Page 1

Analytical Balance

HR-250AZ / HR-251AZ

HR-150AZ / HR-100AZ

HR-250A / HR-251A

HR-150A / HR-100A

1WMPD40

02375C

Page 2

© 2013 A&D Company, Limited. All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed, or translated into

any language in any form by any means without the written permission of A&D Company,

Limited.

The contents of this manual and the specifications of the instrument covered by this

manual are subject to change for improvement without notice.

Windows, Word and Excel are the registered trademarks of the Microsoft Corporation.

Page 3

Contents

Basic Operation

1. Introduction .......................................................................................................................................... 5

1-1. About This Manual .......................................................................................................................... 5

1-2. Features ........................................................................................................................................... 5

1-3. Compliance ...................................................................................................................................... 6

2. Unpacking the Balance ....................................................................................................................... 7

2-1. Unpacking ........................................................................................................................................ 7

2-2. Installing the Balance ...................................................................................................................... 8

3. Precautions .......................................................................................................................................... 9

3-1. Before Use ....................................................................................................................................... 9

3-2. During Use ..................................................................................................................................... 10

3-3. After Use ......................................................................................................................................... 11

3-4. Power Supply ................................................................................................................................. 11

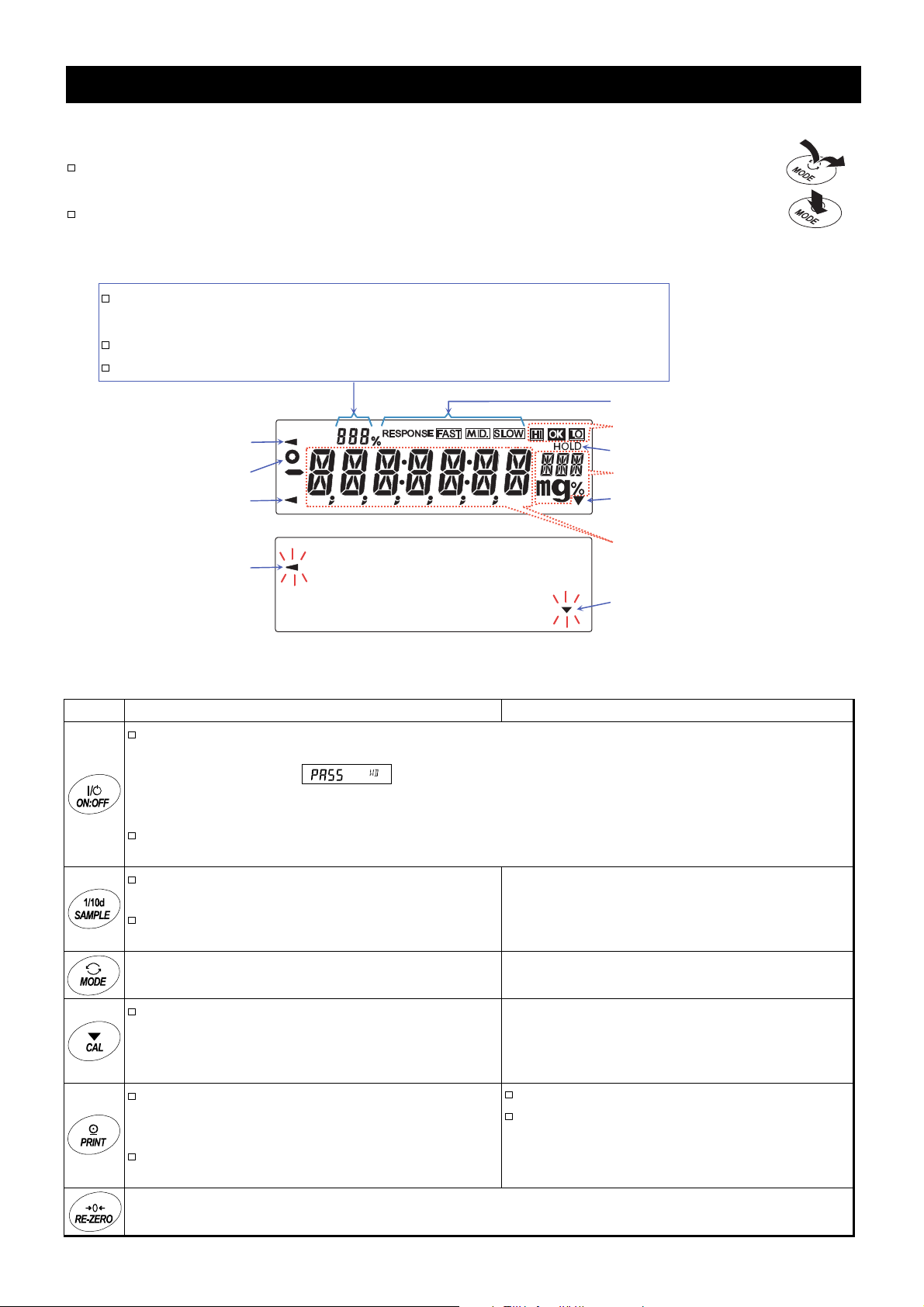

4. Display Symbols and Key Operations ............................................................................................. 12

Adapting To The Environment

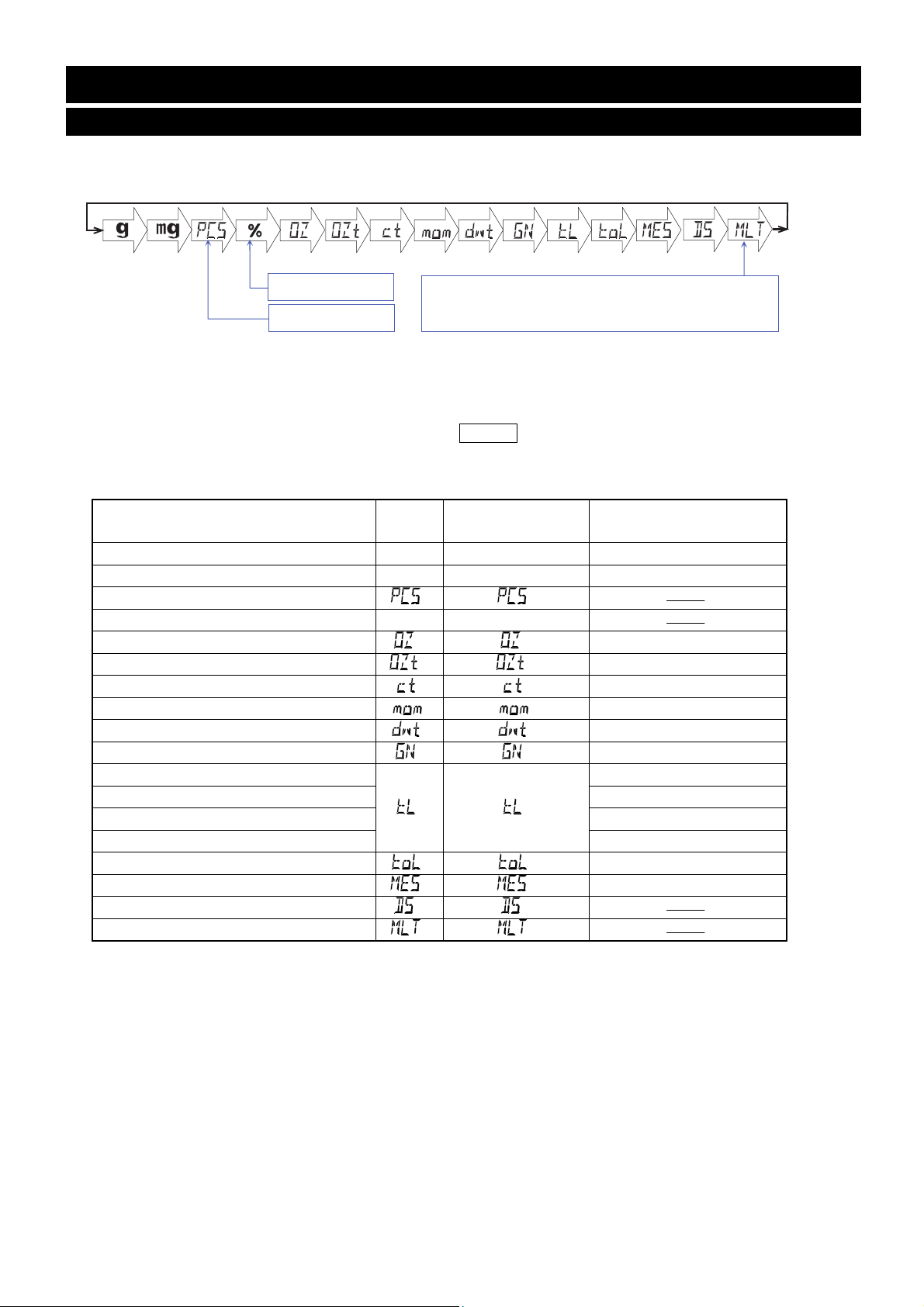

5. Weighing Units .................................................................................................................................. 13

5-1. Units ............................................................................................................................................... 13

5-2. Storing Units ................................................................................................................................... 15

6. Weighing ............................................................................................................................................ 16

6-1. Basic Operations (g, mg, ct, mom)............................................................................................... 16

6-2. Smart Range ................................................................................................................................. 18

6-3. Counting Mode (PCS) ................................................................................................................... 19

6-4. Percent Mode (%) ......................................................................................................................... 21

6-5. Statistical Calculation Mode .......................................................................................................... 22

6-6. Statistical Calculation Mode (Example of Use) ............................................................................ 26

7. Response Adjustment....................................................................................................................... 28

8. Calibration (

8-1. Calibration Mode ........................................................................................................................... 29

8-2. Calibration Using the Internal Mass

8-3. Calibration Test Using the Internal

8-4. Correcting the Internal Mass Value 1 (Only for the HR-AZ Series)

8-5. Correcting the Internal Mass Value 2

8-6. Calibration Using an External Weight .......................................................................................... 34

8-7. Calibration Test Using an External Weight .................................................................................. 35

Functions

9. Function Switch and Initialization ..................................................................................................... 36

9-1. Permit or Inhibit .............................................................................................................................. 36

9-2. Initializing the Balance ................................................................................................................... 38

10. Function Table ................................................................................................................................... 39

10-1. Structure and Sequence of the Function Table ........................................................................... 39

10-2. Displays and Keys ......................................................................................................................... 39

10-3. Details of the Function Table ......................................................................................................... 40

10-4. Description of the Class "Environment, Display" ......................................................................... 44

10-5. Description of the Item "Data Output Mode" ............................................................................... 46

10-6. Description of the Item "Data Format".......................................................................................... 47

10-7. Data Format Examples ................................................................................................................. 50

10-8. Description of the Item "Application Function" ............................................................................. 51

10-9. Clock and Calendar Function

Sensitivity Adjustment/Sensitivity Check

(One-Touch Calibration, Only for the HR-AZ Series)

Mass (Only for the HR-AZ Series)

(Only for the HR-AZ Series)

(Only for the HR-AZ Series)

) ........................................................................... 29

............................................ 30

.................................................. 31

................................................. 32

................................................. 33

............................................................. 52

3

Page 4

10-10. Comparator Function .................................................................................................................... 54

11. ID Number and GLP Report ............................................................................................................. 55

11-1. Setting the ID Number .................................................................................................................. 55

11-2. GLP Report .................................................................................................................................... 56

12. Underhook ......................................................................................................................................... 61

13. Density Measurement (Specific Gravity) ......................................................................................... 62

14. Programmable-Unit ........................................................................................................................... 67

15. Password Function ........................................................................................................................... 68

15-1. Balance Software Versions 1.70 to 1.85 ...................................................................................... 68

15-2. Balance Software Versions 1.860 and Later ............................................................................... 69

15-3. Using the Password Function ...................................................................................................... 70

15-4. Entering the Password Before Weighing ..................................................................................... 71

15-5. Logging Out ................................................................................................................................... 73

15-6. Storing or Changing the Password .............................................................................................. 73

15-7. How to Change the Password ..................................................................................................... 74

15-8. Deleting the Password (U5ER 01 to 10) ......................................................................................... 75

15-9. If the Password Is Lost or Forgotten ............................................................................................ 75

Interface And Communication

16. RS-232C Serial Interface .................................................................................................................. 76

17. Connection to Peripheral Equipment ............................................................................................... 77

17-1. Connection to the AD-8121B Printer ............................................................................................ 77

17-2. Connecting to the AD-8127 Printer .............................................................................................. 78

17-3. Connection to a Computer............................................................................................................ 78

17-4. Using Windows Communication Tools (WinCT) ......................................................................... 79

18. Commands ........................................................................................................................................ 80

18-1. Command List ............................................................................................................................... 80

18-2. Acknowledge Code and Error Codes .......................................................................................... 81

18-3. Settings Related to RS-232C ....................................................................................................... 83

19. Key Lock Function ............................................................................................................................ 84

19-1. Locking All the Keys ...................................................................................................................... 84

19-2. Locking the Specified Keys ........................................................................................................... 84

20. Checking the Balance Software Version ......................................................................................... 85

Maintenance

21.

Maintenance ...................................................................................................................................... 85

22. Troubleshooting ................................................................................................................................. 86

22-1. Checking the Balance Performance and Environment .............................................................. 86

22-2. Error Codes ................................................................................................................................... 87

22-3. Other Display ................................................................................................................................. 88

22-4. Asking for Repair ........................................................................................................................... 88

23. Options and Peripheral Equipments ................................................................................................ 89

24. Specifications ..................................................................................................................................... 92

25. External Dimensions ......................................................................................................................... 94

26. Terms/Index ....................................................................................................................................... 95

26-1. Terms.............................................................................................................................................. 95

26-2. Index ............................................................................................................................................... 96

4

Page 5

1. Introduction

This manual describes how the HR-AZ / HR-A series balance works and how to get the most out of it

in terms of performance. Read this manual thoroughly before using the balance and keep it at hand

for future reference.

Operation may vary depending on the software version of the balance. To check the software version

of your balance, refer to "20. Checking the Balance Software Version".

1-1. About This Manual

This manual consists of the following five parts:

Basic Operation

Adapting To The Environment

Functions

Interface And Communication

Maintenance

...........................................

.................................

......

......

......................................

Describes precautions on handling the balance, balance

construction and basic balance operation.

Describes response adjustment and calibration.

Describes various functions of the balance.

Describes the interface which transmits data and controls the

balance.

Describes maintenance, error codes, troubleshooting,

specifications and options.

1-2. Features

The HR-AZ series balance is equipped with an internal mass for one-touch calibration.

Casing construction, strong protection against dust and moisture.

Multiple weighing units with most of the common units used around the world.

Standard RS-232C serial interface to communicate with a computer and to output the Good

Laboratory Practice (GLP) / Good Manufacturing Practice (GMP) compliant report.

Since the HR-AZ series balance has a built-in clock function, the measured value can be output to a

printer with the date and time. (Changing the clock setting can be limited to the administrator only.

Refer to "15. Password Function")

You can restrict the balance users or the changes to the balance settings by the password function.

The key lock function disables the balance key operation and enables the balance to be operated only

by commands from external device.

Statistical calculation mode to statistically calculate the weight data, and display or output the sum,

maximum, minimum, range (maximum-minimum), average, standard deviation and coefficient of

variation.

Comparator Indicators, displaying the comparison results.

Hold Function, provided for weighing a moving object such as an animal.

Breeze break, provided for better stability if drafts are present.

Underhook, provided for suspended weighing.

As options, the USB interface (FXi-02), the Ethernet interface (FXi-08) and the built-in battery unit

(FXi-09) are available.

