TM

ION

rel. 24-10

-B Series

User Manual

© Copyright Andrew Wireless Systems Srl

Andrew Wireless Systems Srl

Via Pier De Crescenzi 40

48018 Faenza, Italy

Tel: +39 0546 697111

Fax: +39 0546 682768

This publication is issued to provide outline information and

is not aimed to be part of any offer and contract.

The Company has a policy of continuous product

development and improvement and we therefore reserve

the right to vary information quoted without prior notice.

System and Customer care is available world-wide through

our network of Experts.

The company is certifi ed ISO 9001 and ISO14000.

3MN024-010

Index

1. Introducing ION-B 10

1. Introducing ION-B 11

1.1 The Features 11

1.2 Brief Description of ION-B 11

1.3 ION-B Features 12

1.4 ION-B Typical Applications 13

2. Equipment Overview 16

2. Equipment Overview 17

2.1 Introduction 17

2.2. The ION-B Remote Unit and its relevant accessories 17

2.3. The ION-B Master Unit 19

2.4. ION-B additional options 22

2.5. Block Diagrams 24

3. TFAx Remote Unit 29

3.1. Introduction 30

The Main Tasks of the TFAx Unit: 30

Different Types of Remote Units 31

3.2. Case A Remote Unit 33

Dimensions and Weight: 33

RF ports: 33

Optical ports: 33

Visual Alarms: 34

Dry Contact Alarms: 34

Power Supply 34

Warnings (to be read before Remote Units are installed) 35

Dealing with optical output ports 35

Handling optical connections 35

TFAx Case A installation 36

Installing a Case A Remote Unit WITHOUT the TKA kit 36

Installation of the Case A Remote Unit WITH the TKA04 installation kit 38

TFAx Case A Start-Up 44

TFAx Case A Troubleshooting 44

3.3. Case B Remote Unit 45

Dimensions and Weight: 45

RF ports: 46

Optical ports: 46

Visual Alarms: 46

Dry Contact Alarms: 46

Power Supply 47

Dealing with optical output ports 48

Handling optical connections 48

TFAx Case B installation 49

Installing a Case B Remote Unit WITHOUT the TKA kit 49

Installation of the Case B Remote Unit WITH the TKA04 installation kit 51

TFAx Case B Start-Up 52

TFAx Case B Troubleshooting 57

4

ION-B User Manual

Quick troubleshooting procedure 62

Dry-contact troubleshooting 62

Fibre optic DL troubleshooting 63

3.4. Case R Remote Unit 65

Dimensions and Weight 65

RF ports: 66

Optical ports: 66

Visual alarms: 66

External alarms 66

Power supply: 67

Warnings (to be read before Remote Units are installed) 67

Dealing with optical output ports 67

Choosing a proper installation site for the Remote Units 67

Handling optical connections 67

TFAx Case-R installation 68

TFAx Case R Troubleshooting 72

3.5. Case-R2 Remote Unit 73

Dimensions and Weight 73

RF ports: 74

Optical ports: 74

Visual alarms: 74

External alarms 74

Power supply: 75

Warnings (to be read before Remote Units are installed) 75

Dealing with optical output ports 75

Choosing a proper installation site for the Remote Units 75

Handling optical connections 75

TFAx Case-R2 installation 76

TFAx Case R2 start-up 80

TFAx Case-R or Case-R2 troubleshooting 81

Quick troubleshooting procedure 85

Dry-contact troubleshooting 85

Fibre optic DL troubleshooting 85

3.7. Case F Remote Unit 87

Dimensions and Weight 87

RF ports: 88

Optical ports: 88

Visual alarms: 88

External alarms 88

Power supply: 88

Warnings (to be read before Remote Units are installed) 89

TFAx Case-F installation 90

TFAx Case F start-up 93

TFAx Case F troubleshooting 93

Quick troubleshooting procedure 95

Fibre optic DL troubleshooting 95

4. Rack-based Master Unit 99

4.1. TPRNx4 Subrack 101

Major TPRN features 101

TPRN models 101

220 Vac powered sub-racks (TPRN14 / TPRN24) 102

-48Vdc powered sub-rack (TPRN34) 102

TPRN power supply 103

Universal mains 103

5MN024-010

-48 Vdc 103

TPRN ports 104

RS232 serial port 104

RS485 port 105

Sub-D 15 poles male connector 105

PIN 106

Name 106

Meaning 106

TPRN alarms 108

Warning (recommended for system designing and installing) 108

Providing correct heat dissipation 108

Minimizing equipment costs 108

TPRN Installation 109

TPRN Troubleshooting 111

4.2. Fast MiniRack, TPRF31 113

Major TPRN Features 113

Dimensions and Weight 114

On/Off Switch and Power Supply 114

Reset and Store/Clear buttons 114

Reset 114

Store/Clear 114

Visual Alarms 115

TPRF31 Ports 115

RS232 Serial Port 115

RS485 Port 116

Auxiliary Inputs 118

External Alarms 119

Warning (recommended when designing or installing) 120

Providing correct heat dissipation 120

TPRF31 Installation 120

Mounting the TPRF31 on a wall 122

TPRF31 Start-Up 122

TPRF31 Troubleshooting 124

4.3. Master Optical TRX, TFLN 127

Main tasks carried out by the TFLN module 127

Downlink (DL): 127

Uplink (UL): 127

RF ports 127

Optical ports 127

TFLN Visual Alarms 128

TFLN power supply 128

Warnings (to be read before TFLN installation) 128

Dealing with optical output ports 128

Handling optical connections 129

Inserting or removing TFLN modules 129

TFLN Positioning 130

TFLN Installation 130

TFLN Start-Up 131

Removing a TFLN Module 133

TFLN Troubleshooting 133

Quick Troubleshooting Procedure 134

Fibre Optic UL Troubleshooting 134

4.4. Two-way Splitter/Combiner, TLCN2 137

Description: 137

RF Ports 137

TLCN2 Main Applications 137

TLCN2 Insertion Loss 138

6

ION-B User Manual

Warnings 138

TLCN2 Installation 138

4.5. Four-way Splitter/Combiner,TLCN4 139

Description: 139

RF Ports: 139

TLCN4 Main Applications 139

TLCN4 Insertion Loss 140

Warnings 140

TLCN4 Installation 140

4.6. RF Dual Band Coupler TLDN 141

Description: 141

RF Ports 141

TLDN Main Applications 141

TLDN Insertion Loss 142

Warnings 142

TLDN Installation 142

4.7. RF Tri Band Coupler TLTN 143

Description: 143

TLTN Models 143

RF orts 143

TLTN Main Applications 144

TLTN Insertion Loss 144

Warnings 144

TLTN Installation 144

4.8. RF Duplexer, TDPN 145

Description: 145

RF Ports 145

TDPN Main Applications 145

TDPN Insertion Loss 145

Warnings 145

TDPN Installation 146

4.9. Base Station Interface TBSI 147

Description 147

RF Ports 147

TBSI Main Applications 147

TBSI Insertion Loss 148

Warnings 148

TBSI Installation 148

4.10. Power Limiter TMPx-10 149

Description 149

RF Ports 149

TMP Main Applications 149

TMP Visual Alarms 149

TMP Power Supply 150

TMP Insertion Loss 150

Warnings 150

Inserting or Removing TMP Modules 150

Before to install the TMP Module 150

Setting the GSM 900 MHz / DCS 1800 MHz jumper (only for TMP2-10) 150

TMP Installation 151

Removing a TMP Module 152

TMP Troubleshooting 152

Quick Troubleshooting Procedure 152

7MN024-010

5. Confi guration Examples 155

5. Confi guration Examples 156

5.1 Introduction 156

5.2. Multi-operator applications 156

5.3. Multi-sector applications 159

5.4. Fast MiniRack applications 162

6. Warning and Safety Requirements 163

6. Warning and Safety Requirements 164

Environmental Conditions 164

Installation Site Features 164

Safety and Precautions During Installation or Maintenance 165

Power Supply Connection 166

Safety and Precautions for Lasers 166

Health and Safety Warnings 167

RSS Canadian standards 167

Electromagnetic Fields and RF Power 167

Warning Labels 171

7. TECHNICAL SUPPORT 172

7. TECHNICAL SUPPORT 173

Returning Equipment 174

Appendixes 175

Appendix A: System Commissioning 176

Appendix B: EU Guidelines for WEEE Disposal 180

Disposal Guidelines 180

8

ION-B User Manual

9MN024-010

1. Introducing ION-B

10

ION-B User Manual

1. Introducing ION-B

1.1 The Features

ION-B is an innovative platform designed in order to provide an effective and fl exible

coverage to a large variety of indoor scenarios.

Thanks to its high modularity, its low power consumption, and its full-transparency to protocols

and modulation formats, ION-B is the perfect plug&play solution to distribute any wireless

standard (including GSM, GPRS, EDGE, CDMA, W-CDMA, and WLAN IEEE 802.11b/g) to the inbuilding environments requiring reliable and interference-free communications, as well as high

traffi c capacity and maximum fl exibility about future expansions.

These unique features make the ION-B platform suitable also for applications to critical areas

experiencing diffi culties in establishing and keeping phone calls, while its compact design

always guarantees a minimum aesthetic impact.

1.2 Brief Description of ION-B

ION-B is a Distributed Antenna System (DAS) based on the Radio-over-Fibre (RoF) technology,

and capable of carrying wireless mobile signals through the 800MHz - 2500MHz frequency

range regardless of their protocol and their modulation format.

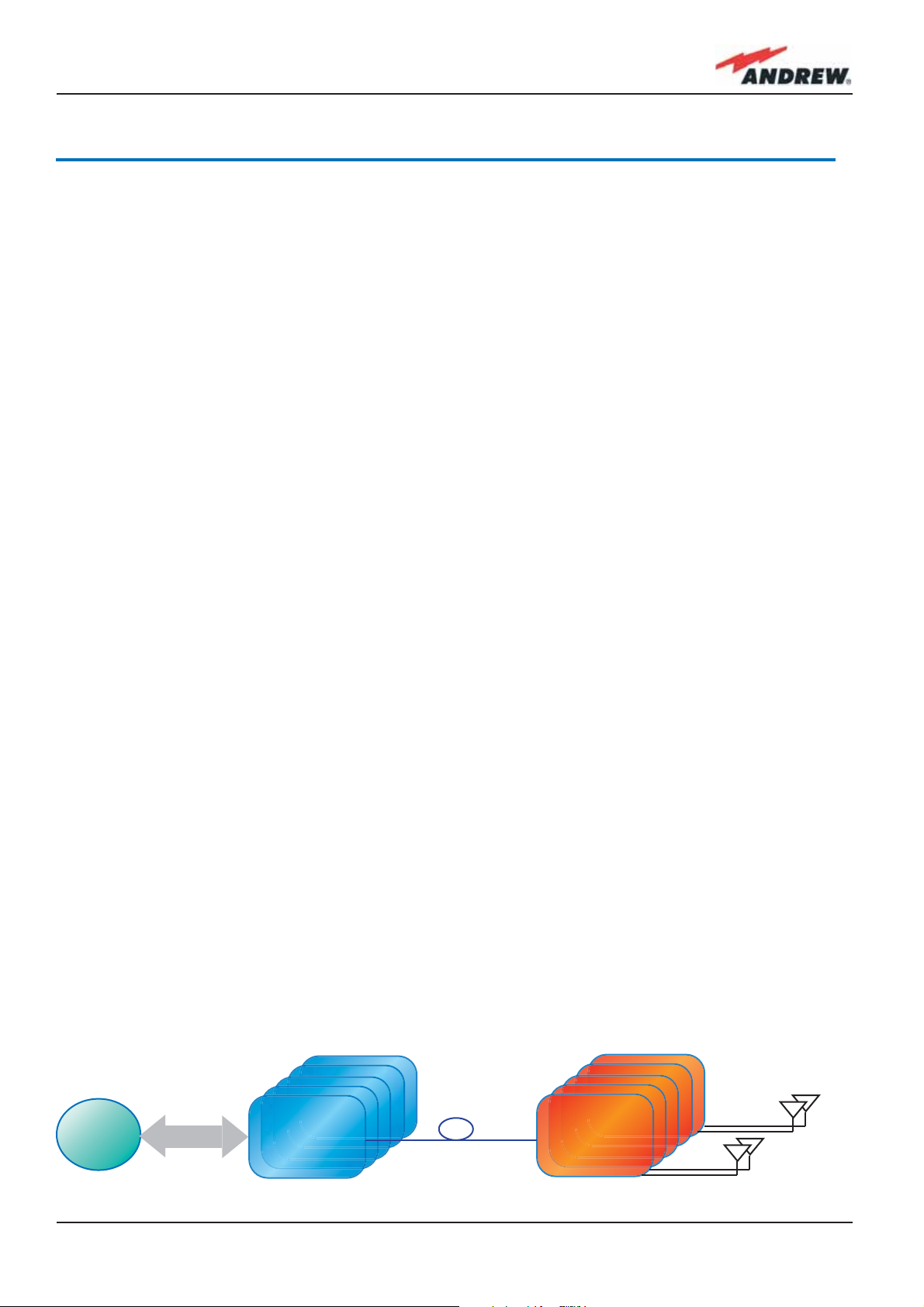

The system has two basic components, a Master Unit and a Remote Unit. The Master Unit

is made of one or more subracks typically connected to the BTS (Base Tranceiver Station)

through either a repeater (RF interface) or a coaxial cable.

