Page 1

DE

EN

FR

andronic 3060

Next generation high speed CNC control

Page 2

2

Page 3

andronic 3060

Machine tools which are continuously advanced by the latest machine and processing

technologies require ever increasing performance of CNC control units. Quick data

processing, short block cycle times, high computational accuracy and interpolation

speed are important prerequisites which must be fullled by quick machine tool con-

trol systems.

For years, andron has been focusing on the highest performance, and with the

andronic series, it offers high-end CNC control systems for demanding applications

of all kinds.

Along with the fully digital drive control units of the ServoOne series, we offer you an

overall package which leaves nothing to be desired. High performance from control to

drive and sufcient power reserves to guarantee a constant traverse speed even with

vast data volumes.

With more than 30 years’ experience, we now develop control systems for high-speed

applications for a wide range of machine kinematics. Nowadays considered by others

as world novelty, the concept of an open CNC control has been successfully used for

years by andron.

andronic 3060. Dynamics of a new generation.

3

Page 4

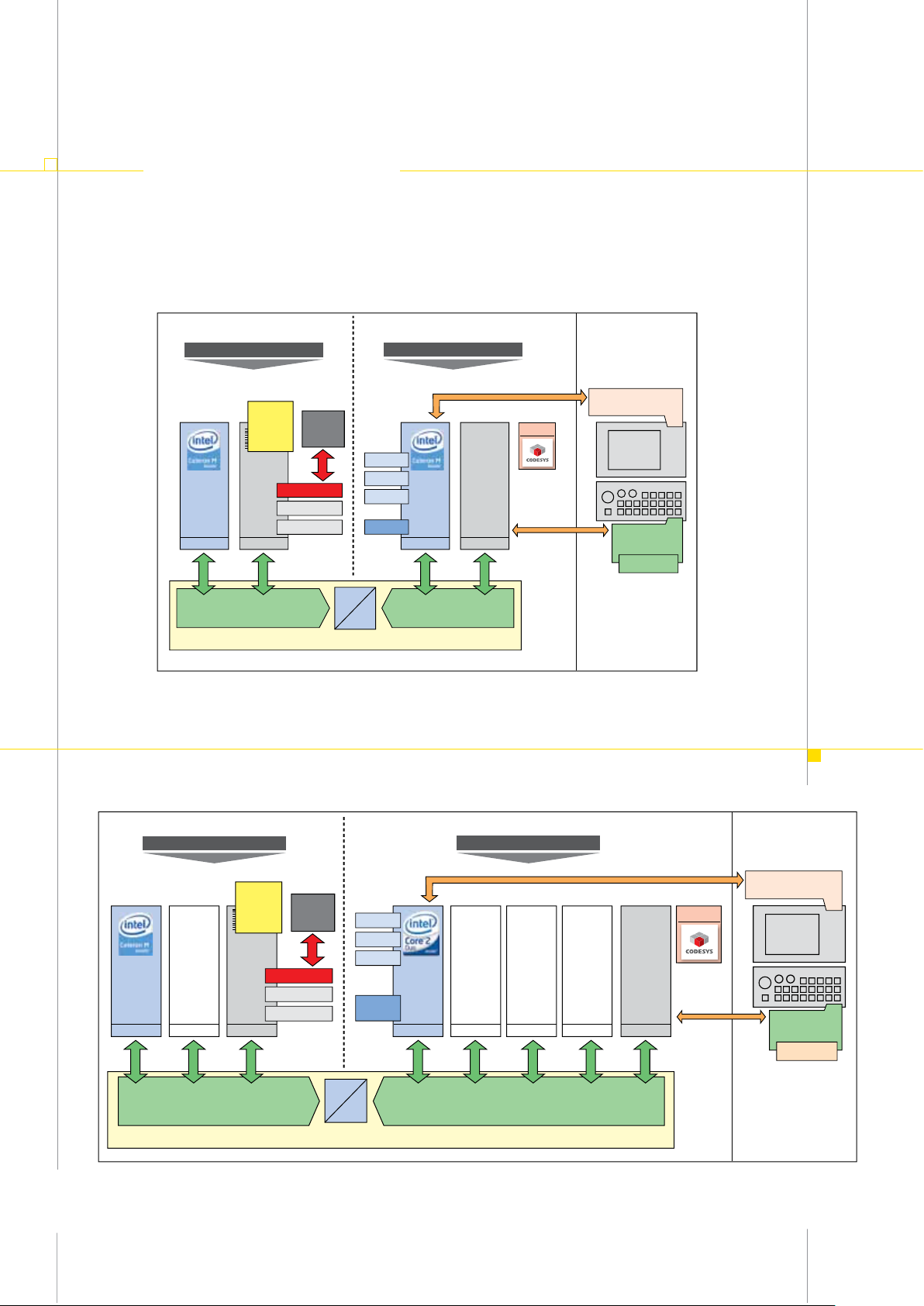

andronic 3060 Multi processor system

We are presenting the new CNC generation andronic 3060, a multi processor system

with modular power adaptation, integrated Soft-PLC and Windows® technology.

High functional security by using selected industrial PC components, the standardized

digital sercos interface and the current eld bus systems like EtherCAT, Probus,

InterBus or CANopen as interface to all I/O periphery devices present the openness

and exibility of the control system.

The principal item of the system designated andronic 3060 are two powerful Intel®

processors communicating with one another via a PCIe-to-PCIe bridge. One processor

is responsible only for the control kernel (NC computer) and the other for the user

interface (HMI computer).

The separation of functions allows separating processes and guarantees the complete-

ly undisturbed work sequence on the NC level whereas, independently and completely

separated from the former, the computing power required on the HMI level for data

handling or other actions does not lead to any capacity problems such as speed dis-

ruption or interruption to the work sequence.

