MR Booster Manual

Order No. MN001808-1

Issue 7/99

©

Copyright 1999 Mikom

All Rights Reserved

Field Support

If you need technical assistance with the MR Booster contact MIKOM at:

Technical Hotline: (800) 800-3224

All rights reserved. No part of this publication, or any software included with it, may be

reproduced, stored in a retrieval system, or transmitted in any form or by any means,

including photocopying, electronic, mechanical, recording, or otherwise, without prior

written permission of the copyright holder.

This document contains proprietary information of MIKOM. The contents are confidential

and any disclosure to persons other than the officers, employees, agents, or subcontractors of

the owner or licensee of this document, without prior written consent of MIKOM, is strictly

prohibited.

Page - ii - MR Booster Manual (MN001808-1, 7/99)

Safety Information

The MR Booster equipment has been designed for maximum safety when installed, operated,

and maintained according to the instructions in this manual. Do not bypass any of the safety

features of this equipment or operate this equipment in an improper environment.

All wiring external to the equipment should comply with the current edition of the Electrical

Code or any national wiring rules that apply.

Publication Notice

The information in this document is subject to change without notice. MIKOM shall not be

liable for technical or editorial errors or omissions that may occur in this document, or for

incidental or consequential damages resulting from the furnishing, performance, or use of this

document.

MR Booster Manual (MN001808-1, 7/99) Page - iii -

LIMITED WARRANTY

to the first consumer (the "Warranty Period").

to have been defective in the respects aforesaid during the Warranty Period.

term with respect to any part or parts repaired or replaced by ALLEN TELECOM

WARRANTY PERIOD SPECIFIED ABOVE.

WARRANTY OR OF ANY IMPLIED WARRANTY.

for it any obligation or liability other than as herein expressly stated.

MIKOM, a division of ALLEN TELECOM INC. ("ALLEN

TELECOM"), warrants, on the terms and conditions hereto set forth, all products

manufactured by it to be free under normal use and service from defects in

materials and workmanship for a period of one (1) year from the date of shipment,

ALLEN TELECOM's obligation under this Warranty is limited to prompt

repair or replacement of the product, at its option, without charge, at an authorized

ALLEN TELECOM dealer or at the factory of ALLEN TELECOM in Cleveland,

Ohio, when the product is returned to an authorized dealer or to the factory with

all transportation charges prepaid and examination of the product shall disclose it

The Limited Warranty Period shall not be extended beyond its original

hereunder.

The Warranty Period shall not apply to any product which has been

repaired or altered in any manner by anyone other than ALLEN TELECOM or an

authorized outlet of ALLEN TELECOM, or if the defect , malfunction or failure

of the was caused by damage by lightning, flood or other acts of nature or by

power surges, or from unreasonable use, or from improper installation or

application, or to any product which has not been maintained or used in

accordance with the operating specifications set forth in ALLEN TELECOM's

written instructions.

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE ARE LIMITED IN DURATION TO THE

UNDER NO CIRCUMSTANCES SHALL ALLEN TELECOM BE

LIABLE FOR ANY CONSEQUENTIAL DAMAGES FOR BREACH OF THIS

ALLEN TELECOM neither assumes nor authorizes any person to assume

Page - iv - MR Booster Manual (MN001808-1, 7/99)

Contents

Page

Section 1. Introduction................................ ................................ ........................ 1

1.1 About This Manual................................ ................................ ................................ ........1

1.2 Conventions Used in This Manual................................ ................................ ................ 2

1.3 Terminology................................ ................................ ................................ .................. 2

Section 2. System Description................................ ................................ ............. 3

2.1 Introduction................................ ................................ ................................ ................... 3

2.2 System Overview................................ ................................ ................................ .......... 3

2.3 Theory of Operation ................................ ................................ ................................ ......5

2.3.1 Downlink Path ................................ ................................ ................................ ..5

2.3.2 Uplink Path ................................ ................................ ................................ .......6

2.3.3 System Control ................................ ................................ ................................ .6

2.4 System Components................................ ................................ ................................ ......9

2.4.1 Power Supply................................ ................................ ................................ ....9

2.4.2 Downlink Power Amplifier................................ ................................ .............. 9

2.4.3 Logic Controller Board................................ ................................ ..................... 9

2.4.4 PA Combiner/Splitter Module................................ ................................ ........ 10

2.4.5 Uplink Low Noise Amplifier................................ ................................ .......... 10

2.4.6 Duplexers................................ ................................ ................................ ........ 11

2.4.7 RF Cable ................................ ................................ ................................ .........11

2.4.8 Fan Assembly................................ ................................ ................................ ..11

2.4.9 VSWR Module................................ ................................ ............................... 11

2.4.10 Downlink Driver Amplifier................................ ................................ ............ 12

2.4.11 Input/Output Panel................................ ................................ .......................... 12

Section 3. Installation................................ ................................ ........................ 15

3.1 Introduction................................ ................................ ................................ ................. 15

3.2 Site Selection................................ ................................ ................................ ............... 15

3.2.1 Equipment Inventory ................................ ................................ ...................... 15

3.2.2 Installation Tools and Equipment ................................ ................................ ...16

3.2.3 Site Requirements................................ ................................ ........................... 16

3.3 Installation ................................ ................................ ................................ ................... 17

3.3.1 Mechanical................................ ................................ ................................ ......17

3.3.2 Electrical Connections ................................ ................................ .................... 20

3.3.3 RF Connections................................ ................................ ............................... 21

3.3.4 Logic Controller Board................................ ................................ ................... 22

3.4 Installation Checklist ................................ ................................ ................................ ...24

3.5 System Optimization................................ ................................ ................................ ...25

3.5.1 Downlink Gain Setting ................................ ................................ ................... 25

3.5.2 Downlink Power Measurement................................ ................................ ......25

3.5.3 Uplink Gain Setting................................ ................................ ........................ 26

MR Booster Manual (MN001808-1, 7/99) Page - v -

Contents

Section 4. Setting Up for Initial Operation ................................ ...................... 27

4.1 Introduction................................ ................................ ................................ ................. 27

4.2 Connecting a Terminal................................ ................................ ................................ 28

4.3 Basic Commands................................ ................................ ................................ ........ 29

4.3.1 Syntax................................ ................................ ................................ ............. 29

4.3.2 Entering Commands................................ ................................ ....................... 30

4.3.3 Commonly Used Commands................................ ................................ ......... 30

4.3.4 Escaping From Continuous Cycle................................ ................................ .. 31

4.3.5 Ending a Session ................................ ................................ ............................ 31

4.4 Using SET Menus................................ ................................ ................................ ....... 32

4.4.1 Moving Forward................................ ................................ ............................. 32

4.4.2 Moving Backward................................ ................................ .......................... 33

4.4.3 Exiting................................ ................................ ................................ ............ 33

4.5 Setting Initial Parameters................................ ................................ ............................ 33

4.5.1 Checking System Status................................ ................................ ................. 33

4.5.2 Setting PA Parameters................................ ................................ .................... 33

Section 5. Troubleshooting................................ ................................ ............... 35

5.1 Introduction................................ ................................ ................................ ................. 35

5.2 System Status Indicators................................ ................................ ............................. 35

5.2.1 Logic Controller LED Indicators ................................ ................................ ... 35

5.2.2 Power Supply LED Indicators................................ ................................ ........ 36

5.2.3 Logic Controller Software Alarms and Monitoring Parameters .................... 36

5.3 Removing and Replacing Failed Parts................................ ................................ ........ 36

Section 6. Specifications................................ ................................ .................... 37

Appendix A:TBD ................................ ................................ ......................... A-1

Parts & Accessories

A. Introduction................................ ................................ ................................ .......... Parts-1

B. Model Numbers................................ ................................ ................................ ... Parts-1

C. Suggested Spares................................ ................................ ................................ .Parts-2

D. Replacing Parts and Accessories ................................ ................................ ......... Parts-3

Page - vi - MR Booster Manual: (MN001808-1, 7/99)

Section 1. Introduction

1.1 About This Manual

This manual provides installation, operating, and maintenance instructions for the

MR Booster. It is intended for anyone who installs or maintains MR Booster

equipment.

Section 1. Introduction: Provides a brief overview of the manual contents and

terminology.

Section 2. System Description: Describes the basic functionality, features, and

technical details of an MR Booster.

Section 3. Installation: Explains the procedures for mounting the MR Booster and

making all connections.

Section 4. Setting Up for Initial Operation: Describes the procedures for

connecting and operating a local terminal.

Section 5. Troubleshooting: Describes the procedures for locating and fixing

problems that can occur in an MR Booster.

Section 6. Specifications: Lists mechanical, electrical, and environmental

specifications of the MR Booster.

Appendices

A. TBD

Parts & Accessories Order Information

Provides information about MR Booster model and part numbers, and suggested

spares.

MR Booster Manual (MN001808-1, 7/99) Page 1

1. Introduction

void any existing warranties.

CAUTION:

1.2 Conventions Used in This Manual

The following special notations are used to draw attention to particularly important

information:

WARNING! Warning statements alert you to situations that can

cause equipment damage. Failure to heed warning statements may

Caution statements alert you to situations that can

cause interruption or serious degradation of service. For optimum

system performance, observe caution statements.

NOTE: Notes contain helpful hints or reminders of important information.

1.3 Terminology

The following table lists the meanings of frequently used acronyms in this manual.

For descriptions of these system components, refer to Section 2.

Acronym Definition

BDA

BTS

MR

Bi-Directional Amplifier

Base Transceiver Station

Mikom Repeater

Table 1-1. Definitions

Page 2 MR Booster Manual (MN001808-1, 7/99)

Section 2. System Description

2.1 Introduction

This section describes the basic functions and features of an MR Booster, including:

• System overview

• Theory of operation

• System components

2.2 System Overview

The MR Booster is a broadband, bi-directional amplifier (BDA) used to extend the

coverage area in a wireless communications network. The booster is specifically

designed to interface with the MIKOM MR series repeater. It can also be used with

an existing repeater or a base transceiver station (BTS) that needs a downlink power

boost.

Figure 2-1 illustrates a typical MR Booster application with a repeater, and Figure 22 illustrates a typical application with a BTS. The booster is connected directly to the

coverage antenna port from the repeater or BTS and boosts the downlink signal

power while maintaining dynamic range on the uplink. The booster performs several

basic functions to enhance network coverage:

• The repeater or BTS downlink RF output is filtered, amplified and transmitted,

via the mobile coverage antenna, using high efficiency RF power amplifiers.

