User’s Manual

for

MMR8L L

Single Band Remote Unit

ID No: 163511 Page 1

© Copyright 2005 Mikom GmbH

All rights reserved.

User’s Manual for Remote Unit

MMR8L L

All information contained in this manual has been revised thoroughly. Yet Mikom

accepts no liability for any omissions or faults.

Mikom reserves the right to change all hard- and software characteristics without

notice.

Names of products mentioned herein are used for identification purposes only and

may be trademarks and/or registered trademarks of their respective companies.

No parts of this publication may be reproduced, stored in a retrieval system,

transmitted in any form or by any means, electronical, mechanical photocopying,

recording or otherwise, without prior written permission of the publisher.

Mikom GmbH An Andrew Company, 27-January-2005

Page 2 M0106ASB.doc

TABLE OF CONTENTS

1. GENERAL 5

1.1. USED ABBREVIATIONS 5

1.2. HEALTH AND SAFETY WARNINGS 6

1.3. PREAMBLE 8

1.4. INTERNATIONAL CONTACT ADDRESSES 9

2. INTRODUCTION 11

2.1. PURPOSE 11

2.2. THE MMR8L L SINGLE BAND REMOTE UNIT 11

3. FUNCTIONAL DESCRIPTION 13

3.1. GENERAL 13

3.2. COMPONENTS OF THE MMR8L L REMOTE UNIT 14

4. INSTALLATION 15

4.1. MECHANICAL INSTALLATION 15

4.1.1. General 15

4.1.2. Wall and Pole Mounting 16

4.2. ELECTRICAL INSTALLATION 17

4.2.1. General 17

4.2.2. Connections 18

4.2.3. Grounding 18

4.2.4. Power Connection 19

4.2.5. Connection of the Antenna Cables 20

4.2.6. Optical Fibre Cable Connection 20

4.2.7. Protective Tube Kit 24

5. COMMISSIONING 27

5.1. GENERAL 27

5.2. AUTO-LEVELLING 27

6. ALARMS 29

6.1. BITE AND ALARMS 29

6.2. HANDLING OF ALARMS 29

6.3. ALARM STATUS 29

6.4. LED ALARMS 30

6.5. EXTERNAL ALARM INPUTS AND OUTPUTS 31

6.6. TROUBLESHOOTING 32

ID No: 163511 Page 3

User’s Manual for Remote Unit

MMR8L L

7. MAINTENANCE 33

7.1. MAINTENANCE 33

7.2. GENERAL 34

7.3. REPLACEMENT OF POWER SUPPLY 35

8. APPENDIX 37

8.1. LAYOUT 37

8.2. SPECIFICATIONS 38

8.2.1. Electrical Specifications 38

8.2.2. Environmental and Safety Specifications 39

8.2.3. Mechanical Specifications 40

8.3. PARTS LIST 40

9. INDEX 41

10. LIST OF CHANGES 42

FIGURES AND TABLES

figure 3-1 Configuration of an MMR8L L remote unit................................................ 13

figure 3-2 MMR8L L, base........................................................................................ 14

figure 3-3 MMR8L L, lid ............................................................................................ 14

figure 4-1 Wall mounting........................................................................................... 16

figure 4-2 Pole mounting .......................................................................................... 16

figure 4-3 Connector flange...................................................................................... 18

figure 4-4 Grounding bolt.......................................................................................... 18

figure 4-5 AC mains plug.......................................................................................... 19

figure 4-6 DC mains plug.......................................................................................... 19

figure 4-7 Protective plug assembly.......................................................................... 22

figure 4-8 Tube kit installation................................................................................... 25

figure 6-1 Connecting board..................................................................................... 31

figure 7-1 Locker with key......................................................................................... 34

figure 7-2 Front and top cover screws...................................................................... 34

figure 7-3 Position of mains power switch................................................................. 34

figure 7-4 Power supply screws................................................................................ 35

figure 8-1 Layout of the remote unit.......................................................................... 37

table 1-1 List of international contact addresses......................................................... 9

table 6-1 LED alarms................................................................................................ 30

table 7-1 Specified torques for various screw types ................................................. 33

Page 4 M0106ASB.doc

1 General

1. GENERAL

1.1. USED ABBREVIATIONS

ALC Automatic Level Control

AMPS American Mobile Phone System or Advanced Mobile Phone System

APAC Automatic Power Adjustment Circuit

BCCH Broadcast Control Channel

BITE Built In Test Equipment

BTS Base Transceiver Station

CDMA Code Division Multiple Access

CEPT Conférénce Européenne des Postes et Télécommunications

CF Center Frequency

CFO Center Frequency Offset

DL Downlink

EDGE Enhanced Data Rates for GSM Evolution

ESD Electrostatic Discharge

ETS European Telecommunication Standard

ETSI European Telecommunication Standards Institute

FSK Frequency Shift Keying

GSM Global System for Mobile Communication

I2C-Bus Inter Integrated Circuit Bus (Philips)

ID No Identification Number

IF Intermediate Frequency

LMT Local Maintenance Terminal

MS Mobile Station

NSO Network Supervision Option

OMC Operation and Maintenance Center

PCMCIA Personal Computer Modem Communication International Association

PCS Personal Communication System

PSTN Public Switched Telephone Network

Rev Revision

RF Radio Frequency

RLP Radio Link Protocol

RSSI Receive Signal Strength Indication

RTC Real Time Clock

RX Receiver

SCL Serial Clock

SDA Serial Data

TCH Traffic Channel

TDMA Time Division Multiple Access

TX Transmitter

UL Uplink

UMTS Universal Mobile Telecommunication System

UPS Uninterruptible Power Supply

VSWR Voltage Standing Wave Ratio

ID No: 163511 Page 5

User’s Manual for Remote Unit

1.2. HEALTH AND SAFETY WARNINGS

1. Only suitably qualified personnel is allowed to work on this unit and only after

becoming familiar with all safety notices, installation, operation and maintenance

procedures contained in this manual.