4

Page 5

The control is available in two versions. The extremely compact control andronic 3060S for

standard applications and the bit bigger control andronic 3060L with enough performance for

high-end applications.

andronic 3060S andronic 3060L

5

Page 6

Technology Architecture

rO

andronic 3060S

NC controller HMI controllerOperating panel

andron Realtime Kernel

mobile mobile

NC CPU

board

SHB SHB

NC BUS (PCIe)

2-divided backplane with PCIe to PCIe bridge and a fan speed controller

andronic 3060L

LPN adapter

NCM2

Laser puls

generator

Handwheel

4 In/4 Outputs

NCM2 board

PCIe x1

To the

servo

controllers

sercos II/III

(max. 4)

PCIe

Microsoft Windows XP Pro

e.g.

USB 2.0

Ethernet

DVI/VGA

SATA HD

PCIe

HMI BUS (PCIe)

HMI CPU

board

optional

e.g. EtherCat, Modbus, Pronet, PowerLink,

Feldbus interface

master card

PCIe x1

Ethernet IP or Probus, CANopen, DeviceNET, ...

Soft PLC

USB touch controller

DVI/VGA TFT display

Op. panel logic BTL

Feldbus slave card

16 in/16 outputs

optional

6

NC controller HMI controlle

andron Realtime Kernel

LPN adapter

NCM2

Laser puls

generator

mobile mobile

NC CPU

board

SHB SHB

free PCI slot

PCI PCIe x1

NCM2 board

PCIe x1

NC BUS (PCIe)

2-divided backplane with PCIe to PCIe bridge and a fan speed controller

To the

servo

controllers

sercos II/III

(max. 4)

Handwheel

4 In/4 Outputs

PCIe

PCIe

USB 2.0

Ethernet

DVI/VGA

SATA HD

e.g.

HMI CPU

Microsoft Windows XP Pro

board

Free PCIe x1

slot

HMI BUS (PCIe)

e.g. for high end graphic cards

Free PCIe x16

slot

PCIe x16 PCI

optional

e.g. InterBus-S feldbus PCI card

Feldbus interface

Free PCI slot

master card

PCIe x1

e.g. EtherCat, Modbus, Pronet, PowerLink,

Ethernet IP or Probus, CANopen, DeviceNET, ...

Soft PLC

perating panel

USB touch controller

DVI TFT display

Op. panel logic BTL

Feldbus slave card

16 in/16 outputs

optional

Page 7

7

Page 8

andronic 3060 Features

Interpolation

The andronic system supports a large number of interpolation types, allowing simultaneous interpolation of a maximum of 16 axes.

Interpolation types: Linear (G00, G01), circle in the principal planes (G02, G03) and circle in the

space (G05), spline contours (cubic B-spline G31 - G35), third degree polynomials (G30), fth

degree polynomials (G305) and contours of a series of linear elements, circles, space circles, third

and fth degree polynomials.