Each Remote Unit is connected with a dedicated pair of single-mode optical fi bres (one for

UL and one for DL) to the Master Unit. These optical fi bres work on 1310 nm wavelenght and

provide low losses and almost unlimited bandwidth, available for future system developments.

ION-B is a modular system whose basic components are:

• one Master Unit made of one or more subracks, each providing 12 module slots. Each

slot can host either an active or a RF passive device (chosen among the wide range of ION-B

options), in order to meet the planned design requirements;

BTS

RF Interface

TFLN

Figure 1: ION-B system block diagram

Unit

Remote

11MN024-010

• a variable number of Remote Units (TFAx), whose function is feeding the antenna passive

network;

• a proper number of indoor antennas, suitable to provide radio coverage to the area.

ION-B is fully compatible with any type of indoor antennas;

• the optical cables required to connect the 19” subracks to the TFAx.

1.3 ION-B Features

The following lines report a brief summary of ION-B main features:

• multiband 2G, 2.5G and 3G – 802.11b WLAN compatible: ION-B is completely transparent

to any transmission protocol and modulation format, and it can distribute any 2G, 2.5G,

3G wireless standard. In addition, it allows to carry also the WLAN (802.11b/g) service

over the same infrastructure;

• modular confi guration for fl exible design: by properly setting some parameters like

the amount of RUs and the antenna locations, the ION-B architecture can follow the

environment specifi c features in order to obtain the most effective radio-coverage of the

indoor area. The modularity of the system allows easy modifi cations for future growth and

increasing traffi c;

• easy to install: the intelligent plug & play ION-B system includes an Automatic Gain

Control (AGC), that eliminates system gain variations regardless of optical loss. This avoids

the need for fi eld adjustments, thus reducing design, installation and optimization time.

• low-power consumption: establishing a “quasi line-of-sight propagation” towards all

mobile phones inside the area, ION-B works with low power levels. Low power levels

have two great advantages: 1) allow mobile phones to work at lower power levels, thus

limiting the radiated emissions and increasing their battery life; 2) allow a better control of

interference effects between adiacent cells.

• central supervision functions: all individual alarms of ION-B system are stored in an internal

fl ash memory, and available to both local and remote connections. Detailed alarm

information is provided by special software (i.e. by Supervision or Maintenance software

tools) running on a locally connected host, as well as any information about alarm status

and alarm history is available to remote connections via TCP/IP protocols, SNMP agent,

or HTTP servers. This alarm information is visible also by means of LEDs present on the front

panels of both the MU and the RUs;

• multiple-carriers system: there are no restrictions on the number of carriers that the ION-B

can convey. Obviously, the more carriers per service, the less power per carrier;

• remote power supply: in case mains cannot be used for the Remote Units, ION-B offers a

centralised power supply option, which distributes both a DC low-voltage (-48V) power

and the optical signals through a composite fi bre optic/copper cable;

• wide variety of RF passive devices: the connections between the DAS and the local

BTSs are able to be arranged so as to get the best fi t for the customers needs. ION-

12

ION-B User Manual

B equipment provides RF splitters/combiners, cross band couplers, attenuators, and

duplexers for UL/DL paths, thus allowing maximum in design fl exibility;

• high reliability: high MTBF (Mean Time Between Failure).

1.4 ION-B Typical Applications

Due to its unique features, the ION-B is an ideal solution for radio coverage in a variety of

situations:

• Multi-operator shared infrastructures: each mobile operator has its own carrier

which needs to be transported without interfering the others. The ION-B is capable

of transmitting multiple carriers simultaneously while providing independent level

adjustments for each of them, ensuring maximum performance and reducing

infrastructure costs.

• High rise buildings: RF signals from surrounding macrocells or external BTSs are usually quite

strong inside high rise buildings and can cause so much interference that indoor mobile

communications often become impossible. By strategically placing antennas along the

exterior walls of the building, the signal to noise ratio can be optimised. This interference

control solves many problems, such as the “ping pong” effect that sometimes is

experienced when a mobile frequently changes from indoor to outdoor coverage.

• Exhibitions, conventions, and shopping centres: the critical aspect of these environments

is their high traffi c loads, which are furthermore also highly variable. Thus, the main goal

in these cases is to set up radio coverage enabling the effective management of these

variable traffi c loads, with neither undervalued nor overvalued infrastructure expenses.

A unique feature of the ION-B is that RF frequencies can be allocated quickly when and

where they are needed, thus reducing implementation costs. This makes the ION-B an

ideal solution for temporary or last minute requests (such as conferences).

• Airports: require both modular and fl exible radio coverage in order to meet their current

needs while also foreseeing future expansions. The ION-B is able to manage heavy

traffi c loads, providing a high level of quality with minimum environmental impacts, its

modularity also allows for future expansions.

• Corporate buildings: inside a corporate building, frequent disruptions during mobile

communications may limit business transactions. These environments are often complex

and densely populated while having specifi c requirements: heavy traffi c capacity, high

expectations regarding quality of service, full compatibility with wireless standards and

future expandability. The ION-B guarantees high quality radio coverage in all of the

above conditions and maintains maximum fl exibility while managing any possible traffi c

conditions.

• Subways and densely populated metropolitan areas: These areas are distinguished

by large surface areas, and may require RUs to be placed far away from the BTSs.

The ION-B guarantees signal integrity for distances up to 3km, while through the

13MN024-010

wideband interconnect link option, distances of 20km can be reached. Moreover, these

environments require gradual investments, because initially operators tend to provide

radio coverage only in the busiest areas, and then extend it in order to reach complete

coverage later. The modularity of the ION-B helps operators to gradually expand the

system. Often, large cities set up seamless and reliable radio systems for emergency

services. In these cases, the required RF infrastructure needs to be unobstrusive and

environmental friendly; this can be achieved using an ION-B DAS. When redundancy

is required, two interleaved ION-B systems can be used, management and supervision

for these systems can be remotely established by means of an external modem and an

open protocol such as SNMP.

14

ION-B User Manual

15MN024-010

2. Equipment Overview

16

ION-B User Manual

2. Equipment Overview

2.1 Introduction

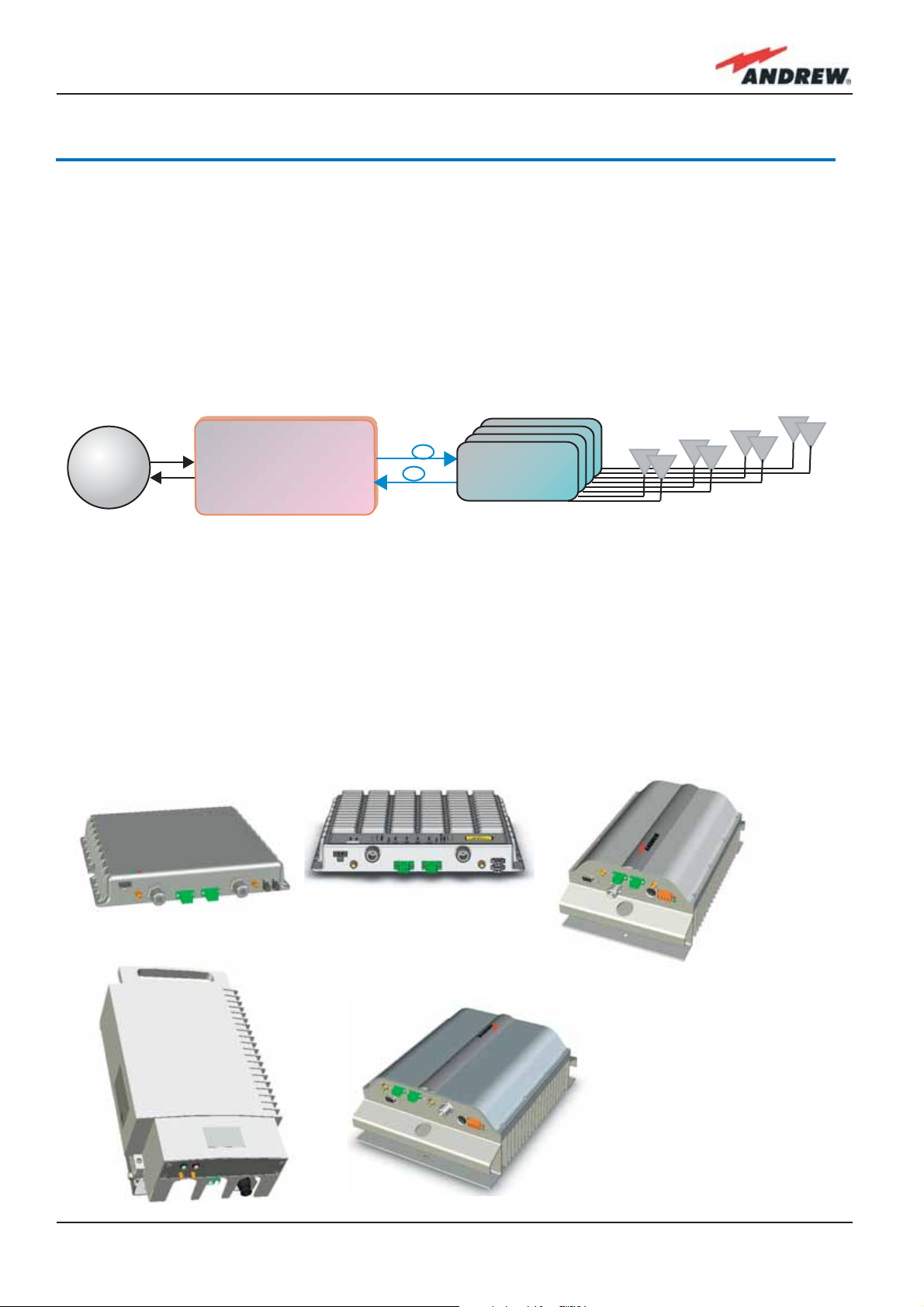

The basic components of an ION-B system (please refer to fi g. 2.1.) are the following:

• a Master Unit, able to bring the mobile signals from the BTS to different Remote Units and

vice-versa, thus remotising the distribution and collection of any mobile signals via fi beroptic

cables;

• a variable number of Remote Units, conveying and receiving mobile signals through lowpower antennas.

BTS

A brief introduction to the main components of the ION-B system’s Master and Remote

Units is presented in the following text. The details of each component can be found in the

subsequent sections of this manual.