• Uplink RF signals from handsets in the coverage area are received at the mobile

antenna, amplified by an LNA, and passed directly to the repeater or BTS.

• Control and alarm monitoring is maintained by MR repeater software or through

two relay contact outputs from the booster.

• Power supply and power amplifier soft-fail redundancies offer increased

reliability.

• A separate uplink diversity path is available as an option.

• Downlink output VSWR monitoring is available as an option.

MR Booster Manual (MN001808-1, 7/99) Page 3

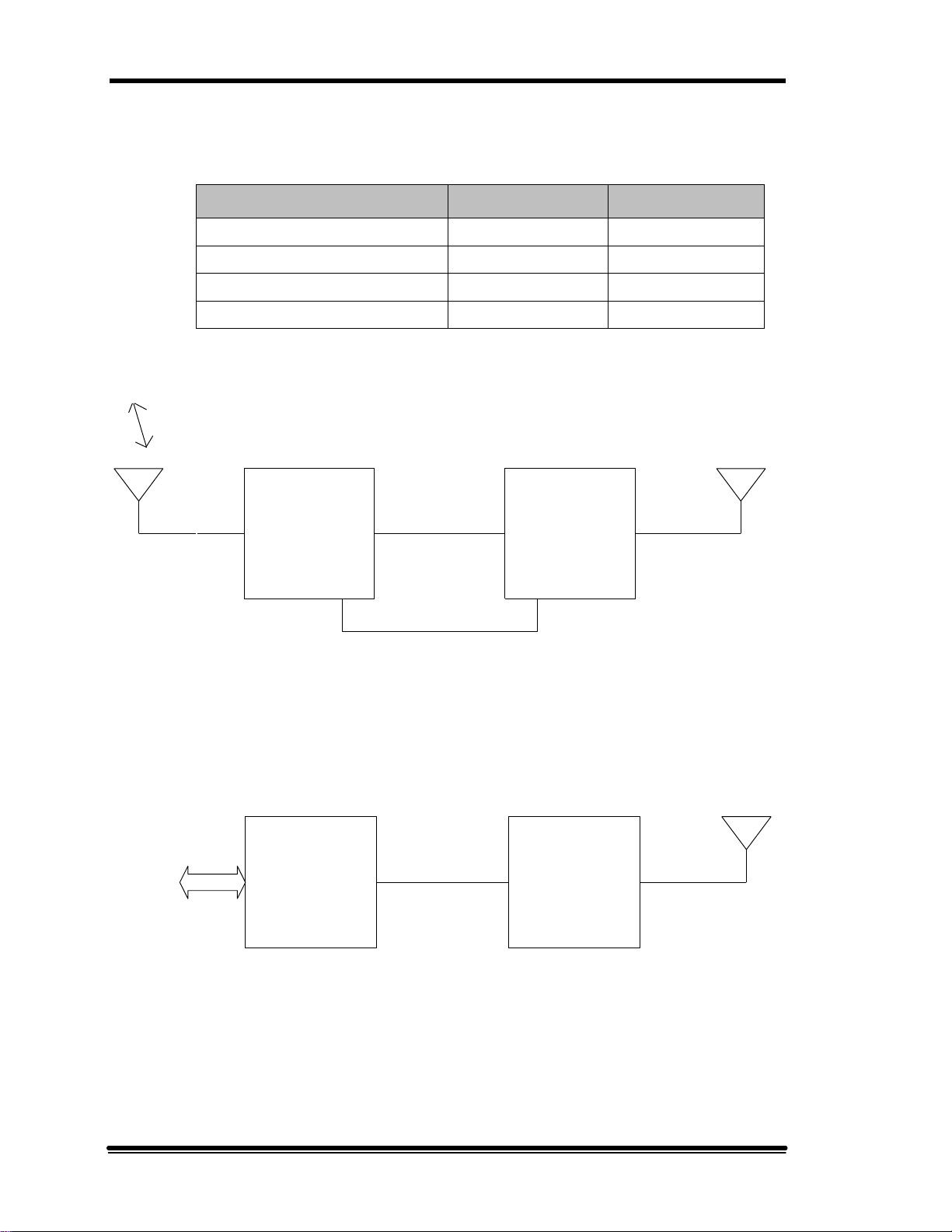

2. System Description

• The Booster is available in one of two output power options (medium and high)

and four frequency ranges:

Band Uplink Downlink

AMPS800 full band 824-849 MHz 869-894 MHz

LMR8-00 full band 806-824 MHz 851-869 MHz

PCS1900 ADB band 1850-1885 MHz 1930-1965 MHz

PCS1900 extended EFC band 1875-1910 MHz 1955-1990 MHz

TO/FROM

BTS

DONOR

ANTENNA

PORT

REPEATER

Table 2-1. Frequency chart

REPEATER

PORT

MOBILE

ANTENNA

PORT

BOOSTER

COVERAGE

ANTENNA

MR

MOBILE

PORT

TO/FROM

MOBILE

SWITCHING

OFFICE

I2C BUS

CONTROL

Figure 2-1. Typical MR Booster Application (Repeater)

BTS

REPEATER

PORT

COVERAGE

ANTENNA

PORT

MR

BOOSTER

Figure 2-2. Typical MR Booster Application (BTS)

COVERAGE

ANTENNA

MOBILE

PORT

Page 4 MR Booster Manual (MN001808-1, 7/99)

Repeater or BTS

main port

PA

COMBINER/

SPLITTER

+26V-A

POWER AMPLIFIERS

+26V-B

PA

COMBINER/

SPLITTER

2. System Description

Main coverage

antenna

MOBILE

DUPLEXER

RPTR

DUPLEXER

Repeater or BTS

diversity port

+26V-A +26V-B

POWER

SUPPLY

A

+12V

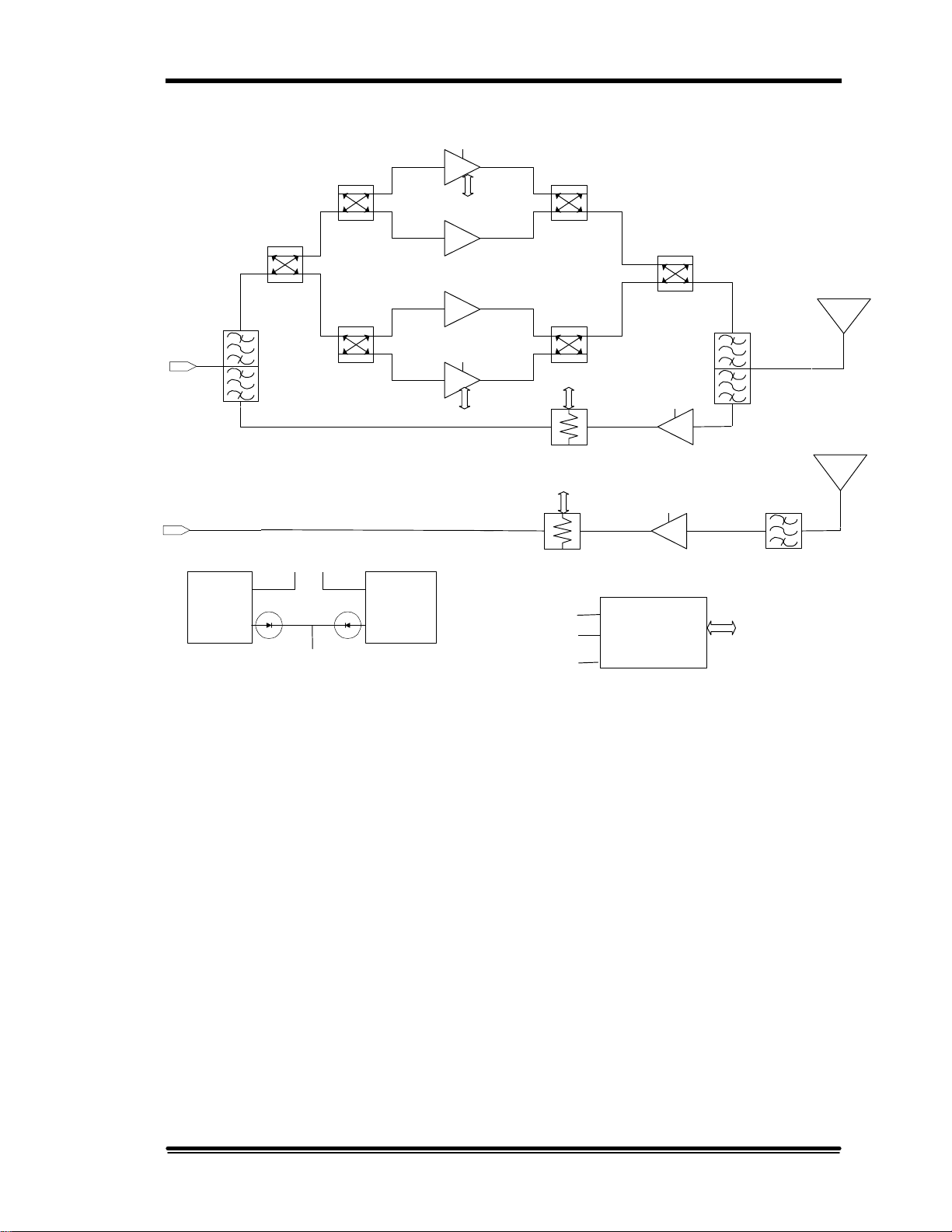

Figure 2-3. MR Booster functional block diagram

2.3 Theory of Operation

A block diagram of the basic high-power MR Booster system is shown in Figure 2-3.

In order to simplify the discussion, a repeater-booster installation is assumed as in

Figure 2-1.

POWER

SUPPLY

B

MAIN LNA

DIVERSITY LNA

+12V

+26V

CONTROLLER

I2C

+12V

LOGIC

+12V

Diversity coverage

antenna

UL FILTER

CONTROL I/O

2.3.1 Downlink path

Duplexed RF from the repeater’s coverage antenna port is connected to the

booster downlink port. The repeater duplexer then routes the downlink signal

frequencies to the PA combiner/splitter module.

MR Booster Manual (MN001808-1, 7/99) Page 5

2. System Description

The downlink signal frequencies are then routed to the PA combiner/splitter

module by the repeater duplexer. In the high-power option, the RF is split

into four separate paths by the hybrid combiner/splitter module and

distributed to four RF PAs. In the medium-power option, the RF is split into

two separate paths and distributed to two RF PAs.

