Page 1

Page 2

andronic 2060

2

Operating Instructions

Editing/Illustrations Pasternak

Version V 1.0

Author Pasternak, Scholz

Filename operating_instructions_andronic_2060 _v1_0.doc

Trademark All product names or trademarks are properties of their respective owners.

Copyright © andron GmbH 2005. All Rights Reserved.

Validity There could be additional functions running in the control who are not mentioned in this

Published by andron GmbH, Schlätterstraße 2, 88142 Wasserburg, Germany

Date 29.04.2005

Tools This documentation was created with Microsoft Word 2000 and Adobe Illustrator.

Copying this document, giving it to others and the use or communication of the contents thereof

without express authority, are forbidden. Offenders are liable for the payment of damages. All rights

are reserved in the event of the grant of a patent or the registration of a utility model or design.

documentation. It insists no claim for this functions, in case of a new delivery or a service case.

All rights are reserved with respect to the content of this documentation and the availability to the

product.

Telephone +49 (0) 8382/9855-0, Fax +49 (0) 8382/9855-50

e-Mail:

info@andron.de

www.andron.de

Page 3

Operating Instructions

andronic 2060

Table of contents

Table of contents.................................................................. 3

Revisions.............................................................................. 3

Notice ..................................................................................4

Safety notes ......................................................................... 4

Warning notes and symbols............................................ 4

Use as directed.............................................................. 5

Introduction ...........................................................5

Field of applications ................................................5

Not used as directed ...................................................... 5

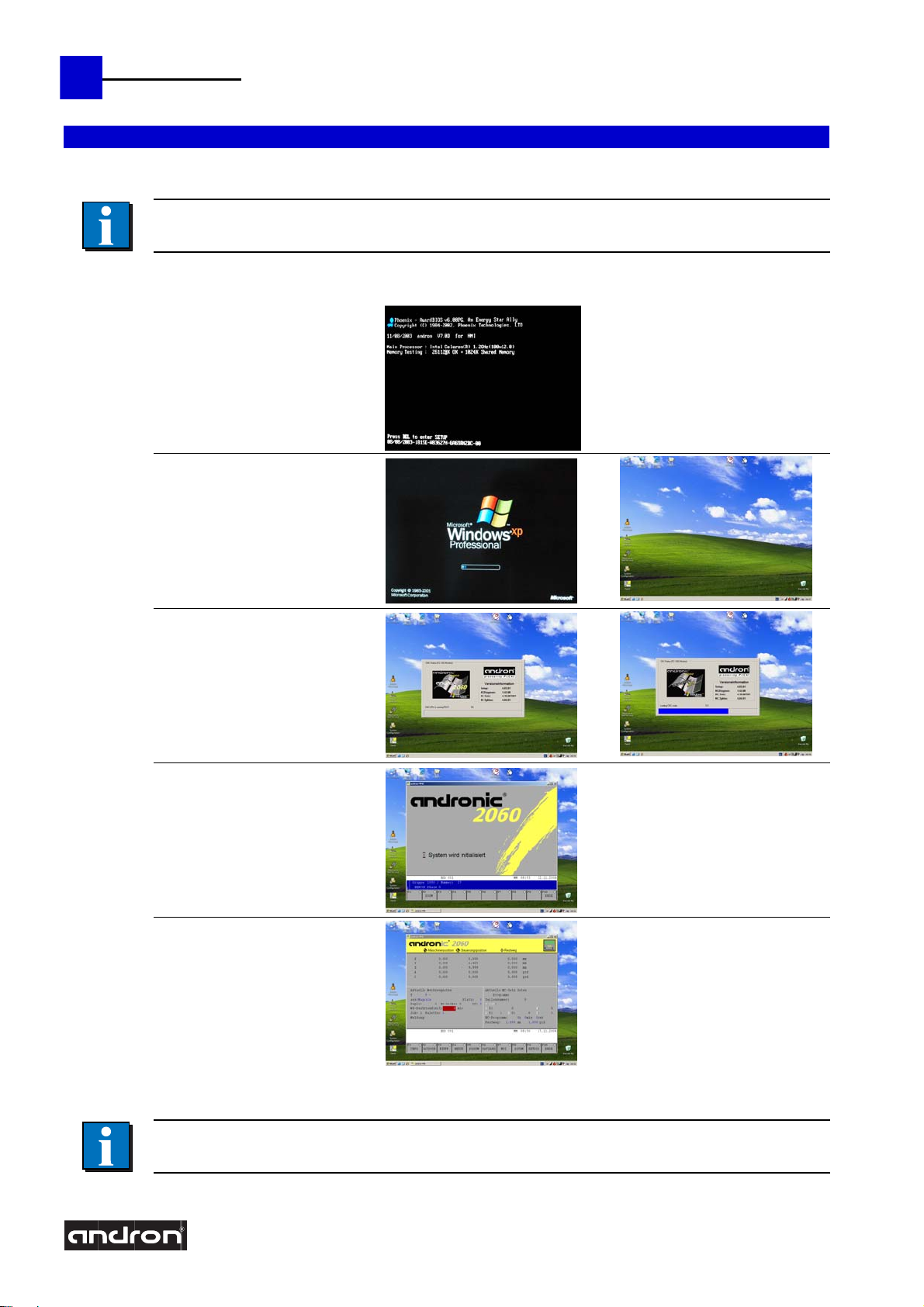

Switch on, start-up phase, turn off......................................... 6

Switch on...................................................................... 6

Start-up phase............................................................... 6

Turn off......................................................................... 6

