22. Introduction

This section describes the TPR family (19” Sub rack). The TPR is part of the

Britecell system and host all plug-in modules such as TFL-card, TLC

splitter/combiner, TFL-BSI Base Station Interface and control modules.

A TPR sub-rack, when fully equipped, can support up to 6 TFL Local Units, one 2way splitter-combiner, two 3-way splitter-combiners, one Base Station Interface,

and one control module. Therefore this complete configuration supports up to 24

TFA Remote Units and up to 48 antennas.

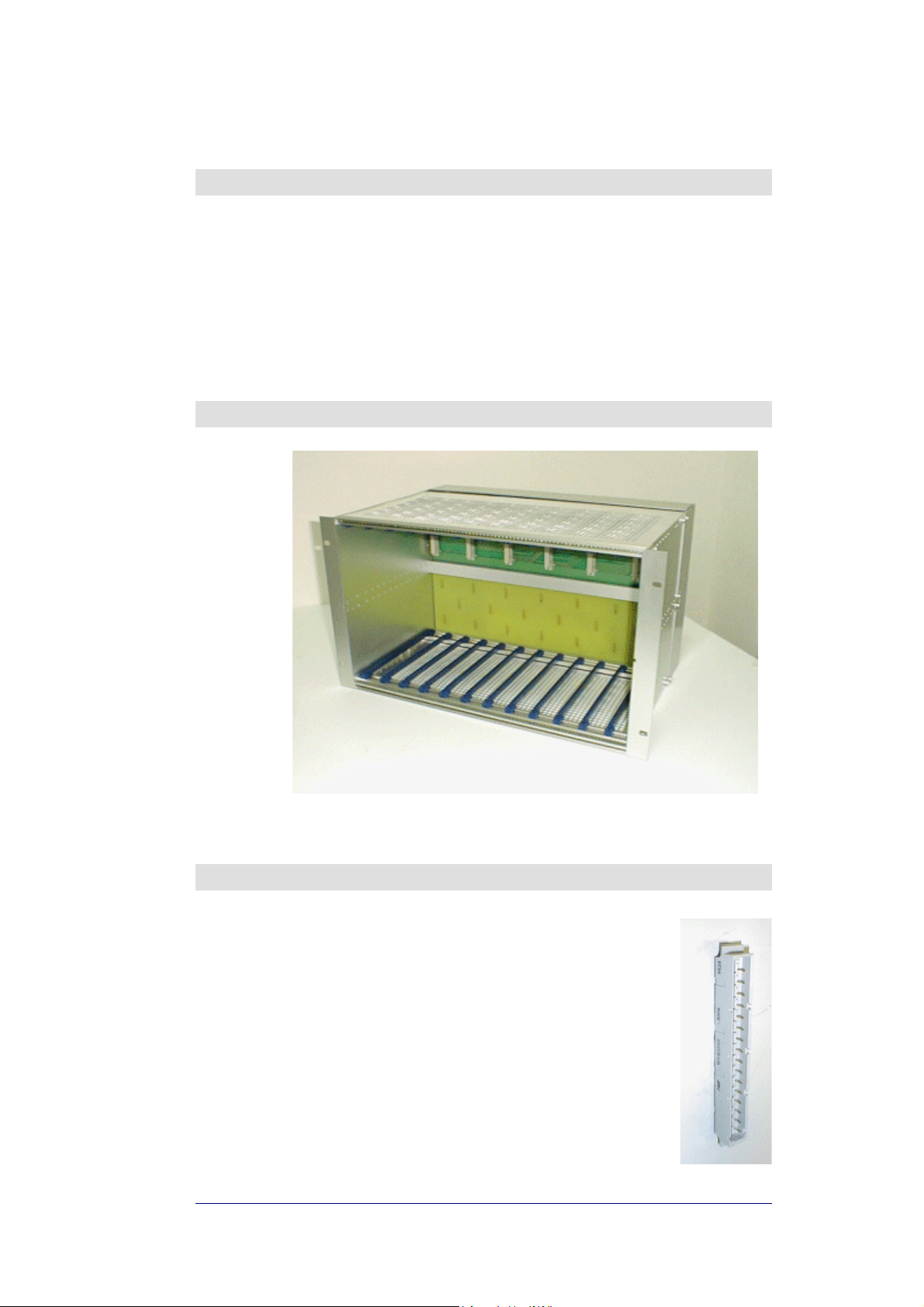

23. Part description

Fig. 22 TPR912

24. Warnings

Local interfaces may not be placed next to each other; one 7te

module is always required between them.

TFL local interface cards can only be fitted in slots 1, 3, 5, 7, 9,

and 11 of the sub-rack, slot 1 being the left most one.

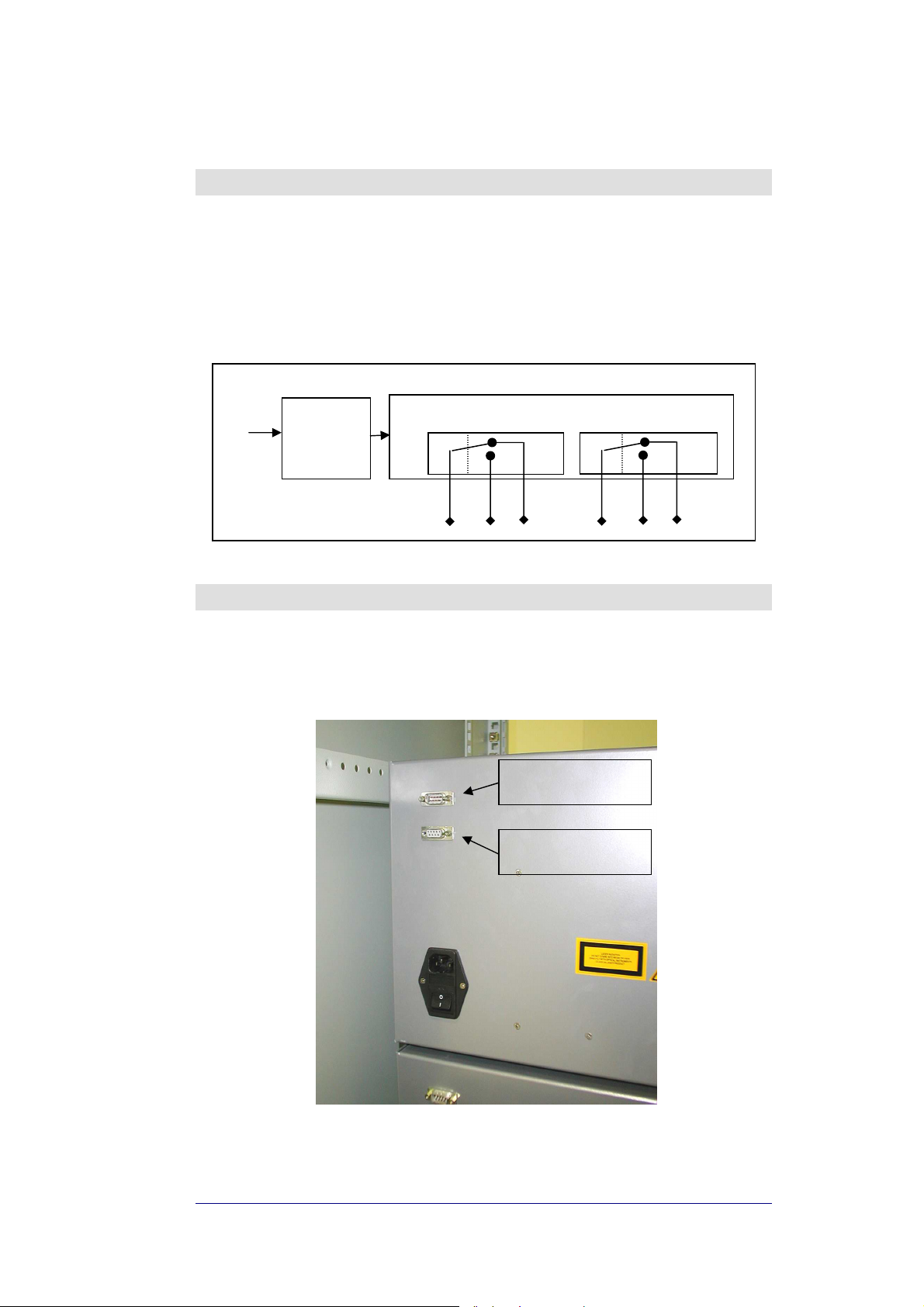

WARNING: any slot capable of accepting an TFL that is

9

unused must be fitted with a dummy plug to avoid alarms

being generated (see Fig. 23)

WARNING: do not remove or insert any module into TPR

9

subrack, without switching the power supply off.

BRITECELL System Manual MN010-04 June 2003 Page 36 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

Fig. 23 - Dummy connector

25. Functional description

The TPR subrack provides:

• power supply to the active plug-in cards (12VDC);

• alarm logic and relays;

• mechanical housing and positioning.