NOTE: The multiple amplifiers provide soft-fail redundancy to maintain

minimum output power capability should one or more fail in the field.

The PA outputs are summed in a second combiner/splitter, then routed to the

mobile-side duplexer. The duplexer routes the downlink RF output to the

coverage antenna, which transmits to handsets in the booster coverage area.

2.3.2 Uplink path

Mobile handset transmissions are received at the mobile duplexer port and

routed to the LNA input by the mobile duplexer. The amplified LNA output

is then routed to the repeater duplexer, which is connected to the installed

repeater’s coverage antenna port.

A diversity option offers a second, identical uplink path when diversity is in

use in the donor BTS or repeater.

2.3.3 System control

Control functions include PA keying, fan control, and uplink attenuation

setting. Monitored parameters include PA output power, status, system

temperature, power supply temperature, DC output voltage and status, and

input power source (ac or dc).

Resident software can be accessed via the supplied serial interface cable with

a laptop computer and terminal-emulation software to initialize and customize

the unit during installation or to perform troubleshooting.

The booster can be remotely controlled after installation with a Mikom MR

series repeater via the I2C bus interface cable.

For other applications, or if remote control is not required, a pair of relay

closure outputs from the booster can be user-configured and routed to the

donor system to flag system problems after installation.

Page 6 MR Booster Manual (MN001808-1, 7/99)

Power

Power

Mobile

Uplink

Logic

Controller

Board

Repeater

Combiner/

2. System Description

Supply

Splitter

Amplifiers

LNA

Duplexer

Duplexer

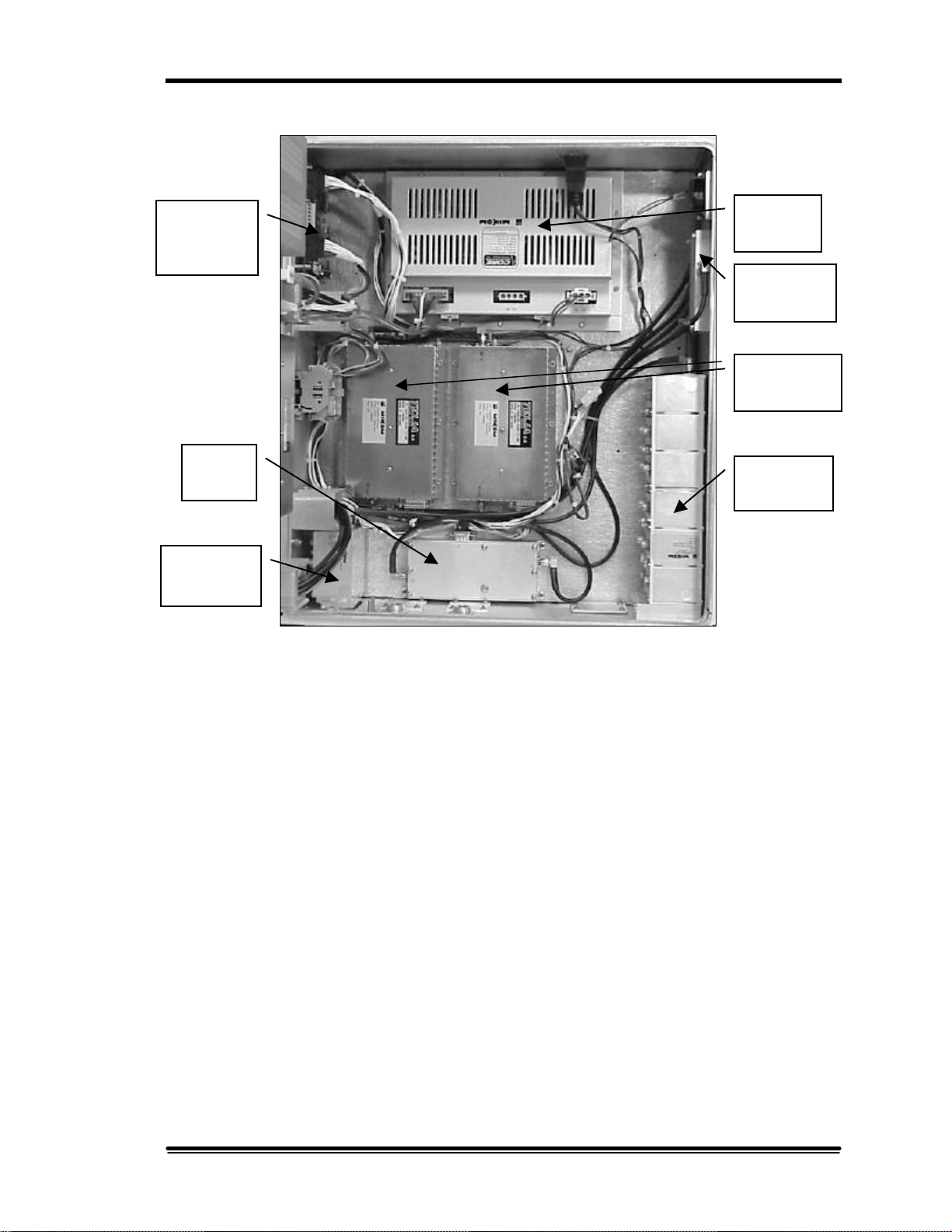

Figure 2-4. MR Booster (inside cabinet)

MR Booster Manual (MN001808-1, 7/99) Page 7

2. System Description

Power

Power

Combiner/

Splitter

Supply

Amplifiers

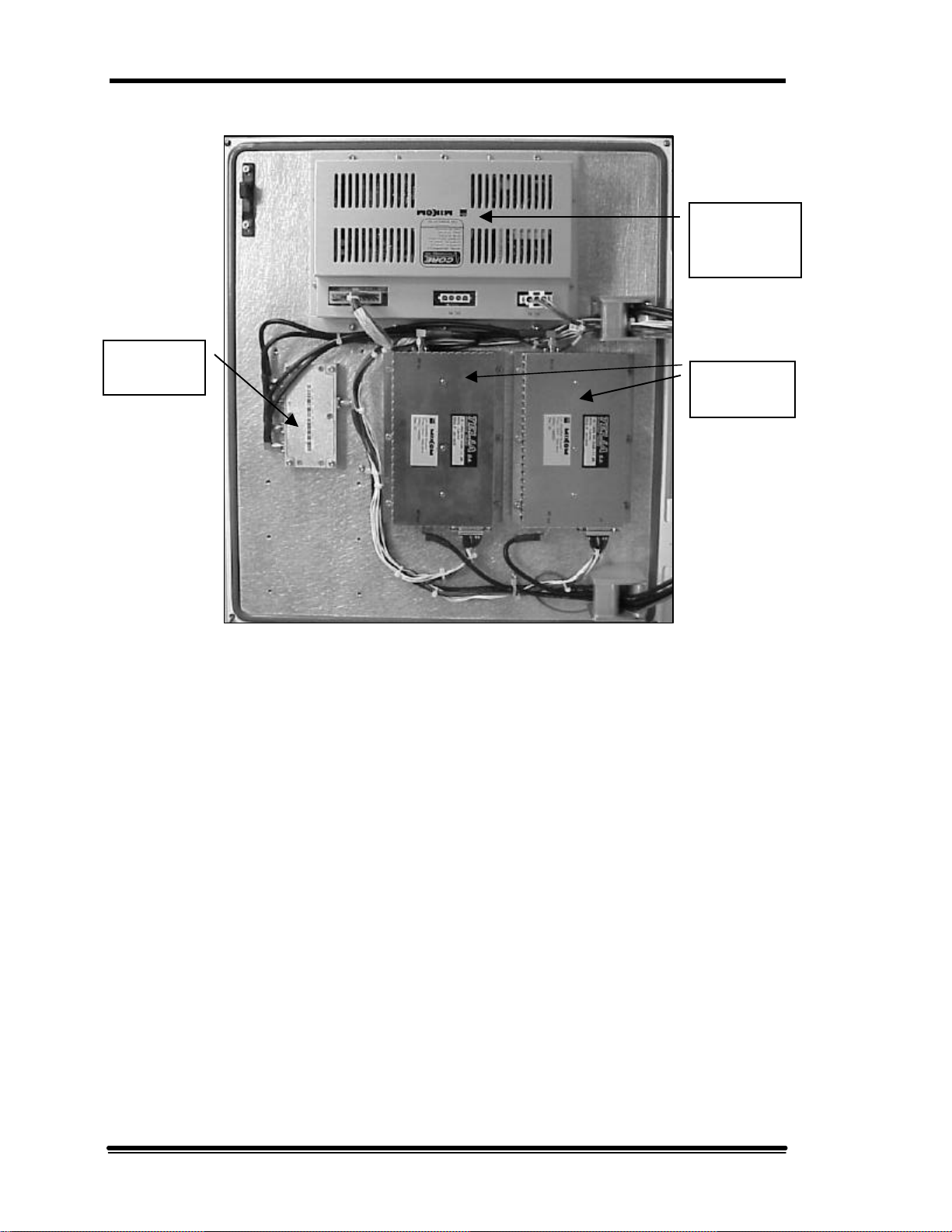

Figure 2-5. MR Booster (inside door)

Page 8 MR Booster Manual (MN001808-1, 7/99)

2.4 System Components

2.4.1 Power Supply

The MR Booster provides two high-efficiency power supplies with 26 VDC

and 12 VDC outputs (see Figures 2-4 and 2-5). The 26 V output is split

evenly between the system PAs to provide soft-fail redundancy. The 12 V

output is diode-connected at the controller and the LNAs, ensuring that both

will function if a power supply fails. The power supply has thermal

shutdown capability.

The AC supply input is auto-ranging to handle 115 and 220 volt, 50 or 60 Hz

systems. During loss of AC mains, the booster will automatically switch over

to the DC input for operation with a BBU.

2.4.2 Downlink Power Amplifier

The downlink power amplifiers (see Figure 2-4) provide low distortion

amplification of downlink RF signals using proprietary feedforward

correction techniques. After duplexer, splitter and combiner losses, the PAs

provide 20 dB nominal gain for the booster in the downlink signal path.

2. System Description

The amplifiers are powered by the 26 VDC output of the power supplies. To

provide maximum output power and soft-fail redundancy, the downlink power is

shared between either four (high-power option) or two (medium-power option)

PAs. Each PA provides output power and temperature status information to the

system controller and provides both overcurrent and overtemperature protection

circuitry.