Connecting the USB interface, by cable to a Windows computer, allows transmission of the weight

data to Excel or Word. The Ethernet interface allows connection of the balance to a personal computer

through a LAN. The battery unit allows use of the balance where a power source is not available.

The AD-8920A remote display, that is sold separately, allows reading the weight value in a place

away from the balance.

5

Page 6

The optional AD-1688 data logger provides easy weighing data management.

The optional AD-1687 weighing environment logger provides easy management of the weighing

data, such as environmental data for the weighing and so on.

1-3. Compliance

Compliance with FCC Rules

Please note that this device generates, uses and can radiate radio frequency energy. This device has

been tested and has been found to comply with the limits of a Class A computing device pursuant to

Subpart J of Part 15 of FCC rules. These rules are designed to provide reasonable protection against

interference when this device is operated in a commercial environment. If this unit is operated in a

residential area, it may cause some interference and under these circumstances the user would be

required to take, at his own expense, whatever measures are necessary to eliminate the interference.

(FCC = Federal Communications Commission in the U.S.A.)

6

Page 7

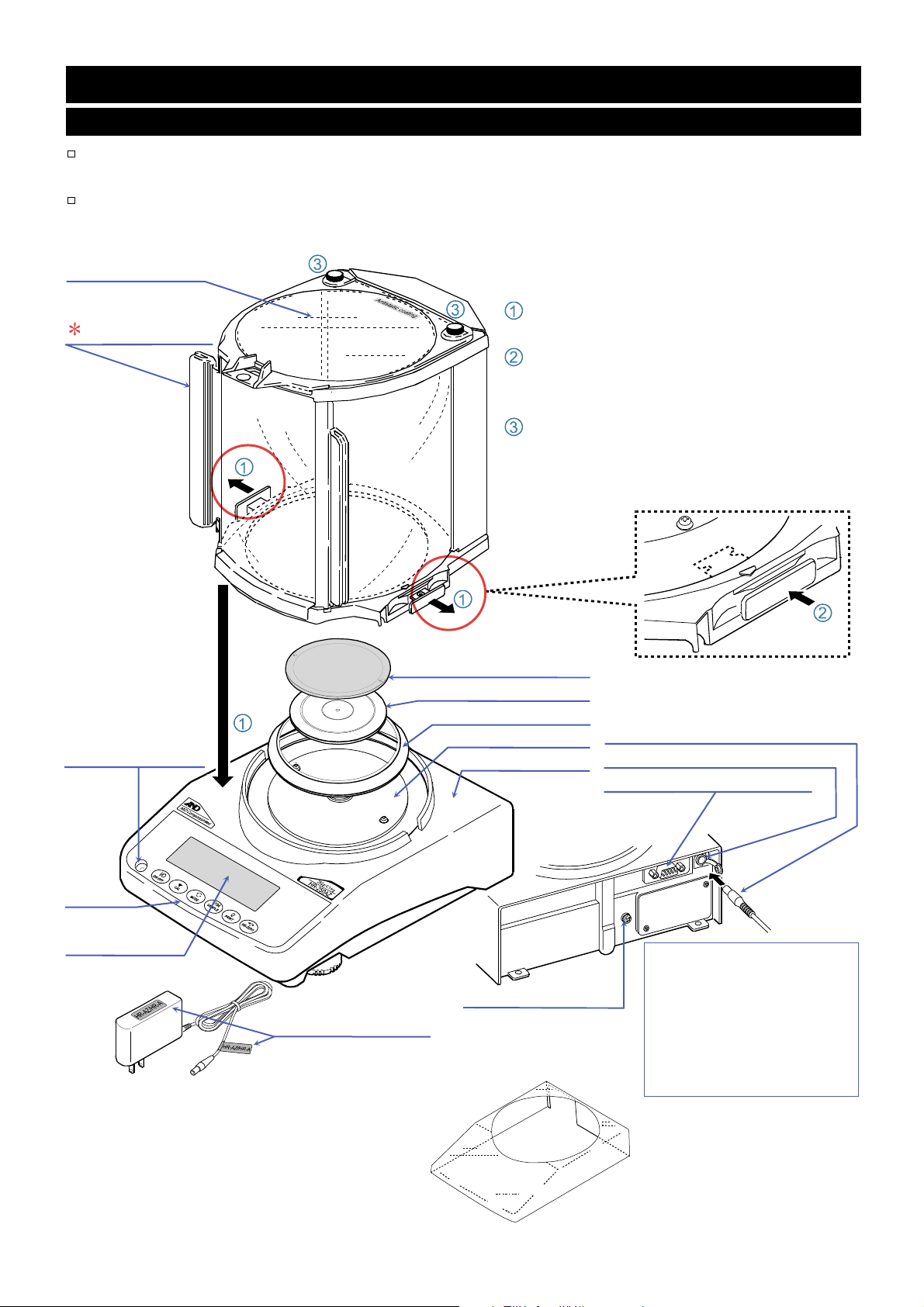

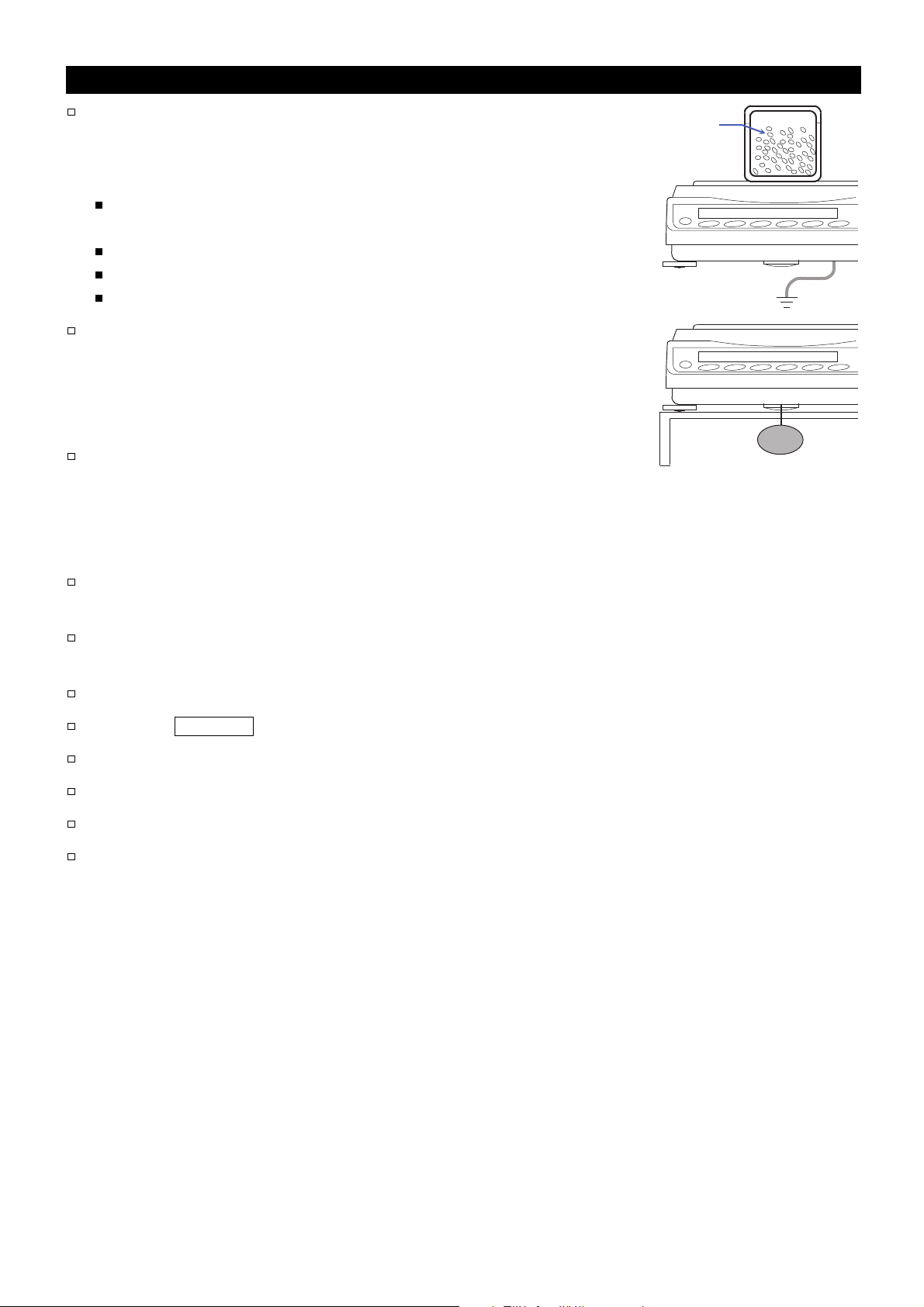

2. Unpacking the Balance

2-1. Unpacking

The balance is a precision instrument. Unpack the balance carefully. Keep the packing material to be

used for transporting the balance in the future.

See the illustrations to confirm that everything is included.

Install the large breeze break when drafts are present

Top door

Large breeze break

Antistatic coating

Bubble spirit level

Keys

Display

AC adapter

AX-TB-248

AC adapter ID label

Leveling foot

Weighing pan

Pan support

Breeze break ring

Dust plate

Main unit

Grounding terminal

Main unit cover

AX-FXi-31

(PET resin)

How to install the large breeze break

Follow the numbered sequence.

Pull out the locking handles, and install the

large breeze break on the main unit.

Push in the locking handles.

Confirm that both of the locking handle

hooks are under the dust plate.

How to open the top door

If removing either of the securing screws

(3) on the top door, the top door may be

pivoted on the remaining screw.

AC adapter plug

AC adapter jack

RS-232C serial interface

Main unit rear side

The AC adapter plug is

protected against dust and

may be difficult to insert.

When inserting the plug,

turn the plug while pushing

on it.

7

Page 8

Notes

Confirm that the AC adapter type is correct for your local voltage and receptacle type.

Do not use the AC adapter provided with the balance for other models or equipment with

which the AC adapter may not be compatible.

If you use the wrong AC adapter, the balance and other equipment may not operate properly.

2-2. Installing the Balance

Install the balance as follows:

1. Place the balance on a solid weighing table. Refer to "3. Precautions" for installing the balance.

2. Assemble the pan support, weighing pan, breeze break ring and breeze break, on the balance as

shown in the illustration on page 7.

3. Adjust the leveling feet to level the balance. Confirm it using the bubble spirit level.

4. Confirm that the AC adapter type is correct for the local voltage and power receptacle type.

5. Connect the AC adapter to the balance. Warm up the balance for at least one hour with nothing on the

weighing pan.

Note

The AC adapter plug is protected against dust and may be difficult to insert. When inserting

the plug, turn the plug while pushing on it.

8

Page 9

3. Precautions

To get the optimum performance from the balance and acquire accurate weight data, note the

following:

3-1. Before Use

Install the balance in an environment where the temperature and humidity are not excessive. The best

operating temperature is about 20°C / 68°F at about 50% relative humidity.

Install the balance where it is not exposed to direct sunlight and it is not affected by heaters or air

conditioners.

Install the balance where it is free of dust.

Install the balance away from equipment which produces magnetic fields.

Install the balance in a stable place avoiding vibration and shock. Corners of rooms on the first floor

are best, as they are less prone to vibration.

The weighing table should be solid and free from vibration, drafts and as level as possible.

Level the balance by adjusting the leveling feet and confirm it using the bubble spirit level.

Red circle

Bubble

OK NG

Bubble spirit level

Leveling foot

Make sure that the bubble is in the center of the red circle.

UP

DOWN

DOWN

Leveling foot

UP

When the bubble is off to the left :

Turn the leveling foot on the front right in the

clockwise direction.

When the bubble is off to the backward position :

Turn both leveling feet on the front in the

clockwise direction at the same time.

Ensure a stable power source when using the AC adapter.

Plug in the AC adapter and warm up the balance for at least one hour.

Calibrate the balance before use or after having moved it to another location. Refer to "8. Calibration

(

Sensitivity Adjustment/Sensitivity Check

Caution: Do not install the balance where flammable or corrosive gas is present.

)".

When the bubble is off to the right :

Turn the leveling foot on the front left in the

clockwise direction.

When the bubble is off to the forward position:

Turn both leveling feet on the front in the

counterclockwise direction at the same time.

9

Page 10

3-2. During Use

Discharge static electricity from the material to be weighed

(hereinafter referred to as the sample). When a sample could

have a static charge, the weight data is influenced. Ground

the balance and try the following:

Eliminate static electricity using the optional AD-1683 DC

static eliminator.

Try to keep the ambient humidity above 45%RH.

Use a metal shield case for a charged sample.

Wipe charged plastic samples with a moistened cloth.

This balance uses a strong magnet as part of the balance

assembly, so please use caution when weighing magnetic

materials such as iron. If there is a problem, use the underhook

on the bottom of the balance to suspend the material away

from the influence of the magnet.

Eliminate the temperature difference between a sample and

the environment. When a sample is warmer (cooler) than the

ambient temperature, the sample will be lighter (heavier) than

the true weight. This error is due to a rising (falling) draft

around the sample.

Charged material

Material case

Grounding

Magnetic material

Make each weighing gently and quickly to avoid errors caused by the evaporation of moisture from

the sample or the absorption of moisture by the sample.

Do not drop things upon the weighing pan, or place a sample on the pan that is beyond the balance

weighing capacity. Place a sample in the center of the weighing pan.

Do not use a sharp instrument such as a pencil to press the keys. Use your finger only.

Press the RE-ZERO key before each weighing to eliminate possible errors.

Calibrate the balance periodically so as to eliminate possible errors.

Take into consideration the affect of air buoyancy on a sample when more accuracy is required.

Keep the balance interior free of dust and foreign materials.

The breeze break (The HR-AZ / HR-A series) is provided as a standard accessory. An anti-static

treatment has been applied to the breeze break components, but they may be charged with static

electricity when they are unpacked or when the humidity is low. If the weight value is unstable even

when there are no drafts or the balance has a problem with repeatability, remove the breeze break. Or

wipe the clear plates with a moistened cloth, use the optional AD-1683 DC static eliminator or apply an

anti-static spray.

10

Page 11

3-3. After Use

Avoid mechanical shock to the balance.

Do not disassemble the balance. Contact the local A&D dealer if the balance needs service or repair.

Do not use organic solvents to clean the balance. Clean the balance with a lint free cloth that is

moistened with warm water and a mild detergent.

The edge of the weighing pan is sharp. Use much care when cleaning the pan.

Avoid dust and water so that the balance weighs correctly. Protect the internal parts from liquid spills

and excessive dust.

The breeze break parts have an antistatic coating. Washing these parts with water, etc., will diminish

the antistatic coating function.

3-4. Power Supply

When the AC adapter is connected, the balance is in the standby mode if the standby indicator is on

(refer to "4. Display Symbols and Key Operations"). This is a normal state and does not harm the

balance. For accurate weighing, allow the balance to reach equilibrium with room temperature, and

then warm up the balance for at least one hour before use.

