SYSTEM INSTALLATION MANUAL

Rel. 4

Copyright Tekmar Sistemi s.r.l.

This document contains information, which is the property of Tekmar Sistemi S.r.l.

The contents are confidential, any reproduction of all or part of this publication, without

the written consent by Tekmar Sistemi s.r.l is forbidden.

This publication is issued to provide outline information and is not deemed to form any part

of any offer and contract. The company has a policy of continuous product development

and improvement and we therefore reserve the right to vary any information quoted

without prior notice.

Britecell is designed & manufactured by

BRITECELL System Manual MN010-04 June 2003 Page 2 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

1. INDEX

1. INDEX .......................................................................................................3

GENERAL INFORMATION ...................................................................................6

2. HOW TO READ THIS MANUAL..................................................................... 7

3. INSTALLATION & SAFETY REQUIREMENTS.................................................. 8

3.1. Environmental conditions: .................................................................8

3.2. Installation site features ....................................................................8

3.3. Power connection .............................................................................9

3.4. Safety and precautions during the installation..................................... 9

3.5. Safety and precautions for lasers .......................................................9

3.6. Warning Labels............................................................................... 10

BRITECELL SYSTEM......................................................................................... 11

4. SYSTEM DESCRIPTION ............................................................................. 12

4.1. Services ......................................................................................... 13

4.2. Block diagram................................................................................. 13

4.3. Functional description ..................................................................... 14

5. EQUIPMENT DESCRIPTION....................................................................... 15

5.1. Britecell™ subracks ........................................................................ 15

5.2. Subrack modules ............................................................................15

5.3. Remote equipment ......................................................................... 16

TFL local unit .................................................................................................. 17

6. Introduction ............................................................................................. 18

7. Part description ........................................................................................ 18

8. Warnings ................................................................................................. 19

8.1. Connectors care and cleaning .......................................................... 19

8.2. Laser caution.................................................................................. 19

9. Functional description ............................................................................... 20

9.1. Block diagram................................................................................. 20

9.2. Down link operations ...................................................................... 20

9.3. Up link operations ........................................................................... 21

10. Alarms and settings ................................................................................ 21

11. Installing and cabling.............................................................................. 23

11.1. TPR housing................................................................................ 23

11.2. Power supply .............................................................................. 23

11.3. RF inputs .................................................................................... 23

11.4. Optical connections ..................................................................... 24

12. Start-up ................................................................................................. 24

13. Troubleshooting ..................................................................................... 25

TFA remote unit .............................................................................................. 26

14. Introduction ........................................................................................... 27

15. Part description ...................................................................................... 27

16. Warnings ...............................................................................................28

16.1. Connector care and cleaning ........................................................ 28

16.2. Laser caution .............................................................................. 28

17. Functional description ............................................................................. 29

17.1. Block diagram ............................................................................. 29

17.2. Down link operation..................................................................... 29

17.3. Up link operations. ...................................................................... 30

18. Alarms and settings ................................................................................ 30

18.1. LED alarms ................................................................................. 30

18.2. External alarms ...........................................................................30

18.3. Setting uplink gain (PGR) ............................................................. 31

19. Installing and cabling.............................................................................. 32

BRITECELL System Manual MN010-04 June 2003 Page 3 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

19.1. Location...................................................................................... 32

19.2. Power supply and grounding ........................................................ 32

19.3. RF combined ports ...................................................................... 33

19.4. Optical fibres connection .............................................................. 33

20. Start-up ................................................................................................. 33

21. Troubleshooting ..................................................................................... 34

TPR 19" subrack.............................................................................................. 35

22. Introduction ........................................................................................... 36

23. Part description ...................................................................................... 36

24. Warnings ...............................................................................................36

25. Functional description ............................................................................. 37

25.1. Block diagram ............................................................................. 37

26. Alarms ................................................................................................... 37

27. Installation and cabling ........................................................................... 40

27.1. Location...................................................................................... 40

27.2. Power supply .............................................................................. 40

28. Start up ................................................................................................. 42

29. Troubleshooting ..................................................................................... 42

TFL-BSI RF attenuator .....................................................................................43

30. Introduction ........................................................................................... 44

31. Part description ...................................................................................... 44

32. Warnings ...............................................................................................44

33. Functional description ............................................................................. 44

33.1. Down link operation..................................................................... 44

33.2. Uplink operation .......................................................................... 45

34. Installation and cabling ........................................................................... 45

34.1. TPR housing................................................................................ 45

35. Calculation of attenuation setting ............................................................ 45

35.1. Downlink..................................................................................... 45

35.2. Uplink ......................................................................................... 45

TLC RF combiner - splitter................................................................................ 46

36. Introduction ........................................................................................... 47

37. Part description ...................................................................................... 47

38. Functional description ............................................................................. 47

39. Warnings ...............................................................................................47

40. Installation and cabling ........................................................................... 47

40.1. TPR housing................................................................................ 47

THYB common path RF combiner ..................................................................... 48

41. Introduction ........................................................................................... 49

42. Part description ...................................................................................... 49

43. Functional description ............................................................................. 49

44. Warnings ...............................................................................................49

45. Installation and cabling ........................................................................... 49

TFB booster ....................................................................................................50

