Page 1

2060

Introduction

1

Basics and overviews

2

Connection requirements

3

Operating panels

4

HMI/NC CPU card

5

NC multifunction card

6

TECHNICAL

HANDBOOK

andron GmbH

Schlätterstrasse 2

D-88142 Wasserburg / Bodensee

Phone:

Fax:

info@andron.de www.andron.de

+49 (0) 8382/9855-0

+49 (0) 8382/9855-50

Fieldbus interface card

7

8

9

PLC interface signals

10

Error messages

11

SPE / WPROM

12

Soft PLC / CoDeSys

13

Bootphase / BIOS codes

14

15

Page 2

Introduction

Page 3

Introduction

2

Technical Handbook

Editing/Illustrations Pasternak

Version V 1.1

Date 16.01.2007

Author Pasternak

Tools This documentation was created with Microsoft Word 2000 and Adobe Illustrator.

Trade mark All product names or trademarks are properties of their respective owners.

Copyright © andron GmbH 2007. All rights reserved.

Published by andron GmbH, Schlätterstr. 2, D-88142 Wasserburg/Bodensee

Copying this document, giving it to others and the use or communication of the contents thereof without express

authority, are forbidden. Offenders are liable for the payment of damages. All rights are reserved in the event of the

grant of a patent or the registration of a utility mode l or design.

Validity There could be additional functions running in the control who are not mentioned in this documentation. It insists no

claim for this functions, in case of a new delivery or a service case.

All rights are reserved with respect to the content of this documentation and the availability to the product.

Telephone +49 (0) 8382/9855-0, Fax +49 (0) 8382/9855-50

e-Mail:

info@andron.de

www.andron.de

01_introduction.doc

Page 4

Table of contents

Revisions........................................................................................................................................................ 4

General hints..................................................................................................................................................5

Safety notes...................................................................................................................................................6

Warning notes and symbols .....................................................................................................................6

Use as directed ....................................................................................................................................... 7

Introduction..................................................................................................................................... 7

Field of applications..........................................................................................................................7

Not used as directed................................................................................................................................7