ION-B Master Unit

Fig. 2.1: Basic scheme of an ION-B system

Remote Unit

TFAx

2.2. The ION-B Remote Unit and its relevant accessories

(b)

(a)

(c)

(e)

(d)

Fig. 2.2:

Different versions of the

ION-B Remote Units:

(a) Case-A Remote Unit

(b) Case-B Remote Unit;

(c) Case -R Remote Unit;

(d) Case-R2 Remote Unit;

(e) Case-F Remote Unit

17MN024-010

The Remote Unit (TFAx) is a device which provides optical-to-electrical downlink conversion

and electrical-o-optical uplink conversion, thus allowing a bidirectional transmission of

signals between the Master Unit and the remote antennas. It is available in 3 different power

confi gurations (Low/Medium/High), housed by 4 different architectures (Case B, Case R, Case

R2 and Case F), so as to fulfi l different coverage and band requirements.

In downlink, each TFAx receives an optical signal from the Master Unit, performs an optical-toRF conversion, and transmits the resulting signal to the 2 antenna ports.

In uplink, it receives an RF signal from the remote antennas, provides an RF-to-optical

conversion, and conveys the converted signal to the Master Unit through optical fi bres.

The ION_B Remote Units are available both with power supply 90÷264 Vac and with power

supply -72÷-36 Vdc. Each ION-B Remote Unit is provided with a suitable external power

adapter (TPSNx: please refer to table 2.1).

Last, each ION-B Remote Unit has a wideband auxiliary channel, which can be exploited for

dedicated RF distribution.

Remote UnitS and accessories

Unit name/

Module name

TFAx-case A

TFAx Case B

TFAx Case R

TFAx Case R2

TFAx Case F

TFBWx

TKA04

TPSN 1-40

TPSN 1-80

Description Dimensions (L x W x H)

Remote Unit

Remote Unit

Remote Unit

Remote Unit

Remote Unit

WLAN booster

Remote Unit installation kit

External power supply

External power supply

200 x 240 x 38 (mm)

240 x 240 x 38 (mm)

330 x 200 x 122.5 (mm)

330 x 250 x 122.5 (mm)

546 x 253 x 207 (mm)

240 x 200 x 38 (mm)

340 x 240 x 55 (mm)

175 x 80 x 54 (mm)

18

TPSN 3-30

TPSN 3-80

External power supply

External power supply

Table 2.1: Different cases of ION-B Remote Units,

with dedicated ION-B accessories.

175 x 80 x 51 (mm)

ION-B User Manual

2.3. The ION-B Master Unit

The ION-B Master Unit is a widely-fl exible system. Its modular feature allows it to be developed

both for simple installation-friendly, unobstrusive applications to complex installations, involving

a virtually unlimited number of subracks, and distributed through several fl oors of a building or

through a 20km distance.

The following text presents a brief overview of the components of these units.

The TPRF31 Fast MiniRack is a 19” x 1HE fastMiniRack housing 2 slots: it can therefore

accommodate 2 of the single-slots (7TE x 4HE)

ION-B cards presented in the following. Thanks to

Fig. 2.3 TPRF31 subrack

its turnable brackets, the TPRF31 is suitable both

for wall and rack-mounting, and can therefore be used both as a stand-alone unit (for simple

ION-B installations) and as an integration of a bigger and more complex ION-B system .

The TPRN sub-rack is a 19”x 4HE subrack with 12

slots, each one sized 7TE x 4HE. As each ION-B

module takes up one or two slots, each Master

Unit can host up to 12 modules, depending on

the design confi guration and requirements.

Fig. 2.4 TPRN subrack

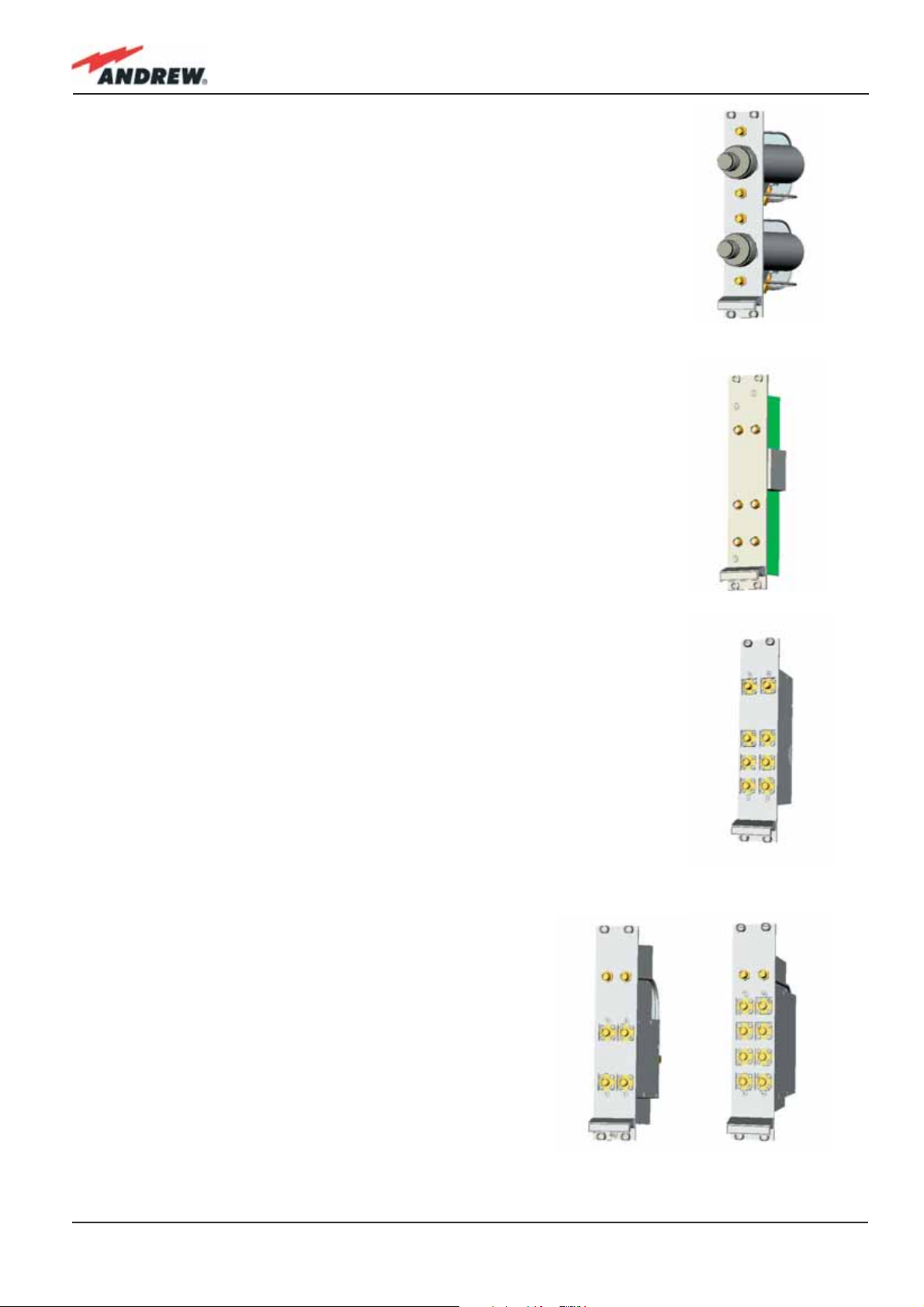

The Master Optical TRX (TFLN): in downlink, it provides an RF-to-optical

conversion of the signal coming from the BTS, and transmits it to 4 optical

outputs, so as to feed 4 TFAx. In uplink, it provides optical-to-RF conversion for

4 optical signals coming from the RUs, and it combines them into a single RF

output, while providing automatic gain control in order to balance the fi bre

losses. Module dimensions:

Width = 7TE, Height = 4HE (one slot in the master unit sub-rack).

The Duplexer (TDPN): it combines the downlink (DL) and the uplink (UL)

paths into a single one, while maintaining the required isolation. The module

dimensions are: Width = 7TE, Height = 4HE

Fig. 2.6 TDPN card

Fig. 2.5 TFLN card

19MN024-010

The variable RF attenuators (TBSI): they provide independent

attenuations (adjustable from 0 to 30dB, with 1dB steps) on uplink and

downlink RF paths, and allow the designer to optimize the signal level

close to the BTSs. TBSI is an override attenuator, its dimensions are: Width =

7TE, Height = 4HE.

Fig. 2.7 TBSI card

The Dual Band Coupler (TLDN): in downlink, it combines a low band RF

signal (800 to 1000 MHz) and a high band RF signal (1700 to 2500 MHz) into

a common RF port; in uplink, it splits a composite signal between a low

band RF port and a high band RF port. Module dimensions are: Width = 7

TE, Height = 4 HE.

Fig. 2.8 TLDN card

The Tri Band Coupler (TLTN): in downlink, it combines a Low Band signal, a

Middle Band signal, and a High Band signal into a communal one; in uplink,

it splits the triple band signal among the three RF single band paths.

Please refer to table 4.7.1 or to the bulletin PA-100596-EN for further

information about the different band confi gurations.

Module dimensions are: Width = 7 TE, Height = 4 HE.

Fig. 2.9 TLTN card

The RF splitters/combiners (TLCN2 and TLCN4): TLCN2

is a 2-way splitter/combiner. TLCN4 is a 4-way splitter/

combiner. They can be used in a variety of different

situations, such as:

• To connect a BTS with several master optical TRXs.

In uplink, the TLCN2 (or TLCN4) combines 2 (or 4) RF

signals which come from different master optical

TRXs into a common RF signal entering the BTS. In

downlink, the TLCN2 (or TLCN4) splits the downlink

composite RF signal which comes from the BTS into 2

(or 4) RF ports, entering different master optical TRXs.

20

(a) (b)

Fig. 2.10 TLCN2 (a) and TLCN4 (b) cards

ION-B User Manual

• To connect several BTSs to a master optical TRX. In downlink, the TLCN2 (or TLCN4)

combines the RF signals coming from different BTSs into a common RF signal, entering the

master optical TRX. In uplink, the TLCN2 (or TLCN4) splits the composite RF signal coming from a

master optical TRX into 2 (or 4) RF signals entering different BTSs.

The Power Limiter (TMPx-10): it monitors the DL power coming from the

BTS and attenuates it by 10 dB in case it surpasses a programmable

threshold level.

The TMP2-10 Power Limiter is for 2G and 2.5G signals, working at 900

MHz and 1800 MHz.

The TMP3-10 Power Limiter is for 3G signals.

Both modules are 7TE wide and 4HE high.