46. Introduction ........................................................................................... 51

47. Part description ...................................................................................... 51

48. Warnings ...............................................................................................51

49. Functional description ............................................................................. 51

49.1. Block diagram ............................................................................. 51

49.2. Description.................................................................................. 52

50. Alarms ................................................................................................... 52

51. Installation and cabling ........................................................................... 52

51.1. Location...................................................................................... 52

51.2. Power supply and grounding ........................................................ 53

51.3. RF combined ports ...................................................................... 53

52. Start up ................................................................................................. 53

53. Troubleshooting ..................................................................................... 54

BRITECELL System Manual MN010-04 June 2003 Page 4 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

TPA antenna ................................................................................................... 55

54. Introduction ........................................................................................... 56

55. Functional description ............................................................................. 57

56. Installation and cabling ........................................................................... 58

56.1. Location...................................................................................... 58

56.2. Location examples ....................................................................... 59

56.3. Wall mount ................................................................................. 59

56.4. Connectivity ................................................................................ 60

57. Troubleshooting & maintenance .............................................................. 60

SYSTEM INSTALLATION................................................................................... 61

58. Installation and cabling ........................................................................... 62

58.1. Local unit and subrack location .................................................... 62

58.2. Remote unit and antennas location............................................... 62

58.3. Fibre-Optic Cables .......................................................................62

58.4. Power Supply .............................................................................. 65

59. SYSTEM START-UP ................................................................................. 65

60. MAINTENANCE ....................................................................................... 66

60.1. Plug-in cards removal ..................................................................66

60.2. Optical equipment .......................................................................66

OTHER INFORMATION .................................................................................... 67

61. TERMINOLOGY....................................................................................... 68

62. WARRANTY CONDITIONS ....................................................................... 68

63. DECLARATION OF CONFORMITY............................................................. 70

64. TECHNICAL SUPPORT............................................................................. 70

APPENDIX....................................................................................................... 71

65. APPENDIX A - Britecell system design basics ............................................ 72

65.1. Indoor propagation...................................................................... 72

65.2. Fibre-optic transmission ............................................................... 73

65.3. Coverage method ........................................................................ 74

66. APPENDIX B - Britecell input power level setting....................................... 75

66.1. Down link power levels ................................................................75

66.2. Down link power levels: remote unit + booster ............................ 76

67. APPENDIX C - Classifying hazardous areas .............................................. 77

68. APPENDIX D - Health and safety warnings ............................................... 78

BRITECELL System Manual MN010-04 June 2003 Page 5 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

GENERAL INFORMATION

y

y

2. HOW TO READ THIS MANUAL

This manual provides equipment specifications, operational descriptions,

application, and installation information as well as a troubleshooting guide. It is

intended to be a comprehensive document used to install and operate a Britecell

system.

The manual consists of many sections.

The first main section includes a global description of the Britecell system, major

equipment warnings, warranty information, customer service and support as well

as troubleshooting guidelines.

Other sections describe specific components, which are used to build or expand a

Britecell system. Each section points out warnings and installation instructions.

GENERAL SECTION:

• general & safety requirements

• s

stem description

TFL section

TFA section

Subrack section

…

SYSTEM SECTION

• installation requirements

• start-up

• maintenance

OTHER INFORMATION

• terminology

• warranty & support

• declaration of conformit

APPENDIX

BRITECELL System Manual MN010-04 June 2003 Page 7 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

3. INSTALLATION & SAFETY REQUIREMENTS

3.1. Environmental conditions:

This equipment is designed to be installed inside buildings.

Operating temperature: +5 to +40°C

Do not install in corrosive atmosphere or in critical environmental conditions such

as hazardous classified areas (for example see appendix C).

3.2. Installation site features

A trained technician should carry out the installation of the donor rack. Since the

system is designed for indoor installation, the rack should be installed in a dry and

suitable location where:

• no explosion risks is present;

• the environment is not classified as a high-risk one in case of fire;

• suspended particles are not to be found in great concentration;

• the environment is not subject to any traffic which could cause crash

damages;

• the site is properly located with respect to the ergonomic positioning of the

working environments;

• the system is placed in a private room, protected against any possible

violation;

• the system must not be exposed to ultra-violet rays;

• the site must be accessible by maintenance personnel;

• the site must be dry, with low humidity;

• the site must guarantee proper space for cables and natural ventilation to the

system;

• 2 meters must be kept from the rack to any heating opening.

The remote units should be mounted in reasonable locations as well:

• do not install inside heating or conditioning;

• do not install inside cable pipeline, fire-prevention site, (fire escape, lift

tunnels, emergency exits, which have to guarantee defined safety standards);

• keep into consideration that the temperature in the upper part of a room is

higher than at 2 meters height. For false ceiling installation, verify that the

environment temperatures do not exceed allowed limits;

• remote unit requires its own power and a connection to the mains can be

needed;

• keep into consideration that the remote unit transmits RF signal and safety

volume must be respected (refer to country regulations for safety volume

magnitude);

• remote units are typically installed next to the ceiling and for safety reasons

they must be properly mounted;

• remote units must be accessible for tests and maintenance.

