digital panel meters user guid e

DPM8180-2 Process Meter

features

CE approved and marked

Large (14.2mm) red LED characters

Choice of inputs (4-20mA, 10-50mA, 1-5V, 0-10V)

Engineering read-outs e.g. pressure, flow, level

Offset and span adjustable

Adjustable sensor excitation output (5-24V dc)

Display hold facility

The DPM8180 is a low cost, high performance mains powered

signal process panel meter. Engineering units such as

pressure, flow, temperature and level can be displayed.

It has an adjustable, 5-24V dc (50mA) excitation supply for

powering transmitters and active transducers without the need

for an external supply.

User calibration is performed by adjusting DIP switches and

multi-turn potentiometers to choose the input format and set

the corresponding display values

OPERATING SPECIFICATION

Line voltage 115/230V +10%, -20%

Line frequency 50/60 Hz

Accuracy +/- 0.1% of reading +/- 1 digit

Temperature coefficient 100 PPM/C

Operating temperature 0 to 50°C

Storage temperature -10 to 60°C

Humidity below 85% RH

Power consumption 6 VA

CMRR 110dB

.

meters

anders

ELECTRICAL SPECIFICATION

Range 4-20mA 10-50mA 1-5V 0-10V

Input impedance 10 Ohms 10 Ohms 1 MOhm 1 MOhm

Maximum input 200mA 200mA 100V 100V

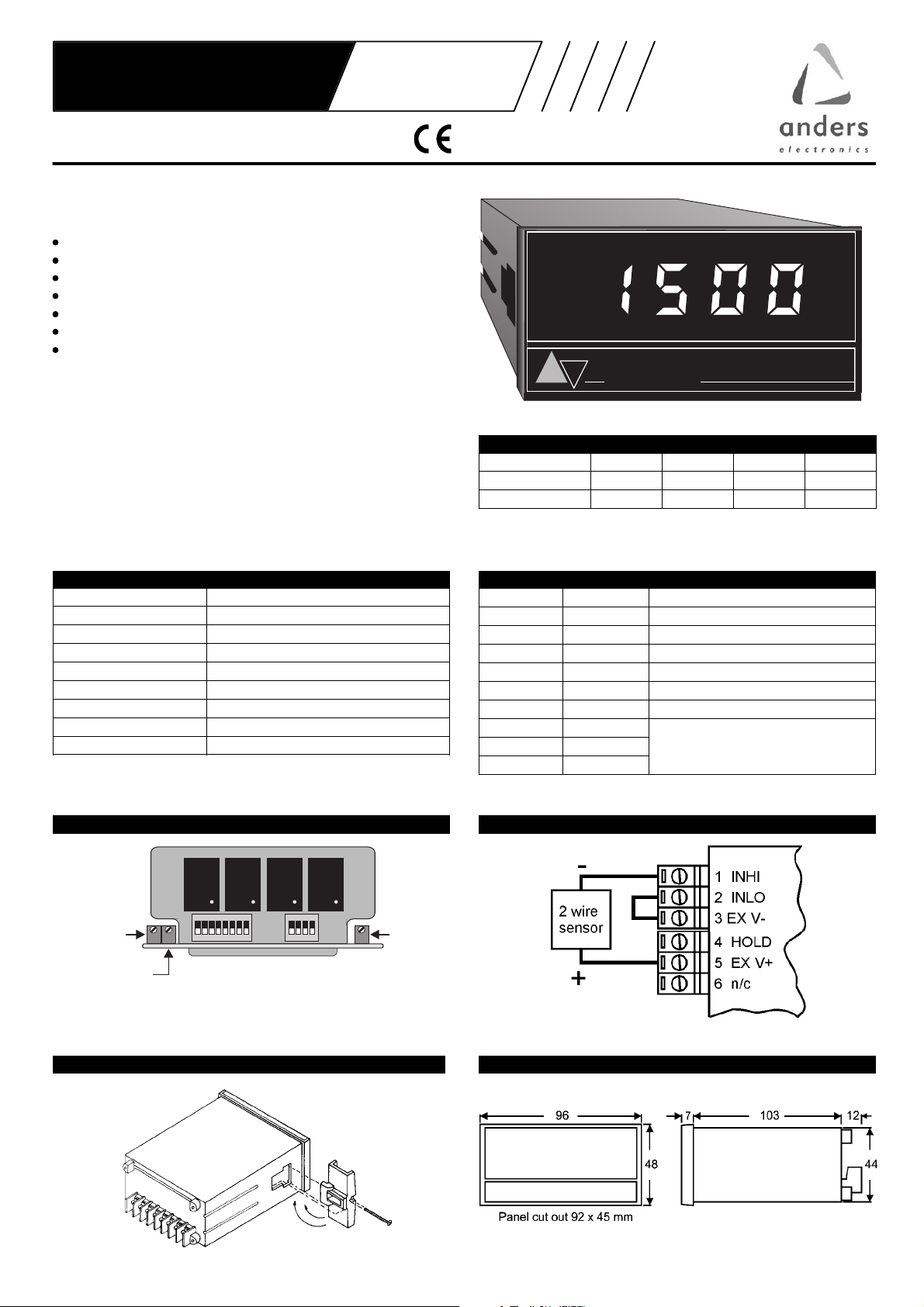

TERMINAL DEFINITIONS

TERMINAL SYMBOL DESCRIPTION

1 IN HI Sensor input signal high

2 IN LO Sensor input signal low

3 EX V- Excitation voltage -ve o/p

4 HOLD Connect to pin 2 to hold display

5 EX V+ Excitation voltage +ve o/p

6 n/c No connection

7 230V

8 115V AC power source

90V

DPM8000

series

RPM

8

8

8

Excitation

voltage

adjust (P1)

Offset trim (P2)

FIGURE 3 INSTALLATION DIAGRAM

DP8180-2V4 Rev. 4 09/03

ON

1234567 8

SW1

Offset

EDG

EDG

ON

1234

SW2

Span

8

FIGURE 2 CONNECTING A 2 WIRE SENSORFIGURE 1 FRONT VIEW (COVER REMOVED)

Span

trim (P3)

FIGURE 4 DIMENSIONS

STEP BY STEP INSTRUCTIONS

Remove instrument from protective plastic bag and clip

1

off front cover.

Pull off the three green safety terminals from the rear of

2

the meter. The complete panel meter assembly can now

be removed from its case by carefully levering the base of

the LED display board over the plastic retaining lug while

pushing gently on the terminal pins at the rear.