Coordinate systems, zero points, reference points................... 7

Machine zero point unequal control zero point ................. 7

Machine zero point equal control zero point..................... 7

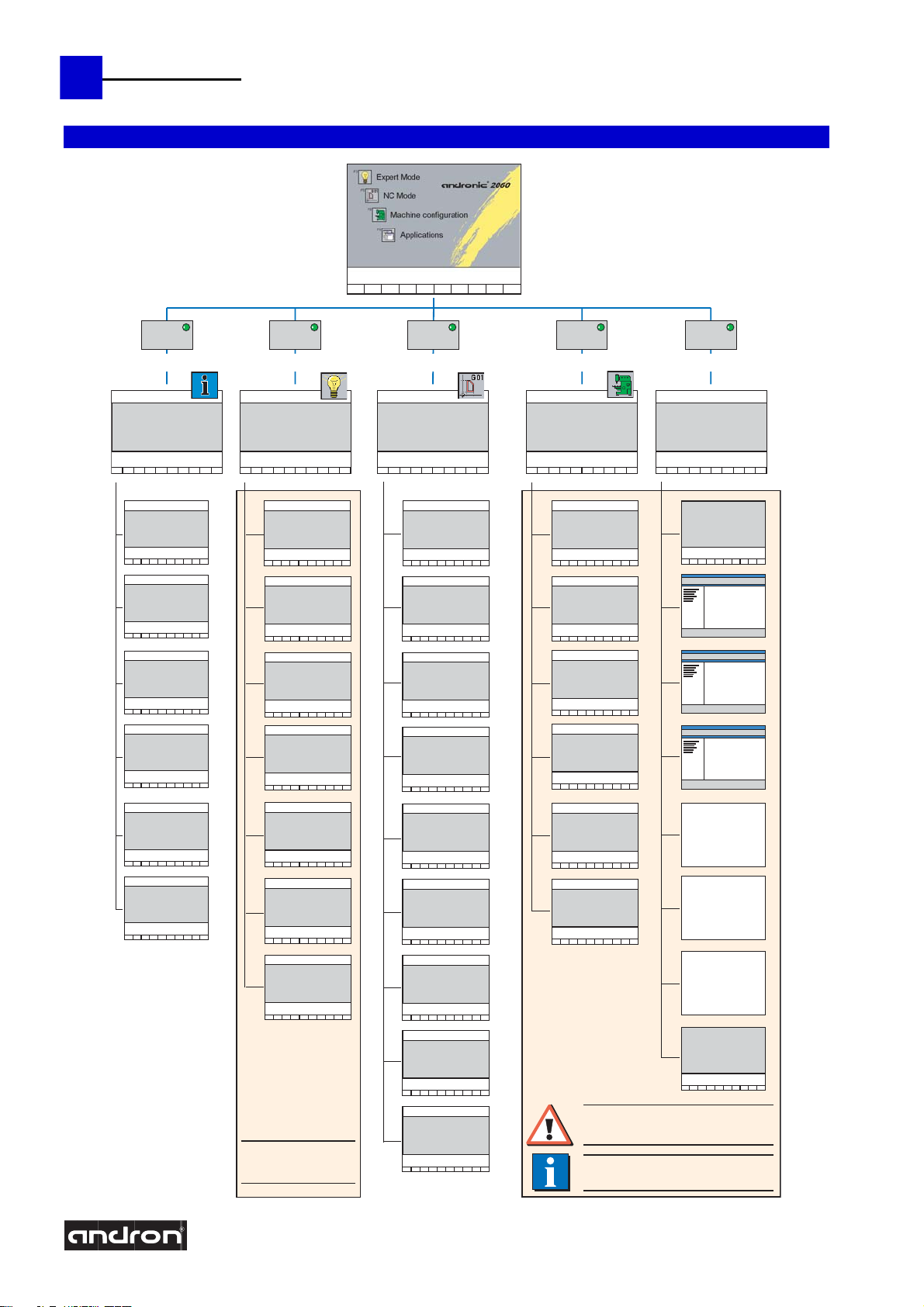

Menu overview ..................................................................... 8

Operating panel keys ............................................................ 9

The Info system.................................................................. 12

Change database......................................................... 12

Error list...................................................................... 12

System information...................................................... 12

Start application program ............................................. 12

System messages ........................................................ 12

Configuration............................................................... 12

NC Mode ............................................................................ 13

Create/modify NC program (EDIT)................................ 13

G&M editor........................................................... 13

Position display (POSIT)............................................... 13

RESTART.............................................................. 13

INPUT.................................................................. 14

TOOL................................................................... 14

POS-CHG.............................................................. 14

G&M-DIS.............................................................. 14

MDI ..................................................................... 14

PRESET................................................................ 14

Program specific configuration (PRCON)........................ 14

Program directory (DIR)............................................... 14

Delete program (DELETE)............................................. 14

Zero point offset (0-OFFS) ............................................15

PASSW .................................................................15

Teach..........................................................................15

Load automatic program (AUTOM) ................................15

DNC function (DNC) .....................................................15

G&M-CNV .............................................................15

Tool management ...............................................................16

Overview of functions...................................................16

Activation of the tool management (TOOL) ....................16

Select magazine assignment table (TL-SEL) ...................16

Edit magazine assignment table (TT-EDIT) ....................17

DEFPAGE F2 .........................................................17

Edit tool data (TL-EDIT)................................................18

Optional parameter ...............................................18

Tool dimensions....................................................18

Tool life acquisition................................................19

Additional correction values ...................................19

Special functions ...................................................19

Delete magazine assignment table (TT-DEL)..................19

Delete tool file (TL-DEL) ...............................................19

Search tool (TL-SEAR) ..................................................19

Options (OPTION) ........................................................20

RESET ..................................................................20

Expert Mode........................................................................21

Parameter entry (PARIN) ..............................................21

DEFPAGE..............................................................21

Position display (POSIT) ...............................................21

INPUT ..................................................................21

MM/INCH..............................................................21

POS-CHG..............................................................21

AXES....................................................................21

PRESET ................................................................21

Directories (DIR) ..........................................................21

Delete ident file (DELETE) .............................................22

Load automatic program (AUTOM) ................................22

Create/modify default ident file (DEFIDN)......................22

NEWNAME.............................................................22

Technial Data......................................................................23

Revisions

Version Date

V 1.0 29.04.2005 First edition Pa/Scho

Additions and changes Initials

3

Page 4

andronic 2060

4

Operating Instructions

Notice

In the creation of this handbook, we have made the greatest effort and have taken the greatest care. We reserve the

right to make changes to this handbook and to the controller or the programs, which are made necessary by technical

progress, without previous notice. In later versions, additional pages may be inserted. We would appreciate your

information as to errors in the handbook or how the handbook may be improved.

We accept no responsibility for damage resulting from neglect of the instructions contained in this handbook.

We are neither liable for nor responsible for actual or alleged loss or damage, whether direct or indirect, which is caused

by the operated or delivered equipment or the software programs, and which are claimed by a customer or another

natural person or a legal entity. This clause includes faulty service, lost business transactions, loss of expected profit or

consequential damages which occur due to the use of the equipment sold by us or software generated by us.

This instruction manual, the program descriptions belonging to it as well as other objects sold or supplied with the

controller, are protected by copyright. All rights are reserved. This handbook, the programs, and all other copyrighted

objects may be neither completely nor partially copied or in any other manner duplicated, without the previous written

consent of andron GmbH. Legally created copies, made with the permission of andron GmbH, of a part of or the

complete handbook, the computer programs or other copyrighted objects, must have the same copyright notice as the

original material.

We accept absolutely no responsibility for damage due to faulty installation !

Before the connection and the start-up of the control, it is imperative that

the documentation is carefully read!

Safety notes

Warning notes and symbols

Meaning of the symbols used in this document:

Symbol Meaning Symbol Meaning

This notice contains general and additional

information as well as rules and prohibitions

pertaining to damage prevention.

Danger notices for personnel and machine

damage, i.e. information as well as rules

and prohibitions pertaining to personal

injury and material damage prevention.

Important information or cross-

references to further descriptions.

Danger to life !!!

Page 5

Operating Instructions

andronic 2060

5

Use as directed

Introduction andron products are developed and produced according to the latest technologies. They are not delivered unless they

The following requirements must be met before using andron products to ensure proper use:

Field of applications

have been tested for service reliability.

The products may only be used as directed. If they are not used as directed, material damage and personnel injury may

result.

andron assumes no liability for damages due to inappropriate use. andron is not liable for payment of

The corresponding safety instructions for use as directed must be read and understood by all who operate one of

our products.