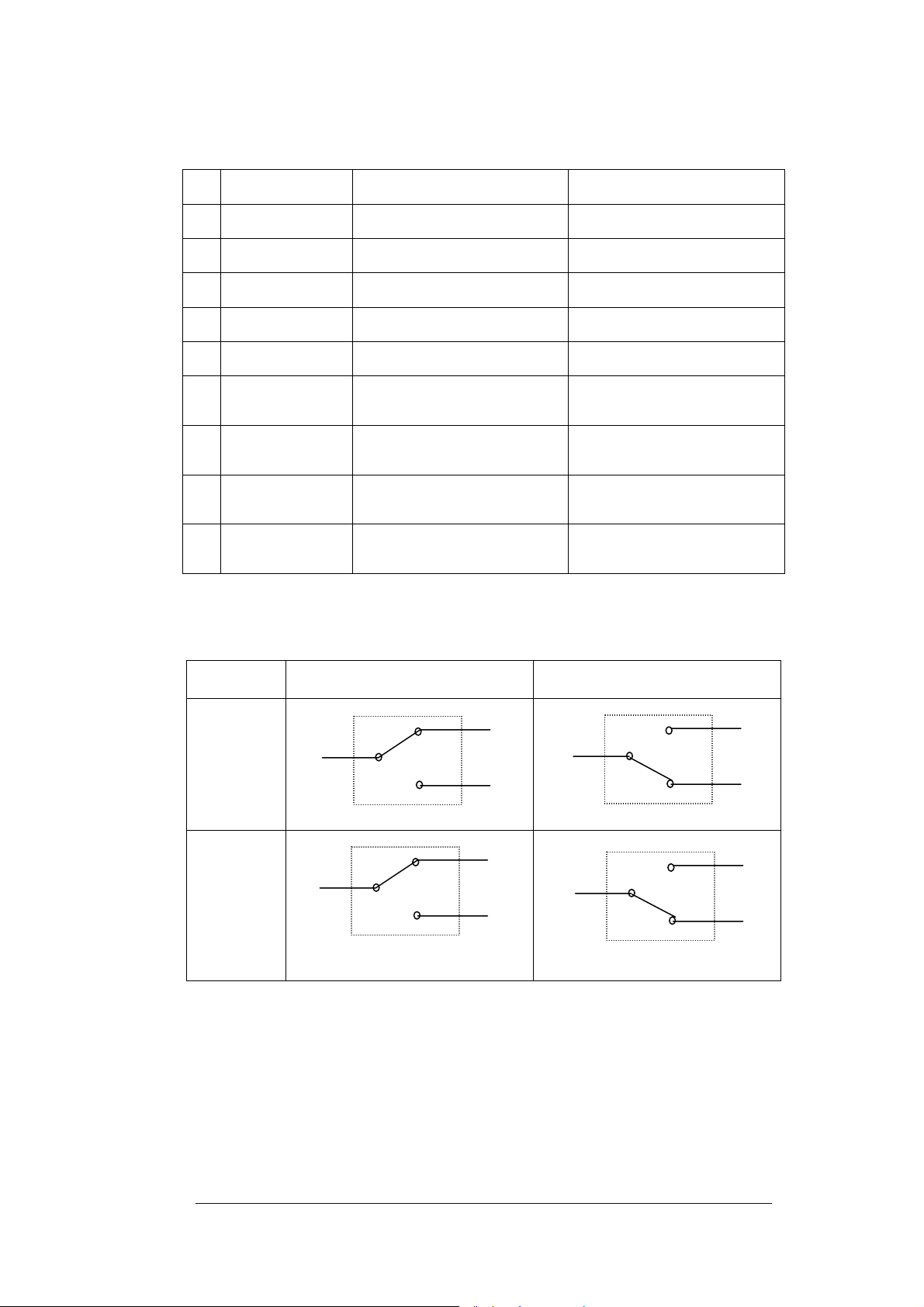

25.1. Block diagram

MAINS

AC/DC

or

DC/DC

converter

backplane, logic & relays

DL UL

Fig. 24 – TPR block diagram

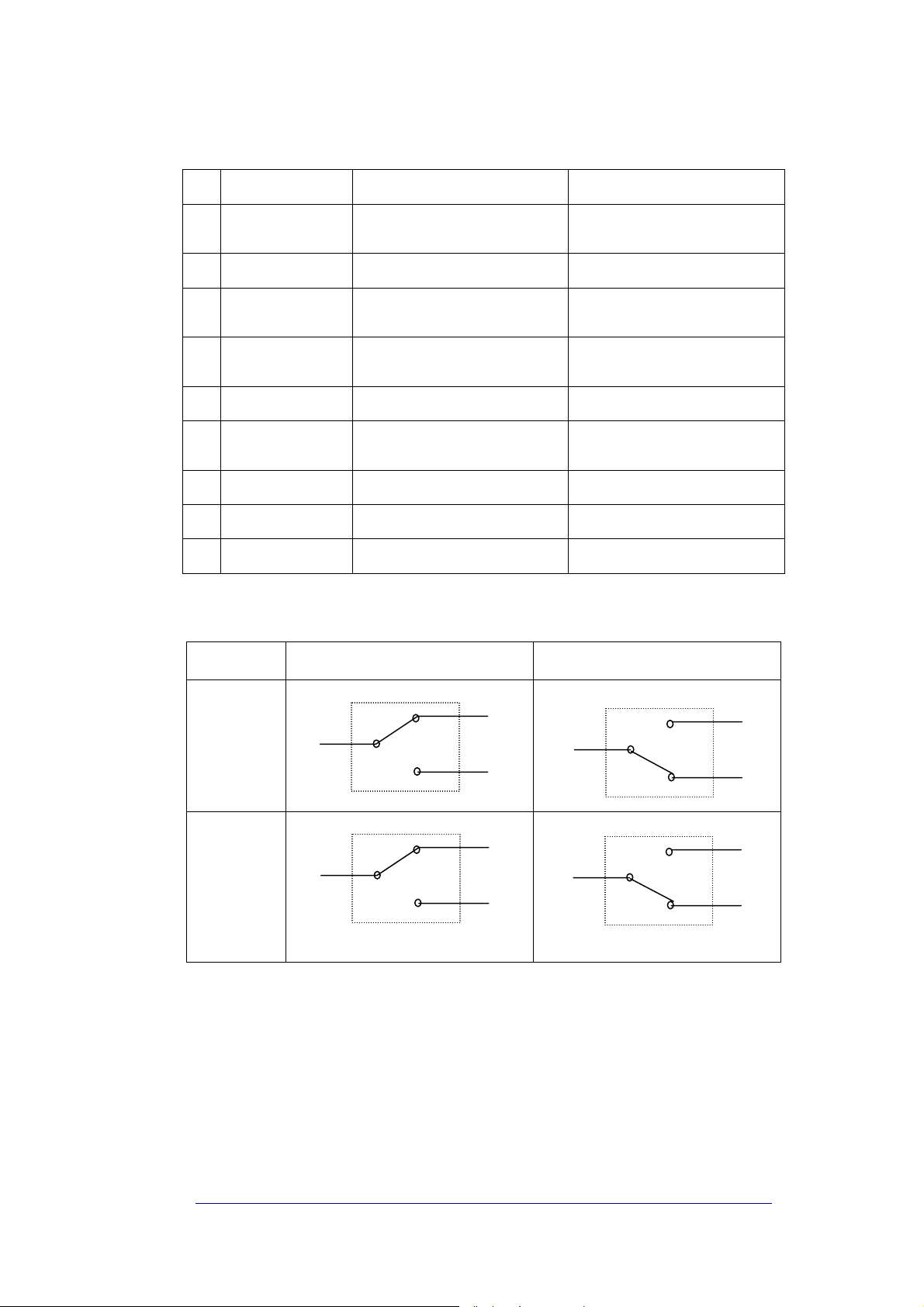

26. Alarms

The TPR sub-rack has a built-in alarm circuit: any fault in TFL or TFA causes a

contact relay close or open.

A sub-D 9 pins male connector at the back of the sub-rack gathers summary and

specific alarms of master/local subrack (see Tab. 6)

Fig. 25 alarm relay connector

Sub-D Male

Master sub-rack alarms

Sub-D Female

Slave sub-rack alarms

BRITECELL System Manual MN010-04 June 2003 Page 37 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

Master/Local Sub-rack Alarm status (SUB-D Male)

PIN Name Meaning Description

1 not connected

2 DL Summary Alarm Common contact

3 not connected

4 UL Summary Alarm Common contact

5 not connected

6 DL Summary Alarm

7 DL Summary Alarm

8 UL Summary Alarm

9 UL Summary Alarm

To choose in conjunction with PIN 2,

Normally Closed

To choose in conjunction with PIN 2,

Normally Open

To choose in conjunction with PIN 4,

Normally Closed

To choose in conjunction with PIN 4,

Normally Open

Tab. 6 Master sub-rack alarm connector pinout

2 - 6 = Open circuit if Local Sub rack

Downlink is in alarm

2 – 7 = Short circuit if Local Sub rack

Downlink is in alarm

4 - 8 = Open circuit if Local Sub rack

Uplink is in alarm

4 – 9 = Short circuit if Local Sub rack

Uplink is in alarm

normal condition (no alarm) Alarm Condition

Down Link

2

6

2

7

Up Link

8

4

4

9

If a slave sub-rack is connected via TSU012 Control Unit or TFLB Interconnect Link

Unit, alarms from slave/remote sub rack are also reported through the TPR back

plane at the auxiliary DB9 female connector, providing alarm relay logic similar to

the master ( see Tab. 7)

NOTE: TPR subrack provides connections for more detailed alarms, at the right

most slots (see TSU012 control unit product specification)

6

7

8

9

BRITECELL System Manual MN010-04 June 2003 Page 38 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

Slave/Remote Sub-rack Alarm status (SUB-D Female)

PIN Name Meaning Description

1 UL Summary Alarm

2 UL Summary Alarm Common contact

3 DL Summary Alarm

4 DL Summary Alarm

5 DL Summary Alarm Common contact

6 UL Summary Alarm

7 not connected

8 not connected

9 not connected

To choose in conjunction with PIN 2,

Normally Open

To choose in conjunction with PIN 5,

Normally Closed

To choose in conjunction with PIN 5,

Normally Open

To choose in conjunction with PIN 2,

Normally Closed

Tab. 7 Slave sub-rack alarm connector pinout

2 – 1 =Short circuit if Remote Sub

rack Uplink is in alarm

5 - 3 =Open circuit if Remote Sub

rack Downlink is in alarm

5 – 4 =Short circuit if Remote Sub

rack Downlink is in alarm

2 - 6 =Open circuit if Remote Sub

rack Uplink is in alarm

Normal Condition (no alarm) Alarm Condition

Down Link

Up Link

5

3

5

4

3

4

6

2

2

1

6

1

BRITECELL System Manual MN010-04 June 2003 Page 39 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

27. Installation and cabling

27.1. Location

The TPR sub-rack should be placed as near as possible the BTS or the RF repeater.