BRITECELL System Manual MN010-04 June 2003 Page 8 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

3.3. Power connection

Power connection has to be carried out following all the necessary precautions:

• it must be properly made according to the due diligence rules (ex.: CEI rules,

IEC rules, etc.);

• in accordance with the rules for safety against direct or indirect contacts;

• in accordance with the rules for safety against the over current (short circuit,

overloading);

• in accordance with the rules for safety against over tension;

• connection is to be carried out by proper and competent staff

3.4. Safety and precautions during the installation

During installation the following means and tools will be needed:

Typical electrician tools:

cross-point screwdriver, scissors, pliers, nippers, drill and bits, screw for fixing

remote units to the wall.

Typical means:

proper ladder, scaffolding or air platform for ceiling installation of remote units.

N.B: cautions should be used when installing at a height upper than 2 meters.

9

Personnel who are installing this equipment should be informed about the

possible risks and safety measures when elevated.

3.5. Safety and precautions for lasers

The laser used in Britecell contains an optical transmitter, which has a power level

that is not dangerous to a person's health. However it is classified as class III B

(norm EN60825) equipment. It is nevertheless prudent in the installation phase to

observe the following rules:

Never look directly at the internal optic connector exit of the transmitter

9

apparatus when it is switched on. The wavelength of the laser is not visible to

the human eye, which means that long-term damage will not immediately be

known.

9

When working with the optical connectors, check at each end that both

transmitting lasers are switched off.

BRITECELL System Manual MN010-04 June 2003 Page 9 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