If the products include hardware, the original condition must not be changed. Software products must not be de-

compiled and the source codes must not be changed.

Damaged or faulty products must not be integrated or put into operation.

It must be guaranteed that the products have been installed according to the instructions specified in this manual.

The control is used for control panel integration, integration into housing or the door of the switch cabinet or for

machine tool housing integration.

It must be ensured that required mounting, installation and environment conditions are fulfilled.

The control can only be used with the configurations described in this manual. Furthermore, the use of a andron

software or firmware is necessary.

Each control system must be parameterized an programmed by competent service personnel before operation.

damages. The user is liable at his own risk if the products are not used as directed.

Not used as directed

The control is „not used as directed“ if it is used in a field of application not specified or if it is used under op erating

conditions or with technical data not specified in this manual.

The control must not be used if it is exposed to operating conditions which do not fulfill the determined environmental

conditions, e.g. use with water or with extreme temperature differences or extreme maximum temperatures is not

allowed.

Page 6

andronic 2060

6

Operating Instructions

Switch on, start-up phase, turn off

Switch on

Start-up phase

1.

2.

The switching on the control as well as the entire system can be realized in different ways,

Switch on the control

Bootphase of the HMI CPU

Loading of the HMI

operating system

therefore observe the informations of the machine manufacturer!

3.

4.

5. Control is ready for operation

Turn off

Bootphase of the NC CPU

Loading of the NC operating system

Start-up of the

SERCOS phases

from 0 up to 4

To turn off the control as well as the entire system observe also the informations of the

machine manufacturer!

Page 7

andronic 2060

Operating Instructions

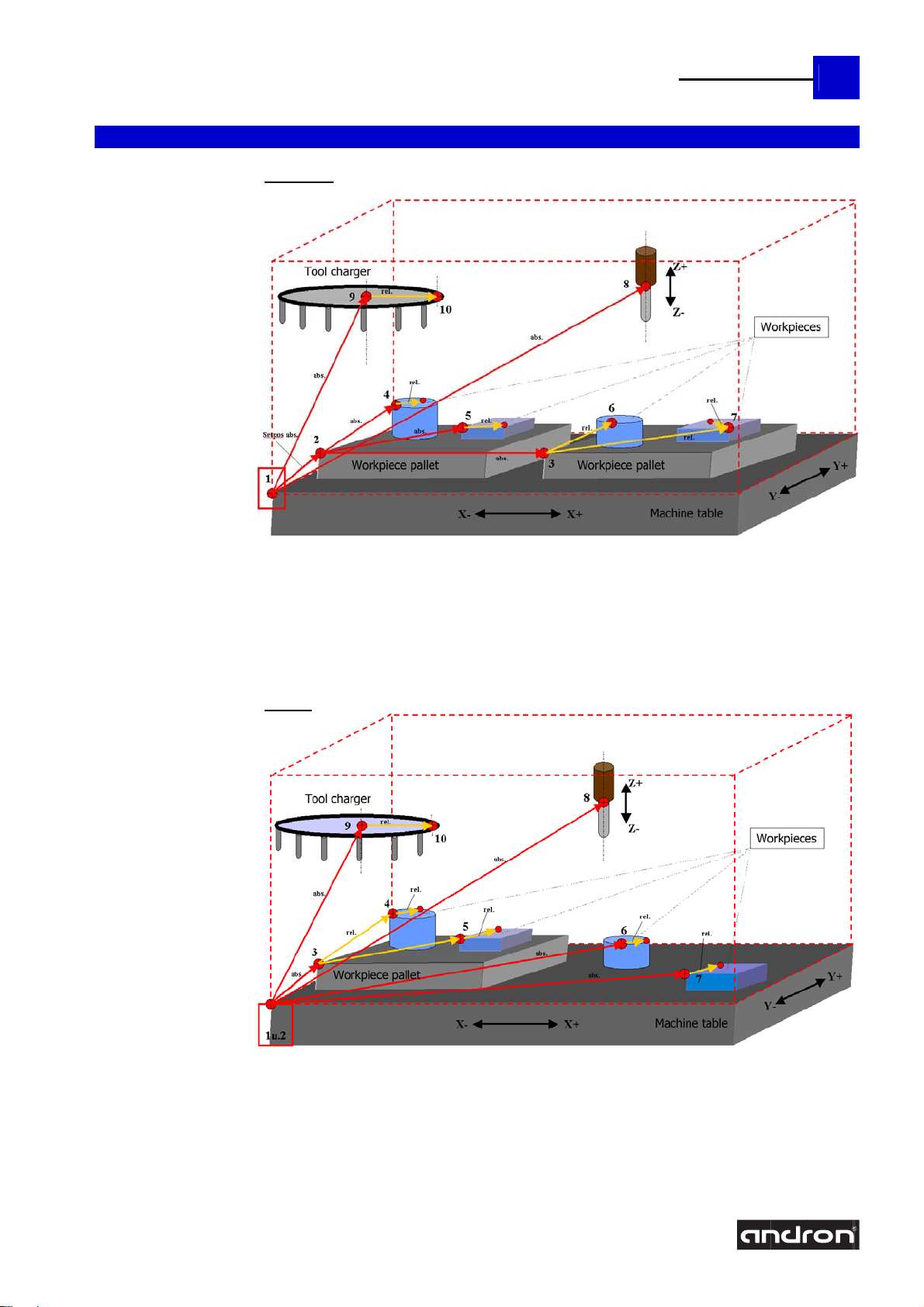

Coordinate systems, zero points, reference points

Machine zero point unequal control zero point

7

1 Machine zero point

2 Control zero point (Setpos)

3 Zero point workpiece pallet

4/5/6/7 Workpiece zero point (There can be even further relative zero points [G92] from this point on the

8 Workpiece zero point (The respective tool length always calculates from this point.)

9 Tool changer reference point

10 Charger position

Machine zero point equal control zero point

workpiece.)

Attention: Observe difference between full radius and shank cutter!

1 Machine zero point

2 Control zero point (Setpos) here Setpos = 0

3 Zero point workpiece pallet

4/5/6/7 Workpiece zero point (There can be even further relative zero points [G92] from this point on the

workpiece.)

8 Workpiece zero point (The respective tool length always calculates from this point.)

Attention: Observe difference between full radius and shank cutter!