The sub-rack location should be easy to reach by the users in order to allow alarm

monitoring.

WARNING! do not close the air circulation subrack grids (top and bottom) with

9

panels or obstacles.

If the subrack mounting location does not have a good air circulation, leave at

9

least one unit (1HE) free between subracks.

27.2. Power supply

The connection to the mains has to be carried out following all the necessary

precautions, including the following:

• in accordance with diligence rules (ex. CEI rules, IEC rules, etc.);

• in accordance with the rules for the safety against direct or indirect contacts;

• in accordance with the rules for the safety against over current (short circuit,

overloading);

• in accordance with the rules for the safety against the over tension;

• the connection is to be carried out by properly trained technicians.

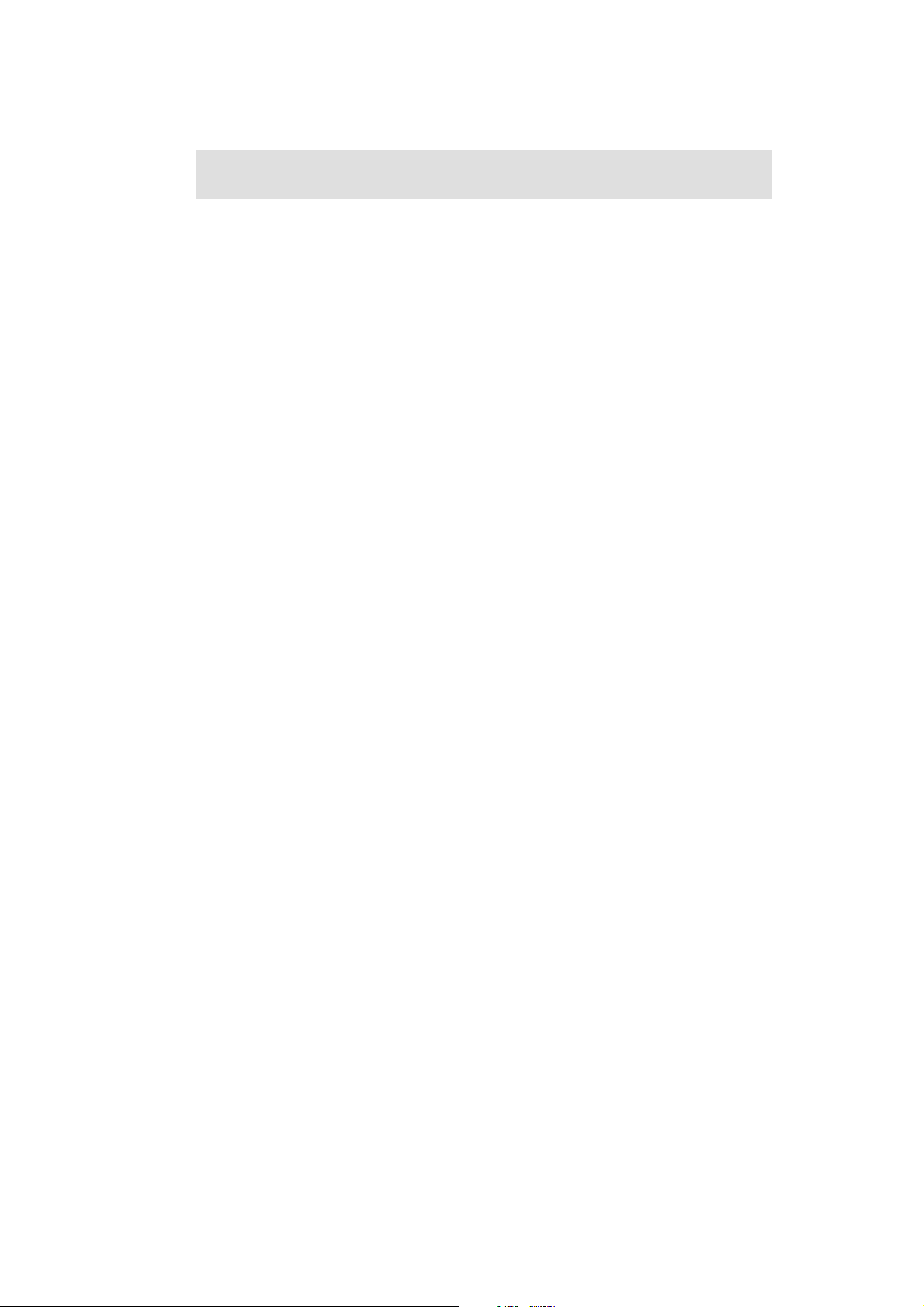

27.2.1. Universal mains

Universal main (85-264VAC, 50/60Hz) apply to TPR912 model only. Mains

connector is placed on the back panel (see Fig. 26 mains connector)

Fig. 26 mains connector

The TPR912 model has an internal AC/DC converter. With 220VAC power supply

the efficiency is 75%. Each TFA has a power consumption of 12W, therefore a fully

equipped configuration (6 TFLs) requires (12W x 6) / 0.75 = 96W.

This formula is helpful in verifying the overall power consumption.

BRITECELL System Manual MN010-04 June 2003 Page 40 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

27.2.2. DC negative supply

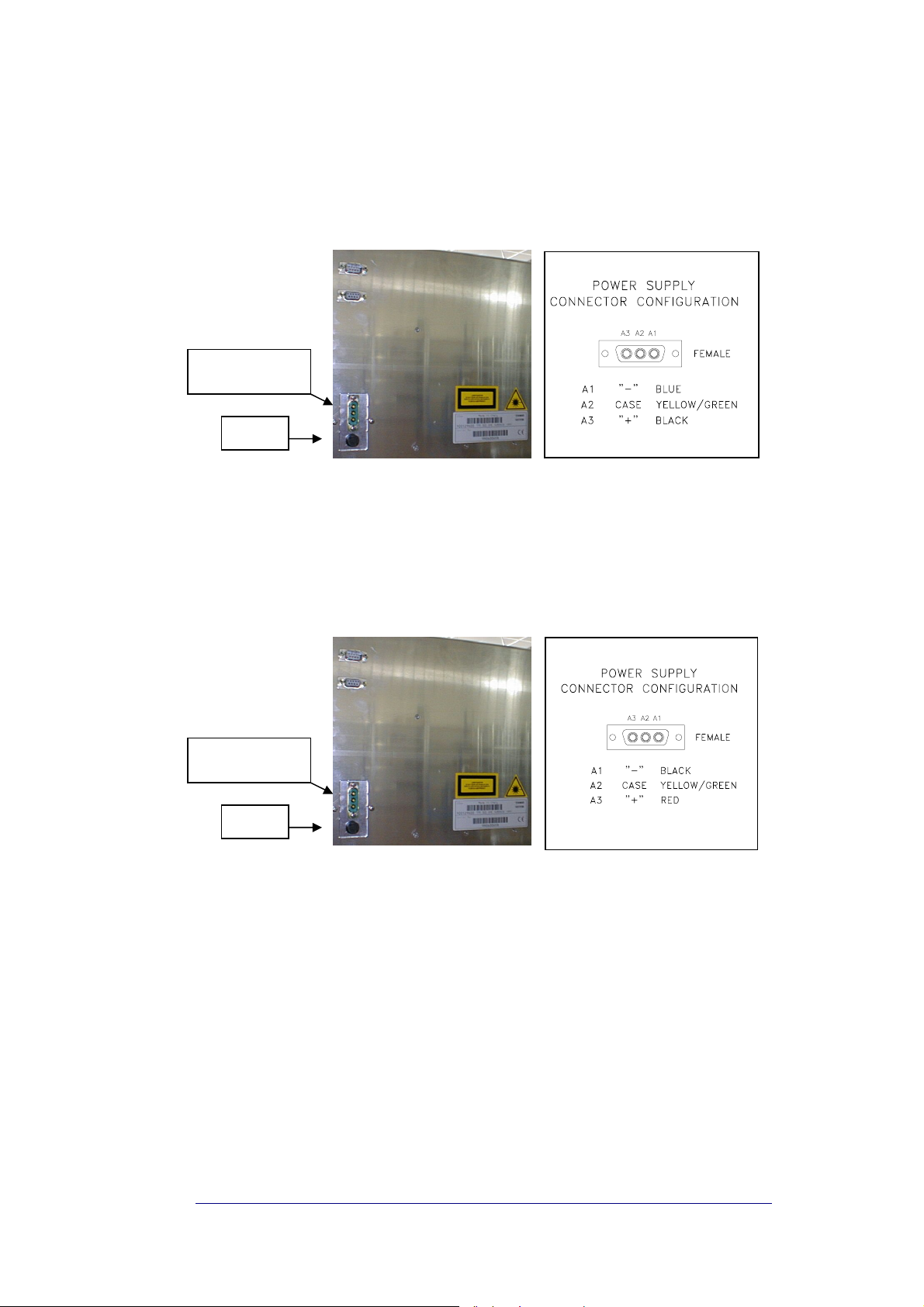

Direct current ( –72 to –36 VDC) apply to TPR922 model only. Power connector is

placed on the back panel (see

Fig. 27 VDC Connector (TPR922 only))

MALE POWER

CONNECTOR

FUSE

Fig. 27 VDC Connector (TPR922 only)

TPR922 model has an internal DC/DC converter: power consumption is the same

as above.

