Page 1

V 6.05.08.02

G&M Code Programming Manual

Page 2

2

andronic 2060/30 60

G&M Code Programming Manual

Version

V 6.05.08.02

Release Date

26.07.2013

Author(s)

Vol/Scho/Vo

Editing/Illustrations

Pa

Trademark

All product names and trademarks are the exclusive possession of their respective owners.

Protection no te

© andron GmbH 2013. All Rights Reserved.

Liability

There may be fur ther co ntrol funct ions th at are ope rational b ut not des cribed in this doc umentatio n. No leg al right

Published by

andron GmbH, Schlätterstraße 2, 88142 Wasserburg, Germany

A member of the LTi group of companies

Passing on and copy ing t his doc umen t, uti liz atio n and c om munic at ion o f its co nten ts is not allow ed, un less expl icitly

authorized. Violators are liable for damages. All rights, especially if a patent is granted or a utility model is

registered, are reserved.

exists, however, to these functions when a new system is delivered or the system is serviced.

The contents of this documentation and the delivery options of the products are subject to modifications.

Telefon +49 (0) 8382/9855-0, Fax +49 (0) 8382/9855-50

e-Mail: info@andron.de

www.andron.de

gm_code_programming_manual_v6.05.08.02.doc

Page 3

andronic 2060/30 60

3

G&M Code Programming Manual

Content

Content ..................................................................................................................................................................... 3

Revisions................................................................................................................................................................... 6

General information .................................................................................................................................................. 7

Address letters ............................................................................................................................................................. 7

Safety instructions .................................................................................................................................................... 8

Warnings and symbols ................................................................................................................................................. 8

Designated use ............................................................................................................................................................ 9

Use of the unit contrary to its designated use ................................................................................................................ 9

Components of a NC program ................................................................................................................................. 10

Tool management ................................................................................................................................................... 11

Functions of the tool management .............................................................................................................................. 11

Duplo tools ........................................................................................................................................................ 11

Tool data ................................................................................................................................................................... 11

M Functions ............................................................................................................................................................ 14

Extensions of M commands (option) ............................................................................................................................ 15

G Functions ............................................................................................................................................................. 16

Explanations .............................................................................................................................................................. 16

G00 Positioning in rapid traverse ................................................................................................................................. 17

G01 Positioning at the feed rate .................................................................................................................................. 18

G02 Circular interpolation - Clockwise .......................................................................................................................... 19

G03 Circular interpolation - Counterclockwise............................................................................................................... 19

G04 Dwell time .......................................................................................................................................................... 20

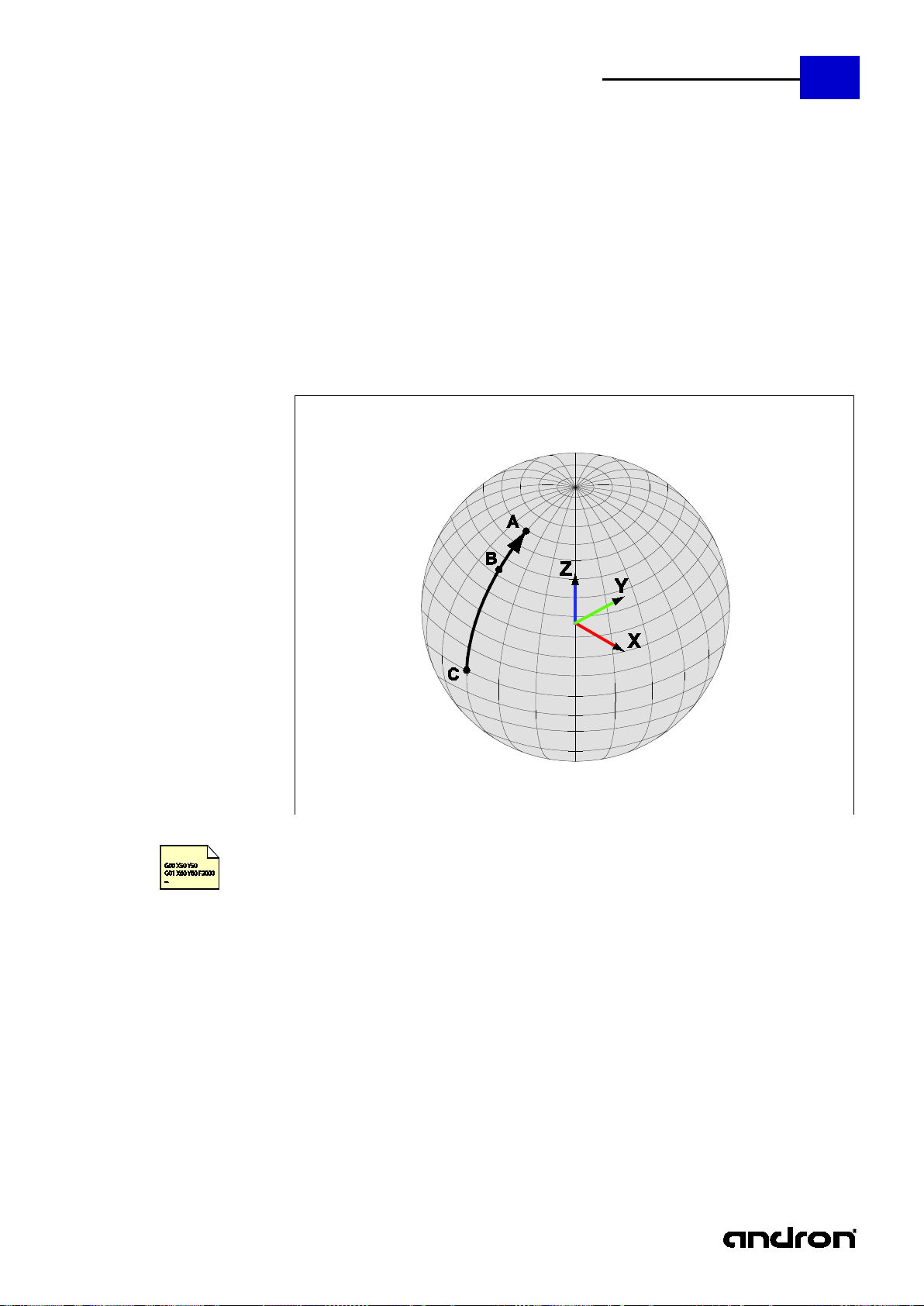

G05 Spatial arc interpolation ....................................................................................................................................... 21

G14 Macro call ........................................................................................................................................................... 22

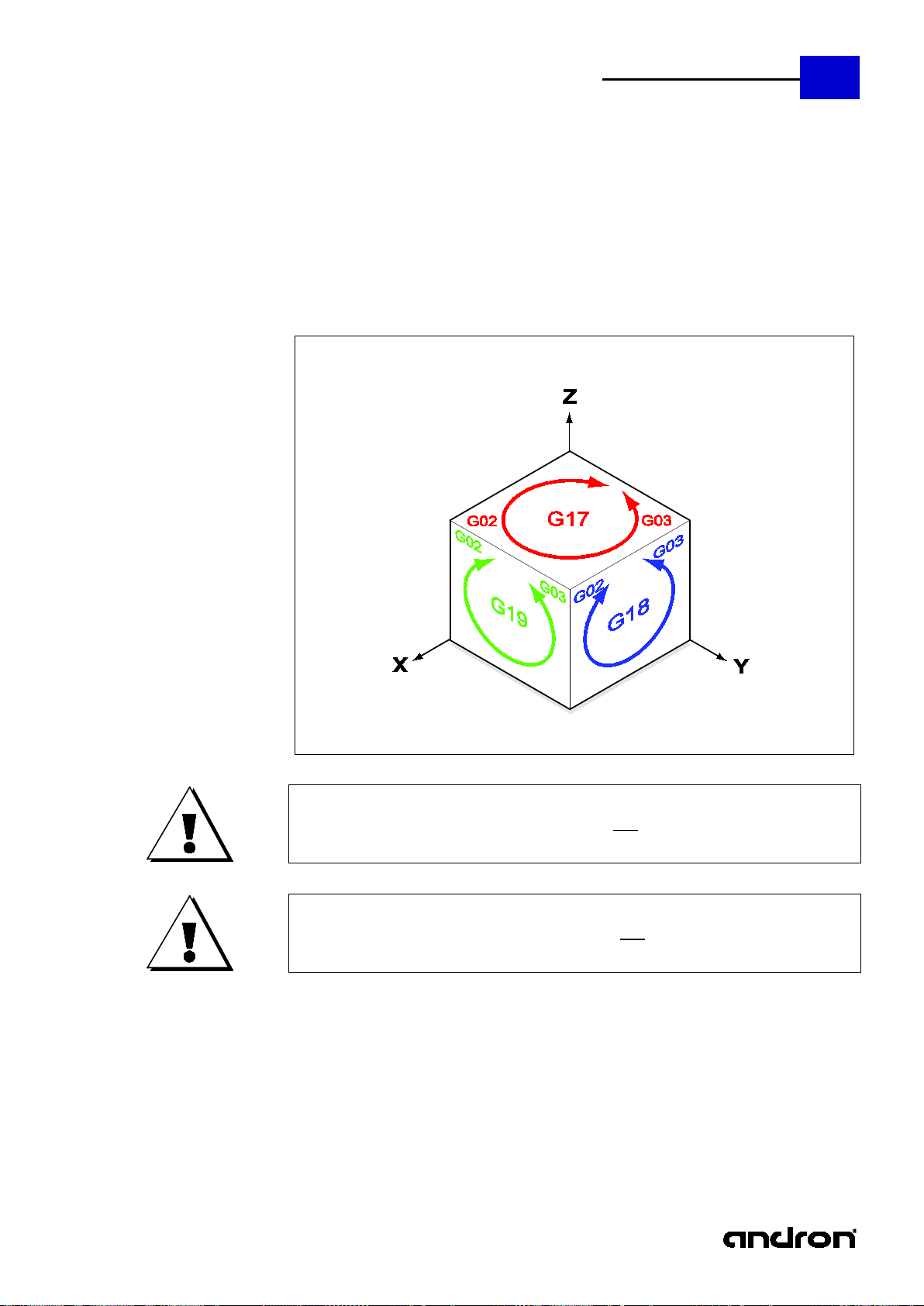

G17 Plane XY ............................................................................................................................................................. 23

G18 Plane ZX ............................................................................................................................................................. 23

G19 Plane YZ ............................................................................................................................................................. 23

G22 Sub program call ................................................................................................................................................. 24

G23 Text - Functions .................................................................................................................................................. 25

G25 RTCP H On/Off .................................................................................................................................................... 26

G26 Free plane .......................................................................................................................................................... 29

G29 Axis transformation ............................................................................................................................................. 32

G30 Spline interface (online spline) ............................................................................................................................. 34

G305 P5-Interpolation (Online Polynomial) .................................................................................................................. 35

G31-G35 Spline interface (offline spline) ...................................................................................................................... 36

G40 Deletion of the milling cutter radius correction ...................................................................................................... 37

G41 Milling cutter radius correction left ....................................................................................................................... 38

G42 Milling cutter radius correction right ..................................................................................................................... 39

G43 Milling cutter radius correction up to..................................................................................................................... 40

G44 Milling cutter radius correction via ........................................................................................................................ 41

Zero offsets and coordinate rotation ............................................................................................................................ 42

G50/G51/G52 P R ESET ................................................................................................................................................ 43

G50 Deactivate PRESET .............................................................................................................................................. 44

G51 activate PRESET .................................................................................................................................................. 45

G52 program PRESET ................................................................................................................................................. 46

G53 Deletion of the zero offset ................................................................................................................................... 47

G54 - G59 Zero offset and coordinate rotation ............................................................................................................. 48

G70 Units of measurement inch .................................................................................................................................. 50

G71 Units of measurement mm ................................................................................................................................... 51