9 Tool changer reference point

10 Charger position

Page 8

andronic 2060

8

Operating Instructions

Menu overview

INFO EXP NC MACON SYSTEM

F3 F5 F8 F10F1

Informations

and messages

Change current

database

Error

directory

System

informations

Application

programs

System

messages

Expert

Mode

INFO INFO INFO

Informations

and messages

F2 F2

PARIN

Parameter input

F3 F3

POSIT

Position display

F5

F6

DIR

Directory selection

DELETE

Delete identfile

F4

F5

NC

Mode

Informations

and messages

EDIT

Create/modify

program

POSIT

Position display

PRCON

Program data

DIR

NC program

directory

Machine

configuration

Informations

and messages

PosConf

F5

Position protocol

configuration

PM-Conf

F6

Pallet management

configuration

LookAhd

F7

Look Ahead

G&M code configuration

TL-CONF

F8

Tool magazine

configuration

System

applications

PANEL

Back to user

F1F1F1F1

environment

F2

F3

F4

F5

EEPROM

Machine data

SERCOS Para-

meter Editor

DBTMAN

Data base

manager

Special

function 1

SPE

Configuration

AUTOM

F8

automatic program

DEFIDN

F9

Create/modify

default identfile

EXPERT-MODE

only optional

available

Start

F6

F7

F8

F9

DELETE

Delete NC program

0-OFFS

Zero point offset

AUTOM

Start automatic

program

DNC

DNC function

CONFIG

F9

G&M code

configuration

Configuration and start-up

area, only accessible for

authorized personnel!

Descriptions to this you can find

in the start-up manual.

F6

F7

F10

Special

function 2

Special

function 3

EXIT

Exit panel

menu_overview_e.eps

Page 9

andronic 2060

Operating Instructions

Operating panel keys

andron supports the control with a basic PLC program for the operating and control functions described

Feed step switch

60

40

20

10

6

2

0

%

0

below. It is possible that the machine manufacturer delivers a own PLC program with different functions

80

90

100

110

120

100

and extensions. If there are no further informations the following description is valid.

With this step switch you can modify the feed rate in manual and automatic mode between 0% and 125%. A switchover between the speed

keys "0", "Feed step switch" and "100" is always possible within the operating modes.

Rapid traverse/Creep feed 0%: The rapid traverse or the creep feed rate is set to 0% for all operating modes (manual, automatic or

0

MDI mode), which leads to an immediate stop of the selected axes (depending on the brake reaction of the drives). No more positioning

command is carried out. For example, the execution of started NC block programs with traversing instructions is stopped until the key "100"

or the key "Feed step switch" (observe switch position) is pressed.

Feed step switch: The rapid traverse or the creep feed rate can be set from 0% to 125%, according to the feed step switch position, for

all operating modes (manual, automatic or MDI mode). The step switch has a multiple function. In position "0%" the axes stop; in position

"100%" the axes move at the defined rapid traverse or creep feed rate. From position 100% to 125% you can raise the defined speed in

percent up to a maximum of 125%.

Rapid traverse/Creep feed 100%: The rapid traverse or the creep feed rate is set to 100% for all operating modes (manual, automatic

100

or MDI mode).

9

95

90

100

85

80

70

60

50

%

IIII

60

40

80

20

90

10

6

2

120

0

%

0

!

100

95

90

100

85

105

80

70

60

MOVE

50

110

115

120

%

III

SET

ALL

A

X

100

110

+

Zustands-LEDs

Spindle speed step switch

With this step switch you can modify the spindle speed between 50% and 125%.

105

110

115

120

B

Y

Supply voltage 24 V DC is applied at the operating panel.

Spindle stop: The selected spindle is stopped. A restart of the corresponding spindle is

only possible by the key "NC START” (e.g. MDI mode: S10000 M3).

Spindle I: The key “Spindle 1” is free programmable. It can be used for the activation of

the spindle control 1, for example.

II

Spindle II: The key “Spindle 2” is free programmable. It can be used for the activation of

the spindle control 1, for example.

C

Z

0001

001

01

MDI

PLC

ANM013

Feed release is missing or or was removed.

!

Keyboard lock is shown.

!

A PLC error message is active.

Keylock switch

The keylock switch has 3 positions which are provided for the following functions:

Hand-, automatic-, MDI and set up mode

at opened machine cabinet.

: In the set up mode it is possible to work with reduced speed

Keyboard lock: All keys are locked, with exception of the key NC Stop and NC Reset.

Hand-, automatic-, MDI mode:

panel_keys_1_e.eps

Page 10

andronic 2060

10

Operating Instructions

100

120

+

110

ALL

MOVE

80

70

60

95

90

100

85

105

110

115

120

50

%

III

A

B

C

SET

ALL

Y

Z

X

0001

001

01

MDI

PLC

ANM013

The control takes three different types of position for each axis into account.

The reference points of the axes are already defined from the machine manufacturer. The absolute and relative positions can be

set by the machine operator (SET) according to requirements. They can be moved (MOVE) or set (SET) at another position for

each single axis, i.e. each preselected axis, or for several axes (ALL), i.e. the axes defined in the EEPROM in the defined succession.

The reference points can only be moved.

SET

MOVE

With this key you can move single or several axes to the relative zero, absolute zero or reference point .

SET

With this key you can set the relative or absolute zero for single or several axes.

60

40

80

20

90

10

6

2

0

%

0

!

100

Absolute, relative and reference point keys

MOVE

Reference point

All axes have a machine-related reference point or zero. These can be automatically moved in succession in the operating mode HAND either for each

single axis or for several axes (axes and succession definable in the EEPROM).

Procedure for one axis:

Preselect the axis Push the botton REFERENCE POINT Push the botton MOVE

>>>>

>>

Procedure for all defined axes:

Push the botton REFERENCE POINT Push the botton ALL Push the botton MOVE

>>

>> >>

Relative position

The relative position can be automatically set or moved in the operating mode HAND either for each single axis or for several axes. For the setting or

the motion of several axes, the axes and the succession are defined in the EEPROM. You can move a relative position only after it has been set.

With NC STOP, the relative position is set by the control. Previous relative positions were deleted.

Machine keys

+

Travel and

positioning keys

Procedure "Set" for one axis:

Preselect the axis Push the botton RELATIVE ZERO POINT Push the botton SET -> the relative zero point is set

>>

>> >>

Procedure "Set" for all defined axes:

>> >> >>

Push the botton RELATIVE ZERO POINT Push the botton ALL Push the botton SET -> the relative zero points are set

Procedure "Move" for one axis:

Preselect the axis Push the botton RELATIVE ZERO POINT Push the botton MOVE -> the relative zero point is moved

>> >> >>

Procedure "Move" for all defined axes:

>> >> >>

Push the botton RELATIVE ZERO POINT Push the botton ALL Push the botton MOVE -> the relative zero points are mo

ved

Absolute zero point

The absolute zero can be automatically set or moved in the operating mode HAND either for each single axis or for several axes. For the setting or

the motion of several axes, the axes and the succession are defined in the EEPROM. The setting of the absolute zero point works like SETPOS = 0 (all

axes).

Procedure "Set or Move" for one axis or for all defined axes:

With the NC-Start key a program is started in automatic mode. For this purpose, the following conditions must be fulfilled:

The axes must be referenced

A program has been loaded

The operating mode "AUTOMATIC" is selected

With the NC-Stop key you stop the automatic execution of a program and simultaneously the relative position of all axes were stored. The

stop becomes active at the end of the current program line. This state is signaled by the LED which is constantly on. At the same time the

LED of the NC-START key flashes, which allows to continue the program from the stopped point. If you move one or more axes after actuating

the key NC STOP in manual mode, the position on NC STOP can be reached again with the key REPOS.

