

Page 17

andronic CNC

XPanel Operating instructions

At present, the following controls are available.

StatePosit2x2

(Standard display)

A8Setter

(Setter display)

The reference status was color-

StateProgInfoGM

Visualization of the NC block program information

17

(2x2):

(2x2):

Metric display of a max. of 5 axes. The axis designator,

machine with reference status, workpiece with manual

preset offset, remaining path and dimension are displayed.

Which axes and in which order they are shown, can be

defined via the configuration file XPanel.exe.Config. By

default, the axes XYZAC are shown. The two figures in

parentheses behind the name of the control indicate its

size in field rows and columns for which the control was

designed.

In this illustration, all axes have been referenced, and the

Metric display of a max. of 8 axes. The axis designator with reference status and manual preset offset, Sercos,

drive, machine, work piece, remaining path and dimension are displayed.

For reasons of space, both the manual preset offset and the refe rence status are shown in the axis designator

column.

Z axis has been assigned a manual preset offset.

coded in the axis designator:

green referenced

red not referenced

(2x2):

Modal G functions, M-D-E words, federate, spindle speed (Nominal/Actual), start and current NC program,

previous program time and line number of current program.

Page 18

18

andronic CNC

XPanel Operating instructions

StateMDIAlpha

MDI Control:

MDI is enabled by pressing the f u nction ke y F8 MDI or by cl ic king i nto the tex t inpu t f ield. The background color

The status line above the four keys is used both for user guidance and for displaying compilation error

positioned in the faulty NC block line.

buffer. Execution can start.

(2x2):

Input of multi-line NC block instructions.

The length of the MDI source is limited by the

size of the transfer buffer.

of the text input field changes and becomes focus e d, while the status line and the CNC buffer are deleted.

MDI is disabled by pressing the "Disab le MDI" key or by c licking on a different c ontrol. The text input field turns

gray and loses the focus.

messages.

Key "Delete All" or Ctrl+A: Text input field is deleted, CNC buffer is empty.

Key "Alpha": another window containing predefined strings is displayed and becomes focused if it was

already visible. The strings in this window can be transferred to the text input field and the selected text

position via Drag & Drop, double-click or by press ing the Enter key. Upon transfer, the text input field

becomes focused, allowing you to continue writing immediately behind the inserted string. The text s trings

have been defined in the MDIKeys-config file and are not lang ua ge-specific.

The file is located in the directory: ...\andron\Panel\Plugins

Note: a string can only be transferred by pressing the Enter key if the string was selected and the Alpha

window is focused.

Key "Compile": The contents of the text input field is compiled, transferred to the CNC buffer, and a status

message is output. As the Enter key will also trigger compiling, Ctrl+Enter is used for the line feed.

Key "Disable MDI": MDI is disabled. If MDI is still being executed, it cannot be disabled.

MDI with Alpha keys window

In the event of faulty compilation, an error message is

output in the MDI status line, and the cursor is

The MDI status line signals that the MDI instruction

was compiled correctly and transferred to the CNC

Page 19

andronic CNC

XPanel Operating instructions

StateGMSrcView1

Display of the NC block currently to be

StateTool (1x1):

Display of the data relevant to the spindle

StateUser1 (1x1):

Display of user notes.

StateFeedGaug1

Explicit and graphic display of the

StateFeedSpindle

Display of nominal/actual values for federate

StateFeeds (1x1):

Editing of the fixed feed both for linear and

StatePLCTimer

Display of the first 4 PLC timers. They can be

StateLookAhead

Display of the currently used LookAhead data.

19

(2x2):

(1x1):

executed in the CNC, including the filename,

the current and maximum line number and a

max. of 3 single-line texts.

The texts are defined in the NC block via G2 3.

The NC block can only be displayed if it is not

more recent than the code executed in the

CNC.

tool.

A maximum of 2 multi-line texts are possible.

The display area for the texts can be moved

by means of a pointer device. (SplitWindow)

nominal/actual feedrate The green triangle

represents the nominal value, and the actual

value is shown as a red bar.

(1x1):

(1x1):

(1x1):

and speed.

rotary axes.

started, stopped and reset via the PLC.

Resolution: 1 sec

Page 20

20

andronic CNC

XPanel Operating instructions

StateVersionInfo

Display of the installed versions of the

StateGM (1x1):

Display of the MDE NC block parameters

StateGMSrcView

Display of the NC block currently to be

If this control is used in

StateUser (1x1):

Display of user-specific information, suc h as

StateFeed (1x1):

Display of the nominal/actual feed. The actual

StateFeedGaug

Here the same data as in StateFeed are

StateSercosSpindle

Display of the Sercos spindle "0". In addition

The torque value is

StateSpindle (1x1):

This control is used for displaying an analog

Controls not used at the present time

(2x2):

(1x1):

individual modules. In contrast to the control

version, not the entire information is available

for the demo versions.

and of the active G commands.

executed in the CNC, including filename,

current and maximum line number. The NC

block can only be displayed if it is not more

recent than the code executed in the CNC.

machine runtime, current fixed paths and

user information.