Introduction

Technical Handbook

3

01_introduction.doc

Page 5

Introduction

4

Technical Handbook

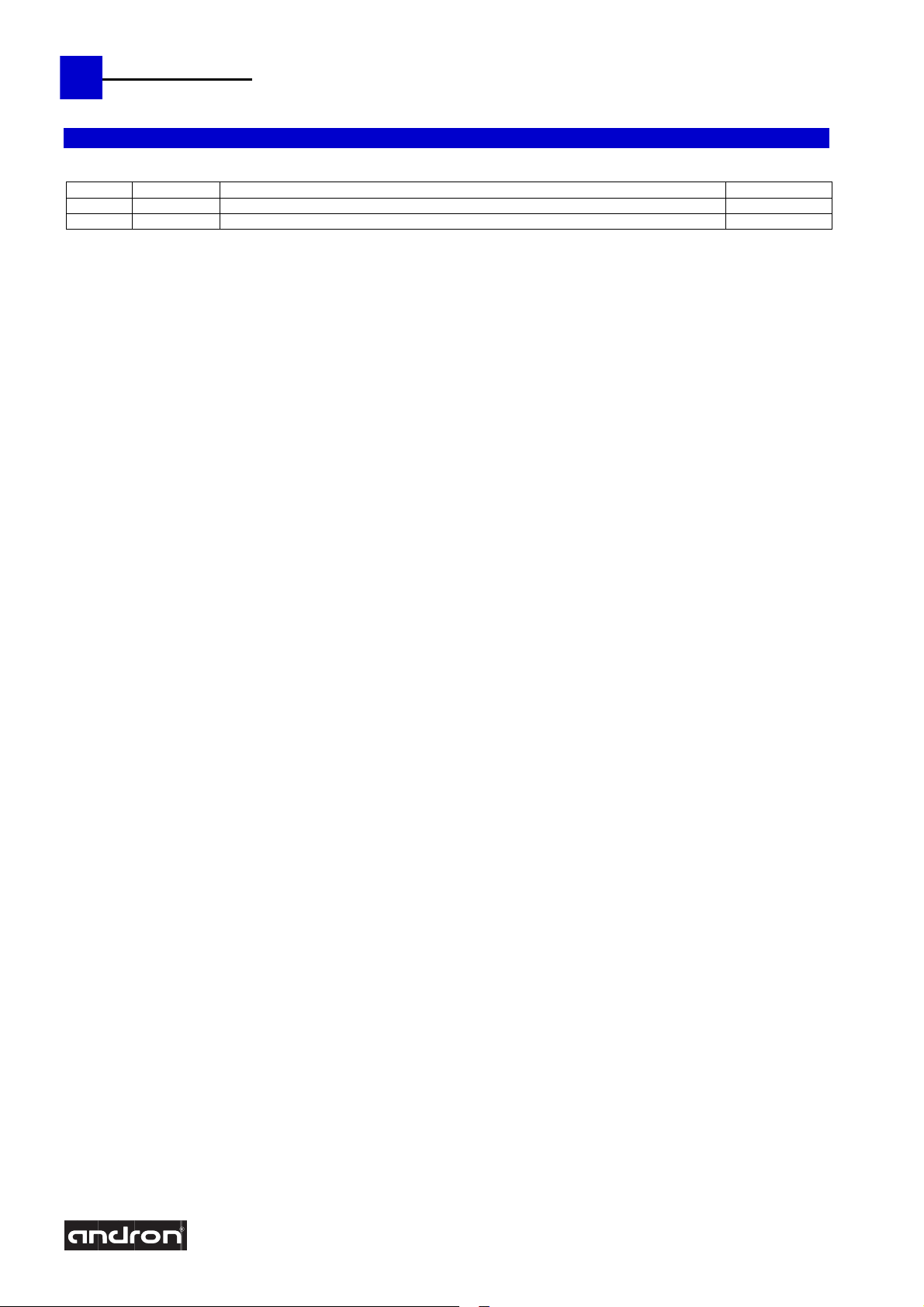

Revisions

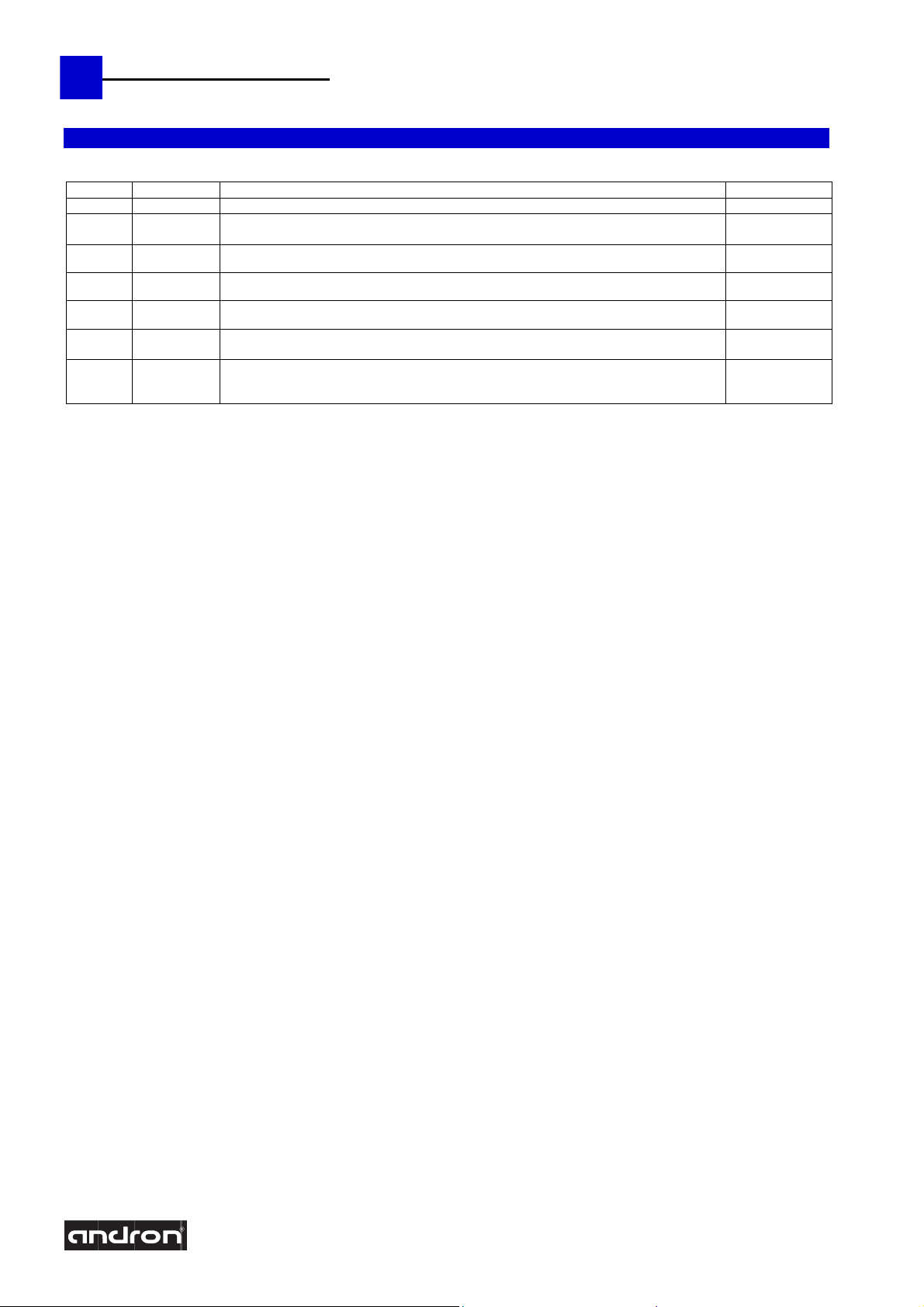

Version Date Additions and changes Initials

V 1.0 07.07.2003 First edition Pa

V 1.1 16.01.2007 Layout change to DIN A4 Su

01_introduction.doc

Page 6

General hints

In the creation of this handbook, we have made the greatest effort and have taken the

Introduction

Technical Handbook

greatest care. We reserve the right to make changes to this handbook and to the

controller or the programs, which are made necessary by technical progress, without

previous notice. In later versions, additional pages may be inserted. We would appreciate

your information as to errors in the handbook or how the handbook may be improved.

We accept no responsibility for damage resulting from neglect of the instructions

contained in this handbook.

We are neither liable for nor responsible for actual or alleged loss or damage, whether

direct or indirect, which is caused by the operated or delivered equipment or the software

programs, and which are claimed by a customer or another natural person or a legal

entity. This clause includes faulty service, lost business transactions, loss of expected

profit or consequential damages which occur due to the use of the equipment sold by us

or software generated by us.

We accept absolutely no responsibility for damage

This technical handbook, the programme descriptions belonging to it as well as other

objects sold or supplied with the controller, are protected by copyright. All rights are

reserved. This handbook, the programmes, and all other copyrighted objects may be

neither completely nor partially copied or in any other manner duplicated, without the

previous written consent of andron GmbH. Legally created copies, made with the

permission of andron GmbH, of a part of or the complete handbook, the computer

programmes or other copyrighted objects, must have the same copyright notice as the

original material.

Before connecting and starting up the control, the following documentation

due to faulty installation !

must absolutely be read!

5

01_introduction.doc

Page 7

Introduction

6

Technical Handbook

Safety notes

Warning notes and symbols

Meaning of the symbols used in this document:

Symbol Meaning

This notice contains general and additional information as well as

rules and prohibitions pertaining to damage prevention.

Danger notices for personnel and machine damage, i.e. information

as well as rules and prohibitions pertaining to personal injury and

material damage prevention.

Danger to life !!!

Danger of electrostatic discharge.

Important information or cross-references to further descriptions.

01_introduction.doc

Page 8

Use as directed

Introduction andron products are developed and produced according to the latest technologies. They

are not delivered unless they have been tested for service reliability.

The products may only be used as directed. If they are not used as directed, material

damage and personnel injury may result.

andron assumes no liability for damages due to inappropriate use. andron is not liable for

The following requirements must be met before using andron products to ensure proper

Field of applications The control is used for control panel integration, integration into housing or the door of

Not used as directed

The control is „not used as directed“ if it is used in a field of application not specified or if

payment of damages. The user is liable at his own risk if the products are not used as

directed.

use.

The corresponding safety instructions for use as directed must be read and

understood by all who operate one of our products.

If the products include hardware, the original condition must not be changed.

Software products must not be de-compiled and the source codes must not be

changed.

Damaged or faulty products must not be integrated or put into operation.

It must be guaranteed that the products have been installed according to the

instructions specified in this manual.

the switch cabinet or for machine tool housing integration.

It must be ensured that required mounting, installation and environment conditions are

fulfilled.

The control can only be used with the configurations described in this manual.