Direct current (16 to 24 VDC) to be applied to TPR932 model only. Power

connector is placed on the back panel (see Fig. 28 VDC Connector (TPR932 only))

MALE POWER

CONNECTOR

FUSE

Fig. 28 VDC Connector (TPR932 only)

TPR932 model has an internal DC/DC converter: power consumption is the same

as above.

BRITECELL System Manual MN010-04 June 2003 Page 41 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

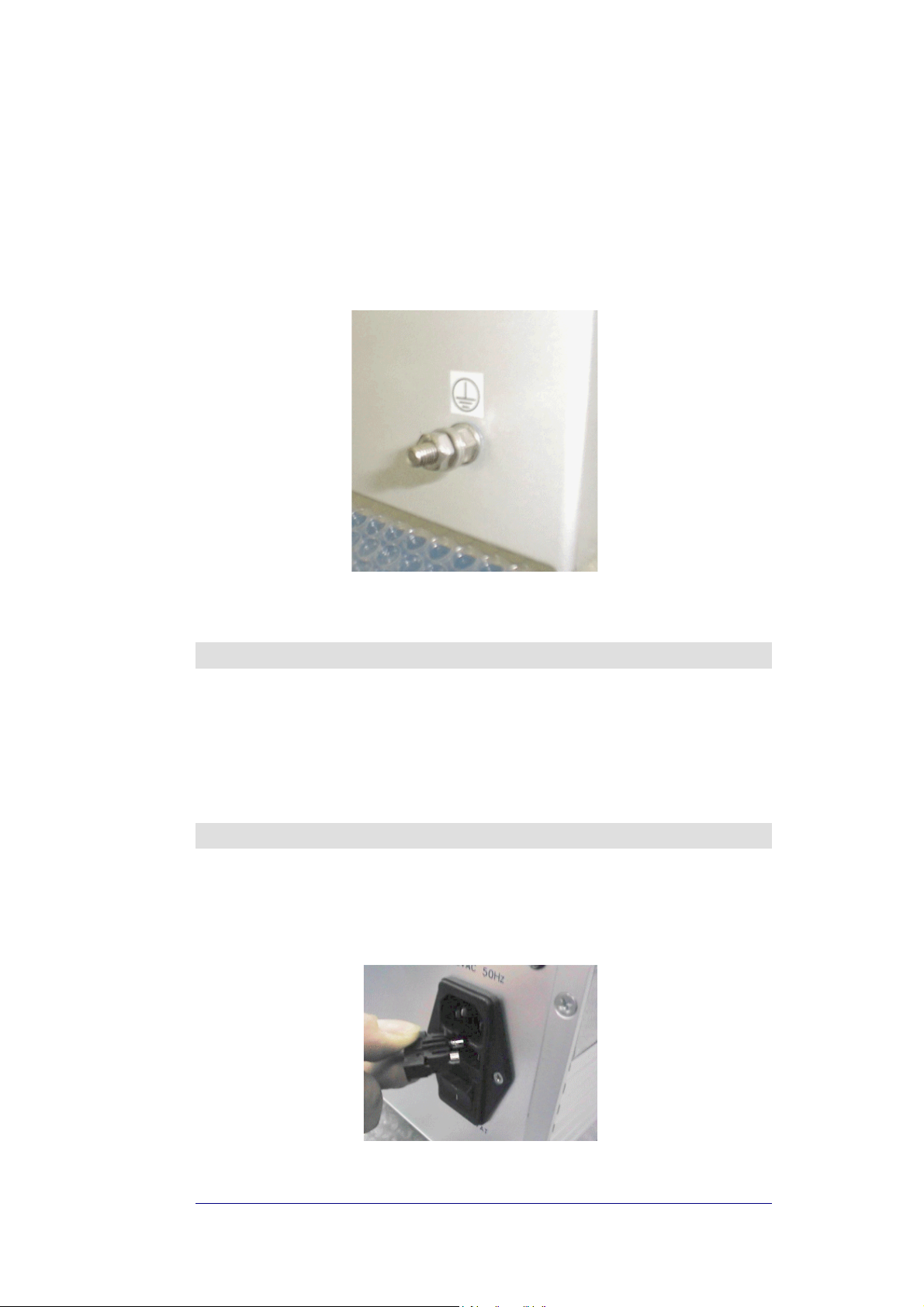

27.2.3. Grounding

Ground terminals are part of power supply connectors, as showed in previous

figures (Fig. 26 mains connector, Fig. 27 VDC Connector (TPR922 only), Fig. 28

VDC Connector (TPR932 only)).

An external grounding terminal, with screw, is available at the back panel (see Fig.

29 ground)

Fig. 29 ground

28. Start up

WARNING: Verify voltage levels before connecting and powering on the

9

subrack

Please refer to system start-up section for further details.

29. Troubleshooting

The way a fuse is changed depends on the subrack version (refer to the

datasheet). One or two fuses are present on the back of the rack, which needs to

be replaced when they fail

BRITECELL System Manual MN010-04 June 2003 Page 42 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

Fig. 30 fuse

TFL-BSI RF attenuator

30. Introduction

This section describes the TFL-BSI (Base Station Interface). The TFL-BSI is part of

the Britecell system and allows the operator to optimise the signal level the BTS or

repeater and the Britecell system. It includes two independent variable attenuators

(30 dB, one dB step) for uplink and downlink RF path.

A single attenuator version is available, for downlink only or uplink only operations.

31. Part description

Fig. 31 - TFLBSI

Downlink RF input (from BTS)

Downlink attenuation settings

Downlink RF output (to TFL)

Uplink RF output (to BTS)

Uplink attenuation settings

Uplink RF input (from TFL)

32. Warnings

9

Maximum RF composite input power must not exceed 30 dBm.

9

SMA connectors must be screwed with a proper dynamometric key.

33. Functional description

33.1. Down link operation

If the RF signal coming from the BTS or repeater in downlink path has a power

level, which is not adequate to the TFL’s characteristics, an attenuator is required.

BRITECELL System Manual MN010-04 June 2003 Page 44 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

33.2. Uplink operation

The RF signal coming from the mobile through the TFA and TFL in the uplink

direction may not be an optimal level. When this is the case, the uplink attenuator

is used to prevent the BTS from being over driven.

34. Installation and cabling

34.1. TPR housing

The TFL-BSI is a modular plug-in card designed to be put in a 6 HE sub-rack (TPR

family).

The TFL-BSI interfaces with the BTS transmitter and receiver through N-female

connectors and with Britecell with SMA-female connectors.

The connection with the BTS may be direct, if the BTS’s transmitter and receiver

are separated, or through a circulator or a common path RF combiner (please refer

also to THYB section).

When the system is air interfaced through a repeater a common path RF combiner

is required in order to separate the uplink and downlink path.

The connection between TFL-BSI and Local Units may be direct or through a

combiner stage (please refer to TLC section) depending on the system’s

configuration.

35. Calculation of attenuation setting

35.1. Downlink

Calculation of Downlink TFL-BSI setting is made in order to supply Britecell Local

Unit with correct DL input power.

)(]dB[

PILILPA

−−−=

where:

P

IL

IL

P

@POI_Input

Dir.Coupler

Comb.Net

DL_BC_Max

[dBm/c]= RF power level per carrier at POI input:

[dB]= Directional coupler insertion loss (if present);

. [dB]= Combining Network insertion loss;

[dBm/c]= Max input power per carrier at Local Unit input.

35.2. Uplink

Calculation of Uplink TFL-BSI setting is made to meet BTS uplink blocking

requirements.

where:

P

LU_UL@Blocking

[dBm]= Local Unit output power when Remote Unit is at blocking

level (3 dB C/N degradation);

P

BTS@Blocking

[dBm]= BTS receiver blocking level;

SM = Safe margin (typically 3 dB).

)]([]dB[

BlockingBTSNetbCCpouplerDirBlockingULLUblkULBSI

@.om.@___

MaxBCDLNetbCCpouplerDirInputPOIDLBSI

__.om._@_

+−+−=

SMPILILPA

BRITECELL System Manual MN010-04 June 2003 Page 45 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

TLC RF combiner - splitter

36. Introduction

This section describes the TLC splitter/combiner. The TLC is part of Britecell

system and provides a family of 2-way and 3-way RF power combiners in order to

allow several local interface modules to be connected to common UL and DL RF

paths, for interfacing to the BTS.

All units have internal pads (one per path) to achieve predefined insertion loss.