2x2 field or larger, the size

of the font will be

changed.

feed is also shown on a progress bar. The

upper range limit (here 3000) can be

configured jointly for all 3 controls in the XML

file Posit.Views.dll.config.

(1x1):

shown.

Instead of the progress bar, an analog display

instrument is used.

_0 (1x1):

to the nominal speed, the actual speed and

actual torque of the Sercos spindle "0" are

shown both explicitly and graphically by

means of a progress bar. The upper range

limit for the actual speed (here 40,000) can

be configured jointly for all 3 controls in the

XML file Posit.Views.dll.config.

spindle.

Except for the torque, the same da ta as in

StateSercoSpindle are visualized.

displayed in percent.

Negative values are shown

in both displays in the

color lavender blush.

Page 21

andronic CNC

XPanel Operating instructions

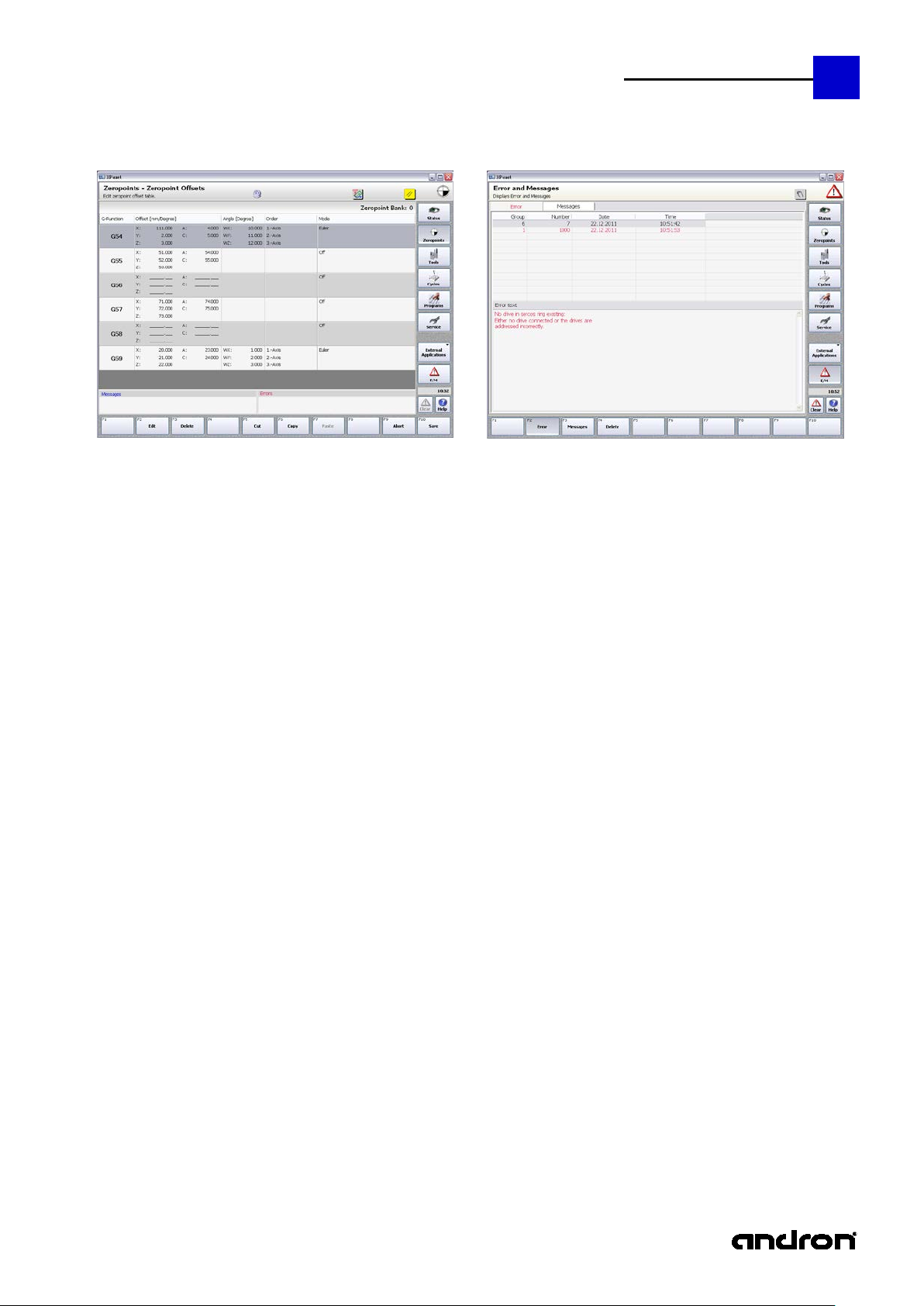

The main

F2

Preset Manual:

Zero points , Manage Zeropoint offsets

menu of the

zero points

21

Illustration: The main menu of the zero points

Definition of the workpiece zero

point

This input screen can be used to offset

the workpiece zero point axisspecifically or to delete an offset again.