Furthermore, the use of a andron software or firmware is necessary.

Each control system must be parameterized an programmed by competent service

personnel before operation.

it is used under operating conditions or with technical data not specified in this manual.

The control must not be used if it is exposed to operating conditions which do not fulfill

the determined environmental conditions, e.g. use with water or with extreme

temperature differences or extreme maximum temperatures is not allowed.

Introduction

Technical Handbook

7

01_introduction.doc

Page 9

Basics and overviews

Page 10

Basics and overviews

2

Technical Handbook andronic 2060

Version V 1.6

Date 24.02.2010

Author Pa.

Editing/Illustrations Pa.

Tools This documentation was created with Microsoft Word 2000 and Adobe Illustrator.

Trade mark All product names or trademarks are properties of their respective owners.

Copyright © andron GmbH 2010. All rights reserved.

Validity There could be additional functions running in the control who are not mentioned in this documentation. It insists no

Published by andron GmbH, Schlätterstr. 2, D-88142 Wasserburg/Bodensee

Copying this document, giving it to others and the use or communication of the contents thereof without express

authority, are forbidden. Offenders are liable for the payment of damages. All rights are reserved in the event of the

grant of a patent or the registration of a utility mode l or design.

claim for this functions, in case of a new delivery or a service case.

All rights are reserved with respect to the content of this documentation and the availability to the product.

Telephone +49 (0) 8382/9855-0, Fax +49 (0) 8382/9855-50

e-Mail: info@andron.de

www.andron.de

02_basics_and_overviews.doc

Page 11

Table of contents

Table of contents............................................................................................................................................3

Revisions........................................................................................................................................................ 4

Hardware description......................................................................................................................................5

HMI computer.........................................................................................................................................5

NC computer...........................................................................................................................................5

Operating panels.....................................................................................................................................6

Connector and interface summary ................................................................................................................... 7

Survey of hardware components...................................................................................................................... 8

andronic 2060S ....................................................................................................................................... 8

andronic 2060L .......................................................................................................................................9

Survey of the operating panel connections ..................................................................................................... 10

Block diagram............................................................................................................................................... 11

Overview of the units.................................................................................................................................... 12

Front view of the andronic 2060S........................................................................................................... 12

Front view of the andronic 2060L ........................................................................................................... 13

Computer dimensions ................................................................................................................................... 14

Operating panel dimensions .......................................................................................................................... 15

Technical data.............................................................................................................................................. 16

Basics and overviews

Technical Handbook andronic 2060

3

02_basics_and_overviews.doc

Page 12

Basics and overviews

4

Technical Handbook andronic 2060

Revisions

Version Date Additions and changes Initials

V 1.0 03.07.2003 First Edition Pa

V 1.1 24.07.2003

V 1.2 26.08.2003 Additions: Profibus DP version Pa

V 1.3 18.03.2004 Additions: NCIO card with 37-pin I/O connector Pa

V 1.4 09.12.2005 Additions: Connector X80, X81 Pa

V 1.5 17.01.2007

V 1.6 24.02.2010

Change of CPU processor: Celeron CPU now with 1.2 GHz instead of 733 MHz

Change of harddisk: Fujitsu 2.5“ HD now with 40 GB instead of 20 GB

Layout change to DIN A4; New connector assignment X17, X19 and X60;

New HMI-CPU for andronic 2060L

Additions: Connector and interface summary (X2, X13, X19.5, X27, X42)

Update: Technical data (CPUs, HD, ...)

Pa

Su

Pa

02_basics_and_overviews.doc

Page 13

Hardware description

The andronic 2060 is a compact multiprocessor CNC system with HMI and NC computer

Basics and overviews

Technical Handbook andronic 2060

and an integrated Soft-PLC in one housings. Both computer systems communicate

together via fast PCI to PCI Bridge that is integrated on the common bus back plane. The

data transfer compared with previous systems rose up about the factor 50 and allows an

essentially faster communication between both computers.

The control is available in two versions. The extrem compact control andronic 2060S,

which is about 60 % smaller than the predecessor unit without any performance loss. The

bit bigger control andronic 2060L surpasses all previous standards in performance.

5

HMI computer

NC computer The NC computer contains a Celeron® plug-in CPU and a NC multifunction board (NCM) as

The HMI computer contains a Intel

with integrated Ethernet-, VGA- and IDE-Controller. The InterBus-S or Profibus-DP board

enables the connection to the operating panel and further I/O units. Beside the internal

hard disk, several USB interfaces for the connection of external devices like CD/DVD-ROM

or CD writer are available. For special applications further PCI boards can be configured

optionally in the andronic 2060L.

communication processor between the drive units and the control with all necessary

connections.

Besides the fast I/O interface and the four handwheel connectors, the NCM board has up

to four SERCOS interfaces available.

®

Celeron® M, Pentium® M or a Celeron® plug-in CPU

02_basics_and_overviews.doc

Page 14

Basics and overviews

6

Technical Handbook andronic 2060

Operating panels

Display operating panel

ANV03

XGA 15“ TFT display

Connection via standard VGA interface

Touch screen with USB interface

Standard dimensions 19“ x 7HE

Customer designs of inquiry

Machine operating panel

ANM013

Connected with control via InterBus-S or Profibus

Connection for further InterBus-S modules

Override switches for spindle and feedrate

EMERGENCY STOP button

Key switch for automatic and set-up mode with locking function

All keys with light-emitting diode confirmation

44 free assignable machine function keys

Connection of additional 16 input/ 16 output

Standard dimensions 19“ x 4HE

02_basics_and_overviews.doc

Page 15

Basics and overviews

Technical Handbook andronic 2060

7

Connector and interface summary

X Interface Module Connector Connection

X1 Mains power supply Power supply 3-pin mains plug 100-240V, 50/60Hz

X2 24V Power Input Power supply 2-pol. connector 24V Input

X5.1 Parallel interface LPT1 HMI CPU 25-pin SUB-D connector (female)

X9.1 Serial interface COM1 HMI CPU 9-pin SUB-D connector (male)

X11 Keyboard/Mouse interface HMI CPU 6-pin PS/2TM connector (female)

X13 RPO Remote-Power-On/Off RPO adapter 4-pin terminal connector

X17.1 VGA interface HMI CPU 15-pin mini SUB-D con. (female) X17.1 ⇔ X60.1

X17.2 DVI interface HMI CPU DVI connector (female) X17.2 ⇔ X60.2

X19.1 Ethernet interface HMI CPU RJ-45 connector

X19.2 Ethernet interface HMI CPU RJ-45 connector

X19.5 EtherCAT interface (andronic 3060) HMI CPU RJ-45 connector

X20.x USB interfaces HMI CPU USB connector (Type A)