11

Page 12

s

r

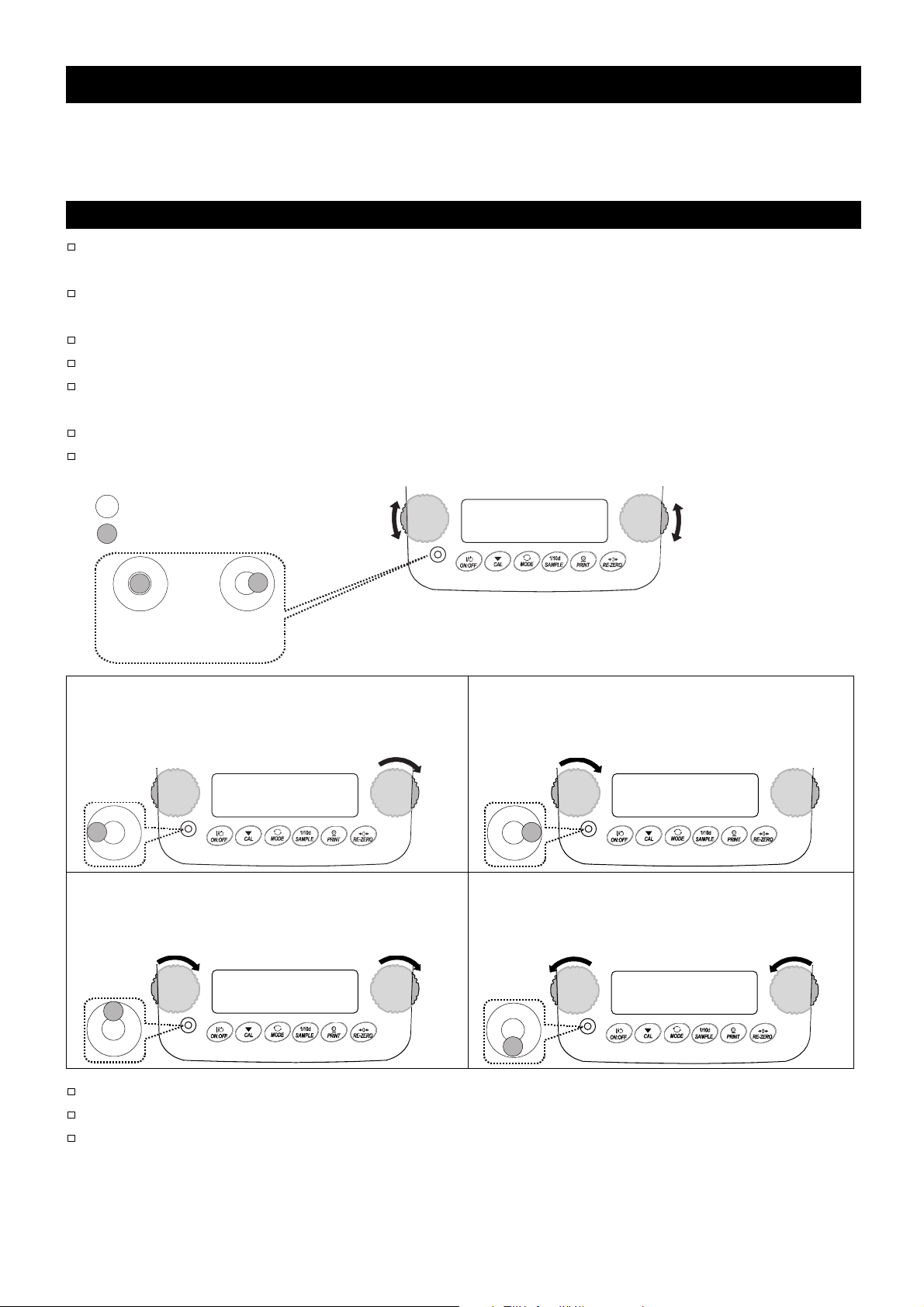

4. Display Symbols and Key Operations

Key Operations

Key operations affect how the balance behave. The basic key operations are:

"Press and release the key immediately" or "Press the key" ....................................................

= normal key operation during measurement

"Press and hold the key" .............................................................................................................

Display Symbols

Displays the weight data relative to the weighing capacity, in percentage, in

Each key, when pressed or when pressed and held, functions as follows:

the weighing mode (Capacity indicator)

Number of statistical data (Statistical calculation mode)

Displays the setting value in the function mode

Processing indicato

Stabilization indicator

Standby indicator

Processing indicator

Blinking

Response indicator

Comparator indicators

Hold mode indicator

Units

Interval output mode

standby indicator

Weight data

Internal output mode

active indicator

Key When pressed When pressed and held (for 2 seconds)

Turns the display on or off. The standby indicator is displayed when the display is turned off.

The weighing mode is enabled when the display is turned on. When the display is turned on,

the password input (

mode is enabled if the password function is not used. Refer to "15-4. Entering the Password

Before Weighing".

This key is available anytime. Pressing the key during operation will interrupt the operation and

turn the display off.

In the weighing mode, turns the minimum

weighing value on or off.

In the counting or percent mode, enters the

sample storing mode.

Switches the weighing units stored in the function

table. Refer to "5. Weighing Units".

Cancels the operation when performing

settings. With the HR-AZ series, enters the

calibration mode using the internal mass.

(One-touch calibration)

Outputs the weight data to a printer or personal

computer using the RS-232C serial interface,

depending on the function table settings.

Confirms the operation when performing

settings.

) is displayed if the password function is used. The weighing

Enters the function table mode.

Refer to "10. Function Table".

Enters the response adjustment mode.

Enters the calibration mode.

No function at the factory setting

By changing the function table:

Outputs "Title block" and "End block" for

GLP/GMP compliant report. (Refer to "11-2.

GLP Report".)

Sets the display to zero.

12

Page 13

5. Weighing Units

5-1. Units

With the HR-AZ / HR-A series balance, the following weighing units and weighing modes are

available:

A unit or mode can be selected and stored in the function table as described below.

If a weighing mode (or unit of weight) has been turned off, that mode or unit will be missing in the

sequence. Tael has four varieties, one of which can be selected and installed at the factory.

To select a unit or mode for weighing, press the MODE key.

For details about the units and modes, see the table below:

Percent mode

Counting mode

Programmable-unit (No unit displayed. For details,

refer to "14. Programmable-Unit".)

Name (unit, mode) Display

Gram g g 1 g

Milligram mg mg 0.001g

Counting mode

Percent mode % %

Ounce (Avoir)

Troy Ounce

Metric Carat

Momme

Pennyweight

Grain (UK)

Tael (HK general, Singapore)

Tael (HK jewelry) 37.429 g

Tael (Taiwan) 37.5 g

Tael (China) 31.25 g

Tola (India)

Messghal

Density mode

Programmable-unit (Multi-unit)

Function table

(Storing mode)

Conversion factor

1 g =

28.349523125 g

31.1034768 g

0.2 g

3.75 g

1.55517384 g

0.06479891 g

37.7994 g

11.6638038 g

4.6875 g

13

Page 14

The tables below indicate the weighing capacity and the minimum display for each unit, depending on

the balance model.

Capacity

Unit

HR-100AZ

HR-100A

HR-150AZ

HR-150A

HR-250AZ

HR-250A

Minimum Display

Gram 102 152 252 0.0001

Ounce (Avoir) 3.59 5.36 8.88 0.00001

Troy Ounce 3.27 4.88 8.10 0.00001

Metric Carat 510 760 1260 0.001

Momme 27.2 40.5 67.2 0.0001

Pennyweight 65.5 97.7 162.0 0.0001

Grain (UK) 1574 2346 3889 0.002

Tael (HK general, Singapore) 2.69 4.02 6.66 0.00001

Tael (HK jewelry) 2.72 4.06 6.73 0.00001

Tael (Taiwan) 2.72 4.05 6.72 0.00001

Tael (China) 3.26 4.86 8.06 0.00001

Tola (India) 8.74 13.0 21.6 0.00001

Messghal 21.7 32.4 53.7 0.0001

HR-251AZ / HR-251A

Unit

Precision Range Standard Range

Capacity Minimum Display Capacity Minimum Display

Gram 62 0.0001 252 0.001

Ounce (Avoir) 2.18 0.00001 8.88 0.0001

Troy Ounce 1.99 0.00001 8.10 0.0001

Metric Carat 310 0.001 1260 0.01

Momme 16.5 0.0001 67.2 0.001

Pennyweight 39.8 0.0001 162.0 0.001

Grain (UK) 956 0.002 3889 0.01

Tael (HK general, Singapore) 1.64 0.00001 6.66 0.0001

Tael (HK jewelry) 1.65 0.00001 6.73 0.0001

Tael (Taiwan) 1.65 0.00001 6.72 0.0001

Tael (China) 1.98 0.00001 8.06 0.0001

Tola (India) 5.31 0.00001 21.6 0.0001

Messghal 13.2 0.0001 53.7 0.001

14

Page 15

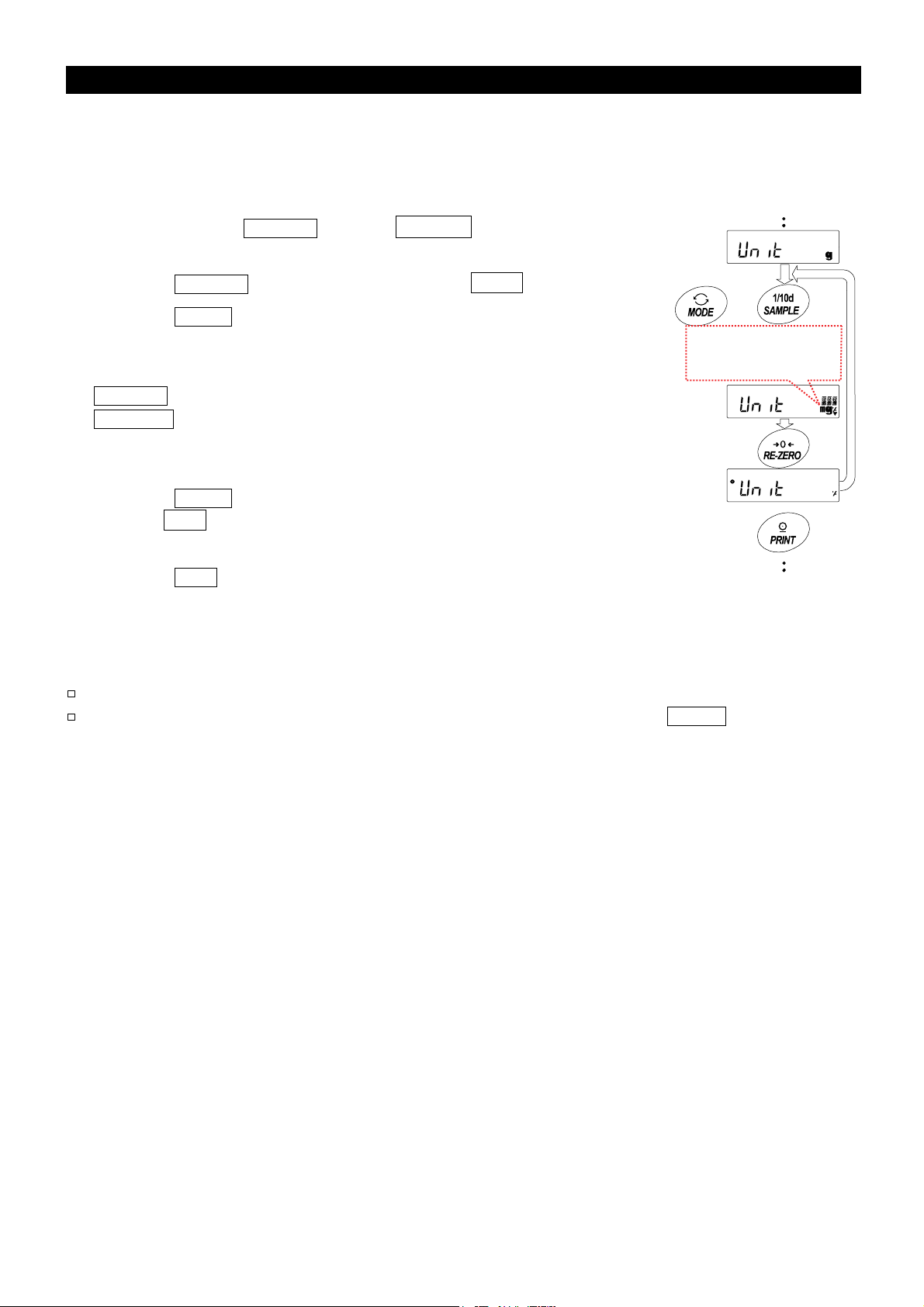

5-2. Storing Units

The units or modes can be selected and stored in the function table. The sequence of displaying the

units or modes can be arranged in the function table so as to fit the frequency of use.

Select a unit or mode and arrange the sequence of display as follows:

1 Press and hold the SAMPLE key until ba5fnc of the function

table is displayed.

2 Press the SAMPLE key several times to display Unit .

3 Press the PRINT key to enter the unit selection mode.

4 Specify a unit or mode in the order to be displayed using the

following keys.

SAMPLE key ........ To sequentially display the units.

RE-ZERO key ....... To specify a unit or mode.

The stabilization indicator appears when the displayed unit or

mode is specified.

5 Press the PRINT key to store the units or modes. The balance

displays end and then displays the next menu item of the

function table.

Select or

Displays the units

sequentially.

Specify

Store

6 Press the CAL key to exit the function table. Then the

balance returns to the weighing mode with the unit specified

first in step 4.

Notes

When the power is turned on, the scale displays the unit specified first in step 4.

In the weighing mode, to select a unit or mode for weighing, press the MODE key.

15

Page 16

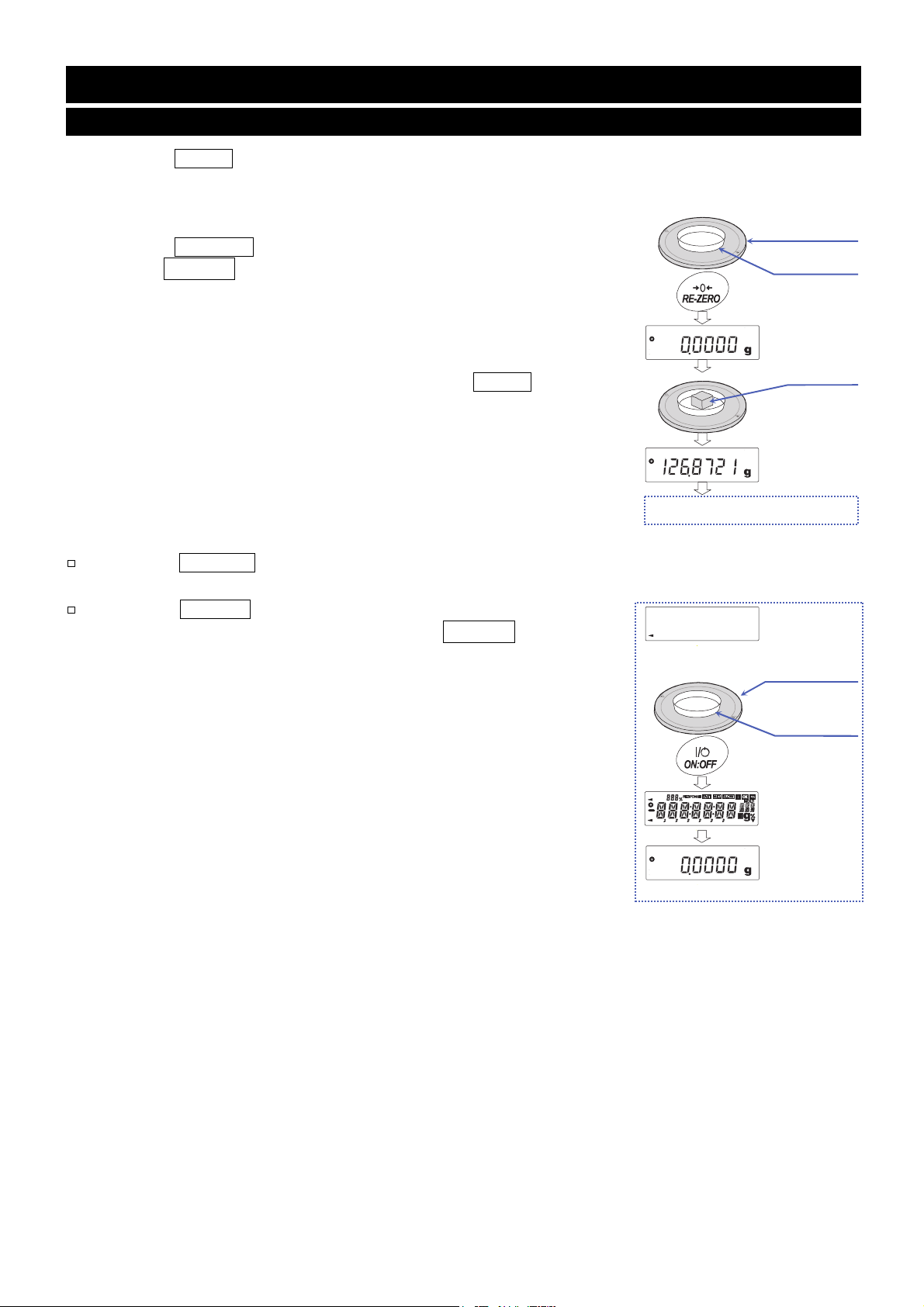

6. Weighing

6-1. Basic Operations (g, mg, ct, mom)

1 Press the MODE key and select a unit.

Select the "g" in this example.