The correction value of a button can

also be included in the calculation. An

offset is shown axis-specifically in the

status display.

Page 22

22

andronic CNC

XPanel Operating instructions

F3

Preset Table:

F2: Edit selected preset group

F3: Delete a preset group

F4-

Zero point Offsets

Saved preset offset

In the same way as the zero point

offsets, a preset offset (G5 1) can also

be stored. In contrast to the zero

points, the preset table contains all 10

possible groups.

Preset offsets can be stored as the

result of measurement cycles or

entered directly by the user.

F10

F5-F7: Cut & Paste functions for a group

F9: Discard changes

F10: Save changes

Groups 0 to 99

The groups 0 - 5 are directly

addressable. All other groups are

selected by explicitly specifying the

group in an input dialog.

Each group contains the translatory and

rotatory offsets for the G functions

G54-G59. The parameter modification

of a zero point offset group is done in

the same way as that of a preset

group.

Page 23

andronic CNC

XPanel Operating instructions

Overview of

any number of tool maga zines

The main

Tool management

23

functions

menu of the

tool

management

100 tool magazine slots per tool magazine

clear overview of the magazine slots

tool status information in the magazine table

any number of tools per tool type

input forms tai lored to tool types

variable or fixed coding of slots

duplo tools

tool life control / wear control

3 different types of status indication

limitation of maximum speed

speed control

9 pairs of correction values

Tool-dependent measuring data input for the laser tool measurement system

Numerous adaptation possibilities at the machine:

chain or disk mag azine, pick-up, manual change in any combination up to a total of 100 locations,

correction of position for every single magazine location,

programming of the tool change procedures in G&M code format

Different options:

tool can be changed , despite tool life has expired ,

interruption of the NC program during speed reduction of the tool management,

in case of tool magaz ine problems, all tools can be changed manually without intervening within th e tool

management,

worn-out tools can be disabled by the breakage control, but NC program is not aborted when an error

occurs.

Illustration: The main menu of the tool management

Page 24

24

andronic CNC

XPanel Operating instructions

F2

Tool Management / Tool Library

After selecting the tool type, a ll to ols of this type will be s hown in an overview . As concise information,

Tool input form

The forms of the individual tool types all have the same

Geometry:

consideration for compilation.

The radius dimension limit will be checked when loading the tool. If the tool to be loaded is

As a result of the two-level tool type /

tool display, a tool can be quickly

created, edited, deleted, renamed and

duplicated. Moreover, all tool

magazines can be searched for the

selected tool.

Since the spindle tool must be often

modified, it has been placed on a

separate function key (F8).

status, length, radius and modification date a re available. Moreover, the name and T number of the

spindle tool are shown. An hourglass in the tool column identifies the spindle tool.

The Tool and Modification date columns can be sorted. The status display immediately show s whether

the tool can still be used or must be replaced.

The selected tool can be edited by pressing "Edit" function key, the Enter key or by double-click.

For each tool type, an input form tailored specifically to that type is available.

Note: There are situations in which the CNC does not allow a tool file to be edited. Conversely,

Example shank cutter:

Length, offset and correction are

Radius , offset and correction are

the program sequence is stopped when the magazine assignment table is edited by the

user.

structure. One page for the geometry definitions, one pag e

for the technology data and, dep ending on the compl exity o f

the tool, 1-2 measuring data pages.

added by the control and the

result will be set as active tool

length when changing the tool.

added by the control system and

the result will be taken into

outside the range limits (wear), the duplo tool will be loaded, if one has been defined and is valid.

If this tool does not meet the requirements either, mac hining will be aborted and an error

message output.

The tool size in slots defines the size in magazine slots (see magazine assignment)

Fixed slot de fines whether the is always managed on the same slot in the magazine. If the slot

coding is variable, the CNC will search a suitable magazine slot, depending on the tool size.

Page 25

andronic CNC

XPanel Operating instructions

Additional correction values: Apart from the length and the radius of the tool, it is possible to call

assignment table (ST column) will be set to red.

Technology:

Measuring Data 1:

Measuring Data 2:

25

up from the NC program the length and radius data for 8 further p airs of correction values. To

this end, the NC address "D" or "D0=" is used with the number of the desired pair of correction

values. When calling the tool, the first pair of correction values will automatically become active if

no other pair has been activated with D2 (or D0=2) to D9 (or D0=9).

Tool status: To be able to use a tool, all three check boxes must be checked. Tool breakage can

be changed by measurement (load cell or laser), while wear control is influenced by the tool life

and the radius dimension limit. If one check box is not c hecked, the status of the magazine

This page contains stored data on the

tool life, speeds and cooling.