G72 Deletion of mirror image machining and scaling .................................................................................................... 52

G73 Mirror image machining ....................................................................................................................................... 53

G73 Scaling ............................................................................................................................................................... 54

G77 Cycle execution on a circle ................................................................................................................................... 55

G78 Point definition .................................................................................................................................................... 56

G79 Cycle execution ................................................................................................................................................... 57

gm_code_programming_manual_v6.05.08.02.doc

Page 4

4

andronic 2060/30 60

G&M Code Programming Manual

General cycle definition (drilling and milling cycles) ...................................................................................................... 58

G81 Drilling cycle ....................................................................................................................................................... 59

G83 Deep-hole drilling cycle ........................................................................................................................................ 60

G84 Tapping cycle ...................................................................................................................................................... 62

G87 Rectangular pocket milling cycle ........................................................................................................................... 64

G88 Slot milling cycle.................................................................................................................................................. 66

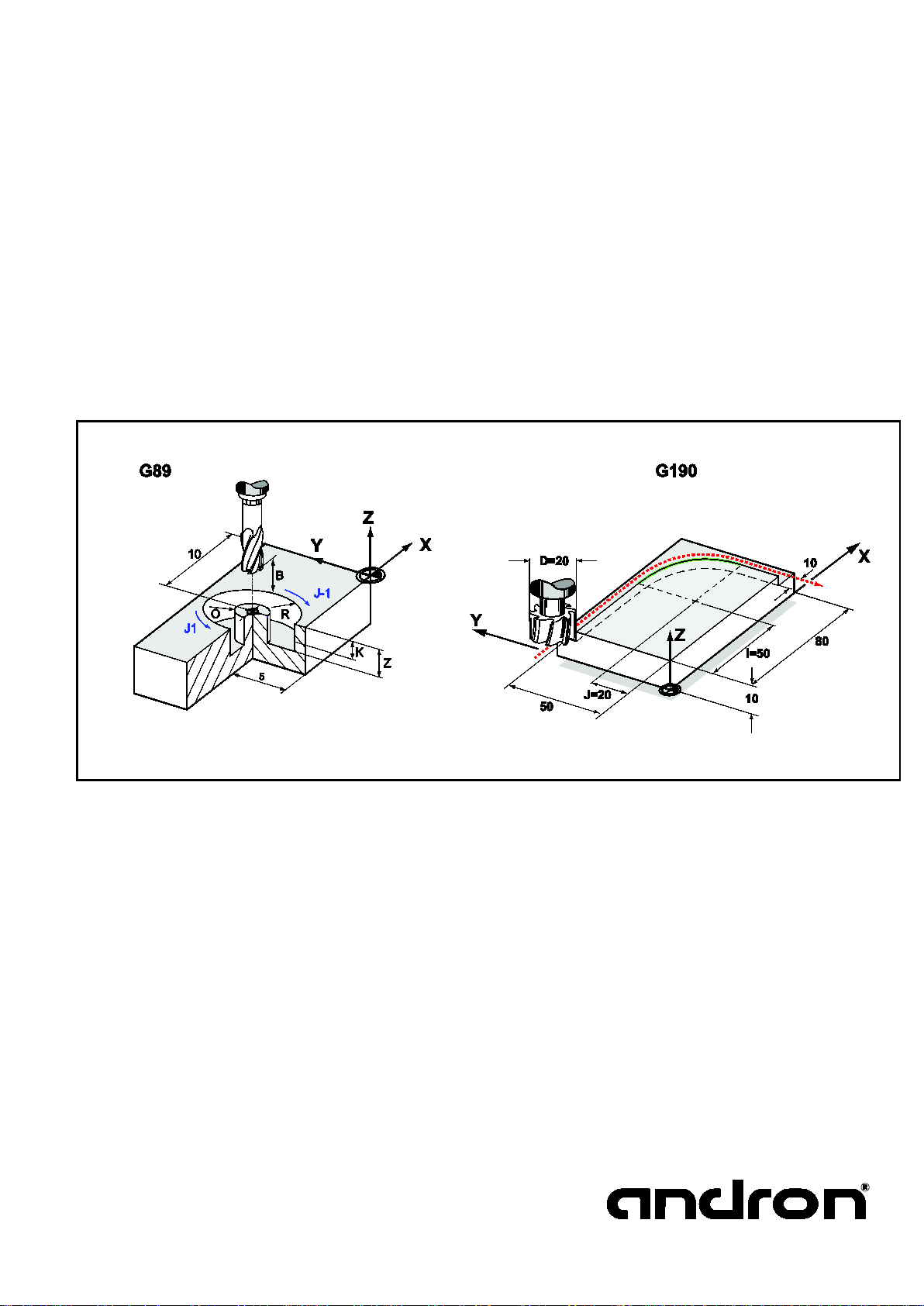

G89 Circular / ring pocket milling cycle ........................................................................................................................ 68

G90 Absolute measure ................................................................................................................................................ 70

G91 Relative measure ................................................................................................................................................. 71

G92 Relative zero point offset coordinate rotation ........................................................................................................ 72

G93 Absolute zero point offset coordinate rotation ....................................................................................................... 73

G94 Speed programming ............................................................................................................................................ 75

G95 Time programming .............................................................................................................................................. 76

G110 PLC Output setting ............................................................................................................................................ 77

G111 PLC Output deleting ........................................................................................................................................... 77

General cycle definition (measuring and setup cycles) .................................................................................................. 80

G181 Probe calibration................................................................................................................................................ 81

G182 Distance measurement ...................................................................................................................................... 87

G183 Straight line probing .......................................................................................................................................... 89

G184 Shaft probing .................................................................................................................................................... 91

G185 Bore probing ..................................................................................................................................................... 93

G186 Point measurement ............................................................................................................................................ 95

G187 Measuring plate calibration ................................................................................................................................. 97

G188 Tool length measuring plate ............................................................................................................................. 101

G189 Tool breakage control measuring plate ............................................................................................................. 103

G190 Absolute circle center ....................................................................................................................................... 105

G191 Relative circle center ........................................................................................................................................ 106

G281 Ramp participation........................................................................................................................................... 107

G282 Coordinates ..................................................................................................................................................... 108

G282,0 Switching workpiece coordinate system WCS / machine coordinates system MCS ............................................. 108

G282,1 Resynchronising axis positions of active NC processes ..................................................................................... 108

G282,2 Modulo on / off ............................................................................................................................................. 109

G283 Multi-axis probing ............................................................................................................................................ 110

G285 Probe SETPOS ................................................................................................................................................. 113

G286 Look Ahead Switch On/Off ............................................................................................................................... 116

G288 Set Look Ahead parameters ............................................................................................................................. 117

G288,0 LookAhead basic parameter .................................................................................................................. 117

G288,1 time-based axes ................................................................................................................................... 118

G288,2 Rounding axis ...................................................................................................................................... 119

G288,3 Contour accuracy of individual axes ....................................................................................................... 120

G288,4 Time base factor is axis-specific ............................................................................................................ 121

G289 Multi-function cycle .......................................................................................................................................... 122

G289 C Disable execution of external cycles ............................................................................................................... 123

G289 E Error Exit from G&M code.............................................................................................................................. 124

G289 L Tool length correction ................................................................................................................................... 125

G289 N Reload PRCON ............................................................................................................................................. 126

G289 R Adopt tool radius .......................................................................................................................................... 127

G289 X Adopt measurement values ........................................................................................................................... 128

G289 Z Enabling of G73 / G93 with cycles .................................................................................................................. 129

G481 Bore setup ...................................................................................................................................................... 130

G481 SE01 setup 2 bores .......................................................................................................................................... 132

G481 SE02 setup 4 bores .......................................................................................................................................... 133

G482 Shaft setup ..................................................................................................................................................... 135

G482 SE03 Setup 2 shafts ......................................................................................................................................... 137

G482 SE04 Setup 4 shafts ......................................................................................................................................... 138

G483 Setup slot/rectangular pocket inside ................................................................................................................. 140

G484 Setup slot/rectangle outside ............................................................................................................................. 143

G485 Setup 2 sides .................................................................................................................................................. 146

G487 Determine space point ..................................................................................................................................... 149

G488 Simple measurement block............................................................................................................................... 152

G581 Continuous operation cycle rotation .................................................................................................................. 156

G582 Continuous operation cycle oscillation ............................................................................................................... 157

G585 Position log ..................................................................................................................................................... 159

G586 Activation of job list processing ........................................................................................................................ 160

G586 Job list processing ........................................................................................................................................... 160

G587 I Variable -> PLC ............................................................................................................................................. 161

G587 O Set feed/spindle potentiometer ..................................................................................................................... 162

G589 Approach reference point ................................................................................................................................. 163

gm_code_programming_manual_v6.05.08.02.doc

Page 5

andronic 2060/30 60

5

G&M Code Programming Manual

G688 Setup command - Workpiece Machining ............................................................................................................ 164

G688,2 Surface plane milling ................................................................................................................................... 165

G688,3 Frame milling .............................................................................................................................................. 166

G688,10 Thread milling ........................................................................................................................................... 167

G781 Calibration OFFSET .......................................................................................................................................... 169

G781,1 Spindle offset ............................................................................................................................................... 173

G782 Read/write data of the CNC ............................................................................................................................. 174

G782,0 / ,1 Data of the tool management ................................................................................................................. 174

G782,0 I/R Read data of the CNC .............................................................................................................................. 175

G782,0 E Adjust error reaction cycles ........................................................................................................................ 176

G782,1 Write data of the CNC ................................................................................................................................... 177

G782,2 Read PLC variables ....................................................................................................................................... 178

G782,3 Write PLC variables ....................................................................................................................................... 179

G782,4 Read axis position ........................................................................................................................................ 180

G782,5 Read definition of the external cycle interface ................................................................................................ 181

G782,6 Reading the execution definition of the external cycle interface ....................................................................... 182

G782,8 Read sercos parameter ................................................................................................................................. 183

G782,9 Checking the assignment of communication variables ..................................................................................... 184

G782,10 Reading the active offsets ........................................................................................................................... 185

G783,0 Read/Write zero points ................................................................................................................................. 186

G784,0 Read in communication variable .................................................................................................................... 187

G784,1 Emit communication variables ....................................................................................................................... 188

G787 Apaptive Control .............................................................................................................................................. 189

G788,1 Probing the surface Z axis ............................................................................................................................ 190

G788,2 Corner and angle against the positive X axis ................................................................................................. 191

G788,3 Rectangle centre point and angle against X – individual measurement ............................................................ 192

G788,5 Rectangle centre point and angle against X – follow-up measurement ............................................................ 193

G788,10 Detecting the surface using 3 points (optional) ............................................................................................ 195

G789 Timer cycles .................................................................................................................................................... 196

Block search .......................................................................................................................................................... 198

Job list .................................................................................................................................................................. 201

Usage options .......................................................................................................................................................... 201

Inputs ..................................................................................................................................................................... 201

Usage notes .................................................................................................................................................... 202

Start of the job list ................................................................................................................................................... 203

Syntax: ........................................................................................................................................................... 203

Parameter programming ...................................................................................................................................... 204

Flexible G&M code Programming (FlexProg) ........................................................................................................ 205

General ................................................................................................................................................................... 205

Restrictions .............................................................................................................................................................. 206

General program structure ........................................................................................................................................ 206

Data types ............................................................................................................................................................... 206

Functions (general) .................................................................................................................................................. 207

Function declaration ................................................................................................................................................. 207

Macros and Q parameters ........................................................................................................................................ 207

Function definition ................................................................................................................................................... 208

Variables ................................................................................................................................................................. 208

Communication variables .......................................................................................................................................... 209

Status of communication variables ............................................................................................................................ 209

Expressions and operators ........................................................................................................................................ 210

Mathematical funktions ............................................................................................................................................. 210

Assignment of NC addresses ..................................................................................................................................... 211

Comment marks....................................................................................................................................................... 211