2. Read and obey all the warning labels attached to the unit. Make sure that the

warning labels are kept in a legible condition and replace any missing or

damaged labels.

3. Obey all general and regional installation and safety regulations relating to work

on high voltage installations, as well as regulations covering correct use of tools

and personal protective equipment.

4. Keep operating instructions within easy reach and make them available to all

users.

5. It is the responsibility of the network provider to implement prevention measures

to avoid health hazards which may be associated to radiation from the antenna(s)

connected to the unit.

6. For US and Canadian installations: To comply with FCC RF exposure compliance

requirements, the following antenna installation and device operating

configurations must be satisfied: A separation distance of at least 40 cm must be

maintained between the antenna of this device and all persons. RF exposure

compliance may need to be addressed at the time of licensing, as required by the

responsible FCC Bureau(s), including antenna co-location requirements of

1.1307(b)(3). Maximum permissible antenna gain, including coaxial cable loss, is

0 dBi.

7. Make sure access is restricted to qualified personnel.

8. Use this equipment only for the purpose specified by the manufacturer. Do not

carry out any modifications or fit any spare parts which are not sold or

recommended by the manufacturer. This could cause fires, electric shock or other

injuries.

9. Due to power dissipation, the remote unit may reach a very high temperature.

10. Before opening the unit or (dis-)connecting the mains connector at the remote

unit, ensure that mains supply is disconnected.

11. ESD precautions must be observed! Before commencing maintenance work, use

the available grounding system to connect ESD protection measures.

12. This unit complies with European standard EN60950.

MMR8L L

Page 6 M0106ASB.doc

1 General

13. Make sure the system settings are according to the intended use (see also

product information of manufacturer) and regulatory requirements are met.

14. Although the remote unit is internally protected against overvoltage, it is strongly

recommended to earth the antenna cables close to the remote unit’s antenna

connectors for protection against atmospheric discharge.

15. Laser radiation – Class 1! Do not stare into the beam; do not view it directly or

with optical instruments.

ID No: 163511 Page 7

User’s Manual for Remote Unit

1.3. PREAMBLE

Mikom An Andrew Company is a leading manufacturer of coverage equipment for

mobile radio networks, specializing in low cost, high performance, RF and optical

repeaters. Our optical distributed networks and RF repeater systems provide

coverage for every application: outdoor use, indoor installations, tunnels, subways

and many more.

Mikom has engineering and manufacturing facilities in Germany, Italy and the USA.

In addition, it maintains many field engineering offices throughout the world.

Mikom GmbH operates a quality management system which complies with the

requirements of ISO 9001. All equipment is manufactured using only highly reliable

materials. In order to ensure constant first-rate quality of the products, a

comprehensive quality assurance has been conducted at all fabrication stages. Every

component leaves the factory only after a thorough final acceptance test,

accompanied by a test certificate guaranteeing optimal function.

The declaration of conformity for the product is available on request via the local

offices or from Mikom GmbH An Andrew Company directly.

Any intervention must be carried out by authorized persons only. If technical

assistance for the product is required, please contact the local office or Mikom

directly at one of the following addresses:

Mikom GmbH An Andrew Company

Industriering 10

86675 Buchdorf

Germany

Phone: +49 (0) 9099 69 0

Fax: +49 (0) 9099 69 930

email: WIsupport.germany@andrew.com

for The Americas:

Mikom US An Andrew Company

Phone: +1 (919) 771-2570

email: WIsupport.us@andrew.com

When set-up is performed according to this manual, the system will operate without

complications for a significant length of time.

MMR8L L

Page 8 M0106ASB.doc

1 General

1.4. INTERNATIONAL CONTACT ADDRESSES

in Australia

6 Stuart Street

Padstow NSW 2211

Australia

Phone: +61 (2) 9774-4200

Fax: +61 (2) 9774-4500

email:

WIsupport.australia@andrew.com

in the UK

Guildgate House

Pelican Lane

Newbury

RG14 1NX, Berkshire, U.K.

Phone: +44 (1635) 569-695

Fax: +44 (1635) 569-463

email:

WIsupport.uk@andrew.com

in France

Z.I. des Ebisoires

78370 Plaisir

France

Phone: +33 (1)30-79-15-36

Fax: +33 (1) 30-55-55-37

email:

WIsupport.france@andrew.com

in China

Rm 915 Chevalier

Commercial Centre; 8 Wang

Hoi Rd; Kowloon Bay SAR,

Hong Kong

Phone: +852 3106-6100

Fax: +852 2751-7800

email:

WIsupport.china@andrew.com

in the USA

108 Rand Park Drive

Garner

NC 27529

USA

Phone: +1 (919) 771-2570

Fax: + 1 (919) 771-

email:

WIsupport.us@andrew.com

in Canada

1815 Ironstone Manor, # 12

Pickering, Ontario L1W 3W9

Canada

Phone: +1 (905) 839-3474

Fax: +1 (905) 839-4663

email:

WIsupport.canada@andrew.com

in Switzerland

Tiergartenweg 1

4710 Balsthal

Switzerland

Phone: +41 (6238) 61260

Fax: +41 (6238) 61261

email:

WIsupport.switzerland@andrew.com

in the Czech Republic

U Morusi 888

530 06 Pardubice-Svitkov

Czech. Republic

Phone: +42 (0406) 301280

Fax: +42 (0406) 301298

email:

WIsupport.czechrep@andrew.com

table 1-1 List of international contact addresses

in Italy

Via De Crescenzi 40

48018 Faenza

Italy

Phone: +39 0546 697111

Fax: +39 0546 682768

email:

WIsupport.italia@andrew.com

in Austria

Weglgasse 10

2320 Schwechat

Austria

Phone: +43 (1) 706 – 3999

Fax: +43 (1) 706 – 39999

email:

WIsupport.austria@andrew.com

ID No: 163511 Page 9

For your notes:

User’s Manual for Remote Unit

MMR8L L

Page 10 M0106ASB.doc

2 Introduction

2. INTRODUCTION

2.1. PURPOSE

Cellular telephone systems transmit signals in two directions between base

transceiver station (BTS) and mobile stations (MS) within the signal coverage area.