2 Place a container on the weighing pan, if necessary.

Press the RE-ZERO key to cancel the weight (tare). The balance

displays 0.0000 g. (The decimal point position depends on the

balance model.)

3 Place a sample on the pan or in the container.

4 Wait for the stabilization indicator to turn on. Read the value.

While the stabilization indicator is on, pressing the PRINT key will

output the weight value, using the RS-232C serial interface.

* Peripheral equipment, that is sold separately, such as a

printer or a personal computer is required.

5 Remove the sample and container from the pan.

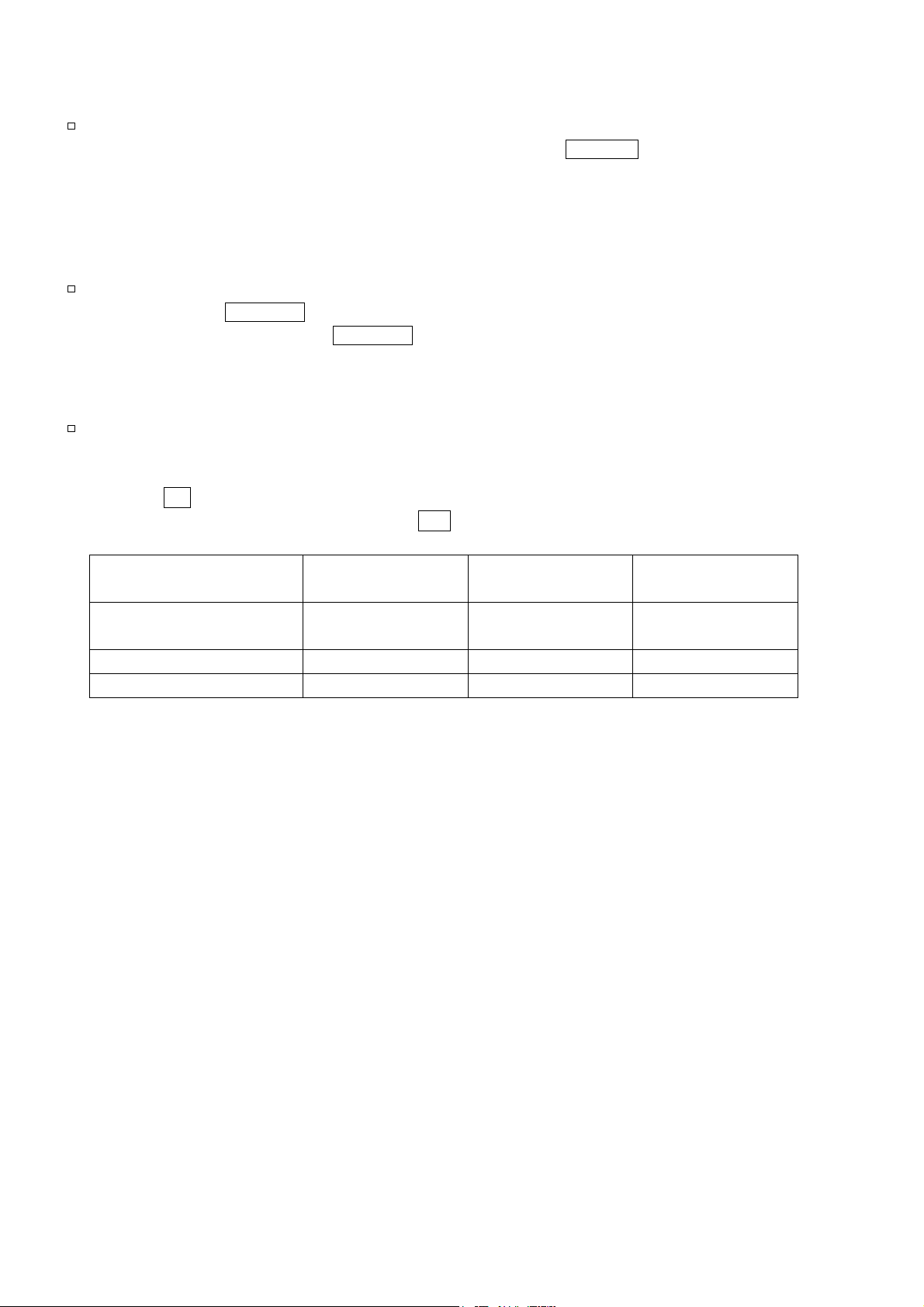

Notes

Press the SAMPLE key to turn on or off the minimum

weighing value.

When the ON:OFF key is pressed with a container placed

on the weighing pan, the balance displays 0.0000 g and

weighing is started.

Weighing pan

Container

Sample

Remove the sample

Display off

Weighing pan

Container

16

Page 17

Zero Operation, Tare Operation and Weighing Range

When weighing is started

The balance will determine the reference zero point when the ON: OFF key is pressed to enter the

weighing mode.

Depending on the load condition at that time, the balance will automatically judge whether to perform

zero or tare operation. The condition for determining which is used is "Power-on zero range", and

when power on zero range is exceeded, the tare operation is performed.

Re-zero operation

By pressing the RE-ZERO key, the display can be set to zero.

The re-zero operation with the RE-ZERO key will automatically judge whether to perform zero or

tare operation. The condition for determining which is used is "Zero range", and when zero range is

exceeded, the tare operation is performed.

Weighing range

The range that the balance can weigh varies depending on the model.

When the total amount (net weight + tare weight) displayed for each model exceeds the maximum

display, E is displayed to indicate that the weighing range is exceeded.

When exceeded in the negative direction, -E is displayed.

Model

HR-250AZ / HR-250A

HR-251AZ / HR-251A

HR-150AZ / HR-150A Approx. ± 15 g Approx. ± 3 g Approx. -7 g or less

HR-100AZ / HR-100A Approx. ± 10 g Approx. ± 2 g Approx. -5 g or less

Power-on

zero range

Zero range -E display range

Approx. ± 25 g Approx. ± 5 g Approx. -12 g or less

17

Page 18

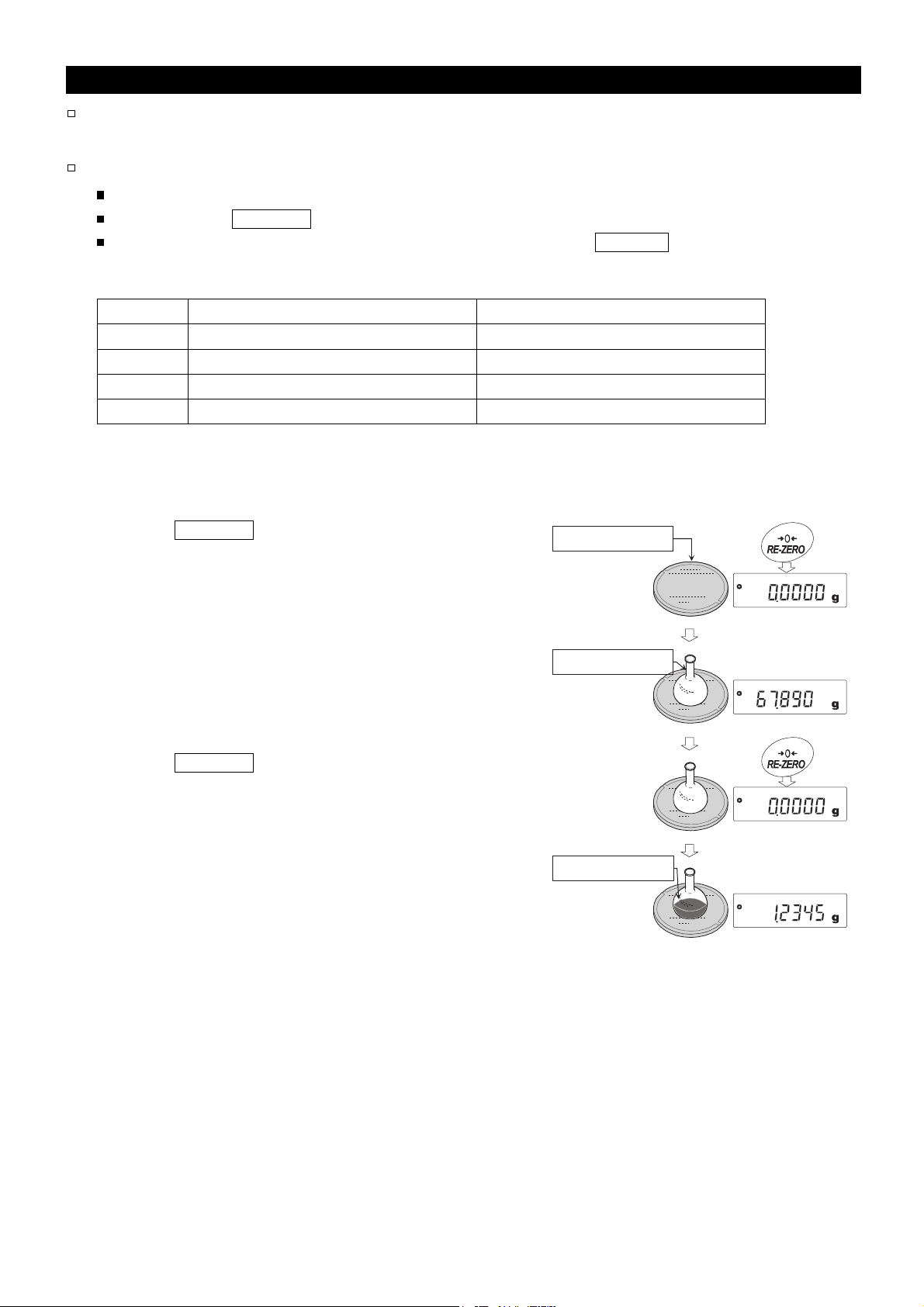

6-2. Smart Range

The smart range for the HR-251AZ / HR-251A consists of the standard range and precision range

(high resolution).

Smart range function

The range switches automatically, depending on the value displayed.

Pressing the RE-ZERO key allows weighing in the precision range, regardless of the tare value.

The range can be fixed to the standard range by pressing the SAMPLE key.

Precision Range and Standard Range for the HR-251AZ/HR-251A

Unit Precision range Standard range

Gram 0.0000 g to 62.0009 g 62.001 g to 252.008 g

Milligram 0.0 mg to 620009 mg 62001 mg to 252008 mg

Carat 0.000 ct to 310.005 ct 310.01 ct to 1260.04 ct

Momme 0.0000 mom to 16.5336 mom 16.534 mom to 67.202 mom

Refer to page 13 for other units.

Example

1 Press the RE-ZERO key to use the precision range.

The balance displays zero.

2 Place a container (tare) on the weighing pan.

When the weight value displayed exceeds the

precision range value, the balance will switch to the

standard range.

3 Press the RE-ZERO key.

The balance displays zero and switches to the

precision range.

4 Place a sample in the container.

When the weight value displayed is within the

precision range value, the balance will perform a

weighing, using the precision range.

Weighing pan

Container

Sample

Precision range

Standard range

Precision range

Precision range

18

Page 19

C

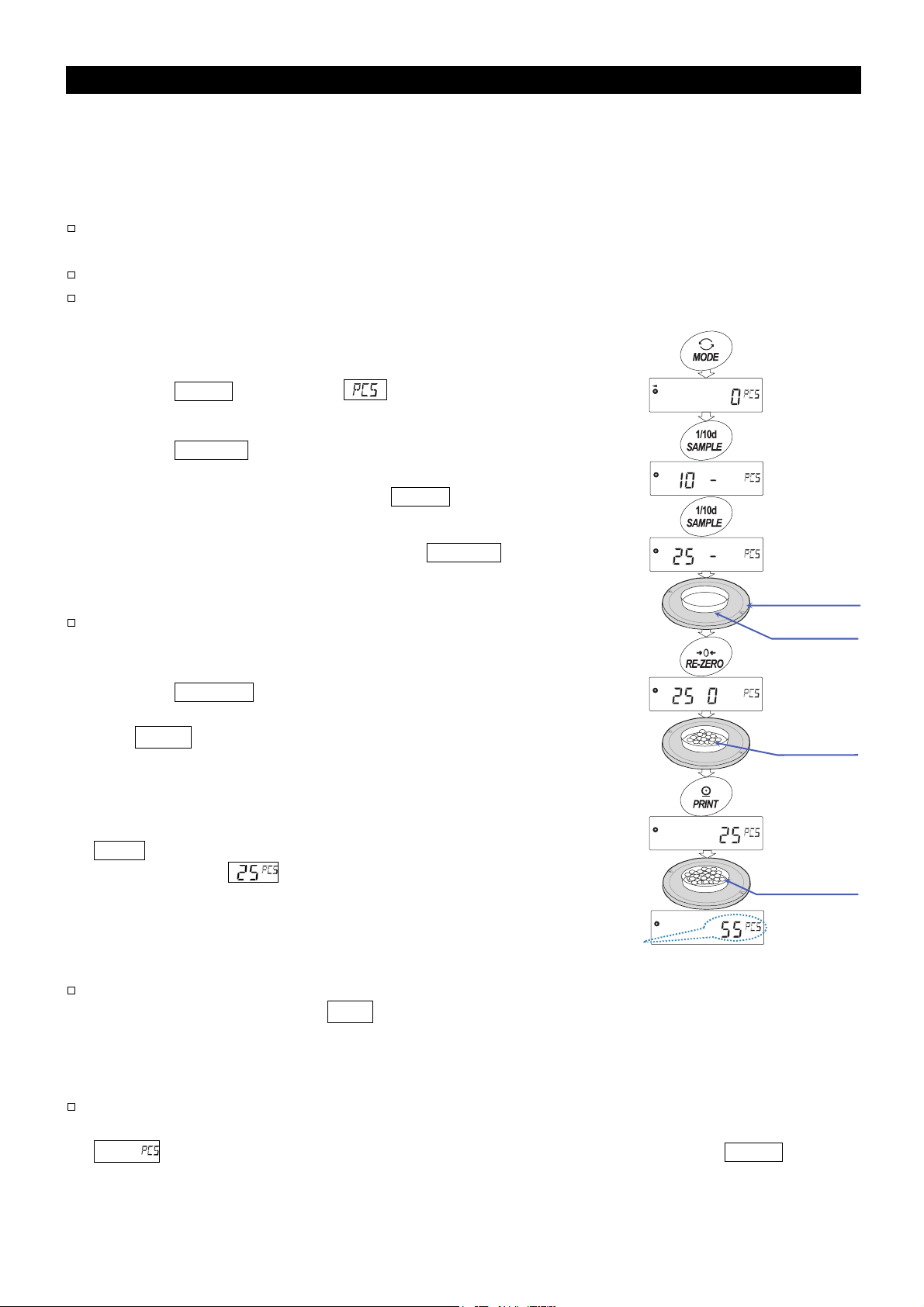

6-3. Counting Mode (PCS)

This is the mode to determine the number of objects in a sample based on the standard sample unit

mass. The unit mass means the mass of one piece of the sample. The smaller the variables in each

sample unit mass are, the more accurate the counting will be. The balance is equipped with the

Automatic Counting Accuracy Improvement (ACAI) function to improve the counting accuracy.