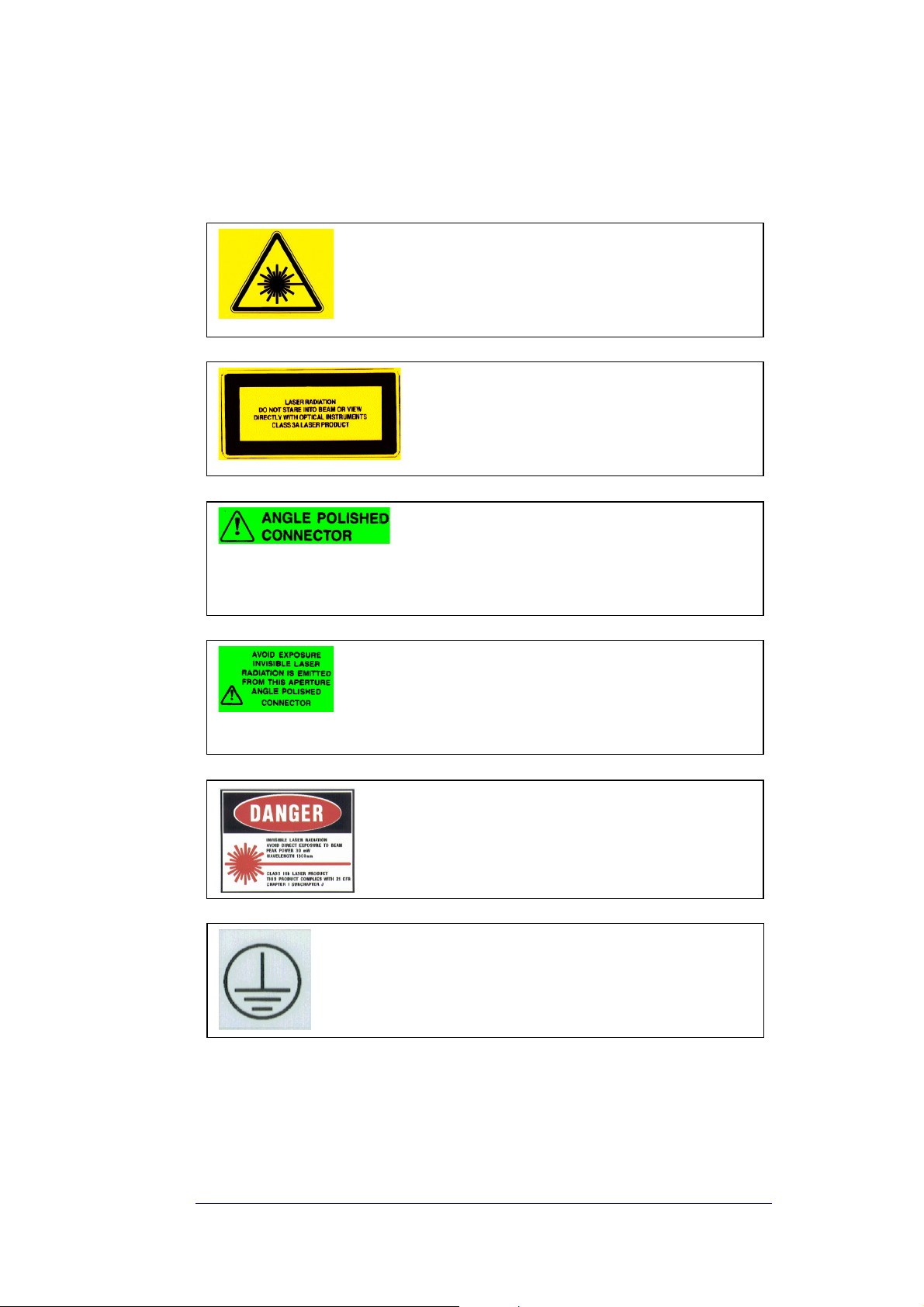

3.6. Warning Labels

Caution! - invisible laser radiation from

this aperture

Caution! - Laser radiation. Do not stare

into the beam or view directly with optical

instruments –

CLASS 3A laser product

Caution! - angled polished connector

Caution! - invisible laser radiation from

this aperture –

angle polished connectors

Caution! - possible invisible laser radiation,

max. power 30mW,

wavelength 1300nm,

laser product CLASS III B

GROUND - Use this terminal for a safety

ground connection of the equipment.

BRITECELL System Manual MN010-04 June 2003 Page 10 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

BRITECELL SYSTEM

4. SYSTEM DESCRIPTION

Britecell is a low power distribution system designed to provide indoor coverage for

mobile communication networks.

.The whole system is based on the fiberoptic transmission of multiple RF carriers

from an optical donor unit interfacing to the BTSs (TFL) and an optical remote unit

located in remote sites (TFA) near an antenna.

The transmission of the uplink and downlink RF signals is attained by using bidirectional fiberoptic links. Furthermore it is possible to reach and feed multiple

remote antennas by distributing a number of fiberoptic links in a star configuration.

The system has been designed to make use of the concept of “low power

distributed antenna system” (DAS). The premise of the DAS system is to achieve

good link quality through the use of many lower power radiating points (fed by

TFAs).

The advantage of this system is lower costs and higher reliability. This is possible

because high power amplifiers are both costly and less reliable than low power

devises.

Britecell is very simply and including a built-in AGC. As such it requires a minimum

design, installation and set-up effort, in contrast with a comparable active cable

systems, which require considerable uplink and downlink design and optimisation.

A rack complete with 6 donor units (TFLs), a remote unit (TFA) and two antennas

BRITECELL System Manual MN010-04 June 2003 Page 12 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

The system.

4.1. Services

The Britecell system can operate with single band or dual-band. The following is a

list of possible standards with related frequencies:

FREQUENCY OPTIONS BANDWIDTH [MHz]

UHF GSM900+GSM1800 UHF 406:512 406:512

VHF paging GSM900+PCS VHF paging --- 270:290

TRUNKING RADIO

AMPS+PCS

TRUNKING RADIO

AMPS AMPS+DCS PDC800 810:830 940:960

GSM900 TRUNKING+PCS AMPS 824:849 869:894

PDC1500 E-GSM+GSM1800 E-GSM 880:915 925:960

GSM1800 E-GSM+PCS GSM 890:915 935:960

PCS UMTS (UTRA FDD) PDC1500 1429:1453 1477:1501

E-GSM GSM1800 1710:1785 1805:1880

PCS 1850:1910 1930:1990

UMTS 1920:1980 2110:2170

Tab. 1 - services

uplink downlink

805:825 850:870

4.2. Block diagram

This is a basic system configuration. The overall system design and coverage

project may need different architectures, and different ancillary configurations.

Fig. 1

Low

Band

High

Band

BTS

TX

BTS

RX

TX

RX

Card 1

TFL

-6 dB

TLC

DL-variable

Attenuator

TFL

BSI

UL-variable

Attenuator

DL-variable

Attenuator

TFL

BSI

UL-variable

Attenuator

TLC

2501

-4 dB

TLC

2502

-4 dB

2503

-6 dB

-6 dB

TLC

2503

-6 dB

Card 2

TFL

Card 3

TFL

Card 4

TFL

Card 5

TFL

Card 6

TFL

TPR 912

Max 1.5 Km Opt. Fiber

TFA

TFA

TFA

TFA

TFA

TFA

TFA

TFA

TFA

TFA

TFA

TFA

TFA

TFA

TFA

TFA

TFA

TFA

Fig. 2 - Block diagram

BRITECELL System Manual MN010-04 June 2003 Page 13 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

4.3. Functional description

The basic system blocks are the fiber donor unit TFL (Local Unit) and the fiber

remote unit TFA (Remote Unit).

They are connected in both directions (uplink and downlink) through single mode

optical fibre.

The system has a built-in Automatic Gain Control (AGC), which automatically

adjust the up link and down link gain in order to compensate for optical link loss

This allows the downlink transmit power and the up link sensitivity to be virtually

independent on fibre length and on the number of splices or optical connectors

present along the fibre link.

Each Local unit can support and constantly monitor up to 4 remote units.

Moreover up to 6 central units can be housed, together with power supply, in the

same subrack 19”.

The TFA feeds up to two coverage antennas. In this way it is possible to set up a

network of 24 transceivers and up to 48 coverage antennae (see Fig.2).

The connection between the BTS and Britecell system can either be direct or,

through a repeater.

In Fig. 1, a typical direct connection to BTS is showed for a dual band system. The

building blocks of the combining network are:

• two/three way combiners and splitters (TLC2502/3);

• cross-band couplers (TLC2501);

• variable attenuators (TFL-BSI).