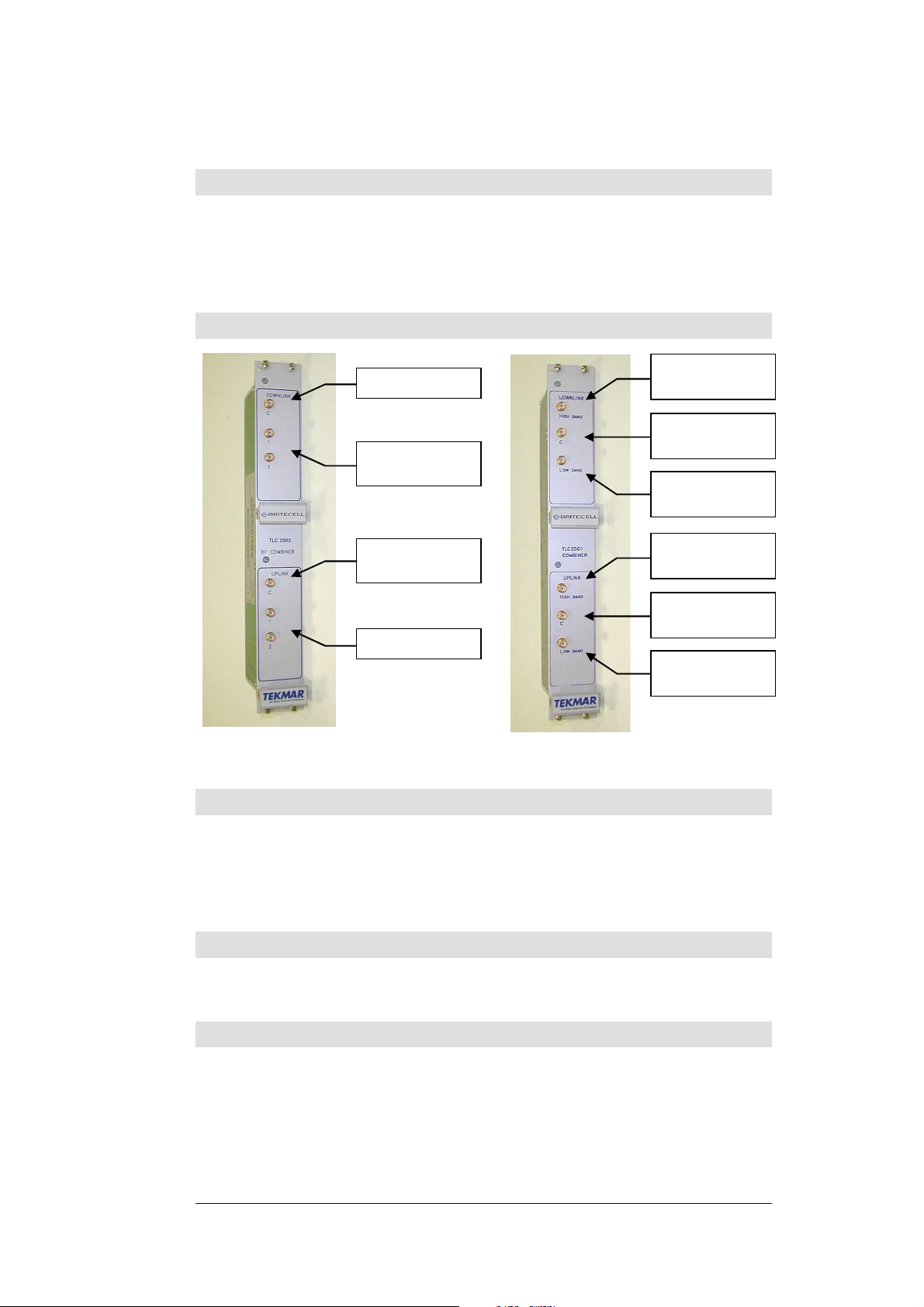

37. Part description

Downlink RF input

Downlink RF

splitted outputs

Uplink RF

combined output

Uplink RF inputs

Fig. 32 TLC2502 Fig. 33 TLC2501

Downlink RF

High Band input

Downlink RF

combined output

Downlink RF

Low Band input

Uplink RF

High Band output

Uplink RF

combined input

Uplink RF

Low Band output

38. Functional description

TLC2502/3 is a two/three way splitter for downlink path and combiner for uplink

path. For insertion loss values refer to datasheets.

TLC2501 is a crossband coupler, designed to combine or split hi-band signal and

low band signal in dual band systems. Insertion loss in this case is minimal (see

datasheets).

39. Warnings

9

Maximum RF composite input power must not exceed 24 dBm.

9

SMA connectors must be screwed with a proper dynamometric key.

40. Installation and cabling

40.1. TPR housing

The TLC is a modular plug-in card, suited to be contained in a 6 HE Sub rack (TPR

family).

The 2-way TLC module interfaces with the BTS transmitter and receiver through

TFL-BSI and with TFL Local Units directly or through 3-way splitter/combiner.

BRITECELL System Manual MN010-04 June 2003 Page 47 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

THYB common path RF

combiner

41. Introduction

This section describes the THYB common path RF combiner family. THYB is part of

Britecell system and it allows combining of downlink and uplink path into a single

one, while maintaining required isolation and stability.

This component has been designed for Britecell system configuration requiring

single RF connector carrying both DL and UL signals when system is interfaced

through a diplexed BTS.

42. Part description

Fig. 34 THYB

DL/UL RF combined

input/output

Uplink RF

input

Downlink RF

output

43. Functional description

THYB is a bi-directional hybrid RF combiner/splitter. It can be chosen in single or

dual band version. It’s provided with uplink pass-band filters to improve UL

isolation performances.

THYB typical application is in conjunction with diplexed BTS where DL and UL

paths are provided in single RF connector.

For insertion loss value, refer to datasheets.

44. Warnings

9

Maximum RF composite input power must not exceed 30 dBm.

9

SMA connectors must be screwed with a proper dynamometric key.

45. Installation and cabling

THYB is a modular plug-in card, suited to be contained in a 6 HE Sub rack (TPR

family). THYB interfaces with BTS transceiver through ‘C’ connector (type SMAfemale). THYB interfaces with Britecell downlink and uplink paths through ‘DL’ and

‘UL’ connectors respectively (type SMA-female).

BRITECELL System Manual MN010-04 June 2003 Page 49 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

TFB booster

46. Introduction

The TFBxx is an optional part of the Britecell system and it’s intended to enhance

transmit power of Britecell remote transceivers TFA in order to maintain an output

power of 10 dBm per carrier when operating with up to 8 carriers.

Typical TFB configuration is together with TFA remote unit and TPA passive

antennae.

TFB is housed in the same metallic case as TFA and contains one amplifier for each

direction (uplink and downlink).

47. Part description

power on led (green)

alarm led (red)

power supply

alarm relay contact

(normally closed)

RF port to TFA

Fig. 35 TFB RF booster

warm side

RF port to

coverage antenna

48. Warnings

CAUTION! Do not connect the booster to TFA without first switching power

9

supply off.

49. Functional description

49.1. Block diagram

High Band Booster

TFA remote unit

Fig. 36 block diagram

BRITECELL System Manual MN010-04 June 2003 Page 51 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

ALC

AMP

AMP

TPA antenna

(

(input)

49.2. Description

TFB booster is a bi-directional RF amplifier designed to:

• improve the coverage area of the antennae connected to the remote unit

while maintaining same amount of distributed RF carriers;

or

• improve number of distributed RF carriers while preserving the same

coverage area.

Only single band version is available.

To enhance both RF ports of TFA remote unit, two TFB boosters are needed.

Downlink operation:

in downlink path, the booster performs an overall gain of 14

dB. ALC (automatic level control) circuit provides automatic limitation of excess

output power.

Uplink operations:

in uplink path, the booster has an overall gain of 4 dB, which

decreases the uplink noise figure (increasing system sensitivity).

50. Alarms

TFB provides a logic alarm related to excess current draw. The alarm output must

be connected to TFA external alarm input , as shown in Fig. 37

TFB relay contact

output)

Fig. 37

TFA relay contacts

51. Installation and cabling

WARNING: for a proper connection of TFB to the Britecell system through the

9

TFA. Please refer to the system coverage design for additional information.

51.1. Location

TFB booster unit shall be installed close to TFA remote unit and radiating

antennas, as to minimise coaxial cable length.

The unit is intended to be installed on walls, flat or orthogonal surface.

For a proper unit cooling take care of the warm unit side as indicated in Fig. 35

Installation must provide the correct positioning, and cables must be run so that

accidental damage is prevented.

BRITECELL System Manual MN010-04 June 2003 Page 52 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

51.2. Power supply and grounding

51.2.1. Universal mains (85-264VAC, 50/60Hz)

Mains

Fig. 38 -Mains connector

51.2.2. DC negative supply –72 to –36 VDC.

DC connector and part number:

Fig. 39 - VDC connector

Ground

Mains

51.3. RF combined ports

Antenna port must be directly connected to radiating antennas through RF

jumpers.

TFA port must be connected to combined port of TFA remote unit.

52. Start up

A preliminary verification of TFB correct operation is:

• power-up the TFB

• verify the following led status

LED Colour Status

Alarm Red OFF if internal operations ok

Power On Green ON

For a full functionality test please refer to the system start-up section

BRITECELL System Manual MN010-04 June 2003 Page 53 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

53. Troubleshooting

In case of alarm LED is active, check first if the air circulation around the unit is

acceptable and that environmental conditions (operating temperature, supply

range) are among specified operating limits.