Notes

For counting, use samples with a unit mass of at least ten or more times the minimum

weighing value of the balance.

If the sample unit mass variable is too large, it may cause a counting error.

To improve the counting performance, use the ACAI function frequently or divide the samples

into several groups and count each group.

Selecting the Counting Mode

1 Press the MODE key to select (counting mode).

Storing a Sample Unit Mass

2 Press the SAMPLE key to enter the sample unit mass storing

mode.

Even in the storing mode, pressing the MODE key will switch

to the next mode.

3 To select the number of samples, press the SAMPLE key

several times. It may be set to 10, 25, 50 or 100.

Note

A greater number of samples will yield more accurate

Weighing pan

ontainer

counting result.

4 Place a container on the weighing pan, if necessary.

Press the RE-ZERO key to cancel the weight (tare).

The number specified in step 3 appears.

e.g.: 25 0 is displayed if 25 is selected in step 3.

Samples

25 piecies

5 Place the number of samples specified on the pan.

In this example, 25 pieces.

6 Wait for the stabilization indicator to turn on. Press the

PRINT

balance displays (counting mode) and is set to

key to calculate and store the unit mass. The

Place sample

to be counted

count samples with this unit mass. To improve the

accuracy of the unit mass, go to step 8.

The counting result

Notes

If the balance judges that the mass of the samples is too light and is not adequate to be used

as the unit mass, it displays lo . In that case, store the mass by some quantity.

For example, when the model with the minimum weighing value of 0.0001 g is used and 10

pieces of samples weigh 0.0005 g. Store 100 pieces of samples as 10 and multiply the

weighing result by 10.

If the balance judges that the mass of the samples is too light to aquire accurate weighing, it

displays an error requiring the addition of more samples to the specified number. For example,

150- appears to require 25 more samples. Add 25 samples and press the PRINT key.

When the unit mass is stored correctly, the balance proceeds to the counting mode.

19

Page 20

For a more accurate counting operation, use samples with a unit mass of at least ten or more

times the minimum weighing value of the balance. For example, when a balance with a

mimimum weighing value of 0.0001 g is used, the recommended sample unit mass is 0.001 g

or more.

The sample unit mass stored, even if the AC adapter is removed, is maintained in non-volatile

memory.

Counting Operation

7 Place the samples to be counted on the pan.

While the stabilization indicator is on, pressing the PRINT key will

output the weight value (number of objects), using the RS-232C

serial interface.

Note

Peripheral equipment, that is sold separately , such as a

printer or a personal computer is required.

Counting Mode Using the ACAI Function

The ACAI is a function that improves the accuracy of the unit mass

automatically by increasing the number of samples and averaging

the unit mass variable to minimize the weighing error, as the

counting process proceeds.

8 If a few more samples are added, the processing indicator turns on. To prevent an error, add three or

more. The processing indicator does not turn on if overloaded. Try to add the same number of

samples as displayed.

Processing indicator

9 The balance re-calculates the unit mass while the processing indicator is blinking. Do not touch the

balance or samples on the pan until the processing indicator turns off.

10 Counting accuracy is improved when the processing indicator turns off.

Each time the above operation is performed, a more accurate unit mass will be obtained. There is no

definite upper limit of ACAI range for the number of samples exceeding 100. Try to add the same

number of samples as displayed.

11 Remove all the samples used in ACAI and proceed with the counting operation using the improved

unit mass.

20

Page 21

C

s

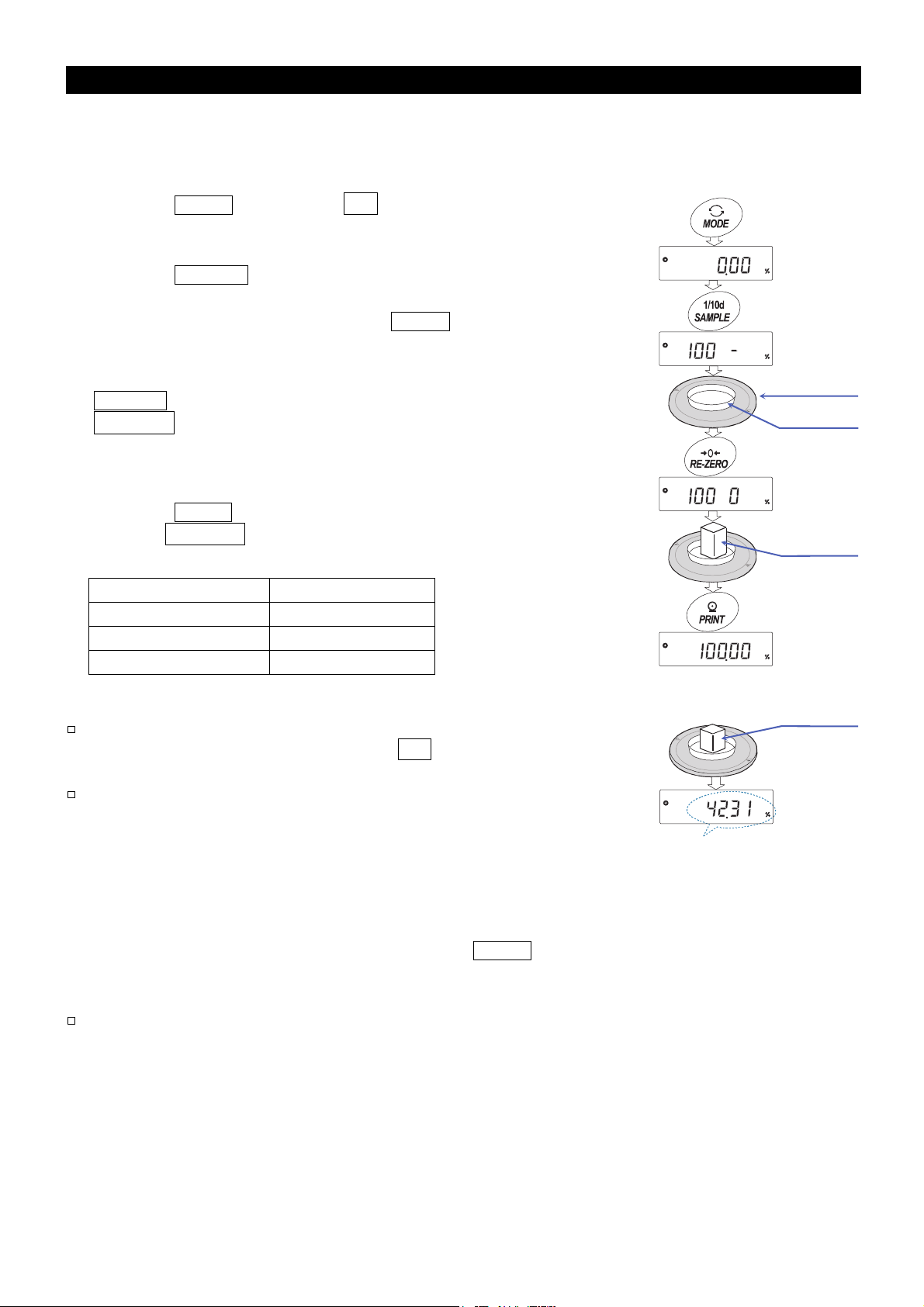

6-4. Percent Mode (%)

This is the mode to display the weight value in percentage compared to a 100% reference mass and

is used for target weighing or checking the sample variable.

Selecting the Percent Mode

1 Press the MODE key to select % (percent mode).

Storing the 100% Reference Mass

2 Press the SAMPLE key to enter the 100% reference mass

storing mode.

Even in the storing mode, pressing the MODE key will switch to

the next mode.

3 Place a container on the weighing pan, if necessary. Press the

RE-ZERO

100 0 % .

4 Place the sample to be set as the 100% reference mass on the

pan or in the container.

5 Press the PRINT key to store the reference mass. The balance

displays 100.00 % . (The decimal point position depends on the

reference value.)

0.0100 g to 0.0999 g 1 %

0.1000 g to 0.9999 g 0.1 %

1.0000 g or more 0.01 %

Notes

If the balance judges that the mass of the sample is too light

to be used as a reference, it displays lo . Do not use the

sample.

The reference mass stored, even if the AC adapter is

removed, is maintained in non-volatile memory.

key to cancel the weight (tare). The balance displays

100 % mass Minimum display

Weighing pan

ontainer

Sample

100%

Place

to be weighed

ample

6 Remove the sample.

Weighing result compared to

100% reference mass

Reading the Percentage

7 Place a sample to be compared to the reference mass on the pan.

The displayed percentage is based on the 100% reference mass.

While the stabilization indicator is on, pressing the PRINT key will

output the weight value, using the RS-232C serial interface.

Note

Peripheral equipment, that is sold separately , such as a

printer or a personal computer is required.

21

Page 22

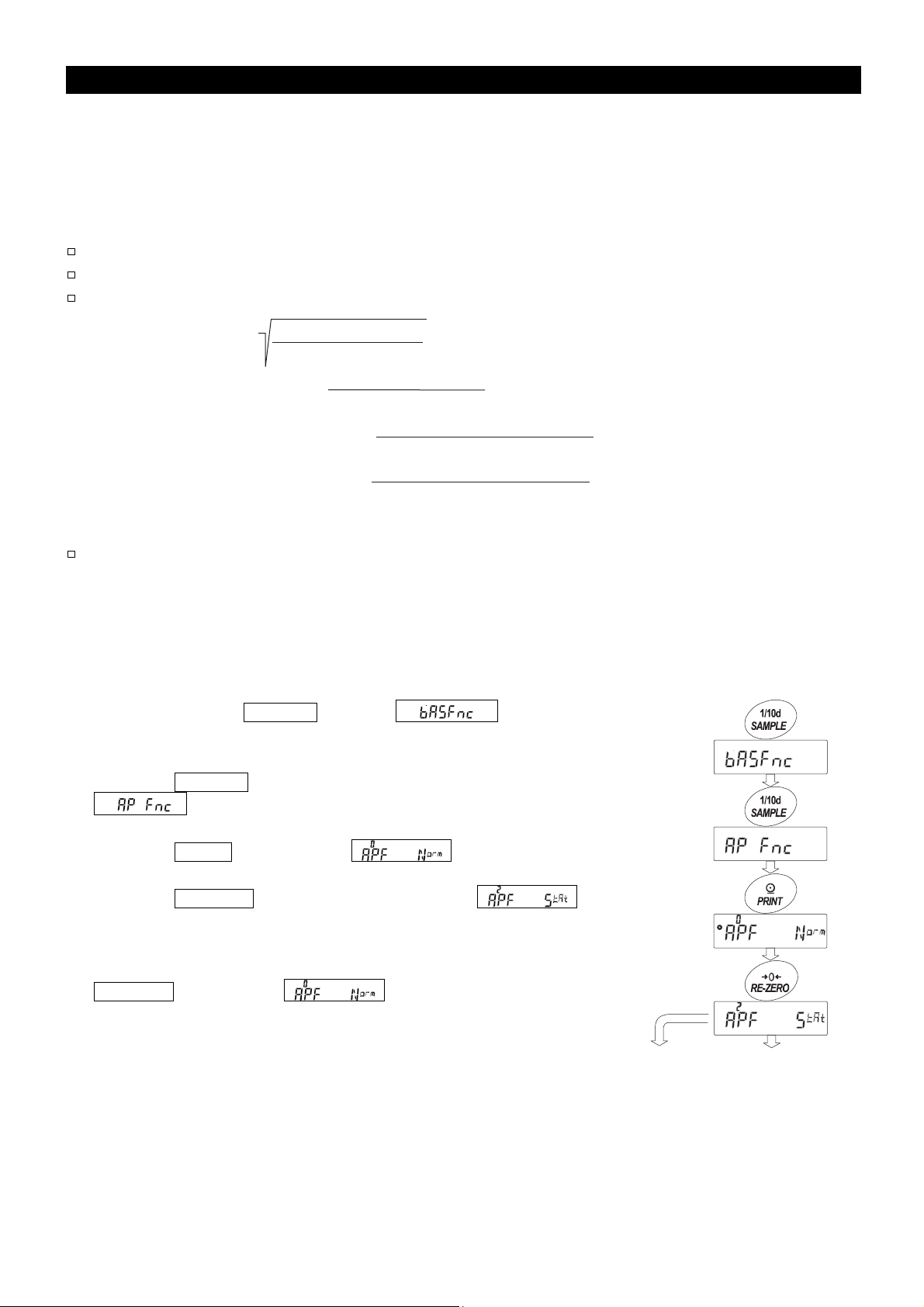

6-5. Statistical Calculation Mode

The statistical calculation mode statistically calculates the weight data, and displays or outputs the

results. To use the statistical calculation mode, set the "Application function (apf)" parameter of

"Application (ap fnc)" in the function table to "2", as described below.

Statistical items available are number of data, sum, maximum, minimum, range (maximum-minimum),

average, standard deviation, coefficient of variation and relative error. What statistical items to output

can be selected from the four modes in the function table.

The wrong data input can be canceled by the key operation, if immediately after the input.

Turning the balance off will delete the statistical data.

The standard deviation, coefficient of variation and relative error are obtained by the equation below:

Standard deviation = where Xi is the i-th weight data, N is number of data.

Coefficient of variation (CV) = x 100 (%)

Relative error of maximum value = x 100 (%)

Relative error of minimum value = x 100 (%)

Note

When data with the minimum weighing value turned off are used in the statistical calculation,

results will be displayed with the minimum weighing value turned off. (The minimum weighing

value will be rounded off.)

6.5.1. Getting Started

N・Σ(Xi)2 - (ΣXi)2

N・(N - 1)

Standard deviation

Average

Maximum value - Average

Average

Maximum value - Average

Average

Switching to the Statistical Function Mode (Changing the Function Table)

1 Press and hold the SAMPLE key until of

the function table is displayed, then release the key.

2 Press the

SAMPLE key several times to display

.

3 Press the

PRINT key to display

4 Press the RE-ZERO key several times to display .

To select statistical items to output, go to step 5.

To store the statistical function mode setting, go to step 7.

To disable the statistical calculation mode, press the

RE-ZERO key to select .

To store the setting To select statistical

go to step 7. go to step 5.