2.4.3 Logic Controller Board

The logic controller board (see Figure 2-4) monitors and controls internal

booster functions, and provides alarms to the donor system. The controller

contains an I2C bus interface for remote control by a Mikom MR series

repeater. The controller is powered by the 12 VDC supply.

System configuration information is retained in an on-board EEPROM. For

installation or troubleshooting, the board-resident software can be accessed

from an MR repeater, or from an on-site laptop computer. The controller can

set:

• uplink gain

• PA key/unkey

• fan speed control (high/low/off)

MR Booster Manual (MN001808-1, 7/99) Page 9

2. System Description

The controller monitors the status of the following system components:

• PA power output

• PA temperature

• PA shutdown

• power supply temperature

• average 26 VDC and 12 VDC output voltages

• AC mains presence

• VSWR input (when installed)

The controller also routes the DC power to the VSWR module.

For general use, two alarm outputs are provided that can be user-configured

during installation. The outputs are normally open relay contact pairs, which

are closed when no alarm condition is present. These signals are provided on

four of the seven pins of a terminal block on the controller board.

2.4.4 PA Combiner/Splitter Module

The PA combiner/splitter module (see Figure 2-4) splits the input signal,

distributes it to the PAs and combines it after amplification. Identical hybrid

design is used to ensure maximum amplitude and phase matching of the

downlink signal.

2.4.5 Uplink Low Noise Amplifier

The LNA (see Figure 2-4) maintains dynamic range for uplink mobile

signals. The LNA provides low noise figure and high input IP3 so the booster

does not decrease sensitivity or increase distortion in the system.

The gain of the LNA chain after duplexer and cable losses is nominally 20 dB

with the uplink attenuation set to 0 dB. Using the internal software, the gain

can be reduced by increasing the attenuation in 1 dB steps up to 15 for

optimal IP3, or where equal uplink and downlink booster gain is not

necessary. The same LNA is used in the diversity option and the attenuation

setting is ganged so each uplink path is set for equal gain.

Page 10 MR Booster Manual (MN001808-1, 7/99)

2.4.6 Duplexers

CAUTION:

proper MIKOM part numbers.

The duplexers (see Figure 2-4) provide isolation between uplink and

downlink paths, and band-limit the signals that are either passed to the donor

hardware, or transmitted at the mobile antenna. The small repeater duplexer

provides adequate UL/DL isolation. The mobile duplexer offers low insertion

loss to maximize downlink output power and uplink noise figure. Forward

and reverse directional coupler outputs are provided on the mobile duplexer.

The coupler outputs are routed to the VSWR module when that option is

installed.

2.4.7 RF Cables

The RF cables are a critical part of the MR Booster, particularly in the

downlink function. Low loss provides maximum output power and cable

propagation delays must be properly controlled so that the amplifiers are

combined with low phase error.

2. System Description

Never substitute RF cables in the booster. Use only

2.4.8 Fan Assembly (High-power only)

Dual DC fans (not shown) maintain a low cabinet temperature in the high

power option. The fans are sealed to withstand all weather conditions. The

plenum and ducting structure of the booster is designed to move air over all

heat fins, even if one fan fails. The fans can be disabled or operated at low

speed for climates where over-heating will not be a problem. The logic

controller provides the fan interface.

2.4.9 VSWR Module (Optional)

The VSWR module (not shown) monitors the downlink output VSWR. The

customer is alerted to potentially damaging antenna mismatch. The module

receives ± 12 VDC from the controller and coupled outputs from the mobile side

duplexer. The coupled signals are processed the output VSWR is routed to the

logic controller.

MR Booster Manual (MN001808-1, 7/99) Page 11

2. System Description

2.4.10 Downlink Driver Amplifier (Optional)

An ultra-linear driver amplifier (not shown) provides more downlink gain or

boosts the linear output power. Contact technical support for availability and

details.

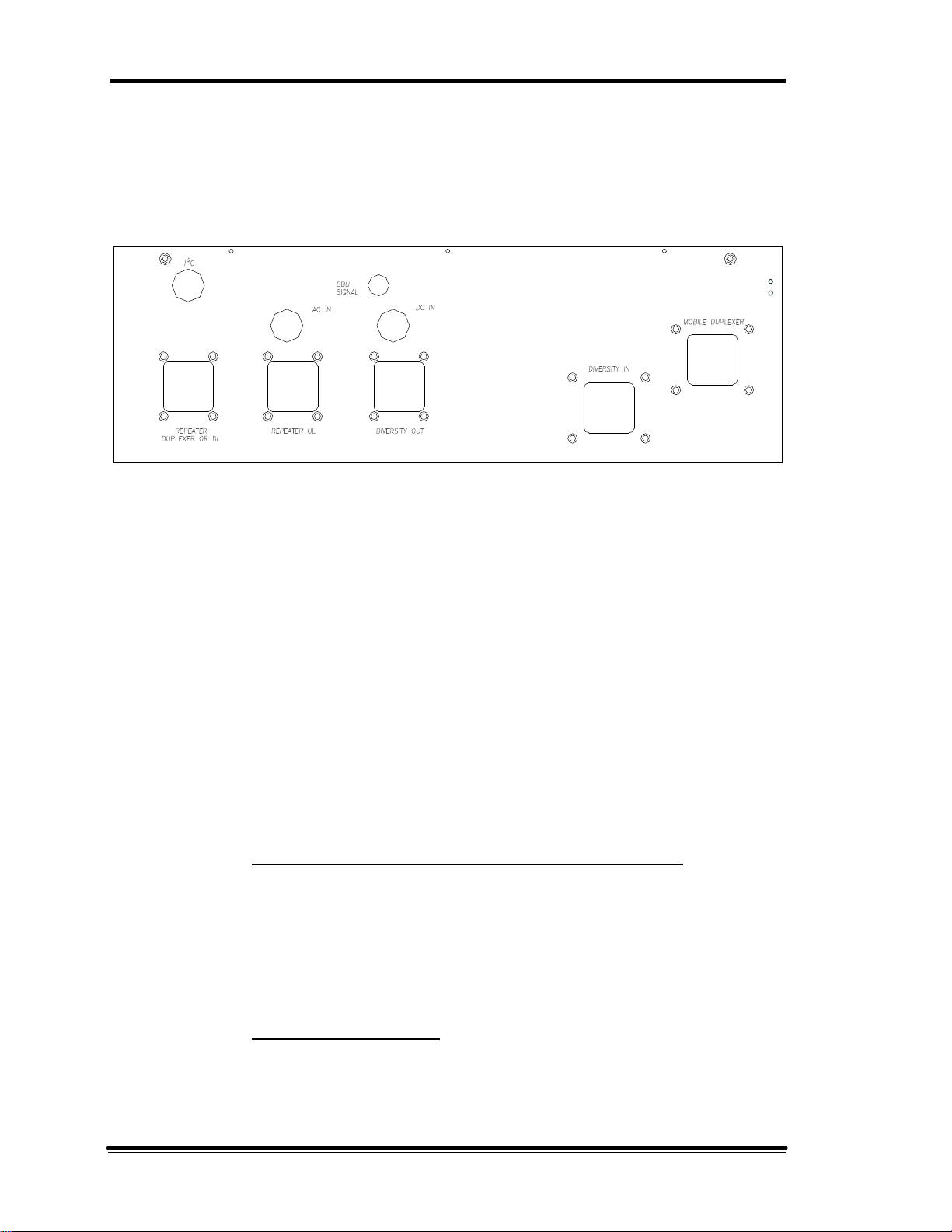

Figure 2-5. Input/output panel

2.4.11 Input/Output Panel

All system inputs and outputs are accessible from the bottom panel of the

cabinet (see Figure 2-5). All RF connectors are 7-16 female bulkhead. All

unused RF ports have gasketed plates covering the connector cutout.

Control, alarm, and power connections are made via multi-conductor cables

routed through weatherproof glands. Unused glands are filled with removable

plugs.

NOTE: The customer is responsible for ensuring a weatherproof seal on

glands not set up in the factory.

Following are the descriptions of the available I/O connections:

• Repeater Duplexer or DL (optionally repeater DL only): Connected to

the repeater’s mobile coverage antenna port. It accepts downlink signals

from the repeater and outputs the uplink RF to the repeater.

NOTE: If the MR Booster must interface with a non-duplexed system,

this port can be used to route the downlink output from the repeater to the

booster.

• Repeater UL (optional): This port is used only when the repeater has

non-duplexed mobile input and output. The uplink output is then routed

through this connector from the booster to the repeater.

Page 12 MR Booster Manual (MN001808-1, 7/99)

2. System Description

• Mobile Duplexer: Connected to the repeater’s coverage antenna.

• Diversity In (optional): The diversity coverage (mobile) antenna is

connected to the diversity input port.

• Diversity Out (optional): The diversity output is routed to the repeater’s

uplink diversity path input port.

• AC IN gland: The AC input cable is passed through this gland and

connected to the WAGO terminal block inside the cabinet.

• DC IN gland: If a DC input is used, the multi-conductor cable is passed

through this gland and distributed to the DC input connector of the power

supplies. Contact the factory for further details if using a customersupplied BBU or DC source.

• I2C gland: The I2C control cable is routed through this gland and

connected to the logic controller board inside the cabinet. The far end of

the cable is connected to the MR series repeater control bus.

• BBU signal gland: This gland is provided to interface to a BBU alarm or

sense output.

MR Booster Manual (MN001808-1, 7/99) Page 13

3.1 Introduction

This section describes the procedures for installation of an MR Booster and system

optimization. The Installation Checklist at the end of this section provides a concise

summary of the installation steps. Section 4 will provide initial software instructions.

3.2 Site Selection

The site chosen for the MR Booster must meet requirements related to location,

power, space, mounting surface, environment, and antenna isolation.

3.2.1 Equipment Inventory

The following table lists items shipped with the MR Booster. Use a separate

table for each booster installed.