If problems persists please refer to service or technical support.

BRITECELL System Manual MN010-04 June 2003 Page 54 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

TPA antenna

54. Introduction

This section describes the TPA antenna family. The TPA is part of Britecell system

and provides the field shaped coverage.

TPA realises the physical radiating points, for radio transmission/reception, towards

mobile stations. Each TPA is connected to the relevant Remote Unit TFA by means

of coaxial jumper. TPA family ranges from single band stand-alone to dual band

Fig. 40 TPAx10 single band antenna Fig. 41 TPAx20 dual band antenna

Fig. 42 TPAx30 dual band antenna

BRITECELL System Manual MN010-04 June 2003 Page 56 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

55. Functional description

The TPA extends cellular coverage in such indoor environments that can't be

economically and easily reached by radio mobile network signals.

RF signals going through walls, metallic structures and any other obstacle inside

buildings are attenuated up to 1000 times (30 dB), thus creating problems for the

users of mobile phones.

TPA together with TFA solves this problem by providing a suitable amplification,

which compensates the fading effect due to various artificial obstacles placed

between mobile phones and Radio mobile Network.

The TPA can be high-gain directional or low-gain semi-directional, see product

family datasheet for detailed radiation patterns

The appliance to the following instructions grants the best functioning, the

maximum safety and the lowest inference with other electrical devices.

Any misuse and any violation of the device compromise its functioning and exclude

any warranty.

TFA

Remote Unit

Fig. 43 block diagram

Coverage area

TPA antenna

BRITECELL System Manual MN010-04 June 2003 Page 57 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

56. Installation and cabling

56.1. Location

Britecell transmits low-power radio signals in a given area. It is important to

respect the simple installation instructions as follows, in order to achieve a good

communication quality and to avoid malfunctions, which could bring to a selfinhibition of the device.

The TPA passive antenna’s placing should be chosen in order to grant the

maximum indoor radio coverage. The largest field is located perpendicular to the

TPA. Antennas have to be mounted at a minimum height of 2.5m from the ground.

They should not be placed near trees, plants, metal grids or other obstacles, which

could disturb their functioning and lead to a worsening of the device's

performance.

COVERAGE

ANTENNA

Fig. 44 antenna position

Minimum Coverage

Direction

CORRECT

Fig. 45 radiation pattern

2.50 m

WRONG

Maximum Coverage

Direction

BRITECELL System Manual MN010-04 June 2003 Page 58 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

56.2. Location examples

Fig. 46 Rectangular room Fig. 47 Corridor

Fig. 48 Garage

56.3. Wall mount

Fig. 49 Front view fig. 50 Side view

BRITECELL System Manual MN010-04 June 2003 Page 59 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

56.4. Connectivity

There is either an N-female connector or a RG223 pigtail attached to the TPA

antenna to realise connection to the TFA.

WARNING: use only low loss 50Ω RF cable to connect TPA antenna to TFA.

9

WARNING: do not connect the antenna without switching off the power supply

9

to the TFA.

57. Troubleshooting & maintenance

The device has no particular maintenance requirements. It is advisable to check

periodically the cable connecting the external antenna, in order to avoid any

erosion or cut which could reduce its lifetime.

BRITECELL System Manual MN010-04 June 2003 Page 60 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

SYSTEM INSTALLATION

58. Installation and cabling

Britecell is designed to be simple and fast to install and commission. It requires a

minimum number of tools and equipment. However, it is necessary to observe

local regulations when planning and implementing an RF system and safety

conventions must be strictly adhered to at all times. One unique hazard with

Britecell is the presence of optical equipment; a thorough working knowledge of

optics, and the safety procedures in their use, is required by the installation,

commissioning and maintenance staff.

58.1. Local unit and subrack location

TFL Local Interface Units should be placed as near as possible to the BTS or the RF

repeater and should be easily accessible as they provide visual alarm information

for the system maintenance.

TPR 19" subrack needs proper air circulation. Take care that the operating

9

temperature range is met.

58.2. Remote unit and antennas location

The most efficient locations for the TFA Remote Transceivers will minimise the

number of antennas required, whilst maintaining the coverage level goal.

Please refer to the system design for the proper antenna location.

The position of the remote unit should be vertical to improve the thermal

9

dissipation.

There should be easy access to the optical and RF cables.

9

58.3. Fibre-Optic Cables

Britecell employs single-mode optic-fibre (SMOF) with the standard characteristic

dimensions of 9µm (core)/125µm (cladding).

The amount of protection needed by the fibre varies from one application to

another. A variety of cable designs are available to meet the requirements of

different installations. Here are some examples:

• Loose tube construction

tube so that it can adjust itself when the cable is distorted; microbending

is almost completely eliminated by this technique. Loose tube cables are

preferred for long distance links and for almost all outdoor applications.

• Tight buffer construction

cushioning material (secondary coating up to an external diameter of

900µm) to improve crush resistance and vibration isolation, minimising

microbending. Tight buffer cables are usually adopted for indoor

applications because they offer small cross-section dimensions and small

bend radius.

: The fibre lies loosely inside a surrounding plastic

: the buffered fibre is completely enclosed in a

BRITECELL System Manual MN010-04 June 2003 Page 62 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

For in-building applications the most common fibre cables are tight buffered cables

with 2 fibres; examples are:

Duplex zip-cord: two simplex units in a zip cord configuration.

External

Dimension

(mm)

2.5 x 5.3 30 11 30 (minor axis)

Maximum

Tension

(kg)

Weight

(kg/km)

Minimum Bend

Radius (mm)

Duplex breakout cable: two individually coloured simplex units over sheathed in

a “figure 0” configuration.

External

Dimension

(mm)

3.6 x 6 30 24 35 (minor axis)

Duplex light duty wiring cable: two individually coloured tight buffered fibres

surrounded by yarn annulus with a polymer over sheath.

External

Dimension

(mm)

5 81 19 40

The main differences between these cables concern the maximum tension that

they can bear; this is an important characteristic to consider as, during laying,

installers often have to pull and to drag cables. For this reason the duplex lightduty wiring cable is preferred, which is light and allows a tight band radius.

Maximum

Tension

(kg)

Maximum

Tension

(kg)

Weight

(kg/km)

Weight

(kg/km)

Minimum Bend

Radius (mm)

Minimum Bend

Radius (mm)

58.3.1. Connecting TFL and TFA with optical cables

A couple of fibre optics connects every Remote Unit with a TFL. It is very

important to well organise the layout of cables in order to avoid mistakes in the

connection (correspondence between a certain remote unit and a TFL).

Furthermore, a well-organised layout, allows good maintenance and

troubleshooting.

Every fibre must be labelled in order to understand which is the correspondence

between TFL port and Remote Unit.

During the connection of the pigtails to the TFL, some rules must be followed.

The pigtail cannot be squeezed or on traction and the minimum bend radius

9

suggested is 4 cm.

Don’t touch the fibre optic head of the optical connector

9

If necessary, clean the connector head by means of alcohol and proper paper

9

Use dry air spray to clean the TFL optical connector. Firstly spray to another

9

direction and then inside the connector as often some water can be on the first

spray.

Do not use other methods behind these to clean the optical connectors.

9

BRITECELL System Manual MN010-04 June 2003 Page 63 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

58.3.2. Optical Cable Laying

Fiberoptic cables can be pre-terminated with appropriate fibre connectors,

however, this often times causes problems if there is not enough space to pull

through the connector, or if the cable lengths become very large. A qualified

installer can make a recommendation on this matter. It is always recommended

that extra fibre length be provisioned. The common (and recommended) method

is to run the fibre cables without connectors attached and splice short preconnectorised tails onto the fibre. This avoids damaging connectors in the cablerunning process and ensures that adequate length is available at each end for

correct routing and strain relief.

Note that angled connectors cannot be fitted in the field due to the accurate

polishing process required; there is no significant loss in performance due to a

fusion splice.

Inside the optical cable trunk, other kinds of cable cannot be installed.

The optical cable must not be stressed as this can cause a high insertion loss, and

it could therefore break. For this reason it is important not to squeeze the cable,

for example tightening the fixing stripes too much.

It’s a good rule of thumb to avoid bending the optical cable within a radius of less

than 10 cm. Consequently, the cable trunk installation must be done respecting

that norm.

The following are pictures of actual cabling, one correct, one incorrect.

WRONG BETTER

fig. 51 - system cabling

BRITECELL System Manual MN010-04 June 2003 Page 64 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

58.4. Power Supply

A Britecell system may be locally (at each remote unit) or distributed powered.

There are advantages with both methods. It may be faster and cheaper to use

local power, however it is easier to back-up a system when the power originates at

a single point. A power supply may be distributed in a composite cable (copper

and fiber), or two separately parallel cables may be run. Note that the cable

containing the copper conductors must carry the appropriate plenum rating and

must be of sufficient conductor area to ensure adequate voltage at the furthest

Remote Unit under full load. Refer to TFA datasheet for power consumption

specifications.

If Local Units subrack is to be co-located with a BTS it is often desirable to power

the entire system from the battery-backed low voltage supply available. The Local

Unit card is fitted with a universal AC power supply module but can be ordered

with -48VDC modules instead. The overall power consumption of a full equipped

subrack will not exceed 110W.