Point definition ......................................................................................................................................................... 211

Instructions ............................................................................................................................................................. 212

Jump marks ............................................................................................................................................................. 212

GOTO/IF ... GOTO/ IF ELSE ...................................................................................................................................... 212

FOR loops ................................................................................................................................................................ 213

WHILE loops ............................................................................................................................................................ 213

DO ... WHILE loops .................................................................................................................................................. 213

SWITCH ... CASE branching ...................................................................................................................................... 214

Sample programs ..................................................................................................................................................... 215

Index .................................................................................................................................................................... 229

gm_code_programming_manual_v6.05.08.02.doc

Page 6

6

andronic 2060/30 60

G&M Code Programming Manual

Version

Date

Additions and changes

Initials

New chapter: G782,8

•

• new structure G688

• Corrections / extensions:

• New chapter: Tool management, job list, G688,x, G788,x

• Corrections / extensions: G 586

• Corrections / extensions: Zeropoints, G29, G189, G481, G485, G781

• New: G585

• Corrections / extensions: G22, G23, G50, G181, G282,0/G282,2 and G781

• New: G29, G305, G787

• Corrections: G17-G19, G50/G51/G52 PRESET, G92, G289, G488

• New: G23, G282,1, G781

Revisions

V6.05.08.02 23.07.2013

V6.05.08.01 12.02.2013

V6.05.08 22.11.2012

V6.05.07 03.09.2012

V 6.05.04 25.01.2012

V 6.5 16.11.2010

V 6.2 01.07.2010 Corrections and layout modifications Pa

• Corrections / extensions: G4, G29, G54-G59, G487, G488, G688, G7 8 1, 1,

G782,5, G782,6, G 78 4, 1, G7 88,10, FlexProg

• Extensions : G18 3, G28 2, G4 81, G4 82, G2 5 RT CP

Vol

Vol

Vol

Vol

Vol

Vol

gm_code_programming_manual_v6.05.08.02.doc

Page 7

andronic 2060/30 60

G&M Code Programming Manual

This manual was prepared with g reat effort and utmost care. N evertheless, this manua l, the control

in later editions. Any information regarding mistakes or

This manual, the associated program descriptions and other objects sold or distributed together w ith

The following documentation must be read before connecting and starting up the control

General information

unit or the programs are s ubject to modifications in th e interest of technical pr ogress without prior

notice. Additional pages may be included

suggestions for improving this manual are greatly appreciated.

We cannot be held liable for damage res ulting from non-observance of the instructions given in this

manual. We cannot be held liable or resp onsible for losses or damag e actually or supposedly caused

directly or indirectly by the units or software programs distributed or delivered by us and claimed by a

customer or another natural or legal person. This clause also applies to insufficient service,

unsuccessful business transaction s, loss of expected profits or consequential d amage resulting from

the use of the units or software distributed by us.

the control unit are subject to copyright. All rights reserved. This manual, the programs and any other

objects protected by copyrig ht may not be copied in p art or entirely or reproduced in any othe r way

without prior approval by andron GmbH. Copies of part of or the entire manual obtained legally and

with the approval of andron GmbH must contain the copyright information as the original material.