Press and hold

(for 2 seconds)

Press several times

Press several times

22

Page 23

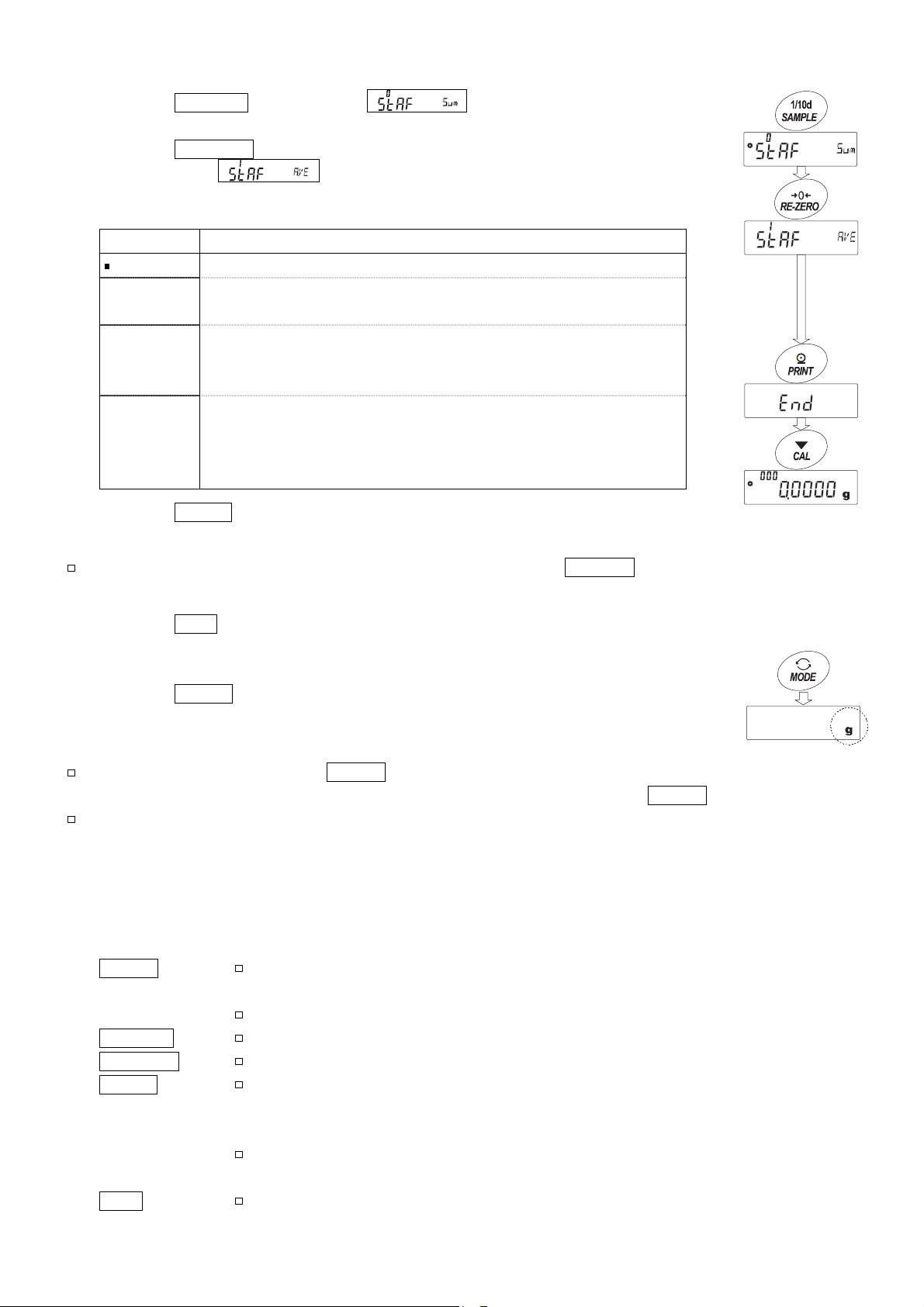

Selecting the Statistical Items to Output

5 Press the SAMPLE key to display .

6 Press the RE-ZERO key to select the output items.

In the example, is selected to output the number of data, sum,

maximum, minimum, range (maximum-minimum) and average.

Parameter Description

0 Number of data, Sum

1

2

3

Number of data, Sum, Maximum, Minimum,

Range (maximum – minimum), average

Number of data, Sum, Maximum, Minimum,

Range (maximum – minimum), Average, Standard deviation,

Coefficient of variation

Number of data, Sum, Maximum, Minimum,

Range (maximum – minimum), Average, Standard deviation,

Coefficient of variation, Relative error of maximum value,

Relative error of minimum value

7 Press the PRINT key to store the setting.

Note

The statistical calculation mode will be enabled using the ON:OFF key or

when the power is turned on.

8 Press the CAL key to return to the weighing mode.

Selecting the Unit

9 Press the MODE key to select the unit to be used for the statistical calculation

mode. In the example shown at the right, gram (g) is selected.

Notes

Selecting the unit using the MODE key is not available after the data is entered. In this case,

clear the data as described on page 25 and select the unit using the MODE key.

When the unit used for the statistical calculation mode is to be enabled upon power-on,

select the unit in "Unit (Unit)" of the function table beforehand.

6.5.2. Using the Statistical Calculation Mode

Entering Data for Statistical Calculation

Use the following keys to operate the statistical calculation mode.

MODE key

When no data has been entered, selects the unit.

SAMPLE key ..... Turns the minimum weighing value on or off, in the weighing mode.

RE-ZERO key

PRINT key ........ Outputs the data number and the weight data and includes the weight data to

Outputs the statistical results while the statistical results are displayed. (Output is

CAL key

........

...

............

When the data is entered, moves between the displaying items (weighing mode,

statistical results and data operation) each time the key is pressed.

Sets the display to zero in the weighing mode.

statistical calculation in the weighing mode. (Output is not in the data format

specified in the function table because of the data number added.)

not in the data format specified in the function table.)

Returns to the weighing mode.

23

Page 24

"

"

1 Press the RE-ZERO key to set the display to zero.

2 Place the sample on the weighing pan and wait for the stabilization

indicator to turn on.

3 Press the PRINT key to add the data displayed to statistical

calculation. The number of data on the upper left of the display

increases by 1.

4 Repeat steps 1 to 3 for each weighing.

Outputting the Statistical Results

5 Each time the MODE key is pressed, the display

changes: the results as selected in "Statistical function

mode output items (5taf)", and .

Weighing pan

Sample

6 While the results are displayed, press the PRINT key to

output the results.

Notes

When the number of data is 1, the coefficient of

variation is displayed as - - - - - - - .

When the average is 0, the coefficient of variation

is displayed as - - - - - - - .

Statistical items are indicated on the upper left of

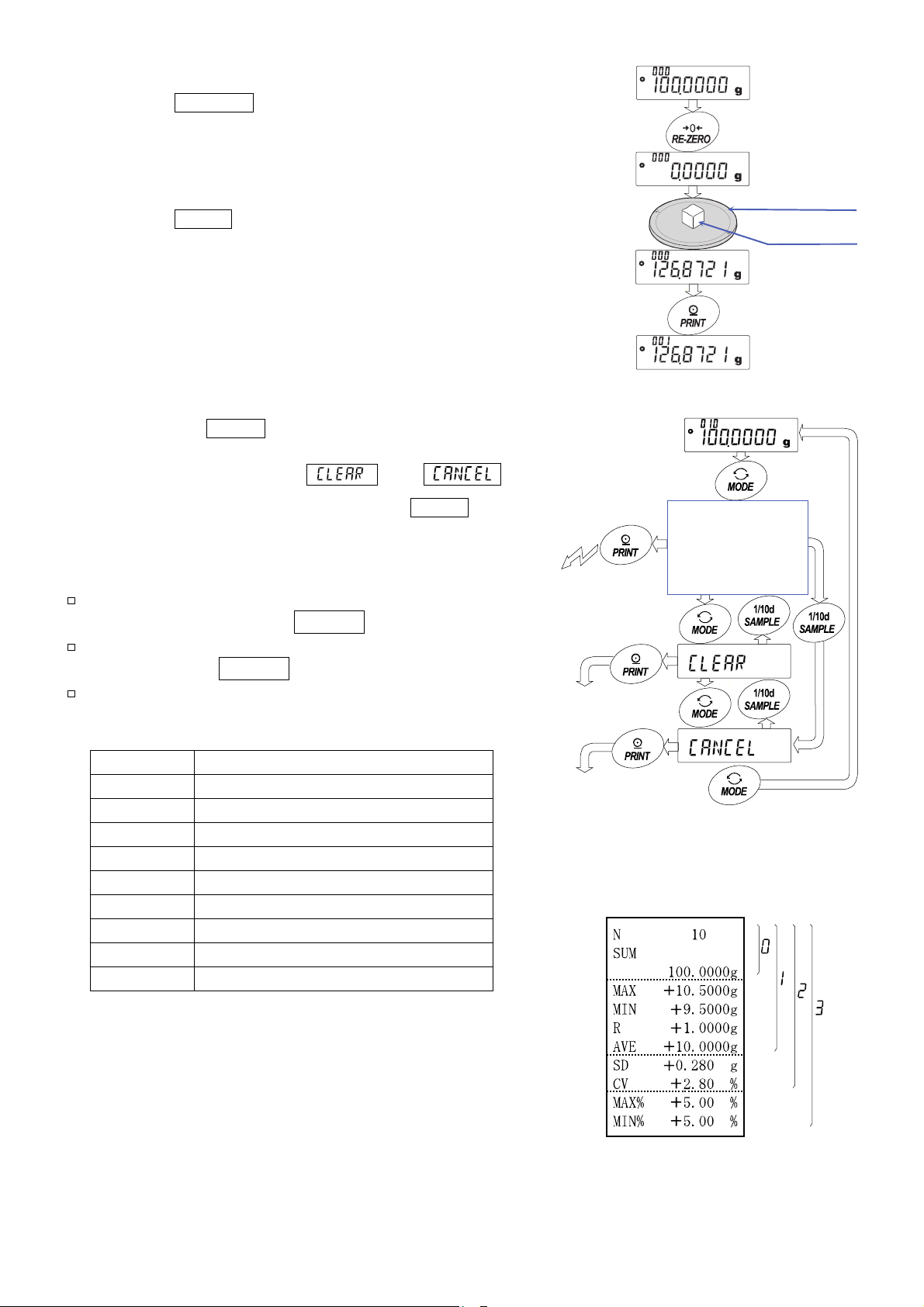

6.5.4. Clearing the

the display using the following symbols.

Symbol Statistical item

5um Sum

6.5.3. Deleting the

1max Maximum

1min Minimum

1r Range (Maximum – minimum)

1ave Average

15d Standard deviation

1Cv Coefficient of variation

Mmax% Relative error of maximum value

Mmin% Relative error of minimum value

Output the results

Statistical Data"

Latest Data"

Output example Function table

Displays the

statistical results

selected in the

function table

parameter

24

Page 25

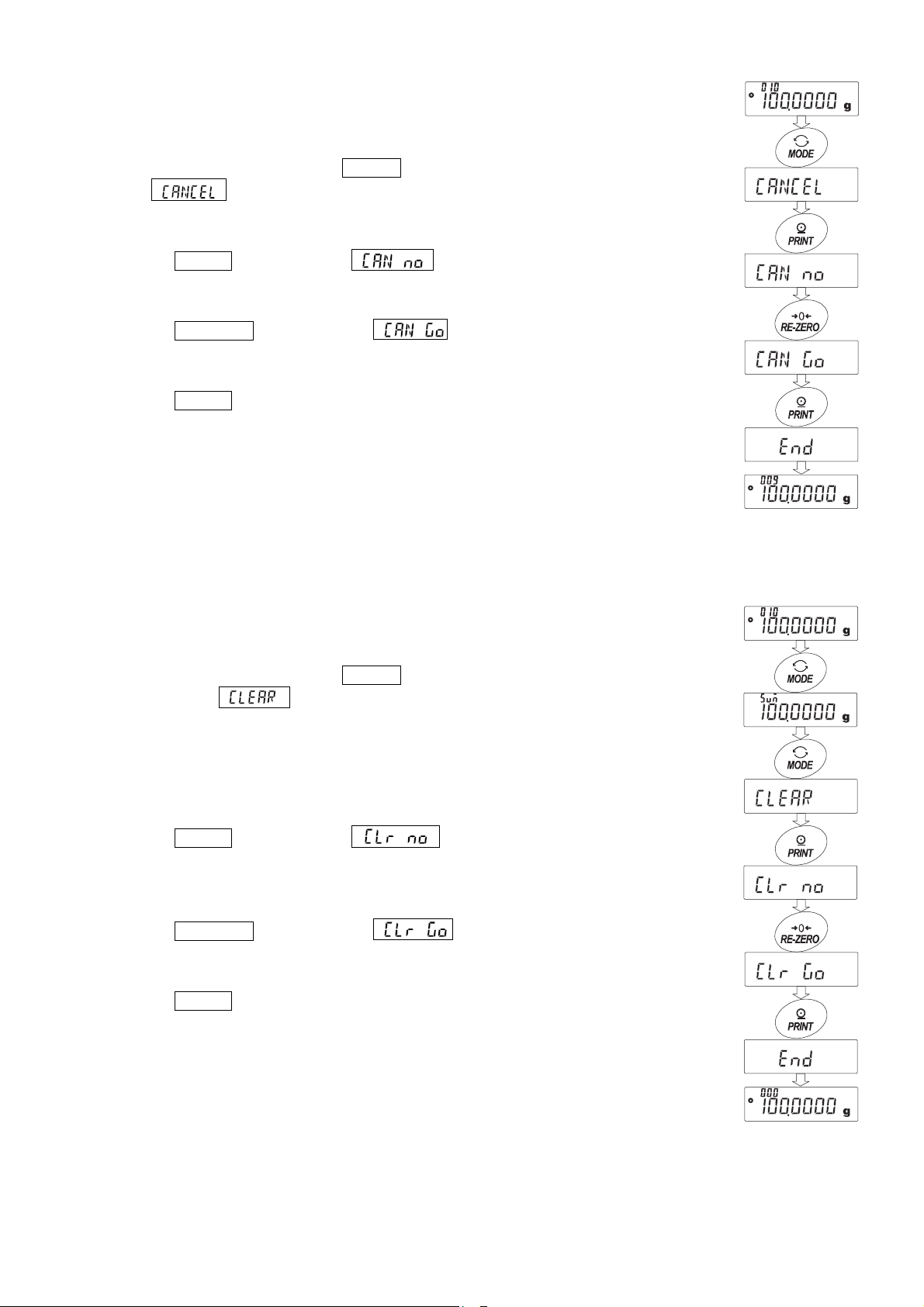

6.5.3. Deleting the Latest Data

When the wrong data is entered, it can be deleted and excluded from

statistical calculation. Only the latest data can be deleted.

1 In the weighing mode, press the MODE key several times to

display 1 .

2 Press the PRINT key to display

.

3 Press the RE-ZERO key to display .

4 Press the PRINT key to delete the latest data and exclude it

from statistical calculation.

The number of data decreases by 1 when the balance returns

to the weighing mode.

6.5.4. Clearing the Statistical Data

Press several times

All the statistical data will be deleted and the number of

data will be 0 (zero).

1 In the weighing mode, press the MODE key several

times to display .

2 Press the

PRINT key to display

.

3 Press the RE-ZERO key to display .

4 Press the PRINT key to delete the statistical data.

The number of data becomes 0 (zero) when the

balance returns to the weighing mode.