A general rule for subrack power consumption is:

(Local Unit consumption [W]) x (cards number) / 0.75 = overall consumption [W]

59. SYSTEM START-UP

In order to avoid damaging the equipment, the following criteria must be used

to start up the system:

1. Verify all the power supply connections.

2. Verify all the RF connections.

3. Verify all the optical connections.

4. Set all the adjustable attenuators on the TFL-BSI at the maximum value of

attenuation.

5. Switch on the local units sub-racks.

6. Check for alarm status and in case of alarm refer to troubleshooting

paragraph.

7. Connect the spectrum analyser at the input of one TFL and measure the level

of the carriers for every operator.

8. Set the adjustable attenuators in order to have the right level of the carriers at

the input of the TFL according to the technical specifications.

BRITECELL System Manual MN010-04 June 2003 Page 65 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

60. MAINTENANCE

60.1. Plug-in cards removal

Always switch off subracks power supply before removing or inserting any

9

active plug-in card.

60.2. Optical equipment

It is a good rule when working with the fibre optic components, to always have

available the appropriate screw covers for closure of the optic connectors that are

not connected. The intrinsic fragility of an optic connection must be highlighted. A

minimum layer of dust causes a notable increase of the insertion loss, therefore.

Always close the optic connectors that are not connected, with the appropriate

9

screw covers.

Always use compressed gas to remove any deposits in the receptacles before

9

closing them.

Use the appropriate cloths to clean the connectors.

9

Do not allow the male connector to come into contact with skin or oily

9

surfaces.

Should it be necessary to clean the optic connector, use pure alcohol only.

9

BRITECELL System Manual MN010-04 June 2003 Page 66 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

OTHER INFORMATION

61. TERMINOLOGY

The following acronyms are commonly used throughout the document:

AC Alternating Current

AM Amplitude Modulation

AMPS Advanced Mobile Phone System (US 800 MHz standard)

BTS Base Transmission Station (cellular system element)

DC Direct Current

DCS Digital Communication System (European 1800 MHz standard)

DL Down-link (radio path from BTS to subscriber)

EMC Electro-Magnetic Compatibility

ETACS Extended Total Access Communications System

(European 800MHz standard)

GSM Global System for Mobile

IMD Intermodulation Distortion

LNA Low-Noise Amplifier

LV Low Voltage

SMOF Single Mode Optical Fibre

PCB Printed Circuit Board

PCS Personal Communications System (US 1900 MHz standard)

RF Radio Frequency

TFA Britecell remote transceiver (also called Fiber Remote Unit)

TFL Britecell local interface unit (also called Fiber Donor Unit)

UL Up-link (radio path from subscriber to BTS)

UMTS Universal Mobile Telecommunication System

62. WARRANTY CONDITIONS

Customer service is granted all over the world during and after the warranty

period.

Allen Telecom warrants to the terms and conditions hereto set forth, all products

manufactured by it to be free under normal use and service from defects in

materials and workmanship for a period of one (1) year from the date of shipment

to the first consumer (the “Warranty Period”).

The warranty applies only if:

a) the warranty period is not expired;

b) the defect is imputable to the product.

Our obligation under this Warranty is limited to prompt repair or replacement of

the product, without charge, when the product is returned to the factory.

The warranty shall not apply to any product which has been repaired or altered in

any manner or if the defect, malfunction or failure of the product was caused by

damage by lightning, flood or other acts of nature or by power surges, or from

unreasonable use, or from improper installation or application, or to any product

which has not been maintained or used in accordance with the operating

specifications set forth in this manual.

Allen Telecom evaluates if the product can be repaired or if it is necessary to

replace the unit.

BRITECELL System Manual MN010-04 June 2003 Page 68 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

In case the product is out of warranty, the customer will be informed about the

cost for repairing or replacing the unit. The service will be provided only after

receiving Customer’s authorisation.

Before returning the goods, the customer should give prior notice to Allen Telecom

through normal return authorisation procedure.

Allen Telecom aims to offer an excellent service. To do that we ask our customer

to enclose to the returned product an accompanying letter, including the following

information

Company name

Address

Contact person

Invoice number

Delivery note

N°. of pieces

Model*

Serial Number*

Lot*

Year*

Description of the

Failure/defect

* refer to the serial label

N.B.: each product must be packaged with care before shipment.

Allen Telecom will issue a check report, which is included in the packing together

with the product being returned. The customer will be informed about any

corrective actions suggested by quality assurance.

BRITECELL System Manual MN010-04 June 2003 Page 69 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

63. DECLARATION OF CONFORMITY

Allen Telecom

Declares

That the device related to this usage and maintenance handbook comply with the

CE mark requirements, according to the Low Tension Rules 73/23/CEE and

Electro-magnetic compatibility Rules 89/392/CEE

Allen Telecom will carefully retain the technical file related to the device design,

together with this usage and maintenance handbook, for a minimum time span of

10 years.

Signature: Managing Director of Tekmar Sistemi S.r.l.

64. TECHNICAL SUPPORT

For further information on the product, not described in this publication, please

contact our helpdesk:

Tekmar Sistemi s.r.l – technical support & system engineering

Via De Crescenzi 40 - 48018- Faenza - ITALY

tel ++39.0546.697111

fax ++39.0546.682768

An online service using our Internet site is available.

web: http//:www.tekmar.it/helpdesk

e-mail: info@tekmar.it

BRITECELL System Manual MN010-04 June 2003 Page 70 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

APPENDIX

65. APPENDIX A - Britecell system design basics

65.1. Indoor propagation

Radio signals from wireless mobile telephone systems are located in the high UHF

spectrum, between 800MHz and 2,2GHz, according to the common standards such

as ETACS, AMPS, GSM, DCS, PCS, UMTS, etc.. At such high frequencies

electromagnetic waves are subjected to phenomena like diffraction and reflection;

these effects become dominant in cellular systems where propagation rarely occurs

in free space.

In a cellular system a single radiation point is normally provided for each cell or

sector, located at the BTS site. This may not have line of sight to every user in the

coverage area.

The simultaneous occurrence of diffraction and multiple reflections (multipaths) in

the indoor environment makes this the most critical, as far as signal propagation

and coverage is concerned. The presence of natural or artificial openings and

obstructions (such as walls) leads to a mean loss term, which is normally higher

than the free space loss.

The point is easily reached in indoor environments where the radio link loss

exceeds the maximum loss, determined by the transmitter power and receiver

sensitivity, for acceptable communication quality. This can happen in a few spots

of a room, affecting uniform coverage, or in entire sections of the building.

A common issue is the need to provide sufficient signal level in all parts of a

structure to dominate the signal from a local external cell, ensuring that calls

originating within the building are set-up on the internal system. This can add a

considerable challenge to the in-building coverage design as very high signal levels

may be required close to external openings, such as doors and windows.

When supplying cellular coverage to indoor environments, in order to reach full

network performances, receive levels at both the BTS and mobile handset must be

kept uniformly high by keeping link loss as low as possible. This can be obtained

using Britecell.

When supplying coverage to indoor composite areas, the radiation points should

be planned to be in line of sight with the mobile so that the radio link loss can be

kept consistently low.

The location of the BTS is no longer determined by the required radiation point;

more practical BTS locations are thus feasible and the radiation point locations can

be optimised to suit the coverage area.

Deploying a Britecell system fulfils these criteria. By using fibre optic guided

propagation very low link losses can be achieved, allowing signals to be carried

long distances in the building without appreciable degradation. Specific areas can

be targeted to fit traffic distribution, regardless of obstructions or location; cell

planning is simplified with minimum or no changes in network parameters setting.

In addition, the use of Britecell can avoid the introduction of further BTS's, where

coverage is required but there are no requirements for more traffic channels. This

can achieve considerable savings in the cellular system rollout.

BRITECELL System Manual MN010-04 June 2003 Page 72 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

65.2. Fibre-optic transmission

Britecell uses an analogue modulation scheme for the transmission of the

composite RF signal through the fibre optic link; the optical carrier is intensity

modulated.

Distortion is critical in cellular systems due to the multiple carriers present and the

regular channel spacing ensures that the products usually occur on the frequency

of another channel.

To minimise these problems Britecell uses high performance single mode lasers as

RF to optical transducers, the characteristics of which are dominant in the link

performance. Single mode optical fibre (SMOF) is employed due to its very low

loss, enabling signals to be carried for long distances when matched with sensitive

optical receivers.

With Britecell optical links in excess of 1.5 km can be achieved without appreciable

degradation of signal characteristics. Care must be taken to keep back reflection of

the optical carrier below -36 dBC to avoid additional link noise and signal

distortion.

We can detect two contributions to back reflection in optical links:

Microscopic variations in the refractive index in the fibre cause scattering of the

light; this depends on fibre length and can be kept within allowable limits by

limiting the length.

Concentrated reflections, due to refractive index discontinuity’s in the fibre are the

dominant source of returned light. These occur mainly at optical connectors so, to

reduce the severity, Britecell uses angled connectors, which direct reflected light

out of the fibre core. Only a negligible portion of light from the interface is

reflected back towards the source; return losses of greater than 60 dB can be

achieved with angled optical connectors.

In case that the system operates on a digital standard, a fundamental parameter

for the transparency is propagation delay through fibre, especially when the indoor

coverage extends an existing outdoor coverage of a BTS because of the need for

an outdoor-indoor overlap area. In this case differential delay between the direct

and repeated paths must be minimised. For example, the upper limit for GSM

systems is 8µs.

The velocity factor of silica glass optical fibre is 0.65, giving a propagation delay in

the fibre of 5ms/km; the Britecell equipment has a negligible contribution.