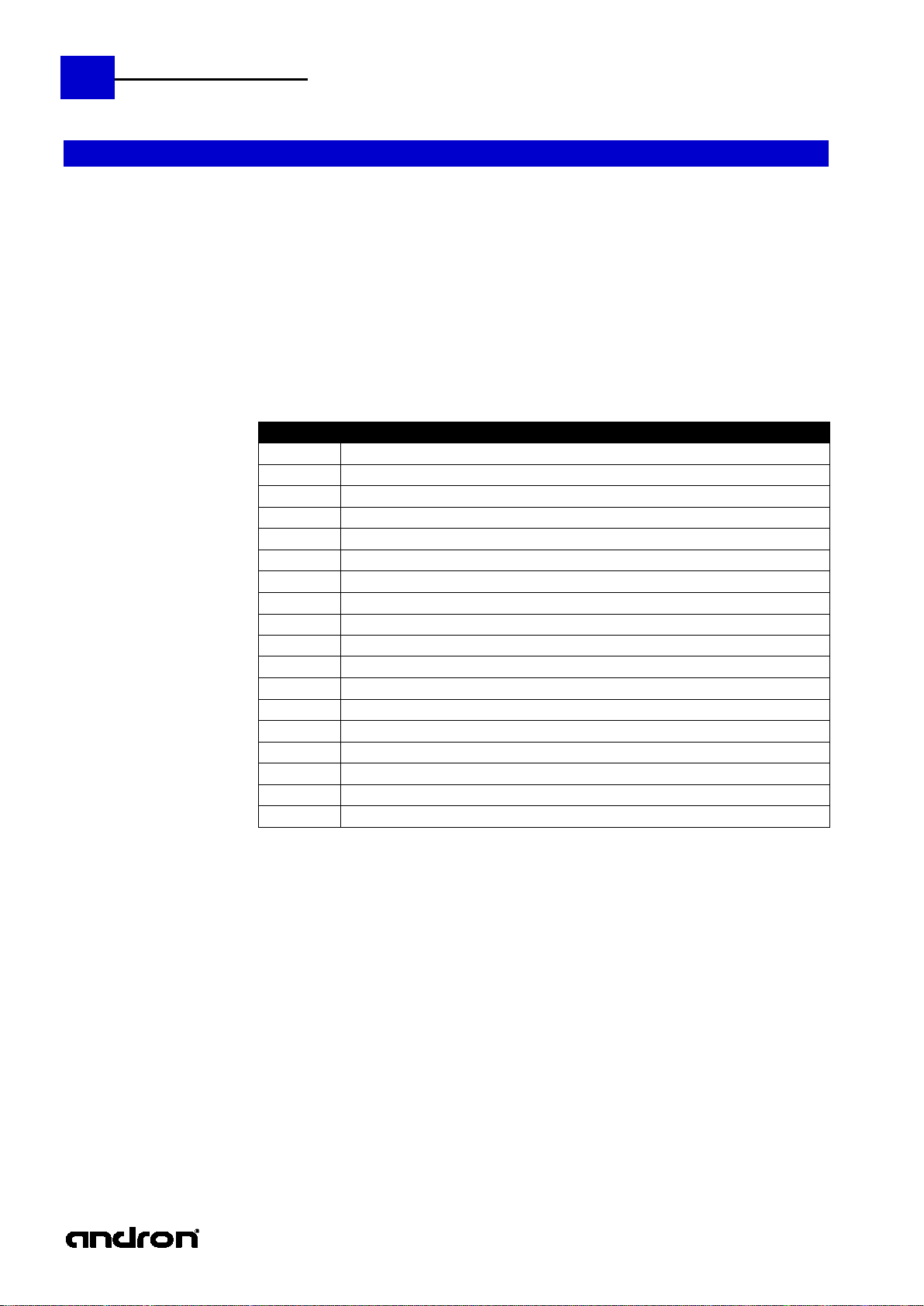

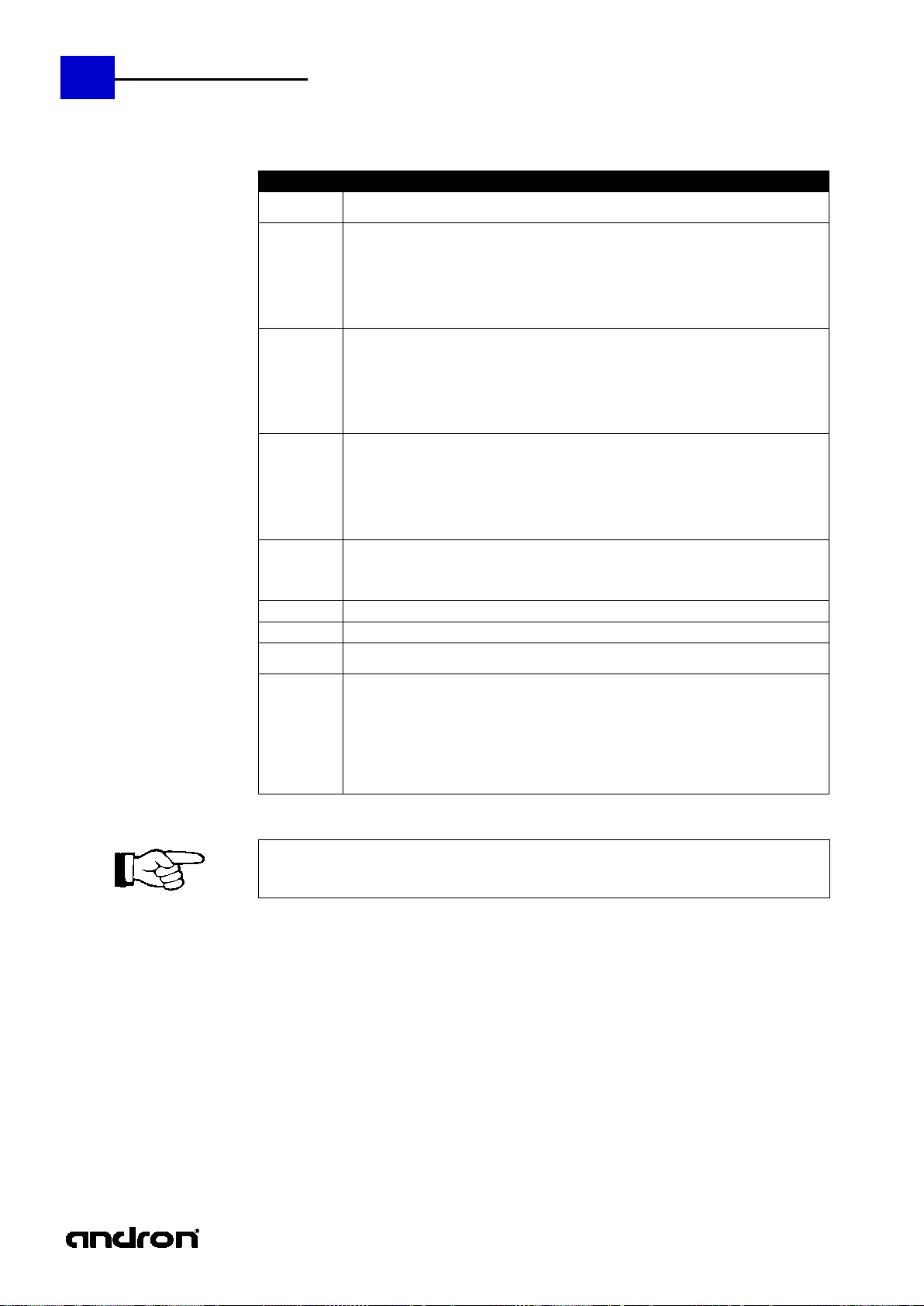

Address letters

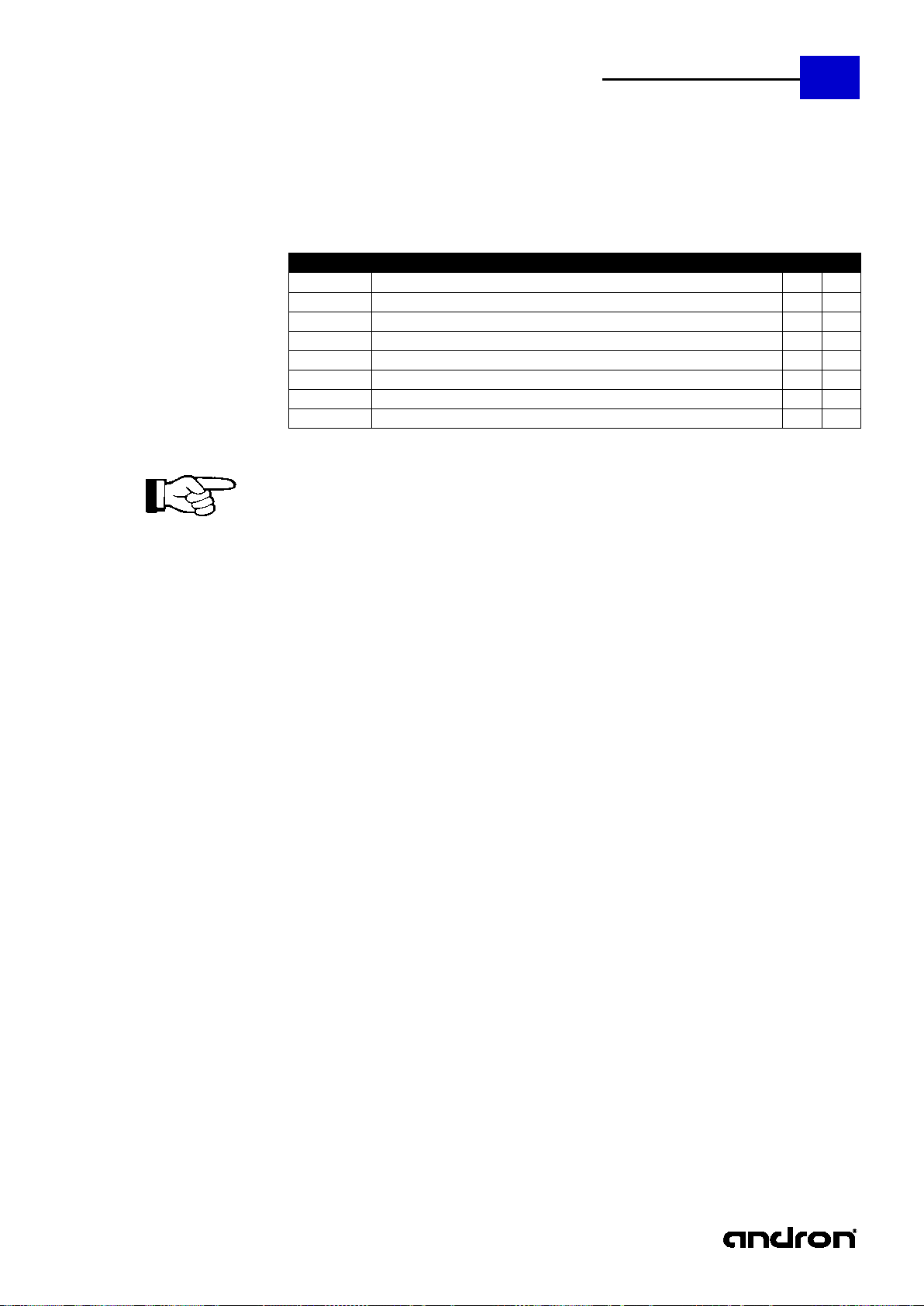

Character Function

7

We shall not accept responsibility for damage resulting from faulty installations!

unit.

N Block number

G Path condition

A, B, C Path information A axis, B axis, C axis

X Path information X axis, dwell time

Y, Z Path information Y axis, Z axis

I, J, K Interpolation parameters, circle center

F Feed ra te, time for G95 (inverse time programming)

O Output address

D Additional information (cutting edge correction table)

E Additional information on the PLC

S Spindle speed

T Tool number

M Machine function

Q Parameter programming

W Command extension

gm_code_programming_manual_v6.05.08.02.doc

Page 8

8

andronic 2060/30 60

G&M Code Programming Manual

This description uses the following warnings and symbols:

Safety instructions

Warnings and symbols

This sign contains general and additional information or instructions

and prohibitions for avoiding damage.

Important information or cross references to other descriptions.

Warning on personal and machine damage, i.e., information or instructions and

prohibitions for avoiding personal and machine damage.

Caution Extremely Dangerous!!!

This symbol indicates an example.

gm_code_programming_manual_v6.05.08.02.doc

Page 9

andronic 2060/30 60

G&M Code Programming Manual

Introduction

andron products are developed and p roduced in accordance with current state-of-the-art m ethods.

In order to guarantee the designated use of the products, the following r equirements must be met,

Anyone handling one of our products in any way must have read and under stood the safety

Areas of application and use

The control unit is designed for incorporation i n a control panel, in the wall or door o f a switching

by specialized personnel.

Using the CNC control outside of the above-mentioned fields of application or under operational

extreme variations in temperature or extreme minimum temperatures.

Designated use

9

Before delivery, their safe operational status is verified.

The products may only be used in accordance with their designated use. Any use contrary to their

designated use may produce situations that result in personal damage or material damage.

As the manufacturer, andron will not give any warranty, will not be liable nor pay for

damages resulting from the use of the products contrary to their designated use. The

user shall bear all the risks of using the products contrary to their designated use.

before using the andron products:

instructions and the designated use.

If the products are hardware, they must be left in their original state, i.e., no constructional

changes may be made. Software products must not be decompiled, and their source codes must

not be changed.

Damaged or defective products may not be installed or put into operation.

Provisions must be made that the products are installed in accordance with the regulations given

in the documentation.

cabinet or directly in the enclosure of a mac hine tool. Make sure that the mounting, ins tallation and

environmental conditions are observed.

The designated use also requires the use of a soft- or firmwa re offered by andron for the control unit.

Each control system must be submitted prior to startup to suitable parameterization and programming

Use of the unit c o n t rary to its desi g nated use

conditions and technical data other than those described in the documentation is considered "contrary

to the designated use".

Serious injuries - Life-threatening injuries

The control unit may not be used if it is subject to operational conditions that do not meet the

prescribed environmental conditio ns. For example, it is prohibited to operate it underwater, under

gm_code_programming_manual_v6.05.08.02.doc

Page 10

10

andronic 2060/30 60

G&M Code Programming Manual

The sequence of a machining process on the machine is described by the NC program. It c onsists

Example

G02 X50 Y0 I25 J0 F2000 S10000 M3 T7 M6

G02

Path condition circle in clockwise direction

X50

X coordinate

Y0

Y coordinate

I25

Auxiliary parameter circle center X coordinate

J0

Auxiliary parameter circle center Y coordinate

F2000

Feed speed 2000 mm/min

S10000

Spindle speed 10000 1/min

M03

Machine function 'Spindle on'

M06

Machine function 'Change tool'

Special signs

%

The rest of the line is interpreted as a comment

;

The rest of the line is interpreted as a comment

[ ]

Jump mark, index at FlexProg

/*...*/

Encapsulated comment at FlexProg

( )

Comment, function bracket at FlexProg

Components of a NC program

mainly of a sequence of program r ecords. In a all the necessary information for a work step ar e

included. Record numbers can be entered under the address N.

With the andronic control, the programming is also permissible without block numbers.

With program words, as a general principle, a dif ferentiation is made betwe en modal ( latching) and

non-modal words. A word is modal if its value remains effective until it is overwritten by another

value, or the end of the program has been reached. In contrast, non-modal words only have an effect

within the block in which they have been programmed.

The following can be programmed within a block.

Character Function

N Block number (optional)

G Path condition

A Path information A axis

B Path information B axis

C Path information C axis

X Path information X axis, dwell time

Y Path information Y axis

Z Path information Z axis

I, J, K Interpolation parameters, circle center

F Feed speed, dwell time, time display at G95 (Invers Time Programming)

O Output address

D Auxiliary information (correction memory)

E Additional information on the PLC

S Spindle speed

T Tool number

M Machine function

Q Parameter programming

W Command extension

gm_code_programming_manual_v6.05.08.02.doc

Page 11

andronic 2060/30 60

G&M Code Programming Manual

• 100 tool magazine slots per tool magazine,

In the magazine assignment table, a duplo tool can be specified for every tool. This duplo tool is used

A cycle which blocks a tool cannot automatically load a duplo tool and continue the NC program. If

reaction to the problem can be adjusted using FlexProg.

Every tool type has an adjusted input screen. Some parameters are always required, others are

missing, the NC program is cancelled with an error message.

Obligatory parameters:

• Length

• Tool size

Optional parameters:

• Pages 1 and 2:

• Coolant control

Tool management

Functions of the tool management

• any number of tool magazines in the database,

• configurable tool types,

• 1 tool magazin, several pick-up places,

• several magazin assignment table files,

• variable or fixed coding of slots ,

• duplo tools,

• 3 different types of status indication,

• 9 tool dimensions per tool usable,

• tool life control with remaining tool life indication,

• limitation of maximum speed,

• tool dependent speed output,

• rotation direction control,

• coolant control,

• wear control (option),

• Numerous adaptation possibilities at the machine:

• chain or disk magazine, pick-up, manual change in any combination up to a total of 100

locations,

• correction of position for every single magazine location ,

• programming of the tool change procedures in G&M code format,

• Different options:

• tool can be changed, despite tool life has expired ,

• interruption of the NC program during speed reduction of the tool management,

• in case of tool magazine problems, all tools can be changed manually without

intervening within the tool management,

• Support of tool magazines with PLC- or sercos drive,

11

Duplo tools

Tool data

when changing the tool if the programmed tool is blocked. The duplo tool can have another duplo

tool. Thus, a chain can be determined by replaceme nt tools .

such behaviour is desired, the error reaction of the cycle can be adjusted using G782,0 E0 and the

optional. The tool data are checked only when the NC program runs. If obligatory parameters are

• Release by the operator

• Radius (in case of milling cutters)

• Allowance for length and radius

• Wear for length and radius

• Positive and negative tolerance of the radius

• Status for idle time and tool breakage

• Page 3:

• Service life data

• Nominal speed

• Maximum speed

• Speed direction control

gm_code_programming_manual_v6.05.08.02.doc

Page 12

12

andronic 2060/30 60

G&M Code Programming Manual

Tool dimensions:

• Length, allowance and wear are added by the control system and the result will be set as active

• Entry: upper and lower overall dimension.

TCP active:

• Information for RTCP function. Activate (1) if the 5-axis NC program for the ball centre

(Tool-Center-Point - TCP) has been calculated.

Tool size:

The size number stands for the number of half places occupied to one side.

out of its magazine place for half a place to each side).

Fixed-place coding:

This parameter permits the fixed-place coding of tools with the tool size 1 which are normally part of

maintain a fixed place in the magazine or a weight optimisation of heavy tools can be obtained.

Additional correction values:

Apart from the length and the radius of the tool, it is possible to call up from the NC program the

using D2 (or D0=2) to D9 (or D0=9).

Service life recording:

• In order to use the service life recording, a total service life must be entered in the respective

service life has been deleted, the total service life is valid again.

tool length when changing the tool.

The allowance is entered by the operator and is used for specifying an allowance on the

workpiece.

The wear is determined and entered by Blum cycles if wear de termination has been activated or

by load cell cycle "G189 load cell tool breakage control".

• Radius, allowance and wear are added by the control system and the result will be taken into

consideration during execution of the NC progra m .

The allowance is entered by the operator and is used for specifying an allowance on the

workpiece.

The wear is determined and entered by Blum cycles if wear determination has been activated.

• Radius dimension limit: tolerance limits monitoring. The total radius must be within the tolerance

limits.

• Program cancellation in case of unacceptable extent of wear.

• No specification of the radius tolerance means that radius tolerance will not be monitored.

(i.e. a tool of size 1 occupies two half places, consequently exactly one place; a tool of size 2 s ticks

a variable tool management. Thus, in case of variable place coding, for example a touch probe can

length and radius data for 8 further pairs of correction values. To this end, the NC address "D" or

"D0=" with the number of the desired pair of correction values is used. When calling up the tool, the

first pair of correction values will automatic ally become active if no other pair has been activated

tool file. After the first use of the tool by the machine, the status and the remaining service life

will automatically be entered in the tool data.

• If a prewarning limit has been entered, a message will appear in the position display as soon as

this limit has been reached.

• The remaining service life can be changed at any time.