X21 CNC fault NCM card 2-pin terminal connector

X22 I/O Interface (option) NCIO card 37-pin SUB-D connector (female)

X23.1 NCM-NCIO Bus NCM card 9-pin SUB-D connector (female)

X23.2 NCM-NCIO Bus (option) NCIO card 9-pin SUB-D connector (male) X23.2 ⇔ X23.1

X24.1 SERCOS transmitter (TX) NCM card Fibre optic connector

X25.1 SERCOS receiver (RX) NCM card Fibre optic connector

X24.2 SERCOS transmitter (TX) OPT card Fibre optic connector

X25.2 SERCOS receiver (RX) OPT card Fibre optic connector

X26 Keyboard interface NC CPU 6-pin PS/2TM connector (female)

X27 I/O interface (only andronic 3060) NCM2 card 10-pin terminal connector

X30 Handwheel interface NCM card 9-pin SUB-D connector (male) to the handwheel

X40.x 4 USB interfaces ^ANV03 USB connector (Typ A) X40.x ⇔ X63

X41 USB interface (input) ^ANV03 USB connector (Typ B) X41 ⇔ X20.x

X42 ANV04 key pad (USB) ^ANV04 USB connector

X50 InterBus-S interface InterBus-S card 9-pin SUB-D connector (female) X50 ⇔ X70

X51 Diagnosis interface InterBus-S card 9-pin SUB-D connector (male)

X52 Profibus-DP interface Profibus card 9-pin SUB-D connector (female) X52 ⇔ X76

X60.1 VGA interface ^ANV03 15-pin mini SUB-D con. (female) X60.1 ⇔ X17.1

X60.2 DVI interface ^ANV03 DVI connector (female) X60.2 ⇔ X17.2

X62 Power supply 24V, DC ^ANV03 2-pin terminal connector 24V, DC (TFT)

X63 USB touch controller ^ANV03 USB connector (Typ B) X63 ⇔ X40.x

X70 InterBus-S interface (in) ^ANM013 9-pin SUB-D connector (male) X70 ⇔ X50

X71 InterBus-S interface (out) ^ANM013 9-pin SUB-D connector (female)

X72 16 Inputs ^ANM013 2 x 8-pin terminal connector

X73 16 Outputs ^ANM013 2 x 8-pin terminal connector

X75.1 Power supply 24V, DC ^ANM013 2-pin terminal connector 24V, DC (BTL)

X75.2 Power supply 24V, DC ^ANV03 2-pin terminal connector 24V, DC (USB)

X76 Profibus-DP interface * ^ANM013 9-pin SUB-D connector (female) X76 ⇔ X52

X80 Handpilot AHP interface LWI card RJ-45 connector X80 ⇔ (AHP)

X81.x Fibre optic generator interface LWI card 4x Fibre optic connector

02_basics_and_overviews.doc

Page 16

Basics and overviews

E

5

0

40

R

8

Technical Handbook andronic 2060

Survey of hardware components

andronic 2060S

24V DC

Power USB

X75.2

24V DC

24V DC

to the

drives

Power TFT

X62

Power BTL

X75.1

SERCOS (1st ring)

SERCOS (2nd ring)

X24/25.2

2

X24/25.1

95

90

100

105

110

115

120

%

III

SET

ALL

MOV

X70 X71

LPT1

USB 1.1

X5.1

X20.2

USB-HUB

(USB 2.0)

but only with USB 1.1

X40.4

X40.3

X40.2

External USB 1.1

devices (HD, floppy

memory stick, ...)

X40.1

X41

USB Touch

X63

VGA

X60

ANV03

I/O

X72

X73

A

B

C

Y

Z

X

.01 .001

.1

?

PLC

ANM012

16 Inputs

16 Outputs

InterBus-S

INTERBUS-S

INTERBUS-S

Power

110-

240 V AC

X1

TX

RX

TX

RX

STA ERR

RUN RDY

DIAG

SCL

X19

Ethernet

X17

VGA

X50

InterBus-S

LAN

X20.1

USB 1.1 (out)

X26

NC Keyb.

X23

CNC Fault

X21

X9.1

COM1

X11

Keyb./

Mouse

16 In / 16 Out

Fast I/O Interface

Illustration: Connection survey of the operating panel and the andronic 2060S control with further external devices

02_basics_and_overviews.doc

INTERBUS-S

Page 17

E

5

0

40

R

andronic 2060L

24V DC

Power USB

X75.2

Basics and overviews

Technical Handbook andronic 2060

9

24V DC

24V DC

to the

drives

Power

110-

240 V AC

USB-HUB

(USB 2.0)

X40.4

X40.3

X40.2

External USB 2.0

devices (HD, floppy

memory stick, ...)

X40.1

X41

USB Touch

X63

Power TFT

X62

ANV03

VGA

X60

I/O

16 Inputs

16 Outputs

INTERBUS-S

Power BTL

X75.1

95

90

2

100

105

110

115

120

%

III

A

B

SET

ALL

MOV

C

Y

Z

X

.01 .001

.1

?

PLC

ANM012

X72

X73

INTERBUS-S

X70 X71

InterBus-S

SERCOS (1st ring)

SERCOS (2nd ring)

InterBus-S

LAN

Ethernet

X24/25.2

X24/25.1

X50

X19

Keyb./

Mouse

X11

STA ERR

X1

TX

RX

TX

RX

RUN RDY

DIAG

1

2

X20.1

USB 2.0 (out)

X17

3

4

VGA

X5.1

LPT 1

SCL

X26

NC Keyb.