Press several times

25

Page 26

(

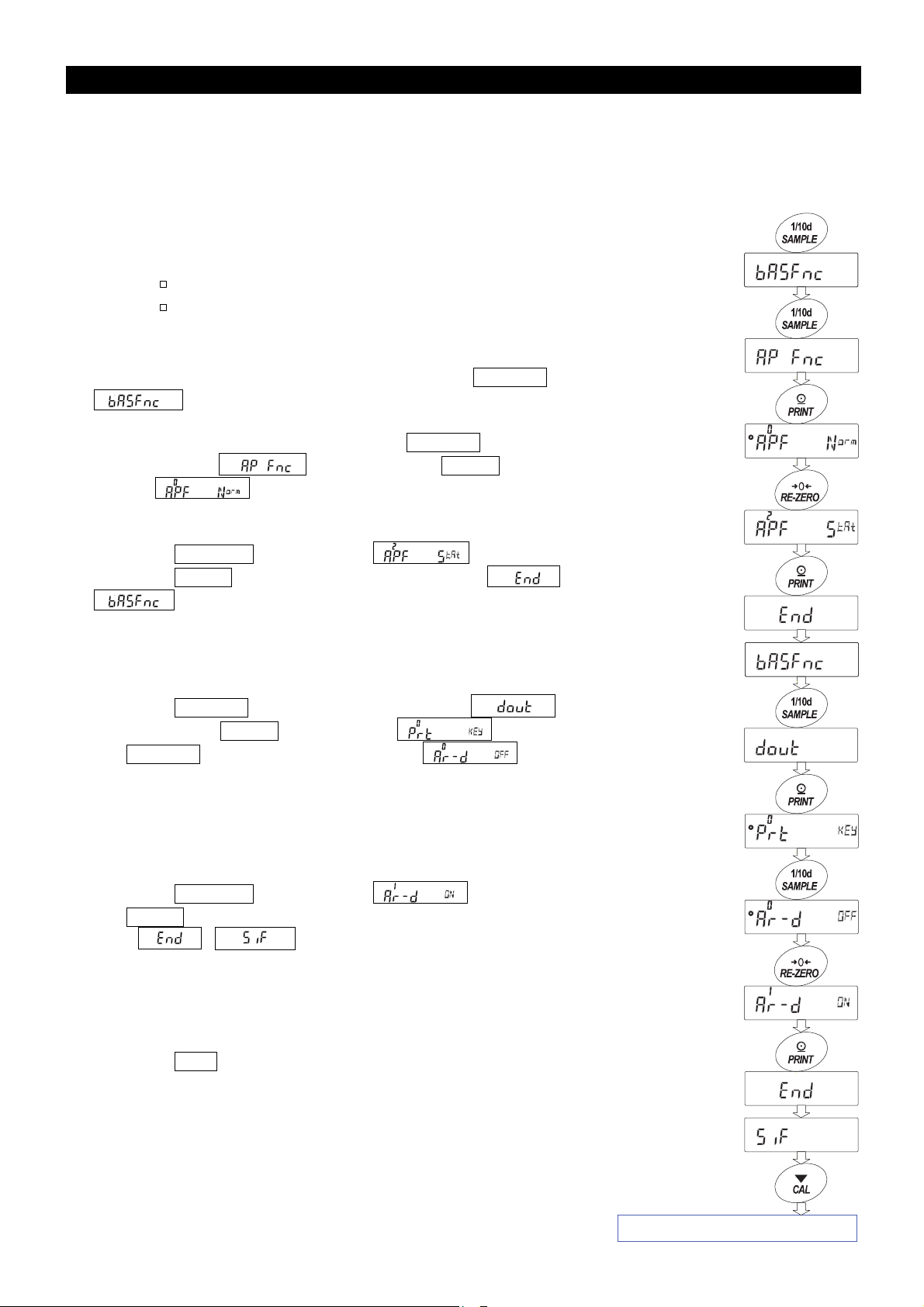

6-6. Statistical Calculation Mode (Example of Use)

Here, as an example of use of the statistical calculation mode, mixing of the multiple formulae such as

medicine is described. The mixing process is recorded using the balance and the printer.

In the example, the HR-250AZ and the compact printer AD-8121B (dump print mode) are connected

using the RS-232C serial interface.

6.6.1. Getting Started

Changing the Function Table

Changes To enable the statistical calculation mode

To enable "Zero after output"

Enabling the Statistical Calculation Mode

1 Enter the function table menu. Press and hold the SAMPLE key until

of the function table is displayed, then release the key.

2 Select the application function. Press the

times to display . Then, press the PRINT key to

display .

3 Change the application function parameter to "2".

Press the RE-ZERO key to display .

Press the PRINT key to confirm the change. After ,

is displayed.

SAMPLE key several

Enabling "Zero After Output"

4 Select "Zero after output".

Press the SAMPLE key several times to display .

Then, press the PRINT key to display , and press

the SAMPLE key several times to display .

5 Enable "Zero after output".

Press the

the PRINT key to confirm the change.

After , is displayed.

RE-ZERO key to display . Then, press

Returning to the Weighing Mode

6 Press the CAL key to return to the weighing mode.

Press and hold

for 2 seconds)

Press several times

Press several times

Press several times

Return to the weighing mode

26

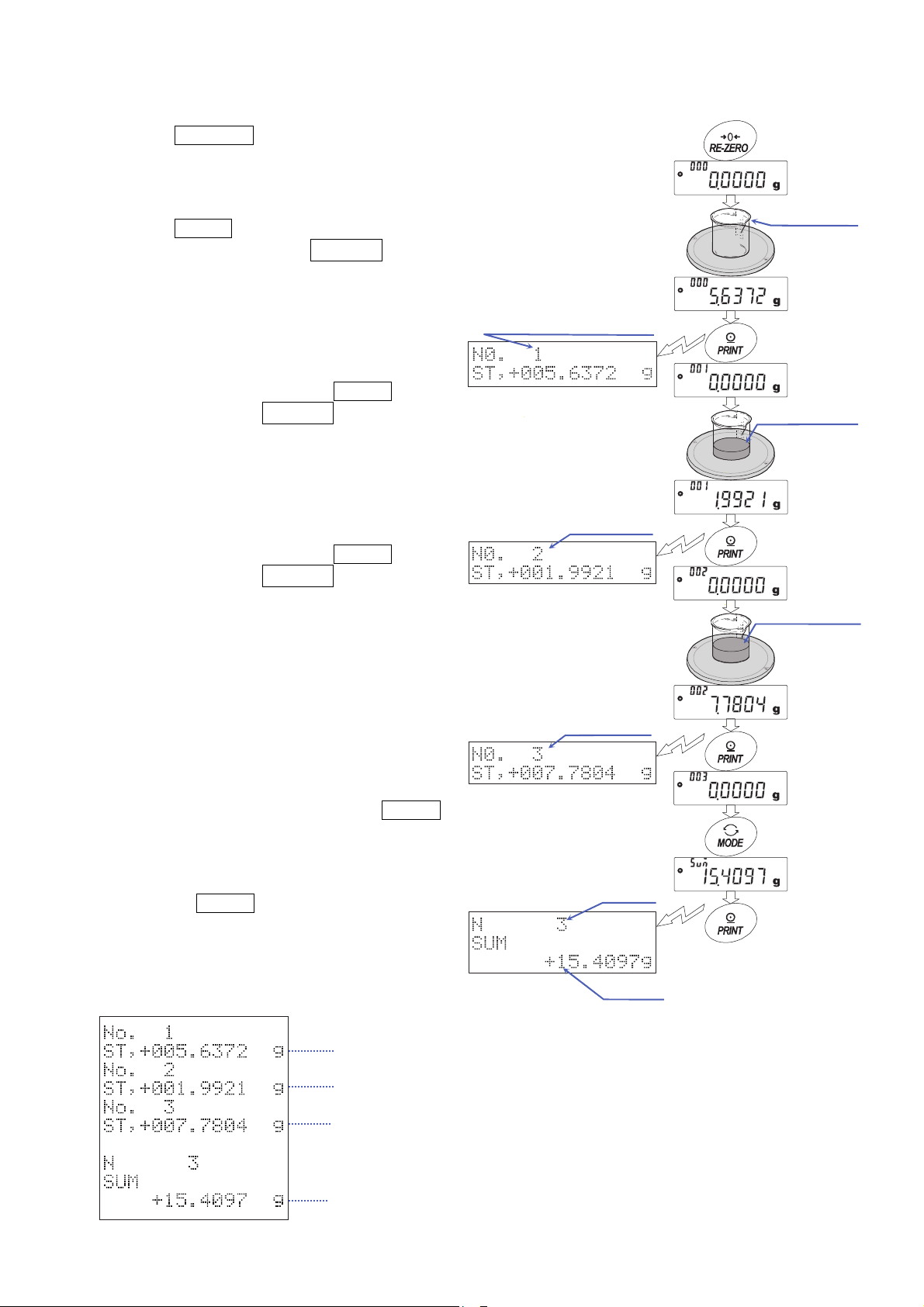

Page 27

6.6.2. Using the Statistical Calculation Mode

1 Press the RE-ZERO key to set the display to zero.

2 Place a container on the weighing pan.

Press the PRINT key to cancel the weight

(tare). The balance displays 0.0000 g. (Storing

the tare value)

The tare value data is output when the

peripheral output equipment is connected.

3 Weigh formula 1 and press the PRINT key.

The balance displays 0.0000 g. (Storing the

weight value of formula 1)

The weight value data is output when the

peripheral output equipment is connected.

4 Weigh formula 2 and press the PRINT key.

The balance displays 0.0000 g. (Storing the

weight value of formula 2)

The weight value data is output when the

peripheral output equipment is connected.

5 When there are some more formulae to be

added, repeat step 4.

6 After mixing is complete, press the

MODE key

to display the statistical results.

7 Press the

PRINT key to output the number

of data saved including the tare value and the

total weight.

Output example

Tare value (Container )

Container

Formula 1

Sample 1

Formula 1+2

Sample 2

Number of data

saved including

the tare value

Tot a l v a lu e

Tare value

Formula 1

Formula 2

Total value

27

Page 28

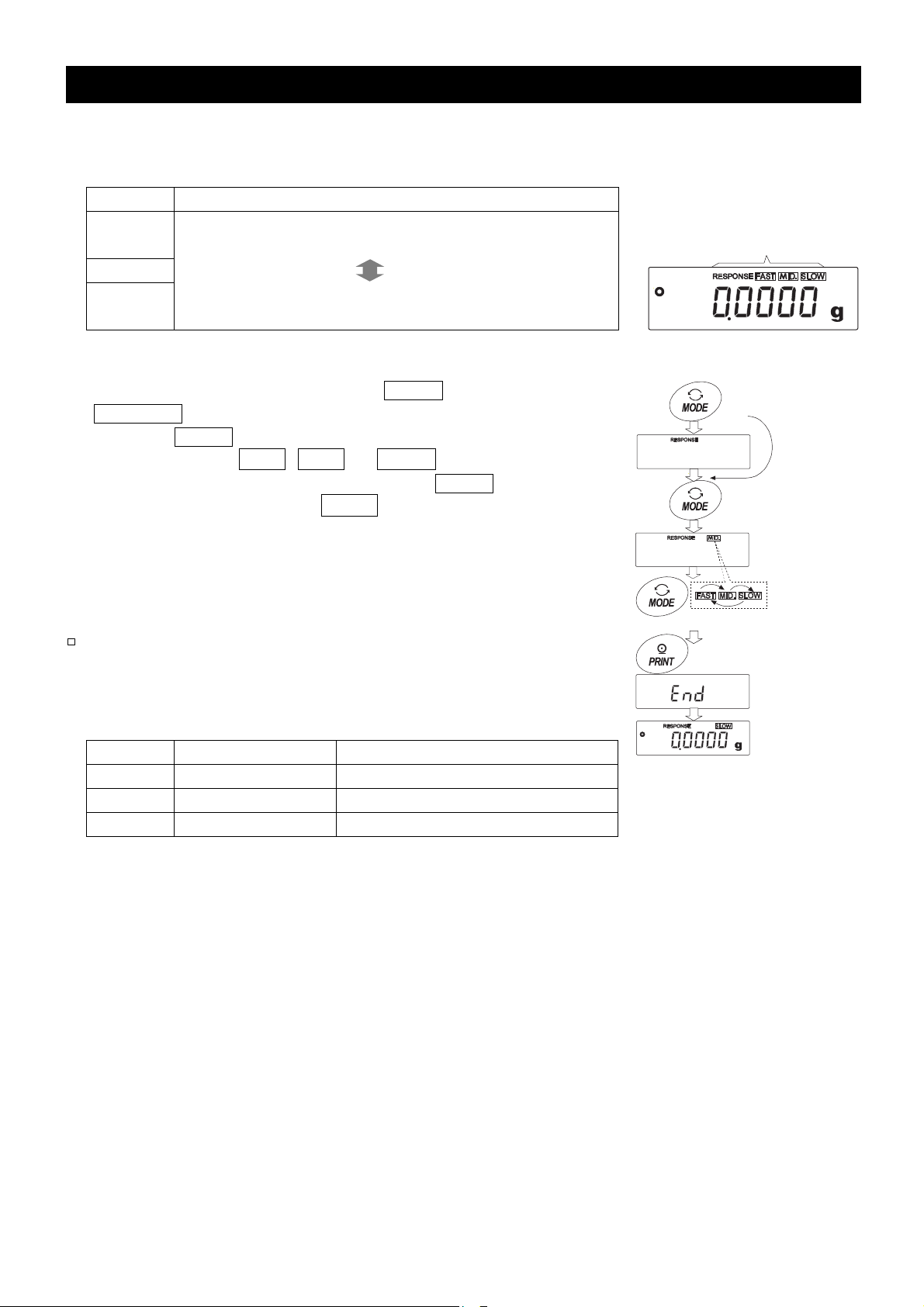

7. Response Adjustment

This function stabilizes the weight value, reducing the influence on weighing that is caused by drafts

and vibration at the place where the balance is installed.

The function has three stages as follows and can be changed by simple key operation.

Indicator Description

FAST

MID.

SLOW

Operation

1 Press and hold (about 2 seconds) the MODE key until

RESPONSE is displayed. And then, release the key.

2 Press the MODE key to select a rate of the response

adjustment. Either FAST, MID. or SLOW can be selected.

3 After a few seconds of inactivity, or when the PRINT key is

pressed, the balance displays eend . Then, it returns to the

weighing mode and displays the updated response indicator.

The weighing speed update result remains displayed for 30

seconds.

Note

Setting the response rate automatically changes the

"Condition (Cond)" and "Display refresh rate (5pd)"

parameters of "Environment, Display (ba5fnc)" in the

function table, as shown below:

Indicator Cond (Condition) 5pd (Display refresh rate)

FAST 0 1 (Approx. 10 times/second)

MID. 1 0 (Approx. 5 times/second)

SLOW 2 0 (Approx. 5 times/second)

When the balance is to be used with other setting

combinations, set each parameter in the function table.

Fast response, but prone to drafts and vibration.

Good for target weighing.

Slow response, but strong against drafts and vibration

Good for weighing which requires a stable display.

Response indicator

Press and hold

(for 2 seconds)

Release and

press again

Each pressing the key

or after while

28

Page 29

8. Calibration (

Sensitivity Adjustment/Sensitivity Check

)

8-1. Calibration Mode

Since the balance's resolution is high, weighing values may change due to gravity and daily

environmental changes. It is necessary to perform calibration (sensitivity adjustment) with the weight in

order to keep the weighing values from changing even if gravity or the environment changes.

Calibrate the balance if it is installed for the first time or relocated, or when the weighing values change

significantly in daily inspection.

Calibration means to adjust the weighing value of the balance using the reference weight or internal

mass. Calibration test means to weigh with the reference weight and compare how much the result

deviates from the reference value. (Calibration test does not perform adjustment.)

Calibration (Sensitivity Adjustment)

Calibration using the internal mass ············· Using the internal mass, adjust the balance with a single

touch. (Only for the HR-AZ series)

Calibration using an external weight ············ Using an external weight, adjust the balance.

Calibration Test (Sensitivity Check)

Calibration test using the internal mass ············ Checks the accuracy of weighing using the internal mass

and outputs the result. (Only for the HR-AZ series)

* No adjustment is made.

