Anchor Hocking Glass NAVI-TRAC, NAV40GBL-1104 User Manual

40’ Wide Gabled End System

Quality, Craftsmanship and Service since 1892

NAV40Gbl-1104

Copyright © Anchor Industries 2004

Please read all assembly / installation instructions before the installation or removal of this product.

1100 Burch Dr., Evansville, IN 47725

Ph. 812-867-2421 • Fx. 812-867-0547

E-mail: tents@anchorinc.com • www.anchorinc.com

Navi-Trac

ANCHOR

FRAME TENT SYSTEM

5.0”

2.3”

TABLE OF CONTENTS

Page No. Assembly Step

3 Introduction with Frame Terminology Illustration

4 Component Illustrations

5 40’ Navi-Trac Component List Table

6 40’ Navi-Trac Component List Table Cont’d

7 Safety Guidelines

8 Squaring the Tent Footprint Layout and Diagonals Chart

9 Assembling the first Beam

Assembly Layout of all Beams (Butterflying First Two Beams)

10 Erecting the First Beam and Stabilizing the First Beam

Erecting the Second Beam

11 Connecting the First Two Beams

Installing Purlins

Completing First Bay

12 Completing the Top Frame

Installing the Gabled End Frame

Guying Out the Completed Frame

13 Installing the Mid Panels and Gabled End Panels

Tensioning Fabric Panels

14 Completing the Gabled End Unit

Alternate Hip End/ Gabled End Configuration

15 Combining Hip and Gabled End Assembly Steps

Component Changes for Hip/ Gabled End Configuration

16 Limits of Liability

2

3

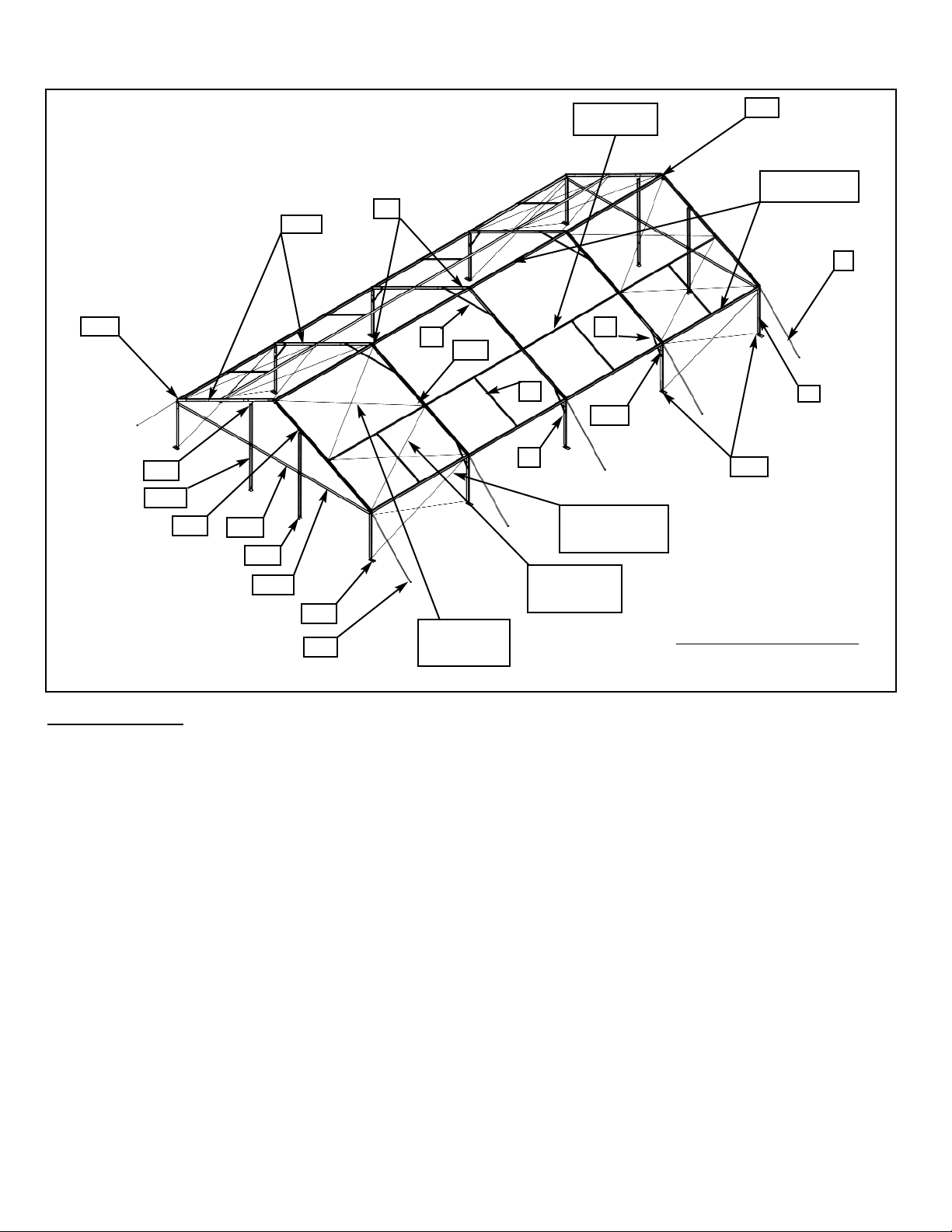

40’ Gabled Navi-Trac Frame Terminology

INTRODUCTION:

Like the hip-end version, the gabled end NAVI-TRAC frame is made up of extruded aluminum members joined