With change of the automatic operating mode, the program can be continued with NC Start.

The NC-RESET key terminates the automatic processing of a program. It is no more possible to continue the processing of the program from

the stopped point. For the control unit, the program has been definitely terminated. You can restart the program by NC-START.

This key switches between rapid traverse and creep feed rate in the set-up and standard mode. The appertaining speed values for set-up or

standard mode are filed in the EEPROM of the control unit: after the control unit has run up, the set-up mode (parameter set 2) is active

with its EEPROM parameters Set up feed rate (creep feed) and Set up rapid traverse. After a search for reference, the set-up mode is

left and the standard mode becomes active. In the standard mode, the following EEPROM parameters are available: Manual feed rate

(creep feed) and Manual rapid traverse. The rapid traverse is indicated by the LED which comes on.

With the trevel key "+" you can move a preselected axis in the positive direction in the manual mode.

+

Procedure:

Step mode due to the preselected feed or fixed path key.

Constant traveling, if no feed or fixed path key is activated.

With the travel key "-" you can move a preselected axis in the negative direction in the manual mode.

Procedure:

(see travel key "+")

(see RELATIVE POSITION)

panel_keys_2_e.eps

Page 11

andronic 2060

Operating Instructions

Machine keys

PLC

The key SINGLE BLOCK processes an automatic program block by block. After having operated the key, a stop is carried out at the following points:

In the expert mode after each positioning and I/O command of the program

In the NC mode at block end of each NC program line. If the residual path display is activated in the EEPROM, the residual path is displayed to the block end.

The automatic program can be further processed in single block by the NC-START key. If the single block is deactivated, the processing is continued to the end of the

automatic program.

The key OPTIONAL STOP stops the processing of a G&M code program. The G&M code automatic program can be processed to the next M01 function by the NC-START

key. If the function OPTIONAL STOP is deactivated, the processing is continued to the end of the automatic program.

With this key (REPOS) the interruption position of an automatic program can be approached again. In this case all individual movements which can be executed in

manual mode are summed up to a one travel distance. This travel distances are moved back to the interruption position in inverse order.

Proceeding:

>>

Program abort in the operating mode automatic by actuating the key NC stop. Change of operating mode to manual mode.

>>

Travel in manual mode by pre-selection of the desired axis and acknowledging the traverse keys "+" or "-" (RePos LED is blinking).

Actuating the key REPOS: Re-approaching of the interruption position in inverse order of the individual travel distances.

>>

Change of operating modes to the automatic mode. Actuating the NC start key: the automatic program is continued from the interruption position on.

>> >>

In the operating mode MDI (manual data input) it is possible to carry out a up to three G&M codes via an overlaid edit window.

The key cannot be selected, because it is activated over the operating interface.

..

Proceeding:

>>

Press the function key F7 (MDI function in the andronic operating interface) Enter a G&M code line. The input must be closed with ENTER.

After having operated the NC-START key, the entered program line is executed.

>>

The operating mode MANUAL MODE is automatically active

after the run-up of the control unit and is signaled by the

LED which comes on. In the manual mode it is possible to:

The operating mode AUTOMATIC MODE can be activated only after a reference move has been carried out. In the automatic

mode it is possible to process a loaded program. The automatic mode is started by operating the NC-START key.

to start the reference move

traverse or set the absolute or relative zero point

move the axes manually

>>

>>

11

20

10

6

2

0

0

!

Travel keys

001

01

60

40

80

90

%

100

0001

95

90

100

85

105

80

MOVE

70

60

110

115

120

50

%

III

A

B

C

SET

ALL

01

001

0001

Y

Z

X

With this key you can carry out a defined linear or rotational feed. The feed value is stored in the file

"Parametersettings.ini" and can be changed in the program SYSCONFIG. In order to carry out a feed, activate the

fixed path key and an axis. Now you can cover the entered feed value via a jog direction key (+/-)

By selecting the handwheel key, you can carry out a motion of the axis via handwheel in the desired resolution

(handwheel increment), having first preselected the axis and operated the feed key. This is only possible in the

operating mode HAND.

These keys allow a movement in the dimensions 0.1, 0.01 and 0.001 mm or inch. The activation of a feed key is

confirmed by a light emitting diode. By selecting another feed key, the feed selected before becomes inactive. This

is only possible in the operating mode HAND.

0001

001

01

MDI

PLC

ANM013

100

110

120

+

Vorgehensweise:

Select the desired feed Preselect the desired axis Press the corresponding travel direction key (+/-)

>> >> >>

Every time you press a travel key, a jogging is carried out at the feed value

>>

To use this function it is necessary to activate the incremental width in the EEPROM.

Manual travel keys

A

B

Y

X

The manual travel keys consist of the axis keys A, B, C, X, Y and Z. The preselection of the required axis takes place by operating the corresponding

key and is indicated by a light emitting diode (diode comes on). You can deactivate an axis by operating the key once again (light emitting diode

goes off). You can move an axis by preselecting it and operating a travel key. The axis moves as long as the jogging key is pressed.

C

If a limit switch is approached when moving an axis, the corresponding axis drive stops immediately. The LED of the axis selection key and the

LED of the jog direction key, by which the limit switch has been approached last, flash. This indicates that you can depart the limit switch by the

jog direction key which is not flashing. Once the limit switch is free again, both light emitting diodes go off.

Z

If an axis is preselected, which is not defined in the EEPROM of the control unit, the LED of the selected axis flashes and an error message is

displayed, which disappears after correct axis preselection.

panel_keys_3_e.eps

Page 12

andronic 2060

12

Operating Instructions

The Info system

The Info system (INFO) can be called up in all operating

Change database

With ACCPT (Accept) or ENTER it is possible to select a database path from the preselected paths.

modes with the function key F1.

With the info selection box, following informations, news

and programs are accessible:

(Select and start with F1 [SELECT] or ENTER)

With the SYSTEM CONFIGURATOR it is possible to generate an new database. Further configurations can

be done with the DATABASE MANAGER.

Error list

Possible error messages of the control will be displayed in plain text with the error group, error number, date and time.

With ERR-NR error group and error numbers can be entered and displayed in plain text

VERS (Version) displays the version number of the error list.

System information

The software versions of all software modules and the control number will be displayed.

Start application program

Out of this menu the following programs can be executed:

DATABASE MANAGER: Program for managing the database.

SYSTEM CONFIGURATOR: Program to configure system specific parameters like language or database path.

POSITION ANALYSER: The traversing path analysis gives a rough overview of a programmed contour. After the

automatic start of a program, with the call up of the traversing path analysis parallel to the running of the machine,

up to four selected axes can be displayed.

G+M EDITOR: Start of the G+M editor

System messages

System messages will be displayed. ACT.MES (actual message) jumps to the message with the highest priority (only

with multiple screen pages).

Configuration

Fixed path key MM/INCH: Switch linear fixed path key and position menu between MM and INCH.

Page 13

Operating Instructions

andronic 2060

NC Mode

Create/modify NC program (EDIT)

The G&M code program conforming to DIN 66025/ISO 6983 is a widely-used standard, and the most frequently used

type of tool machine programming. The G&M code converter is used to produce the control code required for processing

in automatic mode from the existing NC-SET.