Section 3. Installation

MR Booster

Site: Installer:

q MR Booster

Tuck Pack:

q Manual

q 6mm T-handle wrench

q 4mm T-handle wrench

q 3mm T-handle wrench

2

q I

C bus cable

q Serial cable

q Drilling template

q Keys for security cover

Serial #:

Serial Part #:

MN001808-1

G71A0031-2

G71A0031-3

G71A0031-1

G15A0309-1

G15A0327-1

G27AT000-1

???N/A

Table 3-1. Equipment List

MR Booster Manual (MN001808-1, 7/99) Page 15

3. Installation

3.2.2 Installation Tools and Equipment

You will need the following tools and equipment for installation of the MR

Booster:

Factory supplied:

• 6mm T-handle wrench to mount cabinet to bracket

• 4mm T-handle wrench to open/close cabinet door

• DB-9 to DB-9 serial control cable

• I2C bus cable (if applicable)

Customer supplied:

• M8 carriage bolts, flat washers, split lock washers, and drivers to bolt the

mounting bracket to a wall or pole

• Laptop computer with serial port and terminal emulation software (e.g.,

ProComm)

• Coaxial RF cables terminated with a 7-16 male connector

ü for donor port

ü for repeater port or RX port (if applicable)

ü for diversity input (if applicable)

ü for diversity output (if applicable)

ü for TX port (if applicable)

• >30 dB, 60 W attenuator

• RF power meter with 20 dBm power-handling capability

• Miscellaneous RF test cables and adapters

3.2.3 Site Requirements

Space: The MR Booster dimensions are 742 mm (H) x 466 mm (W) x 287

mm (D) (29.2 x 18.3 x 11.3 inches) with fans, 535 mm (H) (21.1 inches)

without fans. Allow a minimum of 500 mm in front of the booster for door

clearance, 30 mm below for cable access, and 150 mm on either side for

access to mounting hardware.

Mounting surface: The cabinet should be mounted to a vertical surface with

a load-bearing capacity of at least 55 kg. It may be mounted to a wall or a

pole.

Page 16 MR Booster Manual (MN001808-1, 7/99)

Environment: The MR Booster is in a weatherproof cabinet that can be

operated at ambient temperatures between -30°C to +55°C.

Power: The cabinet requires 90-264 VAC, 50-60 Hz at 600 Watts maximum,

or 21-28 VDC, 20 Amps maximum (when equipped for DC operation).

Antenna isolation: When the MR Booster is used with a repeater, the

isolation between the donor and mobile antennas must be at least 15 dB

greater than the composite system gain of the repeater plus booster for

optimum performance.

3.3 Installation

3.3.1 Mechanical

Use the supplied template, shown in Figure 3-1, to drill holes to mount the

MR Booster mounting bracket. Install the mounting bracket with two M8

carriage bolts for pole mounting, and four M8 carriage bolts for surface

mounting. Use a flat washer and split lock washer under the head of each

bolt.

3. Installation

WARNING! The MR Booster may weigh up to 51 kg

(112.4 lbs), depending on options; use two people to lift the

booster onto the mounting bracket.

Lift the repeater up and set the top M10 screws into the recesses provided in

the top of the mounting bracket. Align the holes in the cabinet with the holes

in the mounting bracket, then install and tighten the four M8 socket-head cap

screws using the supplied 6mm T-handle wrench.

To access the inside of the cabinet (see Figure 3-2), use the supplied 4mm Thandle wrench to unscrew the four M5 socket-head cap screws that secure the

door to the main cabinet.

MR Booster Manual: (MN001808-1, 7/99) Page 17

3. Installation

Figure 3-1. Drilling template (not to scale)

Page 18 MR Booster Manual (MN001808-1, 7/99)

Door

Access

Screws

3. Installation

Figure 3-2. Door access screws

MR Booster Manual: (MN001808-1, 7/99) Page 19

3. Installation

3.3.2 Electrical Connections

AC: The unit is shipped with the internal AC connections already made. The

cable extends 10 feet outside the cabinet to allow termination to a junction

box or other connection to the AC mains. Since the power supply inputs are

autoranging, no special accommodations are required to connect to standard

voltage and frequency.

The wires are attached to a WAGO connector inside the cabinet as follows:

Wire Color WAGO Color

Brown (hot) Gray

Blue (neutral) Blue

Green/Yellow (ground) Screwed to ground lug

Table 3-2. Wire Chart

DC: Please consult MIKOM at 1 (800) 800-3224 for applications with a

customer-owned DC power source or battery-backup unit.

Page 20 MR Booster Manual (MN001808-1, 7/99)

3.3.3 RF Connections

RF cables to the MR Booster must be terminated with a 7-16 male RF

connector. A low-loss, 50 ohm cable with superior shielding is recommended

for all RF connections. See Section 2.4.11 for I/O options.

3. Installation

Figure 3-3. I/O connections

Minimum configuration (see Figure 3-3) consists of two cables:

• From the duplexed port of the donor repeater to the Repeater Duplexer

connector on the booster.

• From the Mobile Duplexer port of the booster to the coverage antenna.

MR Booster Manual: (MN001808-1, 7/99) Page 21

3. Installation

J1

J6

J7

Terminal

Block

I2C Bus

Connection

Serial

Connection

Figure 3-4. Logic Controller Board

3.3.4 Logic Controller Board

Several connections are made through the I/O panel on the bottom of the

repeater. Figure 3-5 shows the position of applicable connectors.

I2C bus: To enable control functions, such as alarms, from a Mikom repeater,

connect the supplied I2C cable connector to J7 on the logic controller board.

Pass the cable through the I2C gland on the I/O panel. The cable can then be

routed to the MR Repeater’s I2C connector.

Serial control: Connect the female DB-9 end of the supplied serial cable to

J6 on the logic controller board. Route the cable through the door of the

booster and close it (the door seal will prevent the cable from being crushed).

Connect the male end of the serial cable to serial port 1 of the laptop

computer. After initialization or troubleshooting has been completed, this

cable can be removed.

Page 22 MR Booster Manual (MN001808-1, 7/99)

3. Installation

Alarm outputs: The alarm output wires are available from terminal block J1

on the logic controller board. A multiple-conductor cable must be passed

through the I2C gland. The alarm function is defined through software in the

initialization process. Pin out is as follows:

Pin Function

1 Alarm 1

2 Alarm 1 return

3 Alarm 2

4 Alarm 2 return

5 External digital alarm input (optional)

0-5 V TTL level input

6 Ground reference

7 External analog alarm input (optional)

0-30 V analog alarm input

Table 3-3. Alarm pin out

WARNING! Inspect the unit after cabling to ensure that unused

connector holes have plates and gaskets applied, and that unused

glands have stops inserted. All connections should be completed

and weatherproofing ensured before AC mains or DC power is

applied.

MR Booster Manual: (MN001808-1, 7/99) Page 23

3. Installation

3.4 Installation Checklist

The following checklist provides a summary of the procedures for installing an MR

Booster system.

Step Item/ Action Description Check

1

2

3

4

5

6

7

8

9

10

11

MR Booster Site Drawing

Equipment List:

MR Booster

AC or DC power source

Uplink source

Downlink source

Installation tools:

M8 carriage bolts To install mounting bracket

6mm and 4mm drivers To mount cabinet to bracket, open door

Serial control cable To connect terminal to booster

terminal To initialize booster

I2C bus cable (if applicable)

Coaxial cables

>30 dB, 60 W attenuator

RF power meter

Miscellaneous RF test cables

Run cable to site

Mount the equipment

Attach cables

Connect terminal to J6 on the

logic controller board

Power up booster

Initialize booster

Close cabinet and screw shut

Optimize system

Master copy of the site plan noting the MR

Booster location and serial number.

Power, uplink, downlink, I2C (if applicable)

See Section 3.3.

Power, uplink, downlink, I2C (if applicable),

alarm outputs (if applicable)

For initialization.

See Section 4, Setting Up for Initial Operation

See Section 3.5, System Optimization

Table 3-4. Installation checklist

Page 24 MR Booster Manual (MN001808-1, 7/99)

TO/FROM

BTS

REPEATER

DONOR

ANTENNA

PORT

Figure 3-5. Typical MR Booster Application (Repeater)

3.5 System Optimization

MOBILE

ANTENNA

PORT

CONTROL

REPEATER

I2C BUS

PORT

MR

BOOSTER

3. Installation

COVERAGE

ANTENNA

MOBILE

PORT

Refer to Figure 3-5 for an example of an application in which the MR Booster is used

to boost a repeater. For additional information regarding system optimization, please

contact Mikom technical support at 1 (800) 800-3224.

3.5.1 Downlink Gain Setting

The downlink gain is generally determined by the output power that provides

coverage of the hole that the MR Booster is filling. This power should not

exceed the specifications in Section 6 for differing technologies and number

of carriers. The gain of the repeater must be adjusted via the operational

software so that the desired output power equals the system gain (repeater

plus booster) plus the input power received from the BTS.

The input power can be determined from the downlink RSSI reading of the

repeater for each applicable RF channel. For greatest accuracy, the factory

test data sheet enclosed with the MR Booster can be used to determine the

booster gain near each channel of interest.

3.5.2 Downlink Power Measurement

To ensure that the proper output power is reached, measure the composite

power coming out of the mobile duplexer port. Use a power meter capable of

handling 100 mW with a 30 dB, 60 W power attenuator on the mobile

connector for an accurate measurement without damage. The composite

power measured by the meter, after calibrating out the loss of the attenuator,

should be approximately equal to the desired power per carrier plus 10logN,

where N is the number of carriers.

MR Booster Manual: (MN001808-1, 7/99) Page 25

3. Installation

3.5.3 Uplink Gain Setting

In most cases, the repeater gain is adjusted to make the uplink gain equal to

the downlink gain to maintain a balanced link. Adjust the repeater gain, leave

the MR Booster LNA gain set to maximum, and the overall system noise

figure is minimized.

In cases where unusually strong in-band interferers are present, it may be

necessary to decrease the LNA gain in order to increase the overall system

input intercept point. The amount of attenuation added depends on the

required system intercept point, – the maximum allowable system noise

figure and the dynamic range of the repeater.

Page 26 MR Booster Manual (MN001808-1, 7/99)

Section 4. Setting Up for Initial Operation

4.1 Introduction

All MR Booster operating parameters are under software control and can be changed

from a terminal connected via serial link to the booster. The booster has default

settings for optional parameters. These parameters may need to be adjusted for

proper operation in your network.

This section describes procedures for:

• Connecting the terminal

• Becoming familiar with system commands

• Programming initial parameters

The checklist in Table 4-1 presents a brief overview of these procedures. For

descriptions of all operating parameters, see Appendix A, Control Software. If

problems occur during setup, refer to Section 5, Troubleshooting.

MR Booster Manual (MN001808-1, 7/99) Page 27

4. Setting Up for Initial Operation

Setup Checklist

? 1. Terminal connected:

? a. Terminal powered up and set to 9600-N-8-1, full duplex, send carriage return

only, no CTS/RTS, no XON/XOFF.

? b. MR Booster repeater powered up.