by weldments. The aluminum frame members themselves are extruded with channels into which the NAVITRAC fabric “kedar” is fed. However, the gabled end version of the Navi-Trac differs from the Hip End version

in a number of ways:

1. All the beams are parallel to each other.

2. Beam base plates are hinged for pivoting to a vertical position. End Upright plates are fixed, non-pivoting.

3. The eave fittings are the MCW style that allows a simple drop-in action for purlin installation, rather

than the slip joint of the hip end configuration.

4. Fabric middle bays are installed into the channels of adjacent beams one bay at a time.

5. Gabled End fabric is intalled simply into the outer channel of the end beams and tensioned to the

Gabled End uprights.

6. X-Cabling extends into the overhead rafter area to compensate for the lack of hip end support.

7. Corner guys are in one direction only, parallel to the beams.

It is possible to combine the hip end and gabled end styles within one building unit (see kit #3); however

this assembly manual focuses on the gabled end configuration only. The last few pages describe the

hip/gabled combination and refer the customer to the hip end assembly manual for the hip end part of

the building unit.

R21-9

P1, P2 OR P3

(OPTIONAL)

U8

BHW

RWE

RW

G

T-42

X-4, 5 or 6

(OPTIONAL

BAY SPACING)

X-1, 2 or 3

(OPTIONAL BAY

SPACING

MCW

X-7, 8 or 9

(OPTIONAL

BAY SPACING)

EE10

ER10, 15, 0R 20

(OPTIONAL)

BFW

T-30

EW15

U8

XRB

MCW

B3

UGT

UG-15

GRW

P1

B4

See Component List Table on

Pages 5 & 6 for component

descriptions.