• After expiry of the service life, the status of the tool will be set to the value " 0"-blocked- during

the next tool change and the tool will not be loaded again. If a dup lo tool is available, it will

automatically be used.

• The option "Use of tools beyond service life limit" can be activated in the magazine

configuration. In this case, the continuation of the machining process will be offered if no

released duplo tool is available.

• In order to reactivate a blocked tool, the service life status must be set to "1"-released- and the

remaining service life must be deleted or set to a value greater than zero. If the remaining

gm_code_programming_manual_v6.05.08.02.doc

Page 13

andronic 2060/30 60

13

G&M Code Programming Manual

Special functions:

•

Speed specification

: If a nominal speed is defined in the tool data, this value will be set as

be supported by the machine manufacturer.).

Measurement data:

• Entering the measurement data for the BLUM laser measuring cycles for tools measuring (see

entering the data for G387 "Cutter control on rounded cutting geom etry"

G382- Temperature

Address

Designation

Function in the Blum cycle

X

RTOL

Max. allowed zero-point correction in the X/Y axis in case of comparative

measurement

Z

LTOL

Max. permissible zero-point correction in the Z axis in case of

comparative measurement

G383- Tool length measurement

Address

Designation

Function in the Blum cycle

Z

LTOL

Permissible wear tolerance for tool length

G384 - Setting length and radius

Address

Designation

Function in the Blum cycle

D

CUT

Number of the tool cutters for the cutter control

H

R_MeP

Radial measuring position for length measurement (OL)

J

L_MeP

Axial measuring position for radius meas urement (OR)

O

RBREAK

Permissible concentricity tolerance during cutter control (TOL)

X

RTOL

Permissible wear tolerance for tool radius

Z

LTOL

Permissible wear tolerance for tool length

G385- Cutter control on straight

Address

Designation

Function in the Blum cycle

D

CUT

Number of the tool cutters for the cutter control

O

RBREAK

Permissible concentricity tolerance during cutter control (TOL)

G386 - Tool breakage control

Address

Designation

Function in the Blum cycle

H

R_MeP

Eccentric control position

Z

LTOL

Permissible length tolerance for tool breakag e detection (TOL)

G387- Cutter control on rounded

Address

Designation

Function in the Blum cycle

D

CUT

Number of the tool cutters for the cutter control

H

R_MeP

Radial offset to the starting point of the corner radius (O)

E

CR

Corner radius / cutter radius / ball head radius (CR)

I

TA [degree]

Starting angle Alpha to the symmetrical axis (a )

J

TB [degree]

Target angle Beta to the symmetrical axis (b)

Z

LTOL

Control way on the tool shank (W)

O

RBREAK

Permissible form tolerance during cutter control (TOL)

spindle speed during the tool change if no speed has bee n programmed in the NC block. The

speed specified in the tool data applies only to the respective tool. The output is carried out in

the main spindle mode 1 for spindle 0 and in the main spindle mode 2 for the selected spindle.

•

Maximum speed limitation

as spindle speed during the tool change if the speed programmed in the NC block is greater than

the maximum speed. In the tool management options, it is possible to define whether the NC

program will be interrupted with a message in case of a speed reduction or whether the speed

has to be reduced automatically.

Speed direction control

•

rotation which will be compared with the programmed direction during each spindle start in order

to prevent the use of a tool with wrong direction of rotation.

Coolant disabling

•

zero means: Coolant can be used for this tool. If "One" has been entered, the NC program will

compare each coolant request with the coolant disabling of the tool. If an unacceptable coolant

has been programmed, the NC program will be cancelled and an error message displayed.

•

Tool measuring:

description of the BLUM laser measuring cycles). When calling up the cycle, the tool-specific

measurement data are transferred to the cycle if they are NOT included in the NC program.

• When executing the Blum cycles, the parameters from the NC program have top priority. In the

NC program, not specified parameters are used from tool data and, if not available there either,

from the presettings of the cycle.

• The tool type corner radius milling cutter and die sinking cutter have an additional parameter for

: This function allows ce rtain coolants to be disabled for the tool. No entry or

This function activates tool measuring during tool change (This function must

: If a maximum speed is entered in the tool data, this value will be set

: The speed direction control serves to define for the tool a direction of

compensation of the NC axes

of centric tools

of the tool with concentricity

cutting geometry

cutting geometry

control

gm_code_programming_manual_v6.05.08.02.doc

Page 14

14

andronic 2060/30 60

G&M Code Programming Manual

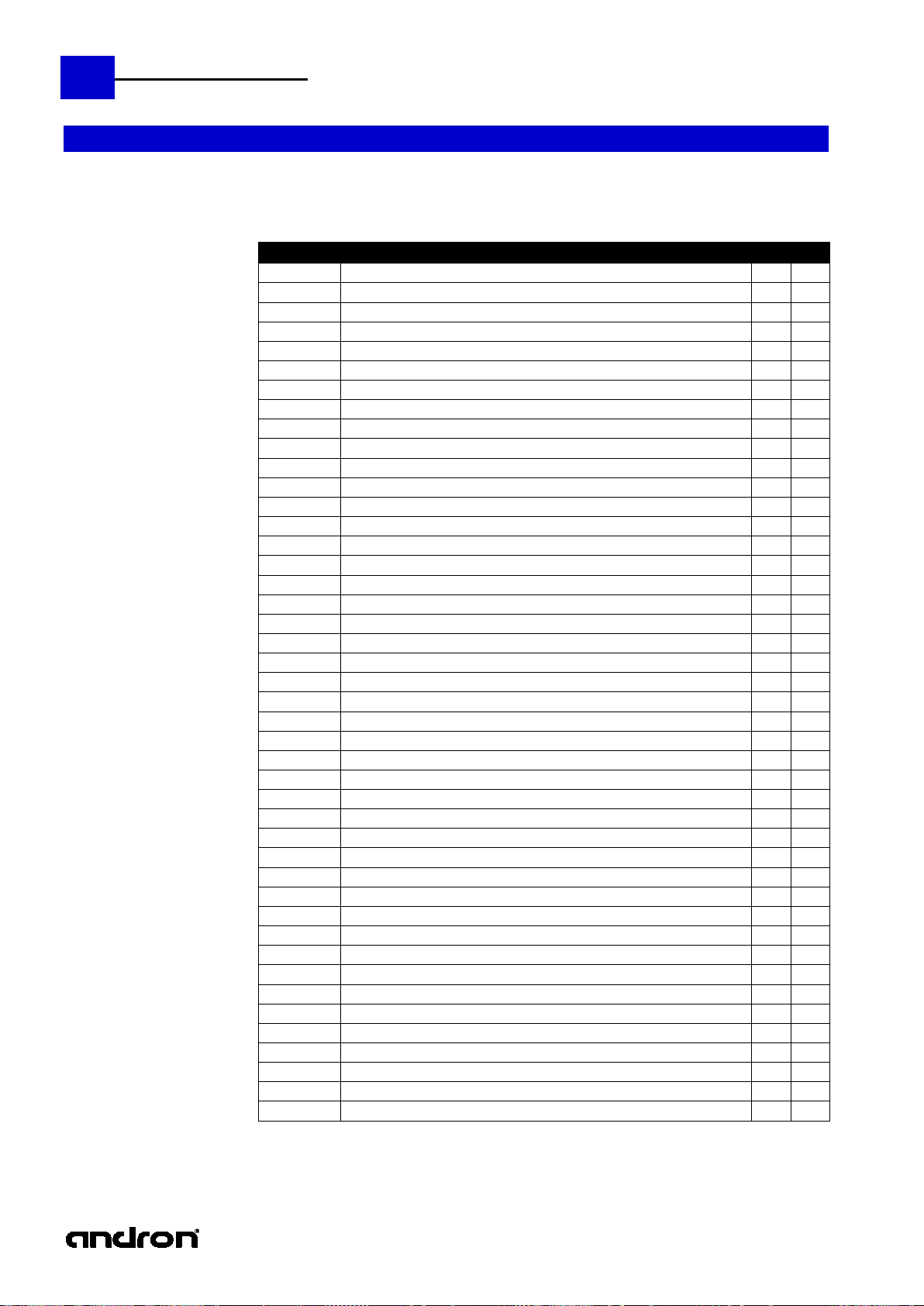

The M functions initiate certai n machine func tions. These fu nctions may differ depending on machine

type/manufacturer.

M01

Optional stop

1

M02

End of program

1

M03

Spindle 0 On (clockwise)

2

M04

Spindle 0 On (anticlockwise)

2

M05

Spindle stop

1

M06

Tool change (active spindle)

2

M07

Coolant 1 On (not according to DIN 66 025)

2

M08

Coolant 2 On (not according to DIN 66 025)

2

M09

Coolant Off

M10

Clamping On

M11

Clamping Off

M12

Pallet change

2

4

M13

Spindle 0 On, clockwise rotation and coolant 1 On

2

M14

Spindle 0 On, counterclockwise rotation and coolant 1 On

2

M19

Spindle stop with defined end position; angular position at "S" in degrees

1

M30

End of program with spindle 0 Off

1

M50

Coolant 3 On

2

M51

Coolant 4 On

2

M67

Open collet

2

3 M68

Close collet

2

3

M69

Open tool gripper (variable pocket code)

2

3

M70

Close tool gripper (variable pocket code)

2

3 M99

End of program with neutral position approach

1

M100

Programmed stop with optional restart position

1

M103

Spindle 1 On clockwise

2

6

M104

Spindle 1 On anticlockwise

2

6 M105

Spindle 1 stop

1

6 M106

Tool change in spindle 1 (reserved M command)

2

6

M121

Unclamp pallet

2

4

M122

Clamp pallet

2

4 M123

Manual pallet change

2

4 M203

Spindle 2 On clockwise

2

6

M204

Spindle 2 On anticlockwise

2

6

M205

Spindle 2 stop

1

6 M206

Tool change in spindle 2 (reserved M command)

2

6 M303

Spindle 3 On clockwise

2

6

M304

Spindle 3 On anticlockwise

2

6

M305

Spindle 2 stop

2

6 M606

Manual tool change from tool magazine

2

3 M610

Read tool data from PLC

2

3

M611

Prepare tool magazine

2

3

M640

Start position log

2

5 M641

Stop position log

2

5

M Functions

M Function A.* A.*

M00 Programmed stop 1

1

2

2

gm_code_programming_manual_v6.05.08.02.doc

Page 15

andronic 2060/30 60

G&M Code Programming Manual

Different machine configurations require machine functionalities which can only be achieved in

collaboration with andron.

Spindle change from selected spindle to spindle 0

2

Spindle change to spindle 1

2

Spindle change to spindle 0

Spindle change to spindle 2

2

Spindle change to spindle 0

2

6

Spindle change to spindle 3

Spindle change to spindle 0

2

* Comments on the M commands:

1

Function is effective at end of block

2

Function is effective at start of block

3 freely definable in tool change configuration

4 freely definable in pallet management configuration

5 freely definable in position log configuration

6 reserved commands (optional)

Extensions of M comman d s (option)

M Function A.* A.*

Spindle change from 0 to selected spindle (PLC) 2 6

15

6

6

2 6

6

2 6

6

gm_code_programming_manual_v6.05.08.02.doc

Page 16

16

andronic 2060/30 60

G&M Code Programming Manual

Property:

MODAL means that the command/function remains active until it is

Topic:

The G functions can be divided into the following topics:

Position:

DEF = Default (active after starting the control unit)

--- = Not pre-set

G Functions

Explanations

overwritten.