Fig. 2.11 TMPx-10 card

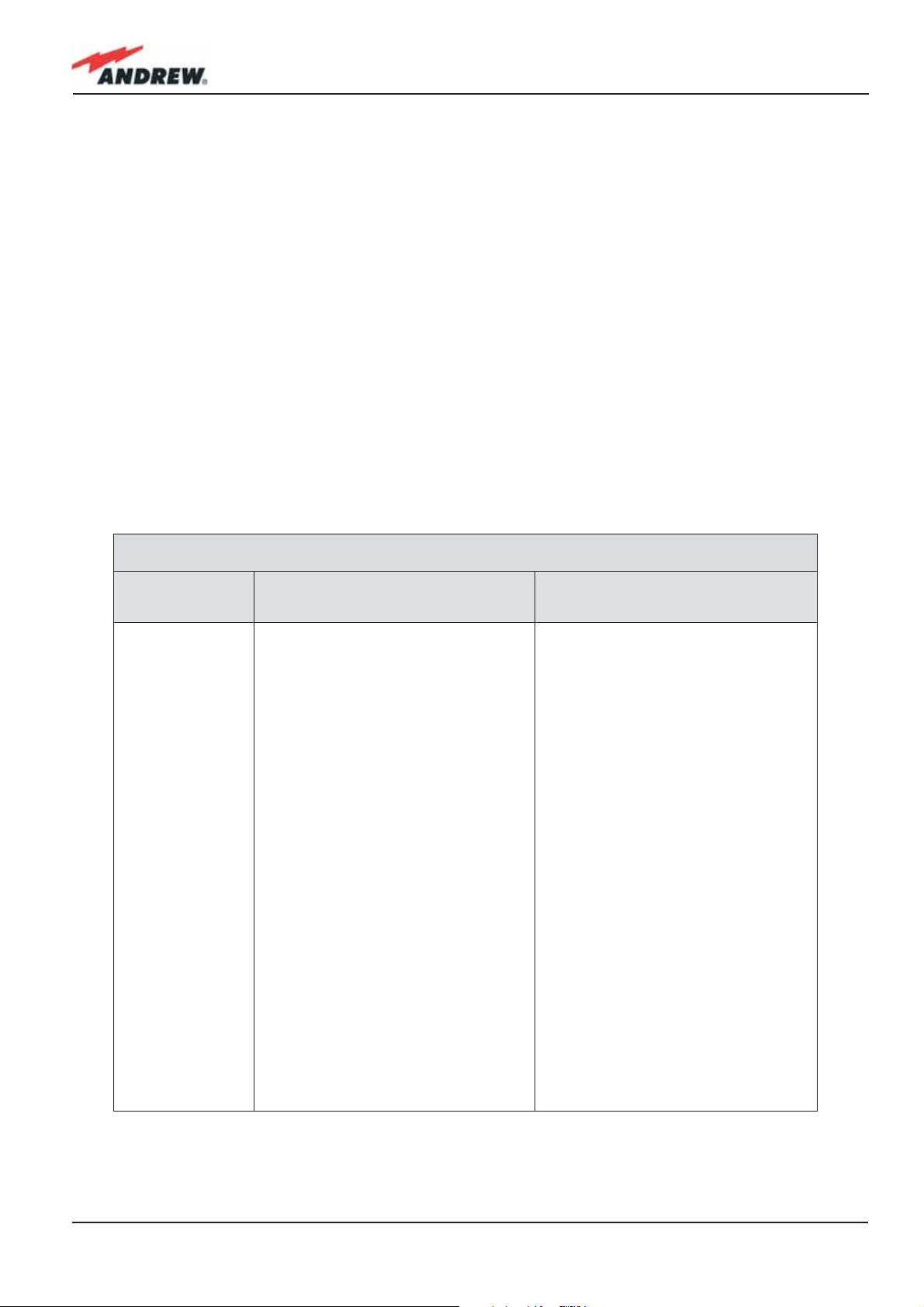

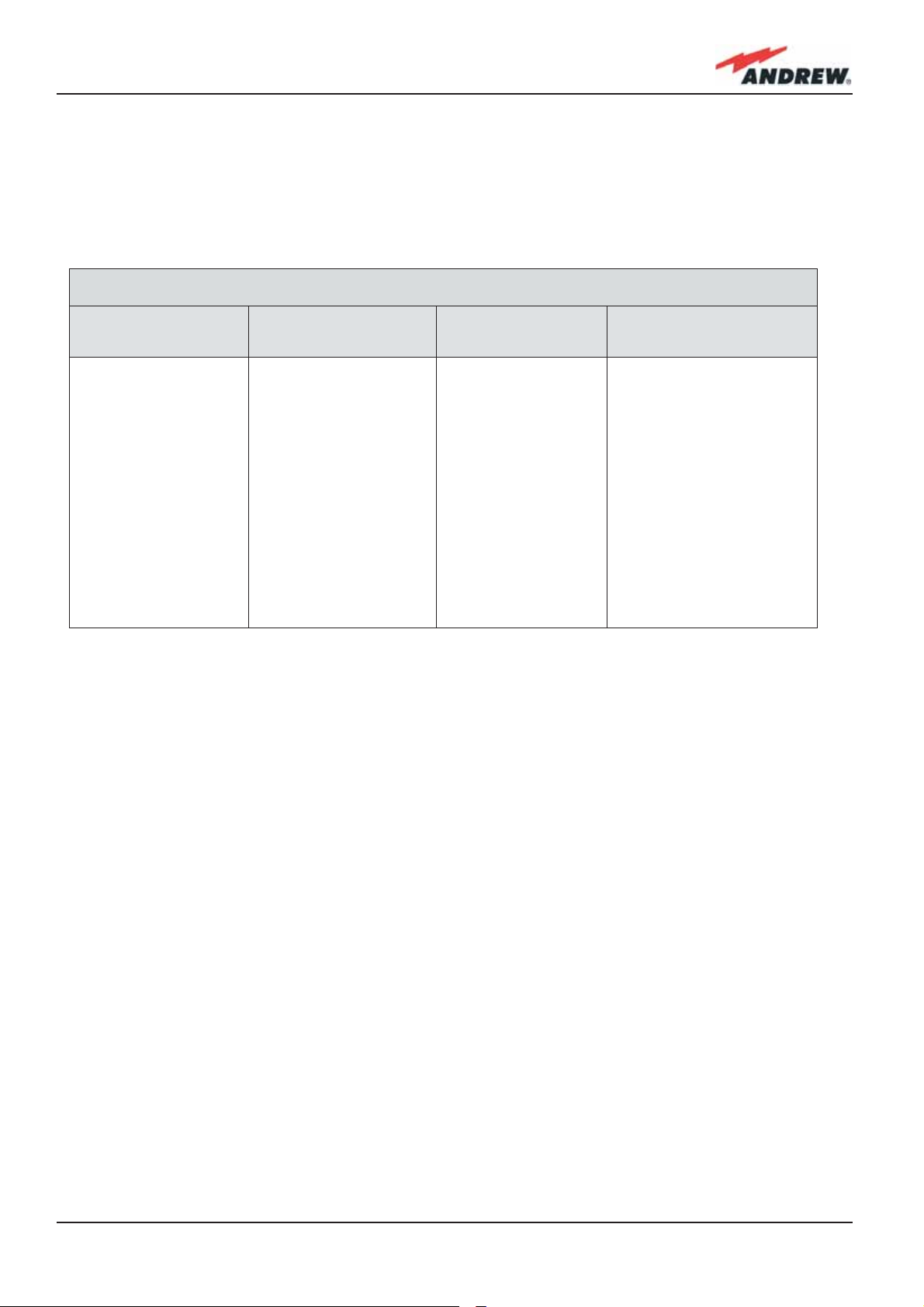

Table 2.2 shows an overview of the basic

components of the ION-B Master Unit.

Basic components of ION-B Master Units

Unit name/

Module name

TPRF31

TPRN04

TPRNx4

TFLNx

TLCN 2

TLCN 4

TBSI 2-30

TDPNx

Description Dimensions, H x W ( x D)

Fast MiniRack

Passive subrack

Active subrack

Master Optical TRX

2-way splitter

4-way splitter

Adjustable attenuator

UL/DL duplexer

19” x 1HE x 286mm

19” x 4HE x 350mm

19” x 4HE

7TE x 4HE

7TE x 4HE

7TE x 4HE

7TE x 4HE

7TE x 4HE

TLDNx

TLTNx

TMPx-10

Table 2.2: Overview of the components and accessories for the ION-B master unit

Dual band coupler

Tri band coupler

10 dB power limiter

7TE x 4HE

7TE x 4HE

7TE x 4HE

21MN024-010

2.4. ION-B additional options

The basic ION-B structure described above can be furtherly expanded or supported by a

range of ION-B options, including:

• A supervision unit (TSUN), enabling to supervise and manage the ION-B system through

any PC or Laptop, thanks to a web-interface supporting the TCP/IP, FTP, HTTP, protocols,

and fully compatible with general purpose SNMP managers.

• RF boosters, which can be connected to the auxiliary channels of the ION-B Remote

Units, thus providing RF coverage in some particular frequency bands (e.g. AWS 1700 MHz

in US, Wi-Fi, or Wi-Max);

• A wide range of Interconnect Link options (TIL), i.e. a set of master-slave modules which

enable to expand the ION-B system through additional subrack stations, up to 20 km

away from the main one.

• A Remote Powering Unit (TRSN), providing -48Vdc power supplying through composite

fi beroptic/copper cables

Table 2.3 shows an overview of these ION-B accessories and of the corresponding Andrew

bulletins you should refer to for further information.

(a)

(e)

(f)

(b)

(d)

(c)

(g)

22

Fig. 2.12: TSUN supervision unit, available both as a plug-in card (a) and as a stand-alone module (b) ;

Wi-Fi (c) and (AWS 1700 MHz) boosters; Interconnect-link master modules (e) and slave modules (f);

TRSN Remote Powering units (g)

ION-B User Manual

Although the following table tables show a brief overview of the main ION-B additional

options, we strongly recommend you to contact your reference Andrew Salesperson or

Product Line Manager in order to have For a full overview of the ION-B options,

Main ION-B additional options

Unit name/

Module name

ION-B Supervision Unit

(TSUN 1, 3, 6)

ION-B Wi-Fi options

TIL Interconnect link

RF dedicated booster

TRSN Remote Power Units

Table 2.3: Overview of the components and accessories for the ION-B rack-based master unit

Reference Bulletin Reference Manual

PA-100596-EN

PA-100928-EN

BR-102130-EN

PA-102073-EN

PA-102072-EN

MN023

MN031

MN032

MN033

Mechanical

Decription

Available both as a plug-in card

and as a stand-alone unit

Different solutions available

multi-module master side

+ multi-module slave side

(each one made of a variable

number of plug-in cards)

stand alone unit,

240 x 200 x 38 mm

19” x 3HE (low power version)

19” x 1HE (medium power

version)

23MN024-010

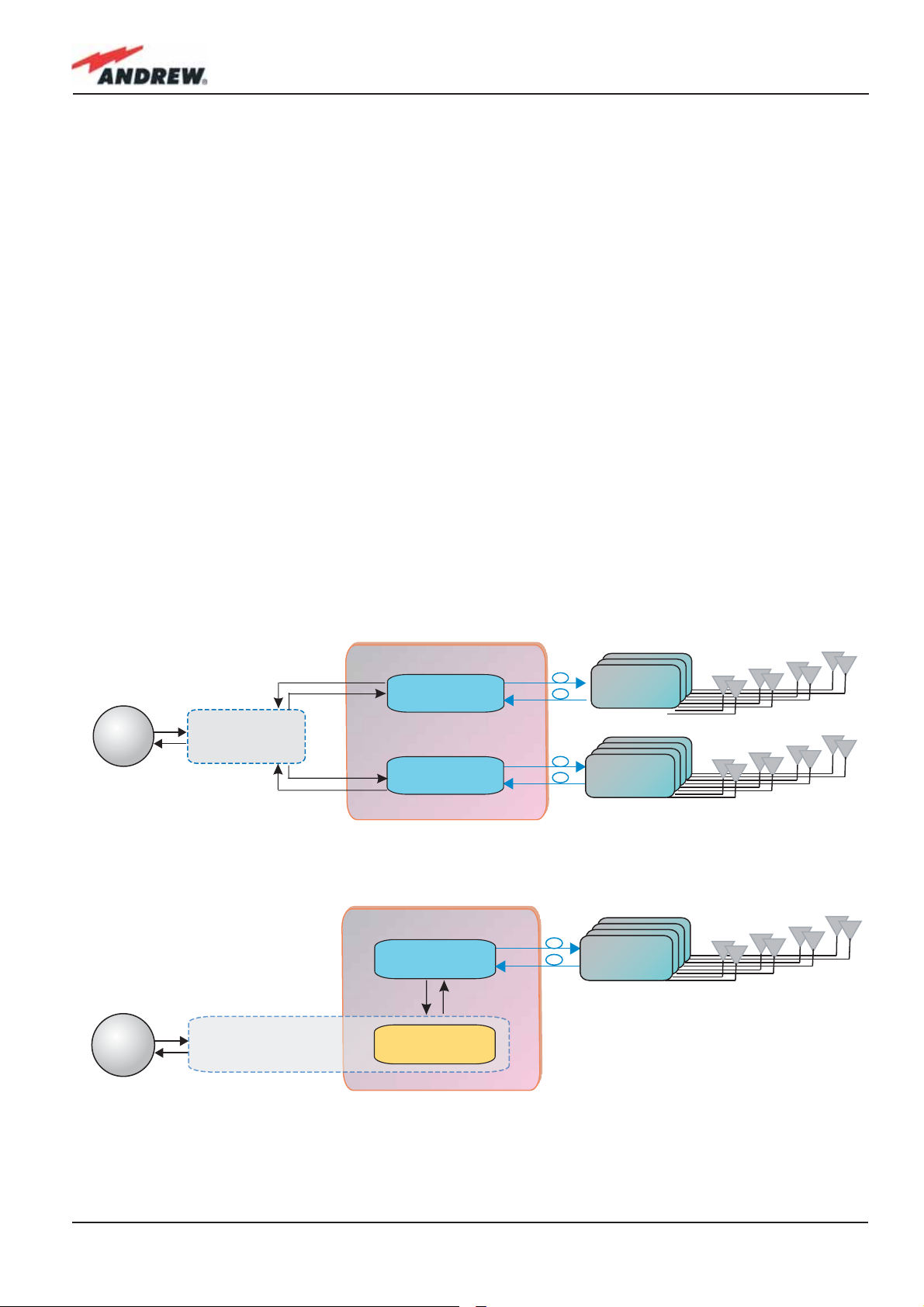

2.5. Block Diagrams

In order to better understand the functionalities of the different units and modules, some block

diagrams of the ION-B system are presented here.