Optical fibre needs only a little care to be taken in system implementation and

maintenance to avoid possible malfunction. It offers many major advantages in inbuilding coverage design, apart from the ability to carry signals long distances.

Significant additional benefits are:

• High bandwidth capacity

• Electromagnetic Compatibility (EMC) of fibre optics is inherent in all

environments; fibre is insensitive to electromagnetic fields, lightning or

radiation and produces no interference to other equipment.

• SMOF cables for indoor applications can be very thin, easy to install and to

hide; thus they permit a low visual impact on the environment and a

minimum effort in their laying.

• Support structures can be minimal and no plenum-rated jacketing is

required for use inside structures (unless copper conductors are

incorporated).

Refer to the following sections for more information on the design and installation

fibre cabling in Britecell systems

BRITECELL System Manual MN010-04 June 2003 Page 73 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

65.3. Coverage method

The greatest benefit of Britecell fibre optic distribution system is the possibility to

place non obtrusive antennas where the coverage is needed, i.e. near the mobile

users.

The coverage targets, in terms of signal levels, are meant to be achieved by

placing radiating points inside the building.

Antenna locations are selected in order to:

• minimise path loss to mobiles in the public areas of the building,

• minimise number of remote antenna sites.

A careful planning of antenna position allows to achieve a low attenuation radio

link, since it minimises the effect of obstacles and it brings the radiating points

close to the mobile stations, often achieving a quasi line of sight propagation.

This also greatly reduces the fading effects. As a result, good quality radio links

can be achieved with low down link and up link transmit powers.

The low power Distributed Antenna System (DAS) provides uniform and well

confined coverage inside buildings.

BRITECELL System Manual MN010-04 June 2003 Page 74 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

b

66. APPENDIX B - Britecell input power level setting

66.1. Down link power levels

In order to achieve spurious products below the limits set forth in various

governmental specifications (eg. -36 dBm for GSM900, –30 dBm for GSM1800) the

input power at the TFL downlink input port should be set according to the

following table. FCC specifications (-13 dBm- AMPS, PCS) are somewhat more

lenient and are also dependent on spectral mask requirements.

TFL DL RF

input

TFL UL RF

output

NOTES:

DL power levels for Britecell 900 MHz and Britecell 1800 MHz

TFLxxxx4H-x

TFAxxxx

b

a

NUMBER OF

CARRIERS

(N)

Max power per carrier at

TFL DL RF input (a)

P

/carrier [dBm]

IN TFL

Max power per carrier at

TFA RF output (b)

P

/carrier [dBm]

OUT TFA

2 3,0 10,0

3 0,7 7,7

4 -0,3 6,7

5 -1,2 5,8

6 -1,8 5,2

7 -2,3 4,7

8 -2,7 4,3

9 -3,1 3,9

10 -3,4 3,6

11 -3,7 3,3

12 -4,0 3,0

14 -4,5 2,5

16 -4,9 2,1

18 -5,2 1,8

20 -5,6 1,4

22 -5,8 1,2

26 -6,4 0,6

30 -7,1 -0,1

34 -7,6 -0,6

40 -8,3 -1,3

BRITECELL System Manual MN010-04 June 2003 Page 75 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

66.2. Down link power levels: remote unit + booster

TFL DL RF

input

TFL UL RF

output

NUMBER OF

CARRIERS

(N)

NOTES:

DL power levels for Britecell 900 MHz + TFB915

DL power levels for Britecell 1800 MHz + TFB1815

The DL levels at Booster output assume that the cable connecting TFA and booster

has 1 dB loss.

TFLxxxx4H-x

TFAxxxx

b

c

TFBxxxx

b

a

Max power per

carrier at TFL DL RF

input (a)

P

/carrier

IN TFL

[dBm]

Max power per

carrier at TFA RF

output (b)

P

OUT TFA

/carrier

[dBm]

Max power per

carrier at TFB RF

output (c)

P

OUT TFB

/carrier

[dBm]

1 0,0 7,0 20,0

2 -4,0 3,0 16,0

3 -6,3 0,7 13,7

4 -7,3 -0,3 12,7

5 -8,2 -1,2 11,8

6 -8,8 -1,8 11,2

7 -9,3 -2,3 10,7

8 -9,7 -2,7 10,3

9 -10,1 -3,1 9,9

10 -10,4 -3,4 9,6

11 -10,7 -3,7 9,3

12 -11,0 -4,0 9,0

14 -11,5 -4,5 8,5

16 -11,9 -4,9 8,1

18 -12,2 -5,2 7,8

20 -12,6 -5,6 7,4

22 -12,8 -5,8 7,2

26 -13,3 -6,3 6,7

30 -13,8 -6,8 6,2

34 -14,1 -7,1 5,9

40 -14,6 -7,6 5,4

BRITECELL System Manual MN010-04 June 2003 Page 76 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

f

67. APPENDIX C - Classifying hazardous areas

Hazardous Area

A hazardous area is defined as: "An area in which a flammable substance in the

form of gas or vapour or dust, when mixed with air, is present in such proportions

that it can explode when in contact with an ignition source.

Area Classification

Hazardous areas are classified with respect to the potential danger or an explosion,

and the areas are divided into zones:

CONDITIONS CE Code EC

Continuously Hazardous Division 1

Periodically Hazardous Division 1

Occasionally Hazardous Division 2

Gases & vapour classification

Gases are grouped together basing on the amount of energy required to ignite the

most explosive mixture of the gases with air. Equipment is classified into groups

according to the gases and vapours for which it is suitable and must be selected

with a grouping, which covers the gases and vapours which, will be present where

it is to be installed:

Group Representative Gas Ignition Energy

I

IIA

IIB

IIC

GAS CE CODE IEC

Acetylene Class I, Group A Group IIC

Hydrogen, Butadiene, Ethylene Oxide, Propylene Oxide, or Acrolein Class I, Group B Group IIC

Ethylene, Cyclopropane, Ethyl Ether, or Ethylene Class I, Group C Group IIB

Propane, Acetone, Alcohol, Ammonia, Benzine, Benzol, Butane,

Gasoline, Hexane, Laquer Solvent vapours, Naptha, Natural Gas

Coal Mines

Combustible Dusts Class II

Ignitable Fibres or Flying Class III

To ensure the suitability of electrical equipment for use in hazardous areas, the

equipment is certified and uses various techniques known as Methods of

Protection. As not all Methods of Protection are suitable for all hazardous areas,

care must be taken to select equipment, which is suitable for use in the Zone in

which it is installed.

Zone 0 Zone 1 Zone 2

Ex ia - Intrinsic safety

Ex s - Special protection i

specifically certified for Zone 0

* may be suitable for Zone 1

BRITECELL System Manual MN010-04 June 2003 Page 77 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

Zone 0 - An area in which an explosive gas/air mixture is

continuously present or is present for long periods.

Zone 1 - An area in which an explosive gas/air mixture is

likely to occur under normal operating conditions.

Zone 2 - An area in which an explosive gas/air mixture is

unlikely to occur, but if it occurs, it will be of short duration.

Methane

Propane

Ethylene

Hydrogen

Method suitable for Zone 0

Ex ib - Intrinsic Safety

Ex d - Flameproof enclosure

Ex e - Increased safety

Ex m - Encapsulation

Ex s - Special protection

320 Microjoules

300 Microjoules

160 Microjoules

40 Microjoules

Class I, Group D Group IIA

Gaseous Mines Group 1

Method suitable for Zone 0 or l

Ex N - Type of protection N

Ex o - Oil immersion*

Ex q - Powder filling*

Ex p - Pressurised or purging

68. APPENDIX D - Health and safety warnings

Antenna installation must conform within the following guidelines to meet FCC RF

exposure limits, otherwise an environmental evaluation is required if:

Broadband PCS (subpart E):

Non building mounted antennas: Height above ground level to lowest point of

Building-mounted antennas: Total power all channels>2000W ERP (3280W EIRP)

Narrowband PCS (subpart D):

Non-building-mounted antennas: Height above ground level to lowest point of

Building-mounted antennas: Total power of all channels > 1000 W ERP (1640 W

Cellular Radiotelephone Service

(Part 22, subpart H):

Non-building-mounted antennas: Height above ground level to lowest point of

Building-mounted antennas: Total power of all channels > 1000 W ERP (1640 W

Paging and Radiotelephone Service

(Part 22, subpart E):

Non-building-mounted antennas: Height above ground level to lowest point of

Building-mounted antennas: Total power of all channels > 1000 W ERP (1640 W

Private Land Mobile Radio \

Specialized Mobile Radio (Part 90):

Non-building-mounted antennas: Height above ground level to lowest point of

Building-mounted antennas: Total power of all channels > 1000 W ERP (1640 W

antenna< 10m Radio (Part 24) and total power of all

channels > 2000 W ERP (3280 W EIRP)

antenna < 10m Radio (Part 24) and total power of

all channels > 1000 W ERP (1640 W EIRP).

EIRP).

antenna < 10m Radio (Part 22) and total power of

all channels > 1000 W ERP (1640 W EIRP).

EIRP).

antenna < 10m Radio (Part 22) and total power of

all channels > 1000 W ERP (1640 W EIRP).

EIRP).

antenna < 10m Radio (Part 90) and total power of

all channels > 1000 W ERP (1640 W EIRP).

EIRP).

BRITECELL System Manual MN010-04 June 2003 Page 78 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

Loading...

Loading...