Calibration test using an external weight ·········· Checks the accuracy of weighing using an external weight

(target weight) and outputs the result.

* No adjustment is made.

Cautions

When calibrating, be sure to install the provided large breeze break.

Do not allow vibration, drafts, or temperature change to affect the balance during calibration.

Besides periodic calibration and before each use, perform calibration when:

The balance is installed for the first time.

The balance has been moved.

The ambient environment has changed.

Do not allow vibration or drafts to affect the balance during calibration.

To output the GLP/GMP compliant report using the RS-232C serial interface, set "GLP output ( info )"

of "Data output ( dout )". For details, refer to "10. Function Table". To display the GLP output, a printer

or personal computer is required.

Calibration test is available only when "GLP output ( info )" of "Data output ( dout )" is set to "1", "2" or

"3".

Caution on Using an External Weight

The accuracy of an external weight will influence the accuracy of weighing. Select an appropriate

weight as listed below:

Model Usable Weight Adjustable Range

HR-250AZ / HR-250A 250 g, 200 g, 100 g, 50 g

HR-251AZ / HR-251A 250 g, 200 g, 100 g, 50 g, 20 g

HR-150AZ / HR-150A 150 g, 100 g, 50 g

HR-100AZ / HR-100A 100 g, 50 g

The calibration weight in bold type: factory setting.

The calibration weight value can be adjusted within the range above.

29

-0.0150 g to +0.0150 g

Page 30

Display

This indicator means "the balance is measuring data". Do not allow

vibration or drafts to affect the balance while this indicator is displayed.

8-2. Calibration Using the Internal Mass

This function calibrates the balance using the internal mass. The only operation required is to press

the CAL key.

Notes

Level the balance by adjusting the leveling feet and confirm that the bubble is in the center of

the spirit level.

Poor level adjustment may cause a calibration error while using the internal mass.

(One-Touch Calibration, Only for the HR-AZ Series)

Operation

1 Connect the AC adapter and warm up the balance for at least one hour with nothing on the weighing

pan.

2 Place the provided large breeze break on the balance and press the

3 The balance displays Calin and performs calibration using the internal mass. Do not allow

vibration or drafts to affect the balance.

4 The balance displays end after calibration. If the "GLP output (info)" parameter of the function

table is set to "1" or "2", the balance displays glp and outputs "Calibration Report" using the

RS-232C interface or stores the data in memory. For details on the calibration report format, refer to

"11-2. GLP Report".

5 The balance will automatically return to the weighing mode after calibration.

CAL key.

About the Internal Mass

The mass of the internal mass may change due to corrosion or other damage caused by the operating

environment, or due to aging. Check the internal mass periodically. Correct the internal mass value as

necessary. For details, refer to "8-4. Correcting the Internal Mass Value 1 (Only for the

and "8-5. Correcting the Internal Mass Value 2

To maintain the weighing accuracy, perform the internal mass value correction periodically.

(Only for the

HR-AZ

Series)

".

HR-AZ

Series)

"

30

Page 31

8-3. Calibration Test Using the Internal

This function tests the balance accuracy using the internal mass. .

Calibration test does not perform calibration.

This is available only when the "GLP output (info)" parameter is set to "1", "2" or "3".

1 Connect the AC adapter and warm up the balance at least one hour.

2 Refer to "10. Function Table" to set "GLP output (info)"

to "1" or "2"

3 Press and hold the CAL key until CC in is

displayed, then release the key.

4 The balance measures the zero point.

Prevent vibration and drafts to affect the balance.

5 The measured zero point data is displayed.

6 The balance measures the internal mass.

Prevent vibration and drafts to affect the balance.

7 The value of the internal mass is displayed.

The normal range of the value is as follows:

Mass

(Only for the HR-AZ Series)

Press and hold

Release

Model The Internal Mass The Normal Range

HR-100AZ / HR-150AZ 100.0000 g

±0.2 mg

HR-250AZ 200.0000 g

HR-251AZ 200.0000 g ±2 mg

8 If GLP output is set, glp is displayed, the calibration test

report is output to the RS-232C interface. Refer to "GLP

output (info)" of the function table, "11-2. GLP Report".

end is displayed after the calibration.

9 The balance automatically returns to the weighing mode.

GLP output

31

Page 32

8-4. Correcting the Internal Mass Value 1

The HR-AZ series balance can correct the internal mass value using an external weight..

Method 1: Calibrate the balance using the internal mass. Measure the external weight. Calculate the

correction value. And store it in the balance.

The adjustable range of the internal mass value is as follows:

Model Correction Reference Value Adjustable Range

HR-100AZ 100 g

HR-250AZ / HR-251AZ 200 g

(Only for the HR-AZ Series)

-0.0150 g to +0.0150 g HR-150AZ 100 g

Operation

Example : Correcting the weight value by +0.0003 g in 100 g using the HR-150AZ.

If correcting the weight value by +0.0003 g in 50 g, use the correction value of +0.0006 g as the

correction reference value is 100 g.

100.0000 g 100.0003 g

1 Perform calibration using the internal mass (one-touch calibration).

Place the external weight on the weighing pan to obtain the correction

value.

Correct the internal mass by +0.0003 g in

100 g. Calibrate with the corrected internal

mass.

The same mass

Corrected mass

value

2 With the factory setting, the balance cannot correct the internal mass

value. Refer to "9. Function Switch and Initialization" and set the internal

mass value correction switch to 1.

3 In the weighing mode, press and hold the SAMPLE key to

display ba5fnc .

4 Press the SAMPLE key several times until C5 in 1 is displayed.

If C5 in 1 is not displayed, perform step 2.

5 Press the PRINT key.

Correct the internal mass value using the following keys:

RE-ZERO key

MODE key

PRINT key

CAL key

6 Press the CAL key to return to the weighing mode.

7 Press the CAL key to perform calibration using the internal mass.

8 Confirm that the internal mass value has been corrected properly by

placing the external weight on the weighing pan.

If the internal mass value has not been corrected properly, repeat the

procedure to adjust the correction value.

...

........

........

...........

To increase the value by one.

To decrease the value by one.

To store the correction value and

display the next menu item of the

function table.

To cancel the operation and return to the

weighing mode.

The balance displays

-0.0150 g after +0.0150 g.

Press and hold

(for 2 seconds)

Press several

times

32

Page 33

A

8-5. Correcting the Internal Mass Value 2

The HR-AZ series balance can correct the internal mass value using an external weight.

Method 2: Calibrate the balance using the external weight. The balance performs automatic

calibration using the internal mass, corrects the internal mass value and stores it in the

balance. The corrected mass value is maintained in non-volatile memory even if the AC

adapter is removed.

The usable calibration weights and the adjustable range are as follows:

Model Correction Reference Value Adjustable Range

HR-100AZ 100 g, 50 g

HR-150AZ 150 g, 100 g, 50 g

HR-250AZ 250 g, 200 g, 100 g, 50 g

HR-251AZ 250 g, 200 g, 100 g, 50 g, 20 g

The calibration weight in bold type: factory setting.

The calibration weight value can be adjusted within the range above.

(Only for the HR-AZ Series)

-0.0150 g to +0.0150 g

Operation

1 With the factory setting, the balance can not correct the internal mass

value. Refer to "9. Function Switch and Initialization" and set the

internal mass value correction switch to 1.

Press and hold

(for 2 seconds)

2 In the weighing mode, press and hold the SAMPLE key to

display ba5fnc .

3 Press the SAMPLE key several times until C5 in 21 is

displayed. If C5 in 2 is not displayed, perform step 1.

4 Press the PRINT key to display Cal 0 .

Refer to "8-6. Calibration Using an External Weight", to

perform the calibration.

5 After calibration, remove the weight.

The balance displays

6 Cal. is displayed and the balance corrects the internal

mass value automatically

7 After correcting the internal mass value, the balance

displays Cal.

automatically using the corrected internal mass value.

8 The balance displays end and returns to the weighing

mode.

9 Confirm that the internal mass value has been

corrected properly by placing the external weight

used for the correction procedure on the

weighing pan.

If the internal mass value has not been corrected

properly, repeat the procedure to adjust the

correction value.

in

and performs the calibration

. Press the PRINT key.

djusting the internal mass value

Calibrating with internal mass

Press several times

Calibration using an

external weight

Place the weight

Remove the weight

33

Page 34

8-6. Calibration Using an External Weight

This function calibrates the balance using an external weight.

Operation

1 Connect the AC adapter and warm up the balance for at

least one hour with nothing on the pan.

2 Press and hold the CAL key until Calout is displayed,

and then release the key.

Press and hold

3 The balance displays Cal 0 .

If you want to change the calibration weight (a list of usable

weights is shown on page 29), press the SAMPLE key and

go to step 4.

If you use the calibration weight value stored in the

balance, go to step 5.

4 Specify the calibration weight value as follows:

SAMPLE key

....

To switch the display condition to: "All of the

segments blinking" (target weight selection

mode) or "The last three digits blinking" (value

adjustment mode).

RE-ZERO key

MODE key

...

To increase the value.

........

To decrease the value.

To select the calibration weight or adjust

the value.

PRINT key

........

To store the new weight value. Even if the

AC adapter is removed, the data is

maintained in non-volatile memory.

CAL key

...........

To cancel the operation and return

to Cal 0 .

Release

Select a

weight

e.g. Calibration mass

100.012 g

Release

5 Confirm that there is nothing on the pan and press the PRINT

key. The balance measures the zero point. Do not allow

vibration or drafts to affect the balance. The balance displays

the calibration weight value.

6 Place the displayed calibration weight on the pan and press

the

PRINT key. The balance measures the calibration

weight. Do not allow vibration or drafts to affect the balance.

7 The balance displays end . Remove the weight from the pan.

8 When the GLP output is set, the balance displays glp and

outputs "Calibration Report".

9 The balance will automatically return to the weighing mode.

10 Place the calibration weight on the pan and confirm that the

value displayed is within ±2 digits of the specified value. If it is

not within the range, check the ambient conditions such as

drafts and vibration, also check the weighing pan. Then, repeat

steps 2 to 9.

Place calibration

weight

Remove

GLP output

34

Page 35

8-7. Calibration Test Using an External Weight

This function tests the balance weighing accuracy using an external weight and outputs the result.

This is available only when the "GLP output (info)" parameter is set to "1" or "2". (Calibration test

does not perform calibration.)

Operation

1 Connect the AC adapter and warm up the balance for at

least one hour with nothing on the pan.

2 Press and hold the CAL key until CCout is displayed,

and then release the key.

3 The balance displays CC 0 .

If you want to change the target weight (a list of usable

weights is shown o n page 29), press the SAMPLE key and

go to step 4.

If you use the target weight value stored in the balance,

go to step 5.

4 Specify the target weight value as follows:

SAMPLE key

RE-ZERO key

MODE key

PRINT key

CAL key

....

...

........

........

...........

To switch the display condition to: "All of the

segments blinking" (target weight selection

mode) or "The last three digits blinking" (value

adjustment mode).

To increase the value.

To decrease the value.

To select the target weight or adjust the value.

To store the new weight value. Even if the

AC adapter is removed, the data is

maintained in non-volatile memory.

To cancel the operation and return to CC 0 .

e.g. Calibration mass

100.012 g

Press and hold

Release

Select a

weight

Release

5 Confirm that there is nothing on the pan and press the PRINT

key. The balance measures the zero point and displays the

measured value. Do not allow vibration or drafts to affect the

balance. The balance displays the target weight value.

6 Place the displayed target weight on the pan and press

the

PRINT key. The balance measures the target

weight and displays the measured value. Do not allow

vibration or drafts to affect the balance.

7 The balance displays end .

Remove the weight from the pan.

8 When the GLP output is set, the balance displays glp and

outputs "Calibration Test Report".

9 The balance will automatically return to the weighing mode.

Place calibration

weight

Remove

GLP output

35

Page 36

9. Function Switch and Initialization

9-1. Permit or Inhibit

The balance stores parameters that must not be changed unintentionally. There are two switches for

the purpose of protecting these parameters. You can select either the "permit" or "inhibit" switch. The

"inhibit" switch protects parameters against unintentional operations.

Changing the function switch, can be restricted by the password function. When using balance

software version 1.860 or later, the function switch and password function can be used to restrict

calibration (sensitivity adjustment) functions.

The function switch types are as follows:

HR-AZ series HR-A series

Function Table

Function switch

Calibration Using the Internal Mass

Calibration Using an External Weight

Internal Mass Value Correction

Operation

1 Press the ON:OFF key to turn off the display.

2 While pressing and holding the PRINT key and the SAMPLE key, press the ON:OFF key.

The balance displays p5 .

3 Press the PRINT key. Then the balance displays the function switches.

4 Set the switches using the following keys.

SAMPLE key

RE-ZERO key

PRINT key

CAL key

....

...

........

...........

To select the switch to change the parameter. The selected switch blinks.

To change the parameter of the switch selected.

0:To inhibit changes. 1:To permit changes

To store the new parameter and return to the weighing mode.

To cancel the operation ( Clr is displayed.)

To return to the weighing mode, press the CAL key once again.

Function Table

Calibration Using an External

Weight

36

Page 37

Switches (HR-AZ Series)

Function Table

To inhibit changes on the function table

To permit changes on the function table

Calibration Using the Internal Mass (One-Touch Calibration)

Software versions 1.43 to 1.85: To inhibit calibration using the internal mass

To permit calibration using the internal mass

Calibration Using an External Weight

Software versions 1.43 to 1.85: To inhibit calibration using an external weight

To permit calibration using an external weight

Not Used

Internal Mass Value Correction

To inhibit correction

To permit correction

Switches (HR-A Series)

Function Table

To inhibit changes on the function table

To permit changes on the function table

Not Used

Calibration Using An External Weight

Software versions 1.43 to 1.85: To inhibit calibration using an external weight

To permit calibration using an external weight

Not Used

Not Used

(The display shown left indicates the factory settings)

Software versions 1.860 and later:

PA55 0 To inhibit calibration using the internal mass

PA55 1,2 To inhibit calibration using the internal mass when a user

(U5ER) or a guest (GUE5t) is logged in.*1

Software versions 1.860 and later:

PA55 0 To inhibit calibration using an external weight

PA55 1,2 To inhibit calibration using an external weight when a user

(U5ER) or a guest (GUE5t) is logged in.*1

*1 The operation is permitted when

logged in as an administrator (AdMIN)

(The display shown left indicates the factory settings)

Software versions 1.860 and later:

PA55 0 To inhibit calibration using an external weight

PA55 1,2 To inhibit calibration using an external weight when a user

(U5ER) or a guest (GUE5t) is logged in.*1

*1 The operation is permitted when

logged in as an administrator (AdMIN)

37

Page 38

9-2. Initializing the Balance

This function returns the following parameters to factory settings.

Calibration data

Function table

The sample unit mass value (counting mode), 100% reference mass value (percent mode)

External calibration weight

Function switch settings

Statistical data

Internal mass value (Only for the HR-AZ series)

Note

Be sure to calibrate the balance after initialization.

Operation

1 Press the ON:OFF key to turn off the display.

While pressing and holding the PRINT key and the SAMPLE key,

press the ON:OFF key. The balance displays p5 .

2 Press the SAMPLE key to display Clr .

3 Press the PRINT key.

To cancel this operation, press the CAL key.

4 Press the RE-ZERO key.

5 Press the PRINT key to initialize the balance.

The balance will automatically return to the weighing mode.

Press and hold Press

38

Page 39

10. Function Table

The function table reads or rewrites the parameters that are stored in the balance. These parameters

stored, even if the AC adapter is removed, are maintained in non-volatile memory.

10-1. Structure and Sequence of the Function Table