3

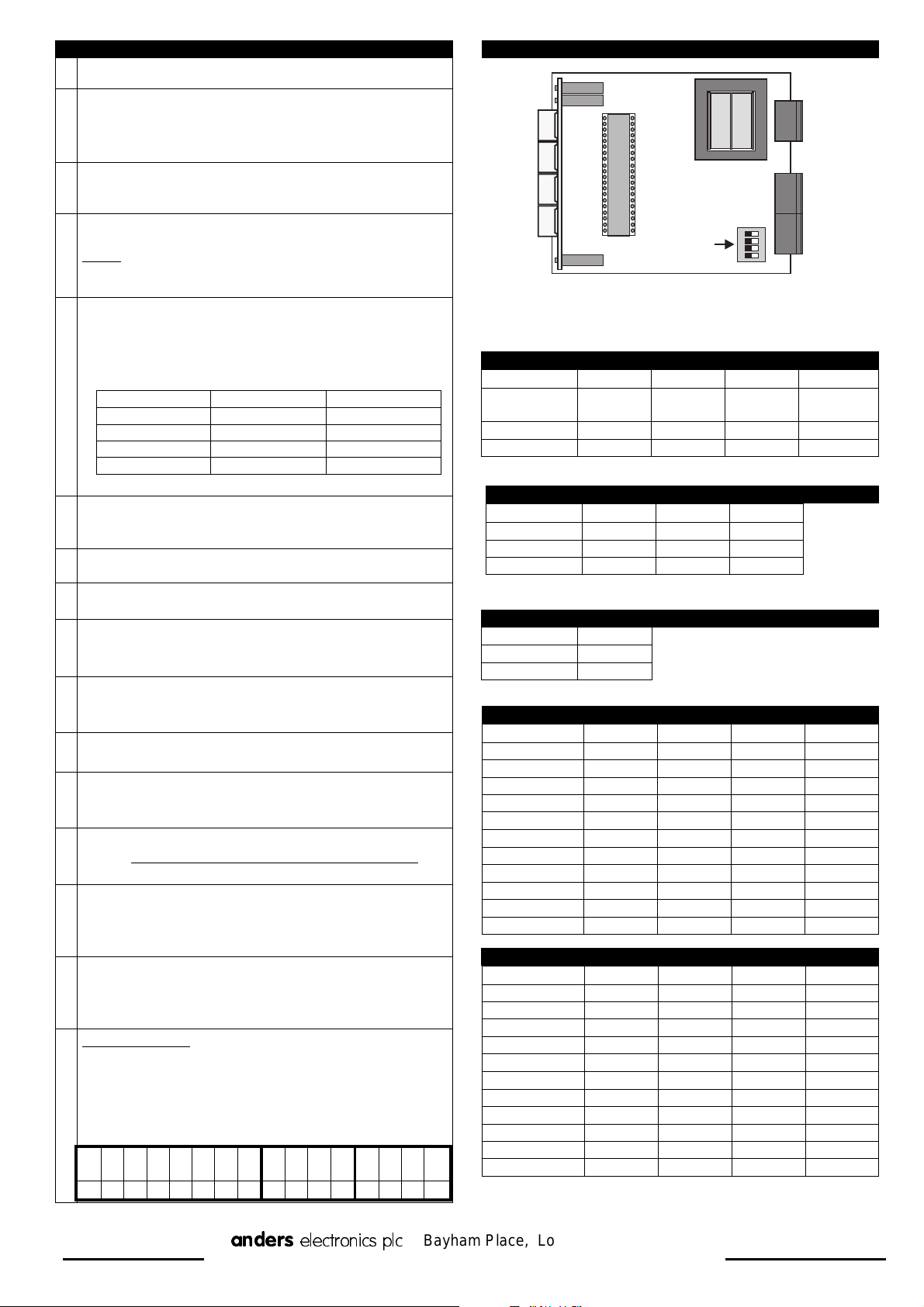

Select the required input format from

switches on SW3 accordingly (see fig.5). Return the meter

assembly to the case and replace the green terminals.

Decide the display range required and set the decimal

4

point using SW1(1 to 3), according to

NOTE

If your display is for example 0 - 35.0, then the

number of counts (R2) is still 350 for the calculations in

step 5 below.

For your chosen display range, apply the formulae from

5

the list below, for your chosen input format. For example,

for a 4-20mA input and display range of -100 to 500, the

lower reading R1 = -100 (at 4mA) and the upper reading

R2 = 500 (at 20mA).

Input format Offset figure (OF) Span figure (SF)

Note: the offset figure (OF) can have a negative value.

Using your value for OF, set offset switches SW1(5 to 8)

6

according to

according to the polarity of OF as indicated in

Using your value for SF, set span switches SW2(1 to 4)

7

according to

Make electrical connection to the meter with reference to

8

the Terminal Definition table on page 1.

Apply an accurate lower input signal, e.g. 4mA, and adjust

9

the offset trim potentiometer (P2) until the display reads

your R1 value

Apply an accurate upper input signal, e.g. 20mA and

10

adjust the span trim potentiometer (P3) until the display

reads your R2 value.