Interpolation speed:

Max. 16 axes simultaneous with a physical axis resolution from 1/10 µm > 300 m/min

Compensation

Various axis and geometry errors can be compensated by the andronic control, i.e. compensation

of grid errors, cross errors, temperature errors, axis errors and spindle pitch errors.

Transformation

The andronic system supports complex coordinate transformations, such as translations, rotations, 5-axis RTCP, but also the Cartesian calculation of parallel kinematics (tripod, pentapod,

hexapod).

Look Ahead (foresighted CNC)

Dynamic look-ahead buffer providing a foresight of up to 25000 blocks. Symmetric position set

point lter for soft contour transitions.

Monitoring of machine limit values (max. axis speed, acceleration, jerk as a result of the active

position set point lter).

Monitoring of the programmed geometry (speed control on the basis of the max. contour deviati-

on in conjunction with the active position set point lter).

8

Page 9

Position set point assignment with 125µs / block cycle time < 100µs

Our CNC drive solution consisting of the open andronic 3060 CNC control and the ServoOne digital

drive control units is the fastest one currently available worldwide. Highest computing power in the

control system and drive control unit allows for a position set point assignment (sercos cycle time) of

125µs. The sercos interface located between drive and control provides real time synchronisation at

microsecond level.

Superimposed, independent coordinate systems

During each CNC process, it is possible to simultaneously move all the 16 axes in a particular coordinate system independently from all the others. Moreover, each process contains independent background

jobs for rotating axes, oscillating or execution of recurring contours. The execution of background jobs

may also be continued in semi-automatic mode (manual to automatic). The axis movement is a sum

of the movements made during execution of all processes and jobs.

Position-synchronous switching signals using additional hardware

Within a contour resulting from a series of G01, G02, etc, a pulse signal or permanent signal can be

switched on or off without exact stop at precisely dened positions (time resolution 10ns) (with 2m/s,

this results in a switching position resolution of 0.04µm). The pulse signal is dened by the pulse

length (typ. 500 ns) and the pulse interval in mm.

9

Page 10

andronic Operating interface XPanel

The pleasantly designed and clearly structured operating interface can be operated

intuitive. The Microsoft .NET based panel has a various number of conguration pos-

sibilities and can be adjusted problem-free onto the needs of the end user. The use of

future-pointing technologies during the development allows a simple migration onto

the new operating system Windows® 7.

Our andronic CNC controls has a wide range of applications from the classical machine

applications like milling, honing, grinding and eroding up to high dynamic processing.

For this reason we put a lot of value during the design of the new panel in individual

adjustment options and a optimal usability.

10

Page 11

CODESYS Programming system

With the latest-version CODESYS V3 you can program the andronic 3060 in the languages of IEC

61131-3. The application of international standards provides for a familiar programming environment

and uniform programming methodology, which also minimizes the required training and project plan-

ning commitment.

Nevertheless, programming in the current version CODESYS V2 is still possible.

Programming in the 5 languages of IEC 61131 and CFC

Docking Views technology to customize the workspace to your needs

Project archive for rapid exchange of applications

Object-oriented programming delivers enormous application benets

Context-sensitive online help

Display and edit variables in online mode

‚Online Program Change‘ function to reduce development lead time

Break points for error analysis and step-by-step commissioning

Break points with conditions to detect program errors in an even more targeted way

Single-step mode for tracking changes

Watchdog timer

11

Page 12

Smoother running and higher surface quality with PIKO interpolation

The output resolution for contour interpolation of the andronic 3060 was increased

from 1x10-7 m (0.0001 mm) to 0.6x10

polation cycle of 125 µsec in up to 16 CNC axes.

The pico value constitutes the internal computer precision and the output to the

digital sercos drives. It should not be confused with the machining tolerance at a

machine. (The picometer range is, for example, the range for the structures on the

surface of molecules.)

However, the higher computing resolution results in a more accurate interpolation in

speed and acceleration of the drives and thus in smoother running of the machine

tools. This results in a higher surface quality of the workpiece produced and in lon-

ger tool lives. This leads to a welcome reduction in costs in the production sector.