If no speed has been defined in the NC

program, the nominal speed will be

used. If too high a speed has been

defined, the maximum speed will be

used.

Here the input parameters for

measuring the tool are defined.

Depending on the complexity of the

tool, further tool parameters are

defined.

see BLUM operating instructions

Page 26

26

andronic CNC

XPanel Operating instructions

F3

Magazine Management

F1 New: a new empty table is created.

F5

Magazine Assignment Table

If a slot contains faulty entries or if the tool has not been defined sufficiently, an exclamation mark will

1st column as in the current magazine assignment.

Magazine selection:

The control can manage any desired

number of magazine assignment tables.

Since these tables are stored as files,

only characters also allowed in the NT

file system (NTFS) can be used. The

name of magazine currently used in the

CNC is shown on the left-hand side of

the window. The right-hand list box

shows all assignment tables, the

current table being identified by an

hourglass.

F2 Edit: the selected table is opened and can be edited.

Instead of F2, it is also possible to use the Enter key or a double-click on the selected table.

F3 Delete: the selected table is deleted.

F4 Rename: the selected table is renamed.

F5 Duplicate: the selected table is copied

F8 Apply: the selected table becomes the current magazine assignment table

F10 Back: return to the previous level

Note: the current magazine assignment can be neither deleted nor renamed.

Per assignment, up to 100 slots a re

available, depending on the tool sizes.

They can be divided via the

configuration (see Service/Tool

Management) into magazine, pickup

and manual slots.

An entry in the magazine assignment

table consists of the T-number, the tool

type, the tool name, the tool status, the

tool size, the slot assignment and the

duplo T-number.

There are situations in which the CNC does not allow machining. Conversely, the program

sequence can be stopped when the magazine assignment table is edited by the user.

appear in the unnamed column (on the far left). The spindle tool is identified by an hourglass in the

Page 27

andronic CNC

XPanel Operating instructions

F2 Edit: edits the selected slot entry. Instead of F2, it is also possible to use the Enter key or a

27

double-click. The T-number may have a max. of 8 digits and only appear once in the assignment.

The tool type is selected from all available types via a list. The tool is also selected according to

tool type. If the tool, due to its size, does not fit in this slot, a message is output during the

selection. The next 3 columns are set automatically, i.e., the data from the selected tool file ar e

shown. ST is green if all three check boxes of tool status have bee n checked in the tool file. GR

indicates the size of the tool and BE the slot assignment. In the above illustration, slot three

contains the tool T2 of the shank cutter type. The tool name is "Shank cutter L120 R7". The tool

is ready for use has a size of 2 slot unit, which is why it requires half of its adjacent slots. The

duplo tool is T102.

F3 Delete: deletes a slot entry from the table. The spindle tool must not be deleted.

F4 Move: marks a slot entry in the table for moving. Pressing this key produces a red frame

around the selected slot. The entry can be moved using the UP/DOWN cursor. The moving cycle

is finished by pressing the Enter key. Moving by means of the pointer device (mouse, touch) is

also possible. The slot to be moved is selected with left mouse button and moved while holding

down mouse button. While it is being moved, the slot also has a red frame. The cycle is finished

by releasing the left mouse button.

F7 Edit Tool: the tool of the selected slot can be edited directly.

F8 Tool Library: the tool library is opened.

F9 Abort: editing is finished without applying the changes.

F10 Save: editing is finished, applying the changes.

Note: the tool names are unique and type-independent. For example, if there is a drill "abc",

there can be no shank cutter "abc".

There are situations in which the CNC does not allow machining. Conversely, the program

sequence can be stopped when the magazine assignment table is edited by the user.

Page 28

28

andronic CNC

XPanel Operating instructions

F4

Tool Management - Settings

If the tool management does not find a tool with remaining tool life, the execution of the G&M code

Optional tool management settings.

1. Tool with expired tool life is

inserted after inquiry, if no other

tool is available.

This option is intended to facilitate that

a tool is used longer than the entered

tool life.

program is cancelled.

If the tool management does not find a tool with remaining tool life, the G&M code program is only

interrupted. value is set as spindle speed during the tool change. This fact is indicated by a message.

The execution of the G&M code program can be continued with the first released tool without

remaining tool life. The NC program can be canceled with NC-Reset.

2. G&M code program is interrupted by the tool management in case of speed reduction

If a value for the maximum speed of the current tool is entered and the speed programmed in the

G&M code program is higher than the maximum speed the speed of the spindle is reduced

automatically.

The spindle speed is reduced to the maximum speed of the tool without interruption of the G&M

code program.

In case of a speed reduction the G&M code program is interrupted with a message to provide the

possibility to decide whether to cancel the program or to continue at reduced speed. A new NC start

continues the G&M code program at reduced speed.