? 2. System status (SSS) and alarm (ALA) report checked; no DISABLED and no

alarms shown.

? 3. System parameters programmed:

? a. Gain

? b. PA settings reviewed.

? c. Alarm settings reviewed.

? d. Alarm report reset (ALA=0, press Enter).

? 4. RF performance checked.

Table 4-1. Setup Checklist

4.2 Connecting a Terminal

The MR Booster can communicate with a PC running a terminal-emulation program

such as ProComm, or a conventional ASCII, RS-232 terminal.

1. Using the supplied serial cable, connect the PC COM PORT to J-1 on the

controller board (see Figure 3-4 on Page 22).

2. Power up the terminal and set it to the following parameters:

• 9600 baud

• Non parity

• 8 data bits, 1 stop bit

• Full duplex (no local echo)

• Send carriage return only

• Disable AUTO XON/XOFF

NOTE: Some terminal emulation programs generate extraneous characters that

may cause interference when communicating with the booster.

Page 28 MR Booster Manual (MN001808-1, 7/99)

3. Power up the MR Booster. After about two seconds, the terminal should respond

with a welcome message.

• If the response is garbled, check the terminal setup.

• If there is no response, turn the booster OFF, then ON again. If there is still

no response, turn the unit OFF. Recheck the power hookup and the terminal

hookup and configuration.

4.3 Basic Commands

Following are basic rules and key commands for use with the MR Booster operating

software.

Symbol Definition

4. Setting Up for Initial Operation

>

<CTRL>

<ESC>

4.3.1 Syntax

System commands consist of three letters followed by a maximum of three

data fields, as follows:

COM [FIELD 1 -] [FIELD 2 =] [FIELD 3] Enter

• COM: Three-letter command.

• FIELD 1: Up to four hex characters followed by a dash (-).

• FIELD 2: Up to four hex characters followed by an equal (=) sign.

• FIELD 3: Up to two hex characters.

Command Prompt. The system uses this prompt character to indicate

it is ready to accept commands.

Control Key. Used in combination with other keys.

Escape Key. Escape is a single key marked ESC on most keyboards.

Table 4-2. Command Definitions

• Enter: Press the Enter key after each command.

NOTE: Few commands require entry of data fields. After a command has

been entered, the system will prompt for data it needs. The system will ignore

unneeded data fields.

MR Booster Manual: (MN001808-1, 7/99) Page 29

4. Setting Up for Initial Operation

4.3.2 Entering Commands

When entering commands:

• After the three-letter command has been entered, spaces may be added to

separate the fields.

• Leading zeros may be omitted.

• Use DELETE or BACKSPACE to correct mistakes.

• Press Enter at the end of each command.

4.3.3 Commonly Used Commands

Table 4-3 lists the most commonly used commands. The most complex

command is SET. This command is structured to ensure that parameter entry

can be done easily and accurately. The other commands, which are much

simpler, require little or no subsequent data input. Their actions are completed

in a matter of seconds.

NOTE: To become familiar with these commands, try each command

(except SET) and observe the system's response.

CAUTION: RES will momentarily interrupt any calls

currently being boosted. Otherwise, the system commands do

not interfere with calls being boosted.

Page 30 MR Booster Manual (MN001808-1, 7/99)

Command Meaning Purpose

4. Setting Up for Initial Operation

HEL

HEL A

SET

SSS

ALA

RES

PWR

Help Lists the syntax and function of the primary

commands.

Help All Lists the syntax and function of all commands.

Set up

Prompts a menu-driven entry mode used to inspect

or change all MR Booster operating parameters.

(To exit this command, press <CTRL> X and answer

N, press Enter.)

Show System Status

Lists current repeater parameter settings and

conditions of monitored input parameters.

Alarm report Reports on number of alarm conditions since last

system reset.

Reset Resets the booster. Parameters in effect when the

command is issued will be saved.

Power display Repeatedly lists power readings on the PAs.

(To exit this command, press <ESC> or <CTRL> Z.)

Table 4-3. System Commands

4.3.4 Escaping From Continuous Cycles

Some commands, such as RSS, enter a mode in which the program does

something continuously. To get out of this mode and return to the command

prompt, press <ESC> or <CTRL> Z.

4.3.5 Ending a Session

The RES command preserves extensive parameter changes made during a

session. It ensures that all parameter changes take effect, since all hardware is

initialized after a reset. Also, all alarms conditions counter to 0.

MR Booster Manual: (MN001808-1, 7/99) Page 31

4. Setting Up for Initial Operation

MAIN MENU AMPLIFIERS

POWER SUPPLIES

ACCESSORIES

ALARMS

LNA ATTENUATOR SETTING

POWER SUPPLY 1-2

FAN CON TROL

VSWR

MAX POWER SUPPLY TEMP

MAX PA TEMP

EXTERNAL I/O

CRITICAL ALARMS

TYPE

MAX POWER ALARM POINT

MIN POWER ALARM POINT

POWER SUPPLY TYPE

DIGITAL INPUT ALARM STATE

ANALOG INPUT THRESHOLD

ANALOG INPUT ALARM STATE

OUTPUT 1 STATE

OUTPUT 2 STATE

PA POWER HI ALARM

PA POWER LO ALARM

PA TEMP HI ALARM

PA OUT OF SERVICE ALARM

PA OVERCURRENT/OVERDRIVE ALARM

AC POWER LOST ALARM

POWER SUPPLY REGULATION ALARM

VSWR HI ALARM

DOOR OPEN ALARM

EXTERNAL DIGITAL INPUT TRIPPED

EXTERNAL ANALOG INPUT TRIPPED

EXTERNAL ROM ALARM

EEPROM ALARM

Figure 4-1. SET Command Menu Map

4.4 Using SET Menus

Use the local terminal to configure the MR Booster. From the command prompt (>),

the SET command launches the setup utility, which displays a progression of menus.

The menus provide a guided path to each booster parameter. The menu map in

Figure 4-1 illustrates the SET menu paths. For descriptions of all SET menus and

commands, see Appendix A, Control Software.

4.4.1 Moving Forward

After each command has been entered, a menu is displayed, with a character

in front of each item. To select an item, type the character and press Enter.

The next menu (or the parameter to be changed) will be displayed.

Page 32 MR Booster Manual (MN001808-1, 7/99)

4.4.2 Moving Backward

To move backward along a path, type X and press Enter. This indicates a

"Done with this menu" selection. The previous menu will be displayed.

Continue to back out to the main SET menu.

4.4.3 Exiting

To exit SET, press <CTRL> X at any menu level. Or, type X and press

Enter while at the main menu level.

4.5 Setting Initial Parameters

The MR Booster is shipped with the filters set to default center frequencies. Before

operating the unit, set initial parameters. This includes:

• Checking system status.

• Configuring the system for narrowband or wideband (channel number, band

offset, and gain).

4. Setting Up for Initial Operation

• Reviewing and recording power amplifier and alarm settings.

Setting these parameters is the minimum required to provide performance. All

parameters can be changed to fine-tune the system as more information is gathered

about system performance.

4.5.1 Checking System Status

Check the system status to be sure parameters were properly set after factory

testing.

1. At the > prompt, type SSS, press Enter. (The current state of various

parameters is displayed.)

2. At the > prompt, type ALA Enter. (The number of alarm conditions

since last reset is displayed.)

No alarms should be listed. If there are any Out-of-Service or memory

alarms, refer to Section 5, Troubleshooting.

4.5.2 Setting PA Parameters

From the Main Menu, type B, press Enter to display the Power Amplifiers

Menu.

MR Booster Manual: (MN001808-1, 7/99) Page 33

4. Setting Up for Initial Operation

Power Amplifiers Menu

A Downlink PA Power High Alarm Point...................... +33 43 dBm

B Downlink PA Power Low Alarm Point ...................... +20 dBm

Use the following guidelines and recommendations to set the power amplifier

parameters. These settings should provide serviceable operation. Refer to

Section 3.5, System Optimization, to fine-tune and optimize the settings.

Downlink PA Power High Alarm Point: Set to + 33 43 dBm to trigger an

alarm at that setting.

Downlink PA Power Low Alarm Point: Must be set to 6 dB below the

Forward Maximum Wideband Power. Once initial operation is established,

use the SSS command (see Appendix A, SSS Command) to examine the

downlink PA power output under normal operating conditions. Adjust the

downlink PA Power Low Alarm Point to a few dB below the normal

operating power.

Page 34 MR Booster Manual (MN001808-1, 7/99)

Section 5. Troubleshooting

5.1 Introduction

This section describes methods for locating and resolving problems in an MR

Booster. Instructions are given for replacing some of the major modules in the

system; however, it is recommended that Mikom technical support personnel perform

all MR Booster maintenance. Please call 1 (800) 800-3224 for assistance.

5.2 System Status Indicators

The MR Booster has visual indicators on the logic controller and the power supplies

that are the first indicators of basic system functionality. All other troubleshooting

tools are contained within the user software.

5.2.1 Logic Controller LED Indicators

A green and a red LED on the logic controller board indicate the following

conditions:

Green LED Red LED Operational State

Pulsing OFF Normal state, no alarms.

OFF ON Indicates power applied, but operational

software is not running properly.

OFF OFF No +12 VDC

Table 5-1. Logic controller status indicators

MR Booster Manual (MN001808-1, 7/99) Page 35

5. Troubleshooting

DC system power before servicing.

5.2.2 Power Supply LED Indicators

Each power supply has two green LEDs, which indicate:

AC GOOD DC GOOD BDASTATUS

ON OFF AC input present; DC output not functioning

ON ON AC input present; DC +26 V/+12 V outputs

properly.

OK.

OFF OFF

OFF ON AC power not present; DC input present and

AC power not present; DC source not present

or out of proper voltage range.

+26 V/12 V outputs OK.

Table 5-2. Logic controller status indicators

5.2.3 Logic Controller Software Alarms and Monitoring Parameters

The SSS command, which displays the general status of the booster modules,

and the SET command, which is used to monitor or set operating parameters,

can be used to find component failures. See Section 4 and Appendix A for a

detailed description of the software. Please contact Technical Support at 1

(800) 800-3224 for assistance in troubleshooting system problems.

5.3 Removing and Replacing Failed Parts

It is recommended that only higher failure rate and easily accessible items be

removed from the booster cabinet. The supplied 3mm T-handle wrench may be used

to remove and/or replace a power supply or power amplifier.

Other hardware can be removed from the booster with either standard-size metric

Allen keys or Phillips screwdrivers.