Interpolation type

special command

setup command

tool command

cycle command

gm_code_programming_manual_v6.05.08.02.doc

Page 17

andronic 2060/30 60

G&M Code Programming Manual

Property

modal

Topic

Axis movement

Position

---

Syntax

G00

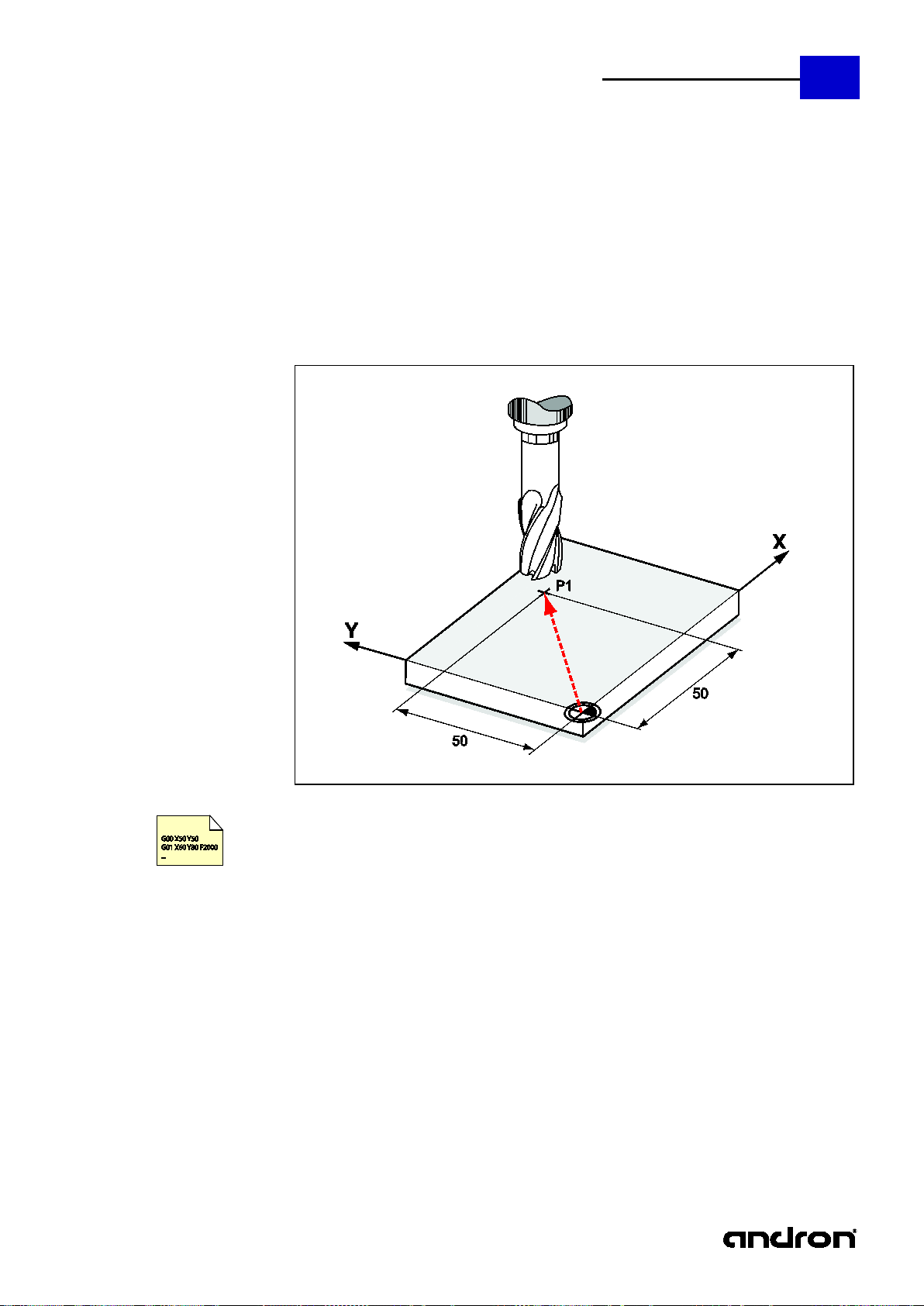

The path information G00 programs rapid traver se movements by specifying the target point. The

sions. The rapid traverse

G00 X50 Y50 ; The axes are moved by interpolation to point P1

G00 Positioning in rapid traver se

target point is reached by enter ing it either in absolute or relative dimen

speed can be defined in the EEPROM.

17

gm_code_programming_manual_v6.05.08.02.doc

Page 18

18

andronic 2060/30 60

G&M Code Programming Manual

Property

modal

Topic

Axis movement

Position

DEF

Syntax

G01

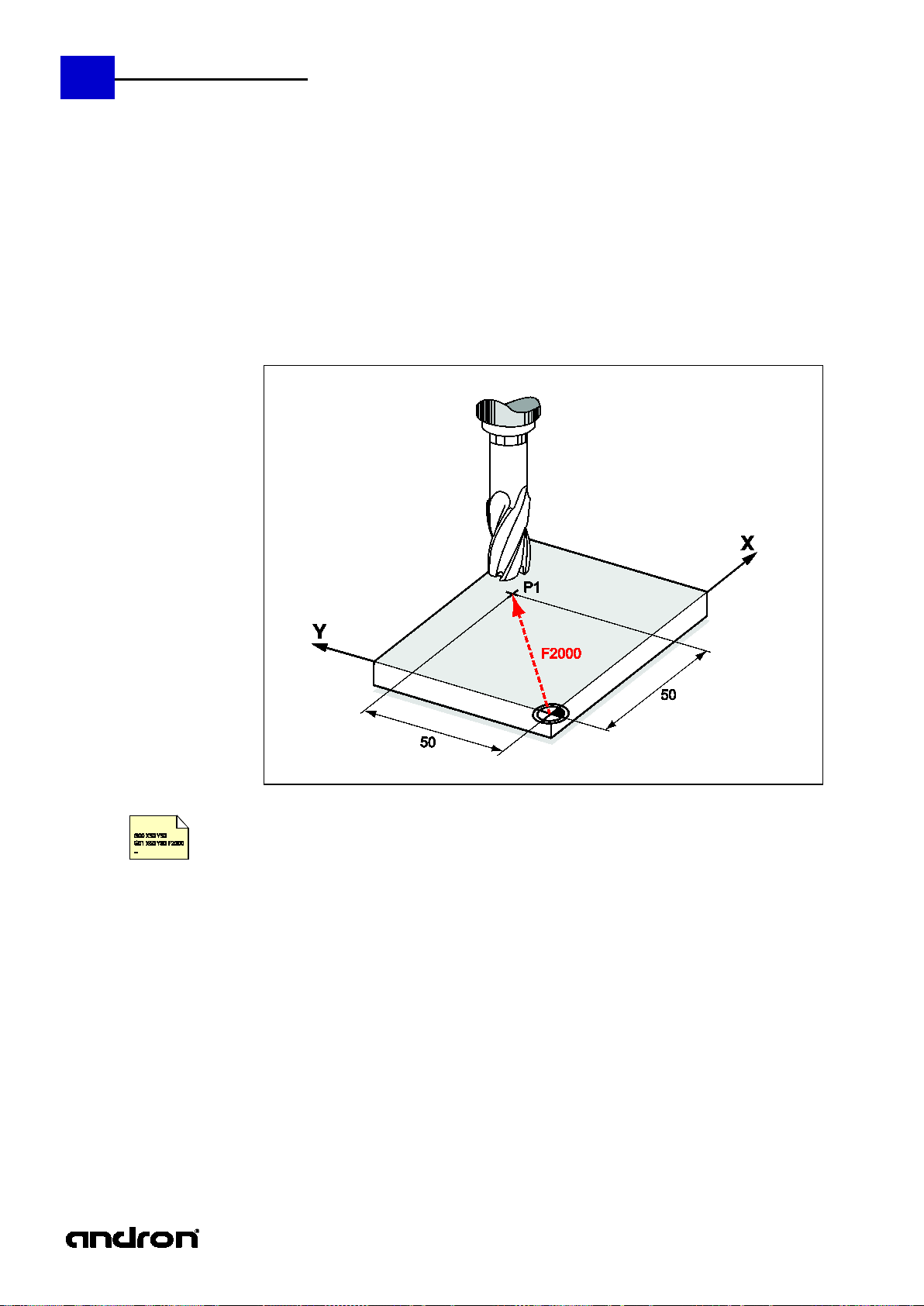

The path information G01 programs feed movements by sp ecifying the target poi nt. The target point

G01 X50 Y50 F2000 ; Positioning at point P1 at 2000 mm/min

G01 Positioning at the feed rate

is reached by entering it either in absolute measure or relative measure. The feed rate c an be defined

in the EEPROM or programmed by means of the F parameter.

gm_code_programming_manual_v6.05.08.02.doc

Page 19

andronic 2060/30 60

G&M Code Programming Manual

Property

modal

Topic

Axis movement

Position

--- Syntax

G02 /G03 <Parameter list>

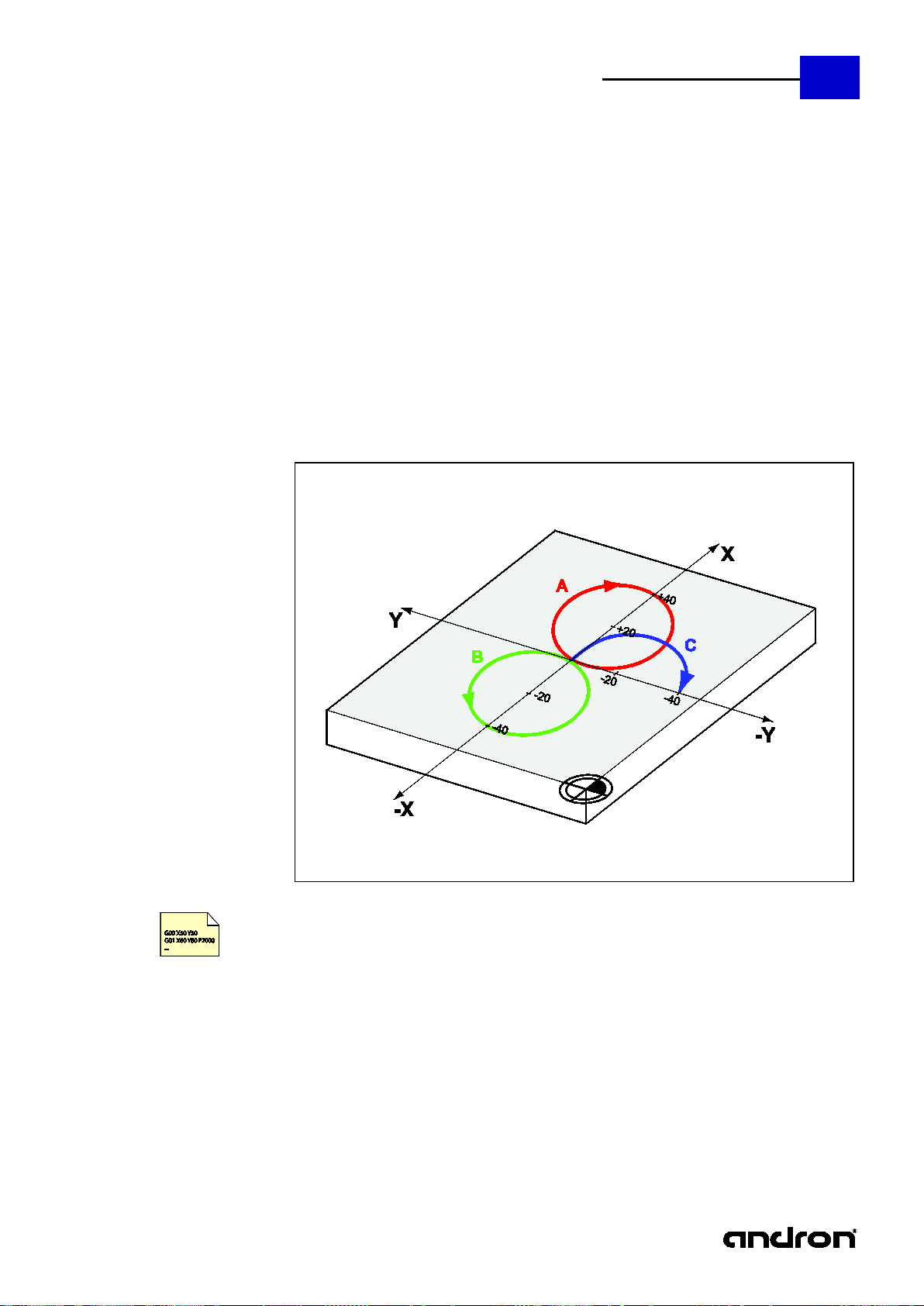

For the circular interpolation, th e axes are moved on an arc from the starting po int to the end po int.