The andronic 2060 software „FlexProg“ is an addition to the conventional G&M code programming.

(see G&M code programming instructions).

Enter program names (maximum 20 alphanumeric

characters) or open selection window with the cursor keys

(↑/↓), select desired program name, and accept it with the

ENTER key. In case a program had been previously

generated or processed, its program name appears on the

input line.

13

G&M editor

With the acceptance of the program name, G&M editor will

be called up. The program will be generated here.

A detailed description of the editor you can find in

the online help of the editor (function key F1)

Position display (POSIT)

RESTART (Simulation record) This function makes it

4. Start the automatic program w ith the key “A utom atic start”. T he NC comp uter simulates the processing

possible to set main programs into an G&M

program. The requirement is that an G&M

program has been loaded into the controller,

the controller is in the automatic operating

mode, and the transferred G&M program

matches the G&M source.

1. Actuate the function key RESTART . T he

simulation record window will open.

2. The cursor is positioned by the operator

to the desired line on which the

simulation record is to be set, or with F2

DEFZEIL it is jumped to the wished line

number.

3. Actuate the function key AUTO. The

program line to be set in place is

communicated to the NC computer.

(without axes movements) up to the program line to be set.

Page 14

andronic 2060

14

Operating Instructions

5. Only now may the (environment) function simulation record be exited with END.

6. With another „NC START“ the currently valid functions as toll or pallet change, clamping (M10/M11)

spindle start or spindle positioning, coolant (M7/M8/M9/M13/M14/M50/M51) and the start of the

position recording are executed. Then the axes will be traversed to the setting point (tool axis last).

7. The automatic program can be processed from the setting point with a renewed actuation of

“Automatic start”.

DEFLINE Positions to any desired line

AUTO The line on which simulation record setting is to be made is transferred to the NC computer

END Concludes the record simulation with reference to the environment; an already executed

record simulation, via automatic start, will not be stopped in the m a in com puter.

INPUT (Hand parameter input) to define the fixed path for linear and rotational axes. When restarting the control

TOOL (Tool management) see the following chapter „Tool management“ POS-CHG (Position display change) Switches the position display between smaller and larger display. G&M-DIS (G&M code display) Opens a window on the monitor and displays the current G&M code program line of the

MDI (Manual data input) A record can be manually entered (via the cursor, function and number keys), and

PRESET (Control position set) Sets the absolute position in the control coordinate system. With SETPOS it is possible

the default fixed path from the file Parametersettings.ini is used (use SysConfig for data entry). Use this key

to reach the quick preparing cyles.

process.

transferred with ENTER. With automatic start, the record will be worked off. The record can be executed

several times. By call up of the MDI function, the input line can be empty or can contain the last-entered

record. The input of up to three records are allowed.

If the manual data entry was achieved before the start of after the end of an automatic program, then

M, F, S, T, D and E words as well as a limited number of G functions are allowed.

If the manual data entry was achieved in the automatic operating mode, then interrupts are only

allowed with M, F, S, T, D and E words.

to delete the control coordinate system

Machine coordinate system = Control coordinate system.

Program specific configuration (PRCON)

To start the program specific configuration you have to

select a program and confirm with ENTER.

Here, look ahead, contour and dynamic parameters can be

adjusted.

A detailed description of the parameters you can

find in the Look Ahead manual.

Program directory (DIR)

Shows all programs available in the database.

Delete program (DELETE)

Deletes selected programs from the database.

Page 15

Operating Instructions

andronic 2060

Zero point offset (0-OFFS)

The table contains the absolute displacement parameters

DEFPAGE Jump to a defined page TEACH (see below) PASSW With entry of a password defined in the

PRTSCR Prints the current screen page

for the G functions G54-G59. They can be manually

entered or transferred as a position.

There are four zero point offset tables. The first is for the

programmable zero points of the machine user. The pages

P1 ... P3 are used from the measuring cycles as a tray for

the measuring values. Only page P3 can be used for

angles values.

menu, it is possible to process writeprotected parameters

15

Teach

ABS/REL Switches, in the controller coordinate system, between absolute and relative position

+/- Switches the algebraic sign

AXIS Definition such as MM/INCH, ABS/REL, +/- or individual axes can be selected

ACCPT Accepts the taught values in the corresponding position parameters

AXES Switches between the defined axis records

MASCHPO Switches to the machine position

FILE File selection at job management

With this function, positions will be read into a menu. The manual teaching procedure allows for the individual teaching

of each position parameter in the menu. For this, the axis and the position parameter to be taught must be manually

selected. With auto-teach, the position parameters to be taught are already in the menu along with teaching information.

The teaching information contains the axis (or axes), the algebraic sign and the representation of the position (mm or

inches, absolute or relative). With a teach call up, all position values of the axes corresponding to the teaching

information in the position parameters will be entered into the menu.

Load automatic program (AUTOM)

Select a program name with the cursor keys and confirm

with ENTER. Then the following menu appears on the

display.

In order to achieve as high a processing speed as possible,

the NC program is converted to a controller-internal

format. The operator decides whether a new conversion

run is necessary, whereby a conversion run will be

automatically suggested when a program …

has been newly generated

has been worked into the control

an available program has been modified

After a possible conversion and loading of the program, the

small position display appears on the screen; the program

can now be started.

DNC function (DNC)

With this function, G&M code source programs are

transferred to the control.

G&M-CNV (G&M converter) Converts an G&M cod e

source program to a internal format

G&M-CPY InsNCSource: Tool to read and send G&M

code files.

Page 16

andronic 2060

16

Operating Instructions

Tool management

Overview of functions

100 tool magazine locations,

any number of tools in the data base,

free configuration of tool types,

several tool magazines,

fixed coding of locations,

duplo tools,

tool life control,

3 different types of status indication,

limitation of maximum speed,

speed control,

9 pairs of correction values,

wear control (option)

Numerous adaptation possibilities at the machine:

chain or disk magazine, pick-up, manual change in any combination up to a total of 100 locations,

correction of position for every single magazine location,

programming of the tool change procedures in NC block format

Different options:

tool can be changed, despite tool life has expired ,

interruption of the NC program during speed reduction of the tool management,

in case of tool magazine problems, all tools can be changed manually without intervening within the tool

management,

Tool magazines are supported by PLC or SERCOS drive

Activation of the tool management (TOOL)

The tool management is activated in the position menu and

is displayed with the following basic menu.

Select magazine assignment table (TL-SEL)

The active magazine assignment table is displayed and a

new one can be selected, if

no tool is in the spindle.

Page 17

Operating Instructions

andronic 2060

Edit magazine assignment table (TT-EDIT)

The magazine assignment table contains the assignation of

the T-number and of the tool (tool designation) to a

magazine location and the reference to a duplo tool.

The magazine assignment tool can be accessed via the

position menu, F4 „TL EDIT“, F3 „TT-EDIT“. Here, an

already present magazine assignment table can be edited

or a new one can be created.