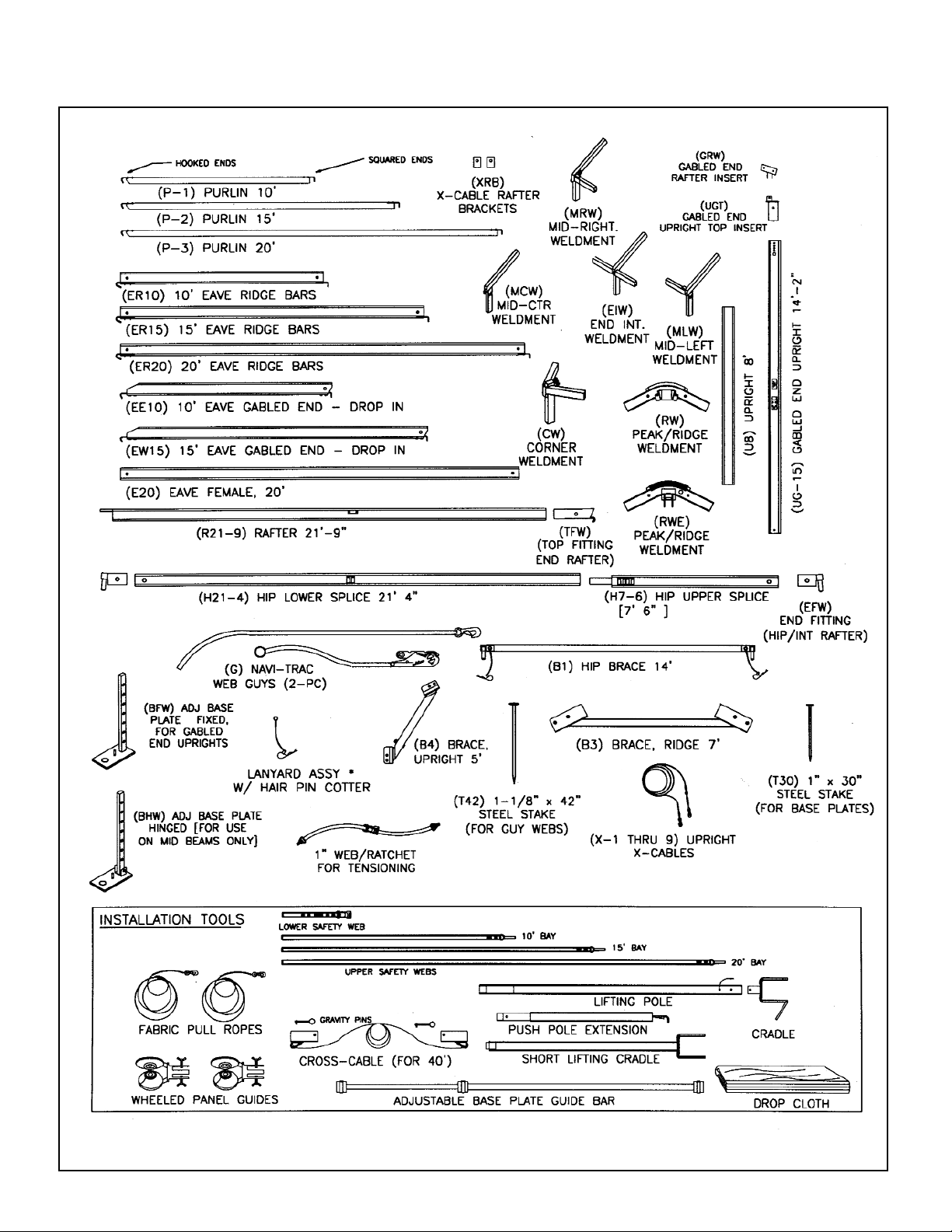

40’ NAVI-TRAC COMPONENT ILLUSTRATIONS

4

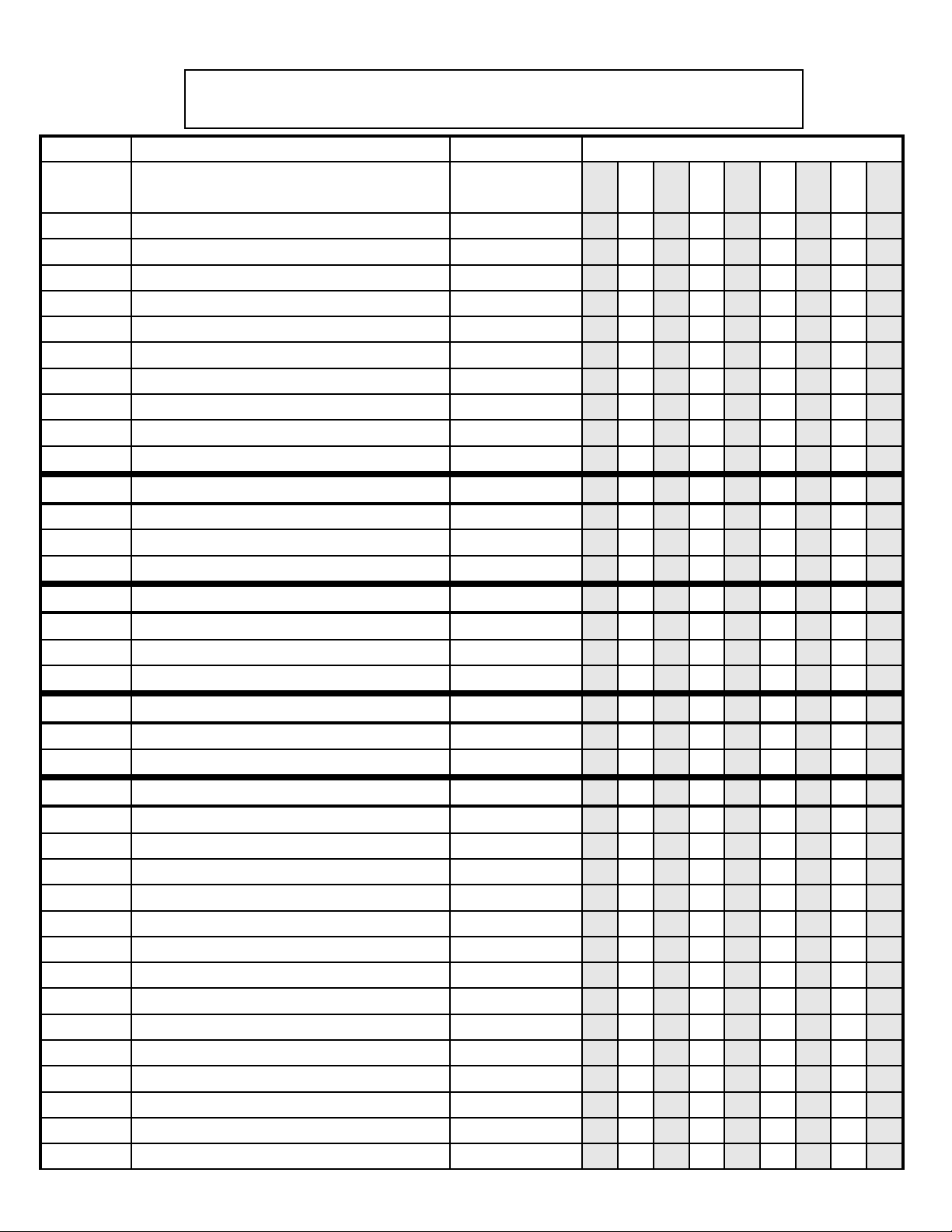

40’ NAVI-TRAC COMPONENT LIST

A MINIMUM GABLED UNIT CONSISTS OF (1) KIT #1, (1) KIT #2 AND (2) EXTENSION MIDS.

TO EXTEND THE LENGTH FURTHER, SIMPLY ADD ADDITIONAL EXTENSION MIDS.

STARTER MIDS ARE REQUIRED WITH HIP ENDS ONLY.

I.D. 40’ GABLED END NAVI-TRAC

LABEL

(LETTER ON

DRAWING)

COMPONENT DESCRIPTION

CODES

(STAMPED OR

TAPED)

GBL

KIT

1

GBL

KIT

2

HIP

KIT

3

20’

MID

STR

20’

MID

EXT

15’

MID

STR

15’

MID

EXT

10’

MID

STR

10’

MID

EXT

EXTRUSIONS W/CHANNELS

E20

EAVE - FEMALE 20’

4

ER10

EAVE/RIDGE - DROP-IN 10’

3 3

ER15

EAVE/RIDGE - DROP-IN 15’

3 3

ER 20

EAVE/RIDGE - DROP-IN 20’

3 3

EE-10

EAVE/GABLED END, DROP-IN 10’

1 1

EW-15

EAVE/GABLED END, DROP-IN 15’

2 2

H21-4

HIP LOWER SPLICE 21-4 (2 pc) 21’-4 (40’)

2

H7-6

HIP UPPER SPLICE (2PC) 7’-6 (40’)

2