3. Suppress tool change sequences. All tools are changed manually.

To guarantee the operating function of the machine in case of damage of the mechanics for the tool

change, all tool change sequences can be forced to manual change without need to change the

magazine configuration and the magazine assignment tab le .

Standard operation

All tool changes are executed as "Manual change".

4. Lock worn-out tools, but do not abort GM program with error (G383/G384).

Cycles G383 and G384 can be used to carry out a wear test of the l ength and rad ius. To do so, a wear

tolerance is specified. If the measured wear exceeds this wear limit, the tool will be locked by the

cycle, and an error code will be returned to the CNC.

The NC program will be finished with an error message if a cycle identifies the tool as "worn-out".

The NC pr ogram will be continued with a worn -out tool. The next tool change of this tool will loa d

the duplo tool, if available, or finish the NC program with an error message.

Page 29

andronic CNC

XPanel Operating instructions

RESET

RESET of the error state of the tool change has not been canceled in the defined state !!

Tool change has not been

29

The tool change is monitored internally by the control. If, due to a pow er cut or similar events, an

undefined state should occur during the tool change, the following tool change is blocked. I n this cas e,

a tool change leads to a program abort and the error message „

canceled in defined state !! Check tool management and reset error.“.

The machine operator must check the tool management, compare it with the ACTUAL state in the tool

magazine and in the spindle, and reset this error state. After this, a tool change is possible again.

Standard operation

Reset error.

Attention ! It is absolutely necessary to check the tool in the spindle and the tool in the

position menu!

Page 30

30

andronic CNC

XPanel Operating instructions

The main

Here it is possible to execute setup

F2

Setup Cycles

For all available setup cycles, input

Cycles

menu of the

cycles

Illustration: The main menu of the cycles

All setup cycles can be executed from

here, and the measurement results can

be saved. The setup cycles are divided

into groups:

Drilling operations

Shafts

Ligaments and grooves

Sides

Space points

Workpiece

Workpiece - Machining

cycles, edit the parameter sets cycle,

establish presettings, display

measuring data and organize job lists.

screens containing parameters for

determining the measurement results

are available.

There is one page each for the setup

parameters and for the measurement

results.

Further information on all setup cycles can

be found i n the

"G&M code programming instructions".

Page 31

andronic CNC

XPanel Operating instructions

F3

Cycles – Data S ets

Edit or create cycle parameter

Further information on the

instructions" or in the Help

F4

Cycles - Presettings

31

For all cycles, a max. of 1000 (0-999)

parameter sets can be created, edited

and saved. The cycles are divided into

five groups:

Drilling and milling cycles

Measuring cycles

Set-up cycles

Continuous operation axes

Blum cycles

sets:

Here data set 1 is given as an example

of the G81 drilling cycle.

individual cycles can be found

in the "G&M code programming

For some NC block cycles, special

presettings can be established and

saved.

Here is the main menu for the following

cycle groups:

Measuring plate (G187, G188,

G189)

Measuring probe (G181, G285)

Blum cycles (G381-G389)

General (G288 Look ahead

parameter

Page 32

32

andronic CNC

XPanel Operating instructions

F5

Cycles – Measuring Results

F9

Cycles – Job Management

View measuring results or measuring

data from various cycles.

Here is the main menu for the following

measuring results:

G789 – Timer

G789 – Time Stamp

G789 – Start Delay

G381 – Laser Calibration

G382 – Temp. Compensation

Here it is possible to define job lists

(000-999), which allow the following

functions:

to start more than one NC

program in a row,

to allocate a pallet number to

every program

to restart an NC program by the

PLC after being aborted by, e.g.

ERROR Exit.

The execution of the job list is

continued with the next released

NC program.

Further information on the

job lists can be found

in the Help "Ncsatz_Bedienung.chm".

A parameter description and further information on the

individual cycles can be found in the "G&M code programming instructions"

or in the Help

Page 33

andronic CNC

XPanel Operating instructions

The main

The program-specific screen is divided

Array

Program

Administration

(B1)

Projects

Programs

33

menu

"Programs"

Illustration: The main menu "Programs"

General: the lists in B1 and B2 can be sorted. The column in which

sorting takes place and whether it is done asce nding or descending

order, can be seen from the triangle in the column heading.

Here both NC block and Expert Mode projects can

be created. A new project is created by pressing

the function key F1. The project is edited by

pressing Edit Project (F4). In an Expert Mode

project, first the menu is selected, and then IDN

and the program are selected. Only those files

are displayed that fit the menu in terms of type.

Optionally, as with the NC block project, a

commentary can be included.

The existing NC block or Expert Mode project is

then displayed in the right upper window.

into four areas.

The two left-hand windows are always

the same, while the two right-hand

windows depend on program

management and the current database

path, which can be set in the left lower

section.

In the upper section (B1) Program

Administration, projects, NC block,

expert (anlog-C) programs and menu

filenames are shown.