The T-number is the tool number used in the G&M

code program. A tool can have different T-numbers in

different magazine assignments.

The number of the duplo tool only refers to a duplo

tool with the same radius, which is used if the status

of the selected tool does not permit that the tool is

used (Tool disabled). The duplo tool must be entered in the same magazine assignment table and have the same

type of tool.

Tool size: hte value of the size means the number of the covered half places. (That means that one tool of the size

1 covers 2 half places, exactely one place, tool of the size 2 towers above each side a half place.)

17

You can select and activate the magazine assignment in the tool management main menu with F2 „SELECT“.

The menu is operated via a line cursor. When activating the magazine management, the menu of the first 10 tools is

displayed and the cursor is positioned in the first line. All further menus tool of the tools 11-20, 21-30 etc. up to 91-99

can be displayed with page-up / page-down.

Line cursor: The cursor marks the whole line, it can be moved up and down with the cursor keys. Only by selecting the

corresponding line with F3 T-EDIT or Enter the input fields for T-number, WZ designation and duplo tool number can be

reached with the cursor keys up/down. If a line is selected, this selection can be cancelled adopting changes by pressing

Escape, or accepting the changes by pressing Enter. Strg-X deletes a field resp. an entire line.

DEFPAGE F2 (Defined page) A defined page in the magazine management is selected. T-EDIT F3 (Line edit) The entries of the selected line can be edited. If the line is selected, the input field can be

moved to the right / to the left via Cursor Up / Down. To insert tool names and data call F4 resp. F6.

Quit the line which is edited now with Enter / Escape.

TL-EDIT F4 (Tool edit) With this function key a tool data entry is selected from the magazine management, and

the program returns to the magazine management, after entering the data and a enquiry „F9-Cancel“

without accepting the changes or with „F10-Save“.

PASSW F5 (Password) With entry of a password defined in the menu, it is possible to process write-protected

parameters

SEL-TL F6 (Tool select) A tool which alread y exists in the data base is transferred to the magazine assignment

table.

CUT F7 (Cut tool input) A tool entry is removed and inserted into a different position.

PASTE F8 (Insert tool input) A tool input is inserted from the clipboard to a magazine location. Already existing

PRTSCR F9 (Print screen) Prints the current screen page

entries are overwritten and before storing, the T-number and the tool designation must be changed,

as these parameter must only appear once in the magazine assignment table. To shift an entry, the

old entry must be deleted before inserting the new one.

Page 18

andronic 2060

18

Operating Instructions

Edit tool data (TL-EDIT)

The tool data blocks (data for a tool) are stored in

individual files. Thanks to this, individual tools can be used

on various tool lists (combination of different tools for one

application), without producing double definitions. The

menu for the tool data entry is selected via the basic menu

of the tool management or via the tool magazine

management, it is created and operated just like a

conventional menu.

For every tool type an individual menu is available.

Therefore a representation of the type can be visualised

graphically. In the message line the tool number and the

WZ designation are displayed to facilitated a better

orientation.

When selecting the tool data input, a pop-up menu appears with the choice of the tool types. After selecting the tool

Optional parameter

Tool dimensions

Length, allowance and wear are added up by the control and set as active length of the tool when changing this

type, the individual tool is selected from all tools via a further pop-up menu.

Length

Radius

Allowance for length and radius

Correction for length and radius

Positive and negative tolerance of the radius

Tool size

tool.

Radius, allowance and wear are added up by the control and considered correspondingly during the conversion of

the program.

In case of tools of the type milling cutter the total radius in the tool management and the total radius valid at the

moment of the conversion are compared after changing the tool. If the changed tool is not within the tolerance

range given for the radius, the machining process is aborted with an error message. This happens in the following

cases: the radius of the duplo tool diverges inadmissibly from the radius of the original tool; the degree of tool wear

is inadmissibly high.

Status for tool life and tool breakage

tool life data

nominal speed

maximum speed

data for further pairs of correction values

Page 19

Operating Instructions

Tool life acquisition

To use the tool life acquisition, a value for the total tool life must be entered in the corresponding tool file. After the

Additional correction values

Apart from length and radius of the tool, the data of length and radius of eight other pairs of correction values can be

Special functions

Speed indication: If a nominal speed is entered in the tool data, this value is set as spindle speed during the tool

first application of the tool by the machine the status and the remaining tool life is entered automatically in the tool

data.

If a medium warning limit is entered, a message is issued in the position indication when the medium warning limit

is reached.

The remaining tool life can be changed at any time.

After the tool life has expired, the status of the tool life is set to „0“-blocked- in the next tool change and the tool is

not changed again. If a duplo tool is available, this will be used automatically.

In the magazine configuration the option „Usage of the tool beyond tool life limit“ can be switched on. Then the

continuation of machining process is offered, if no duplo tool exists which is released.

To reactivate the blocked tool, the status of the tool life must be set to „1“-released- and the remaining tool life is

deleted, or set to a value greater zero. If the remaining tool life is deleted, the total tool life is valid again.

activated from the NC program. For this purpose the NC address „D“ or „D0=“ with the number of the desired pair of

correction values is used. The first pair of correction values is automatically activated, if no other pair has been activated

via D2 (or D0=2) up to D9 (or D0=9).

The correction table it must be filled from the top.

Call in the G&M code: e.g.

change if no speed was programmed in the NC block. The speed given in the tool data is only valid for the

corresponding tool. The value displayed is always for spindle 0.

Maximum speed limitation: If a maximum speed is entered in the tool data, this value is set as spindle speed

during the tool change, if the speed programmed in the NC block is higher than the maximum speed. In the tool

management options it is possible to determine in case of a speed reduction, whether the NC program shall be

interrupted with a message or the speed is to be reduce automatically.

T3 M6 D3

andronic 2060

Delete magazine assignment table (TT-DEL)

Magazine assignment tables can be deleted individually. When the active magazine assignment is deleted, no tool must

be in the spindle and the control must not be in automatic mode.

Delete tool file (TL-DEL)

Deletes individual tools from the data base. After an inquiry the tool is deleted from all magazine assignment tables.

Search tool (TL-SEAR)

This function shows all magazine assignment tables which contain the corresponding tool.

19

Page 20

andronic 2060

20

Operating Instructions

Options (OPTION)

„Tool with expired tool life is inserted after inquiry,

„ G&M code program is interrupted by the tool management in case of speed reduction“

0 = no The spindle speed is reduced to the maximum speed of the tool without interruption of the G&M code

1 = yes In case of a speed reduction the G&M code program is interrupted with a message to provide the

„Suppress tool change sequences. All tools are changed manually.“

0 = no Standard operation

1 = yes All tool changes are executed as „Manual change“.

RESET

„RESET of the error state of the tool change has not

if no other tool is available“

This option is intended to facilitate that a tool is used

longer than the entered tool life.

0 = no

:

If the tool management does not find a tool with remaining

tool life, the execution of the G&M code program is

cancelled.