X23

X21

CNC Fault

X9.1

COM 1

X20.x

USB 2.0

16 In / 16 Out

INTERBUS-S

Fast I/O Interface

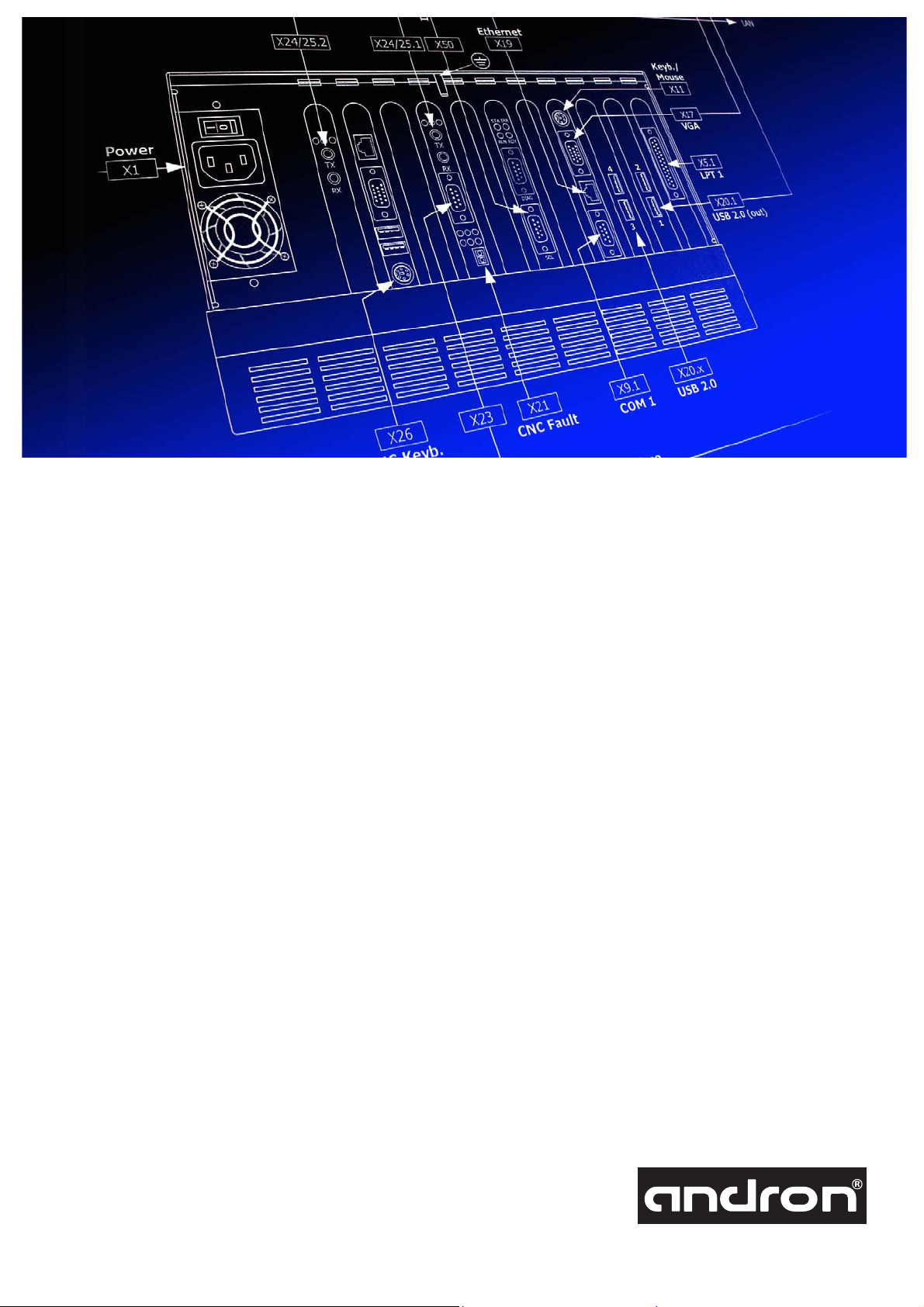

Illustration: Connection survey of the operating panel and the andronic 2060L control with further external devices

02_basics_and_overviews.doc

Page 18

Basics and overviews

10

Technical Handbook andronic 2060

Survey of the operating panel connections

External USB devices

(HD, floppy, memory stick, ...)

Power USB

X75.2

24V DC

USB-HUB

(USB 2.0)

X40.x

X40.1

USB

X63

24V DC

X62

2

1

Power TFT

GND

+24 V

Power BTL

X75.1

24V DC

ANV03

InterBus-S version (BTL09)

X41

InterBus-S cable

X70

VGA

USB Touchcontroller

X60

VGA cable

USB cable (aktive/passive)

X71

X17

X20.1

X50

HMI CPU

HMI CPU

InterBus-S

interface

ANM013

X72X73

16 Outputs

02_basics_and_overviews.doc

16 Inputs

InterBus-S devices

further

Page 19

Block diagram

CNC fault

1 - 2 SERCOS rings

1 - 2 Handwheels

Basics and overviews

Technical Handbook andronic 2060

NC computer HMI computer

Operating panel + 16 I/O´s USB touch controller

NCM board

PCI

16 I/O´s

NCIO board

(optional)

NC CPU board

PCI PCI PCI

External I/O´s TFT display

InterBus-S board

HMI CPU board

11

COM 1, USB 1.1

Ethernet

IDE hard disk drive

Optional (external)

USB hard disk drive

USB memory stick

USB floppy drive

USB CD/DVD-ROM

USB CD writer

2 divided backplane

with PCI to PCI bridge

NC BUS

Illustration: Block diagram of the andronic 2060s

NC computer HMI computer

CNC fault

Fast I/O´s

1 - 4 SERCOS rings

1 - 4 Handwheels

NCM board

PCI

NC CPU board

PCI

PCI

HMI BUS

PCI

Operating panel + 16 I/O´s USB touch controller

External I/O´s TFT display

Reserve

PCI PCI

Reserve

PCI PIGMG

InterBus-S board

HMI CPU board

Schema andronic 2060s-E.eps

COM 1, USB 2.0

Ethernet

IDE hard disk drive

Optional (external)

USB hard disk drive

USB memory stick

USB floppy drive

USB CD/DVD-ROM

USB CD writer

2 divided backplane

with PCI to PCI bridge

NC BUS

PCI

HMI BUS

PCI

Illustration: Block diagram of the andronic 2060L

02_basics_and_overviews.doc

Schema andronic 2060l-E.eps

Page 20

Basics and overviews

12

Technical Handbook andronic 2060

Overview of the units

Front view of the andronic 2060S

Power Supply 300 W

100-240 V, 50/60 Hz

NTGE0060

LED

- 5V

+ 5V

+12V

+ 3.3V

- 5V

OPT

128 MB SDRAM

+PCB0602

NC-CPU

NCM

NCIO (opt.)