G01 X0 Y0 ; Starting point approach

G02 X0 Y-40 R20 ; Clockwis e travel to X0 Y-40. Radius 20 mm (C)

G02 Circular interpola ti on - Clockwise

G03 Circular interpola ti on - Counterclockwise

The movement can take place clockwis e by selecting G03 and counterclockwise by selecting G03.

Circular interpolation must contai n the following parameters and can b e applied in all 3 planes (see

G17 - G18):

G02 or G03 (direction of rotation), end point of the arc, radius of the cir cle (R) or circle c enter (I, J,

K) The center of the arc can be sp ecified in absolute (G190) or relative (G191 ) coordinates. As an

alternative to the center, the arc rad ius can be pr ogrammed directly by entering the address letter R .

However, this only applies to arcs having an angle of rotation of less than 180°.

19

G02 X0 Y0 I20 J0 ; Clockwise travel to X0 Y0. Circle center at X20 Y0 (A)

G03 X0 Y0 I-20 J0 ; Counterclockwise travel to X0 Y0. Circle center at X-20 Y0 (B)

gm_code_programming_manual_v6.05.08.02.doc

Page 20

20

andronic 2060/30 60

G&M Code Programming Manual

Property

modal

Topic

Axis movement

Position

---

Syntax

G04 <Parameter list>

The function G04 allows you to pr ogram a dwell time. The time is sp ecified by the parameter X. The

G04 without parameters is used for interruption of the contour, without any further action to

G04 X11.4 ; Dwell time 11.4 seconds

G04 Dwell time

function is only effective blockwise. The maximum prog rammable dwell time is 655 seconds.

synchronize of read data, LookAhead and position, and the exact position setting of calculation results

or variables.

gm_code_programming_manual_v6.05.08.02.doc

Page 21

andronic 2060/30 60

G&M Code Programming Manual

Property

modal

Topic

Axis movement

Position

---

Syntax

G05 <Parameter list>

This function allows you to describe a spatial arc (spatial circle section). No information such as radius

G01 X0 Y0 Z0 ; Starting point approach

; Intermediate point at X20 Y30 Z30

G05 Spatial arc interpolation

or direction of rotation exists for this function. The interpola tion parameters work in the same way as

G02 / G03.

An G&M code for spatial arc interpolation must contain the following parameters:

G05, end point of the spatial arc in X, Y and Z (A), intermediate point on the spatial arc in I, J and K

(B). The starting point (C) of the spatial arc is determined by the current axis position.

21

G05 X50 Y50 Z0 I20 J30 K30 ; End point at X50 Y50 Z0

gm_code_programming_manual_v6.05.08.02.doc

Page 22

22

andronic 2060/30 60

G&M Code Programming Manual

Property

non-modal

Topic

Special command

Position

---

Syntax

G14 N = [“] Macro name [“] [Pn]

A macro is a closed program part that must be progr ammed only on ce. A ma cro is not exec uted until

it is defined or called by the main program or another macro. In contrast to the genuine

#Rectangle# ; Header containing the name of the macro

## ; End identifier

The optional inverted comma cha racters [“] at the beginning and end of the name only have to be

by a number, indicates how many times the macro is to be executed. The maximum number of

G14 N = Rectangle P3 ; Example macro called three times

G14 Macro call

subprograms, macros are incorporated in the program text. A macro starts with a heade r in which the

name of the macro is defined. No other instructions (not even block numbers) may be programmed in

the header. The name of the macro mus t not contain more than 24 characters and stands between

the character #. The end of the macro definition is marked by a bloc k containing the instructi on ##.

Here, too, no other instructions may be programmed.

G01 X0 Y0 F2000 ; Instructions

X100

Y100

X0

Y0

entered if the name of the macro contains symbols or blan ks. The o p tional addres s lett er 'P', fo llowed

repetitions is: 32

Prior to compiler version V5.3R3: 32 repetitions maximum

From compiler version V5.3R3: 256 repetitions maximum

If a macro has been defined as described above, it can be called in the program as follows.

gm_code_programming_manual_v6.05.08.02.doc

Page 23

andronic 2060/30 60

G&M Code Programming Manual

Property

modal

Topic

Setup command

Position

Preset G17

Syntax

G17 / G18 / G19

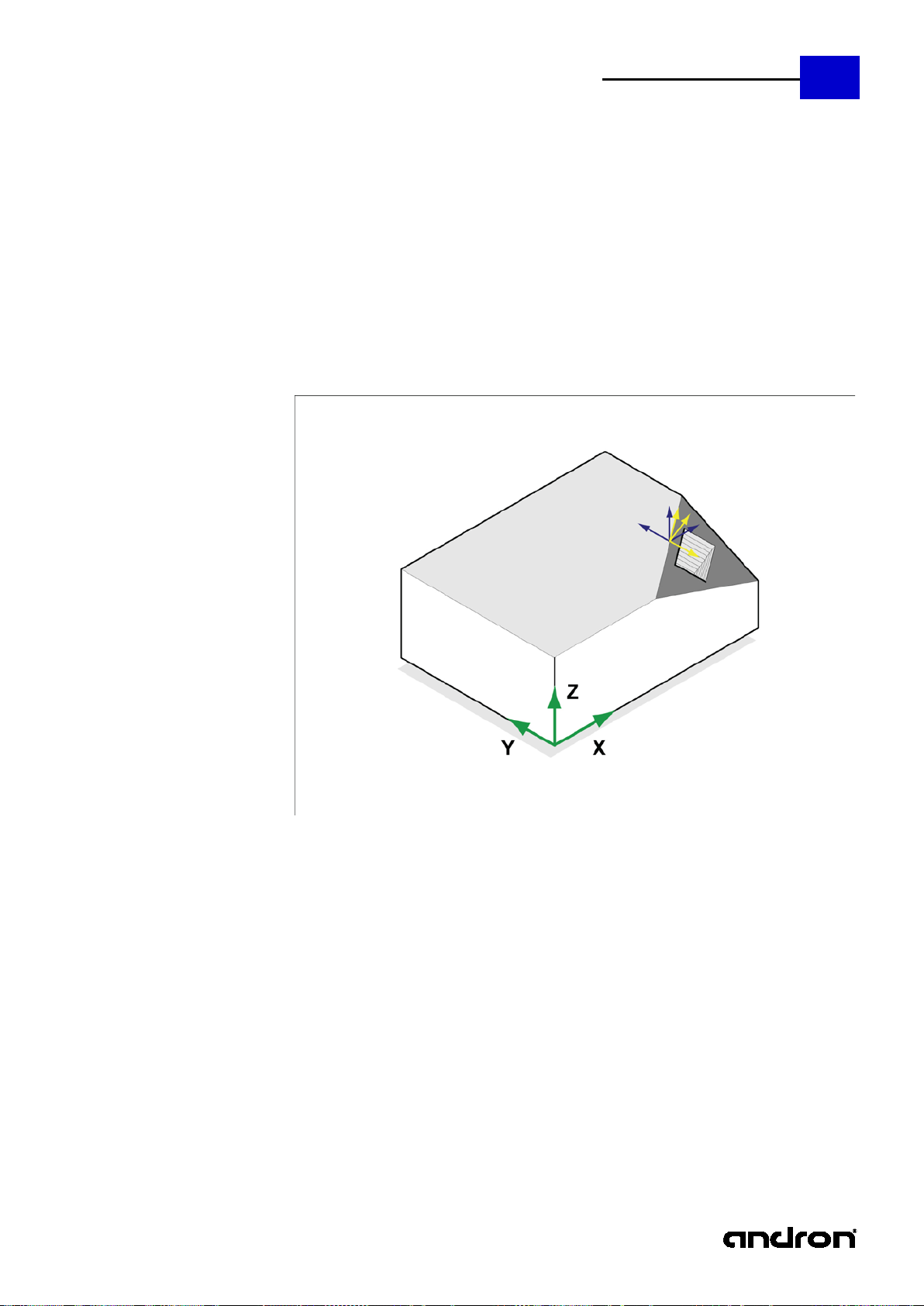

G17 Plane XY

G18 Plane ZX

G19 Plane YZ

23

A change of plane via G17/G18/G19 does not cancel active zero offsets.

A change of plane with G17/G18/G 19 d o es not cancel an active rotation.

gm_code_programming_manual_v6.05.08.02.doc

Page 24

24

andronic 2060/30 60

G&M Code Programming Manual

Property

non-modal

Topic

Special command

Position

---

Syntax

G22 N = [“] Program name [“] [Pn]

G22 N = [“] Database path: Program name [“] [Pn]

Programs that must be repeated several times can be called from a main program by entering G22.

This program is available as a separate NC program in the same database as the calling main

icates how many times the

G22 N = Feed program P3 ; Feed program called three times

G22 Sub program call

program. If the prog ram to be called is not included in the program database of the control, the

database path must also be specified. Enter the designation fr om "Programs / da ta base:" to call the

database path in the Xpanel.

Example:

G22 n="C01:ncprg_name" is loading from the user database path 1

G22 n="S05: ncprg_name" is loading from the system database path 5

The program name may contain 24 characters maximum. The optional inverted comma characters [“]

at the beginning and end of the name only ha ve to be e ntered i f th e progr am name contains symbo ls

or blanks. The optional address letter 'P', followed by a number, ind

program is to be executed. The maximum number of repetitions is: 32534

gm_code_programming_manual_v6.05.08.02.doc

Page 25

andronic 2060/30 60

G&M Code Programming Manual

Property

non-modal

Topic

NC command

Position

---

Syntax

G23 N = “Text “ P<Type> I<Index>

The command G23 can be used to call up different func tions with AS CI I texts. The tar get is alw ays to

transmit a text with a length of 80 character s to the PLC, CNC or the display.

Type - P

Command

Index - I

0 - Default

Transfer text to the PLC

not necessary

1 ASCII variables of the CNC - is not supporte d at the moment

-

2 ASCII parameter of the CNC - is not supported at the moment

-

3 Transfer text to the XPanel user interface

1-3

Default (1)

4 Redefines the measuring log file names of the measuring cycles

start.

not necessary

5 Writes the values of the communication variables into a log file.

(This data is not transmitted during the block search)

IKV index

G23 N=“Drill 3mm“

Text is transmitted to the PLC

G23 P3 N=“Finishing part1“ P3

Text is displayed in the prompt of the XPanel position

G23 P3 N=“ Finishing part1“ P3 I1

Text is displayed in the prompt of the XPanel position

G23 P3 N=“ Finishing outside“ P3 I2

Text is displayed in the prompt of the XPanel position

G23 P4 N=“C:\Messung_123.log“

Beginning with this program line, the measuring cycles

IKV[100] = 1.456

G23 P5 N=“C:\Daten_123.log“ I100

The value of IKV[100] is written into the log file

"C:\Daten_123.log".

G23 Text - Functions

25

"mprot.log". If no path is specified, the data are transmitted to

%andronroot%\System\ (C:\Andron\System\*). Specified paths

are not created by the CNC and must already exist at program

The transmission to the PLC must be prepared in the PLC program.