In the lower section (B2), either ID

files of anlog-C programs or menus are

selected or NC blocks or project files

are displayed.

Sorting can take place both in B1 and

B2 according to column. Since are

designed as split screen, the display

ratio of B1 and B2 can be adjusted.

Page 34

34

andronic CNC

XPanel Operating instructions

An Expert Mode project is advantag eous when starting up a program. Once the project has been selected, the

F1

Creates a new project

F2

Edits the project NC block or the proj ect ID file (depends on the project type)

F3

File Manager: Import/Export of database files

F4

Edits the project

F5

Edits the PRKON file of the project NC block (option in xpanel.exe.config)

F6

Compiles the project NC block

F7

Edits the NC parameters if the project NC block is parameterizable

F8

Compiles the project NC block, if necessary, and transfers it to the CNC or, in the case of an Expert

Mode project, loads IDN and program to the CNC.

F9

Visualization of the NC block by means of 3Division Basic (requires activation in dongle)

F10

Behind organization, a new function bar is hidden. It allows NC block projects and IDN s to be r enamed

Note

When renaming an NC block or an IDN, the project files are not renamed automatically.

ID file can be modified by means of the menu by pressing F2 and then transferred to the CNC togeth er with the

relevant program by pressing F4. In the absence of a projec t, in order to edit the IDN, first the item M enu would

have to be selected in Program A d ministration , t hen the menu and IDN would have to b e selected a n d then IDN

modified. To load the program and IDN , the item anlog-C programs and then the program and IDN w ould have

to be selected.

and also to be deleted. When deleting, a multiple selection is possible as with the Explorer. Upon

pressing F3, the file manager can be started and, upon pressing F9, the database directory can be

changed.

Page 35

andronic CNC

XPanel Operating instructions

Array

Program

Administration

(B1)

NC Programs

F1

New:

F2

Edit:

andron

The andron NC Editor is an optimal tool

F3

File Manager: makes Import/Export of database files easy for the user

F5

Edits the PRKON file of the NC block (option in xpanel. e xe.config)

F6

Compiles an NC block

F7

Edits the NC parameters within a project if the NC block is parameterizable

F8

Compiles an NC block, if necessary, and transfers it to the CNC.

be compiled always or only if it was modified. Default: false.

35

Here new NC blocks can be created, modified,

visualized, compiled and transferred to the CNC.

Creates a new NC block

Edits an existing

NC block using a convenient

NC editor

NC Editor

for editing NC block files of any size. It

contains a configurable NC syntax with

tooltips and integrated help. An NC

wizard and the option of data transfer

from the clipboard complete the software

package.

Note: By entering "CompileAlways" in the X Panel.exe-Config, you can control whether the NC block is to

Page 36

36

andronic CNC

XPanel Operating instructions

F9

Visualization of the NC block by means

F10

Behind organization, a new function bar is hidden. It allows NC blocks to be renamed and also to be

In B1, the existing NC blocks are visualized. If an entry is missing in the "Compiled on" column, the program was

of 3Division Basic

(requires activation in dongle)

deleted. When deleting, a multiple selection is possible as with the Explorer. Upon pressing F3, the file

manager can be started and, upon pressing F9, the database directory can be changed.

not yet compiled. If the entry is shown in red, the NC block source was modified after compiling.

In B2, the first lines of the selected NC block are shown.

If in B1 an NC block was selected that is parameterizable, th is is shown clearly in the Program Administration

area. If a parameter set already exists for this NC block, the item "NC block parameter" is shown in green,

otherwise in red.

Page 37

andronic CNC

XPanel Operating instructions

Array

Program

Administration

(B1)

anlog-C Programs

Array

Program

Administration

(B1)

Menus

F1

Creates a new IDN. The name offered for the IDN is the menu name. If this name already exists, the

F2

Edits an NC block or an ID file (depends on the project type)

F3

File Manager: makes Import/Export of database files easy for the user

F10

Behind organization, a new function bar is hidden. It allows the ID files that match the selected menu to

Note: F2 is only enabled if an IDN was selected and is focused.

37

Here program and IDN are selected and

transferred to the CNC for execution.

F8 Transfers program and IDN to the CNC

F10 Behind organization, a new function bar

is hidden. It allows the ID files that

match the selected program to be

renamed or deleted. Upon pressing F3,

the file manager can be started and,

upon pressing F9, the database

directory can be changed.

Here new ID files can be created or existing ones

edited. Depending on the selected menu, only

those IDNs can be selected that fit this menu.

name is formed from the menu name + index.

be renamed or deleted. Upon pressing F3, the file manager can be started and, upon pr e ssing F9, the

database directory can be changed.

Page 38

38

andronic CNC

XPanel Operating instructions

Array

Database (B2)

In the Database area, the existing valid

Sometimes, the reaction times may be quite long. This is caused by analysis of physical directories that are not

in the

Should the text in the Description

Database paths can be created and changed via the system configuration (in

databases are displayed.