The core of an ION-B system is the ION-B master unit, which generally develops through a

passive section (providing Level adjustments, Signal splitting/combining, and Band coupling),

followed by an Electrical/Optical conversion (allowing the signal to be distributed through

fi beroptic cables to the TFAx Remote Units).

Simple and unobstrusive ION-B installations can be developed through the TPRF31 fast

MiniRacks, which allows a great deal of installation solutions, such as:

- hosting two electrical/optical transceivers, while developing external passive combining

- hosting one electrical/optical transceiver, plus one ION-B interface card (providing splitting/

combining , band coupling or level adjusting).

Please note that more TPRF31 modules can be combined to achieve a more complex, spacesaving system confi guration.

Tipical ION-B confi gurations based on a single TPRF31 Fast MiniRack are shown in fi g. 2-13.

BTS

BTS

External

splitting/combining

section

Splitting/combining section

ION-B Fast Minirack

TFLN

Master Optical Trx

+

TFLN

Master Optical Trx

(a)

ION-B Fast Minirack

TFLN

Master Optical Trx

ION-B passive card

(either splitting/combining

or level adjusting

Remote Unit

TFAx

Remote Unit

TFAx

Remote Unit

TFAx

24

(b)

Fig. 2.13: ION-B confi gurations based on a TPRF31 Fast MiniRack: (a) Confi guration hosting 2 TFLN optical

transceivers; (b) Confi guration hosting 1 TFLN optical transceiver and 1 splitting/combining card

ION-B User Manual

Although TPRF31 proves to be very fl exible, complex distribution systems usually can be better

served by rack-based ION-B Master Units: such ION-B installations are based on one or more

TPRN-subracks, thus exploiting the wide range of ION-B passive cards (TDPN, TMP, TBSI, TLCN2,

TLCN4, TLTN, TLDN), in order to build the passive network which best matches the costumer’s

needs.

Let’s see some examples of such rack-based confi gurations.

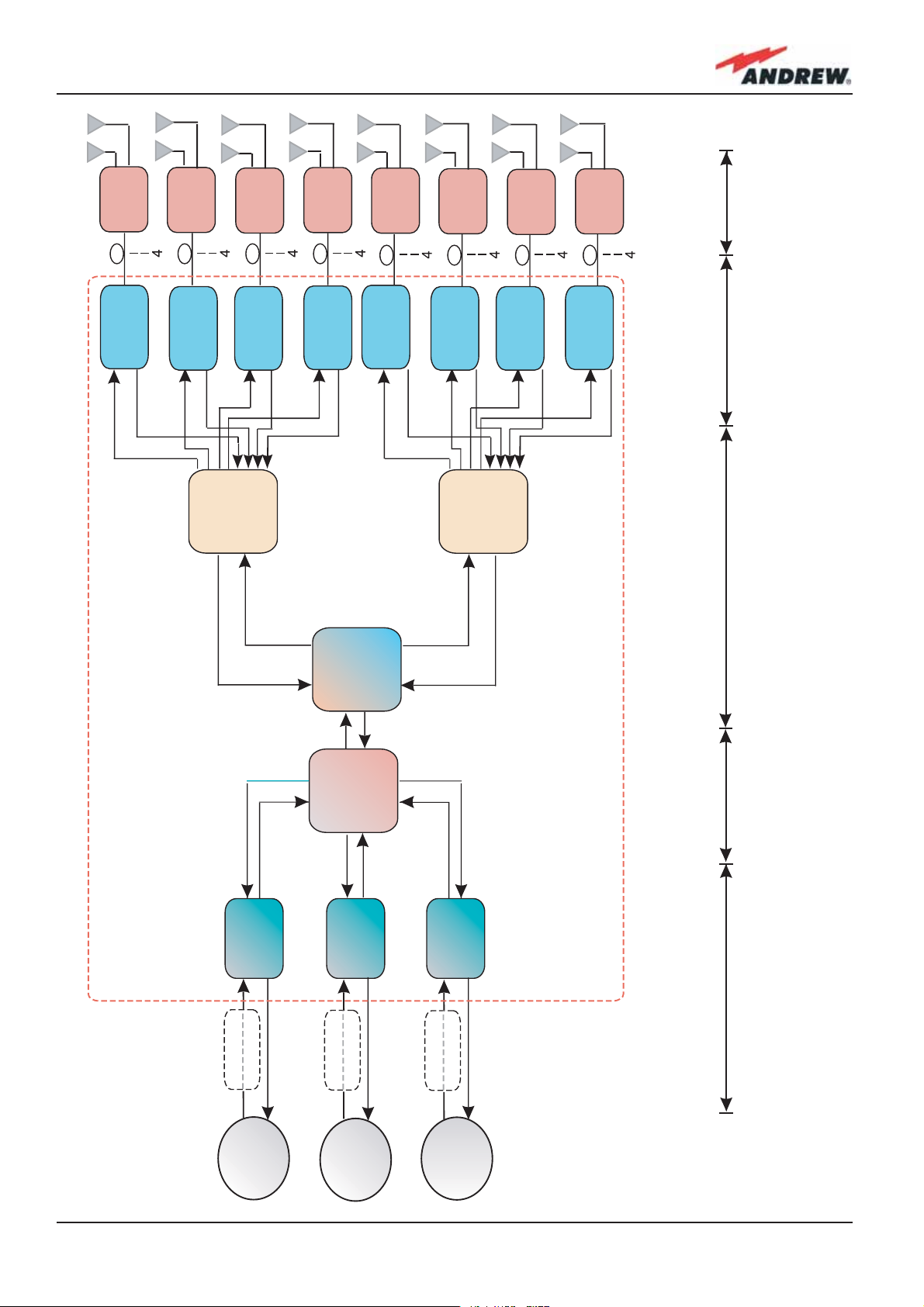

Firstly, assume that the BTSs are not duplexed. In this case, no TDPN module (see fi g. 2.14)

is required. Moreover, assuming that the Master Unit is made up of one or more subracks

located in a single site, we do not need an interconnect link in order to remotise a second

subrack. The scheme of this network confi guration is reported hereafter in fi gure 2.14.

Now let’s consider the same network confi guration, but with duplexed BTSs. In this case, some

TDPN modules (see fi g. 2.7) are required in order to combine UL and DL ports on single RF

channels. The scheme of this network confi guration is reported hereafter in fi gure 2.15.

If we need to expand our ION-B network to a wider area, please note that the Interconnectlink option allows you to use a second subrack station at a distance of up to 20km from the

site where the main subrack station is located.

Please refer to the dedicated Interconnect link brochure (Table 2.3) for further details.

25MN024-010

Frequency

Band 3

BTS

Frequency

Band 2

BTS

Frequency

Band 1

BTS

Fig. 2.14: Block diagram of an

ION-B confi guration supporting

a triple-band system with

DUPLEXED base stations.

,EVELADJUSTMENT

COMBINING

SPLITTING

3ERVICE

Master Unit

Attenuator

Fixed

Duplexer

TDPN

Attenuator

TBSI

Attenuator

Fixed

Duplexer

TDPN

Attenuator

TBSI

Multi-band

Combiner

TLTN

Attenuator

Fixed

Duplexer

TDPN

Attenuator

TBSI

COMBINING

SPLITTING

3IGNAL

%LECTRICAL/PTICAL

CONVERSION

/PTICAL%LECTRICAL

CONVERSION

Optical Trx

Master

TFLN

Remote Units

REMOTE

TFAx

UNIT

Optical Trx

REMOTE

UNIT

Combiner

Master

TFLN

TFAx

Splitter/

TLCN4

Optical Trx

Master

REMOTE

UNIT

TFAx

TFLN

Optical Trx

REMOTE

UNIT

Combiner

Splitter/

Master

TFLN

TFAx

TLCN2

Optical Trx

Master

REMOTE

UNIT

TFLN

TFAx

Optical Trx

Master

REMOTE

UNIT

Combiner

Splitter/

TLCN4

Optical Trx

TFLN

TFAx

UNIT

Master

TFLN

REMOTE

TFAx

Optical Trx

Master

REMOTE

UNIT

TFLN

TFAx

26

ION-B User Manual

TFAx

REMOTE

UNIT

TFAx

REMOTE

UNIT

TFAx

REMOTE

UNIT

TFAx

REMOTE

UNIT

TFAx

REMOTE

UNIT

TFAx

REMOTE

UNIT

TFAx

REMOTE

UNIT

TFAx

REMOTE

UNIT

Remote Units

CONVERSION

/PTICAL%LECTRICAL

TFLN

Master

Master

Optical Trx

TFLN

Master

TFLN

Optical Trx

Master

TFLN

Optical Trx

Master

TFLN

Master

Optical Trx

Optical Trx

CONVERSION

TFLN

Optical Trx

Master

TFLN

Optical Trx

Master

TFLN

Optical Trx

%LECTRICAL/PTICAL

TLCN4

Splitter/

Combiner

TLCN2

Splitter/

Combiner

TLCN4

Splitter/

Combiner

3IGNAL

COMBINING

SPLITTING

Master Unit

TBSI

Attenuator

Fixed

Attenuator

BTS

Band 1

Frequency

TLTN

Combiner

Multi-band

TBSI

Attenuator

Fixed

Attenuator

BTS

Band 2

Frequency

TBSI

Attenuator

Fixed

Attenuator

BTS

Band 3

Frequency

3ERVICE

COMBINING

,EVELADJUSTMENT

Fig. 2.15: Block diagram of an

ION-B confi guration supporting

a triple-band system with NOT

DUPLEXED base stations.

SPLITTING

27MN024-010

28

ION-B User Manual

3. TFAx Remote Unit

29MN024-010

3.1. Introduction

The Main Tasks of the TFAx Unit:

Downlink (DL):

• Optical-to-RF conversion of the input optical signal

• Automatic Gain Control (AGC) of each converted signal, in order to compensate optical

losses;

• RF amplifi cation: the converted RF signal is boosted in order to maintain a good signal-tonoise ratio

• RF fi ltering: a proper fi lter rejects the spurious emissions

• RF duplexing and splitting: the boosted RF signal is conveyed to 2 antenna ports

Uplink (UL):

(b)

(a)

(d) (e)

Fig. 3.1.1: ION-B Remote Units: different cases for different solutions

(c)

• RF amplifi cation: a low noise amplifi er boosts the signal received from antennas in order

to maintain a good signal-to-noise ratio

• RF fi ltering: the boosted signal is cleaned of the spurious emissions

30

ION-B User Manual

• Automatic Level Control (ALC): the RF signal level is adjusted according to blocking

requirements

• RF-to-optical conversion of the signal, which is fi nally conveyed to the output optical port

Different Types of Remote Units

In order to allow radio coverage with different power and band requirements, the ION-B

architecture provides a wide variety of Remote Units. This allows the customer to choose the

solution which best fi ts its coverage and environmental demands.