Page 36 MR Booster Manual (MN001808-1, 7/99)

WARNING! It is recommended that trained Mikom technicians

provide service for the MR Booster. Always remove both AC and

6.1 Specifications

This section provides mechanical and electrical specifications for the MR Booster.

Mechanical Specifications

Section 6. Specifications

Dimensions

Weight

(approximate, fully populated)

Operating temperature

Alarm outputs

(user configurable – available

through I2C/alarm gland)

RF I/O

(7-16 female connectors)

Other I/O

(4 weatherproof glands)

742 mm (H) x 466 mm (W) x 287 mm (D), with fans

(29.2 in x 18.3 in x 11.3 in)

535 mm (H) x 466 mm (W) x 287 mm (D), without fans

(21.1 in x 18.3 in x 11.3 in)

51 kg (112 lbs), 4 PAs, with fans

45 kg, (99 lbs) 2 PAs without fans

-30°C to +55°C

Alarm 1: Closed relay contact indicates alarm state

Alarm 2: Closed relay contact pair indicates system

alarm state

Repeater UL/DL

Mobile Antenna

UL diversity input (optional)

UL diversity output (optional)

Repeater DL only (optional)

AC input

DC input

BBU alarm

I2C/alarm

Table 6-1. Mechanical specifications

MR Booster Manual (MN001808-1, 7/99) Page 37

6. Specifications

Electrical Specifications

Power requirements 90-265 Vac, 50-60 Hz: 600 W max (fully loaded)

Automatic switchover to BBU with loss of AC mains

21-26 Vdc, 20 A max (fully loaded)

Frequency bands

(uplink/downlink)

Downlink gain

Downlink gain

variation

Uplink attenuation

setting

(main and diversity)

Uplink gain variation

Uplink noise figure

(main and diversity)

Uplink input IP

3

(main and diversity)

Downlink output power

per communication

format

(typical performance at

25°C)

AMPS800 full band: 824-849/869-894 MHz

LMR8-00 full band: 806-824/851-869 MHz

PCS1900 ADB band: 1850-1885/1930-1965 MHz

PCS1900 extended EFC band: 1875-1910/1955-1990 MHz

20 dB nominal, 19 dB minimum at upper band edge

±1 dB over any frequency band at 25°C

±2 dB over -30°C to +55°C ambient

0 dB to 15 dB from maximum gain in monotonic 1 dB steps

±1 dB over any frequency band at 25°C

±2 dB over -30°C to +55°C ambient

3 dB typical at 0 dB attenuation

10 dBm typical

# of

carriers

GSM1900,

analog:

TDMA:

med/high pwr

CDMA, iDEN:

med/high pwr

med/high pwr

1 42.5* 45.0* 42.5 45.0 39.5 42.0

2 39.5 42.0 36.5 39.0 33.5 36.0

4 35.5 38.0 32.5 35.0 30.5 33.0

8 31.5 34.0 29.5 32.0 27.5 30.0

Table 6-2. Electrical specifications

* Limited by maximum PA current.

Page 38 MR Booster Manual (MN001808-1, 7/99)

Electrical Specifications (Continued)

6. Specifications

Control modes

Control parameters

Monitor parameters

Module alarms

Stand-alone serial mode: Uplink gain, booster control, and

monitor signals passed via DB-9 connector on controller PCB

(pre-operational), alarms outputs available via I2C/alarm gland

(operational).

Repeater control: All booster control and monitor functions

maintained through MR-701/801 repeater software with

communication via I2C bus.

Stand-alone manual mode: Uplink gain set via switch on

controller PCB, alarms outputs available via I2C/alarm gland.

PA 1-4 shutdown

Fan 1, 2 speed control (high, low, off)

Uplink LNA attenuation setting (0-15 dB)

PA 1-4 output power

PA 1-4 temperature

Power supply 1, 2 temperature

Power supply average DC output voltages (+26 V, +12 V)

PA 1-4 shutdown

ac mains 1, 2 power absent

Table 6-2. Electrical specifications (Continued)

Indoor

MR Booster Manual (MN001808-1, 7/99) Page 39

MR Booster Manual

Appendices

Order No. MN001808-1

Issue 7/99

©

Copyright 1999 Mikom

All Rights Reserved

Contents

Page

MR Booster Manual: Appendices (MN001808-1, 7/99) Page iii

Appendix A: Control Software

A.1 Introduction

Extensive monitoring software included with the MR Booster allows the installer or

service provider to control and monitor the system's performance.

This section includes a description of the terminal interface to the booster, which is

used to set parameters, monitor system status, and report and diagnose problems. It

includes procedures for entering commands and setting parameters and provides

information on interpreting the results.

For instructions on installing the MR Booster, setting initial parameters, and making

adjustments to achieve optimum performance, refer to Section 3, Installation, and

Section 4, Setting Up for Initial Operation.

A.2 Connecting a Terminal

The MR Booster can communicate with a PC running a terminal-emulation program

such as ProComm, or a conventional ASCII, RS-232 terminal.

1. Using the supplied serial cable, connect the PC COM PORT to J-1 on the

controller board (see Figure X-X).

2. Power up the terminal and set it to the following parameters:

• 9600 baud

• Non parity

• 8 data bits, 1 stop bit

• Full duplex (no local echo)

• Send carriage return only

• Disable AUTO XON/XOFF

NOTE: Some terminal emulation programs generate extraneous characters that

may cause interference when communicating with the booster.

MR Booster Manual: Appendices (MN001808-1, 7/99) Page A-1

A. Software Control

3. Power up the MR Booster. After about two seconds, the terminal should respond

with a welcome message.

• If the response is garbled, check the terminal setup.

• If there is no response, turn the booster OFF, then ON again. If there is still

no response, turn the unit OFF. Recheck the power hookup and the terminal

hookup and configuration.

A.3 Basic Commands

Following are basic rules and key commands for use with the MR Booster operating

software.

Symbol Definition

>

<CTRL>

<ESC>

A.3.1 Syntax

System commands consist of three letters followed by a maximum of three

data fields, as follows:

COM [FIELD 1 -] [FIELD 2 =] [FIELD 3] Enter

• COM: Three-letter command.

• FIELD 1: Up to four hex characters followed by a dash (-).

• FIELD 2: Up to four hex characters followed by an equal (=) sign.

• FIELD 3: Up to two hex characters.

Command Prompt. The system uses this prompt character to indicate

it is ready to accept commands.

Control Key. Used in combination with other keys.

Escape Key. Escape is a single key marked ESC on most keyboards.

Table A-1. Command Definitions

• Enter: Press enter at the end each command.

NOTE: Few commands require entry of data fields. After a command has

been entered, the system will prompt for data it needs. The system will ignore

unneeded data fields.

Page A-2 MR Booster Manual: Appendices (MN001808-1, 7/99)

A.3.2 Entering Commands

When entering commands:

• After the three-letter command has been entered, spaces may be added to

separate the fields.

• Leading zeros may be omitted.

• Use DELETE or BACKSPACE to correct mistakes.

• Press Enter at the end of each command.

A.3.3 Commonly Used Commands

Table A-2 lists the most commonly used commands. The most complex

command is SET. This command is structured to ensure that parameter entry

can be done easily and accurately. The other commands, which are much

simpler, require little or no subsequent data input. Their actions are completed

in a matter of seconds.

A. Software Control

NOTE: To become familiar with these commands, try each command

(except SET) and observe the system's response.

CAUTION: RES will momentarily interrupt any calls

currently being boosted. Otherwise, the system commands do

not interfere with calls being boosted.

MR Booster Manual: Appendices (MN001808-1, 7/99) Page A-3

A. Software Control

Command Meaning Purpose

HEL

HEL A

SET

SSS

ALA

RES

PWR

Help Lists the syntax and function of the primary

commands.

Help All Lists the syntax and function of all commands.

Set up

Prompts a menu-driven entry mode used to inspect

or change all MR Booster operating parameters.

(To exit this command, press <CTRL> X and answer

N, press Enter.)

Show System Status

Lists current repeater parameter settings and

conditions of monitored input parameters.

Alarm report Reports on number of alarm conditions since last

system reset.

Reset Resets the booster. Parameters in effect when the

command is issued will be saved.

Power display Repeatedly lists power readings on the PAs.

(To exit this command, press <ESC> or <CTRL> Z.)

Table A-2. System Commands

A.3.4 Escaping From Continuous Cycles

Some commands, such as RSS, enter a mode in which the program does

something continuously. To get out of this mode and return to the command

prompt, press <ESC> or <CTRL> Z.

A.3.5 Ending a Session

The RES command preserves extensive parameter changes made during a

session. It ensures that all parameter changes take effect, since all hardware is

initialized after a reset. Also, all alarms conditions counter to 0.

Page A-4 MR Booster Manual: Appendices (MN001808-1, 7/99)

A.4 SET Command

From the command prompt (>), the SET command launches the setup utility, which

displays a progression of menus. The menus provide a guided path to each booster

parameter. The menu map in Figure A-1 illustrates the SET menu paths. Table A-3

summarizes the alarm parameters that can be programmed using the SET command.

• Moving Forward: After each command has been entered, a menu is displayed,

with a character in front of each item. To select an item, type the character and

press Enter. The next menu (or the parameter to be changed) will be displayed.

• Moving Backward: To move backward along a path, type X and press Enter.

This indicates a "Done with this menu" selection. The previous menu will be

displayed. Continue to back out to the main SET menu.

• Exiting: To exit SET, press <CTRL> X at any menu level. Or, type X and press

Enter while at the main menu level.

A. Software Control

MR Booster Manual: Appendices (MN001808-1, 7/99) Page A-5

A. Software Control

Figure A-1. SET Command Menu Map

Page A-6 MR Booster Manual: Appendices (MN001808-1, 7/99)

A. Software Control

Parameter Options Default Description

PA TEMP - HIGH ALARM POINT 0 (Disabled)

1−100° C

DC POWER - LOW ALARM POINT 0 (Disabled)

0.1−14.9 Volts

AC POWER LOST - ALARM POINT 0 (Disabled)

1−250

PS TEMP ALARM Enabled

Disabled

DOOR OPEN ALARM Enabled

Disabled

EXTERNAL ANALOG INPUT

ALARM STATE (For each of 3 inputs)

EXTERNAL DIGITAL INPUT ALARM

STATE (For each of 3 inputs)

EXTERNAL DIGITAL OUTPUT

CURRENT STATE (For 2 outputs)

0−5 volts

(0) Disabled

(1) Above threshold

(2) Below threshold

(0) Disabled

(1) High

(2) Low

(1) High

(2) Low

(3) High if alarm. . .