HMI-CPU

INTERBUS-S

+LÜF0101

1234

Illustration: Open housing of the andronic 2060S

02_basics_and_overviews.doc

HD 2(Option)

HD 1

Page 21

Front view of the andronic 2060L

Basics and overviews

Technical Handbook andronic 2060

13

Power Supply 300 W

100-240 V, 50/60 Hz

NTGE0060

OPT

NC-CPU

NCM

HMI-CPU

INTERBUS-S

HD 2(Option)

HD 1

- 5V

+ 5V

+12V

+ 3.3V

- 5V

128 MB SDRAM

HD Power

+5V

GND

+5V

GND

256 MB DDR RAM

2x

PW1

LED

+PCB0601

+LÜF0101

1234

Illustration: Open housing of the andronic 2060L

02_basics_and_overviews.doc

Page 22

Basics and overviews

14

Technical Handbook andronic 2060

Computer dimensions

312.0

329.0

214.0

160.0

171.5

Klappdeckel nicht abnehmbar

Hinged lid not removable

428.5

377.5

394.5

293.0

235.0

171.5

494.0

Klappdeckel nicht abnehmbar

Hinged lid not removable

02_basics_and_overviews.doc

Page 23

R

Operating panel dimensions

ANV03

65.0

41.5

482.6 (19")

15" TFT-Display

424.0

Basics and overviews

Technical Handbook andronic 2060

113.0

15

ANV04

65.0

41.5

USB-HUB

USB-HUB

260.0

260.0

(7HE)

273.0

310.5

272.8

155.3

38.0

ANV03

37.8

482.6 (19")

424.0

113.0

7 8 9

456

123

+

0.

α

Esc

Del

15" TFT-Display

273.0

38.0

Ins

Ctrl

Alt

Help

Enter

End

ANV04

(7HE)

310.5

272.8

37.8

ANM013

8.8

10.0

5.5

95

90

80

%

100

100

85

90

100

110

120

+

105

80

110

70

115

60

120

50

%

III

A

B

SET

ALL

MOVE

C

Y

Z

X

.01 .001

.1

?

PLC

ANM012

101.3

241.3

55.0

90.0

139.0

60

40

8.8

20

10

6

2

0

0

!

381.3

02_basics_and_overviews.doc

8.8

37.7

139.3

(4HE)

177.0

Page 24

Basics and overviews

16

Technical Handbook andronic 2060

Technical data

HMI computer andronic 2060L andronic 2060S

CPU card Full-Size slot CP U

Hard disk drive 120 GB / 2.5 inch 120 GB / 2.5 inch

PLC integrated soft PLC (CoDeSys) integrated soft PLC (CoDeSys)

I/O interfaces InterBus-S / Profibus-DP InterB us-S / Profibus-DP

Operating system

NC computer

CPU card Half-Size slot CPU

NCM card NC multifunction card NC multifunction card

Interfaces Handwheel

Celeron M / 1.6 GHz or

Pentium M /1.8 GHz

512/1024 MB DDR RAM

Graphic, Ethernet and

IDE controller onboard

USB 2.0

®

Microsoft Windows

Celeron 1.2 GHz or Celeron M 1.6 GHz

128 MB RAM

Fast inputs for:

Emergency stop, stop, release,

measuring signal

Opener for “Fault“

SERCOS interface (optical) up to 4

rings

2000/XP® Microsoft Windows® 2000/XP®

Half-Size slot CPU

Celeron / 1.2 GHz or Celeron M 1.6 GHz

256/512 MB RAM

Graphic, Ethernet and

IDE controller onboard

USB 1.1/2.0

Half-Size slot CPU

Celeron 1.2 GHz or Celeron M 1.6 GHz

128 MB RAM

Handwheel

Fast inputs for:

Emergency stop, stop, release,

measuring signal

Opener for “Fault“

SERCOS interface (optical) up to 2

rings

Operating system andron realtime op. system andron realtime op. system

General

Internation Protection IP 20 IP 20

Input voltage 100-240 V AC, 50/60 Hz 100-240 V AC, 50/60 Hz

Power consumption max. 300 VA max. 300 VA

Temperature range +5°C … +45°C +5°C … +45°C

Dimensions 293 x 394.5 x 171.5 (WxHxD) 214 x 329 x 171.5 (WxHxD)

Operating panels ANV03/ANV04 ANM013/ANM002

Protection IP 64 (front), IP 20 IP 64 (front), IP 20

Input voltage 24 V DC 24 V DC

Power consumption max. 75 VA max. 225 VA

Temperature range +5°C … +45°C +5°C … +45°C

02_basics_and_overviews.doc

Page 25

Connection Requirements

Page 26

Connection Requirements

2

Technical Handbook

Editing/Illustrations Pa

Version V 5.2

Date 01.02.2007

Author Vo/Pa

Tools This documentation was created with Microsoft Word 2000 and Adobe Illustrator.

Trade mark All product names or trademarks are properties of their respective owners.

Copyright © andron GmbH 2007. All rights reserved.

Validity There could be additional functions running in the control who are not mentioned in this documentation. It insists no

Published by andron GmbH, Schlätterstr. 2, D-88142 Wasserburg/Bodensee

Copying this document, giving it to others and the use or communication of the contents thereof without express

authority, are forbidden. Offenders are liable for the payment of damages. All rights are reserved in the event of the

grant of a patent or the registration of a utility mode l or design.

claim for this functions, in case of a new delivery or a service case.

All rights are reserved with respect to the content of this documentation and the availability to the product.

Telephone +49 (0) 8382/9855-0, Fax +49 (0) 8382/9855-50

e-Mail:

info@andron.de

www.andron.de

03_connection_requirements.doc

Page 27

Connection Requirements

Technical Handbook

Table of contents

Revisions........................................................................................................................................................ 3

General connection requirements..................................................................................................................... 4

Static Electricity..............................................................................................................................................5

Dust and Dirt.................................................................................................................................................. 5

Transport and Mounting.................................................................................................................................. 5

Display....................................................................................................................................................5

Operating panel.......................................................................................................................................5

Electronic Rack / Operating Panel .................................................................................................................... 6

Mounting positions .................................................................................................................................. 6

Location.........................................................................................................................................................6

Mains Connection ........................................................................................................................................... 7

Important information on wiring...................................................................................................................... 8

Shielding and Grounding .................................................................................................................................9

Interference Suppression .............................................................................................................................. 10

Alternating current......................................................................................................................... 10

Direct current ................................................................................................................................ 10

Non-contacting switches (Initiators)........................................................................................................ 11

Mechanical switches .............................................................................................................................. 11

Creeping contacts.................................................................................................................................. 11

Adjustment................................................................................................................................................... 11

Connection values......................................................................................................................................... 12

Operating and ambient conditions.................................................................................................................. 12

Revisions

Version Date Additions and changes Initials

V 5.0 08.07.2003 Revised version Pa

Changes:

V 5.1 16.07.2003

V 5.2 01.02.2007 Layout change to DIN A4 Pa

Operating and ambient conditions

Temperature: Storage/Transport -20°C ... +45°C

Pa

3

03_connection_requirements.doc

Page 28

Connection Requirements

4

Technical Handbook

General connection requirements

The following notes generally must be observed:

Inputs with safety functions (e. g. release feed, emergency stop, ...) must be

All connections are to be made according to the information contained in the

documentation of the control.