1

.

The combining network has to be carefully designed in order to optimise the

connection to the BTS and the system performances.

1

provided that the specified limits are not exceeded

BRITECELL System Manual MN010-04 June 2003 Page 14 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

(please refer to datasheets)

5. EQUIPMENT DESCRIPTION

Britecell is a modular system. Many options and accessories are available,

depending on the desired coverage area. The following is a list of main

accessories, suitable for most applications.

5.1. Britecell™ subracks

The Local Units are located inside a 19” 6HE sub-rack. From this rack, power is

supplied for the all fibre donor units (TFL).

Fig. 3 – 19” sub-rack

Subrack can be supplied by a -48V DC or by universal mains (85-264VAC). See

datasheets for further details.

Power switches and fuses are placed on subrack back panel (see TPR section

below).

5.2. Subrack modules

TFL - LOCAL UNIT TFL-BSI TLC2502

• TFL is the RF to optical converter.

• TFL-BSI is a variable RF attenuator (0-30dB)

• TLC2502 and TLC2503 are RF splitters/combiners

BRITECELL System Manual MN010-04 June 2003 Page 15 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

5.3. Remote equipment

Fig. 4 - TFA remote unit Fig. 5 - TPAxxx -

remote antenna

Fig. 6 - TFB - RF booster

TFA is the optical to RF converter.

TPA is the suggested indoor antenna family.

TFB is the RF booster if needed to extend the coverage area.

TFA can feed up to two antennas while TFB can be connected to one antenna.

Detailed descriptions of these components are available in the sections below.

BRITECELL System Manual MN010-04 June 2003 Page 16 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

TFL local unit

6. Introduction

This section describes the TFL (Local Unit). The TFL is the part of Britecell system

that provides E/O downlink conversion and O/E uplink conversion of RF signal.

The TFL is connected to remote TFA by means of two optical fibres.

The system forms a star configuration. One fibre is dedicated to the transmission

of the downlink signals received from BTS and re-transmitted to the mobile. The

other fibre supports the transmission of up-link signals, received from mobile

through the TFA remote units and destine for the BTS.

The TFL cards are 6HE plug-in modules and are contained in a standard 19”

subrack (TPR family).

7. Part description

Power Supply led (green)

Backplane

Connector

DL Laser Alarm (red)

DL RF Test Port (SMB-m)

DL RF Input (SMA-f)

Downlink

Optical

Connectors

Dummy (used in other application)

Laser off led (yellow)

UL Alarm leds (red)

UL RF Test Port (SMB-m)

UL RF Output (SMA-f)

UL Alarm leds (red)

Fig. 7 – TFL Local Unit part description

Uplink

Optical

Connectors

BRITECELL System Manual MN010-04 June 2003 Page 18 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

8. Warnings

CAUTION! do not remove or insert any module into TPR subrack, without prior

9

switching power supply off.

8.1. Connectors care and cleaning

Optical connectors for single mode fibers are designed for submicron tolerances.

Such a connector has an optical section of only 9 µm diameter. The rules below

must be carefully followed

Do not leave optical connectors open, as they will attract dirt.

9

Do not touch the connector tip. Clean it with a proper tissue before inserting it

9

into the sleeve.

If a better cleaning is needed, use pure ethyl alcohol. Sleeves may be cleaned by

injecting pure gas under pressure.

Do not attempt to insert connectors mechanically incompatible. This will result

9

in severe damage.

The optical connector is a high precision device. It must be handled with care, to

avoid scratches and other mechanical/optical damages that will impair or reduce

the system’s performance.

8.2. Laser caution

The TFL contains semiconductor lasers. Precautions should be taken when

handling, installing or servicing this equipment.

Invisible laser radiation may be emitted from the optical transmitter orifice at the

TFL local interface:

Do not stare into the beam or use optical instruments with powered

9

equipment.

BRITECELL System Manual MN010-04 June 2003 Page 19 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

p

U

p

p

9. Functional description

9.1. Block diagram

Downlink Transmitter

RF IN

50 Ω

AC input from mains

POWER SUPPLY

RF OUT

50 Ω

NIT

2-ways

combiner

IMPEDANCE

MATCHING

NETWORK

VOLTAGE

REGULATOR

VOLTAGE

REGULATOR

2-ways

combiner

CURRENT

GENERATOR

GENERATOR

+8V

+12V

+5V

Uplink Receiver 1

Uplink Receiver 2

Uplink Receiver 3

NOISE

VOLTAGE

CONTROLLED

ATTENUATOR

Laser bias

Opt. power

monitor

TFLMICRO module

Pwr fault

D

A

C

LASER module

LASER DIODE

MONITOR

PHOTODET.

Low RX

opt.power

µPROC.

4 MHz

LNA AMP AMP

A

D

C

PHOTODETECTOR

2-ways opt.