Depending on the bands where the radio coverage has to be provided and on the signal

power required to cover the environment, your Remote Unit will fall into one of the topologies

shown in fi gure 3.1.1.

The following 4 sections of the manual refer to these 4 Remote Unit topologies. Please follow

the instructions described in the section corresponding to the case (A, B, R, R2, F) of your

particular Remote Unit.

The case of your Remote Unit can be easily identifi ed in Figure 3.1: or, as an alternative, you

could contact your Sales representative or check it on the offi cial ION-B Brochure (see fi g.

3.1.2),.

As in fi g. 3.1.2, the “TFAM 91/18/20” Remote Unit proves to be described in the Andrew bulletin

PA-100508-EN. Look through the Remote Unit’s dedicated bulletin in order to get all of the

technical specifi cations concerning the unit itself.

Remote UnitS

Power Class*, dBm Case Product Code Bulletin Code

GSM900 EGSM900 GSM1800 UMTS2100 LMR800 Cellular850 LMR900 AWS1700 PCS1900 PCS1900 Ext.

27 - - 27 - - - - - - B TFAM 90/20 PA-100582-EN

- 27 - 27 - - - - - - B TFAM 91/20 PA-100583-EN

- - 27 27 - - - - - - B TFAM 18/20 PA-100584-EN

- 32 32 36 - - - - - - R2 TFAM91/18/20 PA-101508-EN

- - - - 27 - - - 27 - B TFAM 80/19 PA-100801-EN

- - - - - 27 - - 27 - B TFAM 85/19 PA-100805-EN

- - - - - - - 27 27 - B TFAM 17/19 PA-101848-EN

- - 27 - - 27 - - - - B TFAM 85/18 PA-100808-EN

- - - 27 - 27 - - - - B TFAM85/20 PA-100809-EN

- - - - 21 - 21 - - 27 B TFAM80/92/19E PA-101058-EN

Fig. 3.1.2: Remote Unit description in the offi cial ION-B Brochure (Rev. 03/07)

31MN024-010

TFAM

Case A

32

ION-B User Manual

3.3. Case A Remote Unit

Dimensions and Weight:

Dimensions: 38 x 240 x 200 mm

(1.5 x 9.4 x 7.9 inches)

Weight : please refer to the Remote Unit dedicated bulletin in order to discover any

updated data regarding the weight of the case A Remote Unit

LED alerts

Green =power ON;

Red = major alarm

TFAM

Case A

Power

supply

connector

RF auxiliary

DL channel

output

RF

antenna

port

DL

optical

port

Fig. 3.2.1: TFAx Case A Remote Unit

UL

optical

port

RF

antenna

port

RF auxiliary

UL channel

input

External

alarm

connection

RF ports:

• 2 RF antenna ports, transmitting/receiving signals to/from distributed antennas. RF

antenna ports are duplexed N-female connectors. These RF ports can be connected

to the antennas either directly (ie. through RF jumper cables) or through splitters, thus

allowing more antennas to be fed. Unused RF ports have to be terminated with a 50 Ω

load.

• 1 RF auxiliary input and 1 auxiliary output (designed to receive and transmit additional

signals). Auxiliary input and output ports are SMA-female connectors.

Optical ports:

• 1 optical output port, transmitting UL signals to TFLN master optical TRX

• 1 optical input port, receiving DL signals from TFLN master optical TRX

33MN024-010

Visual Alarms:

TFAM

Case A

Two control LEDs are provided on the TFAx front side (Fig. 3.2.2). The green LED indicates the

power supply status, while the red LED indicates any major Remote Unit failures (please refer to

Table 3.4).

Led colour Meaning

Low optical power at DL input

and/or RF amplifi er failure

of Case-A remote unts

Figure 3.2.2 - LED alarms on

the upper-front side of Case

B Remote Units (including Power version)

Red

Green Power supply OK

Table 3.2.1 - Description of the LEDs

Dry Contact Alarms:

TFAx is provided with two dry contact inputs which

can be connected (through .062” MOLEX plugs)

to any external device. The alarm information

regarding this external device is able to be

signalled through the red LED of the TFAx LED panel

and displayed on the Supervision System in this

Figure 3.2.3:

Dry contacts for external alarms

way.

Power Supply

The Case A Remote Unit is provided with a TPSN external power supply (Fig. 3.2.4 a,b),

available either for universal mains (90 to 264) or for negative supply. (-72 to -36 Vdc).

(b)

34

(c)

(a)

Figure 3.2.4 - The Case-A power supply inlet (a) can

be connected either with the ION-B 220Vac power

adapter (b) or with the -48 Vdc one ( c), depending

on the chosen version.

ION-B User Manual

TPSN external power supplies provide the Case A Remote Unit with +5Vdc power, by means of

a 3-pole connector.

Warnings (to be read before Remote Units are installed)

Dealing with optical output ports

The TFAx Remote Unit contains semiconductor lasers. Invisible laser beams may be emitted

from the optical output ports. Do not look towards the optical ports while equipment is

switched on.

Choosing a proper installation site for the Remote Units

• TFAx Remote Units have to be installed as close as possible to the radiating antennas,

in order to minimize coaxial cable length, thus reducing downlink power loss and uplink

noise fi gures.

• When positioning the TFAx Remote Unit, be sure to place related antennas in such a way

as to minimize the Minimum Coupling Loss (MLC), in order to avoid blocking.

• The TFAx Remote Unit is intended to be fi xed on walls, false ceilings or other fl at vertical

TFAM

Case A

surfaces (TKA installation kits are available, they provide a protective cover for the TFAx

Remote Unit, while making installation easier and faster).

Handling optical connections

• When inserting an optical connector, take care to handle it so that the optical fi bre is not

damaged. Optical fi bres are to be in single-mode (SM) 9.5/125µm.

• Typically, ION-B equipment is provided with SC-APC optical connectors (other connectors

are provided upon request). Inserting any other connectors will result in severe damage.

• Do not force or stretch the fi bre pigtail with curvature radius of less than 5cm. See fi gure

on right for optimal fi bre cabling.

• Remove the adapter caps only just before making connections. Do not leave any SC-

WRONG

Figure 3.2.5 - Handling

optical connections with

ION-B Remote Units.

CORRECT

35MN024-010

APC adapters open, as they attract dirt. Unused optical connectors must always be

TFAM

Case A

covered with their caps.

• Do not touch the connector tip. Clean it with suitable material before inserting each

connector into its sleeve. If connector tips require cleaning, use only pure ethyl alcohol.

TFAx Case A installation

The Case B Remote Unit is able to be fi xed to walls, false ceilings or other fl at vertical surfaces,

either directly or through a TKA04 installation kit (optional).

Installing a Case A Remote Unit WITHOUT the TKA kit

The TFAx kit includes:

1. a Remote Unit TFAx

2. a TPSN external power supply adapter (86 to 264 Vac or -72 to -36 Vdc, according to the

chosen model)

3. a VDE connector or a -48 Vdc plug (according to the chosen model)

The TKA04 kit includes:

A. four screw anchors (fi xing the wall bearing to the wall)

B. fi ve screw anchors (fi xing the TFAx Case A to the wall bearing)

C. a wall mounting box (wall bearing + cover)

D. a splice holder

Please consider these guidelines in order to choose the correct positioning of the Remote Unit

and of its power supply:

• Under no circumstances should any piece of equipment be affected by the heat

(a)

Figure 3.2.6: Example of proper mounting confi guration, which assures proper heat dissipation. Note that the

Remote Unit and its power supply adapter are mounted side-by-side, and the power supply adapter has the

socket downwards. The Figures refer to a 90/264 vac TFAx Case A (an) and to a -36/-72 Vdc TFAx Case A (b).

36

(b)

ION-B User Manual

created by any other piece. The Remote Unit and its external power supply should be

mounted so as to avoid reciprocal heating. Side-by-side confi guration is suggested (Fig.

3.2.6 a,b)

• Remote Units are provided with cooling fi ns which allow the optimization of heat

dissipation. In order for them to function properly, the mounting environment should allow

for the necessary air changeover

• It is strongly recommended not to mount the external power supply on a horizontal

surface because this position does not allow heat dissipation. External power supplies

must be mounted on vertical surfaces.

• In order to assure proper heat dissipation, external power supplies must be mounted in a

vertical position with the power socket downwards (see Fig. 3.2.7 a,b).

Once you have chosen a location for the Remote Unit, please follow these instructions:

1. In order to install the M4 screw anchors (not included) which hold up the TFAx Remote

Unit, drill into the wall according to the proper layout shown in Fig. 3.2.9.

2. Fix the TFAx to the wall by fi rmly tightening the screws into the anchors.

3. In order to install the M4 screw anchors (not included) which hold up the power supply

TFAM

Case A

SPLICE HOLDER

(a)

Fig. 3.2.7. (a) inside of the Splice Tray, with the Splice

Holder positioned properly; closed splice tray (b)

(b)

external adapter, drill into the wall according to the proper layout of your power supply,

shown in fi g.3.3.10b

4. Fix the external power supply adapter to the wall by fi rmly tightening the screw into the

anchors.

5. Fix the splice holder inside the splice tray (not included) See Fig. 3.2.7 a,b.

6. Splice the optical fi bres and close the splice tray. While handling the fi bers, be careful not

to bend them.

7. Fix the splice tray beside the Remote Unit.

8. Connect the external adapter to the TFAx Remote Unit with the proper cable.

9. If the Remote Unit is -48 Vdc powered, use the -48 Vdc plug (included) in order to

37MN024-010

connect the external adapter to the -48 Vdc supply (Fig. 3.2.6 b). If the Remote Unit

TFAM

Case A

is 90/264 Vac-powered, fi x the 90/264 Vac plug (included) onto a power cord (not

included), and use this cable to connect the external adapter to the mains (Fig. 3.2.6 a).

10. Connect the antenna RF cables to the RF antenna ports. Connect the UL and DL optical

connectors.

11. Once the installation is fi nished, please follow the section “TFAx Case A Start-up” in order

to carry out a proper system start up.

Installation of the Case A Remote Unit WITH the TKA04 installation kit

The TFAx Case A kit includes:

1. a Remote Unit TFAx

2. a 50 Ω load

3. a TPSN external power supply adapter (86 to 264 Vac or -72 to -36 Vdc, according to the

chosen model)

4. a VDE connector or a -48 Vdc plug (according to the chosen model)

The TKA04 kit includes:

A. four screw anchors (fi xing the wall bearing to the wall)

B. fi ve screw anchors (fi xing the TFAx Case A to the wall bearing)

C. a wall mounting box (wall bearing + cover)

D. a splice holder

Please consider these guidelines carefully in order to decide the proper positioning of the

(a)

(b)

Figure 3.2.8:

Example of proper mounting confi guration, which assures proper heat dissipation. Note that the Remote Unit and

its power supply adapter are mounted side-by-side, and the power supply adapter has the socket downwards.

The Figures refer to a 90/264 vac TFAx Case A (a) and to a -36/-72 Vdc TFAx Case A (b), respectively.

38

ION-B User Manual

Remote Unit and its power supply:

• Under no circumstances should any piece of equipment be affected by the heat

created by any other piece. The Remote Unit and its external power supply should be

mounted so as to avoid reciprocal heating. Side-by-side confi guration is suggested (Fig.

3.2.8 a,b)

• It is strongly recommended not to mount the external power supply on a horizontal

surface because this position does not allow for heat dissipation. External power supplies

must be mounted on vertical surfaces.

• In order to assure proper heat dissipation, the external power supplies must be mounted

in a vertical position with the power socket downwards (see Fig. 3.2.8 a,b).