Make sure that all soldering points are clean.

Only shielded cables may be used.

The shielding is to be carried out according to the requirements (see "Shielding").

Emergency stop and limit switches must always be designed as break contacts, in

order to cause the control to stop immediately in case of a connecting cable break.

The control is not a mediate Emergency Stop switching element; i. e. an

Emergency Stop must also suspend all movements of a machine immediately

even without a control!

absolutely connected to the control and switches, and the cables must have been

checked as well for their function before the first turn on.

Safety switches must always be connected in series (e. g. emergency stop circuit).

Drives with closed control circuits must have, in addition to limit switches, also

mechanical safety limit switches following those in the path. These must be handled

electrically like an EMERGENCY STOP and must be integrated into the available

emergency stop loop.

Work on the control and the electrical connections may

only be performed with the supply voltage turned off

and by qualified personnel!

03_connection_requirements.doc

Page 29

Connection Requirements

Technical Handbook

5

Static Electricity

When installing or replacing hardware components, you should always discharge the static

electricity on your body as it can cause damage to electronic components or even to entire

assemblies. To discharge the static electricity, touch the metal of the control.

Electronic components such as ICs and memory modules on the pc-boards are very

sensitive to static electrical discharges and are easily damaged by them. Be sure that the

service personnel are suitably grounded before they touch pc-boards and pcb-components.

The drier the surroundings, the more likely it is that static electricity occurs.

When replacing plug-on cards, don't contact the components on the cards or their "golden

fingers". Before components and assemblies are inserted or connected, the control must be

built-in and grounded via the ground stud.

Please handle all electrostatically sensitive pc-boards and assemblies only at

a secured working area.

Use only ESD shielding bags for transporting and handling

pc-boards and components.

Dust and Dirt

Malfunctions in many cases result from dusty, polluted or greasy contacts. Proper

functioning of the control can only be ensured when all components are treated with the

necessary care. When replacing a pc-board pay special attention to the gold-plated contact

surface of the BUS connector as it oxidises rapidly when touched. Use an eraser to clean

the surface when it is dirty.

Transport and Mounting

Instructions for securing it with the available transport safety devices must be observed.

Hard shocks must be prevented under all circumstances, because the display and the builtin hard disk could encounter irreversible damage.

It must be absolutely precluded that electronic components and pc-boards are exposed to

the danger of shorting (wetness, accidental grounding by improper handling and storage

during operation)

Display

Although the electronics and high tension conducting parts of the display are protected

The display must be protected from mechanical loads and shocks.

from being touched by a sheet-steel housing, the following notice is expressly given:

The internal space of the display housing can also be under high tension after

the power has been turned off! The device may only be opened at the factory.

Operating panel

03_connection_requirements.doc

Be careful when mounting the operating panel that the foil is not damaged (e. g. by

pointed or sharp tools, soldering iron, ...).

Page 30

Connection Requirements

T

6

Technical Handbook

Electronic Rack / Operating Panel

An electronic rack sealed according to IP 54/55 with a heat exchanger or an air conditioner

is to be used. The admissible environmental temperature of 45°C for the control in the

electronic rack must not be exceeded. Free circulation of air in the rack must be

guaranteed. In order to guarantee a sufficient ventilation, approx. 100 mm space along the

full width must be left free above and at the front of the control.

High frequency generators, transformers, power generators etc., must not be installed in

the immediate vicinity of the control.

Mounting positions

When mounting the control in the electronic rack or in the operating panel only the

following

mounting positions are allowed.

Location

Illustration: Allowed mounting positions of the con ol modul t

he location of the control is decisive for its proper functioning. The mounting instructions

and the connection instructions therefore must be exactly followed. In case of doubt,

contact our service technicians who will be glad to assist you.

The most important mounting instructions are:

The installation must be performed without heavy shocks. The position of

the control must be such that there are no shock influences, otherwise the

built-in hard disk or the display could be damaged.

The control should not be exposed to external heat sources (e. g. strong

sunshine, heat blowers, etc.); its maximum admissible ambient temperature

= 45°C.

is T

amb

Before turning on the control, ensure that the mains voltage corresponds to

the admissible operating voltage of the control.

Ensure that the mains connection is non-disruptive. If the mains voltage

conditions are critical, a constant voltage controller must absolutely be

used. When checking the mains condition, a full daily routine or a multi-shift

period must be considered.

03_connection_requirements.doc

Page 31

Connection Requirements

Technical Handbook

7

Mains Connection

The mains voltage must correspond with the admissible operating voltage of the control.

This is achieved by connection to the 230 V mains or via a transformer 400/230V

(50/60 Hz).

For installation in the U.S.A., the mains voltage is 115 V.

The mains voltage supplied to the control must not have the same phase as contacts,

relays and other switching elements or devices of the control cabinet.

L1

L2

L3

N

PE

115V/230V

1 2

Trennung.eps

Illustration: Mains power supply of the control connected with a different phase

1 Relays, con actors, magnetic valves, ... t

2 Control

All transformers used must be provided with a protective winding connected to a ground

wire. Thus, the danger of a voltage flashover between windings is decreased and the noise

ratio is also enhanced.

By using U-sections with separate side windings (one side prim., one side sec.), the

protective winding can be omitted.

If the mains voltage conditions are critical, a constant voltage controller must be absolutely

used. When selecting it, the power consumption of the control must be taken into account!

On request, we will deliver suitable transformers or constant voltage controllers.

In general, the regulations of the local electric supply company are to be observed.

03_connection_requirements.doc

Page 32

Connection Requirements

8

Technical Handbook

Important information on wiring

The ground cables must be connected first to divert the static electricity.

For all signal lines, shielded cables are to be used, whereby the shields must only be

connected to the metal connector housing of the connectors on the control side.

For all signal lines, the minimum line cross-section must not be less than 0.25 mm

2

.

All line cross-sections must correspond to the guidelines of the VDE 0113.

Make sure that all solder and squeeze connections are perfectly in order. All

connections are to be established according to our documentation.

All SUB-D connectors must be screwed to the housing.