If weak signal transmissions occur within the coverage area because of indoor

applications, topological conditions or distance from the transmitter, extension of the

transmission range can be achieved by means of an optical distribution system.

Such a system contains an optical master unit and a remote unit. The number of the

remote unit depends on the hardware and software configuration. The remote unit is

connected to the master unit with optical links. The optical loss must be less than 10

dB inclusive optical couplers or splitters.

The master unit is the connection to the base transceiver stations. The configuration

of a master unit depends on the number of the remote units and the frequency range.

The optical transmission uses WDM-systems with a wavelength of 1550 nm in the

uplink and 1310 nm in the downlink.

2.2. THE MMR8L L SINGLE BAND REMOTE UNIT

The MMR8L L is a single-band multi-operator remote unit. It is used in conjunction

with a master unit in the MMR optical distribution system. This system transports the

whole LMR band simultaneously providing a cost effective solution for distributing

capacity from one or more base stations.

The MMR8L L transports signals on the RF layer in a very inexpensive manner. This

means that services from various operators can be transmitted simultaneously from a

cluster of base station to a remote location over the same fibre.

ID No: 163511 Page 11

For your notes:

User’s Manual for Remote Unit

MMR8L L

Page 12 M0106ASB.doc

3 Functional Description

3. FUNCTIONAL DESCRIPTION

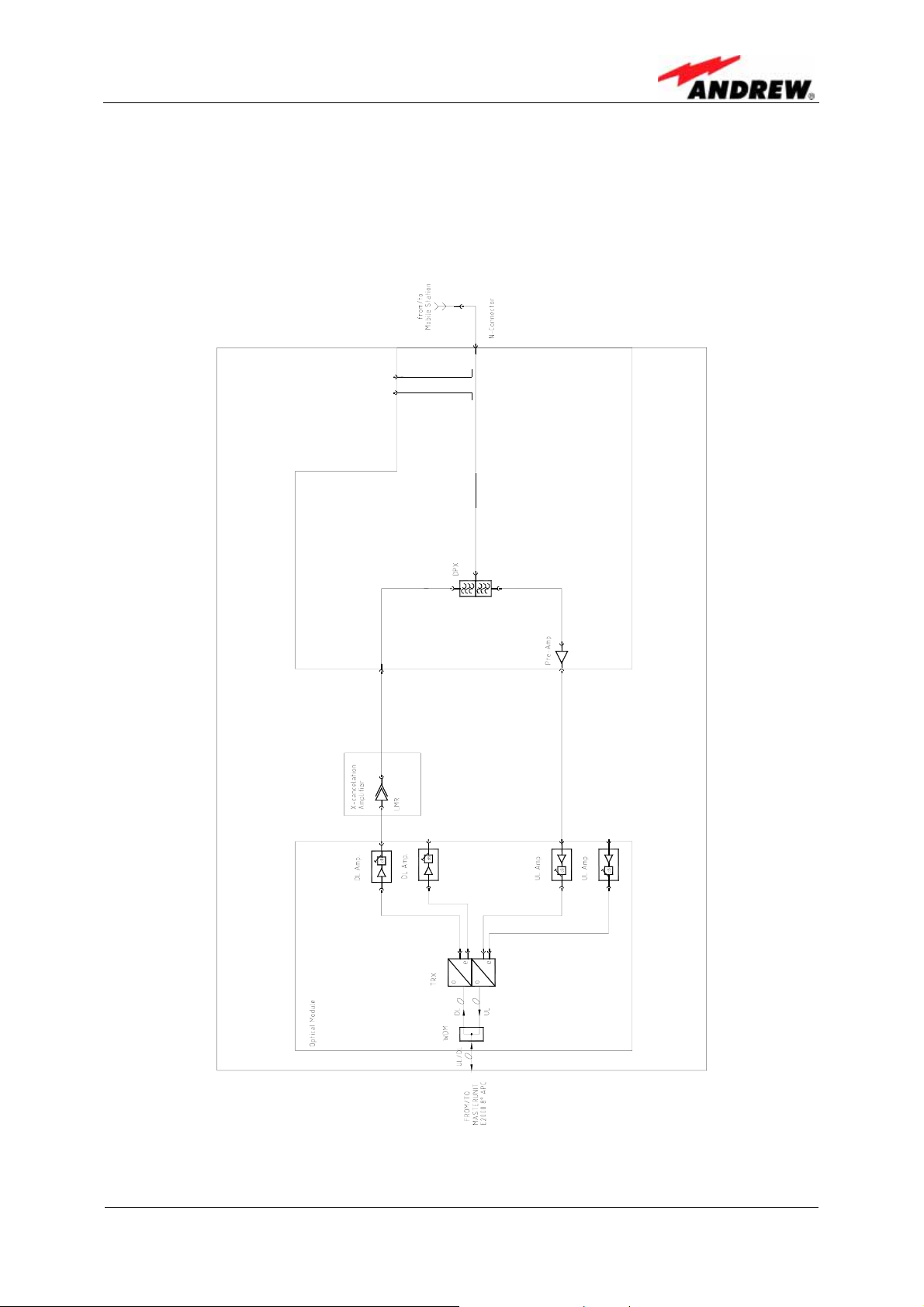

3.1. GENERAL

The following figure shows the configuration of an MMR8L L remote unit.