1= yes

:

If the tool management does not find a tool with remaining

tool life, the G&M code program is only interrupted. value

is set as spindle speed during the tool change. This fact is

indicated by a message. The execution of the G&M code

program can be continued with the first released tool

without remaining tool life. The NC program can be

cancelled with NC-Reset.

If a value for the maximum speed of the current tool is entered and the speed programmed in the G&M code program is

higher than the maximum speed the speed of the spindle is reduced automatically.

program.

possibility to decide whether to cancel the program or to continue at reduced speed. A new NC start

continues the G&M code program at reduced speed.

To guarantee the operativeness of the machine in case of damages of the mechanics for the tool change, all tool change

sequences can be forced to manual change without need to change the magazine configuration and the magazine

assignment table.

been cancelled in the defined state !! Attention ! It

is absolutely necessary to check the tool in the

spindle and the tool in the position menu“

The tool change is monitored internally by the control. If,

due to a power cut or similar events, an undefined state

should occur during the tool change, the following tool

change is blocked. In this case, a tool change leads to a

program abort and the error message „Tool change

has not been cancelled in defined state !!

Check tool management and reset error in

F4-TOOL/F9-OPTION.“. The person operating the

machine must check the tool management and compare it

with the actual state of the tool magazine and the spindle

and enter a „1“ in this option. The next tool change can be

carried out again.

Page 21

Operating Instructions

andronic 2060

Expert Mode

Parameter entry (PARIN)

Enter ident file names (maximum 24 alphanumeric

DEFPAGE (Defined page) Jump to a defined page PASSW (Password) With entry of a password defined

PRTSCR (Print screen) Prints the current screen page

NEWNAME Appears after the key F10 (END) has been actuated, and allows the granting of a new name to an ident

Position display (POSIT)

INPUT

MM/INCH Switches the position display between mm and POS-CHG (Change position display) Switches between

AXES (Axis record) Switches between the defined axis

PRESET (Set control coordinate system) Sets the

Directories (DIR)

PRDIR (Program files) Shows all programs available in

IDIR (Ident files) Shows all ident files available in the

MDIR (Menu files) Shows all menus available in the

DIDNDIR (Default ident files) Shows all default ident files

In the EXPERT MODE, programming on the machine is restricted to the dialogue-led and graphically-supported entry of

geometrical and technological parameters in a menu. The machine operator does not have to worry about axis

movements. He enters the workpiece-related data. The calculation of the required axis movements is performed by the

machine builder developed anlog-C program.

The tool and workpiece-specific data is managed in a database under ident numbers. These menu-driven programs are

developed using the anlog-C programming system.

characters) or open the selection window with the cursor

keys (↑/↓), select desired ident file names, and enter them

with the key ENTER. In case an ident file had been

generated or processed previously, this name will be

displayed on the entry line. Select desired menu and

acknowledge with ENTER. Now the parameters can be

entered.

in the menu, it is possible to process writeprotected parameters

file.

(Hand parameter input) Hand parameters are

made available to the NC computer per

command and not by means of a file. They are

consequently only valid as long as the controller

is switched on. As a rule, these parameters are

used in the Jog operating (fixed path); they can

be made available to the NC computer during

the processing of a automatic program,

however.

inches.

smaller and larger position display.

records, if severals are aveilable

absolute position in the control coordinate

system.

the database

database

database

available in the database

21

Page 22

andronic 2060

22

Operating Instructions

Delete ident file (DELETE)

Deletes selected ident file from the database.

Load automatic program (AUTOM)

Select ident file names and program names with the cursor

(↑/↓) and acknowledge with ENTER. On the screen, the small

position display appears.

The program can now be started if the absolute zero point

has been previously set.

Create/modify default ident file (DEFIDN)

When generating a new ident file, parameters will be transferred from the default ident file (preset file), in case they

have been defined in the menu. In the default ident file, corresponding parameters will be pre-assigned and need not be

entered again when generating a new ident file.

Enter default ident file names (maximum 24 alphanumeric characters) or select an available default ident file, and

acknowledge with the ENTER key. In case a default ident file had been previously generated or processed, its name

appears on the input line. Select a menu and acknowledge with ENTER. The parameters are to be entered here.

DEFPAGE (Defined page) Jump to a defined page

PASSW (Password) With entry of a password defined in the menu, it is possible to process write-protected

PRTSCR (Print screen) Prints the current screen page NEWNAME Appears after the key F10 (END) has been actuated, and allows the granting of a new name to a default

TEACH see „Teach“ at side 15

parameters

ident file

Page 23

Operating Instructions

andronic 2060

Technial Data

Control

andronic 2060L andronic 2060s

23

HMI

CPU card Half-Size Slot CPU

NC

General

CPU card Full-Size Slot CPU

Harddisk 40 GB / 2,5 Inch 40 GB / 2,5 Inch

PLC integrated Soft-PLC (CoDeSys) integrated Soft-PLC (CoDeSys)

I/O interfaces InterBus-S, Profibus-DB InterBus-S, Profibus-DB

Operating system

Free PCI slot 1 -

NCM card NC multifunction card NC multifunction card

Interfaces Handwheel

Operating system andron realtime kernel andron realtime kernel

Protection category IP 20 IP 20

Pentium 4 / 2.4 GHz

512 MB DDR RAM

Grafik-, Ethernet-,

IDE-Controller onboard

USB 2.0

Microsoft Windows

Celeron / 1.2 GHz

128 MB RAM

Fast inputs for:

Emergency Stop, releases,

measuring signals, …

Contact for “CNC fault“

SERCOS interface (fibre optic) up

to 4 rings

Half-Size Slot CPU

Celeron / 1.2 GHz

256/512 MB RAM

Grafik-, Ethernet-,

IDE-Controller onboard

USB 1.1

®

XP® Pro Microsoft Windows® XP® Pro

Half-Size Slot CPU

Celeron / 1.2 GHz

128 MB RAM

Handwheel

Fast inputs for:

Emergency Stop, releases, measuring

signals, …

Contact for “CNC fault“

SERCOS interface (fibre optic) up to

4 rings

Input voltage 100-240 V AC, 50/60 Hz 100-240 V AC, 50/60 Hz

Power consumption max. 300 VA max. 300 VA

Temperature range +5°C … +45°C +5°C … +45°C

Dimensions 293 x 394,5 x 171,5 (WxHxD) 214 x 329 x 171,5 (WxHxD)

Operating panels ANV03 ANM013

TFT color display 15“ (1024x768) Machine operating panel

Protection category IP 64 (front), IP 20 IP 64 (front), IP 20

Input voltage 24 V DC 24 V DC

Power consumption max. 75 VA max. 225 VA

Temperature range +5°C … +45°C +5°C … +45°C

Dimensions 482,6 x 310,5 x 80,0 (WxHxD) 482,6 x 177,0 x 90,0 (WxHxD)

Page 24

andronic 2060

24

Operating Instructions

andron GmbH Schlätterstraße 2 D-88142 Wasserburg/B. Germany

Tel.: +49 (0) 8382/9855-0 Fax: +49 (0) 8382/9855-50 info@andron.de www.andron.de

Loading...

Loading...