If the user has administrator rights, the system

database paths are also displayed. By default,

they are shown in red. The color can be changed

by making a "SystemPathColor" entry in

XPanel.exe.Config.

If the user has administrator rights, but does not

want the system paths to be listed, he can

show/hide them via the "Sys" check box at the

top right in the database area. This setting

remains valid after switching off the control.

Moreover, all database paths are updated by

pressing the Sys key. This is why the key is also

valid if the user has no administrator rights.

present.

Database

The

Organization

The Path column contains the short name for the database path.

Cxx (custom) stands for a user database path, xx indicating the path number.

Sxx (system) stands for the system database path, xx indicating the path number.

The Path column also shows the respective database directory as tooltip.

column be too long, the complete description can also be shown as a tooltip.

Note:

area can be activated either via a pointer device or by pressing F9

toolbar. The data area cannot be activated by pressing the Tab key, but it can be left.

Service\Systemprogramme).

Change Directory

Page 39

andronic CNC

XPanel Operating instructions

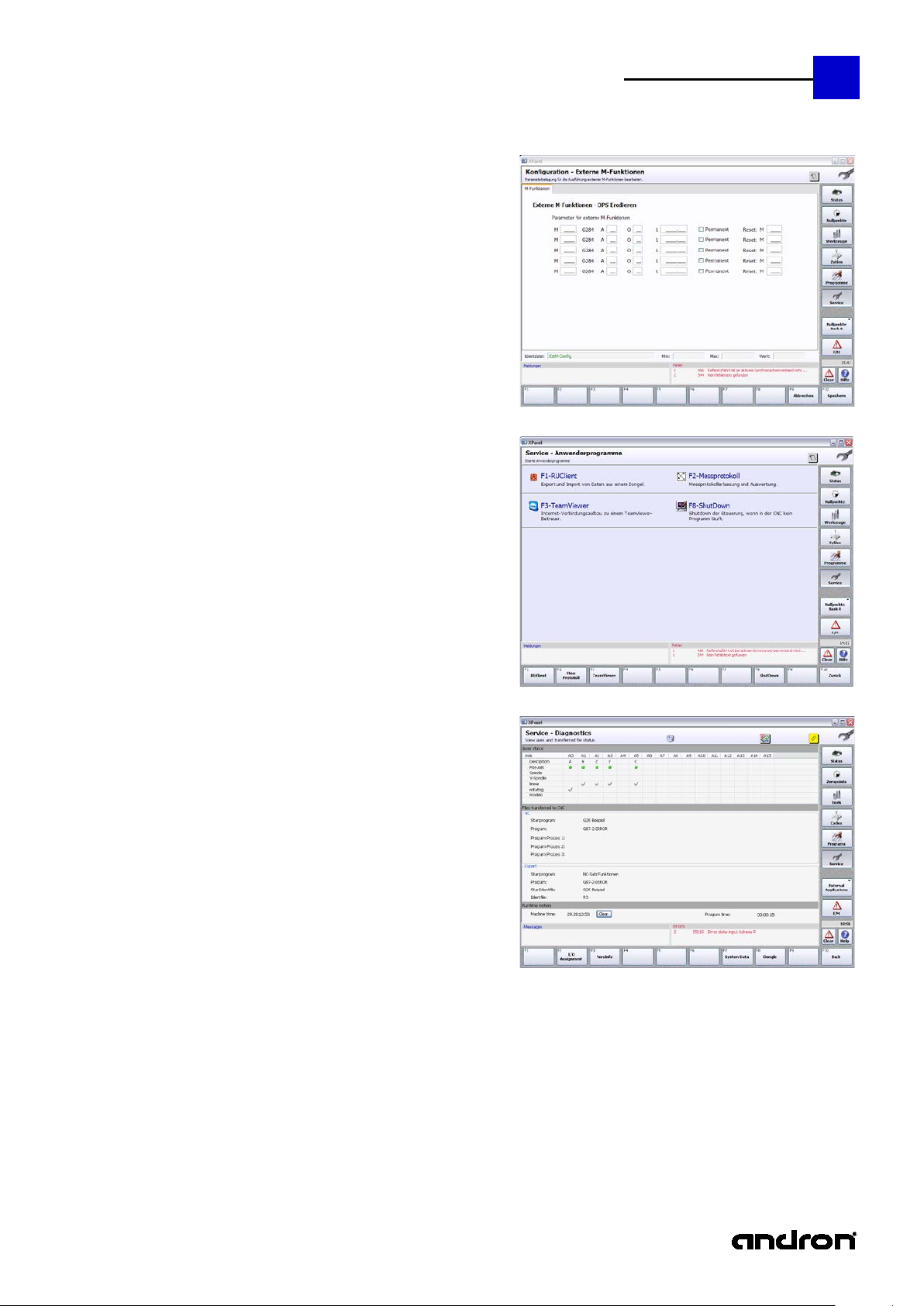

The Service

Here the basic configuration of the

F2

Tool Management

Tool Charger

Service

39

main menu

Illustration: The Service main menu

Configure tool charger and tool

magazine settings.