E1099BR

figure 3-1 Configuration of an MMR8L L remote unit

ID No: 163511 Page 13

User’s Manual for Remote Unit

MMR8L L

3.2. COMPONENTS OF THE MMR8L L REMOTE UNIT

The actual configuration of the remote unit can be seen at the configuration list which

is part of the delivery.

The following figure shows an exemplary view of an MMR8L L remote unit to

illustrate the individual components.

Final

Amplifier

Control

Board

DC/ DC

converter

Connecting

Board

Duplexer

Optical

interface

Power

Supply

figure 3-2 MMR8L L, base figure 3-3 MMR8L L, lid

Page 14 M0106ASB.doc

4 Installation

4. INSTALLATION

4.1. MECHANICAL INSTALLATION

4.1.1. General

Read the health and safety warnings in chapter 1.2 Health and Safety Warnings.

1. Do not install the unit in a way or at a place where the specifications

outlined in the Environmental and Safety Specifications leaflet of the

manufacturer are not met.

2. It is strongly recommended to install the unit vertically. If a different

installation of the remote unit is required, please contact customer service

for further information.

3. It is recommended only to use the mounting hardware delivered by the

manufacturer. If different mounting hardware is used, the specifications for

stationary use of the remote unit must not be exceeded.

) Note: Exceeding the specified load limits may cause the loss of warranty!

4. The unit is considerably heavy. Make sure that a suitable mounting

surface is used. Ensure there is adequate manpower to handle the weight of

the system.

5. Due to power dissipation, the remote unit may reach a very high

temperature. Ensure sufficient airflow for ventilation. Above and below the

unit a minimum distance of 300 mm to ceiling, floor, etc. has to be kept.

Also observe the instructions in the individual mounting procedures.

If any different or additional mounting material is used, ensure that the mounting

remains as safe as the mounting designed by the manufacturer. Ensure that the

static and dynamic strengths are adequate for the environmental conditions of the

site. The mounting itself must not vibrate, swing or move in any way that might cause

damage to the remote unit.

) Note: The remote unit is delivered with a pre-mounted front cover. This

cover is of vital importance for the passive cooling of the unit. Thus,

do not operate the unit without cover.

ID No: 163511 Page 15

User’s Manual for Remote Unit

MMR8L L

4.1.2. Wall and Pole Mounting

Wall and pole mounting equipment for the unit is available. For the according

mounting please refer to the mounting plan (drawing) that is part of the delivery.

V1628M0 V1628M1

figure 4-1 Wall mounting figure 4-2 Pole mounting

Page 16 M0106ASB.doc

4 Installation

4.2. ELECTRICAL INSTALLATION

4.2.1. General

Read the health and safety warnings in chapter 1.2 Health and Safety Warnings.

1. This unit contains dangerous voltages. Loss of life, severe personal injury or

property damage can be the result if the instructions contained in this manual are

not followed.

2. It is compulsory to ground the unit before connecting power supply. A grounding

bolt is provided on the cabinet to connect the ground bonding cable.

3. Although the remote unit is internally protected against overvoltage, it is strongly

recommended to earth the antenna cables close to the remote unit’s antenna

connectors for protection against atmospheric discharge. In areas with strong

lightning it is strongly recommended to insert additional lightning protection.

4. If the mains connector of the remote unit is not easily accessible, a separation

device in the mains circuit must be provided within easy reach.

5. Before connecting or disconnecting the mains connector at the remote unit,

ensure that mains supply is disconnected.

6. Make sure that an appropriate circuit breaker and an overcurrent limiting device

are connected between mains and remote unit.

7. A connection of mains supply to a power socket requires the power socket to be

nearby the remote unit.

8. The remote unit might be supplied from IT mains. (The maximum nominal line to

line voltage must not exceed 400VAC).

9. Incorrectly wired connections can destroy electrical and electronic components.

10. To avoid corrosion at the connectors caused by electrochemical processes, the

material of the cable connectors must not cause a higher potential difference than

0.6V (see electrochemical contact series).

11. It is sufficient to tighten the N antenna connector hand-screwed. Any use of a tool

(e.g. pair of pliers) might cause damage to the connector and thus lead to

malfunctioning of the remote unit.

12. For unstabilized electric networks which frequently generate spikes, it is advised

to use a voltage limiting device.

13. The unit complies with the surge requirement according to EN 61000-4-5 (fine

protection); however, it is recommended to install an additional medium (via local

supply connection) and/or coarse protection (external surge protection) depending

on the individual application in order to avoid damage caused by overcurrent.

14. Observe the labels on the front panels before connecting or disconnecting any

cables.

ID No: 163511 Page 17

4.2.2. Connections

User’s Manual for Remote Unit

MMR8L L

N-connector

mobile / antenna

4.2.3. Grounding

Cable gland (e.g. for

external alarms cable)

LED

figure 4-3 Connector flange

Mains

connector

Optical

connector

figure 4-4 Grounding bolt

Grounding must be carried out. Connect an earth bonding cable to the grounding

connection provided at the outside of the remote unit (see figure 4-3 Connector

flange). Do not use the grounding connection to connect external devices.

After loosening the hex nut, connect the earth bonding cable between the two

washers as illustrated in figure 4-4 Grounding bolt. Then, fasten all parts again with

the hex nut.

Page 18 M0106ASB.doc

4 Installation

4.2.4. Power Connection

Before connecting electrical power to the units, the system must be grounded as

described in the previous chapter.

Mains power must be connected at the mains connector of the unit (see figure 4-3

Connector flange).