This impressive “interpolation in the pico range” is achieved, among other things, as

a result of the highly advanced communication technology and the use of fast Intel

processors in the andronic 3060 CNC controls.

-12

m (0.0000000006 mm) at a constant inter-

12

usually CNCpath interpolation

PIKO interpolation

Increase of the output resolution

in six further decimal points

Ideal contour

Page 13

Programming languages

G&M code programming

The andronic control supports standard G&M code programming in accordance with

DIN 66025 / ISO 6983.

The NC language and parameter programming functionality is considerably enhan-

ced by the exible programming FlexProg, a programming method known from

high-level languages. Programming of complicated processes and calculation is si-

gnicantly simplied by the use of global and local variables, free denition of func-

tions with call-up parameters and return value and the use of control structures for

conditional or repeated execution.

anlog-C programming

CNC programming in anlog-C, high-level language programming in accordance with

ANSI C, comprising more than 250 NC-specic commands for simple control/pro-

gramming of machine tools.

anlog-C has been developed by andron for the creation of NC programs that are

signicantly superior to conventional NC programs according to DIN 66025 with

respect to exibility and execution speed.

andron function interface AFL

The AFL software tool (andron Function Library) allows fast and easy integration of

your own programs and applications, ranging from measurement data evaluation

to the entire user interface (HMI), into the andronic CNC control system. Dened

commands provide access to all database contents and interface signals.

13

Page 14

andron 3Dvision

G&M code visualization, manipulation, model feedback and machine simulation

With its new 3D visualisation and simulation software, andron sets new standards in the eld of

virtual metal cutting for the new andronic CNC generation.

The efcient and realistic simulation solution enables analysis, control and optimisation of NC

programs already before the machining process.

Collision protection, programming of more complex processes, chronological coordination of axis

travels and the exact machining times can be calculated in advance.

The basis of the machining simulation is the exact emulation of the machine tool. Appropriate

programmes help you to create your own machine models with collision bodies and clamping

systems, both with and without CAD programmes.

In order to comply with the users’ requirements, andron has developed three versions with

different functionalities.

D

3

Simple visualization software with

structure analysis and single block

simulation to enable direct control of

the NC contour which has been pro-

grammed.

14

vision

vision PRO

D

3

G&M code visualization, manipulation,

model feedback with integrated postpro-

cessor, access to the andronic data base

and many other features.

vision VM

D

3

Fully integrated machine simulation with

complete ve-axis collision control and

machine builder for creating your own

machine models.

In one sentence: Real down to the last µ

Page 15

The quality of a workpiece and the cycle time

of the machine are substantially determined by

the programming and milling strategy of an NC

programme. Therefore, optimizing compiled NC

codes is all the more important.

Contrary to simulation tools, which are included

in the scope of services of different programming

systems, we focus on real simulations, i. e. all

contour modications inuencing the machining

process such as acceleration and brake reaction,

tolerance, smoothing constants and other internal

inuences are taken into account.

The simulation is not based on a mathematical

model, i. e. on the internal language of a CAM

system, but on the actually generated NC code of

the andronic control system.

15

Page 16

Technical data

System

andronic 3060S andronic 3060L

Backplane

Power supply

Housing

HMI controller

HMI CPU board

Harddisk

PLC

I/O interfaces

Operating system

NC controller

NC CPU board

PCIe backplane with PCIe to PCIe

bridge with integrated fan speed

control

24V DC, 150 VA or

115/230 V AC, 50/60 Hz, 200VA

Standard „small housing“ like in

the andronic 2060s

Half size slot CPU (Intel)

®

Celeron

with 1024 MB DDR RAM

Graphic-, Ethernet-, USB-,

SATA controller onboard

2,5“ SATA 320 GB (SSD optional) 2,5“ SATA 320 GB (SSD optional)

integriated soft PLC (CODESYS) integriated soft PLC (CODESYS)

optionally Probus, CANopen,

DeviceNET, EtherCAT,

Modbus, Pronet

Microsoft Windows

Microsoft Windows® 7 / x32

Half size slot CPU (Intel)