VARIABLE

GAIN AMP.

s

litter

Pwr supply is

Optical

connectors

2-ways opt.

s

2-ways opt.

s

on

litter

litter

Optical

connectors

ALARMS AND

COMMAND SIGNALS

MANAGEMENT

CIRCUITS

STATUS MONITOR

LEDS AND ALA RM

LEDS

V

OPT

ALARMS AND

COMMAD

CONNECTOR

2-ways

combiner

Uplink Receiver 4

Fig. 8 - block diagram

9.2. Down link operations

In down link the TFL fulfils the following operations:

Power level adjustment:

if the RF signal coming from the BTS has a power level which is not

adequate to TFL’s characteristics, an external adjustment is required. It

consists in an attenuation when BTS is connected through a coupler or

through repeater (please refer to TFL-BSI).

E/O Conversion:

RF signal modulates the intensity of an optical carrier through an electrooptic device (laser). One laser is present on each TFL card.

Optical Splitting:

modulated optical carrier is split into 4 ways so that it may be transmitted

on a maximum of 4 optical links.

BRITECELL System Manual MN010-04 June 2003 Page 20 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

9.3. Up link operations

In uplink, signals pass through a duplexer and are then subjected to the following

operations:

O/E Conversion:

there are 4 O/E conversion devices (or optical receivers) in one TFL (one

for each optical link).

Amplification:

amplification is needed to compensate the optical fibre loss (maintaining a

good signal to noise ratio) so that for each link a constant gain is obtained.

RF Combining:

signals coming from all the remotes are combined into a single RF port.

Power level Adjustment:

TFL output may need a level adjustment so that the RF signals are within

the optimum BTS receiving range (please refer to TFL-BSI).

10. Alarms and settings

Two types of local alarm are available:

Visual alarms

the front panel of a TFL Local Unit shows the following status for alarm LEDs:

:

Link LED Colour Meaning (when lit)

= Green Laser is biased

Downlink

Transmitter

Red

Laser optical power under limits

and/or bias is not present.

OFF Yellow Laser has shutdown command.

Uplink receivers

Tab. 2 -Alarm LEDs

Red

Input optical power is lower

than pre-set.

Relay logic alarms detectable on connector:

in the rear of TFL units an alarm interface connector passes information about

summary alarms and specific alarms which can be sent to an OMC (Operating and

Maintenance Centre) via the BTS. In addition the alarms may be monitored from

Britecell’s own OMC (please refer to TPR).

Settings:

No adjustments are required at local interface module.

Four optical receivers are present at each TFL.

Unused receivers

may cause uplink alarms if enabled. In order to avoid UL alarms

unused receivers must be turned off. This can be done simply changing jumper

position as shown on Fig. 9 and Fig. 10 .

Tab. 3 is a chart of the correct jumper positions.

Each receiver has a number silk screen printed on the metal protection, which

corresponds to the relevant UL optical port on the TFL front panel.

The jumper number and relevant receiver status are printed on TFA main board,

so that the operation results very simple.

BRITECELL System Manual MN010-04 June 2003 Page 21 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

RX No.1

RX No.2

RX No.3

RX No.4

Uplink receiver enabling Jumpers

Fig. 9- Uplink jumpers

RX ON RX OFF

Fig. 10- Uplink jumper positions

Receiver Status Jumper position

ON JP1

OFF JP2

ON JP3

OFF JP4

ON JP5

OFF JP6

ON JP7

OFF JP8

Tab. 3 - Jumper positions

BRITECELL System Manual MN010-04 June 2003 Page 22 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

11. Installing and cabling

11.1. TPR housing

The TFL modules are contained in a 6 HE sub-rack (TPR family). The local

interfaces cannot be placed next to each other.

The TFL local interface cards may only be fitted in slots 1, 3, 5, 7, 9, and 11 of the

sub-rack.

Fig. 11 - Subrack slots Fig. 12– Dummy plug

If any slots are unused the backplane connectors must be fitted with a dummy

plug (provided) to avoid alarms being generated (see Fig.15).

Installation of Local Interface should be implemented in accordance with standard

rules related to fixed base equipment.

WARNING: prior to removing or inserting any modules, make sure that the

9

power supply is off.

9

WARNING: the TFL cards must be handled with care in order to avoid

damages to electrostatic sensitive devices.

Should a Local Unit need to be removed, first remove the left adjacent module.

The sub-rack housing if correctly installed (see TPR section) provides also the

proper air circulation to the Local Unit.

11.2. Power supply

TFL cards are powered by the proprietary backplane (Sub-rack TPR family), power

consumption is 12W for each TFL.

11.3. RF inputs

The RF combining and interface section, if properly designed, provides the right

power levels to the TFL.

WARNING: Do not exceed the maximum RF level allowed for downlink input

9

(see TFL datasheets). Please refer to the system design for variable attenuator

settings (see system start-up section)

BRITECELL System Manual MN010-04 June 2003 Page 23 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

11.4. Optical connections

Optical connectors are designed to have proper alignment and mechanical support.

When inserting an optical connector, take care to handle it smoothly enough so as

not to damage the fibre.

Fasten the fibre cable to the provided seating base by means of the included

wrapper.

Remove the dust cap only immediately before making connections.

Do not force or stretch the fibre pigtail with curve radius less than 5 cm. See

9

Fig. 13 for optimal fibre cabling.