Once you have chosen the position of the Remote Unit mounting case, please follow these

instructions:

1. Unscrew the 4 screws which lock the lower cover of the TKA04 wall bearing (see Fig.

3.2.12 a)

2. In order to install the M4 screw anchors (included) which hold up the TKA04 wall bearing,

drill into the wall according to the TKA layout shown in Fig. 3.2.11.

3. Fix the TKA04 wall bearing by fi rmly tightening the screws into the anchors.

TFAM

Case A

4. In order to install the M4 screw anchors (not included) which hold up the power supply

external adapter, drill into the wall according to the power supply layout shown in

Fig.3.3.10 b.

5. Fix the external power supply adapter to the wall by fi rmly tightening the screws into the

anchors (Fig. 3.2.13 b).

6. Carefully open the splice tray by using a screwdriver as in Fig. 3.2.12 c. Fix the splice

holder inside the splice tray (Fig. 3.2.6 a). Splice the optical fi bres and close the splice

tray. While handling the fi bers, take care not to bend them. Close the splice tray.

7. Fix the Remote Unit to the wall-bearing by using the included screws (Fig. 3.2.6 b).

8. If the Remote Unit is -48 Vdc powered, use the -48 Vdc plug (included) in order to

connect the external adapter to the -48 Vdc mains (Fig. 3.2.8 b). If the Remote Unit

is 90/264 Vac-powered, fi x the 90/264 Vac plug (included) onto a power cord (not

included), and use this cable in order to connect the external adapter to the mains (Fig.

3.2.8 a).

9. Connect the antenna RF cables to the RF antenna ports. Connect the UL and DL optical

connectors (Fig. 3.2.12 e). If the power cable has properly been connected to the

mains, both the green and the red LEDs should turn on. The green LED will remain lit to

indicate that the unit is powered on, while the red LED will turn off as soon as the local

unit is switched on (for further details about the start up of the system, please refer to the

section “TFAx Case A Start-up”)

10. Fix the lower cover by fastening the 4 screws (Fig. 3.2.12 f)

39MN024-010

TFAM

Case A

40

Figure 3.2.9 : Case A layout with waal anchor quotes

ION-B User Manual

TFAM

Case A

X

Figure 3.2.10:

Layout of the 220Vac/+5Vdc power adapter,

provided with Case A Remote Units.

41MN024-010

TFAM

Case A

42

Figure 3.2.11: Layout of the TKA installation kit for TFAx Remote Unit, Case A.

ION-B User Manual

(a) (b)

TFAM

Case A

(c)

(e)

Figure 3.2.12: Mounting the TFAx Case A Remote Unit with a TKA installation kit.

Please not that the Figures do not show the mounting of the external power supply.adapter.

(d)

(f)

43MN024-010

TFAx Case A Start-Up

Before the TFAx Remote Unit is switched on, make sure that:

• the modules hosted in the master unit have been connected to each other with RF

jumpers, according to the system design

• every TFLN master optical TRX has been connected to its Remote Units

• each Remote Unit has been connected to its coverage antennas

For a correct system start-up, all the Remote Units have to be switched on prior to the master

unit.

Once the TFAx has been switched on, its behaviour can be summarized as per the following

indicators:

1. When the Remote Unit is turned on, both the LEDs upon the warm side turn on for a

couple of seconds

2. After that, the unit’s green LED remains on (thus indicating proper power supply), while

the red LED switches off as soon as the master unit is turned on (meaning that DL optical

power is OK and no alarms are present).

3. Once the master unit has been switched on, the status of both LEDs should be

those indicated in Table 3.2.1. In case the red LED remains on, please refer to the

Troubleshooting section.

4. After being switched on, the Remote Unit should start up correctly and in order to be

recognized by the supervision management system, the corresponding TFLN master

optical TRX should carry out the discovery phase (please refer to the Supervision System

Manual for more details). During this phase, which can last for up to a max. 4min,

depending on the system complexity, the TFLN LED

any cables or pieces of equipment during the discovery phase! This may result in the

identifi cation failure of the Remote Unit.

Note: in case discovery doesn’t start automatically, check through either the LMT or the

remote supervision for whether it has been disabled (refer to LMT or remote Supervision System

manuals for further information).

blinks. Do not connect/disconnect

TFAx Case A Troubleshooting

Please refer to the TFAx Case A and Case B troubleshooting for a full overview of the

troubleshooting procedures for Case A Remote Units.

44

ION-B User Manual

3.4. Case B Remote Unit

Dimensions and Weight:

Dimensions: 38 x 240 x 240 mm

(1.5 x 9.4 x 9.4 inches)

Weight : please refer to the Remote Unit dedicated bulletin in order to discover any

updated data regarding the weight of the Case B Remote Unit

LED alerts

Green =power ON;

Red = major alarm

(a)

TFAM

Case B

Power

supply

connector

LED alerts

Green =power ON;

Red = major alarm

Power

supply

connector

RF auxiliary

DL channel

output

RF auxiliary

DL channel

input

RF

antenna

port

RF

antenna

port

DL

optical

port

DL

optical

port

UL

optical

port

UL

optical

port

RF

antenna

port

RF

antenna

port

RF auxiliary

UL channel

input

RF auxiliary

UL channel

input

External

alarm

connection

(b)

External

alarm

connection

Fig. 3.3.1: TFAx Case B Remote Unit (a) and TFAx Case B Remote Unit, Power version (b)

45MN024-010

RF ports:

• 2 RF antenna ports, transmitting/receiving signals to/from distributed antennas. RF

antenna ports are duplexed N-female connectors. These RF ports can be connected

TFAM

Case B

to the antennas either directly (ie. through RF jumper cables) or through splitters, thus

allowing more antennas to be fed. Unused RF ports have to be terminated with a 50 Ω

load.

• 1 RF auxiliary input and 1 auxiliary output (designed to receive and transmit additional

signals). Auxiliary input and output ports are SMA-female connectors.

Optical ports:

• 1 optical output port, transmitting UL signals to TFLN master optical TRX

• 1 optical input port, receiving DL signals from TFLN master optical TRX

Visual Alarms:

Two control LEDs are provided on the TFAx front side (Fig. 3.3.2). The green LED indicates the

power supply status, while the red LED indicates any major Remote Unit failures (please refer to

Table 3.4).

Led colour Meaning

Low optical power at DL input

and/or RF amplifi er failure

of Case-B remote unts

Figure 3.3.2 - LED alarms on

the upper-front side of Case

B Remote Units (including Power version)

Red

Green Power supply OK

Table 3.3.1 - Description of the LEDs

Dry Contact Alarms:

TFAx is provided with two dry contact inputs which

can be connected (through .062” MOLEX plugs)

to any external device. The alarm information

regarding this external device is able to be signalled

through the red LED of the TFAx LED panel and

displayed on the Supervision System in this way.

Figure 3.3.3 - Dry contacts for external alarms on (a)

Case B Remote Unit and (b) case-B Power Remote

Unit

46

(a)

(b)

ION-B User Manual

Power Supply

The Case B and Case B, Power version Remote Units are provided with different types of TPSN

external power supplies (Fig. 3.3.4 a,b), available either for universal mains (90 to 264) or for

negative supply. (-72 to -36 Vdc).

TPSN external power supplies for

Case-B Remote Units provide the with +5Vdc power, by

means of a 3-pole connector (Fig. 3.20 c).

TPSN external power supplies for

Case-B, Power version Remote Units provide the with +28Vdc

power, by means of a shielded circular connector (Fig. 3.20 c).

Before installing your Remote Unit, please check you have been provided with the proper

external power supply. Should you have any doubt, please contact your Sales representative.

(b)

TFAM

Case B

(c)

(a)

Figure 3.3.4 - The Case-B power supply inlet (a) can

be connected either with the ION-B 220Vac power

adapter (b) or with the -48 Vdc one ( c), depending

on the chosen version.

Likewise, the Case-B Power version (d) can be

connected either to the ION-B 220Vac power

adapter or to the -48Vdc one (e).

(e)

(d)

47MN024-010

TFAM

Case B

Warnings (to be read before Remote Units are installed)

Dealing with optical output ports

The TFAx Remote Unit contains semiconductor lasers. Invisible laser beams may be emitted

from the optical output ports. Do not look towards the optical ports while equipment is

switched on.

Choosing a proper installation site for the Remote Units

• TFAx Remote Units have to be installed as close as possible to the radiating antennas,

in order to minimize coaxial cable length, thus reducing downlink power loss and uplink

noise fi gures.

• When positioning the TFAx Remote Unit, be sure to place related antennas in such a way

as to minimize the Minimum Coupling Loss (MLC), in order to avoid blocking.

• The TFAx Remote Unit is intended to be fi xed on walls, false ceilings or other fl at vertical

surfaces (TKA installation kits are available, they provide a protective cover for the TFAx

Remote Unit, while making installation easier and faster).

Handling optical connections

• When inserting an optical connector, take care to handle it so that the optical fi bre is not

damaged. Optical fi bres are to be in single-mode (SM) 9.5/125µm.

• Typically, ION-B equipment is provided with SC-APC optical connectors (other connectors

are provided upon request). Inserting any other connectors will result in severe damage.

• Do not force or stretch the fi bre pigtail with curvature radius of less than 5cm. See fi gure

on right for optimal fi bre cabling.

• Remove the adapter caps only just before making connections. Do not leave any SCAPC adapters open, as they attract dirt. Unused optical connectors must always be

covered with their caps.

48

WRONG

Figure 3.3.5 - Handling optical

connections with ION-B Remote Units.

CORRECT

ION-B User Manual

• Do not touch the connector tip. Clean it with suitable material before inserting each

connector into its sleeve. If connector tips require cleaning, use only pure ethyl alcohol.

TFAx Case B installation

The Case B Remote Unit is able to be fi xed to walls, false ceilings or other fl at vertical surfaces,

either directly or through a TKA04 installation kit (optional).

Installing a Case B Remote Unit WITHOUT the TKA kit

The TFAx kit includes:

1. a Remote Unit TFAx

2. a TPSN external power supply adapter (86 to 264 Vac or -72 to -36 Vdc, according to the

chosen model)

3. a VDE connector or a -48 Vdc plug (according to the chosen model)

The TKA04 kit includes:

A. four screw anchors (fi xing the wall bearing to the wall)

B. fi ve screw anchors (fi xing the TFAx Case B to the wall bearing)

C. a wall mounting box (wall bearing + cover)

TFAM

Case B

D. a splice holder

Please consider these guidelines in order to choose the correct positioning of the Remote Unit

and of its power supply:

• Under no circumstances should any piece of equipment be affected by the heat

created by any other piece. The Remote Unit and its external power supply should be

mounted so as to avoid reciprocal heating. Side-by-side confi guration is suggested (Fig.

3.3.6 a,b)

(a)

(b)

Figure 3.3.6: Example of proper mounting confi guration, which assures proper heat dissipation. Note that the

Remote Unit and its power supply adapter are mounted side-by-side, and the power supply adapter has the

socket downwards. The Figures refer to a 90/264 vac TFAx Case B (an) and to a -36/-72 Vdc TFAx Case B (b).

49MN024-010

TFAM

Case B

• Remote Units are provided with cooling fi ns which allow the optimization of heat

dissipation. In order for them to function properly, the mounting environment should allow

for the necessary air changeover

• It is strongly recommended not to mount the external power supply on a horizontal

surface because this position does not allow heat dissipation. External power supplies

must be mounted on vertical surfaces.

• In order to assure proper heat dissipation, external power supplies must be mounted in a

vertical position with the power socket downwards (see Fig. 3.3.6 a,b).

Once you have chosen a location for the Remote Unit, please follow these instructions:

1. In order to install the M4 screw anchors (not included) which hold up the TFAx Remote

Unit, drill into the wall according to the proper layout shown in Fig. 3.3.9.