Magazine and change sequence

control and of the drives is

established.

Changes to the control and drive

configuration may only be made

by trained skilled personnel!

Note: If the user has no administrator

rights, he cannot used the functions

F2 - F6 (possibly F7).

Further i nformation can be found in the Help "Ncsatz_Konfiguration.chm".

Page 40

40

andronic CNC

XPanel Operating instructions

F3

Pallet Management

F4

Position Recording

Configure pallet management

Further information can be found in the Help "Ncsatz_Konfiguration.chm".

Record drive or control positions.

Page 41

andronic CNC

XPanel Operating instructions

F5

Configuration – GM-Code

The pages External M functions and

41

GM-Program settings (approaching

moves, external M-Commands, Block

Scan, special system events, offsets,

options)

Options describe the functionality of the

HMI in the main groups Cycles and

Service.

Changes will not become effective until

the XPanel is restarted.

Further i nformation can be found in the Help "Ncsatz_Konfiguration.chm".

Page 42

42

andronic CNC

XPanel Operating instructions

F6

System Applications

The system programs are used for

configuring the control and the

machine. The control should always be

shut down by pressing F8 ShutDown,

because this function first checks

whether a program is still being

executed on the machine. If this is the

case, the actual shutdown is prevented.

F1-Control Data:

Editing control parameters (EEPROM)

F2-Drive Data

Editing drive parameters (SERCOS)

F3-andron File Manager

Handling database

F4-System Configuration

Configuring of system components

F5-Position Analyser

Online position analysis

F6-DisLogData

Displays NC-Server logfile

F7-Virtual Machine

Virtual machine view

F8-ShutDown

Control Shutdown, if no program is

running at the CNC.

F9-Autologon

Configuration for automatic user login.

The general rule is:

Changes to the control and drive configuration may only be

made by trained skilled personnel!

Page 43

andronic CNC

XPanel Operating instructions

F7

External M-Functions

F8

Service – User programs

F9

Diagnostics

The start page provides information on

Program time is the time of the NC block to be executed.

43

Note:

If there are no external M functions (no

DLL installed), the function will be

shown in the overview, but it cannot be

selected.

Apart from the page of system

programs, there is also a page on which

user-specific programs can be stored.

By default, 4 programs are installed.

However, additional applications can be

added via a configuration file.

Diagnostics is designed not only to

provide the user with information on

the control and the machine, but also

assist him with problems.

This may include axis status, I/O

assignments, program and version

information and dongle data. Under

System Data, the user can view the

assignment CMOS, manual, PLC and

FastPLC parameters. As it is impossible

to visualize all parameters at the same

time, due to their large number, the

user has the option of displaying the

areas of interest.

Axes status:

Existing axes, axis designator, type and reference status. Red denotes not referenced, green

denotes referenced. The axis type - linear, rotating, modulo - is signaled by a check mark.

Files transfered to CNC:

This lists loaded programs, NC blocks and IDNs. In the execution of cycles, the information of the

Expert Mode can also be of assistance.

Runtime meters:

Machine time is the time during which the control was switched on.

Page 44

44

andronic CNC

XPanel Operating instructions

F2

I/O assignment

F3

VersInfo

F7

System data

F8

Dongle

provides all the information on the

signals of the 37-pin Sub-D socket, on

the InterBus-S, the NCIO card and NCM

X1X port.

provides the version information of

individual control components, but also

on another page an overview of the

previous product versions (History).

provides system data. They include

CMOS-RAM, manual, PLC and FastPLC

data. The areas to be displayed can be

defined by means of start and stop

indices.

View dongle information

Page 45

andronic CNC

XPanel Operating instructions

Errors and messages that have occurred during operation are visible in the compre ssed Error/Message display

The main

F2

Errors

F3

Messages

Error and Messages

45

menu Error

and Messages

(E/M)

under the main window. In contrast, in the E/M main menu, an entire page each is available for displaying error

and message texts.

Illustration: Compressed Error/Message display

The error messages can be reset by using the

CLEAR function.

Here errors and messages of the

control and of the machine are

displayed for the operator.

Errors are always shown in RED and

messages in BLUE.

Illustration: The main menu E/M (Errors and me ssages)

To switch between errors and

messages, press the function keys F2

and F3 or click on the tab at the top of

the window.

In contrast to error messages, message

texts cannot be deleted by the user!

This must be handled by the CNC or

PLC.

Page 46

46

andronic CNC

XPanel Operating instructions

Page 47

andronic CNC

XPanel Operating instructions

47

Page 48

48

andronic CNC

XPanel Operating instructions

Loading...

Loading...