R21-9

RAFTER 21’-9

2 1 2 2 2 2 2 2

BRACES

B1

BRACE, HIP 14’ (W/LANYARDS)

4

B3

BRACE, RIDGE 7’

1 1 1 1 1 1

B4

BRACE, UPRIGHT, 5’

1 2 2 2 2 2 2

PURLINS

P1

PURLIN 10’

2 2 2 2

P2

PURLIN 15’

2 2

P3

PURLIN 20’

2 2

UPRIGHTS

U8

UPRIGHT - 8’

2 3 2 2 2 2 2 2

UG-15

END UPRIGHT - 14’-2”

2 2

WELDMENTS, FITTINGS & PLATES

BFW

ADJ. BASE PLATES W/INSERTS (FIXED)

“END” 2 2 3 2 2 2

BHW

ADJ BASE PLATEW/INSERTS (HINGED)

2 2 2 2 2

CW

CORNER WELDMENTS

2

EIW

END INTERMEDIATE WELDMENTS

1

MLW

MID LEFT WELDMENTS

2 2 2

MRW

MID RIGHT WELDMENTS

2 2 2

MCW

MID CENTER WELDMENTS

2 2 2 2

RW

PEAK/RIDGE WELDMENT

1 1 1 1 1 1

RWE

GABLED END RIDGE WELDMENT

1 1

GRW

GABLED END UPRIGHT RAFTER WELD.

2 2

UGT

GABLED END UPRIGHT TOP INSERT

2 2

XRB

X-CABLE RAFTER BRACKET

8 8

TFW

TOP FITTING (END RAFTER) W/HDWR

1

EFW

END FITTING (HIP/INT. RAFTER) W/HDWR

4

5

CONTINUED ON NEXT PAGE

Loading...

Loading...