WRONG OPTIMAL

Fig. 13 – Fibre connection

12. Start-up

A preliminary verification of TFL correct operation is:

1. switch-on the TPR subrack

2. verify the following LED status

Link LED Colour Status

= Green ON

Downlink

Transmitter

Uplink

receivers

For a full functionality test please refer to the system start-up section.

Red OFF

OFF Yellow OFF

Red

Depending upon TFA status,

always off if receiver alarm

disabled

BRITECELL System Manual MN010-04 June 2003 Page 24 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

13. Troubleshooting

Correct alarm interpretation is very useful not only during the installation, but also

during maintenance

TFL laser failure:

replace the faulty transmitter by replacing the TFL unit with a new one.

RX alarm only:

first go to the TFL site and check if optical connectors of TFL are properly

cleaned.

If the problem still exists, go to the TFA site (the TFA which yields also

visual RX alarm at TFL). If the TFA shows a visual alarm, clean the

downlink optical connector.

If the TFA is still alarmed, measure the downlink optical power at TFA

input with an optical power meter and verify if it is higher than –5 dBm. If

it is not, the fibre cable (at least as far as the downlink fibre is concerned)

has some problems. If optical power is higher than –5 dBm, replace the

TFA.

BRITECELL System Manual MN010-04 June 2003 Page 25 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

TFA remote unit

14. Introduction

This section describes the TFA (Remote Unit).

The TFA is part of the Britecell system and provides O/E downlink conversion and

E/O uplink conversion.

The TFA is connected to passive antennas, which transmit and receive from and to

the mobiles.

Each TFA is connected to a TFL through two optical fibres.

This forms a star configuration. One fibre is dedicated to the reception of the

downlink signals that the TFA receives from TFL, and re-transmits to mobile

stations. The other fibre supports the transmission of uplink signals, which each

TFA gathers from the mobiles operating in its coverage area, to the TFL.

TFA can feed antennas through two external RF ports, except UMTS TFA where a

single RF TRx port is provided.

15. Part description

Green LED = power on

Red LED = alarm

Power supply RF TRx port

RX TRx port External alarm

DL opt. port UL opt. port

Fig. 14 – TFA Remote Unit part description

BRITECELL System Manual MN010-04 June 2003 Page 27 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

16. Warnings

16.1. Connector care and cleaning

Do not leave connectors open. Unused optical connectors must always be

9

covered with their caps.

Do not touch the connector tip. Clean it with proper tissue before inserting

9

them into the sleeve.

If better cleaning is needed, use pure ethyl alcohol. Sleeves may be cleaned by

injecting pure gas under pressure.

Do not attempt to insert connectors mechanically incompatible. This will result

9

in severe damage.

The optical connector is a high precision device. It must be handled with care to

avoid scratches and other mechanical/optical damages that will impair or reduce

the system performance.

16.2. Laser caution

The TFA contains semiconductor lasers. Precautions should be taken when

handling, installing or servicing this equipment.

Invisible laser radiation may be emitted from the optical transmitter connector of

the TFA interface:

Do not stare into the beam or use optical instruments with the equipment

9

powered on.

BRITECELL System Manual MN010-04 June 2003 Page 28 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

p

g

17. Functional description

17.1. Block diagram

External Booster alarms

PHOTODETECTOR

RX optical power monitor

LNA AMP

VARIABLE

AMP.

GAIN

Low RX optical

power

A

µPROC.

D

C

4 MHz

D

A

Threshold

circuit

with

adjustable

threshold

level.

MATCHING

NETWORK

CURRENT

GENERATOR

NOISE

GENERATOR

LASER control

module

Note 1: not present in UHF TDD version

LASER DIODE

MONITOR

PHOTODET.

LASER module

VOLTAGE

CONTROLLED

ATTENUATOR

Attenuator

control voltage

DL final amplifier stage out

of allowed range

AMP

Paging RF SMA

connector 50 Ω

AMP

AMP

AMP

DL final amplifier stage

current monitor

Internal LED: DL

final amplifier

stage out of

e

allowed ran

OR

circuit

VOLTAGE

AMP

CONTROLLED

ATTENUATOR

attenuator

control

voltage

UL ATTENUATOR CONTROL

SWITCHES

+12 V

+5 V

-8 V

Fig. 15 – TFA block diagram

AMP

AMP

Diff. AMP

AMP

AMP

Green LED:

Red LED: UL

final amplifier

stage current

out of allowed

range or low

tical power

o

LNA

LNA

DC/DC

converter

Voltage

Regulator

power on

AC input from

POWER SUPPLY

UNIT

(note1)

RF N

50 Ω

RF N

50 Ω

mains

17.2. Down link operation

In the downlink the TFA fulfils the following operations:

O/E Conversion:

the optical signal is demodulated through an opto-electronic device (p-i-n

photodiode).

Amplification & Filtering:

amplification is required to boost the downlink signal after is converted

from light back to RF. Maintaining a good signal-to-noise ratio is critical for

this operation; part of the amplification process automatically takes into

account the variable loss introduced by the optical fibre.

A clean-up filter is used after the amplification process to limit transmission

to the downlink band and to reduce spurious emissions in the uplink band

where they would interfere with the signal coming from the mobile.