The power supply plug is part of the delivery. The correct wiring of the power supply

plug is as follows:

G1055Z0

G1055Z0

figure 4-5 AC mains plug figure 4-6 DC mains plug

For the AC power supply connection, a minimum cross section of 1.5

2

is required and for the DC power supply connection, a minimum

mm

cross section of 2.5 mm

2

is required. Each wire must observe the

applicable national regulations regarding loop impedance, voltage drop,

and methods of installation. Make sure to connect the correct voltage to

the unit.

) Note: Do not connect or disconnect the power cord at the mains connector

while power is on. Turn off mains* power before connecting the

power cord at the remote unit, then, engage mains again.

* Mains power must be interrupted with an external mains breaker. For the mains

breaker, observe the following recommendation:

120 Volt / 20 Amp max. or 240 Volt / 16 Amp, single-phase, 50/60 Hz AC service is

needed, i.e. the external AC breaker should be 20 Amps max. for 120-Volt service or

16 Amps for 240-Volt service.

For the DC power supply, observe the local regulations of the DC service provider.

ID No: 163511 Page 19

User’s Manual for Remote Unit

4.2.5. Connection of the Antenna Cables

The remote unit has an N-type antenna connector or can be delivered with a 7/16

adapter. For its location please refer to figure 4-3 Connector flange. For mounting the

cable connectors, it is recommended to refer to the corresponding documentation of

the connector manufacturer. The bending radius of the antenna cables must remain

within the given specifications.

For the selection of cable and antenna it should be considered that a cable with

higher loss is less expensive but on the other hand it impairs performance.

It is sufficient to tighten the N-type (or 7/16) antenna connectors hand-

tight. The use of a tool (like pliers) may cause damage to the connector

and, therefore, lead to a malfunctioning of the remote unit.

4.2.6. Optical Fibre Cable Connection

In case of a backbone structure it has to be guaranteed that there is a

minimum wavelength difference of 20 nm. This will be guaranteed by

using four different optical interfaces with four different wavelengths

according to ITU grid. Thus, there are also four different remote units.

In one optical backbone, each type of unit can only be used once!

Rules for optical fibre connection

Optical signals are transmitted by use of optical fibres. When connecting these fibres

observe the following instructions.

MMR8L L

) Note: Care should be taken when connecting and disconnecting fibre

optic cables. Scratches and dust significantly affect system

performance and may permanently damage the connector. Always

use protective caps on fibre optic connectors not in use.

In general optical fibres do not need special protective measures. However,

protection against environmental influences e.g. rodents and humidity must be

considered.

The optical fibre is a single mode fibre. Type is E9/125µm with the following minimum

requirements.

Attenuation: <0.36 dB/km @ 1310 nm / <0.26 dB/km @ 1550 nm

Dispersion: <3.5 ps/nm km @ 1310 nm / <18.0 ps/nm km @ 1550 nm

Page 20 M0106ASB.doc

4 Installation

The specified bending radius of the optical fibres must not be exceeded. The pigtails

for the connection between mini master and remote unit must have a sufficient

length. A protection for the feeding into units must be given. For MMR8L L the

system attenuation of the optical fibres, including the connectors, must not exceed

10 dB.

System attenuation and attenuation of optical components must be determined. This

can be achieved by measuring attenuation and reflection with an appropriate

measuring instrument. For pigtails, a total value of < 0.4 dB (measured to a reference

plug) can be assumed due to the dead zone of the reflectometer. These

measurements must be made with a sufficient length of optical fibre, at the in- and

output of the device which has to be measured.

Fibre cable connectors have to be of the same type (E2000APC) as the connectors

used for the unit. The fibre optic cables are connected to the optical transceiver.

) Note: Angled connectors are not compatible with straight optical

connectors; non-compatibility of connectors will result in

permanent damage to both connectors.

Before connecting the fibre cables, follow the procedure below to ensure optimized

performance. It is important that these procedures are carried out with care:

¾ Remove fibre optic protective caps.

¾ Do not bend the fibre optic cable in a tight radius (< 4 cm) as this may cause

cable damage and interrupt transmission.

¾ Using high-grade alcohol and lint-free cotton cleaning swabs, clean the end of

the fibre optic cable that will be inserted in the optical connectors on the donor

interface box.

¾ Blow out the laser receptacle with clean and dry compressed air to remove

any particulate matter.

¾ Connect the fibre optic cables by inserting the cable end into the laser

receptacle and aligning the key (on the cable end) with the keyed slot.

¾ Do not use any index matching gels or fluids of any kind in these connectors.

Gels are intended for laboratory use and attract dirt in the field.

ID No: 163511 Page 21

User’s Manual for Remote Unit

4.2.6.1. Protective Plug

Connection:

A protective plug is provided for the connection of the fibre-optic cables.

MMR8L L

figure 4-7 Protective plug assembly

) Note: Only high-quality connectors must be used for this type of plug.

Qualified brands are Diamond or Huber & Suhner.

Page 22 M0106ASB.doc

4 Installation

For plug assembly observe the following instruction.

1. Pass one or two contacts through the

backshell and the clamp ring.

2. Place the contact(s) on the lower insulation body by pushing the groove of the

contact into the cavity. If there is only one contact, cavity A must be used. Cavity

B is used for the diversity path.*

3. Then, mount the upper insulation body on the lower insulation body. **

Cavity B

Cavity A

Upper insulation body

4. Bring the insulator into the plug. The narrow groove of the insulator must be fitted

into the stamp of the plug.

* To release the contact for disassembling push the inner snap to the side and pull the contact out.

** To release upper and lower insulation body for disassembling, use a small screwdriver and

carefully open the snap-connections at the left and the right side of the insulator without

damaging them.

5. Fasten the insulator by screwing the

backshell tight onto it. Use a spanner

with opening 32 to screw the

backshell tight (no gap).