Repeat steps 9 and 10 until consistent readings are

11

achieved.

If you require the excitation output , measure the voltage

12

with an external voltmeter across pins 5 and 3 and adjust

to the required voltage using potentiometer P3.

When satisfied with the calibration, remove the input

13

signal,

remove all the electrical connections.

Clip the cover back on and insert the meter into the panel

14

cut-out. "Snap" the mounting clips into the side of the

case (refer to installation diagram) and tighten the fixing

screws until secure in the panel - do not over tighten!

With the meter installed in the panel, re-make the

15

electrical connections to the meter with reference to the

Terminal Definition Table on page 1. The meter is now

ready for use.

Worked Example

16

= - 87.5

Following the step by step instructions the switch

positions will be as follows

sw

1-1sw1-2sw1-3sw1-4sw1-5sw1-6sw1-7sw1-8sw2-1sw2-2sw2-3sw2-4sw3-1sw3-2sw3-3sw3-4

off off on off off off off off on off off off on on off off

Note location of components as per fig. 1.

Table 1

Table 2

4-20mA OF=(5xR1 - R2)/4 SF=(R2 - R1)/160

10-50mA OF=(5xR1 - R2)/4 SF=(R2 - R1)/400

1-5V OF=(5xR1 - R2)/4 SF=(R2 - R1)/160

0-10V OF= -R1 SF=(R2 - R1)/200

Table 4

. Set the polarity switch SW

and set the

.

Table 3

Table 5

.

.

turn off the

OF=(5xR1 - R2)/4

OR=(5x0 - 350)/4

auxiliary a.c. power supply

Input 4-20mA Display 0-35.0 Kg

SF=(R2 - R1)/160

SR=(350 - 0)/160

=2.19

1-4

.

and

FIGURE 5 PLAN VIEW SHOWING SWITCH SW3

78945 6

A to D Converter Chip

SW3

Input

format

EDG

ON

1234

123

Key to tables: 0 = switch OFF position

1 = switch ON position

TABLE 1 INPUT FORMAT SETTING

3-1

SW

4-20mA

10-50mA

1100

1 - 5V 0 0 1 0

0 - 10V 0 0 0 1

SW

3-2

SW

3-3

TABLE 2 DECIMAL POINT SELECT SETTINGS

1-1

SW

DP1100

DP2010

DP3001

SW

2-2

SW

3-3

TABLE 3 POLARITY SELECT

Polarity SW

Negative 0

Positive 1

1-4

TABLE 4 OFFSET FIGURE (OF) SETTINGS

Offset Figure SW

1-5

0 - 199 0 0 0 0

200 - 399 1 0 0 0

400 - 599 0 1 0 0

600 - 799 0 0 1 0

800 - 999 0 0 0 1

1000 - 1199 1 0 0 1

1200 - 1399 0 1 0 1

1400 - 1599 0 0 1 1

1600 - 1799 1 0 1 1

1800 - 1999 0 1 1 1

2000 - 2200 1 1 1 1

SW

1-6

SW

1-7

TABLE 5 SPAN FIGURE (SF) SETTINGS

Span Figure SW

2-1

0 - 2 0 0 0 0

2 - 4 1 0 0 0

4 - 6 0 1 0 0

6 - 8 0 0 1 0

8 - 10 0 0 0 1

10 - 12 1 0 0 1

12 - 14 0 1 0 1

14 - 16 0 0 1 1

16 - 18 1 0 1 1

18 - 20 0 1 1 1

20 - 22 1 1 1 1

SW

2-2

SW

2-3

SW

SW

SW

3-4

1-8

2-4

DP8180-2V4 Rev. 4 09/03

DQGHUV

Tel: +44 (0)20 7380 8167 Fax: +44 (0)20 7874 1908 www.anders.co.uk

HOHFWURQLFV SOF

Bayham Place, London NW1 OEU UK

Loading...

Loading...