Celeron

with 512 MB DDR RAM

M / 1.73 GHz

®

M / 1.73 GHz

®

XP® Pro

PCIe backplane with PCIe to PCIe

bridge with integrated fan speed

control

24V DC, 150 VA or

115/230 V AC, 50/60 Hz, 200VA

Standard „large housing“ like in

the andronic 2060L

Full size slot CPU (Intel)

e.g. Pentium® Core2Extreme X9100 / 3,06 GHz

1024 ... 4096 MB DDR RAM

Graphic-, Ethernet-, USB-,

SATA controller onboard

optionally Probus, InterBus-S,

CANopen, DeviceNET, EtherCAT,

Modbus, Pronet,

Microsoft Windows® XP® Pro

Microsoft Windows® 7 / x32

Half size slot CPU (Intel)

e.g. Celeron® M / 1.73 GHz

with 512 MB DDR RAM

NCM2 board

Operating system

General

Protection cat.

Temp. range

Dimensions

NC multifunction board II with:

- sercos II / III interface

- up to 4 handwheels

- fast I/O inputs

- Laser puls generator (optional)

andron realtime kernel andron realtime kernel

IP20 IP20

+5°C … +45°C +5°C … +45°C

214 x 329 x 171,5 (WxHxD) 293 x 394,5 x 171,5 (WxHxD)

NC multifunction board II with:

- sercos II / III interface

- up to 4 handwheels

- fast I/O inputs

- Laser puls generator (optional)

16

Page 17

Display control panel ANV03

The ANV03 display control panel is

equipped with the following compon-

ents and interfaces:

Display control panel ANV04

In comparison with the ANV03, the

display control panel ANV04 has the

following additional features:

Machine control panel ANM013

The machine control panel is equipped

with the following components and

interfaces:

15“ TFT display (XGA)

Touch screen

7-fold USB controller

standard VGA and DVI interface

standard dimensions 19“ x 7 HE

(Special versions upon request)

32 additional keys for direct input

four control switches can be

integrated

Probus or InterBus-S interface

44 free assignable machine keys

EMERGENCY STOP button

override switches for spindle and

feedrate

16 inputs/outputs

connection for further I/O modules

key switch for operating modes

Standard dimensions 19“ x 4 HE

17

Page 18

andronic 3060 Dimensions

214.0

394.5

160.0

312.0

329.0

293.0

235.0

171.5

428.5

171.5

377.5

494.0

18

Page 19

482.6 (19")

41.5

65.0

USB-HUB

260.0

273.0

424.0

15" Touch-Display

113.0

R

310.5 (7HE)

272.8

155.3

55.0

90.0

139.0

8.8

38.0

8.8

10.0

5.5

60

40

20

10

6

2

0

0

!

95

90

80

%

100

85

90

100

120

100

+

105

80

110

70

110

115

60

120

50

%

III

A

B

SET

ALL

MOVE

C

Y

Z

X

.01 .001

.1

?

PLC

101.3

241.3

381.3

ANV03/04 ANM013

Protection IP 64 (front), IP 20 IP 64 (front), IP 20

Input voltage 24 V DC 24 V DC

Power consumption max. 75 VA max. 225 VA

Temperature range +5°C … +45°C +5°C … +45°C

ANV03

37.8

8.8

139.3

177.0 (4HE)

37.7

ANM012

19

Page 20

Everything for a successful automation

© 2013 andron GmbH. All rights reserved. No part of this document may be

reproduced or transferred for any purpose without express authorization in

writing by andron GmbH. Misprints and mistakes reserved, subject to techni-

cal change without notice. Stand: 08.2013 V 2.3

PC-based CNC control systems for integrating highly complex,

customer-specific movement sequences

5 in 1 automation, from controlled complex movement sequences,

drive controllers and motors, HMI Panels, User Tools and

Safety Standards

High power density motor elements and magnetic bearing technology

for high-speed drive systems for system solutions for the turbo generator

and turbo-compressor sector

Machine tool spindle and dressing technology for complete

work piece machining

andron GmbH

Schlätterstraße 2

88142 Wasserburg

GERMANY

Fon +49 (0) 8382

Fax +49 (0) 8382

/

/

Mail info@andron.de

www.andron.de

9855-0

9855-50

LTi DRiVES GmbH

Gewerbestraße 5-9

35633 Lahnau

GERMANY

Fon +49 (0) 64 41

Fax +49 (0) 64 41

Mail info@lt-i.com

www.lt-i.com

/

96 6-0

/

96 6-177

Loading...

Loading...