6. Place the appropriate seal parts (with

one groove for one contact or two

grooves for two contacts) over the

cable(s) and push them into the

backshell.

no gap

Seals with

one groove

ID No: 163511 Page 23

User’s Manual for Remote Unit

MMR8L L

7. Bring the plastic ring over the cable(s), push it into the backshell and compress

the seals and plastic ring by screwing the clamp ring tight (no gap) using a

spanner with opening 20. ***

Screw tight till gap is closed

8. Connect the plug to the optical fibre

connector of the remote unit, again by

9. To lock the connector push the black

locking ring forward.****

fitting a stamp on the plug into the

groove of the connector.

Groove

*** For disassembling, release the clamping ring and remove the seals and the plastic ring first.

**** Locking mechanism: The system of locking the plug is based on a “push-pull” mechanism. The

locking ring has to be pushed forward to lock the connector and pulled back to free the

connection.

Push forward to lock, pull

back to free connection

4.2.7. Protective Tube Kit

As additional protection for the optical fibres, this connector type can be

supplemented by a special tube kit. To fasten the tube correctly, first unscrew the

clamp ring (if already installed) of the original plug kit.

Then, proceed according to the following instruction:

Page 24 M0106ASB.doc

4 Installation

pr ot ecti ve plug

fi br e cabl e

Pl ace the appr opr i at e s eal

par t s ( wi th) one gr oov e for

one contact or t wo gr oov es

f or two contact s ) over t he

cabl e(s ) and push t hem int o

t he back shell .

Push the fibre optic cable

carefully through the tube until

it comes out at the other end.

pl as tic ri ng

reducer

Scr ew t he reducer t o

t he protect i ve plug

backs hel l wi thout gap.

coupling

pr ot ect i v e tube

Other end of tube

G1 055M 0

figure 4-8 Tube kit installation

ID No: 163511 Page 25

For your notes:

User’s Manual for Remote Unit

MMR8L L

Page 26 M0106ASB.doc

5 Commissioning

5. COMMISSIONING

5.1. GENERAL

Read the health and safety warnings in chapter 1.2 Health and Safety Warnings as

well as the description carefully to avoid mistakes and proceed step by step as

described!

• Do not operate the remote unit without terminating the antenna connectors.

The antenna connectors may be terminated by connecting them to their

respective antennas or to a dummy load.

• Only qualified personnel should carry out the electrical, mechanical,

commissioning and maintenance activities that require the unit to be powered

on when open.

• When opening the remote unit do not damage the warranty labels on the

internal devices. The warranty is void if the seals are broken.

• Ensure that all connections have been performed according to chapter 4.2.2

Connections.

5.2. AUTO-LEVELLING

For a proper operation of the auto-levelling function, a defined level has to be set at

the optical interface (DL) of the master unit. For details refer to the software manual

of the master unit.

ID No: 163511 Page 27

For your notes:

User’s Manual for Remote Unit

MMR8L L

Page 28 M0106ASB.doc

6 Alarms

6. ALARMS

6.1. BITE AND ALARMS

The Built-In Test concept comprises the monitoring of the power supplies, the power

amplifiers and the optical interface.

All occurring alarms can be checked via software at the master unit.

6.2. HANDLING OF ALARMS

As soon as the software acknowledges a valid alarm, a message is transmitted to the

master unit.

If the reason for the alarm has been cleared or if the alarm should continue, a new

alarm message will not be repeated. If there was an interruption of at least five

seconds after acknowledgement, a new alarm message will be generated.

6.3. ALARM STATUS

For details refer to the corresponding software documentation of the Master Unit.

ID No: 163511 Page 29

User’s Manual for Remote Unit

A

MMR8L L

6.4. LED ALARMS

For local supervision, a LED on the connector flange of the remote unit gives an

indication of possible reasons for alarms. This table shows possible on-site measures

that could be checked before referring to the master unit alarm list.

LED Indication Alarms Possible on-site measures

Green

No alarm Æ

Status ok

Door alarm Close the door (RUs with door).

Alarms not directly related to RU:

External alarms

Check externally connected devices.

Check fibre loss of optical link.

Orange

Optical alarm Rx

Check optical connectors.

Clean optical connectors.

(MU: Check optical output power of

corresponding OTRx at master unit).

ALC alarm

(MU: Decrease DL input power of affected

band).

Alarms directly related to RU:

Power 28V

Temperature

Change power supply (RUs with door).

Replace the affected remote unit.

Reduce environmental temperature.

Eliminate thermal short circuit.

Disconnect and connect mains. Fans should

Red

Fan

run briefly (SW version > 2.4). If not, replace

the fans at RU.

I²C Disconnect and connect mains.

Optical alarm Tx -

mplifier “Power

Down”

(MU: Change amplifier setting at MU

controller).

Check power switch inside of RU (RUs with

LED off Mains

door).

Check mains cabling.

Check mains power.

table 6-1 LED alarms

For the position of the LED see chapter 6.4 LED Alarms.

Explicit troubleshooting is available in the MU software, (software manual or WEB

Interface).

Page 30 M0106ASB.doc

6 Alarms

6.5. EXTERNAL ALARM INPUTS AND OUTPUTS

There are four alarm inputs and four alarm outputs. The alarm outputs (open

collector output 5 V / 1 mA) are normally low. In case of an alarm they are high active

(5V). They can be used to monitor alarms with an external alarm indicator. Each

alarm output can be set individually to any alarm at the Remote Unit. For details

please refer to the according chapter in the software manual of the Master Unit.

) Note: The manufacturer/ supplier of this system accepts no liability for

damage caused by equipment connected to external outputs or by

effects from such equipment.

With the external alarm inputs, it is possible to monitor the status of connected

devices, e.g. a UPS, via software. All alarm inputs are normally high (5V) without

connection.