Duplexing:

the RF signal enters a duplexer which combines downlink and uplink on a

single port which is then split and goes to two separate antenna ports.

BRITECELL System Manual MN010-04 June 2003 Page 29 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

17.3. Up link operations.

In the uplink the TFA performs the following functions:

Filtering & Amplification:

a filter delimits the uplink band and a low noise amplifier increases the

signal level to minimise the noise figure of the link.

E/O Conversion:

the RF signal coming from the antennas modulates the intensity of an

optical carrier through a laser.

18. Alarms and settings

18.1. LED alarms

For TFA units only visual alarms are provided. Two LEDs represent them:

LED Colour Meaning (when lit)

LD1 Red

No optical power at DL input and/or

amplifier failure

LD2 Green Power supply is on

Tab. 4 – TFA Alarm LEDs

NOTE:

the uplink laser is on only if downlink optical signal is present and

no failure occurs in the TFA; in case of any failure, the uplink laser is

switched off.

It is useful to note that as a downlink failure will be reported to both TFL a TFA, it

is possible to determine a fibre or TFA failure from either the TFA or TFL.

This information can be used in conjunction to others for troubleshooting (see

par.21).

18.2. External alarms

TFA is provided with two external alarm contacts.

These contacts are open under non-alarm condition (normally open).

Fig. 16 - External alarms (dry contacts)

Alarm when closed

BRITECELL System Manual MN010-04 June 2003 Page 30 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

18.3. Setting uplink gain (PGR)

To optimise system performances related to “blocking level” (refer to system

design for further details), TFA units shall include an RF uplink attenuator to adjust

the uplink gain (Pre-settable Gain Reduction – PGR).

Up link gain setting can be easily executed removing the rear lid (see Fig. 17) and

setting SW1 bits (see Fig. 18) according to Tab. 5.

Fig. 17 – TFA PGR dip- switches

Fig. 18 – Dip-switches settings

Gain Reduction bit 1 bit 2 bit 3 bit 4

0 dB OFF OFF ON OFF

5 dB OFF ON OFF OFF

10 dB ON OFF OFF OFF

Tab. 5 - Uplink gain reduction settings

BRITECELL System Manual MN010-04 June 2003 Page 31 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

19. Installing and cabling

19.1. Location

TFA units shall be installed as close as possible to the radiating antennas, so as to

minimise coaxial cable length and reduce downlink power loss and uplink noise

figure.

However, the units should be installed no closer than 2.5 m to the closest mobiles

approach to avoid blocking. If remote units need to be installed very close to

where mobiles are, the internal variable attenuator should be used.

The TFA is intended to be installed on walls, false ceilings or other flat surfaces. A

mounting bracket is available for easy mounting.

Proper installation of the TFA is required for optimal performance. Take care to

install the TFAs "warm side out" as indicated in Fig. 14 The positioning of the unit

and the cables is important so as to avoid accidental damage.

19.2. Power supply and grounding

19.2.1. Universal mains (85-264VAC, 50/60Hz)

mains

Fig. 19 -Mains connector

19.2.2. DC negative supply –72 to –36 VDC.

DC connector and part number:

Fig. 20 - VDC connector

GROUND

mains

BRITECELL System Manual MN010-04 June 2003 Page 32 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

19.3. RF combined ports

These ports should be directly connected to the radiating antennas through RF

jumper cables.

Unused RF output ports must be terminated with a dummy 50Ω load. Optional

boosters (TFB family) also can be connected to one or both of the combined ports

for additional RF downlink power.

19.4. Optical fibres connection

Optical connectors need to have proper alignment and mechanical support. When

inserting an optical connector, take care to handle it smoothly enough so as not to

damage the fibre. Remove the dust cap only immediately before making

connections.

Do not force or stretch the fibre pigtail with curve radius less than 5 cm. See

9

Fig. 21 for optimal fibre cabling.

WRONG OPTIMAL

Fig. 21 - Fibre connection

20. Start-up

To perform a preliminary verification of the TFA:

• power-up the TPA;

• verify the following LED status:

LED Colour Status

if optical received power above

LD1 Red

LD2 Green ON

For a full functionality test please refer to the system start-up section.

BRITECELL System Manual MN010-04 June 2003 Page 33 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

OFF

lower required limit and internal

operations ok

21. Troubleshooting

If an alarm LED is active, check the environmental conditions (operating

temperature, supply range, etc.).

If an alarm persists, it is essential to give a correct alarm interpretation is to solve

the problem.

The uplink laser is switched on only if downlink optical power is present. In case of

any failure, the laser is switched off. By doing this, the unit sends information

about its operating status to the TFL.

If the TFA is alarmed, clean the downlink optical connector.

If the TFA is still alarmed, measure the downlink optical power at TFA input with

an optical power meter and verify if it is higher than –5 dBm. If it is not, the fibre

(at least as far as the down link fibre is concerned) has some problems. If optical

power is higher than -5 dBm, replace the TFA.

BRITECELL System Manual MN010-04 June 2003 Page 34 of 78

The company has a policy of continuous product development and improvement and we therefore

reserve the right to vary any information quoted without prior notice.

TPR 19" subrack

Loading...

Loading...