Mains connection minimum 3 x 1.5 mm

SL connection to the ground stud min. 4 mm

SL busbar to the ground potential minimum 16 mm

2

2

2

The fibre-optic and coaxial cable must not be bent. When laying it, the minimum

bending radius must be not be less than the indicated value.

The bending radius of the SERCOS fibre-optic cable must not be less than 50 mm.

Please note also the information in the respective

chapters of the hardware description

Special care should be taken with reference to the outputs which lead to relays, contactors,

valves, timer switching devices, etc.

The input and output lines should be generally as short as possible and laid at a

distance to high tension lines.

The cable trees for load and control circuits should also be laid separately!

1

Illustration: Separate layout of load and control cables

1 Load circuits (Relays, con actors, valves, ...)

2 Control circuits (Control, ...)

t

03_connection_requirements.doc

2

Last- und Steuerkreis.eps

min. 30 mm

Page 33

Connection Requirements

Technical Handbook

9

Shielding and Grounding

All shields may only be connected on the side of the signal source and must be combined

by means of a ground cable busbar (clamping strip) and connected jointly to the ground

cable potential. The grounding and shielding connections must be established as shown in

the following illustration.

min.

2

O 4mm

Quelle

(Source)

Quelle

(Source)

min. O 16mm

2

PE-Sammelschiene.eps

Illustration: Shielding and grounding of the modules

For all signal cables connected to the control, the shielding is provided on the

control side. For this, only the mating connector and housing made of metal

(conducting) material may be used. The grounding is achieved via the shield on

the connector housing to the PE (SL) busbar.

Illustration: PE ground connection o the control module f

Proper ground connection to the computer and the

operating panel must be ensured.

03_connection_requirements.doc

Observe the VDE regulations!

Page 34

Connection Requirements

10

Technical Handbook

Interference Suppression

When the above mentioned instructions are followed, interference sources can be almost

entirely excluded. However, in spite of care and cabling according to the instructions, the

following section on interference reduction is to be absolutely observed.

Alternating current Switching contactor coils can cause interference in the supply lines. Therefore, especially in

alternating current protective systems via an RC member or varistors parallel to the coils,

interference reduction measures are to be performed.

Guide values for 230 V contactors:

R=100 ohms, C=0.1 µF, U=630 VAC

Direct current • All direct current coils, (relays, solenoids) on the machine must be provided with an

anti-surge diode. This anti-surge diode must be connected in the immediate vicinity

of the coil. The correct polarity must be observed.

-

CR

Varistor

+

Spulen.eps

Illustration: Interference reduction on coils n an alternating and direct current circuit i

We want to emphasise that we assume no liability for proper functioning or any

damage when these instructions have not been followed!

03_connection_requirements.doc

Page 35

T

Non-contacting switches (Initiators)

Mechanical switches

Creeping contacts

The quality of the output signals of the non-contact switches is decisive for the perfect

functioning of the control electronics. In order to prevent oscillation tendencies at the

output of these switches, only stabilized supply voltages may be employed. The neutral

conductor to the initiators must be achieved by connection to the neutral point of the

power supply.

• With mechanical switches, only those with spring contacts should be used. Take

care that the contact pressure and contact material is suitable for the

corresponding switching current.

In general, interference suppression is to be performed for every sink. The

procedures recommended by the manufacturer are to be performed and the

corresponding interference material is to be built in. If these interference

suppression measures are not carried out, malfunctions cannot be excluded.

This is also valid for contactors.

Creeping contacts are often found in pressure and temperature switches. These cause

especially hard to locate disturbances when they take on an instantaneous undefined state

during switching from the "ON" to the "OFF" state and an arc path occurs ("spattering").

hey create electromagnetic waves, as in a spark transmitter, when an inductive load

follows. In such cases, spring switches or non-contacting switches must be installed.

Connection Requirements

Technical Handbook

11

Adjustment

Every machine-specific parameter, except for the adjustment of the drive, is adjusted in the

EEPROM by means of a separate alphanumeric keyboard. No changes must be made on the

individual cards.

Before the first movement of the axes, the following parameters in the EEPROM are

If there is a modification to the cards, not made by one of andron's authorised

service personnel, all guarantees and claims for service under the guarantee are

void.

absolutely to be checked and, as the case may be, to be adapted:

Resolution of the axes

Axes limitations

Speeds

Zero traversing sequence

Ramp curve

Furthermore, it must be ensured that the limit switches are connected to the correct inputs

and are functioning properly. Likewise, this is valid also for the EMERGENCY STOP switch.

In order to prevent damage in the first movement, it must be observed that the override

potentiometer is approx. at the 10% position and that creep traversing mode has been

selected.

We assume no liability for damage, when the connection requirements have not

been fulfilled or have been performed by unauthorised service personnel!

03_connection_requirements.doc

Page 36

Connection Requirements

12

Technical Handbook

Connection values

Computer power supply Input voltage 100-240 V AC, 50/60 Hz

Power consumption max. 300 VA

Display power supply Input voltage 24 V DC, +/- 10%

Power consumption max. 75 VA

USB-Hub power supply Input voltage 24 V DC, +/- 10%

Power consumption max. 75 VA

Input voltage 24 V DC, +/- 10% Operating panel ANM013

Power consumption max. 225 VA

Operating and ambient conditions

In operation Storage/Transport

Ambient temperature +5°C ... +45°C -20°C ... +45°C

03_connection_requirements.doc

Page 37

Operating panel modules

Page 38

Operating panel modules

2

Technical Handbook andronic 2060/3060

Version V 1.2

Date 26.05.2010

Author Pasternak

Editing/Illustrations Pasternak

Tools This documentation was created with Microsoft Word and Adobe Illustrator.

Trade mark All product names or trademarks are properties of their respective owners.

Copyright © andron GmbH 2010. All rights reserved.

Validity There could be additional functions running in the control who are not mentioned in this documentation. It insists no

Published by andron GmbH, Schlätterstr. 2, D-88142 Wasserburg/Bodensee

Copying this document, giving it to others and the use or communication of the contents thereof without express

authority, are forbidden. Offenders are liable for the payment of damages. All rights are reserved in the event of the

grant of a patent or the registration of a utility model or design.

claim for this functions, in case of a new delivery or a service case.

All rights are reserved with respect to the content of this documentation and the availability to the product.

Telephone +49 (0) 8382/9855-0, Fax +49 (0) 8382/9855-50

e-Mail: info@andron.de

www.andr

on.de

04_operating_panel_modules.doc

Loading...

Loading...