The device to be monitored must be connected so that the alarm contacts (contact

on the right is always GND) will be closed in case of an alarm (I max = 8 mA). The

alarm inputs are potential-free with common ground.

For the location of the external alarm inputs and outputs refer to figure 6-1

Connecting board. Settings have to be done via the MMR Master Controller and are

described in the according software documentation.

figure 6-1 Connecting board

ID No: 163511 Page 31

User’s Manual for Remote Unit

6.6. TROUBLESHOOTING

The status of the remote unit can be checked via the MMR Master Unit (for details

please refer to the software manual of the MMR Master Controller). Locally, the

status can be checked at the LED, see chapter 6.4 LED Alarms.

MMR8L L

Page 32 M0106ASB.doc

7 Maintenance

7. MAINTENANCE

7.1. MAINTENANCE

Read the health and safety warnings in chapter 1.2 Health and Safety Warnings.

) Note: The remote unit does not require preventative maintenance

measures.

Maintenance of the MMR8L L should be performed on a FRU (Field Replaceable

Unit) basis only. Do not damage the warranty labels on the components, as this voids

the warranty.

The spare parts list contains only units that can be replaced without tuning or

soldering work.

) Note: Defect parts should only be replaced by original parts from the

supplier. All interventions inside the housing are at one’s own risk.

)

Note: During maintenance ensure that the unit has been disconnected

from mains.

To open the cabinet of the MMR8L L, observe the instructions in chapter 4.1.1

General.

) Note: Before disconnecting any cables, label any unlabeled cables to

ensure correct reconnection.

To replace an FRU, use the appropriate tools. Replacement tools may be ordered

from the supplier. All screws have a right-hand thread, turn the tool clockwise for

tightening and anti-clockwise for loosening.

SMA connectors have a specified torque of 100 Ncm. Use an appropriate tool to

fasten and unfasten these connectors. Do not over-tighten the connectors or screws.

The table below shows various screws with their respective torques.

Screw Type Tallow-drop Socket head cap Countersunk head

Thread size Specified Torque (in Ncm)

M 2.0 40 not in use 40

M 2.5 82 not in use 82

M 3.0 145 100 145

M 4.0 330 330 330

M 5.0 650 tbd. 650

table 7-1 Specified torques for various screw types

) Note: Do not forget to reinstall the front cover after the replacement

procedure to ensure safe operation.

If any FRU not contained in the following chapter needs to be replaced, contact

customer service for additional instructions.

ID No: 163511 Page 33

7.2. GENERAL

Front

cover

Locker

figure 7-1 Locker with key

Three top

cover

screws

User’s Manual for Remote Unit

MMR8L L

• To open the cabinet of the remote unit, first

dismount the locker by unlocking it with the key

(which is part of the delivery) and pulling it out

carefully.

• Then remove the front cover by loosening the

four M5 socket head cap screws (circle-marked

in figure 7-2 on the left). Do not remove those

screws. When they are loosened, the front cover

can be taken off.

figure 7-2 Front and top

cover screws

Mains

power

switch

• To open the cabinet, unscrew the three M5

socket head cap screws (captive) of the top

cover of the remote unit.

• Set the mains power switch inside to On (I):

• Close the cabinet.

) Note: Do not forget to reinstall the front cover

afterwards to ensure safe operation.

• Check the status of the LED. Ensure it is showing

a green light.

figure 7-3 Position of mains

power switch

Page 34 M0106ASB.doc

7 Maintenance

7.3. REPLACEMENT OF POWER SUPPLY

• To remove a power supply,

first disconnect mains,

mains cable and DC cable.

• Unscrew the hexagon

socket head cap screw on

the left-hand side and

loosen the other socket

head cap screw on the

right-hand side (circlemarked) with an Allen key.

• Pull the power supply out.

• Apply heat-conducting

paste to the mounting

figure 7-4 Power supply screws

surface of the new power

supply.

• Carefully insert the new

power supply.

• Fasten the two socket

head cap screws.

• Reconnect all cables.

DC connector

Mains

connector

ID No: 163511 Page 35

For your notes:

User’s Manual for Remote Unit

MMR8L L

Page 36 M0106ASB.doc

8 Appendix

8. APPENDIX

8.1. LAYOUT

figure 8-1 Layout of the remote unit

ID No: 163511 Page 37

User’s Manual for Remote Unit

8.2. SPECIFICATIONS

8.2.1. Electrical Specifications

MMR8L L

Mains power 100 to 240 Vac

Power Supply

36 to 72 Vdc

Power consumption 180 W

Interface

BTS Interface

Antenna Port

Number of connectors 1 single duplexed RF port

Input power Micro: 33/43 dBM typical

Connector N Female or DIN 7/16

Return loss 15 dB

Connectors E2000/APC 8°

Optical return loss 45 dBm minimum

Optical link

Fiber type Single mode E9/125 µm

Optical link budget 0 to 10 dB

Composite input power @

+4 dBm maximum

OTRX master side

System supervision and control

Commands

Alarms

RF on/off; External control ports

Summary

Power supply

Optical UL and DL failure

RF UL and DL failure

Temperature

Door open

Supervision

Composite output power

Frequency ranges

Nominal 20 dB Bandwidth 51 MHz

800 MHz band LMR

UL: 806 to 824 MHz

DL: 851 to 869 MHz

Mean rated output power 1) 40 dBm

@ 1 carrier 40 dBm 3) Analog; 40 dBm

40 dBm TDMA/ EDGE; 40 dBm 3)

3)

WCDMA

Output power 2)

CDMA; 38 dBm

@ 2 carriers 37 dBm

37 dBm

35 dBm

@ 4 carriers 34 dBm

34 dBm

32 dBM

@ 8 carriers 31 dBm

31 dBm

29 dBm

3)