See NcSatz_Konfiguratio n.chm

G23 P0 N=“ Drill 3mm“

menue in line 1.

menue in line 1.

menue in line 2.

of the log file will be named with the specified

designation and the path specification and no longer

with "C:\Andron\mprot.log".

gm_code_programming_manual_v6.05.08.02.doc

Page 26

26

andronic 2060/30 60

G&M Code Programming Manual

Property

modal

Topic

Special command

Position

---

Syntax

G25 <Parameter list>

RTCP describes the functionality of keeping a (TCP - Tool Center Point) constant during the

program but the

RTCP is activated according to the kinematics of the machine

defined in the machine parameters.

The state of RTCP (ON/OFF) is stored in the buffer, e.g. to

The state of RTCP (ON/OFF) stored in the buffer is restored,

sets

G25 RTCP H On/Off

movement of rotatory axes. Despite the use of rotatory axes, the pos ition of the TCP relative to the

workpiece does not change. RT CP normally effects a of the corr esponding axes if one of the rotary

axes is moved.

RTCP can be switched on/ off with the H para meter to G 25. The storing and restoring of RTCP s tates

is administered specifically to the program, i.e. if RTCP is deactivated in the substate RTCP active was stored in the main program, the state RTCP is actively restored after returning

from the sub-program and the RTCP command.

G command Designation Meaning

G25 H0 Switch off RTCP RTCP is deactivated

G25 H1 Switch on RTCP

G25 H2 Save RTCP state

G25 H3 Restore RTCP state

be used with tool change NC sets

e.g. with a temporary deactivation in the tool change NC

gm_code_programming_manual_v6.05.08.02.doc

Page 27

andronic 2060/30 60

27

G&M Code Programming Manual

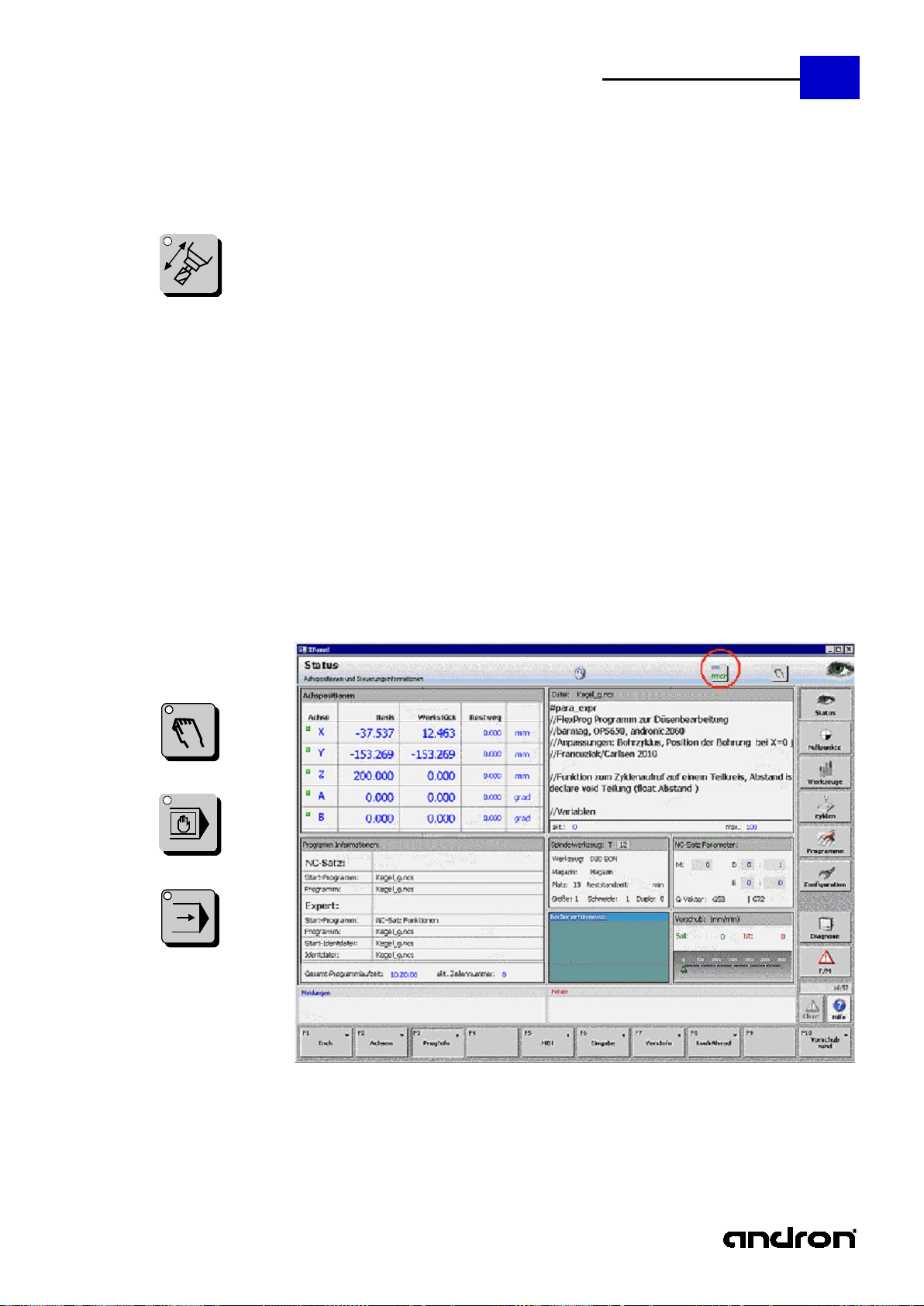

Functional descri pti on

Axis traverse movement in

direction

The use of axis traverse movement in milling lengthwis e axis direction is possible by defining the

Activation/deactivation must be realised by adaptations in the PLC software:

Selection of traverse movement in milling lengthwise axis direction via this key on the machine

operating panel in manual mode (not MDI, not AUTOMATIC interr uption!).

The traverse movement is carried out by p ress ing the tra verse move ment keys in posit ive or negati ve

the tool tip and a positive traverse path is preset by a movement to the tool shank.

Moving in the milling lengthwise axis direc tion is not possible in the automatic mode.

Activation and deactivation of

5-axis transformation

The status of the transfor mation is dis played in the status area in t he top right cor ner on the XPanel

with the text "G25 RTCP” on an icon.

Activation in the manual mode is possible by pre ssing the corresponding key. Activation in the MDI

and automatic mode is also possible by enter ing G25 H1.

In the position display, the p osition in the programm ing coordinate system ( PROG system) is a lways

depending on the position of the rotatory axes.

G25 H1

G25 H0

RTCP can be activated and deactivated as often as required within an NC block program.

Behaviour upon NC RESET

If RTCP is active, it also remains active after an NC RESET.

milling lengthwise axis

cinematic models regardless of an activated transformation.

1. On/Off button

2. LED ON for active / LED OFF for inactive

3. Flashing LED for invalid selection or selection not acknowledged by the CNC

direction (+/- and selection of the c orresponding fixed path 1mm, 0.1 mm, 0.01mm, 0.001mm or free

movement via the +/- keys or the handwheel). A negat ive traverse path is preset by a mov ement to

shown on the display of the control positi ons. Upon activa tion or deac tivation, the coordi nates move

gm_code_programming_manual_v6.05.08.02.doc

Page 28

28

andronic 2060/30 60

G&M Code Programming Manual

EMERGENCY STOP by

programs

RTCP is not reset automatically.

EMERGENCY STOP due to

drive error

RTCP is not reset automatically.

Referencing all axes or one

axis

RTCP is not reset automatically.

Tool change with RTCP active

G25 H2:

at the same time.

G25 H3:

After tool change, the previous status of the RTCP func tion in the tool change program is restored.

Changing axis settings in

The axis setting can be changed manually in the automa tic interruption mode and the program can

maintained. The changed setting is retained until the next rotary axis positioning takes p lace.

Moving axes in MDI with

RTCP active

All axes may be moved in MDI. There is no restriction as a function of the RTCP function.

G72/G73

Mirroring and RTCP

The G73 command makes it possible to acti vate the mirroring around the X or Y axis or a lso both

axes (prior to the activation of RTCP).

Programmed feed F

The programmed feed with active RTCP always refers to the resulting path of all programmed axes.

G288,1:

RTCP, the Time Basis Axis Programming command must be used.

G288,1 X1 Y1 Z1

It is thus possible to move one single axis faster than it was programmed. This is, for example,

Then the programmed feed affects the tool tip. However, the axis limitations with regard to

acceleration and speed are still active.

The command is cancelled by: (See LookAhead)

G288,1 X1 Y1 Z1 A1 C1 (B1)

Block search

During block search, the change-over of the RTCP switching state is only managed internally. When

setting down the tool, the last programmed state will be restored.

operator, PLC, control

RTCP must be deactivated in the tool change program. The status of the function (on or off) is saved

RTCP

be continued. The speed control is, however, optimised with regard to the previous axis setting and is

To ensure that the programmed feed only affects the X, Y and Z axes during five-axis operation with

necessary if important compensation movements of the translatory axes are required due to

movements of the rotatory axes.

The tool is set down in a configurable order. For large angular positions, we therefore

recommend positioning the rotatory axes in the manual mode.

gm_code_programming_manual_v6.05.08.02.doc

Page 29

andronic 2060/30 60

G&M Code Programming Manual

Property

modal

Topic

Setup command

Position

---

Syntax

G26 <Parameter list>

The command is used for defining the rotation of the programmin g coordinate system. It effects a

G26 Free plane

29

rotation around the specified an gles in the given order, the center of rotation is the current zero

point. The aim is the definition of a new machining plane which must not obligatorily be par allel to

one of the main planes. No movement takes place afte r specification of G26. But the display of the

current control position changes to the position with reference to the new system. After the command

was entered the changed coordinate system immediately becomes effective.

gm_code_programming_manual_v6.05.08.02.doc

Page 30

30

andronic 2060/30 60

G&M Code Programming Manual

Switch H is used to define the application of rotation WX, WY and WZ. If H

is not specified, H0 is applied.

The rotations are defined by means of Euler angle resp. solid angle. The angles are

specified. The specification of WX and WY is normally sufficient.

The angular positions are to be applied in a given order, which is specified with I, J,

WZ - Rotation around the Z axis

The defined angles define rotations in the stationary machine coordinate system. The

WZ - Rotation around the existing Z axis

The parameter R can be used to control whether the defined rotation shall take place

all angle variants of H.

These parameters contain the angl es to be set. Parameter H controls how to

determine these angles to reach the new position.

Order of the rotations with H1 where the following ap plies:

For H0 and H2 it is not necessary to specify an order.

Parameters Description

H

defined as follows:

H0

H1

H2

WX - Rotation around the current Z axis

WY - Turning around the new Y axis

WX - Rotation around the new Z axis

The rotations are always executed in this order, I, J and K must not necessarily be

and K. As a default the following order applies: I1 J2 K3 . Independent from the

programmed order, the angles are specified as follows with reference to the machine

coordinate system:

WX - Rotation around the X axis

WY - Rotation around the Y axis

order is therefore not to be specified. An angle defined with WX rotates the coordinate

system around the not-turned X axis of the machine system, no matter if other

rotations already apply.

WX - Rotation around the existing X axis

WY - Rotation around the existing Y axis

R

R1 new rotation is relative to the current coordinate system

R0 new rotation applies in reference to the machine coordinate system

WX, WY, WZ

I, J, K

Since G26 belongs to the group of commands for change of plane, the free plane is

deactivated for G17, G18 and G19. Since G26 allows rotations by 90° and more, a

with reference to the stationary machine axes or sha ll be rotated relative to the

current, already turned system. If R is not specified, R0 is applied. R can be used with

I is the position of the rotation WX around the X axis

J is the position of the rotation WY around the Y axis

K is the position of the rotation WZ around the Z axis

If no order is specified, the following applie s: I1 J2 K3.

If an order is specified for the rotation, all the defined angle s must be programmed

with an information regarding the order.

combination with the main planes is not necessary.

gm_code_programming_manual_v6.05.08.02.doc

Page 31

andronic 2060/30 60

31

G&M Code Programming Manual