2. Fix the TFAx to the wall by fi rmly tightening the screws into the anchors.

3. In order to install the M4 screw anchors (not included) which hold up the power supply

external adapter, drill into the wall according to the proper layout of your power supply,

shown in fi g.3.4.10b

4. Fix the external power supply adapter to the wall by fi rmly tightening the screw into the

anchors.

5. Fix the splice holder inside the splice tray (not included) See Fig. 3.3.7 a,b.

6. Splice the optical fi bres and close the splice tray. While handling the fi bers, be careful not

to bend them.

7. Fix the splice tray beside the Remote Unit.

8. Connect the external adapter to the TFAx Remote Unit with the proper cable.

9. If the Remote Unit is -48 Vdc powered, use the -48 Vdc plug (included) in order to

connect the external adapter to the -48 Vdc supply (Fig. 3.3.6 b). If the Remote Unit

is 90/264 Vac-powered, fi x the 90/264 Vac plug (included) onto a power cord (not

included), and use this cable to connect the external adapter to the mains (Fig. 3.3.6 a).

10. Connect the antenna RF cables to the RF antenna ports. Connect the UL and DL optical

connectors.

11. Once the installation is fi nished, please follow the section “TFAx Case B Start-up” in order

to carry out a proper system start up.

SPLICE HOLDER

Fig. 3.3.7. (a) inside of the Splice Tray, with the Splice

Holder positioned properly; closed splice tray (b)

50

(a)

(b)

ION-B User Manual

Installation of the Case B Remote Unit WITH the TKA04 installation kit

The TFAx Case B kit includes:

1. a Remote Unit TFAx

2. a 50 Ω load

3. a TPSN external power supply adapter (86 to 264 Vac or -72 to -36 Vdc, according to the

chosen model)

4. a VDE connector or a -48 Vdc plug (according to the chosen model)

(a)

(b)

TFAM

Case B

Figure 3.3.8:

Example of proper mounting confi guration, which assures proper heat dissipation. Note that the Remote Unit and

its power supply adapter are mounted side-by-side, and the power supply adapter has the socket downwards.

The Figures refer to a 90/264 vac TFAx Case B (a) and to a -36/-72 Vdc TFAx Case B (b), respectively.

The TKA04 kit includes:

A. four screw anchors (fi xing the wall bearing to the wall)

B. fi ve screw anchors (fi xing the TFAx Case B to the wall bearing)

C. a wall mounting box (wall bearing + cover)

D. a splice holder

Please consider these guidelines carefully in order to decide the proper positioning of the

Remote Unit and its power supply:

• Under no circumstances should any piece of equipment be affected by the heat

created by any other piece. The Remote Unit and its external power supply should be

mounted so as to avoid reciprocal heating. Side-by-side confi guration is suggested (Fig.

3.3.8 a,b)

• It is strongly recommended not to mount the external power supply on a horizontal

surface because this position does not allow for heat dissipation. External power supplies

must be mounted on vertical surfaces.

• In order to assure proper heat dissipation, the external power supplies must be mounted

51MN024-010

TFAM

Case B

in a vertical position with the power socket downwards (see Fig. 3.3.8 a,b).

Once you have chosen the position of the Remote Unit mounting case, please follow these

instructions:

1. Unscrew the 4 screws which lock the lower cover of the TKA04 wall bearing (see Fig.

3.3.12 a)

2. In order to install the M4 screw anchors (included) which hold up the TKA04 wall bearing,

drill into the wall according to the TKA layout shown in Fig. 3.3.11.

3. Fix the TKA04 wall bearing by fi rmly tightening the screws into the anchors.

4. In order to install the M4 screw anchors (not included) which hold up the power supply

external adapter, drill into the wall according to the power supply layout shown in

Fig.3.4.10 b.

5. Fix the external power supply adapter to the wall by fi rmly tightening the screws into the

anchors (Fig. 3.2.13 b).

6. Carefully open the splice tray by using a screwdriver as in Fig. 3.3.12 c. Fix the splice

holder inside the splice tray (Fig. 3.3.6 a). Splice the optical fi bres and close the splice

tray. While handling the fi bers, take care not to bend them. Close the splice tray.

7. Fix the Remote Unit to the wall-bearing by using the included screws (Fig. 3.3.6 b).

8. If the Remote Unit is -48 Vdc powered, use the -48 Vdc plug (included) in order to

connect the external adapter to the -48 Vdc mains (Fig. 3.3.8 b). If the Remote Unit

is 90/264 Vac-powered, fi x the 90/264 Vac plug (included) onto a power cord (not

included), and use this cable in order to connect the external adapter to the mains (Fig.

3.3.8 a).

9. Connect the antenna RF cables to the RF antenna ports. Connect the UL and DL optical

connectors (Fig. 3.3.12 e). If the power cable has properly been connected to the

mains, both the green and the red LEDs should turn on. The green LED will remain lit to

indicate that the unit is powered on, while the red LED will turn off as soon as the local

unit is switched on (for further details about the start up of the system, please refer to the

section “TFAx Case B Start-up”)

10. Fix the lower cover by fastening the 4 screws (Fig. 3.3.12 f)

TFAx Case B Start-Up

Before the TFAx Remote Unit is switched on, make sure that:

• the modules hosted in the master unit have been connected to each other with RF

jumpers, according to the system design

• every TFLN master optical TRX has been connected to its Remote Units

• each Remote Unit has been connected to its coverage antennas

For a correct system start-up, all the Remote Units have to be switched on prior to the master

unit.

52

ION-B User Manual

TFAM

Case B

Figure 3.3.9 : Case B layout with wall anchor quotes

53MN024-010

TFAM

Case B

Figure 3.3.10:

(a) Layout of the 220Vac/+5Vdc power

adapter, provided with Case B Remote Units.

(b) Layout of the 220Vac/+5Vdc power

adapter, provided with Case B Remote Units.

(a)

X

(b)

54

X

ION-B User Manual

TFAM

Case B

Figure 3.3.11: Layout of the TKA installation kit, provided with Case B Remote Units.

55MN024-010

TFAM

Case B

(a) (b)

(c)

(e)

Figure 3.3.12: Mounting the TFAx Remote Unit with a TKA installation kit.

Please not that the Figures do not show the mounting of the external power supply.adapter.

(d)

(f)

56

ION-B User Manual

Once the TFAx has been switched on, its behaviour can be summarized as per the following

indicators:

1. When the Remote Unit is turned on, both the LEDs upon the warm side turn on for a

couple of seconds

2. After that, the unit’s green LED remains on (thus indicating proper power supply), while

the red LED switches off as soon as the master unit is turned on (meaning that DL optical

power is OK and no alarms are present).

3. Once the master unit has been switched on, the status of both LEDs should be

those indicated in Table 3.3.1. In case the red LED remains on, please refer to the

Troubleshooting section.

4. After being switched on, the Remote Unit should start up correctly and in order to be

recognized by the supervision management system, the corresponding TFLN master

optical TRX should carry out the discovery phase (please refer to the Supervision System

Manual for more details). During this phase, which can last for up to a max. 4min,

depending on the system complexity, the TFLN LED

any cables or pieces of equipment during the discovery phase! This may result in the

identifi cation failure of the Remote Unit.

blinks. Do not connect/disconnect

TFAM

Case B

Note: in case discovery doesn’t start automatically, check through either the LMT or the

remote supervision for whether it has been disabled (refer to LMT or remote Supervision System

manuals for further information).

TFAx Case B Troubleshooting

Faults can be revealed by LEDs on the TFAx front panel, as well as by LMT or the Supervision

System (running on the remote supervision unit)

Both the LMT and the Supervision System are able to provide complete information about the

cause of the alarm. As a consequence, troubleshooting procedures can be immediate when

failure detection is carried out directly through either the LMT or the Supervision System.

ION-B modules are designed to exchange information, meaning that each Remote Unit can

receive failure notifi cations from its external equipment through dry-contact connections.

Moreover, the TFAx constantly monitors the optical signal received from its TFLN unit to control

optical losses.

Tables 3.3.2 shows a brief description of the alarms related to the Case B Remote Unit, with

reference to the corresponding alerted LEDs and to the actions to be carried out in case of a

fault.

As the Tables show, minor alarms (low priority alarms) are revealed only by either the LMTs or

57MN024-010

TFAM

Case B

ALARM CODE

(TSUN

description)

Antenna DC

loop alarm

DL optical

power fail

AGC out of

DL RF alarm

in Band 1

DL RF alarm

in Band 2

DL RF alarm

in Band 3

(if present)

External 1

External 2

Power supply

Internal BUS

range

alarm

alarm

alarm

alarm

1

1

ALARM

DESCRIPTION

The optical power

received on the

DL is too low and

can’t no more be

compensated

The optical power

received is under

the allowed

3dB optical loss

but it can be

compensated

HW failure on the

DL low band RF

section

HW failure on the

DL high band RF

section

HW failure on the

DL UMTS band RF

section

Alarm on the

device connected

on dry-contact 1

Alarm on the

device connected

on dry-contact 2

UPS HW failure or

malfunction.

RF is turned OFF

A malfunctioning

on the digital

part involves a

fault in monitoring

functionalities

SUPERVISION

ACTIVE LED

PRIORITY

LEVEL

ALWAYS OK

RED MAJOR

NONE WARNING

RED CRITICAL Return the unit MAJOR

RED CRITICAL Return the unit MAJOR

RED CRITICAL Return the unit MAJOR

RED MAJOR

RED MAJOR

RED MAJOR

RED CRITICAL Return the unit MAJOR

ACTION

RECOMMENDED

Check the DL fi bre

and the TFLN laser

status

Clean optical

connectors

Check the

external device or

alarm connection

Check the

external device or

alarm connection

Check the

external PSU.

If it works properly,

return the unit

RELÉ PRIORITY

LEVEL

(subrack)

MAJOR

MINOR

MAJOR

MAJOR

MAJOR

Temperature

alarm

Over-temperature

alarm

NONE MINOR

Check ventilation

and environment

Table 3.3.2: Description of the alarms of the Case-B Remote Unit, as they

are presented by the LMT application or by the Supervision interface

the Supervision Systems, and not through LEDs. Minor alarms detect

critical situations which should be checked and tested in order to avoid

future possible system faults.

Each Remote Unit is provided with an AGC system which comes in after

the optical-to-RF conversion. This AGC is able to correctly compensate

optical losses when these are estimated to be <3.5 dB. In case optical

losses are > 3.5dB, the LMT application and the ION-B supervision unit

will display a “Warning” alarm: the whole system still work, but AGC is

near to its borderline levels.

The red LED switches on when the estimated optical losses are >4.5 dB,

the AGC not being able to compensate these losses any more.

MINOR

0dBm

Normal

-3.5dBm

Warning

-4.5dBm

Alarm

Fig. 3.3.13:

AGC thresholds

vs LED alerts

58

ION-B User Manual

As shown in the previous table, the same red LED switches on to reveal any major failures. By

following the next troubleshooting procedure, it will be possible to better understand what

problem has occurred.

Note:

Each Remote Unit is provided with an AGC system which kicks in after the optical-to-RF

conversion. This AGC can correctly compensate for optical losses when they are estimated to

be <3.5 dB. In case optical losses are > 3.5dB, the LMT application and the ION-B supervision

unit will display a “Warning” alarm: the whole system still work, but AGC is near to its borderline

levels.

The red LED switches on when the estimated optical losses are >4.5, because the AGC is not

able to compensate for these losses anymore.

TFAM

Case B

start

Verify if any external equip-

ment or any dry contact port

have some problems.

Refer to dry-contact trouble-

shooting (fig.3.16b)

Clean the SC - APC

optical adapters

and connectors

troubleshooting

Is the red LED

ON upon the TFAx?

Yes

Is the red LED

ON upon the TFAx?

Yes

Is the red LED

ON upon the TFAx?

Yes

Optical cable or optical

connections are supposed

to have problems on DL

path. Refer to fibre optic DL

troubleshooting (fig.3.16c)

No

No

No

end

Figure 3.3.14 (a): Flow-chart describing the quick troubleshooting procedure of a TFAx Case B

59MN024-010

start