Analog; 37 dBm

3)

TDMA/ EDGE;

3)

CDMA; 35 dBm

3)

Analog; 34 dBm

3)

TDMA/ EDGE;

3)

CDMA; 32 dBm

3)

Analog; 31 dBm

3)

TDMA/ EDGE

3)

CDMA; 29 dBm

Intermodulation distance -60 dBc

MMR8L L

3)

iDEN;

3)

iDEN;

3)

WCDMA

3)

iDEN

3)

WCDMA

3)

iDEN

3)

WCDMA

Page 38 M0106ASB.doc

8 Appendix

Output tolerance over frequency ± 1.0 dB

Output tolerance over temperature ± 1.0 dB

D

L

Gain 5) +33 dB

ICP3 optimized 4) NF optimized 4)

Gain @ remote unit 6) 58 dB

Output impedance 50 Ohms

ICP3 optimized 4) NF optimized 4)

Input ICP3 +1.5 dBm -9 dBm

)

Noise figure (NF)

U

Gain 5) 33 dB 45 dB

L

Gain @ remote unit 6) 70 dB

7

13.5 dB 6.0 dB

Automatic Level Control (ALC) factory set

Input impedance 50 Ohms

1)

Mean rated output power specified for signals with 0 dB peak to average signals.

Note: The manufacturer' s rated output power of this equipment is for single carrier

operation. For situations when multiple carrier signals are present, the rating would have

to be reduced by 3.5 dB, especially where the output signal is re-radiated and can cause

interference to adjacent band users. This power reduction is to be by means of input

power or gain reduction and not by an attenuator at the output of the device.

2)

Spurious < -13 dBm @ 1 MHz RBW / -73 dBm @ 1 Hz RBW

3)

All dB and dBm figures are typical values.

4)

0 to 10 dB optical loss

5)

Gain calculation from reference point A to B, auto-levelling active (gain range software

adaptable )

6)

Auto-levelling not active

7)

Note: The noise figure (NF) stated above refers to one Remote Unit (RU) per sector. The

NF system increases with the number of the RUs per sector. It is recommended not to

operate above four RUs per sector. With four RUs per sector, the system NF will be

increased by 6 dB.

All data is subject to change without notice!

8.2.2. Environmental and Safety Specifications

) Note: For detailed information, please refer to the Environmental and

Safety Specifications leaflet of the supplier, related to ETS 300 019

(European Telecommunication Standard).

Operating temperature range -33° C to +50° C

Ingress protection IP66

All data is subject to change without notice!

ID No: 163511 Page 39

User’s Manual for Remote Unit

8.2.3. Mechanical Specifications

MMR8L L

) Note: The unit is mounted directly to the wall or pole. Vertical mounting,

and a spacing of 300 mm (11.8’’) above and below is required. Do

not block air inlet and outlet.

Height, width, depth 546 x 190 x 260 mm (21.5 x 7.5 x 10.25 inch)

Weight 16 kg (35 lb)

All data is subject to change without notice!

8.3. PARTS LIST

The following lists contains all parts available for the remote unit. The configuration of

the delivered unit meets the requirements of the customer and can differ depending

on the state of the delivery.

Parts List of the Remote Unit MMR8L L

Designation: ID No FRU

MMR8L L 163506

Control Unit populated Board 1570.5 156470

Cover 160736

DC/ DC converter 28V/ 12V 0.7A 163549

Dpx UL-aktiv 806-824 851-869 162326

Fin.Ampl. 82W 851-869 36dB 161175

Locker 160734

OTRx 8RU 163500

Power Supply Unit DC IN 48V 161751

User's Manual for MMR8L L 163511

Pole Mounting Kit for K-/ L-/ Q-Cabinet 163746

Wall Mounting Kit 162809

The manufacturer reserves the right to replace the spare parts listed above by

equivalent substitutes!

x

x

x

x

x

Page 40 M0106ASB.doc

9 Index

9. INDEX

A

Abbreviations............................................5

Address of Mikom.....................................8

Alarms

Alarm Status..............................................29

Bite and Alarms.........................................29

External Inputs ..........................................31

Handling of Alarms....................................29

LED ...........................................................30

List.............................................................32

Outputs......................................................31

RU.............................................................32

B

Block Diagram........................................13

C

Commissioning.......................................27

Components

Interior.......................................................14

Connection Rules

Optical Fibre Cables..................................20

Optical Fibres............................................20

I

Installation

Electrical................................................... 17

Mechanical ............................................... 15

International Contact Addresses..............9

L

Layout.....................................................37

Levelling.................................................27

M

Maintenance...........................................33

Mounting

General.....................................................15

Wall........................................................... 16

O

Optical Fibre Connection

Protective Plug ......................................... 22

Protective tube kit..................................... 24

Outputs...................................................31

Connections

Antenna.....................................................20

Connector Flange......................................18

Optical Fibre Cable ...................................20

Power........................................................19

E

External Inputs .......................................31

G

Grounding...............................................18

H

Health and Safety Warnings.....................6

P

Parts List ................................................40

Power Supply

Replacement ............................................ 35

Preamble..................................................8

R

Replacement of

Power Supply ........................................... 35

S

Specifications

Electrical................................................... 38

Environmental and Safety ........................39

Mechanical ............................................... 40

T

Troubleshooting......................................32

ID No: 163511 Page 41

User’s Manual for Remote Unit

MMR8L L

10. LIST OF CHANGES

Version Changes Release Date

M0106ASA 14-January-2005

M0106ASB - Chapter 1.2 extended

- Chapter 3 changed

- Chapter 4.1.2 changed

- Chapter 4.2.4 changed

27-January-2005

Page 42 M0106ASB.doc

Loading...

Loading...