(4) Low if alarm. . .

90° C

10.0 Volts Alarm thresholds for power supply

10 x 0.1

minutes

Enabled Enables alarm for power supply

Enabled Enables door open alarm.

0.0 Vdc Defines alarm condition on the

Disabled Defines alarm conditions on the

Disabled Defines alarm conditions on the

Low Defines state of the two general-

Defines PA temperature alarm

condition.

voltages

Defines duration of no ac for alarm.

over temperature.

three analog inputs.

three analog inputs.

three general-purpose inputs.

purpose outputs.

Parameter Options Default Description

CRITICAL ALARMS:

PA Out-of-Service Alarm

PA Temp - High Alarm

PA Power - Low Alarm

ROM Alarm

RAM Alarm

NOVRAM Alarm

PS Voltages - Low Alarm

AC Power Lost Alarm

PS Temp Alarm

Door Open Alarm

External Analog Input Alarm

External Digital Input - Alarms

Log only or

Critical

Critical

Critical

Critical

Critical

Critical

Critical

Critical

Critical

Critical

Critical

Critical

Critical

"Log only" alarm

occurrences will be logged;

total number of occurrences

can be viewed using the

ALA command.

"Critical" alarms will not

only be logged, but also ???

Table A-3. Alarm Parameters

MR Booster Manual: Appendices (MN001808-1, 7/99) Page A-7

A. Software Control

A

A.4.1 Main Menu

Entry: At the > prompt, type SET, press Enter.

Menu:

Main Setup Menu

B Power Amplifiers Menu

D Alarms Menu

E Set Defaults

Purpose: Gives access to setup menus.

NOTE: Use caution with selection E, Set Defaults.

A.4.2 Power Amplifiers Menu

Entry: From the Main Menu, at the > prompt, type B, press Enter.

Menu:

Power Amplifiers Menu Default

Forward PA Power High Alarm Point ................................ ..+33 dBm

B Forward PA Power Maximum AGC Threshold...................... +31 dBm

C Forward PA Power Low Alarm Point................................ ....+20 dBm

D Reverse PA Power High Alarm Point................................ ....+33 dBm

E Reverse PA Power Maximum AGC Threshold...................... +31 dBm

F Reverse PA Power Low Alarm Point................................ .....DISABLED

Purpose: Gives access to each PA parameter.

A: Forward PA Power High Alarm Point

Entry: From the Power Amplifiers Menu, type A, press Enter.

Purpose: To define the maximum acceptable RF power output. If the

level exceeds that figure, an alarm will be logged.

Options:

• Allowable range: +20 to +35 dBm

• Default: +33 dBm

Page A-8 MR Booster Manual: Appendices (MN001808-1, 7/99)

B: Forward PA Power Maximum AGC Threshold

Entry: From the Power Amplifiers Menu, type B, press Enter.

Purpose: To set the RF power level at which the booster will begin to

cut back gain. If this level is exceeded, the gain is reduced by 4 dB

every Gain Control Period until the RF power level is below the AGC

threshold or until the PA is shut down.

Options:

• Allowable range: +20 to +35 dBm

• Default: +31 dBm

C: Forward PA Power Low Alarm Point

Entry: From the Power Amplifiers Menu, type C, press Enter.

Purpose: To define the minimum acceptable RF power output. If the

level exceeds that figure, an alarm will be logged.

A. Software Control

Options:

• Allowable range: +20 to +35 dBm

• Default: +20 dBm

NOTE: The system will not log a PA Power Low Alarm if there is

not sufficient input RSSI to drive the amplifier with the current gain.

D: Reverse PA Power High Alarm Point

Entry: From the Power Amplifiers Menu, type D, press Enter.

Purpose: To define the maximum acceptable RF power output. If the

level exceeds that figure, an alarm will be logged.

Options:

• Allowable range: +20 to +35 dBm

• Default: +33 dBm

MR Booster Manual: Appendices (MN001808-1, 7/99) Page A-9

A. Software Control

A

E: Reverse PA Power Maximum AGC Threshold

F: Reverse PA Power Low Alarm Point

Entry: From the Power Amplifiers Menu, type E, press Enter.

Purpose: To set the RF power level at which the booster will begin to

cut back gain. If this level is exceeded, the gain is reduced by 4 dB

every Gain Control Period until the RF power level is below the AGC

threshold or until the PA is shut down.

Options:

• Allowable range: +20 to +35 dBm

• Default: +31 dBm

Entry: From the Power Amplifiers Menu, type F, press Enter.

Purpose: To define the minimum acceptable RF power output. If the

level exceeds that figure, an alarm will be logged.

Options:

• Allowable range: +20 to +35 dBm

• Default: Disabled

NOTE: The system will not log a PA Power Low Alarm if there is

not sufficient input RSSI to drive the amplifier with the current gain.

A.4.3 Alarms Menu

Entry: From the Main Menu, at the > prompt, type D, press Enter.

Menu:

Alarms Menu Default

PA Temp – High Alarm Point ................................ .............. 90° C

C DC Power – Low Alarm Point................................ .............. 10.0 V

D AC Power Lost – Alarm Point ................................ .............. 10 (x 0.1 Min)

E PS Temp Alarm................................ ................................ ...ENABLED

F Door Open Alarm................................ ................................ ENABLED

G External Analog Inputs Menu

H External Digital Inputs Menu

I External Digital Outputs Menu

J Critical Alarms Menu

Purpose: Gives access to parameters that generate alarm conditions. Each

condition may be designated “log only” or “critical.”

Page A-10 MR Booster Manual: Appendices (MN001808-1, 7/99)

A: PA Temp – High Alarm Point

Entry: From the Alarms Menu, type A, press Enter.

Purpose: To define the maximum acceptable PA temperature.

Temperatures above this limit will cause an alarm to be logged.

Options:

• Allowable range: 0-200º C

• Default: 90º C

C: DC Power – Low Alarm Point

Entry: From the Alarms Menu, type C, press Enter.

Purpose: To specify the +12 V supply voltage alarm threshold. An

alarm is generated if the +12 V reading is equal to or lower that this

voltage. This alarm indicates a problem with the power supply,

harness wiring, or connectors.

A. Software Control

Options:

• Allowable range: 0 (Disabled), 0.1 to 14.9 V

• Default: 10.0 V

D: AC Power Lost Alarm Point

Entry: From the Alarms Menu, type D, press Enter.

Purpose: To specify the duration of an AC power outage that will

cause an alarm to log.

Options:

• Allowable range: 0 (Disabled), 1 to 250 X 0.1 Minutes

• Default: 10 X 0.1 Minutes

E: PS Temp Alarm

Entry: From the Alarms Menu, type E, press Enter.

Purpose: To enable or disable the alarm for the power supply over

temperature.

Options:

• Allowable range: Enabled or Disabled

• Default: Enabled

MR Booster Manual: Appendices (MN001808-1, 7/99) Page A-11

A. Software Control

3

Ext. Analog Input 3 Alarm State

..........

DISABLED

;Input Currently 0.0 Volts

F: Door Open Alarm

G: External Analog Inputs Menu

Entry: From the Alarms Menu, type F, press Enter.

Purpose: To enable or disable the door open alarm.

Options:

• Allowable range: Enabled or Disabled

• Default: Enabled

NOTE: The Door Open Alarm will not log for 10 minutes after an

ALA=0 or RES command. This will allow the operator time to

disconnect the local terminal and close the door.

Entry: From the Alarms Menu, type G, press Enter.

Menu:

External Analog Inputs Menu Default Values

1 Ext. Analog Input 1 Alarm State .......... DISABLED ;Input Currently 0.0 Volts

2 Ext. Analog Input 2 Alarm State .......... DISABLED ;Input Currently 0.0 Volts

Purpose: Allows setting of the alarm conditions for the external

analog inputs. Up to three analog inputs may be connected (see

Section 3.3.4.

Options:

• Allowable entries:

(0) DISABLED

(1) ABOVE

(2) BELOW

• The input alarm points are individually controllable; if above or

below is selected, a threshold between 0.1 and 5.0 V may be

specified.

• Default: (0) DISABLED

Page A-12 MR Booster Manual: Appendices (MN001808-1, 7/99)

A. Software Control

H: External Digital Inputs Menu

Entry: From the Alarms Menu, type H, press Enter.

Menu:

External Digital Inputs Menu Default Values

1 Ext. Digital Input 1 Alarm State ........... DISABLED ;Input Currently HIGH

2 Ext. Digital Input 2 Alarm State ........... DISABLED ;Input Currently HIGH

3 Ext. Digital Input 3 Alarm State ........... DISABLED ;Input Currently HIGH

Purpose: Allows setting of the alarm conditions for the external

digital inputs. Up to three digital inputs may be connected (see

Section 3.3.4).

Options:

• Allowable entries:

(0) DISABLED

(1) HIGH

(2) LOW

• Default: (0) DISABLED

I: External Digital Outputs Menu

Entry: From the Alarms Menu, type I, press Enter.

Menu:

External Digital Inputs Menu Default Values

1 Ext. Digital Output 1 State ................................ ........... LOW

2 Ext. Digital Output 2 State ................................ ........... LOW

Purpose: Allows setting of the state for the external digital outputs.

Up to two digital outputs may be connected. The outputs may be used

to control external equipment (see Section 3.3.4). Also, options (1)

and (2) support using external monitoring equipment to be connected

to the MR Booster.

Options:

• Allowable entries:

(0) LOW

(1) LOW IF CRITICAL ALARM EXISTS

(2) HIGH IF CRITICAL ALARM EXISTS

(3) HIGH

• Default: (0) LOW

MR Booster Manual: Appendices (MN001808-1, 7/99) Page A-13

A. Software Control

N

J: Critical Alarms Menu

Entry: From the Alarms Menu, at the > prompt, type J, press Enter.

Menu:

Critical Alarms Menu Default

J PA OUT-OF-SERVICE ALARM ................................ ........CRITICAL

K PA TEMP – HIGH ALARM ................................ ................ CRITICAL

L PA POWER – HIGH ALARM ................................ ............. CRITICAL

M PA POWER – LOW ALARM................................ .............. CRITICAL

ROM ALARM................................ ................................ ....CRITICAL

P NOVRAM ALARM................................ ............................ CRITICAL

Q POWER SUPPLY VOLTAGE – LOW ALARM................... CRITICAL

R AC POWER LOST ALARM................................ ................ CRITICAL